Tensile Behavior and Microstructure of the 6082 Alloy Sheet with High-Temperature Aging Treatments

Abstract

1. Introduction

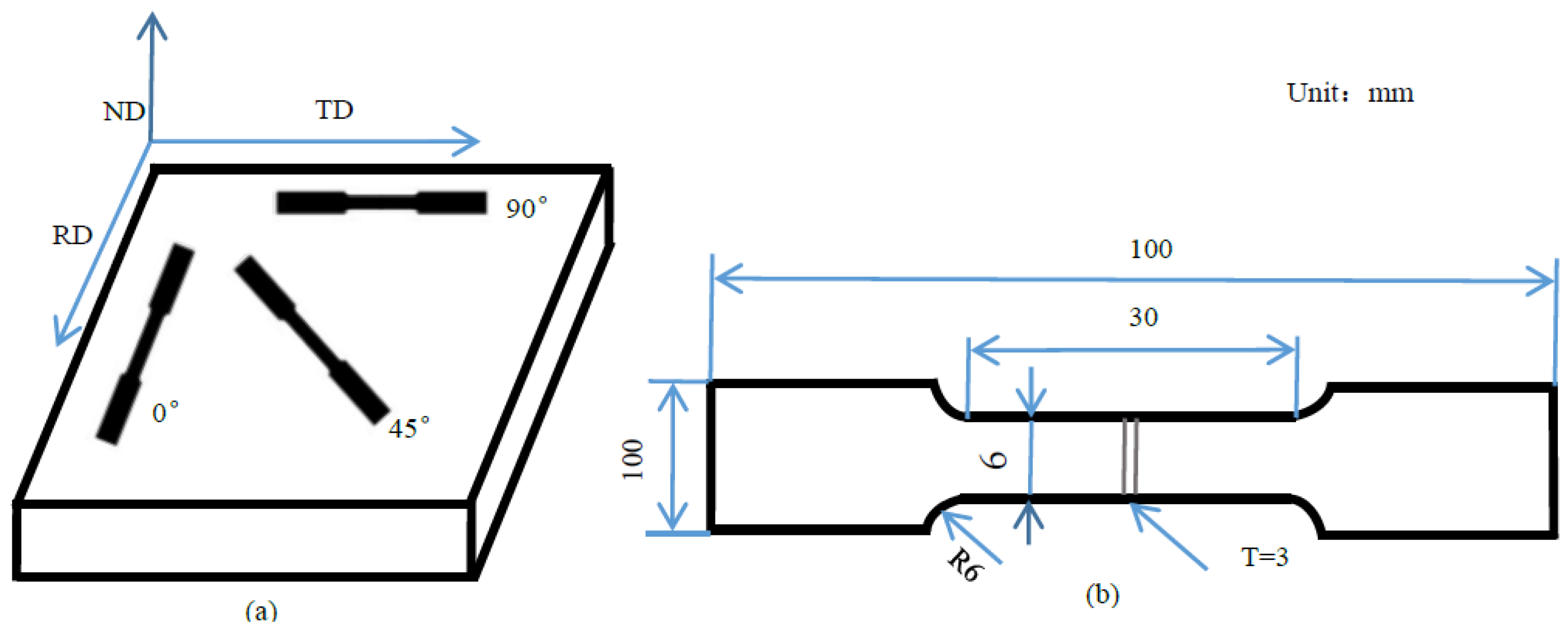

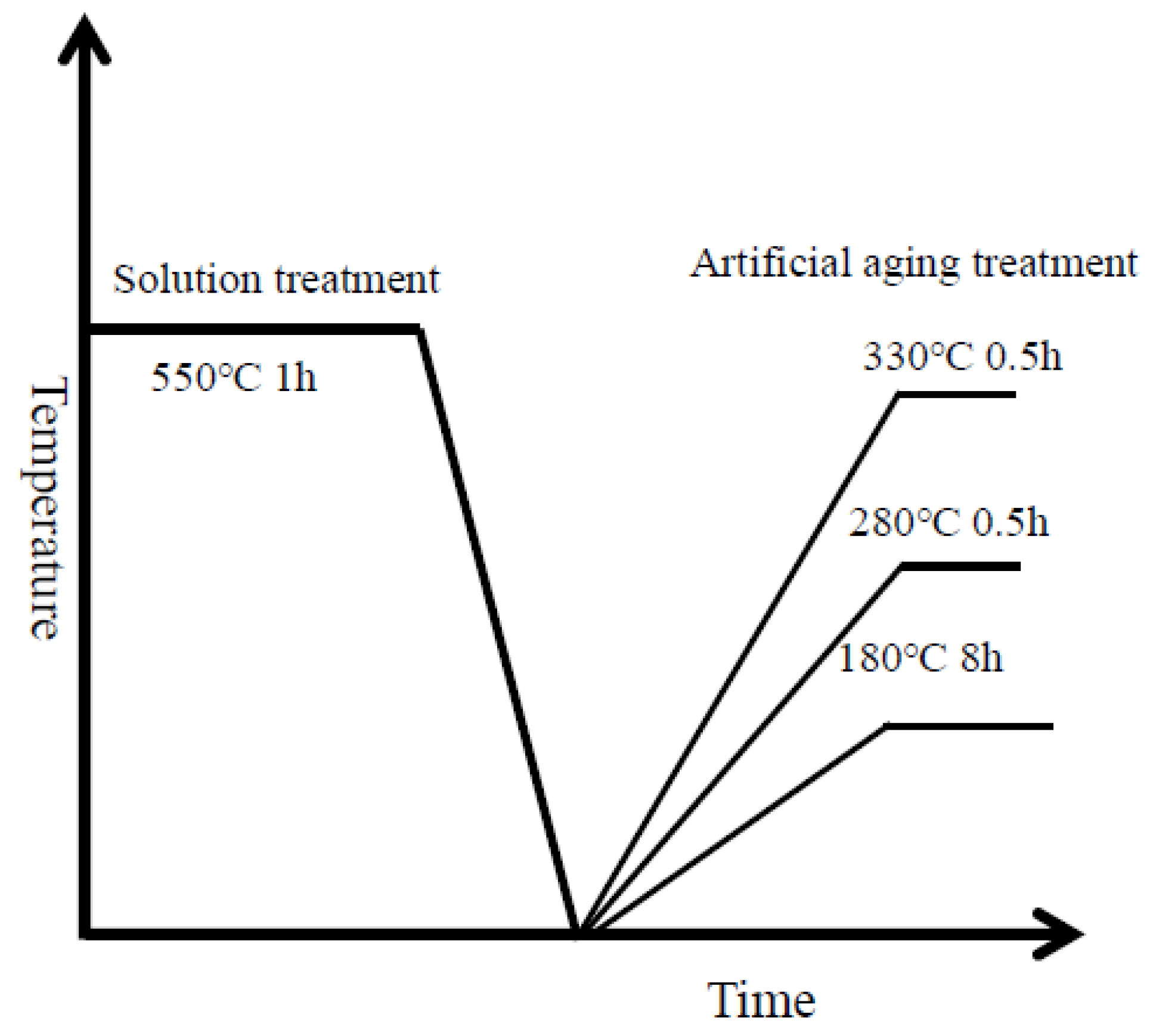

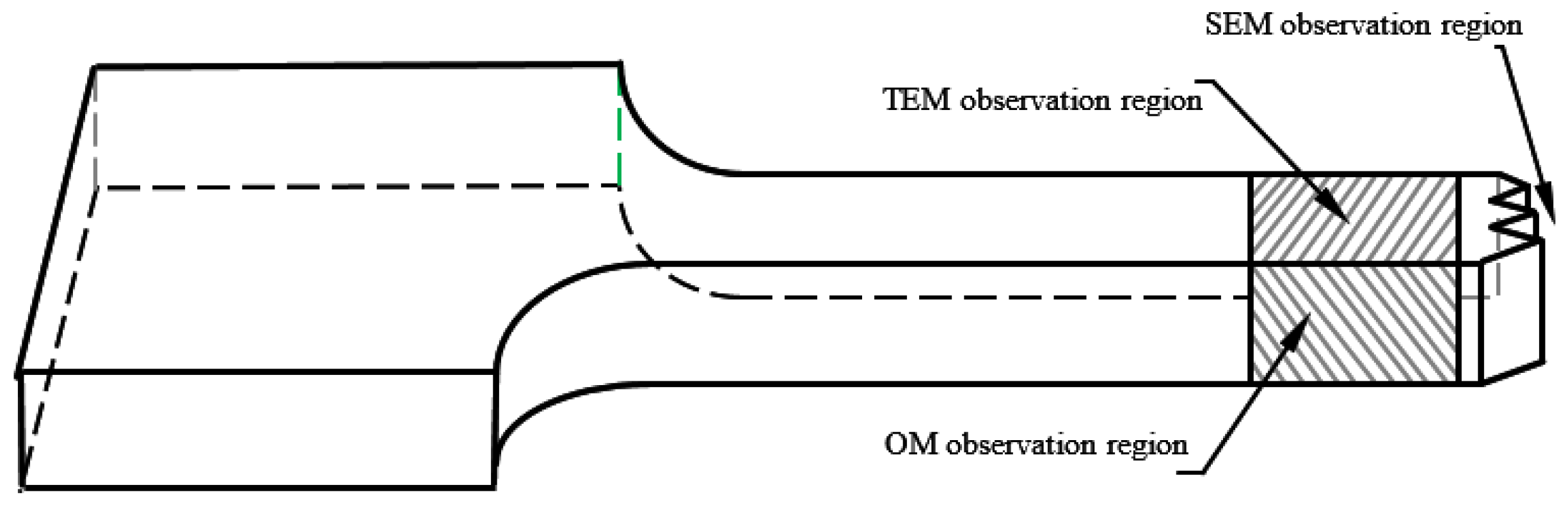

2. Experiment

3. Results and Discussion

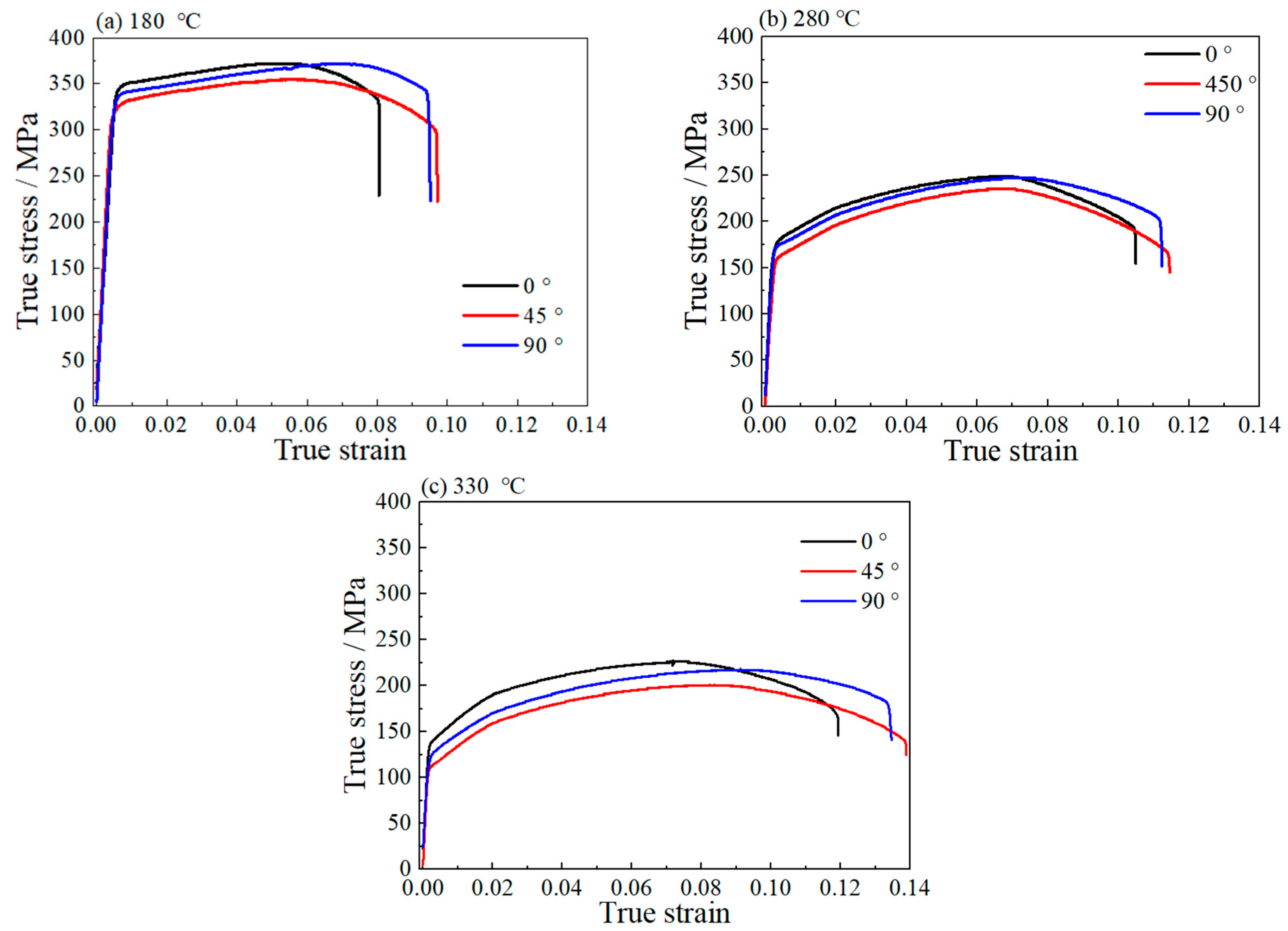

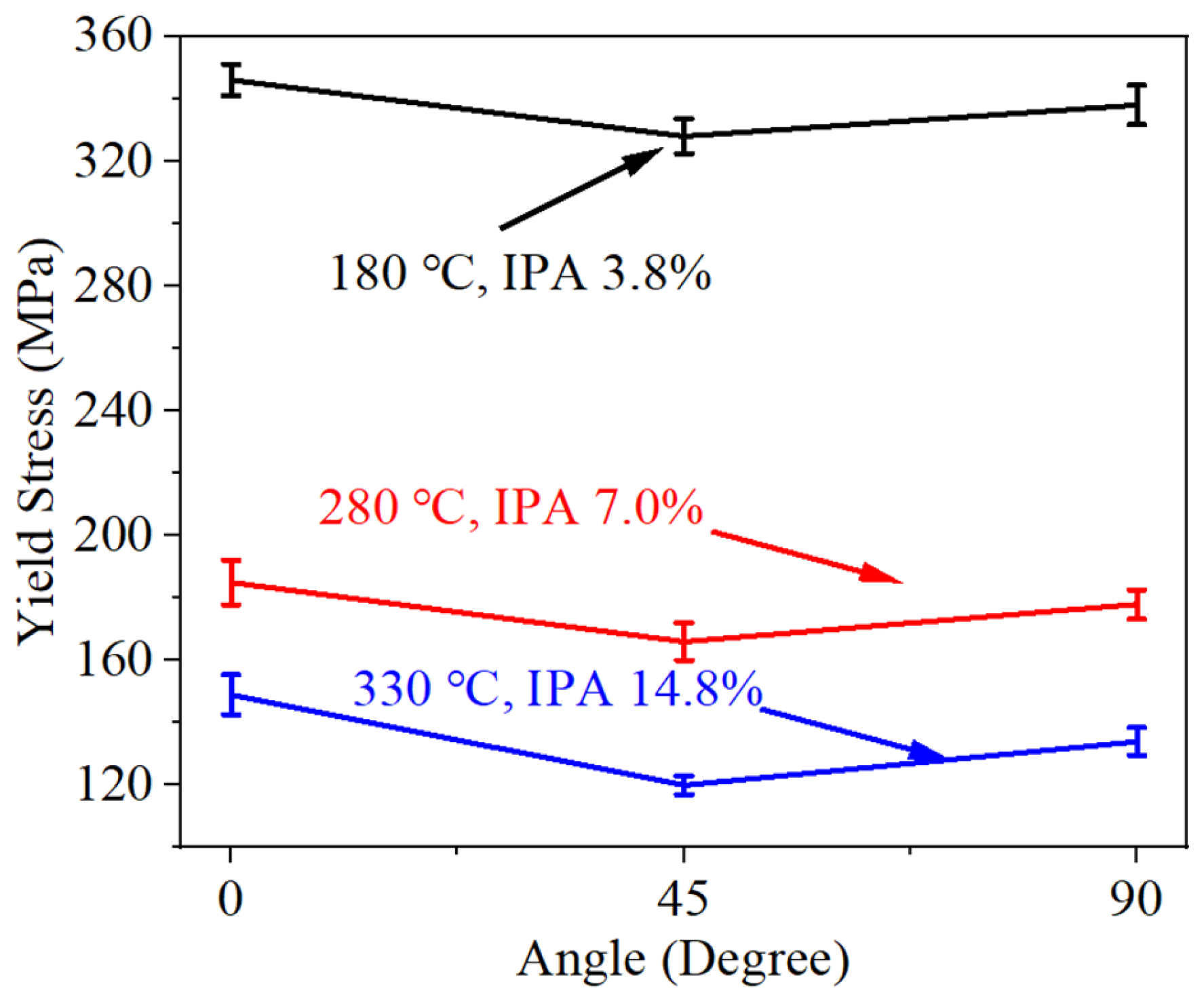

3.1. Tensile Behavior

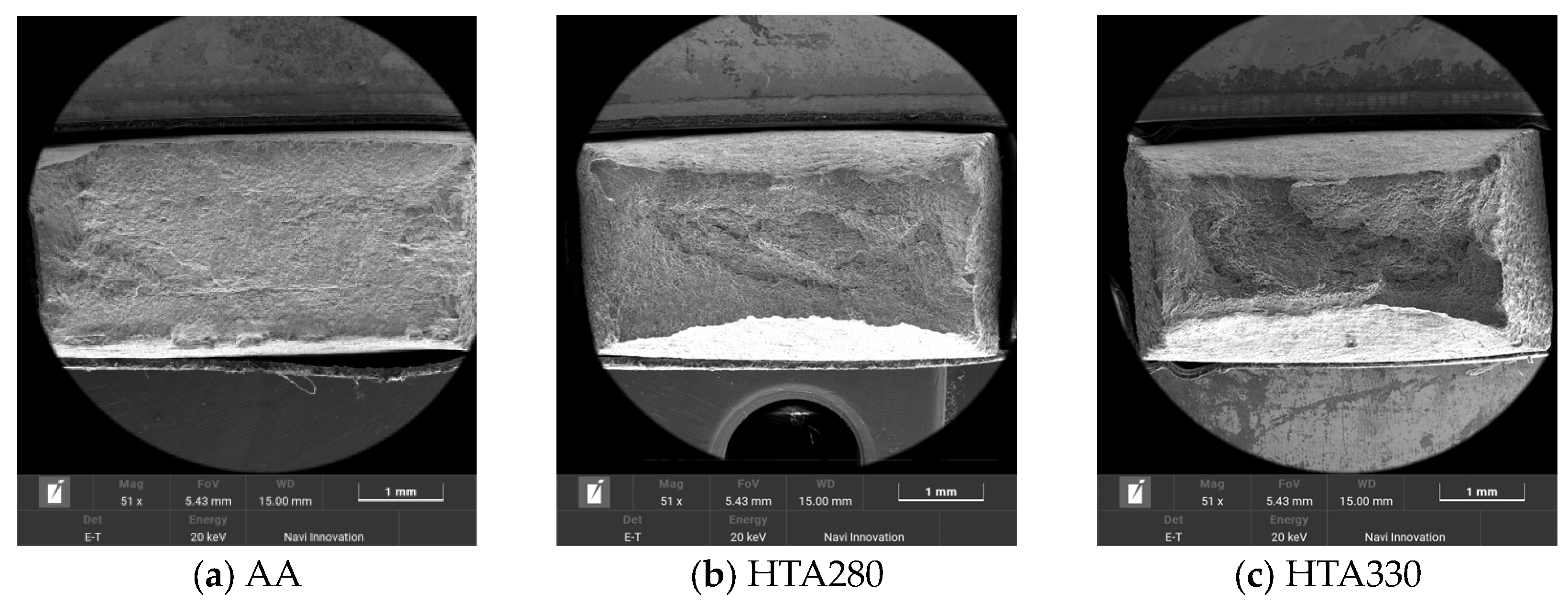

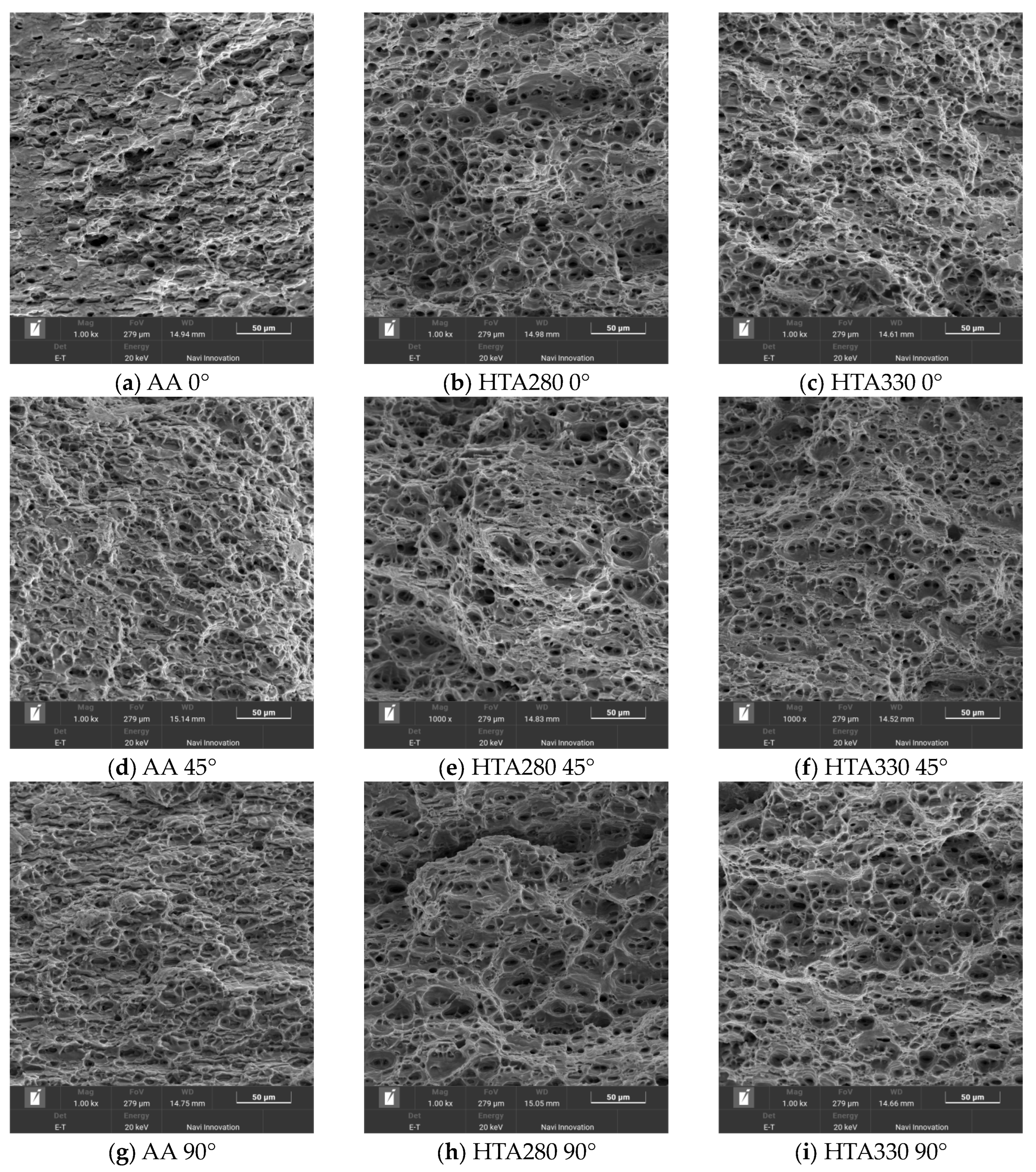

3.2. Fracture Morphology

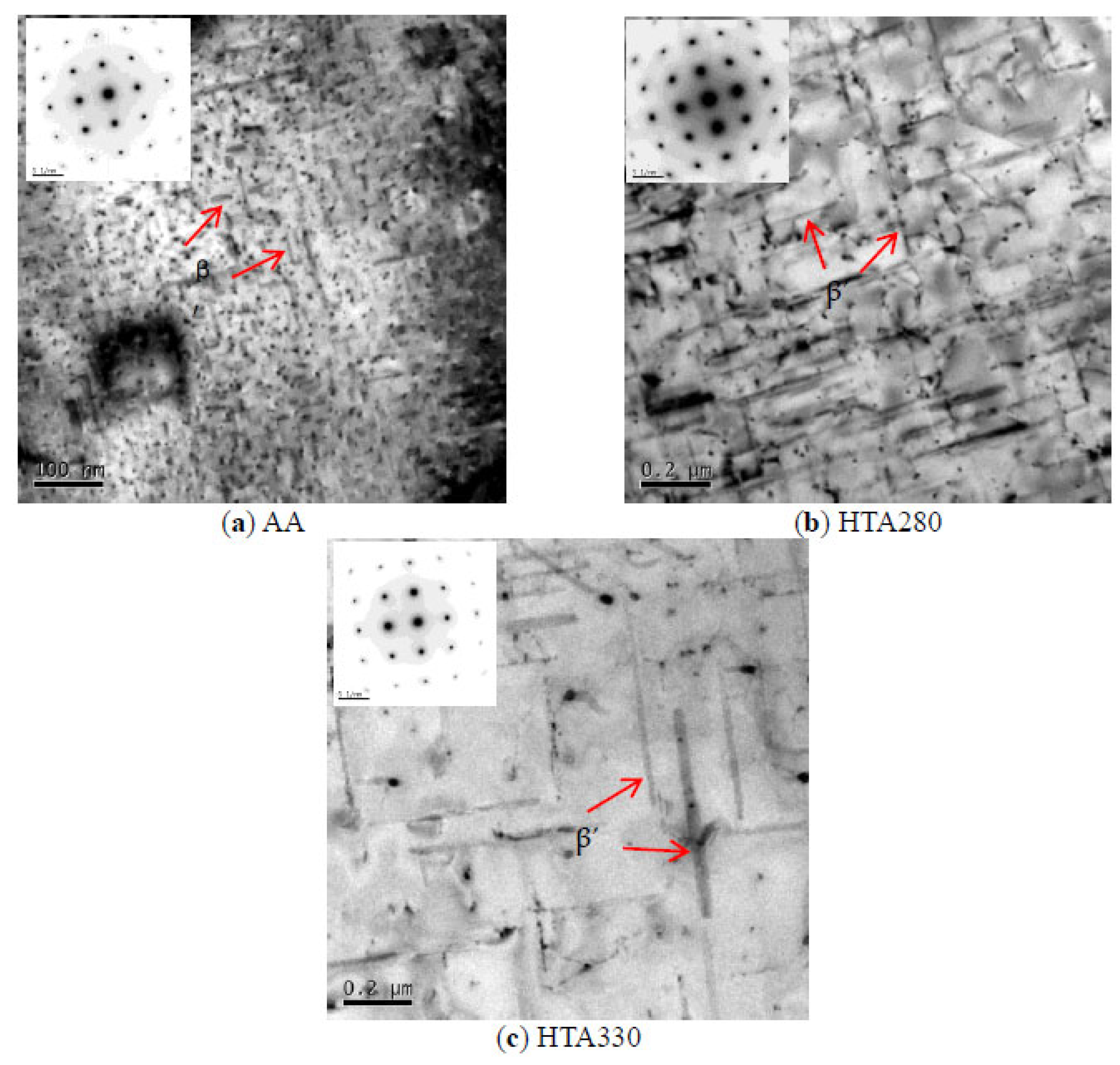

3.3. Microstructure

4. Conclusions

- (1)

- The aging process significantly influences the tensile behavior of 6082 alloy sheets. The alloy aged at 180 °C for 8 h exhibits the highest strength, with the yield strength of samples in all three directions exceeding 320 MPa, but the elongation is the lowest, all less than 10%. With the rise in aging temperature, there is a decrease in the material’s strength, accompanied by an improvement in the elongation. The alloy samples treated with an aging process at 330 °C for 0.5 h have a strength below 150 MPa, and the elongation is above 12%.

- (2)

- The three different aging processes result in relatively higher mechanical properties in the 0° and 90° directions and lower properties in the 45° direction. The HTA330 samples have the greatest IPA value, while AA samples have the lowest. The fibrous grain structure is the main cause of anisotropy in the tensile behavior. The three types of aging treatments exert no considerable influence on the grain morphology.

- (3)

- The alloy that has undergone an aging treatment at 180 °C for 8 h exhibits a multitude of fine precipitates within its matrix. These β″ precipitates effectively pin dislocations during the plastic deformation process of the material, thereby increasing the resistance to deformation. However, as the aging temperature increases, the precipitates within the matrix coarsen and their density decreases, leading to a reduction in the material’s strength. Moreover, the fine precipitates effectively suppress the anisotropy of the material’s mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Derbiszewski, B.; Obraniak, A.; Rylski, A.; Siczek, K.; Wozniak, M. Studies on the Quality of Joints and Phenomena Therein for Welded Automotive Components Made of Aluminum Alloy—A Review. Coatings 2024, 14, 601. [Google Scholar] [CrossRef]

- Hodžić, E.; Domitner, J.; Thum, A.; Sabet, A.S.; Müllner, N.; Fragner, W.; Sommitsch, C. Influence of natural aging on the formability of Al-Mg-Si alloy blanks. J. Manuf. Process. 2023, 94, 228–239. [Google Scholar] [CrossRef]

- Ye, T.; Li, L.; Liu, X.; Liu, W.; Guo, P.; Tang, X. Anisotropic deformation behavior of as-extruded 6063-T4 alloy under dynamic impact loading. Mater. Sci. Eng. A 2016, 666, 149–155. [Google Scholar] [CrossRef]

- Tiwari, A.; Singh, G.; Jayaganthan, R. Improved Corrosion Resistance Behaviour of AlSi10Mg Alloy due to Selective Laser Melting. Coatings 2023, 13, 225. [Google Scholar] [CrossRef]

- Jo, Y.H.; Moon, H.R.; Bae, J.W.; Yoo, J.; Lee, S.G.; Lee, Y.S.; Kim, H.W. Effects of casting speed on microstructural and tensile properties of Al–Mg–Si alloy fabri-cated by horizontal and vertical twin-roll casting. J. Mater. Res. Technol. 2023, 26, 8010–8024. [Google Scholar] [CrossRef]

- Liu, T.; Wu, Y.; Wang, H.; Guo, C. Investigation of Evolution of Microstructure, Mechanical Properties, and Corrosion Resistance of Novel Al-Mg-Si-Ag Alloy. Coatings 2023, 13, 2012. [Google Scholar] [CrossRef]

- Long, R.S.; Boettcher, E.; Crawford, D. Current and future uses of aluminum in the automotive industry. JOM 2017, 69, 2635–2639. [Google Scholar] [CrossRef]

- Di Bella, G.; Borsellino, C.; Khaskhoussi, A.; Proverbio, E. Effect of tool rotation direction on mechanical strength of single lap friction stir welded joints between aa5083 aluminum alloy and s355j0 steel for maritime applications. Metals 2023, 13, 411. [Google Scholar] [CrossRef]

- Ye, T.; Li, L.; Guo, P.; Xiao, G.; Chen, Z. Effect of aging treatment on the microstructure and flow behavior of 6063 aluminum alloy compressed over a wide range of strain rate. Int. J. Impact Eng. 2016, 90, 72–80. [Google Scholar] [CrossRef]

- Hagen, A.B.; Wenner, S.; Bjørge, R.; Wan, D.; Marioara, C.D.; Holmestad, R.; Ringdalen, I.G. Local mechanical properties and precipitation inhomogeneity in large-grained Al-Mg-Si alloy. Mater. Sci. Eng. A 2023, 872, 144222. [Google Scholar] [CrossRef]

- Ye, T.; Wu, Y.; Liu, A.; Xu, C.; Li, L. Mechanical property and microstructure evolution of aged 6063 aluminum alloy under high strain rate deformation. Vacuum 2019, 159, 37–44. [Google Scholar] [CrossRef]

- Zupanič, F.; Žist, S.; Albu, M.; Letofsky-Papst, I.; Burja, J.; Vončina, M.; Bončina, T. Dispersoids in Al-Mg-Si Alloy AA 6086 Modified by Sc and Y. Materials 2023, 16, 2949. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.; Sun, B.; Wang, J.; Liu, Y.; Liu, C. High-temperature age-hardening behavior of Al–Mg–Si alloys with varying Sn contents. J. Mater. Res. Technol. 2021, 14, 2165–2173. [Google Scholar] [CrossRef]

- Zhang, L.; He, H.; Li, S.; Wu, X.; Li, L. Dynamic compression behavior of 6005 aluminum alloy aged at elevated temperatures. Vacuum 2018, 155, 604–611. [Google Scholar] [CrossRef]

- Wang, D.; Liu, S.; Zhang, X.; Li, X.; Zhang, H.; Nagaumi, H. Fast aging strengthening by hybrid precipitates in high pressure die-cast Al-Si-Cu-Mg-Zn alloy. Mater. Charact. 2021, 179, 111312. [Google Scholar] [CrossRef]

- Stojanovic, B.; Bukvic, M.; Epler, I. Application of aluminum and aluminum alloys in engineering. Appl. Eng. Lett. J. Eng. Appl. Sci. 2018, 3. [Google Scholar] [CrossRef]

- Abrar, M.S.U.; Ezaz, K.F.N.; Hasan, M.J.; Pranto, R.I.; Alvy, T.A.; Hossain, M.Z. Speed-dependent impact analysis on a car bumper structure using various materials. Results Eng. 2024, 21, 101927. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, G.; Xu, X.; Wang, Y. Effects of heat treatment on the microstructure, texture and mechanical property anisotropy of extruded 2196 Al-Cu-Li alloy. J. Alloys Compd. 2021, 862, 158102. [Google Scholar] [CrossRef]

- Li, Y.; Xu, G.; Liu, S.; Wang, B.; Peng, X. Study on anisotropy of Al-Zn-Mg-Sc-Zr alloy sheet. Mater. Charact. 2021, 172, 110904. [Google Scholar] [CrossRef]

- Examilioti, T.N.; Li, W.; Kashaev, N.; Ventzke, V.; Klusemann, B.; Tiryakioğlu, M.; Alexopoulos, N.D. On anisotropic tensile mechanical behavior of Al–Cu–Li AA2198 alloy under different ageing conditions. J. Mater. Res. Technol. 2023, 24, 895–908. [Google Scholar] [CrossRef]

- Naumenko, K.; Gariboldi, E. Experimental analysis and constitutive modeling of anisotropic creep damage in a wrought age-hardenable Al alloy. Eng. Fract. Mech. 2022, 259, 108119. [Google Scholar] [CrossRef]

- Engler, O. Effect of precipitation state on plastic anisotropy in sheets of the age-hardenable aluminium alloys AA 6016 and AA 7021. Mater. Sci. Eng. A 2022, 830, 142324. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, J. Microstructure evolution and mechanical responses of Al–Zn–Mg–Cu alloys during hot deformation process. J. Mater. Sci. 2021, 56, 13429–13478. [Google Scholar] [CrossRef]

- Zhao, N.; Ma, H.; Hu, Z.; Yan, Y.; Chen, T. Microstructure and mechanical properties of Al-Mg-Si alloy during solution heat treatment and forging integrated forming process. Mater. Charact. 2022, 185, 111762. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Y.; Liu, Y.; Huang, Y. Influence of substructures on precipitation behavior and mechanical properties of cryogenic rolled Al–Mg–Si alloys during aging treatment. J. Mater. Res. Technol. 2023, 25, 946–959. [Google Scholar] [CrossRef]

- Zhu, X.; Yang, X.; Huang, W.; Qiu, W.; Wang, X.; Guo, F.; Hu, L.; Gong, M. Influence of pre-stretching on the tensile strength, fatigue properties and the in-plane anisot-ropy in Al-Cu-Li alloy AA2099. J. Mater. Sci. Technol. 2023, 145, 249–259. [Google Scholar] [CrossRef]

- Khadyko, M.; Myhr, O.; Hopperstad, O. Work hardening and plastic anisotropy of naturally and artificially aged aluminium alloy AA6063. Mech. Mater. 2019, 136, 103069. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, L.; Ma, Q.; Feng, J.; Li, X. Effect of pre-deformation on creep age forming of AA2219 plate: Springback, microstructures and mechanical properties. J. Mech. Work. Technol. 2016, 229, 697–702. [Google Scholar] [CrossRef]

- Gampert, S.; Siddique, A.B.; Khraishi, T.A. Void Growth and Interaction in a Structural Aluminum Alloy: Experiments and Theory. J. Miner. Mater. Charact. Eng. 2021, 9, 14–37. [Google Scholar] [CrossRef]

- Wciślik, W.; Lipiec, S. Void-induced ductile fracture of metals: Experimental observations. Materials 2022, 15, 6473. [Google Scholar] [CrossRef]

- Jia, Z.; Mu, L.; Guan, B.; Qian, L.-Y.; Zang, Y. Experimental and Numerical Study on Ductile Fracture Prediction of Aluminum Alloy 6016-T6 Sheets Using a Phenomenological Model. J. Mater. Eng. Perform. 2021, 31, 867–881. [Google Scholar] [CrossRef]

- Kong, S.; Liu, Q.; Zhang, Z. Mechanism on material strengthening of metastable precipitate and edge dislocation in Al–Mg–Si alloy. Phys. Status Solidi 2023, 260, 2200478. [Google Scholar] [CrossRef]

- Kong, S.; Yu, Z.; Zhang, X.; Zhang, Z. Coupling strengthening mechanism of precipitate and solute atoms in edge dislocation motion of Al-Mg-Si alloy. J. Mater. Res. Technol. 2024, 30, 134–145. [Google Scholar] [CrossRef]

- Jin, S.; Ngai, T.; Zhang, G.; Zhai, T.; Jia, S.; Li, L. Precipitation strengthening mechanisms during natural ageing and subsequent artificial aging in an Al-Mg-Si-Cu alloy. Mater. Sci. Eng. A 2018, 724, 53–59. [Google Scholar] [CrossRef]

- Chrominski, W.; Wenner, S.; Marioara, C.D.; Holmestad, R.; Lewandowska, M. Strengthening mechanisms in ultrafine grained Al-Mg-Si alloy processed by hydrostatic extrusion—Influence of ageing temperature. Mater. Sci. Eng. A 2016, 669, 447–458. [Google Scholar] [CrossRef]

| Condition | AA | HTA280 | HTA330 |

| IPA | 3.8 | 7.0 | 14.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, E.; Ye, T.; Wang, L.; Qiu, S.; Tian, Y.; Wu, C.; Luo, J.; Wu, Y. Tensile Behavior and Microstructure of the 6082 Alloy Sheet with High-Temperature Aging Treatments. Coatings 2024, 14, 963. https://doi.org/10.3390/coatings14080963

Xia E, Ye T, Wang L, Qiu S, Tian Y, Wu C, Luo J, Wu Y. Tensile Behavior and Microstructure of the 6082 Alloy Sheet with High-Temperature Aging Treatments. Coatings. 2024; 14(8):963. https://doi.org/10.3390/coatings14080963

Chicago/Turabian StyleXia, Erli, Tuo Ye, Lijun Wang, Sawei Qiu, Yiran Tian, Changping Wu, Jing Luo, and Yuanzhi Wu. 2024. "Tensile Behavior and Microstructure of the 6082 Alloy Sheet with High-Temperature Aging Treatments" Coatings 14, no. 8: 963. https://doi.org/10.3390/coatings14080963

APA StyleXia, E., Ye, T., Wang, L., Qiu, S., Tian, Y., Wu, C., Luo, J., & Wu, Y. (2024). Tensile Behavior and Microstructure of the 6082 Alloy Sheet with High-Temperature Aging Treatments. Coatings, 14(8), 963. https://doi.org/10.3390/coatings14080963