The Evaluation of the Cytotoxicity and Corrosion Processes of Porous Structures Manufactured Using Binder Jetting Technology from Stainless Steel 316L with Diamond-like Carbon Coating

Abstract

1. Introduction

2. Materials and Methods

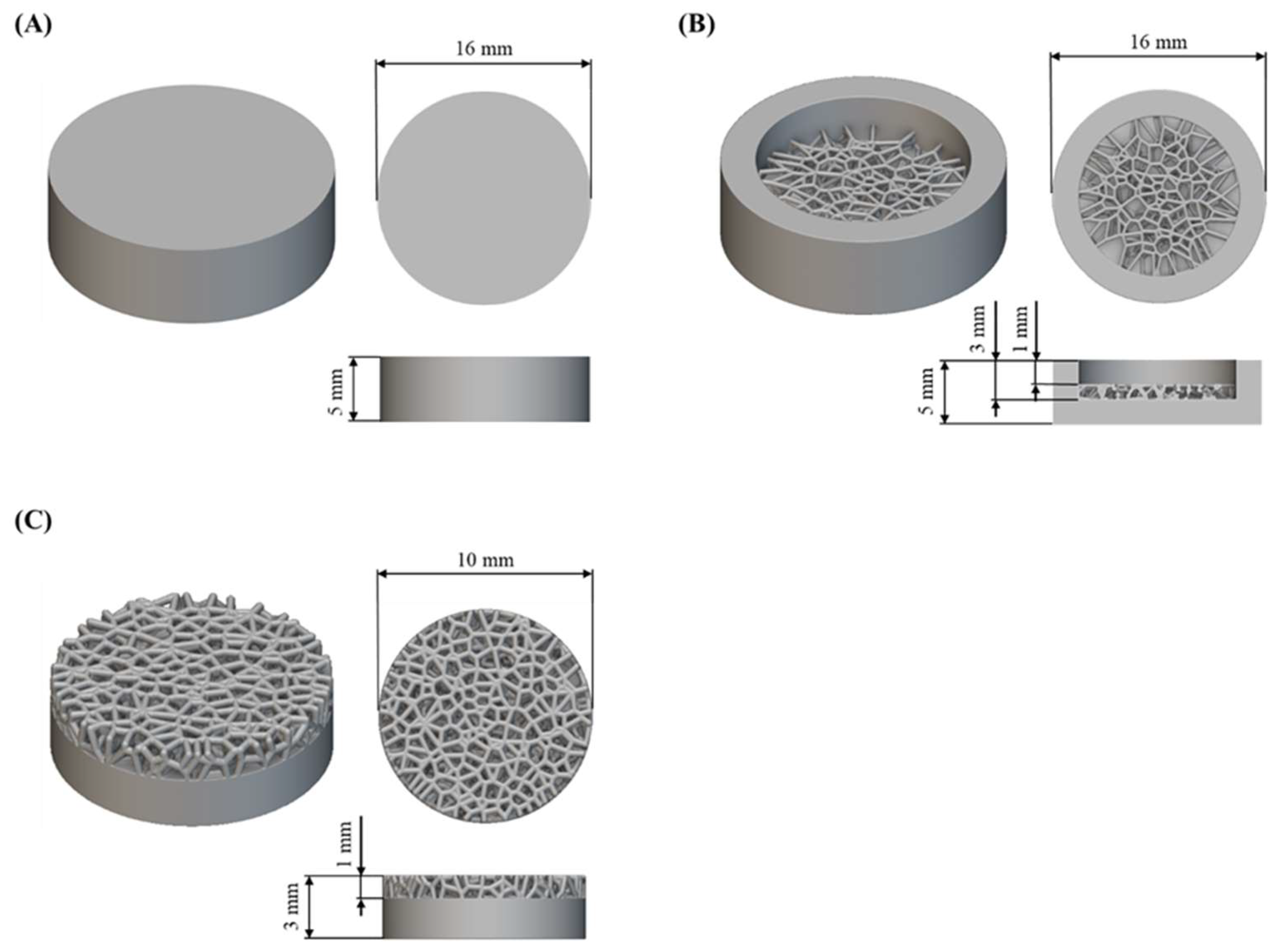

2.1. Sample Fabrication

2.2. DLC Coating Deposition

2.3. Scaning Electron Microscopy

2.4. Electrochemical Corrosion

2.5. Cytotoxicity Test

2.5.1. Cytotoxicity of Samples Was Assessed Based on Tests in Indirect and Direct Contact

- Negative control—fresh culture medium without additives;

- Positive control—fresh culture medium with sodium cyanide added at a concentration of 1.25 mg/mL;

- Reference samples—extract from unmodified discs or unmodified discs;

- Test samples—extract from DLC discs or DLC discs.

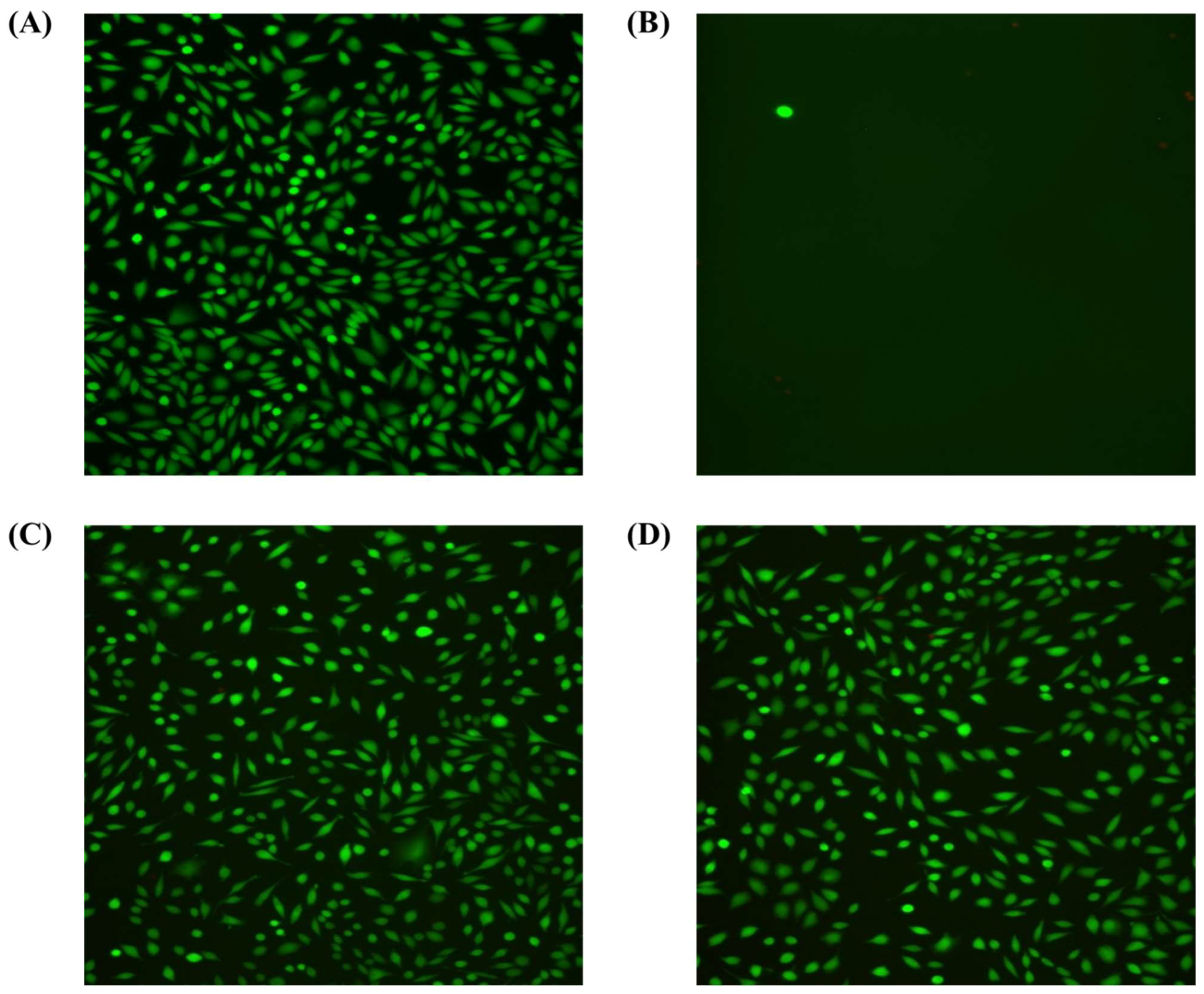

2.5.2. FDA/PI Semi-Quantitative Assessment (Direct Only)

2.5.3. Assessment of Metabolic Activity

3. Materials and Methods

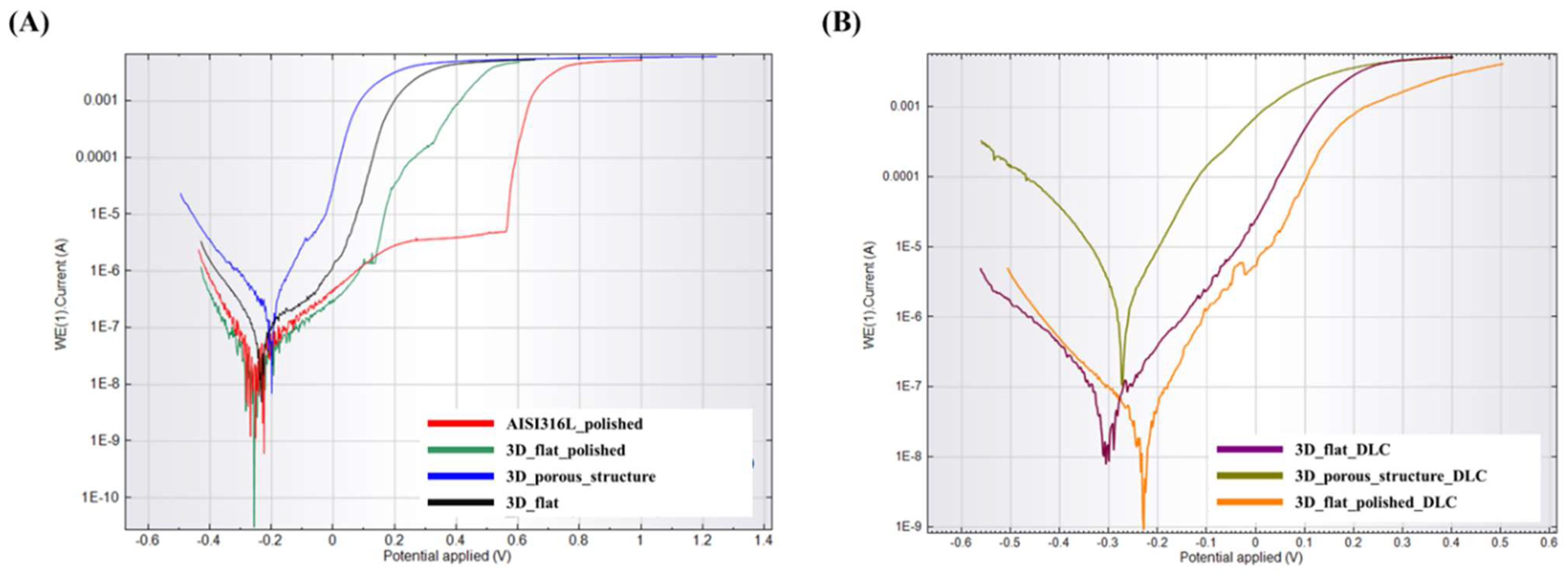

3.1. Electrochemical Corrosion

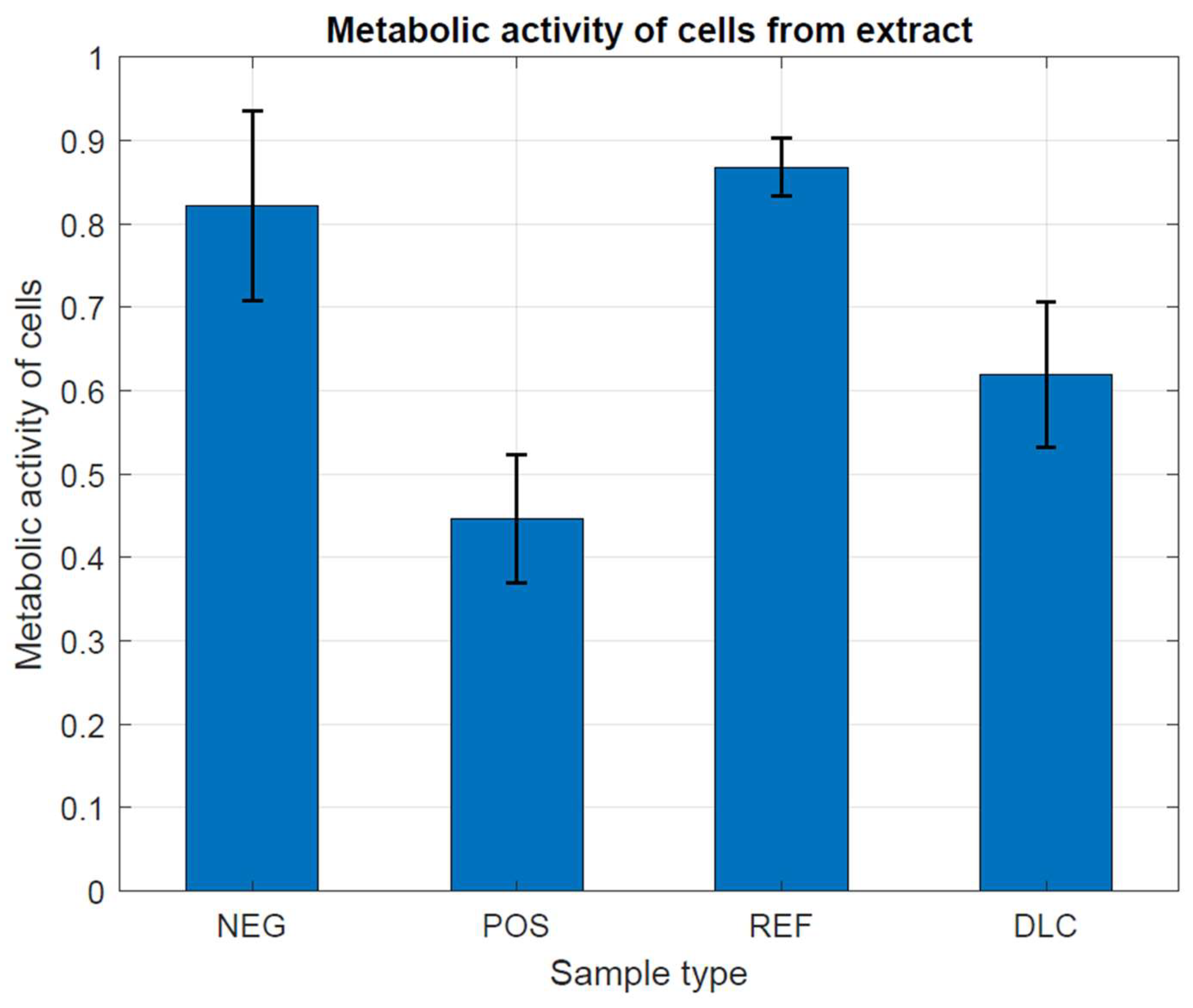

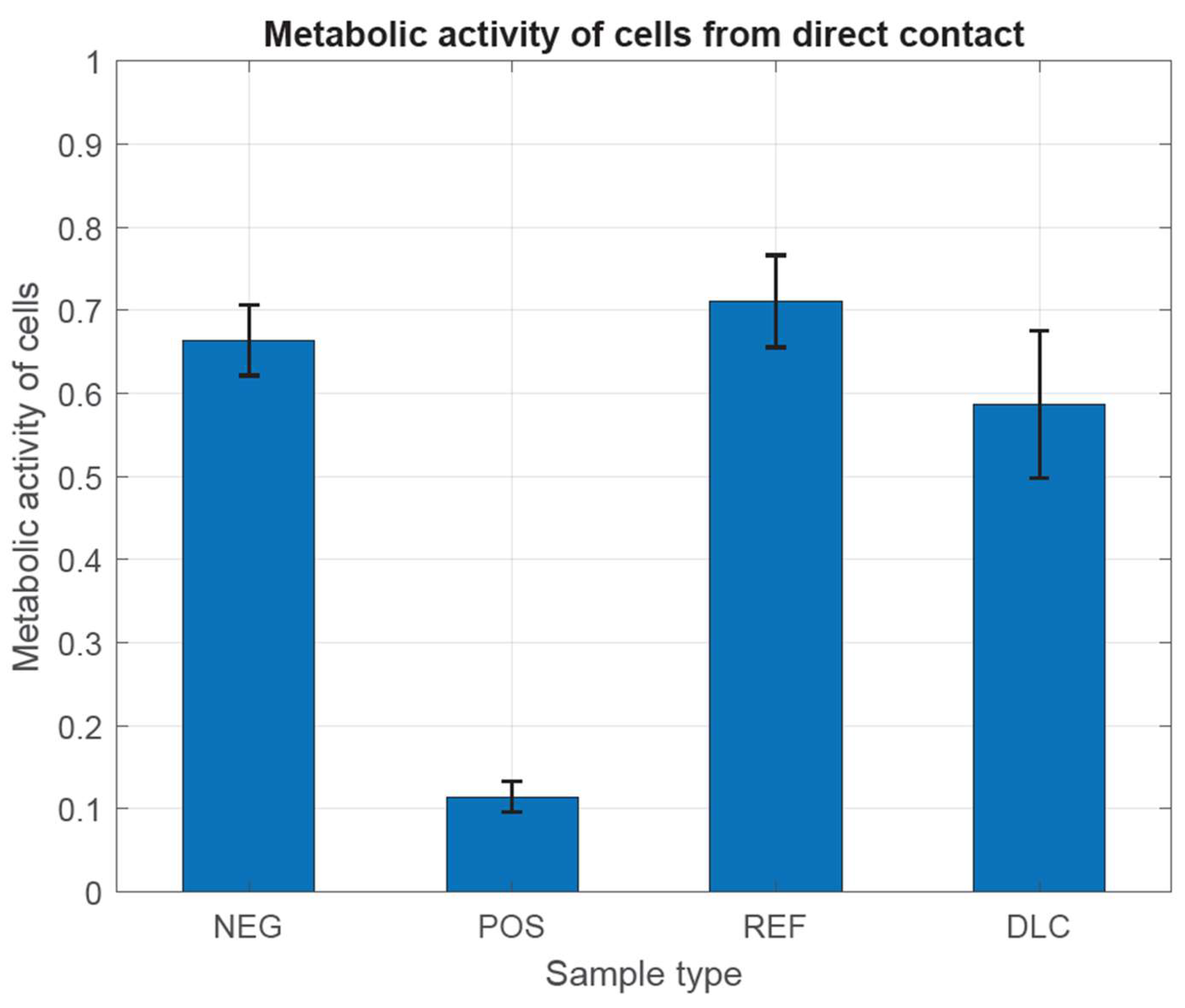

3.2. Cytotoxicity Test

3.2.1. Cell Viability

3.2.2. Assessment of Metabolic Activity

4. Conclusions

- Surface morphology and roughness had the greatest impact on the DLC coating deposition process.

- The DLC coating did not affect the macroporous structure of the elements and, at the same time, tightly covered their surface within the tested range.

- Flat samples with a polished and as-built surface showed higher corrosion resistance both before and after modification with a DLC coating in comparison to the samples with a porous structure. However, this model is difficult to analyze and compare with a flat surface due to the significant development of the tested surface and additional electrochemical phenomena that may occur in surface irregularities.

- The obtained electrochemical corrosion test results indicate the possibility of the discontinuity of the DLC coating, especially on substrates with a porous structure.

- In the presented results of the cytotoxicity studies, no statistical cytotoxic effect was demonstrated for mouse fibroblast cells in the presence of unmodified metal samples and those modified with DLC coatings. No significant differences were observed between DLC-coated samples and uncoated samples. However, the biocompatibility of the tested biomaterials was demonstrated, and the need to modify the parameters of sample design for printing and the parameters of DLC coating production to achieve a uniform coating thickness was highlighted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, L.; Ding, S.; Wen, C. Additive manufacturing technology for porous metal implant applications and triple minimal surface structures: A review. Bioact. Mater. 2019, 4, 56–70. [Google Scholar] [CrossRef] [PubMed]

- Kawar, S.; Vijayavenkataraman, S. Design of 3D printed scaffolds for bone tissue engineering: A review. Bioprinting 2021, 24, e00167. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Mitra, I.; Avila, J.D.; Upadhyayula, M.; Bose, S. Porous metal implants: Processing, properties, and challenges. Int. J. Extreme Manuf. 2023, 5, 032014. [Google Scholar] [CrossRef]

- Rana, M.; Karmakar, S.K.; Pal, B.; Datta, P.; Roychowdhury, A.; Bandyopadhyay, A. Design and manufacturing of biomimetic porous metal implants. J. Mater. Res. 2021, 36, 3952–3962. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, M.; Liu, Z.; Wang, Y.; Dong, W.; Zhao, S.; Sun, D. Biomimetic design strategy of complex porous structure based on 3D printing Ti-6Al-4V scaffolds for enhanced osseointegration. Mater. Des. 2022, 218, 110721. [Google Scholar] [CrossRef]

- Woodard, J.R.; Hilldore, A.J.; Lan, S.K.; Park, C.J.; Morgan, A.W.; Eurell, J.A.C.; Clark, S.G.; Wheeler, M.B.; Jamison, R.D.; Wagoner, A.J. The mechanical properties and osteoconductivity of hydroxyapatite bone scaffolds with multi-scale porosity. Biomaterials 2007, 28, 45–54. [Google Scholar] [CrossRef] [PubMed]

- Murr, L.E. Strategies for creating living, additively manufactured, open-cellular metal and alloy implants by promoting osseointegration, osteoinduction and vascularization: An overview. J. Mater. Sci. Technol. 2019, 35, 231–241. [Google Scholar] [CrossRef]

- Liu, Y.; Rath, B.; Tingart, M.; Eschweiler, J. Role of implants surface modification in osseointegration: A systematic review. J. Biomed. Mater. Res. Part A 2020, 108, 470–484. [Google Scholar] [CrossRef]

- Jahani, B.; Wang, X. The Effects of Surface Roughness on the Functionality of Ti13Nb13Zr Orthopedic Implants. Biomed. J. Sci. Tech. Res. 2021, 38, 30058–30067. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Riva, L.; Ginestra, P.S.; Ceretti, E. Mechanical characterization and properties of laser-based powder bed–fused lattice structures: A review. Int. J. Adv. Manuf. Technol. 2021, 113, 649–671. [Google Scholar] [CrossRef]

- Amani, Y.; Dancette, S.; Delroisse, P.; Simar, A.; Maire, E. Compression behavior of lattice structures produced by selective laser melting: X-ray tomography based experimental and finite element approaches. Acta Mater. 2018, 159, 395–407. [Google Scholar] [CrossRef]

- Du Plessis, A.; Razavi, N.; Benedetti, M.; Murchio, S.; Leary, M.; Watson, M.; Bhate, D.; Berto, F. Properties and applications of additively manufactured metallic cellular materials: A review. Prog. Mater. Sci. 2022, 125, 100918. [Google Scholar] [CrossRef]

- Benedetti, M.; Du Plessis, A.; Ritchie, R.O.; Dallago, M.; Razavi, N.; Berto, F. Architected cellular materials: A review on their mechanical properties towards fatigue-tolerant design and fabrication. Mater. Sci. Eng. R Rep. 2021, 144, 100606. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Y.; Wang, C.; Zhang, A.; Chen, B.; Han, Q.; Wang, J. Design and properties of biomimetic irregular scaffolds for bone tissue engineering. Comput. Biol. Med. 2021, 130, 104241. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Liang, H.; Xie, D.; Mao, N.; Zhao, J.; Tian, Z.; Wang, C.; Shen, L. Design and statistical analysis of irregular porous scaffolds for orthopedic reconstruction based on voronoi tessellation and fabricated via selective laser melting (SLM). Mater. Chem. Phys. 2020, 239, 121968. [Google Scholar] [CrossRef]

- Deering, J.; Dowling, K.I.; DiCecco, L.A.; McLean, G.D.; Yu, B.; Grandfield, K. Selective Voronoi tessellation as a method to design anisotropic and biomimetic implants. J. Mech. Behav. Biomed. Mater. 2021, 116, 104361. [Google Scholar] [CrossRef]

- Liang, H.; Yang, Y.; Xie, D.; Li, L.; Mao, N.; Wang, C.; Tian, Z.; Jiang, Q.; Shen, L. Trabecular-like Ti-6Al-4V scaffolds for orthopedic: Fabrication by selective laser melting and in vitro biocompatibility. J. Mater. Sci. Technol. 2019, 35, 1284–1297. [Google Scholar] [CrossRef]

- Yang, L.; Mertens, R.; Ferrucci, M.; Yan, C.; Shi, Y.; Yang, S. Continuous graded Gyroid cellular structures fabricated by selective laser melting: Design, manufacturing and mechanical properties. Mater. Des. 2019, 162, 394–404. [Google Scholar] [CrossRef]

- Maskery, I.; Sturm, L.; Aremu, A.O.; Panesar, A.; Williams, C.B.; Tuck, C.J.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Insights into the mechanical properties of several triply periodic minimal surface lattice structures made by polymer additive manufacturing. Polymer 2018, 152, 62–71. [Google Scholar] [CrossRef]

- Dong, Z.; Zhao, X. Application of TPMS structure in bone regeneration. Eng. Regen. 2021, 2, 154–162. [Google Scholar] [CrossRef]

- Laskowska, D.; Szatkiewicz, T.; Bałasz, B.; Mitura, K. Mechanical Properties and Energy Absorption Abilities of Diamond TPMS Cylindrical Structures Fabricated by Selective Laser Melting with 316L Stainless Steel. Materials 2023, 16, 3196. [Google Scholar] [CrossRef] [PubMed]

- Williams, D.F. On the mechanisms of biocompatibility. Biomaterials 2008, 29, 2941–2953. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, P.; Das, S.K.; Paulo Davim, J. Tribology of materials for biomedical applications. In Mechanical Behaviour of Biomaterials; Paulo Davim, J., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–45. [Google Scholar] [CrossRef]

- Ali, S.; Abdul Rani, A.R.; Baig, Z.; Ahmed, S.W.; Hussain, G.; Subramaniam, K.; Hastuty, S.; Rao, T.V.V.L.N. Biocompatibility and corrosion resistance of metallic biomaterials. Corros. Rev. 2020, 38, 381–402. [Google Scholar] [CrossRef]

- Zitter, H.; Plenk, H. The electrochemical behavior of metallic implant materials as an indicator of their biocompatibility. J. Biomed. Mater. Res. 1987, 21, 881–896. [Google Scholar] [CrossRef] [PubMed]

- Ude, C.C.; Esdaille, C.J.; Ogueri, K.S.; Kan, H.-M.; Laurencin, S.J.; Nair, L.S.; Laurencin, C.T. The Mechanism of Metallosis After Total Hip Arthroplasty. Regen. Eng. Transl. Med. 2021, 7, 247–261. [Google Scholar] [CrossRef] [PubMed]

- Mushtaq, M.; Qureshi, O.A.; Dua, A.; Khan, S.; Mehraj, M. Metallosis and Nonunion: A Case Series and Literature Review. Cureus 2023, 15, e35385. [Google Scholar] [CrossRef] [PubMed]

- Cañizares, S.; Carrera Barriga, G.C.; Valencia Jarrín, F.; Poveda Freire, C.D. Metallosis After Oxinium Total Knee Arthroplasty in a Patient With Rheumatoid Arthritis: A Case Report. Cureus 2023, 15, e34541. [Google Scholar] [CrossRef] [PubMed]

- Arima, M.; Matsuzawa, T.; Hashimoto, E.; Ochiai, N.; Matsusaka, K.; Inozume, T. A case of metallosis mimicking cutaneous malignant melanoma following total elbow arthroplasty. JEADV Clin. Pract. 2023, 2, 343–346. [Google Scholar] [CrossRef]

- Asri, R.I.M.; Harun, W.S.W.; Samykano, M.; Lah, N.A.C.; Ghani, S.A.C.; Tarlochan, F.; Raza, M.R. Corrosion and surface modification on biocompatible metals: A review. Mater. Sci. Eng. C 2017, 77, 1261–1274. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Mitra, I.; Goodman, S.B.; Kumar, M.; Bose, S. Improving biocompatibility for next generation of metallic implants. Prog. Mater. Sci. 2023, 133, 101053. [Google Scholar] [CrossRef] [PubMed]

- Roy, R.K.; Lee, K.R. Biomedical applications of diamond-like carbon coatings: A review. J. Biomed. Mater. Res. Part B 2007, 83, 72–84. [Google Scholar] [CrossRef]

- Korepanov, V.I.; Hamaguchi, H.; Osawa, E.; Ermolenkov, V.; Lednev, I.K.; Etzold, B.J.M.; Levinson, O.; Zousman, B.; Epperla, C.P.; Chang, H.-C. Carbon structure in nanodiamonds elucidated from Raman spectroscopy. Carbon 2017, 121, 322–329. [Google Scholar] [CrossRef]

- Chauhan, S.; Jain, N.; Nagaich, U. Nanodiamonds with powerful ability for drug delivery and biomedical applications: Recent updates on in vivo study and patents. J. Pharm. Anal. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Zakrzewska, K.E.; Samluk, A.; Wierzbicki, M.; Jaworski, S.; Kutwin, M.; Sawosz, E.; Chwalibog, A.; Pijanowska, D.G.; Pluta, K.D. Analysis of the Cytotoxicity of Carbon-Based Nanoparticles, Diamond and Graphite, in Human Glioblastoma and Hepatoma Cell Lines. PLoS ONE 2015, 10, e0122579. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Peng, J.; Wang, Z.; Xiao, Y.; Qiu, X. Diamond-like Carbon Coatings in the Biomedical Field: Properties, Applications and Future Development. Coatings 2022, 12, 1088. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Whitlow, J.; Pacelli, S.; Paul, A. Multifunctional nanodiamonds in regenerative medicine: Recent advances and future directions. J. Control. Release 2017, 61, 593–602. [Google Scholar] [CrossRef] [PubMed]

- Solarska-Ściuk, K.; Gajewska, A.; Skolimowski, J.; Gajek, A.; Bartosz, G. Cellular redox homeostasis in endothelial cells treated with nonmodified and Fenton-modified nanodiamond powders. Biotechnol. Appl. Biochem. 2014, 61, 593–602. [Google Scholar] [CrossRef]

- Schrand, A.M.; Huang, H.; Carlson, C.; Schlager, J.J.; Ōsawa, E.; Hussain, S.M.; Dai, L. Are Diamond Nanoparticles Cytotoxic? J. Phys. Chem. 2007, 111, 2–7. [Google Scholar] [CrossRef]

- Bociaga, D.; Mitura, K. Biomedical effect of tissue contact with metallic material used for body piercing modified by DLC coatings. Diam. Relat. Mater. 2008, 17, 1410–1415. [Google Scholar] [CrossRef]

- Niemiec, T.; Szmidt, M.; Sawosz, E.; Grodzik, M.; Mitura, K. The Effect of Diamond Nanoparticles on Redox and Immune Parameters in Rats. J. Nanosci. Nanotechnol. 2011, 11, 9072–9077. [Google Scholar] [CrossRef] [PubMed]

- Myrzagali, S.; Omarova, Z.; Zeitkaziyeva, D.; Madet, A.; Xie, Y. Carbon nanoparticle-induced cell death. Carbon Trends 2024, 15, 100352. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, C.; Yue, W.; Wang, X.; Sun, Y.; Bi, W.; Wang, L.; Xu, Y. Sugar-coated cannonballs for effective antibacterial treatments but with negligible cytotoxicity based on silver (copper) -containing carbon dots and their mechanism analysis. Carbon 2024, 224, 119085. [Google Scholar] [CrossRef]

- Shaimoldina, A.; Sergazina, A.; Myrzagali, S.; Nazarbek, G.; Omarova, Z.; Mirza, O.; Fan, H.; Amin, A.; Zhou, W.; Xie, Y. Carbon nanoparticles neutralize carbon dioxide (CO2) in cytotoxicity: Potent carbon emission induced resistance to anticancer nanomedicine and antibiotics. Ecotoxicol. Environ. Saf. 2024, 273, 116024. [Google Scholar] [CrossRef] [PubMed]

- nTopology. 2020. Available online: https://ntopology.com/ (accessed on 2 May 2024).

- Laskowska, D.; Bałasz, B.; Kaczorowski, W.; Grabarczyk, J.; Svobodova, L.; Szatkiewicz, T.; Mitura, K. The DLC Coating on 316L Stainless Steel Stochastic Voronoi Tessellation Structures Obtained by Binder Jetting Additive Manufacturing for Potential Biomedical Applications. Coatings 2022, 12, 1373. [Google Scholar] [CrossRef]

- Bose, S.; Ke, D.; Sahasrabudhe, H.; Bandyopadhyay, A. Additive manufacturing of biomaterials. Prog. Mater. Sci. 2018, 93, 45–111. [Google Scholar] [CrossRef] [PubMed]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Grabarczyk, J.; Batory, D.; Kaczorowski, W.; Pązik, B.; Januszewicz, B.; Burnat, B.; Czerniak-Reczulska, M.; Makówka, M.; Niedzielski, P. Comparison of Different Thermo-Chemical Treatments Methods of Ti-6Al-4V Alloy in Terms of Tribological and Corrosion Properties. Materials 2020, 13, 5192. [Google Scholar] [CrossRef]

- ISO 10993-12:2021; Biological Evaluation of Medical Devices, Part 12: Sample Preparation and Reference Materials, Edition 5. ISO: Geneva, Switzerland, 2021.

- ISO 10093-5:2009; Biological Evaluation of Medical Devices, Part 5: Tests for In Vitro Cytotoxicity, Edition 3. ISO: Geneva, Switzerland, 2009.

- Mitura, K.; Kornacka, J.; Niemiec-Cyganek, A.; Pawlus-Łacgecka, L.; Mydłowska, K.; Sobczyk-Guzenda, A.; Kaczorowski, W.; Ossowska, P.; Bałasz, B.; Wilczek, P. The Influence of Diamond Nanoparticles on Fibroblast Cell Line L929, Cytotoxicity and Bacteriostaticity of Selected Pathogens. Coatings 2022, 12, 280. [Google Scholar] [CrossRef]

| Layer thickness | mm | 0.04 | Recoat speed | mm/s | 50 |

| Saturation | % | 70 | Roller speed | rpm | 500 |

| Ultrasonic intensity | % | 100 | Roller traverse speed | mm/s | 3 |

| Parameter | Ion Pre-Treatment | DLC Coating Deposition |

|---|---|---|

| Pressure, Pa | 2 | 40 |

| RF generator, W | 500 | 1000 |

| Negative bias voltage, V | 1000 | 700 |

| Time, min | 10 | 5 |

| Type of atmosphere | - | CH4 |

| Description | Labels | |

|---|---|---|

| Substrate without DLC Coating | Substrate with DLC Coating | |

| Flat substrate with as-built surface | 3D_flat | 3D_flat_DLC |

| Flat substrate with polished surface | 3D_flat_polished | 3D_flat_polished_DLC |

| Substrate with porous structure | 3D_porous_structure | 3D_porous_structure_DLC |

| Degree of Cytotoxicity | Reactivity | Cell Condition |

|---|---|---|

| 0 | not available | Discrete intra-plasmatic granules, no lysis, no reduction in cell growth |

| 1 | slight | No more than 20% round cells, loosely suffused without intracytoplasmic granules, showing morphological changes, few cell lysis, little inhibition of cell growth |

| 2 | mild | Not more than 50% round cells, devoid of intra-plasmacytic granules, strong cell lysis, not more than 50% inhibition of cell growth |

| 3 | moderate | Not more than 70% of surface containing round cells and lysed, not completely damaged, cell growth inhibition greater than 50% |

| 4 | strong | Almost complete and total cell destruction |

| Substrate Label | Ecor [mV] | Icor [mV] | CR [mm/Year] |

|---|---|---|---|

| Substrates without DLC coating | |||

| AISI316L_polished * | −268 | 39 | 5.64 × 10−4 |

| 3D_flat_polished | −261 | 32 | 4.67 × 10−4 |

| 3D_flat | −234 | 92 | 1.34 × 10−4 |

| 3D_porous_structure | −202 | 210 | - |

| Substrates with DLC coating | |||

| 3D_flat_polished_DLC | −224 | 28 | 4.03 × 10−4 |

| 3D_flat_DLC | −311 | 48 | 7.10 × 10−4 |

| 3D_porous_structure_DLC | −273 | 1544 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laskowska, D.; Mitura, K.; Bałasz, B.; Wilczek, P.; Samotus, A.; Kaczorowski, W.; Grabarczyk, J.; Svobodová, L.; Bakalova, T.; Mitura, S. The Evaluation of the Cytotoxicity and Corrosion Processes of Porous Structures Manufactured Using Binder Jetting Technology from Stainless Steel 316L with Diamond-like Carbon Coating. Coatings 2024, 14, 1018. https://doi.org/10.3390/coatings14081018

Laskowska D, Mitura K, Bałasz B, Wilczek P, Samotus A, Kaczorowski W, Grabarczyk J, Svobodová L, Bakalova T, Mitura S. The Evaluation of the Cytotoxicity and Corrosion Processes of Porous Structures Manufactured Using Binder Jetting Technology from Stainless Steel 316L with Diamond-like Carbon Coating. Coatings. 2024; 14(8):1018. https://doi.org/10.3390/coatings14081018

Chicago/Turabian StyleLaskowska, Dorota, Katarzyna Mitura, Błażej Bałasz, Piotr Wilczek, Aneta Samotus, Witold Kaczorowski, Jacek Grabarczyk, Lucie Svobodová, Totka Bakalova, and Stanisław Mitura. 2024. "The Evaluation of the Cytotoxicity and Corrosion Processes of Porous Structures Manufactured Using Binder Jetting Technology from Stainless Steel 316L with Diamond-like Carbon Coating" Coatings 14, no. 8: 1018. https://doi.org/10.3390/coatings14081018

APA StyleLaskowska, D., Mitura, K., Bałasz, B., Wilczek, P., Samotus, A., Kaczorowski, W., Grabarczyk, J., Svobodová, L., Bakalova, T., & Mitura, S. (2024). The Evaluation of the Cytotoxicity and Corrosion Processes of Porous Structures Manufactured Using Binder Jetting Technology from Stainless Steel 316L with Diamond-like Carbon Coating. Coatings, 14(8), 1018. https://doi.org/10.3390/coatings14081018