Abstract

This study aims to study the formation quality of the film of dental silanes. Two dental silanes, 3-methacryloxyproyltrimethoxysilane (MPS) and 3-acryloyloxypropyltrimethoxysilane (ACPS), were deposited on the silica glass-equivalent model surface (i.e., n-type silicon(100) wafer) by varying the deposition time (5 h and 22 h). The film quality was then evaluated by ellipsometry, surface contact angle (CA) and surface free energy (SFE), atomic force microscopy (AFM) and X-ray photoelectron spectroscopy (XPS) in survey and high-resolution modes on Si2p, O1s and C1s. Ellipsometry confirmed that both silanes at the two different deposition times would produce 0.85–1.22 nm thick self-assembled monolayer on the silicon wafer surface. While the water CA of silanized surfaces (60.7–71.5°) was larger than the surface without silane (29.6°), the SFE values of all silanes (40.0–44.5 mN/m) were slightly less than that of the wafer surface (46.3 mN/m). AFM revealed that the MPS with 22 h silanization yielded a significantly higher roughness (0.597 μm) than other groups (0.254–0.297 μm). High-resolution XPS on C1s identified a prominent peak at 288.5 eV, which corresponds to methacrylate O-C*=O, i.e., the silane monolayer is extended fully in the vertical direction, while others are in defect states. This study proves that different dental silanes under various dipping times yield different chemical qualities of the film even if they look thin physically.

1. Introduction

Resin composite as a filling material in dentistry typically contains polymerizable resin matrix, dental silica glass particles and silane [1,2]. In particular, the glass particles add strength and durability to the resin composite, making it more resistant to wear and tear [3]. Additionally, the glass particles allow the translucency of the resin composite [4,5], and allow light to cure the resin composite at a certain depth [6].

Silane is coated on dental glass to enhance the bond between the glass particles and the resin matrix in the composite material [2]. This silane is an organosilane with the formula R3SiY, where R is an alkoxy group and Y is a carbon chain with a methacrylate, epoxy or other polymerizable group. Thus, silane acts as a coupling agent that is able to promote chemical adhesion between different materials, in this case, the glass particles and the resin. By applying a thin layer of silane to the surface of the glass particles, it is possible to produce a stronger and more stable bond between the glass and the resin matrix [6]. This helps to improve the overall strength, durability and longevity of the dental restoration. Additionally, the use of silane also helps to reduce the chances of post-operative sensitivity and failure of the restoration [7]. Furthermore, silane can also be used to prime dental porcelain [8] and silica-based ceramics such as lithium disilicate [9] to establish a chemical key with resins. On the other hand, silane can be used for multi-functional metal coating in Mg alloys [10] and Ni alloys [11], and it can become a part of a composite material usable in hydrophobic anti-icing coatings [12], universal dental adhesives [13] and anti-biofilm dental resins [14].

One of the main problems with silane on dental glass is that it is sensitive to moisture [15]. Silane needs to be hydrolyzed to become silanol, (HO)3SiY, and the silanol is a reactive material that can (1) self-assemble by condensing itself to form dimers, oligomers and polymers; (2) react with other R3SiY material to form dimers, oligomers and polymers; and (3) induce hydrogen bond formation and dehydration (a.k.a. curing) between the hydroxylated substrate and the self-assembled dimer, oligomer and polymer silanols [16,17]. The reaction is always in equilibrium, so the Si-O is prone to be attacked by moisture. This can result in a weaker bond between the glass particles and the resin matrix, and ultimately lead to failure of the restoration. In addition, if the silane layer is too thick, it can also affect the bonding between the glass and resin matrix [18]. Therefore, preferably, this layer of the silane layer as a film should be a monolayer or an ultra-thin film of high quality.

Various factors [2,19] can affect the formation quality of the silane films, such as the activation of silane coupling agent, and the silanization process on the substrate. In terms of activation, both hydrolysis and condensation reactions are involved. These two reactions are in equilibrium, and the position of the equilibrium depends on the length of the alkyl chain, which controls the rate of the hydrolysis reaction of the alkoxyl (–OR) groups, which comprise SN2 nucleophilic substitution reactions involving the backside attachment of the nucleophile [19,20,21]. Maintaining the pH of the solution in an acidic condition decreases the time of hydrolysis [21,22], and, commonly, acetic acid has been used at pH 4.4–4.5 [23,24,25], because it can not only speed up the hydrolysis but also minimize the condensation reaction [23]. In terms of the silanization process on the substrate, the concentration of the hydroxylated groups on the substrate would favor the condensation of silane film. This could be achieved by chemical treatment, e.g., piranha solution [26,27] and a sulfochromic bath [23,28], and oxygen plasma treatment [27,29] on silica. On the other hand, post-heat treatment would decrease film thickness [30,31] by eliminating water, solvent and other by-products. Hence, the condensation reaction can be improved. Post-rinsing treatment would also lead to a decrease in film thickness by removing the weakly bound or physisorbed silane on the surface [23,30,32], leaving behind the stable chemisorbed region that is crucial to resist hydrothermal attack. While the good silane activation and silanization environments seemed to be easily controlled, the rate (i.e., time) for condensation is still a crucial factor for silane quality.

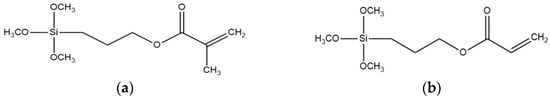

This study aims to study the outcome ultra-structural surface characteristics using two dental silanes (Figure 1), 3-methacryloxyproyltrimethoxysilane (MPS) and 3-acryloyloxypropyltrimethoxysilane (ACPS), on the silica glass-equivalent model surface (i.e., silicon wafer) with variations in the deposition time (5 h and 22 h) using a simple liquid deposition method on ethanol.

Figure 1.

Structures of (a) 3-methacryloxypropyltrimethoxysilane (MPS) and (b) 3-acryloyloxypropyltrimethoxysilane (ACPS).

2. Materials and Methods

2.1. Silicon Wafer Substrate

The substrates used in this study were n-type Si(100) wafers (Dia. 10 cm × 0.5 mm thickness). The substrates were cut into 10 × 10 mm2 pieces. Prior to silane treatment, the wafers were sequentially degreased in a boiling acetone bath for 30 min at ~56 °C and rinsed with deionized water. The wafers were then immersed into freshly prepared piranha solution (1:1 30% H2O2 in H2O: H2SO4) at room temperature for 30 min followed by rinsing with deionized water twice. This was to make sure Si-OH groups on the Si wafer substrate could be increased and to remove organic residues. Then, the wafers were dried by heating on a hot plate for 2 min at around 90 °C and were allowed to cool to room temperature for 1–2 min before silane deposition.

2.2. Silanization

A commercially available, pre-hydrolyzed dental silane primer containing 3-methacryloxypropyltrimethoxysilane (MPS) (RELYX 2721, 3M ESPE) was received and used. To constitute a 100 mL 1% ACPS solution, 1.0 mL ACPS solution (Gelest, 95%) was pipetted to a plastic volumetric flask containing an ethanol solution (a mixture of deionized water (5% w/w) and ethanol (95% w/w)). After adding up to mark, the pH level was adjusted to 4.5 with few drops of 1.0 mol/L acetic acid before letting the solution hydrolyze at room temperature for 2 h. Two hours was chosen to be the hydrolysis duration of 1% ACPS with reference to the literature with respect to the preparation of 2.5% MPS solution [31]. After the silane preparation, the 10 × 10 mm2 silica wafer substrates were subjected to the following treatments:

Group C: No silane and heat treatment.

Group M5: Dipped in MPS for 5 h.

Group M22: Dipped in MPS for 22 h.

Group A5: Dipped in ACPS for 5 h.

Group A22: Dipped in ACPS for 22 h.

For all groups (other than Group C), subsequently, after their respective silane and solvent treatments, they were rinsed in ethanol at room temperature for 1 min to remove unbound deposited materials. They were then subjected to heat treatment in the oven for 16 h for curing.

2.3. Surface Characterization

2.3.1. Ellipsometry

The ellipsometry data were acquired at 45, 55, 65 and 75 degrees by an ellipsometer (RC2, JA Woollam, Lincoln, NE, USA). The analysis was done by using CompleteEASE 6 (JA Woollam, Lincoln, NE, USA) software. The measuring wavelength was from 200 nm to 1600 nm. The thickness of the oxide layer was 2.11 ± 0.07 nm. The reported thicknesses were averaged over at least two measurements on different areas of the samples.

2.3.2. Contact Angle and Surface Free Energy

Contact angle (CA) measurements were carried out on silica substrates to investigate the changes in surface free energy (SFE) of the surfaces before and after silanization. The contact angle was measured at room temperature immediately after the hydroxylation of the silica surface with piranha solution and after the completion of silanization. Deionized water, formamide, diiodomethane and 1-bromonaphthalene were used as the liquids for analysis, with reference to the literature [13]. Water and formamide were used as polar liquids and 1-bromonaphthalene and diiodomethane were used as apolar liquids in the contact angle measurement. Liquid droplets were dispensed onto the surfaces of the samples. Each droplet of liquid was around 3 ± 0.5 μL. The CA values reported were averages of at least four separate measurements on different regions of the silane-coated surfaces. Contact angles were measured using the sessile method within 1 min of disposition, and digital images of the droplets were captured by Canon’s PowerShot G12 digital camera (Tokyo, Japan). ImageJ software (version 1.50) with the Low-Bond Axisymmetric Drop Shape Analysis (LBADSA) Plugin was used to determine the contact angles [33]. With reference to the literature [24], SFE values were calculated by Microsoft Excel (version 2013) with the equations of the van Oss model:

where and represent the dispersive components owing to Lifshitz–van der Waals interactions; and ,,, represent the acid–base components of Lewis acid and base interactions.

2.3.3. Atomic Force Microscopy (AFM)

Three-dimensional topographical images and surface roughness were obtained in air using atomic force microscopy (AFM, Dimension Edge with ScanAsyst™, Bruker, Ettlingen, Germany). All images were taken with PeakForce Tapping mode (Wrocław, Poland). All samples were scanned at a speed of 0.5 Hz using a Scanasyst-Air SiN probe.

2.3.4. X-ray Photoelectron Spectroscopy (XPS)

The XPS (X-ray Photoelectron Spectroscopy/ESCALab 250, Thermo Fisher Scientific Inc., Waltham, MA, USA) technique with a monochromated Al Kα X-ray source in survey (1–1350 eV) and high-resolution modes on Si2p (94–109 eV), O1s (520–550 eV) and C1s (275–300 eV) were used, and Thermo Avantage software (version 5) was used to acquire the raw data and atomic percentages, which were used for analyzing the chemical compositions and surface chemical structures of the silane-coated substrate of all groups.

3. Results

3.1. Ellipsometry

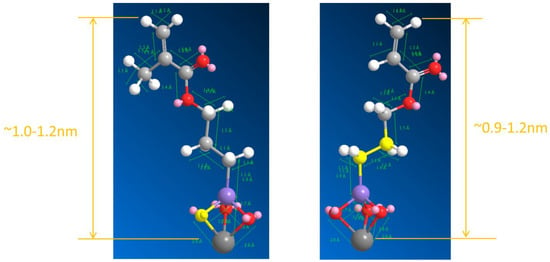

Table 1 summarizes the thicknesses of the treated silica substrates on M5, M22, A5 and A22. The stimulated lengths (Figure 2) of an MPS and an ACPS molecule are both ~1.0 nm at their lowest energy states.

Table 1.

Silane film thickness (nm) after four different silanization protocols.

Figure 2.

Simulated results of (left) MPS and (right) ACPS after energy minimization (ChemOffice 2007).

3.2. Contact Angle and Surface Free Energy

Table 2 shows the measured contact angles and calculated surface free energy of different groups. A drastic increase in water contact angles in samples M5, M22, A5 and A22 suggests that the MPS or the ACPS film has successfully been grafted on the silica substrates. In terms of SFE, it seems to decrease after treatment in both MPS and ACPS, and the SFE decreases with increasing immersion time from 5 h to 22 h.

Table 2.

Contact angles and calculated surface free energy of different groups.

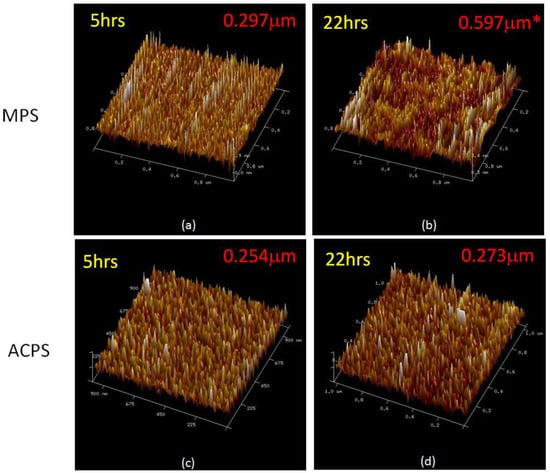

3.3. Atomic Force Microscopy (AFM)

Figure 3 shows the 3D topographical AFM images of MPS- and ACPS-treated silica wafers with immersion times of 5 h and 22 h. The average roughness (Sa) is also shown.

Figure 3.

D Topographical AFM images of MPS-treated (a,b) and ACPS-treated (c,d) silica surfaces with dipping times of (a,c) 5 h and (b,d) 22 h. Image size is 1 μm × 1 μm; * denotes the significant difference (p < 0.05) in average roughness (Sa).

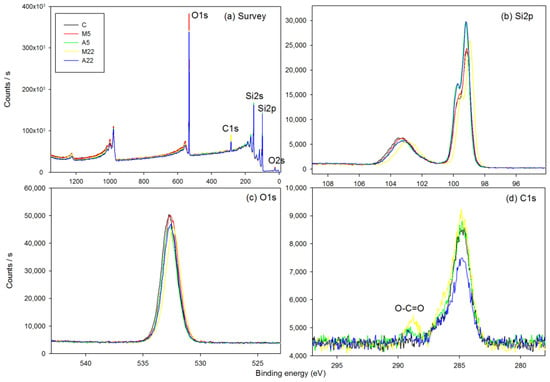

3.4. X-ray Photoelectron Spectroscopy (XPS)

Table 3 displays the elemental compositions of O1s, C1s and Si2p in the control and experimental samples. It can be seen the C1s increases in all silane-coated substrates as well as the coating time. Figure 4 shows the XPS (a) survey scans and high-resolution XPS scans of the (b) Si2p, (c) O1s and (d) C1s of all groups. In particular, in high-resolution scan of the C1s of M22, a prominent peak at 288.5 eV can be observed, which corresponds to O-C*=O in methacrylate.

Table 3.

Atomic percentages of elements in the XPS spectra.

Figure 4.

XPS survey (a) and high-resolution scan spectra of (b) Si2p, (c) O1s and (d) C1s of all groups. For the deconvolution results of high-resolution XPS, please check Supplementary Materials Figure S1.

4. Discussion

Silane coupling agents play an important role in dental resin composite because of their capability of adhesion to different organic and inorganic matrixes with appropriate modifications of the functional groups. These functional organosilanes possess highly ordered features, which makes them a highly interesting topic for research. In this study, a comprehensive characterization of dental silanes MPS and ACPS has been carried out. The understanding of their wettability, SFE, thickness, topography and roughness with respect to different immersion times (5 h and 22 h) has been deepened.

In this study, ACPS and MPS silanes have been successfully coated at the ~1 nanometer scale, as proven in the ellipsometry study (Table 1); they produced a real self-assembled monolayer (SAM) on the silica disc by a simple and practical protocol. Assuming that the thickness of the film formed is close to the length of a molecule of that silane type, the results of the ellipsometry agree with the theoretical film thickness in both the MPS and ACPS cases. For MPS, the thickness of the thin film formed also agrees with the reported value in the literature [12]. The results of the ellipsometry also suggested that there is no significant correlation between silanization time and the thickness of the silane films in both the MPS and ACPS cases. It is worth noting that ACPS has not been extensively studied before to make SAM because of its uniqueness and its uncommonness in applications.

In the contact angle experiment, after being treated with oxidizing piranha solution, a hydrophilic surface was obtained (water contact angle = 29.6 ± 0.2 °). The increase in hydrophilicity is due to an increase in silanol groups on the surface [34]. It is also worth noting that the contact angle will be increased if we expose the sample to an ambient condition after a certain number of hours, due to the adsorption of organic molecules on the unstable hydroxylated surfaces, which could lead to the passivation of the silanol groups [23]. Therefore, hydroxylated wafers should be placed in deionized water or under vacuum immediately after rinsing and before use.

In this study, 5 h and 22 h of silanization were used. In terms of silane coverage, Borges-Muñoz et al. [35] have experimentally determined that 5–24 h are needed for full coverage of silane on a silicon wafer, due to the surface enthalpy and number of hydroxyl groups on the silicon wafer reacting to the silanol on silane. In terms of silane thickness, Yang et al. [36] studied several silanes with carbon chains of 2–17, and found that the alkylsilane aggregation was time-dependent, with >8 h being optimal for making a saturated silane monolayer without aggregation under an ambient temperature. Our study confirmed their findings to be suitable even for the commonly used dental silanes MPS and ACPS.

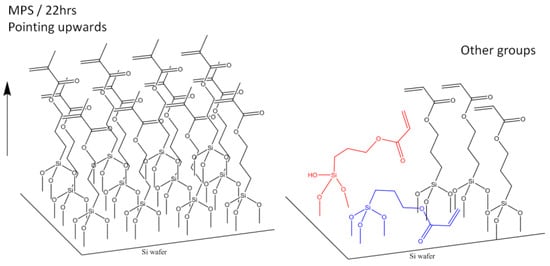

As detected by AFM, the M22 showed a significantly higher surface roughness than the others. This could be due to the formation of mechanically stronger island structures, which is a possible structure of silane monomers aggregated in an orientated order on the surface of the monolayer when the optimal immersion time is achieved, as suggested by the previous literature [37]. Indeed, the high-resolution XPS on C1s (Figure 4d) showed a prominent peak at 288.5 eV, which corresponds to methacrylate O-C*=O [38]. This signal is not conclusively strong in the high-resolution scans of C1s in other groups. So, the M22 has a complete monolayer formation such that the silane layer is oriented fully in the vertical direction, while in other groups, defects occur (Figure 5). Thus, even if the same silane is used, the dipping time would affect the quality of the silane.

Figure 5.

Illustration of the M22 silane monolayer (left) and other groups (right).

Commonly, a dental glass powder contains a variety of elements, while the exact composition may vary depending on the specific brand and type of glass and resin composites. In general, dental glass powders contain silica, barium oxide, alumina, strontium oxide, etc. [39]. Typically, the glass contains 60%–80% silica. To study the silane thin film at the nanoscale, ideally, a super-flat surface with a spectacularly uniform hydroxylated surface should be used. Thus, in this study, a silicon wafer was used as a model Si-containing material to study dental silane. It should be noted that despite the silicon wafer having been long established as a model system in dentistry to perform mechanistic studies of organic films, e.g., the protein adsorption of biofilm [40], the properties of silane monolayers deposited on silicon wafers and dental glass can be significantly different due to their different surface chemical composition, roughness, porosity and adhesion. Nonetheless, in the future, if suitable equipment and technology are developed, we should explore the possibility of directly studying silane film on dental glass.

5. Conclusions

Under the conditions of the present study, it can be concluded that different dental silanes under various dipping times would yield different chemical qualities of the film, even if they look thin physically. This study proved that 5 and 22 h of silanization can sufficiently form silane monolayers for the tested dental silanes, 3-methacryloxypropyltrimethoxysilane (MPS) and 3-acryloyloxypropyltrimethoxysilane (ACPS), at ~1 nm thickness. In particular, the 22 h silanization of MPS on silica was proven by high-resolution XPS; its O-C=O functional group extended fully in the vertical direction, while that of the other groups did not. In the future, better adhesion quality of the silanization of dental glass can be achieved by using proper time and surface treatments. This study also deepens our understanding of MPS and ACPS on silica, which can be promising in future multi-functional biomedical applications such as protein detection and anti-bacterial applications.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/coatings14081005/s1, Figure S1: Deconvolution results of high-resolution XPS.

Author Contributions

Conceptualization, J.K.-H.T.; methodology, X.L., W.W.-Y.S. and J.K.-H.T.; validation, X.L. and J.K.-H.T.; formal analysis, X.L., W.W.-Y.S. and J.K.-H.T.; investigation, X.L. and W.W.-Y.S.; resources, J.K.-H.T.; data curation, X.L. and W.W.-Y.S.; writing—original draft preparation, X.L. and W.W.-Y.S.; writing—review and editing, X.L. and J.K.-H.T.; visualization, X.L., W.W.-Y.S. and J.K.-H.T.; supervision, J.K.-H.T.; project administration, J.K.-H.T.; funding acquisition, J.K.-H.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data of this study are available from the corresponding author upon request.

Acknowledgments

Parts of the results have been reported in the 2021 IADR General Division.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- German, M.J. Developments in resin-based composites. Brit. Dent. J. 2022, 232, 638–643. [Google Scholar] [CrossRef] [PubMed]

- Matinlinna, J.P.; Lung, C.Y.K.; Tsoi, J.K.H. Silane adhesion mechanism in dental applications and surface treatments: A review. Dent. Mater. 2018, 34, 13–28. [Google Scholar] [CrossRef] [PubMed]

- Turssi, C.; Ferracane, J.; Vogel, K. Filler features and their effects on wear and degree of conversion of particulate dental resin composites. Biomaterials 2005, 26, 4932–4937. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, T.; Saito, O.; Mizuno, M.; Tanaka, H. Changes in translucency and color of particulate filler composite resins. Int. J. Prosthodont. 2002, 15, 494–499. [Google Scholar] [PubMed]

- Bai, X.; Chen, Y.; Zhou, T.; Pow, E.H.N.; Tsoi, J.K.H. The chemical and optical stability evaluation of injectable restorative materials under wet challenge. J. Dent. 2024, 146, 105031. [Google Scholar] [CrossRef] [PubMed]

- Shortall, A.C.; Palin, W.M.; Burtscher, P. Refractive index mismatch and monomer reactivity influence composite curing depth. J. Dent. Res. 2008, 87, 84–88. [Google Scholar] [CrossRef] [PubMed]

- Staxrud, F.; Dahl, J.E. Silanising agents promote resin-composite repair. Int. Dent. J. 2015, 65, 311–315. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Tsoi, J.K.-H.; Pow, E.H.-N.; Wong, H.M. Influence of different etching protocols on the reliability of resin bonding to CAD/CAM feldspathic porcelain. Int. J. Adhes. Adhes. 2015, 62, 18–24. [Google Scholar] [CrossRef]

- Tian, T.; Tsoi, J.K.-H.; Matinlinna, J.P.; Burrow, M.F. Aspects of bonding between resin luting cements and glass ceramic materials. Dent. Mater. 2014, 30, 147–162. [Google Scholar] [CrossRef]

- Li, J.; Bai, H.; Feng, Z. Advances in the Modification of Silane-Based Sol-Gel Coating to Improve the Corrosion Resistance of Magnesium Alloys. Molecules 2023, 28, 2563. [Google Scholar] [CrossRef]

- Zhang, C.; Li, T.; Wu, X.; Li, W.; Guo, Y.; Zhang, S.; Zhang, L. Ni-rich cathode materials with enhanced kinetics and hydrophobicity endowed by reactive silane coating. Chem. Eng. J. 2023, 473, 145309. [Google Scholar] [CrossRef]

- Passaro, J.; Bifulco, A.; Calabrese, E.; Imparato, C.; Raimondo, M.; Pantani, R.; Aronne, A.; Guadagno, L. Hybrid Hemp Particles as Functional Fillers for the Manufacturing of Hydrophobic and Anti-icing Epoxy Composite Coatings. ACS Omega 2023, 8, 23596–23606. [Google Scholar] [CrossRef] [PubMed]

- Awad, M.M.; Alhalabi, F.; Alshehri, A.; Salem, M.A.; Robaian, A.; Alghannam, S.; Alayad, A.S.; Almutairi, B.; Alrahlah, A. Silane-Containing Universal Adhesives Influence Resin-Ceramic Microtensile Bond Strength. Coatings 2023, 13, 477. [Google Scholar] [CrossRef]

- Garcia, I.M.; de Souza, V.S.; Balhaddad, A.A.; Mokeem, L.; de Melo, M.A.S.; Scholten, J.D.; Collares, F.M. Ionic Liquid-Based Silane for SiO Nanoparticles: A Versatile Coupling Agent for Dental Resins. ACS Appl. Mater. Interfaces 2024, 16, 34057–34068. [Google Scholar] [CrossRef] [PubMed]

- Drummond, J. Degradation, fatigue, and failure of resin dental composite materials. J. Dent. Res. 2008, 87, 710–719. [Google Scholar] [CrossRef] [PubMed]

- Antonucci, J.M.; Dickens, S.H.; Fowler, B.O.; Xu, H.H.K.; McDonough, W.G. Chemistry of silanes: Interfaces in dental polymers and composites. J. Res. Natl. Inst. Stand. Technol. 2005, 110, 541–558. [Google Scholar] [CrossRef]

- Kannengiesser, J.F.; Morgenstern, B.; Janka, O.; Kickelbick, G. Oligo-Condensation Reactions of Silanediols with Conservation of Solid-State-Structural Features. Chem. A Eur. J. 2024, 30, 202303343. [Google Scholar] [CrossRef] [PubMed]

- Hoikkanen, M.; Honkanen, M.; Vippola, M.; Lepistö, T.; Vuorinen, J. Effect of silane treatment parameters on the silane layer formation and bonding to thermoplastic urethane. Prog. Org. Coatings 2011, 72, 716–723. [Google Scholar] [CrossRef]

- Lung, C.Y.K.; Matinlinna, J.P. Aspects of silane coupling agents and surface conditioning in dentistry: An overview. Dent. Mater. 2012, 28, 467–477. [Google Scholar] [CrossRef]

- Arkles, B.; Steinmetz, J.R.; Zazyczny, J.; Mehta, P. Factors Contributing to the Stability of Alkoxysilanes in Aqueous-Solution. J Adhes. Sci. Technol. 1992, 6, 193–206. [Google Scholar] [CrossRef]

- Pantoja, M.; Díaz-Benito, B.; Velasco, F.; Abenojar, J.; del Real, J. Analysis of hydrolysis process of γ-methacryloxypropyltrimethoxysilane and its influence on the formation of silane coatings on 6063 aluminum alloy. Appl. Surf. Sci. 2009, 255, 6386–6390. [Google Scholar] [CrossRef]

- Bel-Hassen, R.; Boufi, S.; Salon, M.B.; Abdelmouleh, M.; Belgacem, M.N. Adsorption of silane onto cellulose fibers. II. The effect of pH on silane hydrolysis, condensation, and adsorption behavior. J. Appl. Polym. Sci. 2008, 108, 1958–1968. [Google Scholar] [CrossRef]

- Ben Ali, M.; Bessueille, F.; Chovelon, J.; Abdelghani, A.; Jaffrezic-Renault, N.; Maaref, M.; Martelet, C. Use of ultra-thin organic silane films for the improvement of gold adhesion to the silicon dioxide wafers for (bio)sensor applications. Mater. Sci. Eng. C 2008, 28, 628–632. [Google Scholar]

- Villard, N.; Seneviratne, C.; Tsoi, J.K.H.; Heinonen, M.; Matinlinna, J. Candida albicans aspects of novel silane system-coated titanium and zirconia implant surfaces. Clin. Oral Implant. Res. 2015, 26, 332–341. [Google Scholar] [CrossRef] [PubMed]

- Monticelli, F.; Toledano, M.; Osorio, R.; Ferrari, M. Effect of temperature on the silane coupling agents when bonding core resin to quartz fiber posts. Dent. Mater. 2006, 22, 1024–1028. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, X.; Luo, J.; Lu, X. Fabrication and tribological properties of super-hydrophobic surfaces based on porous silicon. Appl. Surf. Sci. 2009, 255, 9430–9438. [Google Scholar] [CrossRef]

- Gunda, N.S.K.; Singh, M.; Norman, L.; Kaur, K.; Mitra, S.K. Optimization and characterization of biomolecule immobilization on silicon substrates using (3-aminopropyl)triethoxysilane (APTES) and glutaraldehyde linker. Appl. Surf. Sci. 2014, 305, 522–530. [Google Scholar] [CrossRef]

- Cloarec, J.P.; Deligianis, N.; Martin, J.R.; Lawrence, I.; Souteyrand, E.; Polychronakos, C.; Lawrence, M.F. Immobilization of homooligonucleotide probe layers onto Si/SiO substrates: Characterization by electrochemical impedance measurements and radiolabelling. Biosens. Bioelectron. 2002, 17, 405–412. [Google Scholar] [CrossRef] [PubMed]

- Clergereaux, R.; Calafat, M.; Benitez, F.; Escaich, D.; de Larclause, I.S.; Raynaud, P.; Esteve, J. Comparison between continuous and microwave oxygen plasma post-treatment on organosilicon plasma deposited layers: Effects on structure and properties. Thin Solid Films 2007, 515, 3452–3460. [Google Scholar] [CrossRef]

- Queiroz, J.R.C.; Benetti, P.; Özcan, M.; de Oliveira, L.F.C.; Della Bona, A.; Takahashi, F.E.; Bottino, M.A. Surface characterization of feldspathic ceramic using ATR FT-IR and ellipsometry after various silanization protocols. Dent. Mater. 2012, 28, 189–196. [Google Scholar] [CrossRef][Green Version]

- Hooshmand, T.; Keshvad, A.; van Noort, R. XPS Analysis of Silane Films on the Surface of a Dental Ceramic. J. Adhes. Sci. Technol. 2009, 23, 1085–1095. [Google Scholar] [CrossRef]

- Nakamura, Y.; Gotoh, T.; Honda, H.; Fujii, S.; Nagata, K. AFM Observation of a Mica Surface Treated with Silane Coupling Agent Having a Mercapto Group. Compos. Interfaces 2010, 17, 395–404. [Google Scholar] [CrossRef]

- Stalder, A.F.; Melchior, T.; Müller, M.; Sage, D.; Blu, T.; Unser, M. Low-bond axisymmetric drop shape analysis for surface tension and contact angle measurements of sessile drops. Colloids Surfaces A Physicochem. Eng. Asp. 2010, 364, 72–81. [Google Scholar] [CrossRef]

- Tan, C.S.; Fan, A.; Chen, K.N.; Reif, R. Low-temperature thermal oxide to plasma-enhanced chemical vapor deposition oxide wafer bonding for thin-film transfer application. Appl. Phys. Lett. 2003, 82, 2649–2651. [Google Scholar] [CrossRef]

- Borges-Muñoz, A.C.; Miller, D.P.; Zurek, E.; Colón, L.A. Silanization of superficially porous silica particles with-aminophenyltrimethoxysilane. Microchem. J. 2019, 147, 263–268. [Google Scholar] [CrossRef]

- Yang, Y.; Bittner, A.M.; Baldelli, S.; Kern, K. Study of self-assembled triethoxysilane thin films made by casting neat reagents in ambient atmosphere. Thin Solid Films 2008, 516, 3948–3956. [Google Scholar] [CrossRef]

- Banga, R.; Yarwood, J.; Morgan, A.M.; Evans, B.; Kells, J. Ftir and Afm Studies of the Kinetics and Self-Assembly of Alkyltrichlorosilanes and (Perfluoroalkyl)Trichlorosilanes onto Glass and Silicon. Langmuir 1995, 11, 4393–4399. [Google Scholar] [CrossRef]

- Hidzir, N.M.; Radzali, N.A.M.; Rahman, I.A.; Shamsudin, S.A. Gamma irradiation-induced grafting of 2-hydroxyethyl methacrylate (HEMA) onto ePTFE for implant applications. Nucl. Eng. Technol. 2020, 52, 2320–2327. [Google Scholar] [CrossRef]

- Yun, J.; Burrow, M.F.; Matinlinna, J.P.; Ding, H.; Chan, S.M.; Tsoi, J.K.; Wang, Y. Design of Multi-Functional Bio-Safe Dental Resin Composites with Mineralization and Anti-Biofilm Properties. J. Funct. Biomater. 2024, 15, 120. [Google Scholar] [CrossRef]

- Ericson, T.; Pruitt, K.M.; Arwin, H.; Lundstrom, I. Ellipsometric Studies of Film Formation on Tooth Enamel and Hydrophilic Silicon Surfaces. Acta Odontol. Scand. 1982, 40, 197–201. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).