Effect of Gas Flow Ratio on the Chemical and Electrochemical Properties of Bismuth-Oxygen Films Deposited in Reactive Phase Sputtering

Abstract

1. Introduction

2. Materials and Methods

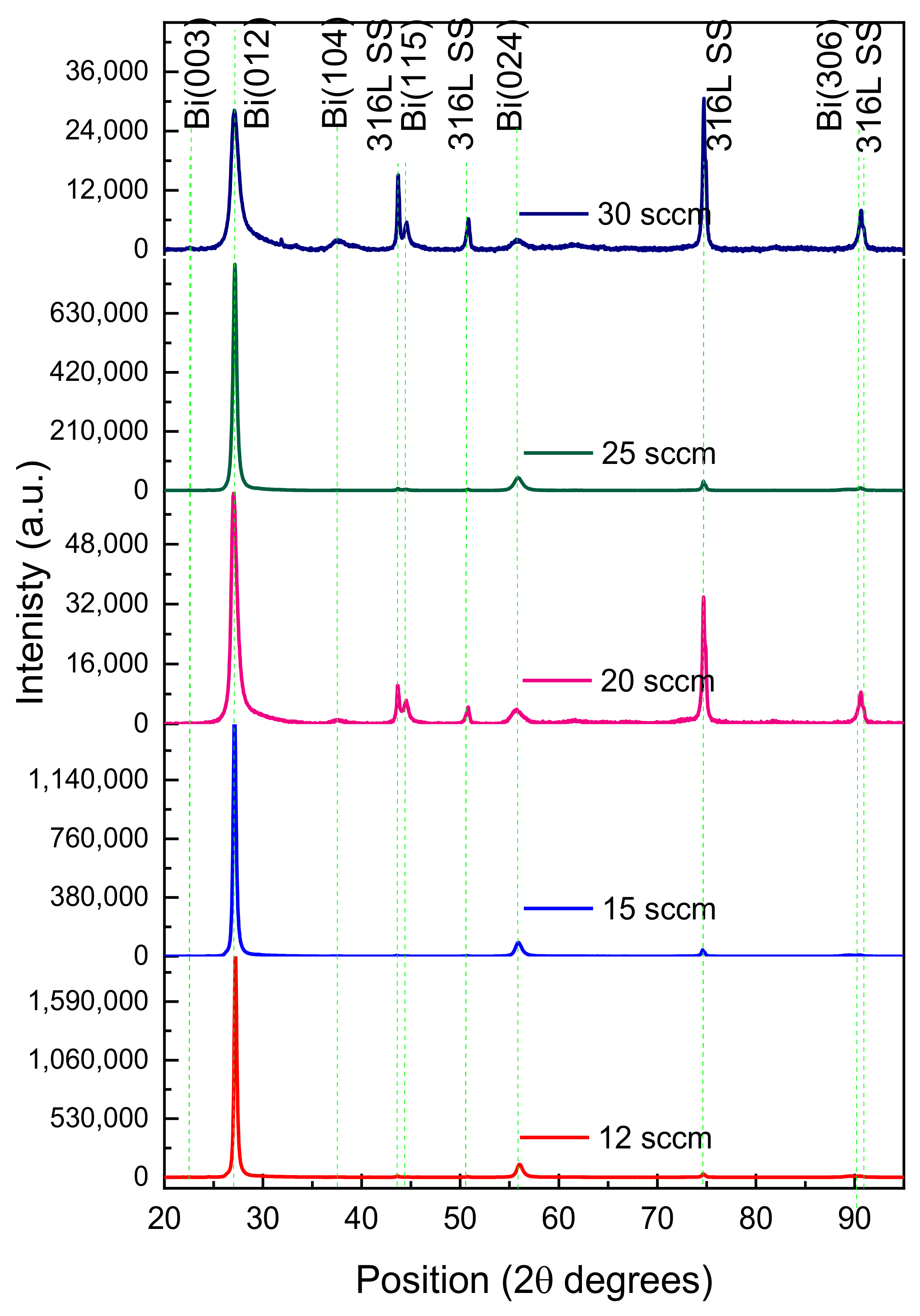

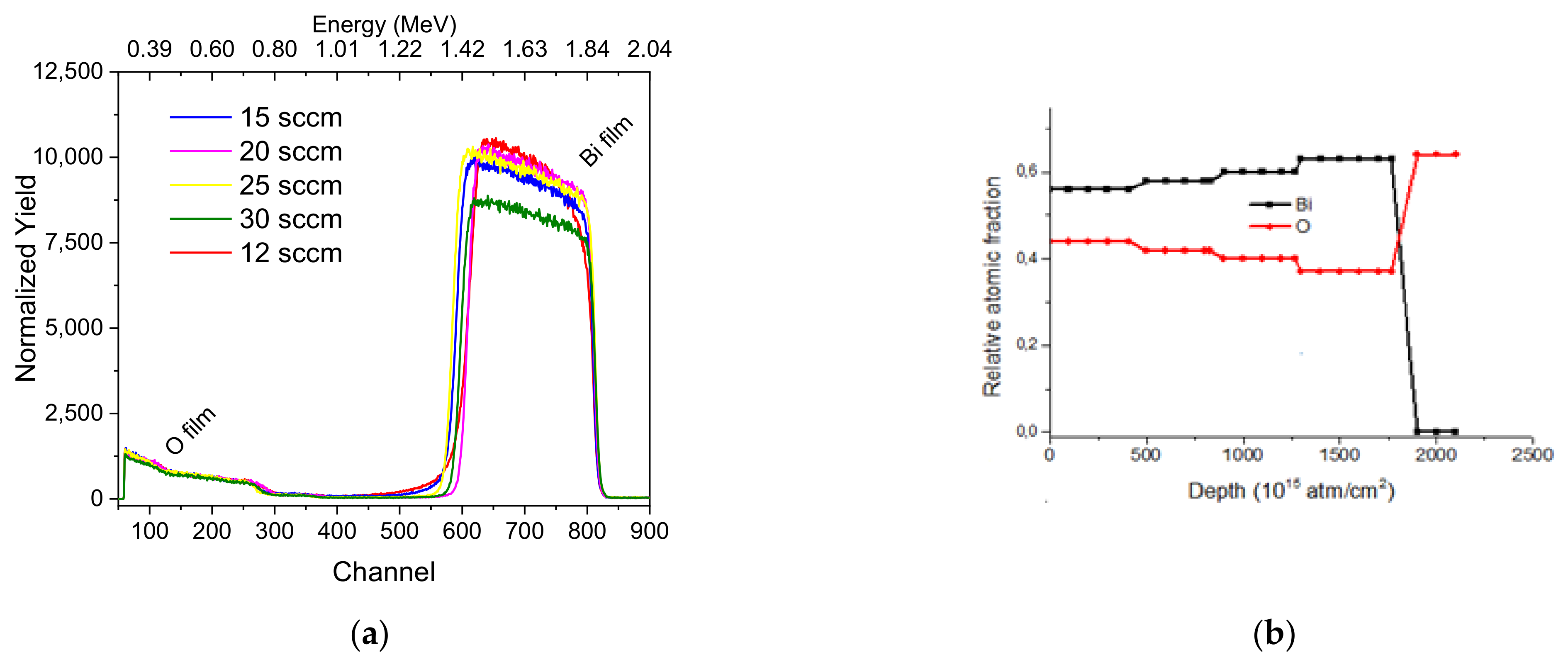

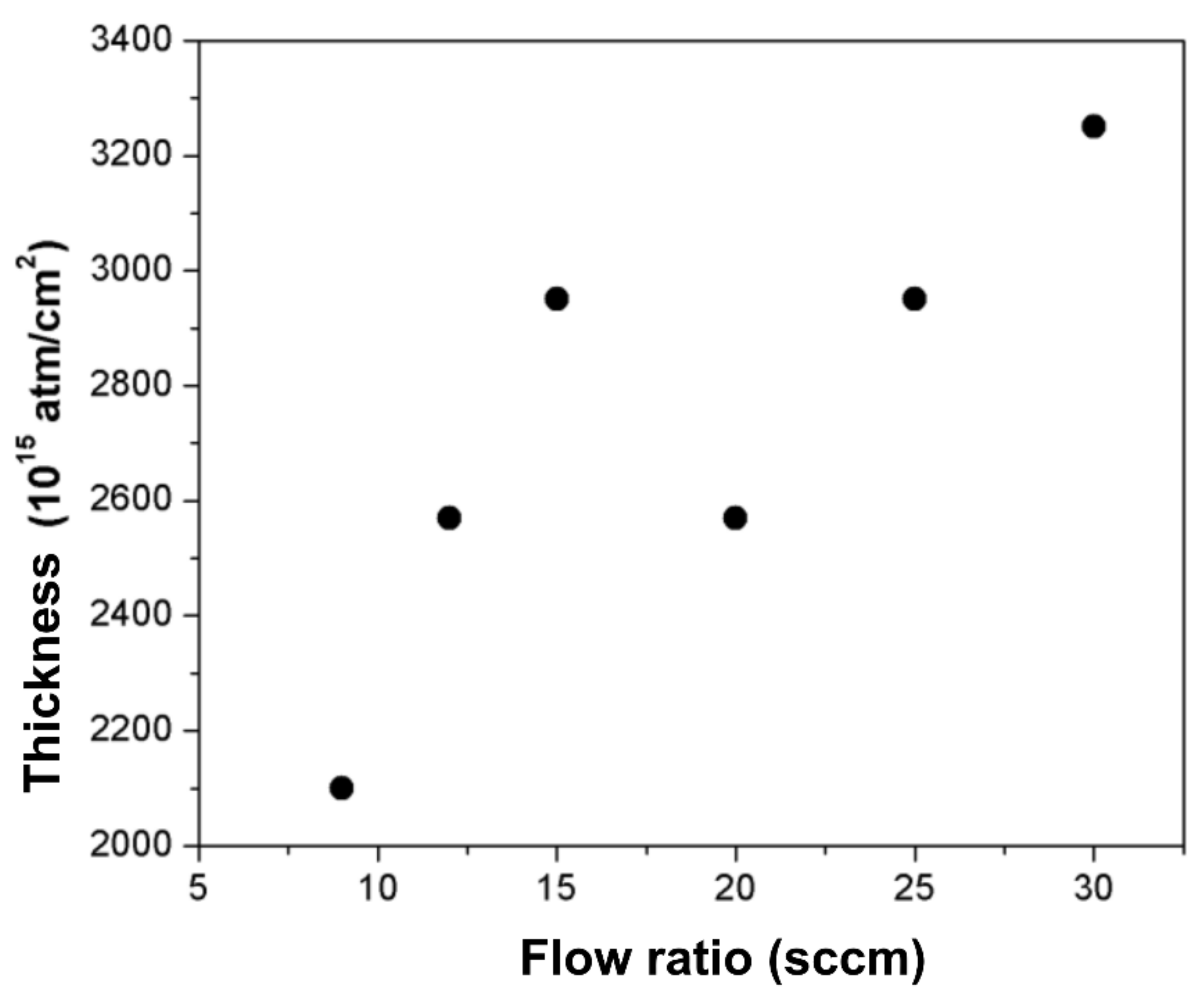

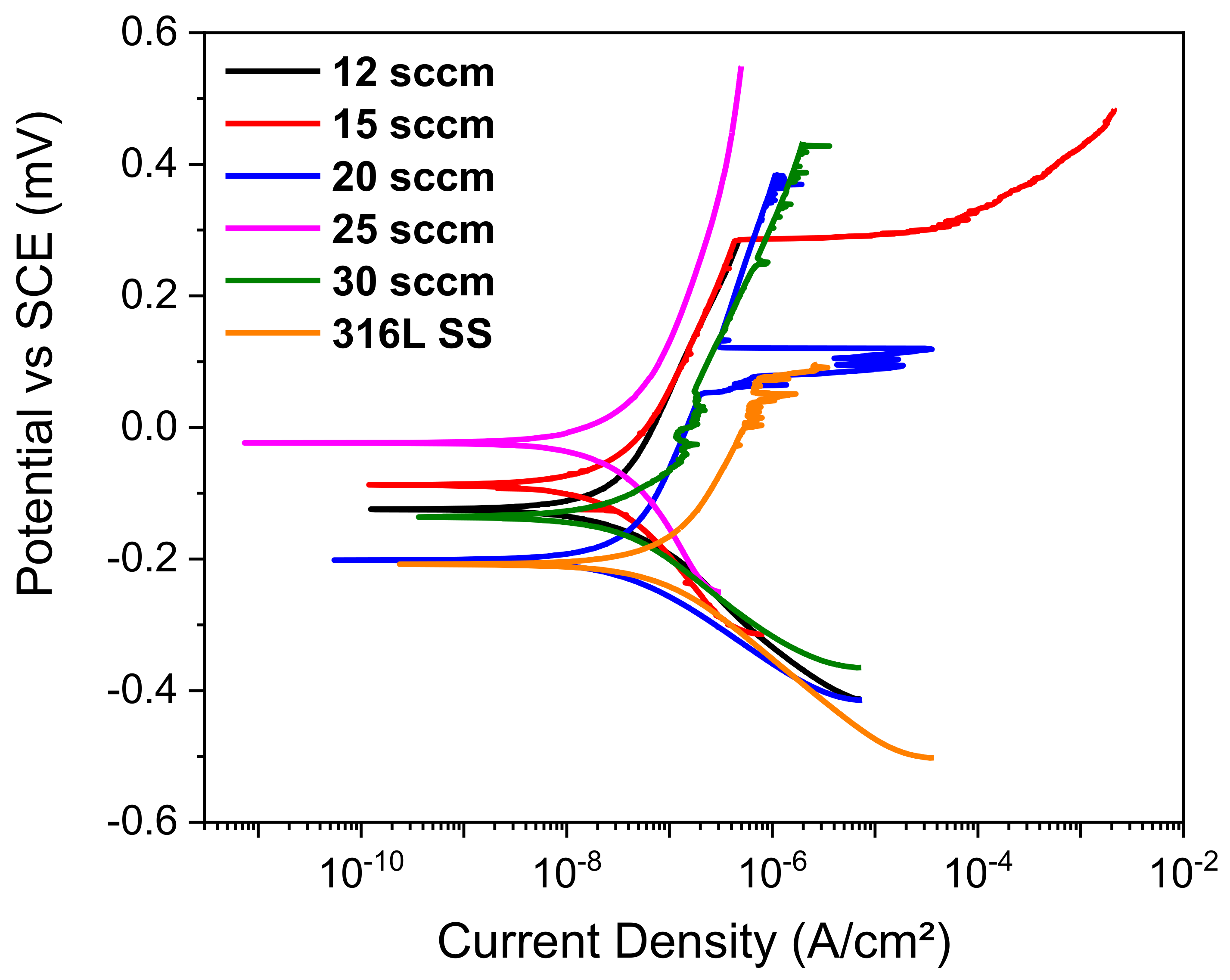

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ratova, M.; Redfern, J.; Verran, J.; Kelly, P.J. Highly efficient photocatalytic bismuth oxide coatings and their antimicrobial properties under visible light irradiation. Appl. Catal. B Environ. 2018, 239, 223–232. [Google Scholar] [CrossRef]

- Bautista-Ruiz, J.; Aperador, W.; Caicedo, J.C. Sol-gel Synthesis of Titanium/Bismuth Oxide Coatings for Biocompatibility Applications on 316L Stainless Steel. Indian J. Sci. Technol. 2018, 11, 1–10. [Google Scholar] [CrossRef]

- Gujar, T.P.; Shinde, V.R.; Lokhande, C.D.; Mane, R.S.; Han, S.-H. Bismuth oxide thin films prepared by chemical bath deposition (CBD) method: Annealing effect. Appl. Surf. Sci. 2005, 250, 161–167. [Google Scholar] [CrossRef]

- Leontie, L.; Caraman, M.; Alexe, M.; Harnagea, C. Structural and optical characteristics of bismuth oxide thin films. Surf. Sci. 2002, 507–510, 480–485. [Google Scholar] [CrossRef]

- Xiaohong, W.; Wei, Q.; Weidong, H. Thin bismuth oxide films prepared through the sol–gel method as photocatalyst. J. Mol. Catal. A Chem. 2007, 261, 167–171. [Google Scholar] [CrossRef]

- Popa, P.L.; Sønderby, S.; Kerdsongpanya, S.; Lu, J.; Bonanos, N.; Eklund, P. Highly oriented δ-Bi2O3 thin films stable at room temperature synthesized by reactive magnetron sputtering. J. Appl. Phys. 2013, 113, 046101. [Google Scholar] [CrossRef]

- Shuk, P.; Wiemhöfer, H.-D.; Guth, U.; Göpel, W.; Greenblatt, M. Oxide ion conducting solid electrolytes based on Bi2O3. Solid State Ion. 1996, 89, 179–196. [Google Scholar] [CrossRef]

- Vega, F.L.A.; Olaya, J.; Ruiz, J.B. Synthesis and corrosion resistance of SiO2-TiO2-ZrO2-Bi2O3 coatings spin-coated on Ti6Al4V alloy. Ceram. Int. 2018, 44, 2123–2131. [Google Scholar] [CrossRef]

- Shan, D.; Zhang, J.; Xue, H.-G.; Zhang, Y.-C.; Cosnier, S.; Ding, S.-N. Polycrystalline bismuth oxide films for development of amperometric biosensor for phenolic compounds. Biosens. Bioelectron. 2009, 24, 3671–3676. [Google Scholar] [CrossRef]

- Franc, J.; Barnier, V.; Vocanson, F.; Gamet, E.; Lesage, M.; Jamon, D.; Jourlin, Y. Submicrometric gratings fabrication from photosensitive organo-silica-hafnia thin films elaborated by sol–gel processing. Thin Solid Films 2012, 520, 6050–6056. [Google Scholar] [CrossRef]

- Leontie, L.; Caraman, M.; Evtodiev, I.; Cuculescu, E.; Mija, A. Optical properties of bismuth oxide thin films prepared by reactive magnetron sputtering. J. Optoelectron. Adv. Mater. 2006, 8, 1221–1224. [Google Scholar] [CrossRef]

- Howson, R.P.; Ja’fer, H.A. Reactive sputtering with an unbalanced magnetron. J. Vac. Sci. Technol. A 1992, 10, 1784–1790. [Google Scholar] [CrossRef]

- Kelly, P.J.; Arnell, R.D. Magnetron sputtering: A review of recent developments and applications. Vacuum 2000, 56, 159–172. [Google Scholar] [CrossRef]

- Olaya, J.; Rodil, S.E.; Muhl, S.; Sánchez, E. Comparative study of chromium nitride coatings deposited by unbalanced and balanced magnetron sputtering. Thin Solid Films 2005, 474, 119–126. [Google Scholar] [CrossRef]

- Marulanda, D.; Olaya, J.J. Unbalanced magnetron sputtering system for producing corrosion resistance multilayer coatings. Dyna 2012, 79, 74–79. [Google Scholar]

- Rösemann, N.; Ortner, K.; Petersen, J.; Schadow, T.; Bäker, M.; Bräuer, G.; Rösler, J. Influence of bias voltage and oxygen flow rate on morphology and crystallographic properties of gas flow sputtered zirconia coatings. Surf. Coat. Technol. 2015, 276, 668–676. [Google Scholar] [CrossRef]

- Ibrahim, S.; Bonnet, P.; Sarakha, M.; Caperaa, C.; Monier, G.; Bousquet, A. Tailoring the structural and optical properties of bismuth oxide films deposited by reactive magnetron sputtering for photocatalytic application. Mater. Chem. Phys. 2020, 243, 122580. [Google Scholar] [CrossRef]

- Dudek, M.; Klemberg-Sapieha, J.E.; Zabeida, O.; Martinu, L. Effect of substrate bias on the micro-structure and properties of nanocomposite titanium nitride-based films. J. Achiev. Mater. Manuf. Eng. 2009, 39, 416–421. [Google Scholar]

- Lu, L.; Shen, H.; Zhang, H.; Jiang, F.; Li, B.; Lin, L. Effects of Ar flow rate and substrate temperature on the properties of AZO thin films by RF magnetron sputtering. Optoelectron. Adv. Mater. Commun. 2010, 4, 596–600. [Google Scholar]

- Al-Mansoori, M.; Al-Shaibani, S.; Al-Jaeedi, A.; Lee, J.; Choi, D.; Hasoon, F.S. Effects of gas flow rate on the structure and elemental composition of tin oxide thin films deposited by RF sputtering. AIP Adv. 2017, 7, 125105. [Google Scholar] [CrossRef]

- Shi, M.; Pang, S.; Zhang, T. Towards improved integrated properties in FeCrPCB bulk metallic glasses by Cr addition. Intermetallics 2015, 61, 16–20. [Google Scholar] [CrossRef]

- Wang, D.; Liu, S.; Ma, X.; Xiao, C.; Gong, X.; Zhu, H.; Niu, F. Enhanced corrosion resistance of 15–15Ti austenitic steel in liquid lead-bismuth eutectic at 550 °C by shot peening processing. Corros. Sci. 2024, 226, 111640. [Google Scholar] [CrossRef]

- Deepak, D.; Raghav, J.; Panghal, A.; Singh, T.; Roy, S.; Roy, S.S. Hybrid framework of sputter deposited vanadium nitride embedded Cu2O/CuO nanostructures for electrocatalytic oxygen evolution reaction. J. Alloys Compd. 2024, 978, 173391. [Google Scholar] [CrossRef]

- Abdallah, B.; Kakhia, M.; Alsadat, W.; Zetun, W.; Hijazy, A. Morphology and corrosion behavior study of thin tin films deposited at different substrates by dc magnetron sputtering. Orbital 2021, 13, 69–78. [Google Scholar] [CrossRef]

- Barrero, D.M.O.; Olaya, J.J.; Moller, A.D. Synthesis and corrosion resistance of Cu-Al-N nanostructured thin films deposited through magnetron sputtering. Mater. Res. Express 2021, 8, 056404. [Google Scholar] [CrossRef]

- Jiang, Q.; Ma, D.; Li, Y.; Chen, C. The Deposition and Properties of Titanium Films Prepared by High Power Pulsed Magnetron Sputtering. Materials 2023, 16, 7294. [Google Scholar] [CrossRef]

- Alharbi, S.O.; Ahmad, S.; Gul, T.; Ali, I.; Bariq, A. The corrosion behavior of low carbon steel (AISI 1010) influenced by grain size through microstructural mechanical. Sci. Rep. 2024, 14, 5098. [Google Scholar] [CrossRef]

- Yin, X.; Wang, Y.; Wang, H.; Zhao, K.; Sun, Y.; Xiao, J.; Zhao, Y.; Gong, F.; Chen, Y. Corrosion behavior and failure mechanism of amorphous Al2O3 coating at high-temperature LBE. Vacuum 2023, 215, 112251. [Google Scholar] [CrossRef]

- Zhang, P.; Yao, Z.; Wang, X.; Zheng, Y.; Cui, K.; Yao, R.; Lin, S.; Liu, Y.; Lu, S.; Wu, X. A novel FeCrAlWx high entropy alloy coating for enhancing lead-bismuth eutectic corrosion resistance. J. Nucl. Mater. 2024, 589, 154844. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, H.; Ren, Q.; Deng, H.; Li, Z.; Du, B.; Zhang, T. Improved corrosion resistance of TiAlCrNbMo alloy to lead-bismuth eutectic by pre-oxidation. J. Mater. Res. Technol. 2024, 28, 707–718. [Google Scholar] [CrossRef]

- Li, Y.; Ma, D.; Liang, J.; Huang, D.; Wang, L.; Ren, D.; Jiang, X.; Leng, Y. Plasma Bombardment-Induced Amorphization of (TiNbZrCr)Nx High-Entropy Alloy Nitride Films. Coatings 2024, 14, 505. [Google Scholar] [CrossRef]

| Flow Rate | Jcorr (A/cm2) | Ecorr (V vs. SCE) | Corrosion Rate (mm/year) | Polarization Resistance (Ohm·cm2) |

|---|---|---|---|---|

| 12 sccm | 7.242 × 10−6 | −0.4125 | 2.612 × 10−7 | 1500 |

| 15 sccm | 8.337 × 10−7 | −0.3142 | 3.007 × 10−8 | 2500 |

| 20 sccm | 7.485 × 10−6 | −0.4142 | 2.700 × 10−7 | 1200 |

| 25 sccm | 3.157 × 10−7 | −0.2503 | 1.139 × 10−8 | 2800 |

| 30 sccm | 7.345 × 10−6 | −0.3648 | 2.649 × 10−7 | 1100 |

| Substrate 316 | 3.735 × 10−5 | −0.5020 | 1.347 × 10−6 | 800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orozco-Hernandez, G.; Olaya-Flórez, J.J.; Alfonso-Orjuela, J.E.; Pineda-Hernandez, D.A.; Restrepo-Parra, E. Effect of Gas Flow Ratio on the Chemical and Electrochemical Properties of Bismuth-Oxygen Films Deposited in Reactive Phase Sputtering. Coatings 2024, 14, 896. https://doi.org/10.3390/coatings14070896

Orozco-Hernandez G, Olaya-Flórez JJ, Alfonso-Orjuela JE, Pineda-Hernandez DA, Restrepo-Parra E. Effect of Gas Flow Ratio on the Chemical and Electrochemical Properties of Bismuth-Oxygen Films Deposited in Reactive Phase Sputtering. Coatings. 2024; 14(7):896. https://doi.org/10.3390/coatings14070896

Chicago/Turabian StyleOrozco-Hernandez, Giovany, Jhon Jairo Olaya-Flórez, Jose Edgar Alfonso-Orjuela, Daniel Alejandro Pineda-Hernandez, and Elisabeth Restrepo-Parra. 2024. "Effect of Gas Flow Ratio on the Chemical and Electrochemical Properties of Bismuth-Oxygen Films Deposited in Reactive Phase Sputtering" Coatings 14, no. 7: 896. https://doi.org/10.3390/coatings14070896

APA StyleOrozco-Hernandez, G., Olaya-Flórez, J. J., Alfonso-Orjuela, J. E., Pineda-Hernandez, D. A., & Restrepo-Parra, E. (2024). Effect of Gas Flow Ratio on the Chemical and Electrochemical Properties of Bismuth-Oxygen Films Deposited in Reactive Phase Sputtering. Coatings, 14(7), 896. https://doi.org/10.3390/coatings14070896