Hydrophobic and Tribological Properties of Biomimetic Interfaces

Abstract

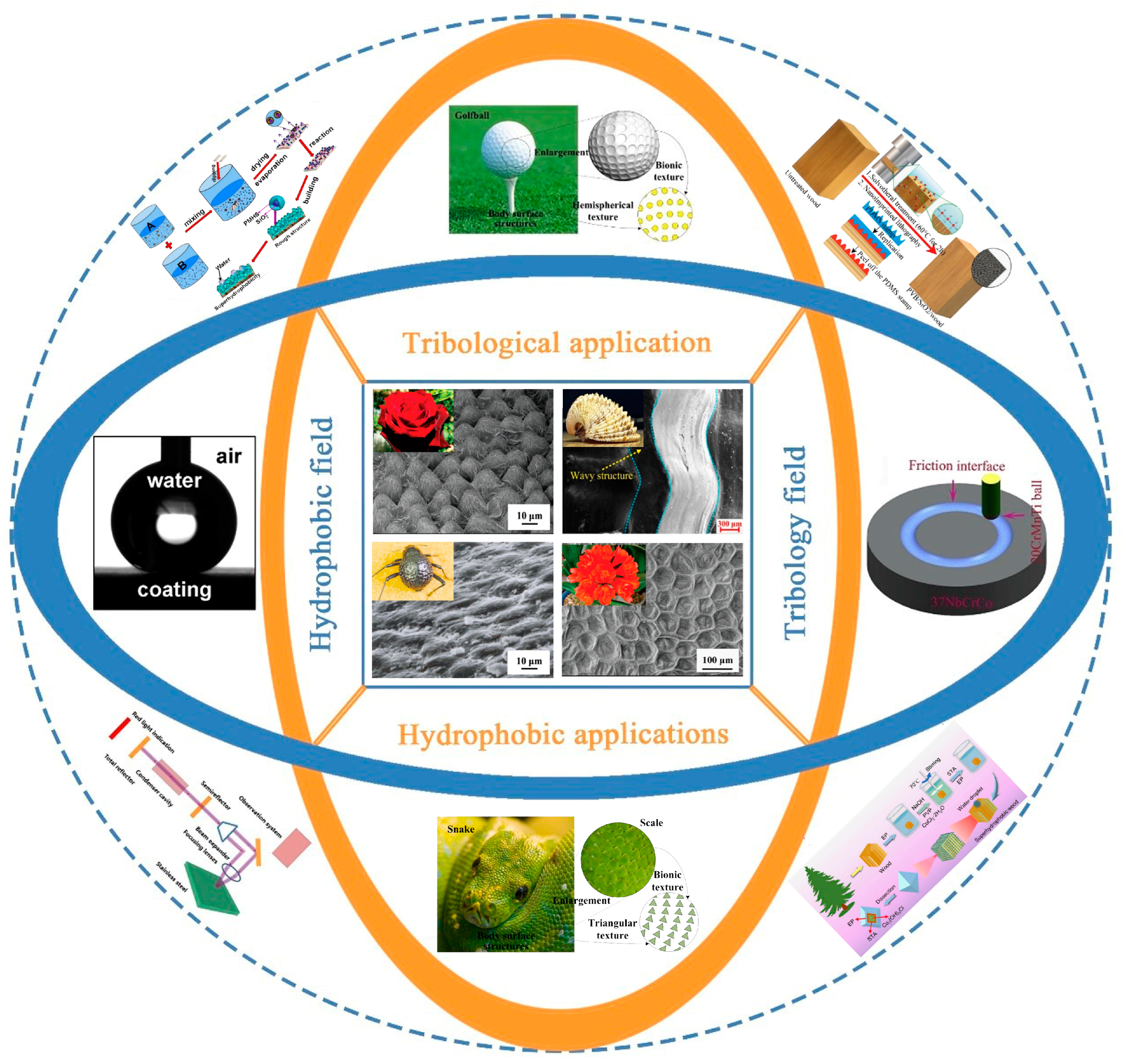

1. Introduction

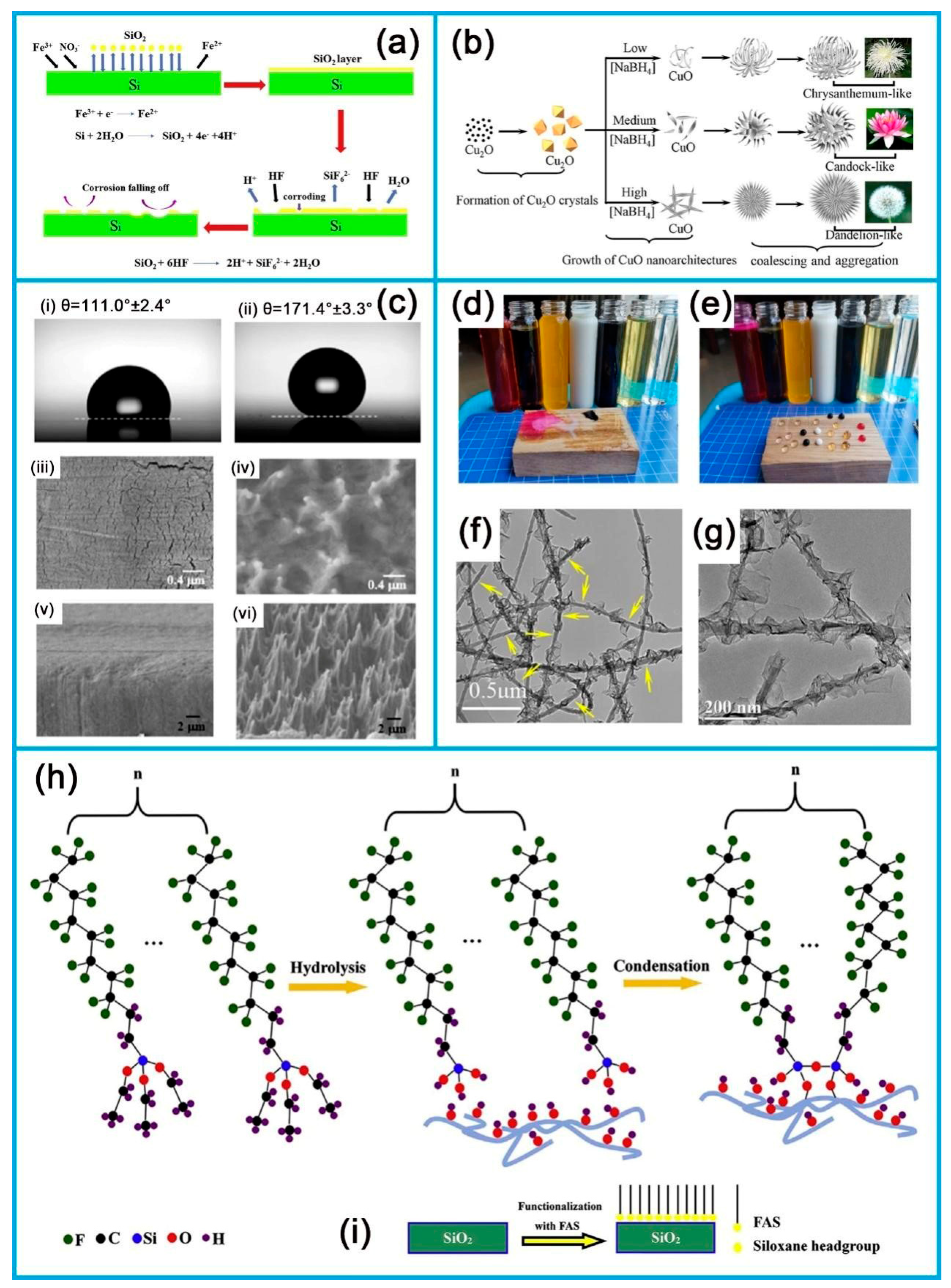

2. Hydrophobic Biomimetic Interfaces

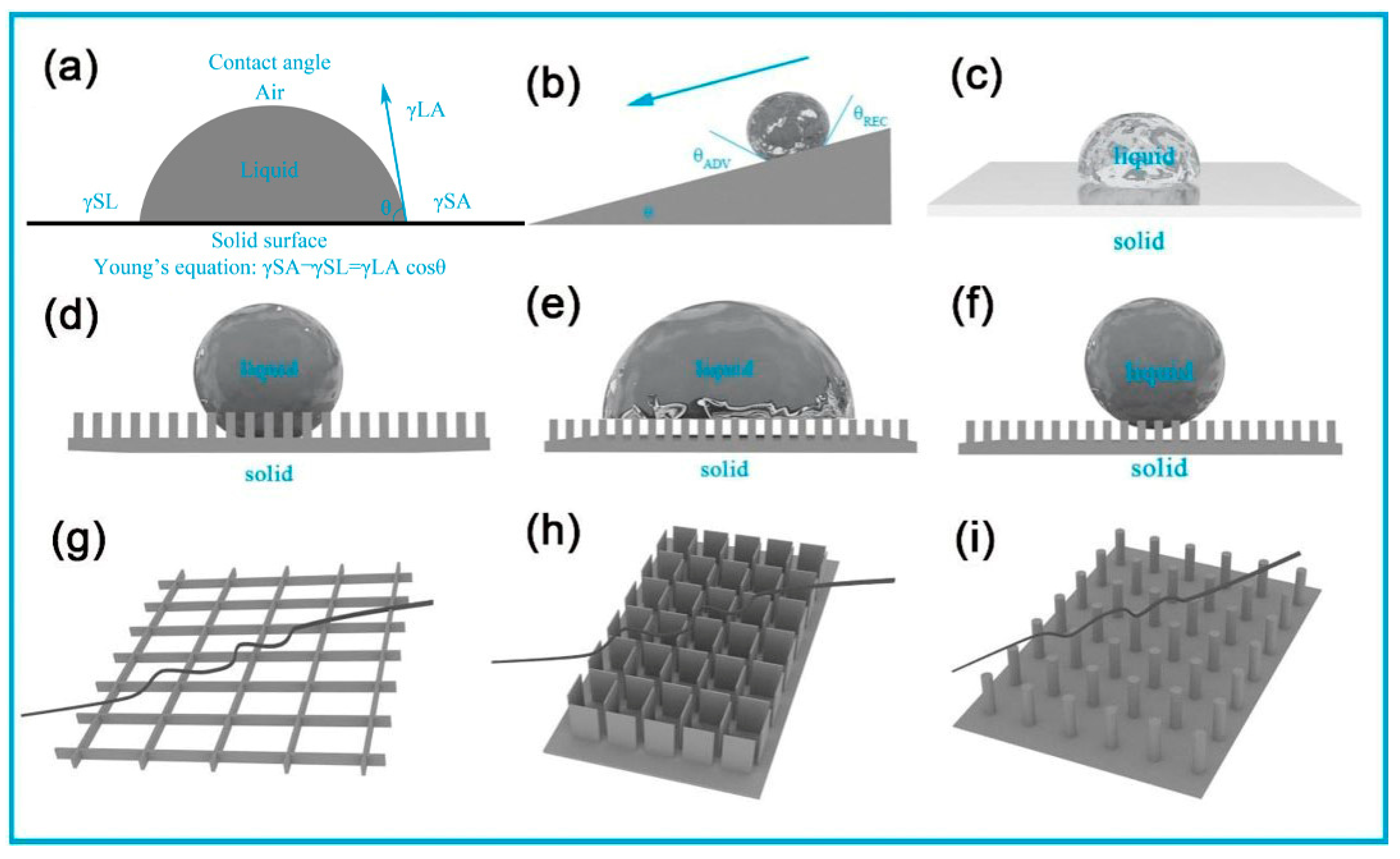

2.1. Theory of Hydrophobicity

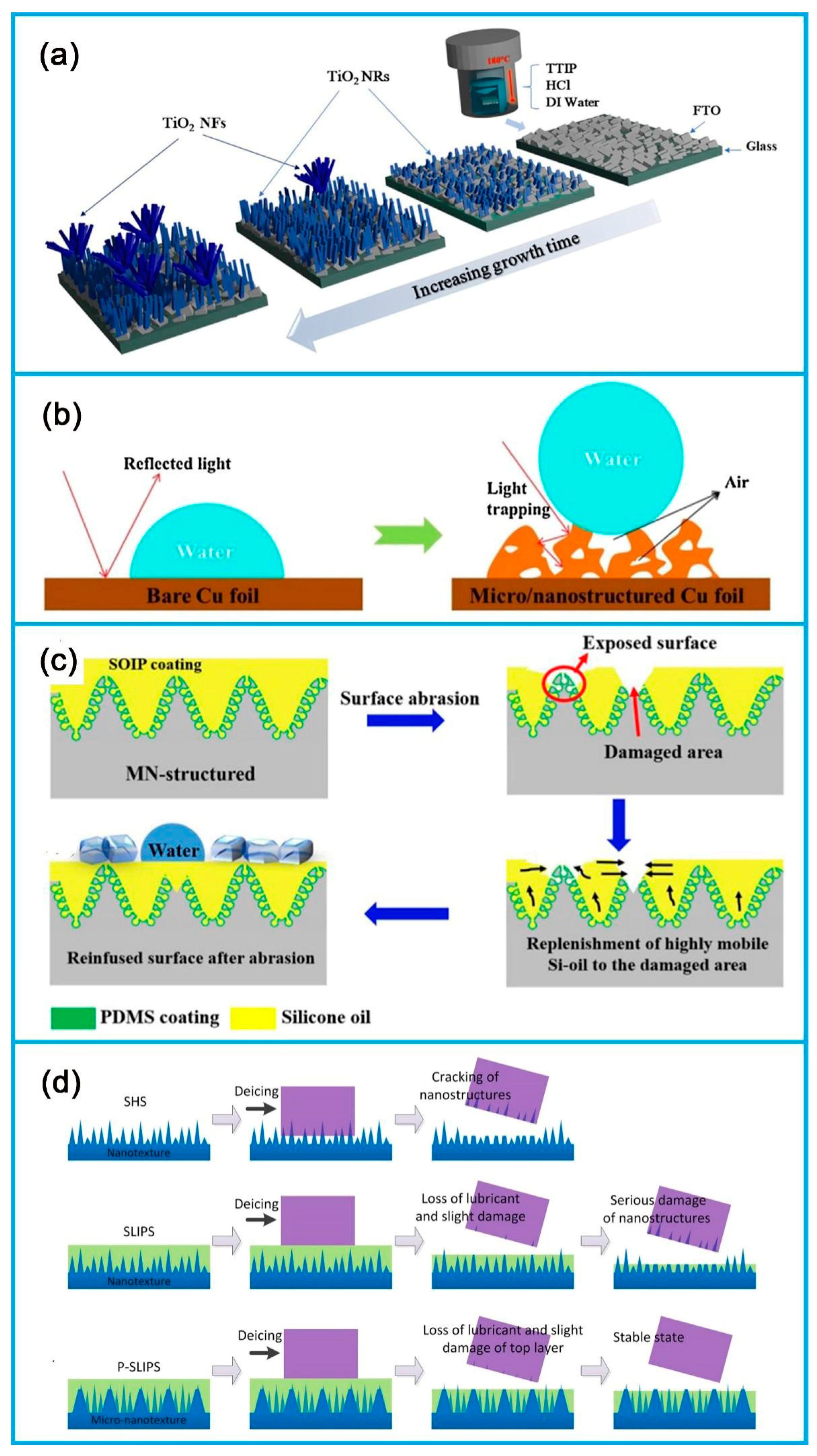

2.2. Experiments of Hydrophobicity

2.3. Hydrophobic Mechanism

| Matrix | Low-Surface-Energy Material | Fabrication Technique | Major Properties | Summary | Morphology | Ref |

|---|---|---|---|---|---|---|

| Glass wafer | - | Sol-gel | Controllable wettability | CA = 161.2 ± 1.3° |  | [106] |

| sc-Si | Fe(NO3)3 | Wet etching | Hydrophobicity | CA = 144.5° |  | [134] |

| Si (100) substrate | - | RF-PECVD | Waterproofness, self-cleaning property and reusability | CA = 158° |  | [136] |

| Cu foil | Sodium laurate | Direct crystallization | Hydrophobicity | CA = 156 ± 2° |  | [137] |

| BCPs | - | RAFT | Hydrophobicity | CA = 128° |  | [155] |

| MgAl-LDH | Melamine sponge | In situ growing | Superhydrophobicity | CA = 163.2° |  | [158] |

| Cu foil | - | Facile hydrothermal | Antireflection and hydrophobicity | CA = 142.6° |  | [165] |

| The structured aluminum | - | Femtosecond laser raster Scanning | Superhydrophobicity | CA = 153 ± 0.8° |  | [168] |

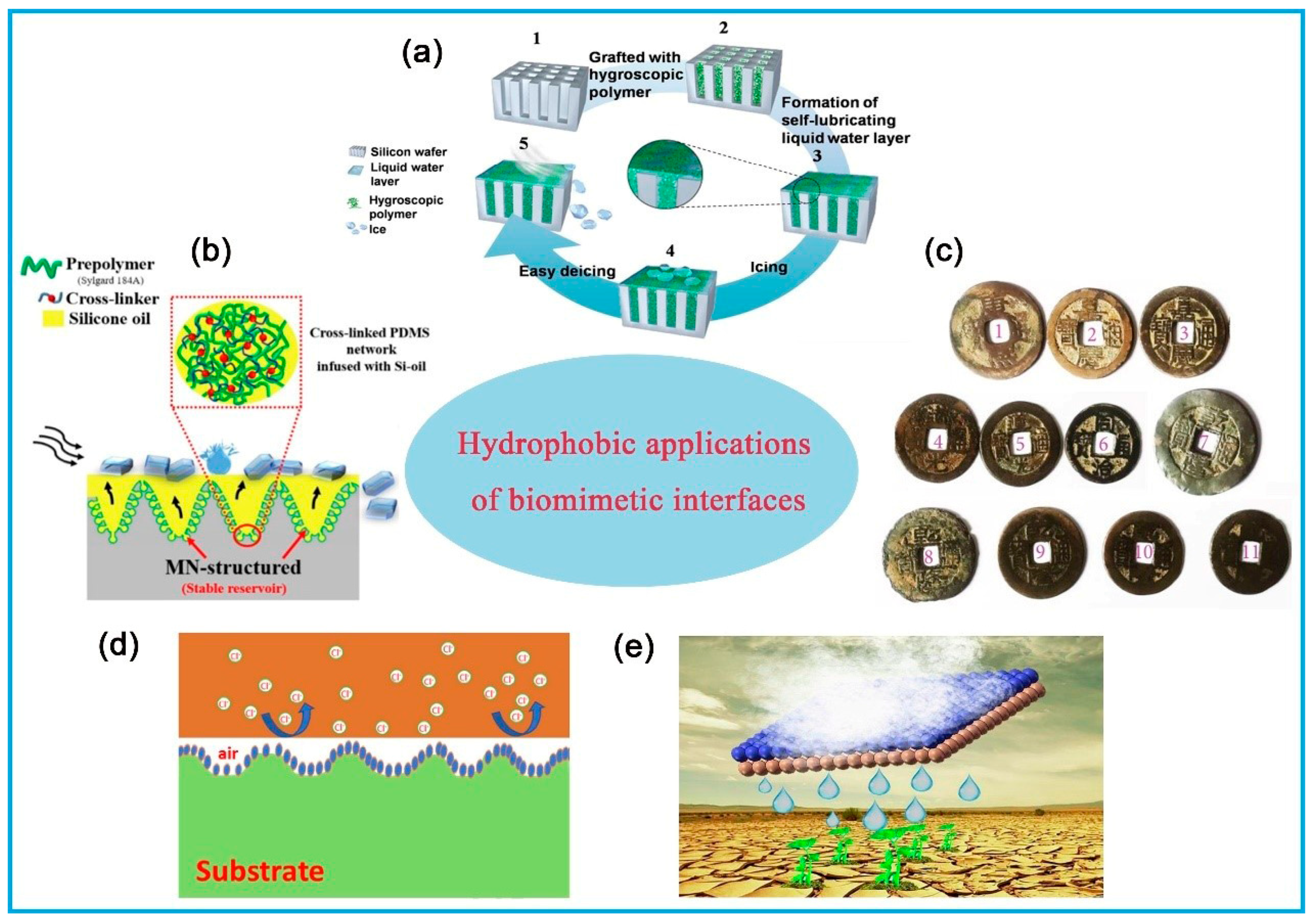

2.4. Hydrophobic Applications

2.5. Bionic Interface Technology

| Bionic Object | Matrix | Preparative Technique | Result | Structure | Comparison |

|---|---|---|---|---|---|

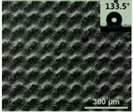

| Rose petal-like microscale structure [227] | 304 stainless-steel | Laser etching and chemical vapor deposition | WCA ~ 133.5° |  | Simple process, low cost, and fast etching rate |

| Mussel-inspired [224] | Polypropylene plate | Adhesion technology and thiol chemistry | SWCA ~ 39° |  | Simple and versatile |

| Butterfly wings, peacock tail feathers, and dolphin skins [235] | 3 mol% yttria-stabilized tetragonal zirconia polycrystal | Laser ablation method | WCA ˃ 150° COF ~ 0.179 |  | High machining efficiency and noncontact |

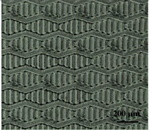

| Sharklet [225,231] | Commercial photosensitive acrylic resin | 3D printing | WCA ~ 61° COF ~ 0.17 |  | High efficiency, high manufacturing flexibility, well machining repeatability, high accuracy, and strongenvironmental adaptability |

| Al2O3/TiC ceramic | Laser surface texturing | WCA ~ 76.3° COF ~ 0.07 |  | ||

| Lotus leaf [229] | UV-curable waterborne polyurethane acrylate | UV nanoimprint lithography | After wear WCA ˃ 150° |  | Efficient, environmentally friendly, energy-saving, enabling, and economical |

3. Biomimetic Interfaces in the Tribology

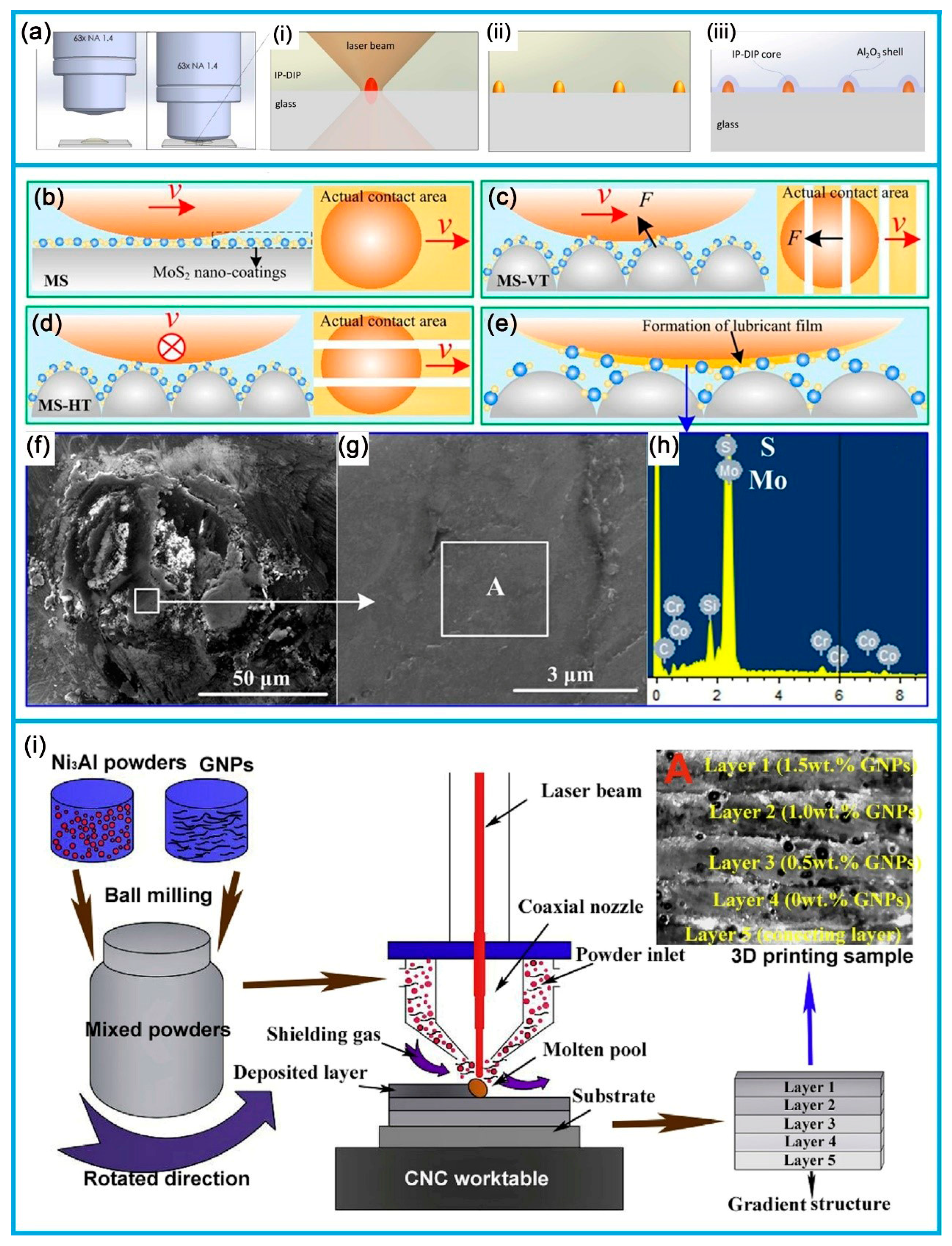

3.1. Dry Friction

3.2. Wet Friction

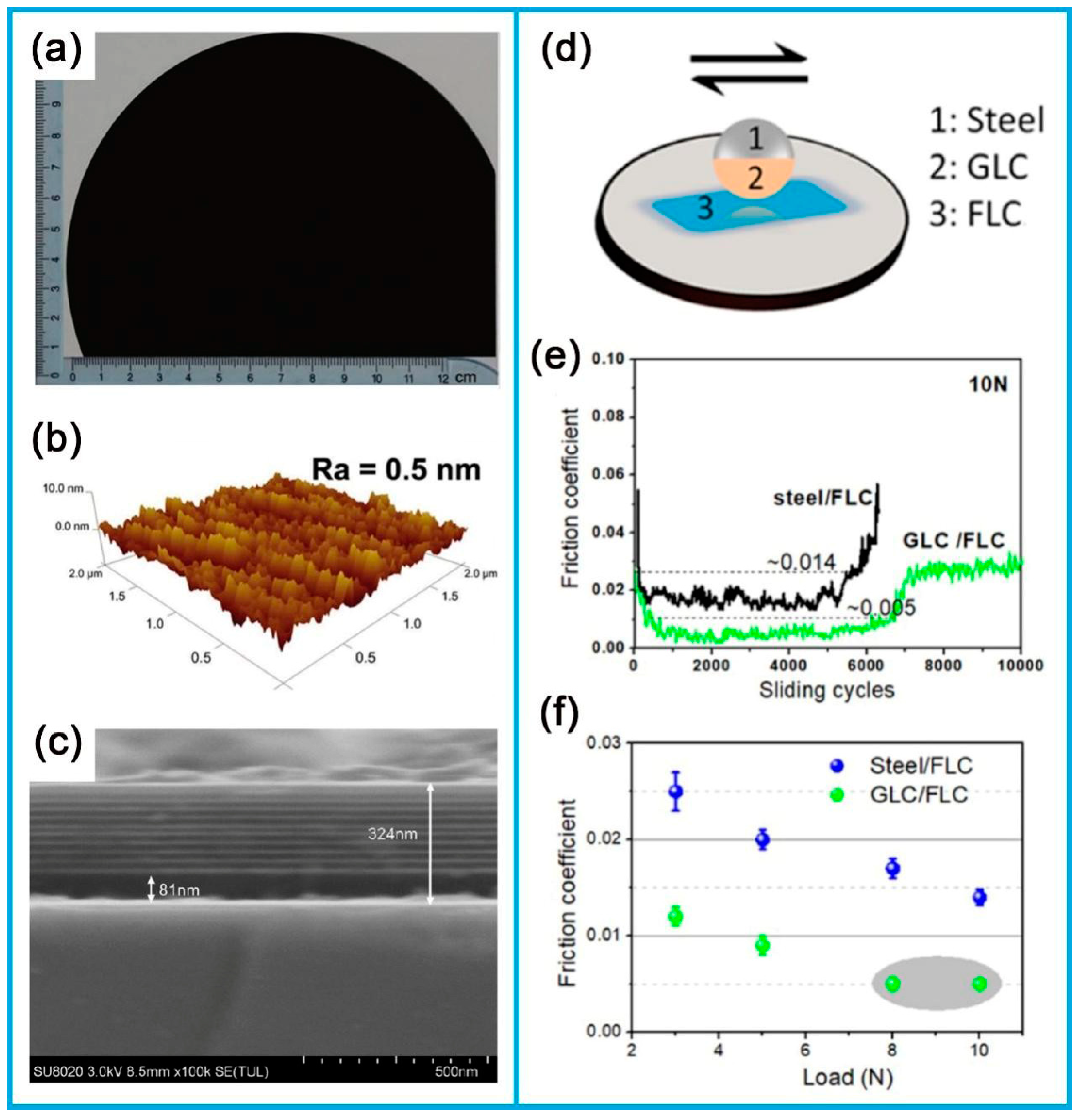

3.3. Ultra-Lubrication

3.4. Application of Frictions

| Matrix/Struct-Ure | Reinforcement | Tested Conditions | Tribological Results | |

|---|---|---|---|---|

| COF | Wear | |||

| SiC-nanoceramic | CNT [290] | Si3N4 ball (ball-on-three-disks, 150 N, 100 rpm, paraffin oil) | 0.12 | Wear rate: ~9.6 × 10−10 mm3/mN |

| AZ61 magnesium alloy | CNTs [257] | block (ring on block, 50 N, 140 rpm speed, 10 min) | ~0.22 | Volumetric loss: 0.96 mm3 |

| PTFE coating | CF [259] | 1045 steel ball (ball-on-disk, 10 N, 200 rpm, 30 min) | ~0.175 | Wear rate: ~2.74 × 10−4 mm3/Nm |

| PTFE | CNF [260] | 45 steel (ring-on-ring, 200 N, 30 min, 25 °C, 1.4 m/s, humidity: 50 ± 5%) | ~0.16 | Volumetric loss: ~9.7 mm3 |

| PTFE | SWCNT [287] | 304 stainless steel (linear reciprocating friction, 250 N, 50.8 mm/s, 25.4 mm) | ~0.19 | Wear rate: ~3.0 × 10−5 mm3/Nm |

| UHMWPE | CNT [288] | EN-31 forged steel ball (ball-on-disc, 5 N, 200 rpm, 120 min) | ~0.12 | Wear rate: ~9.46 × 10−5 mm3/Nm |

| Dimple texture | Nano-MoS2 [263] | Nodular cast iron pin (pin-on-disc, 10 N, 0.05 m/s, 20 °C) | 0.48 | Wear rate: ~3.5 × 10−6 mm3/Nm |

| Pit texture | Graphene [270] | Si3N4 ball (pin-on-disk, 1 N, 180 rpm, RT) | ~0.06 | Wear life: 12,000 cycles |

| The convex textures | Copper nanoparticles [284] | Stainless steel ball (pin-on-disc, 20 N, oil lubrication, RT) | ~0.12 | NM |

| Network structure | SiCnws [285] | Steel ball (ball-on-disks, 120 min, lubricating oil, RT) | ~0.22971 | Wear rate: ~0.08171 × 10−6 mm3/Nm |

| Onion structure | Nanodiamond particles [308] | Al2O3 ball (2.89 Gpa, 1800s) | ~0.009 | NM |

| Hierarchical structure | Graphene sheets and MoS2 [310] | Al2O3 ball (ball-on-disc, 10 N, 0.2 m/s, RT) | ~0.004 | NM |

4. Conclusions and Outlooks

Author Contributions

Funding

Conflicts of Interest

References

- Liu, Y.; Qi, Y.; Sun, H.; Han, N.; Zhou, J.; Song, J.; Zou, M. Bionic design of thin-walled tubes inspired by the vascular structure of bamboo. Thin-Walled Struct. 2023, 186, 110689. [Google Scholar] [CrossRef]

- Zhang, R.; Sun, X.; Han, D.; Zhang, R.; Zhang, H.; Ma, J.; Wen, L.; Zou, M. A bionic mechanical foot with adaptive variable postures travelling on sand. J. Terramechanics 2023, 107, 61–74. [Google Scholar] [CrossRef]

- Jiang, J.; Yao, Z.; Li, Z.; Lu, Y.; Yao, Q.; Gong, X.; Fu, X.; Duan, F. Recognition method for the bionic camouflage cetacean whistle modulated by CPMFSK signals. Appl. Acoust. 2023, 207, 109326. [Google Scholar] [CrossRef]

- Yan, Z.; Yang, H.; Zhang, W.; Lin, F.; Gong, Q.; Zhang, Y. Bionic fish tail design and trajectory tracking control. Ocean Eng. 2022, 257, 111659. [Google Scholar] [CrossRef]

- Sun, S.; Zhi, Y.; Li, X.; Guo, Z. Numerical investigation on cavitating wake dynamic of a propeller with bionic tubercle leading-edge. Ocean Eng. 2022, 252, 111240. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Lu, Y.; Yan, Y.; Zhao, W.; Wu, X.; Zhang, Z. Application and optimal design of the bionic guide vane to improve the safety serve performances of the reactor coolant pump. Nucl. Eng. Technol. 2022, 54, 2491–2509. [Google Scholar] [CrossRef]

- Huang, S.; Qiu, H.; Wang, Y. Aerodynamic performance of horizontal axis wind turbine with application of dolphin head-shape and lever movement of skeleton bionic airfoils. Energy Convers. Manag. 2022, 267, 115803. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, J.; Xie, T.; Fu, L.; Yang, W.; Li, D.; Zhou, L. A new Cu-W bionic shell pearl multilayer structure. Surf. Coat. Technol. 2023, 461, 129433. [Google Scholar] [CrossRef]

- Wang, Z.; Meng, L.; Li, X.; Li, J. Fabrication of core-shell Ni@C@PANI nanocomposite-based bionic coating with multi-bands EWM adaptability inspired by porous structure of pachliopta aristolochiae wings. Prog. Org. Coat. 2023, 179, 107498. [Google Scholar] [CrossRef]

- Sun, X.; Xu, J.; Qi, Z. Mechanism properties of a bird-neck bionic rigid-flexible structure. Fundam. Res. 2022, in press. [Google Scholar] [CrossRef]

- Wang, L. A critical review on robust self-cleaning property of lotus leaf. Soft Matter 2023, 19, 1058–1075. [Google Scholar] [CrossRef] [PubMed]

- Wan, J.; Li, H.; Xu, L.; Yan, J.; Liao, Y.; Wang, X. PDA/PEI-induced in-situ growth of a lotus leaf-like TiO2 nanoparticle film on N-halamine cotton fabric for photocatalytic, self-cleaning and efficient antibacterial performance. Cellulose 2023, 30, 3953–3972. [Google Scholar] [CrossRef]

- Sun, J.; Bauman, L.; Yu, L.; Zhao, B. Gecko-and-inchworm-inspired untethered soft robot for climbing on walls and ceilings. Cell Rep. Phys. Sci. 2023, 4, 101241. [Google Scholar] [CrossRef]

- Duan, J.; Wang, B.; Ji, B.; Sun, W.; Wang, Z.; Dai, Z. Control Strategy of Stable Climbing Mechanics for Gecko-Inspired Robot on Vertical Arc Surface. IEEE Instrum. Meas. Mag. 2023, 26, 48–56. [Google Scholar] [CrossRef]

- Zhang, Z.; Chu, Z.; Zhang, B.; Cui, J. Inchworm-Gecko Inspired Robot with Adhesion State Detection and CPG Control. In Cognitive Systems and Information Processing; Sun, F., Cangelosi, A., Zhang, J., Yu, Y., Liu, H., Fang, B., Eds.; Springer Nature: Singapore, 2023; pp. 70–84. [Google Scholar]

- Sharma, S.K.; Grewal, H.S. Tribological Behavior of Bioinspired Surfaces. Biomimetics 2023, 8, 62. [Google Scholar] [CrossRef] [PubMed]

- Dean, B.; Bhushan, B. Shark-skin surfaces for fluid-drag reduction in turbulent flow: A review. Philosophical Transactions of the Royal Society A: Mathematical. Phys. Eng. Sci. 2010, 368, 4775–4806. [Google Scholar]

- Puukilainen, E.; Koponen, H.-K.; Xiao, Z.; Suvanto, S.; Pakkanen, T.A. Nanostructured and chemically modified hydrophobic polyolefin surfaces. Colloids Surf. A Physicochem. Eng. Asp. 2006, 287, 175–181. [Google Scholar] [CrossRef]

- Zheng, R.; Tshabalala, M.A.; Li, Q.; Wang, H. Construction of hydrophobic wood surfaces by room temperature deposition of rutile (TiO2) nanostructures. Appl. Surf. Sci. 2015, 328, 453–458. [Google Scholar] [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 1997, 202, 1–8. [Google Scholar] [CrossRef]

- Schulz, B.; Frommer, W.B. A plant ABC transporter takes the lotus seat. Science 2004, 306, 622–625. [Google Scholar] [CrossRef][Green Version]

- Su, H.; Luan, B.; Dong, Y.; Zhang, X.; Liu, Z.; Wang, C. Lotus leaf-like Ni-decorated SiC with combined superhydrophobicity and enhanced microwave absorption performance. Colloids Surf. A Physicochem. Eng. Asp. 2022, 650, 129602. [Google Scholar] [CrossRef]

- Yoo, D.; Kim, S.J.; Joung, Y.; Jang, S.; Choi, D.; Kim, D.S. Lotus leaf-inspired droplet-based electricity generator with low-adhesive superhydrophobicity for a wide operational droplet volume range and boosted electricity output. Nano Energy 2022, 99, 107361. [Google Scholar] [CrossRef]

- Klicova, M.; Oulehlova, Z.; Klapstova, A.; Hejda, M.; Krejcik, M.; Novak, O.; Mullerova, J.; Erben, J.; Rosendorf, J.; Palek, R.; et al. Biomimetic hierarchical nanofibrous surfaces inspired by superhydrophobic lotus leaf structure for preventing tissue adhesions. Mater. Des. 2022, 217, 110661. [Google Scholar] [CrossRef]

- Yang, J.; Long, F.; Wang, R.; Zhang, X.; Yang, Y.; Hu, W.; Liu, L. Design of mechanical robust superhydrophobic Cu coatings with excellent corrosion resistance and self-cleaning performance inspired by lotus leaf. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127154. [Google Scholar] [CrossRef]

- Shao, Y.; Zhao, J.; Fan, Y.; Wan, Z.; Lu, L.; Zhang, Z.; Ming, W.; Ren, L. Shape memory superhydrophobic surface with switchable transition between “Lotus Effect” to “Rose Petal Effect”. Chem. Eng. J. 2020, 382, 122989. [Google Scholar] [CrossRef]

- Ebert, D.; Bhushan, B. Wear-resistant rose petal-effect surfaces with superhydrophobicity and high droplet adhesion using hydrophobic and hydrophilic nanoparticles. J. Colloid Interface Sci. 2012, 384, 182–188. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Xin, B.; Zhang, Z.; Wang, Y.; Yu, W.; Hou, C.; Jiang, Y.; Huang, P.; Xu, W. Study on the Preparation of Special Wettability Nanofiber Membranes and Its Application in Oil-water Separation. J. Phys. Conf. Ser. 2023, 2437, 12037. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Superhydrophobic surfaces and emerging applications: Non-adhesion, energy, green engineering. Curr. Opin. Colloid Interface Sci. 2009, 14, 270–280. [Google Scholar] [CrossRef]

- Huang, F.; Motealleh, B.; Wang, D.; Cornelius, C.J. Tailoring intrinsic hydrophobicity and surface energy on rough surface via low-T Cassie–Wenzel wetting transition method. AIChE J. 2023, 69, e17908. [Google Scholar] [CrossRef]

- Drelich, J.; Marmur, A. Physics and applications of superhydrophobic and superhydrophilic surfaces and coatings. Surf. Innov. 2014, 2, 211–227. [Google Scholar] [CrossRef]

- Yin, K.; Yang, S.; Dong, X.; Chu, D.; Duan, J.-A.; He, J. Ultrafast achievement of a superhydrophilic/hydrophobic janus foam by femtosecond laser ablation for directional water transport and efficient fog harvesting. ACS Appl. Mater. Interfaces 2018, 10, 31433–31440. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Zhang, Y.; Xi, J.; Zhu, Y.; Wang, N.; Xia, F.; Jiang, L. Petal effect: A superhydrophobic state with high adhesive force. Langmuir 2008, 24, 4114–4119. [Google Scholar] [CrossRef]

- Parker, A.R.; Lawrence, C.R. Water capture by a desert beetle. Nature 2001, 414, 33–34. [Google Scholar] [CrossRef]

- Qin, S.; Shi, X.; Xue, Y.; Zhang, K.; Huang, Q.; Wu, C.; Ma, J.; Shu, J. Coupling effects of bionic textures with composite solid lubricants to improve tribological properties of TC4 alloy. Tribol. Int. 2022, 173, 107691. [Google Scholar] [CrossRef]

- Wang, Z.; Fu, Q.; Wood, R.J.; Wu, J.; Wang, S. Influence of bionic non-smooth surface texture on tribological characteristics of carbon-fiber-reinforced polyetheretherketone under seawater lubrication. Tribol. Int. 2020, 144, 106100. [Google Scholar] [CrossRef]

- Yang, K.; Ma, H.; Zhao, W.; Li, X.; Liu, H. Investigation of the preparation and tribological behavior of a frictional interface covered with sinusoidal microchannels containing SnAgCu and Ti3SiC2. Tribol. Int. 2020, 150, 106368. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, G.; Li, J.; Chen, J.; Zhang, S.; Wang, J.; Walsh, F.C.; Wang, S.; Xue, Y. Electroplating of non-fluorinated superhydrophobic Ni/WC/WS2 composite coatings with high abrasive resistance. Appl. Surf. Sci. 2019, 487, 1329–1340. [Google Scholar] [CrossRef]

- Liu, X.; Liang, Y.; Zhou, F.; Liu, W. Extreme wettability and tunable adhesion: Biomimicking beyond nature? Soft Matter 2012, 8, 2070–2086. [Google Scholar] [CrossRef]

- Jucius, D.; Guobienė, A.; Grigaliūnas, V. Surface texturing of polytetrafluoroethylene by hot embossing. Appl. Surf. Sci. 2010, 256, 2164–2169. [Google Scholar] [CrossRef]

- Khan, A.; Wang, Z.; Sheikh, M.A.; Whitehead, D.J.; Li, L. Laser micro/nano patterning of hydrophobic surface by contact particle lens array. Appl. Surf. Sci. 2011, 258, 774–779. [Google Scholar] [CrossRef]

- Marchetto, D.; Rota, A.; Calabri, L.; Gazzadi, G.C.; Menozzi, C.; Valeri, S. Hydrophobic effect of surface patterning on Si surface. Wear 2010, 268, 488–492. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, L.; Xue, Q. Design and fabrication of nanopillar patterned Au textures for improving nanotribological performance. ACS Appl. Mater. Interfaces 2010, 2, 788–794. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhong, X.; Meng, X.; Yi, G.; Jia, J. Adhesion and friction studies of nano-textured surfaces produced by self-assembling Au nanoparticles on silicon wafers. Tribol. Lett. 2012, 46, 65–73. [Google Scholar] [CrossRef]

- Ding, Q.; Wang, L.; Wang, Y.; Wang, S.; Hu, L.; Xue, Q. Improved tribological behavior of DLC films under water lubrication by surface texturing. Tribol. Lett. 2011, 41, 439–449. [Google Scholar] [CrossRef]

- Man, H.C.; Chiu, K.; Guo, X. Laser surface micro-drilling and texturing of metals for improvement of adhesion joint strength. Appl. Surf. Sci. 2010, 256, 3166–3169. [Google Scholar] [CrossRef]

- Luo, K.; Wang, C.; Li, Y.; Luo, M.; Huang, S.; Hua, X.; Lu, J. Effects of laser shock peening and groove spacing on the wear behavior of non-smooth surface fabricated by laser surface texturing. Appl. Surf. Sci. 2014, 313, 600–606. [Google Scholar] [CrossRef]

- Maksimov, S. An integral method to study textures of nanosized crystallites in an electron microscope column. Inorg. Mater. 2009, 45, 1598–1609. [Google Scholar] [CrossRef]

- Daniel, M.-C.; Astruc, D. Gold nanoparticles: Assembly; supramolecular chemistry; quantum-size-related properties, and applications toward biology, catalysis, and nanotechnology. Chem. Rev. 2004, 104, 293–346. [Google Scholar] [CrossRef]

- Hu, H.; Chen, H.; Yu, S.; Chen, J.; Wu, G.; Meng, F.; Qu, J.; Li, Y.; Zhu, H.; Xiao, J.Q. Textured Co nanowire arrays with controlled magnetization direction. J. Magn. Magn. Mater. 2005, 295, 257–262. [Google Scholar] [CrossRef]

- Wang, S.; Pang, X.; Guo, X.; Cheng, C.; Liu, Y.; Zhang, Y. Mechanical and tribological properties of WC particles reinforced Cu-20Zn matrix composites. Powder Technol. 2022, 406, 117571. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, F.; Chen, Y.; Zhang, H.; Xiong, B.; Chen, H. Recent progress on carbon-based composites in multidimensional applications. Compos. Part A Appl. Sci. Manuf. 2022, 157, 106906. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, K.; Lin, H.; Zhang, F.; Xiong, B.; Zhang, H.; Zhang, C. Important contributions of multidimensional nanoadditives on the tribofilms: From formation mechanism to tribological behaviors. Compos. Part B Eng. 2022, 234, 109732. [Google Scholar] [CrossRef]

- Chouquet, C.; Gavillet, J.; Ducros, C.; Sanchette, F. Effect of DLC surface texturing on friction and wear during lubricated sliding. Mater. Chem. Phys. 2010, 123, 367–371. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, Y.; Zhu, H.; Yang, H. The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl. Surf. Sci. 2013, 273, 199–204. [Google Scholar] [CrossRef]

- Yang, K.; Ma, H.; Cao, S.; Li, X.; Li, A.; Cao, Z. Analysis of friction interfaces with sinusoidal microchannels and the hybrid lubrication mechanisms of a tribo-film. Appl. Surf. Sci. 2020, 525, 146502. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, F.; Ma, Y.; Cao, Z.; Ma, H.; Zhang, C.; Liang, Y. Simple synthesis of the composite coating and the lubrication mechanisms of the spherical SnAgCu–Al2O3. Wear 2020, 462–463, 203514. [Google Scholar] [CrossRef]

- Yang, K.; Ma, H.; Wang, L.; Cao, Z.; Zhang, C. Analysis of self-regulating tribological functions of the MgAl microchannels prepared in the Ti alloys. Tribol. Int. 2021, 154, 106717. [Google Scholar] [CrossRef]

- Hirano, M.; Shinjo, K. Atomistic locking and friction. Phys. Rev. B 1990, 41, 11837. [Google Scholar] [CrossRef]

- Matta, C.; Joly-Pottuz, L.; Bouchet, M.D.B.; Martin, J.; Kano, M.; Zhang, Q. Goddard III, Superlubricity and tribochemistry of polyhydric alcohols. Phys. Rev. B 2008, 78, 85436. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Z.; Grey, F.; Xu, Z.; Li, X.; Liu, Y.; Urbakh, M.; Cheng, Y.; Zheng, Q. Observation of high-speed microscale superlubricity in graphite. Phys. Rev. Lett. 2013, 110, 255504. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, W.; Xu, X. Robust superhydrophobic magnetic melamine sponge inspired by lotus leaf surface for efficient continuous oil-water separation. Sep. Purif. Technol. 2023, 311, 123251. [Google Scholar] [CrossRef]

- Ji, X.-Y.; Wang, J.-W.; Feng, X.-Q. Role of flexibility in the water repellency of water strider legs: Theory and experiment. Phys. Rev. E 2012, 85, 21607. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Liu, W.; Shang, W.; Chen, J.; Lian, J. Drop impact dynamic and directional transport on dragonfly wing surface. Friction 2023, 11, 737–747. [Google Scholar] [CrossRef]

- Fang, Y.; Sun, G.; Bi, Y.; Zhi, H. Multiple-dimensional micro/nano structural models for hydrophobicity of butterfly wing surfaces and coupling mechanism. Sci. Bull. 2015, 60, 256–263. [Google Scholar] [CrossRef]

- Li, J.; Guo, Z.; Liu, W. Biomimetic Superhydrophobic Materials Construct from Binary Structure: A Review on Design. Properties, and Applications. Adv. Mater. Interfaces 2023, 10, 2201847. [Google Scholar] [CrossRef]

- Chen, X.; Wang, M.; Xin, Y.; Huang, Y. One-step fabrication of self-cleaning superhydrophobic surfaces: A combined experimental and molecular dynamics study. Surf. Interfaces 2022, 31, 102022. [Google Scholar] [CrossRef]

- Xue, C.-H.; Jia, S.-T.; Zhang, J.; Ma, J.-Z. Large-area fabrication of superhydrophobic surfaces for practical applications: An overview. Sci. Technol. Adv. Mater. 2010, 11, 33002. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Y.; Hu, Z.; Zhang, X.; Wu, S.; Wang, R.; Zhu, Y. A novel electrodeposition route for fabrication of the superhydrophobic surface with unique self-cleaning, mechanical abrasion and corrosion resistance properties. Chem. Eng. J. 2016, 303, 37–47. [Google Scholar] [CrossRef]

- Scarratt, L.R.; Hoatson, B.S.; Wood, E.S.; Hawkett, B.S.; Neto, C. Durable superhydrophobic surfaces via spontaneous wrinkling of teflon AF. ACS Appl. Mater. Interfaces 2016, 8, 6743–6750. [Google Scholar] [CrossRef]

- Cully, P.; Karasu, F.; Müller, L.; Jauzein, T.; Leterrier, Y. Self-cleaning and wear-resistant polymer nanocomposite surfaces. Surf. Coat. Technol. 2018, 348, 111–120. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, L.; Sun, W.; Li, S.; Zhu, T.; Liu, W.; Liu, G. Superhydrophobic epoxy coating modified by fluorographene used for anti-corrosion and self-cleaning. Appl. Surf. Sci. 2017, 401, 146–155. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, X.; Li, J.; Liu, J.-H.; Huang, X.-J. ZnO/CuO hetero-hierarchical nanotrees array: Hydrothermal preparation and self-cleaning properties. Langmuir 2011, 27, 6193–6200. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Silberschmidt, V.V.; Hu, Z.-T.; Chen, Z. When superhydrophobic coatings are icephobic: Role of surface topology. Surf. Coat. Technol. 2019, 358, 207–214. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, Z.; Chen, X.; Zou, W.; Jiang, X.; Sun, D.; Yu, M. Color fastness enhancement of dyed wood by Si-sol@PDMS based superhydrophobic coating. Colloids Surf. A Physicochem. Eng. Asp. 2022, 651, 129701. [Google Scholar] [CrossRef]

- Zhao, J.; Sun, R.; Liu, C.; Mo, J. Application of ZnO/epoxy resin superhydrophobic coating for buoyancy enhancement and drag reduction. Colloids Surf. A Physicochem. Eng. Asp. 2022, 651, 129714. [Google Scholar] [CrossRef]

- Cao, L.; Liu, J.; Xu, S.; Xia, Y.; Huang, W.; Li, Z. Inherent superhydrophobicity of Sn/SnOx films prepared by surface self-passivation of electrodeposited porous dendritic Sn. Mater. Res. Bull. 2013, 48, 4804–4810. [Google Scholar] [CrossRef]

- Bhattacharya, P.; Gohil, S.; Mazher, J.; Ghosh, S.; Ayyub, P. Universal, geometry-driven hydrophobic behaviour of bare metal nanowire clusters. Nanotechnology 2008, 19, 75709. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Liu, X.; Tian, Y. Insights into the wettability transition of nanosecond laser ablated surface under ambient air exposure. J. Colloid Interface Sci. 2019, 533, 268–277. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Gu, Q.; Jiang, W.; Zhu, H.; Xu, K.; Ren, Y.; Xu, C. Achieving of bionic super-hydrophobicity by electrodepositing nano-Ni-pyramids on the picosecond laser-ablated micro-Cu-cone surface. Surf. Coat. Technol. 2019, 363, 170–178. [Google Scholar] [CrossRef]

- Lin, Y.; Li, T.; Liu, S.; Shi, Q.; Xu, K.; Zhang, Z.; Wu, J. Interfacial mechanical properties of tetrahydrofuran hydrate-solid surfaces: Implications for hydrate management. J. Colloid Interface Sci. 2023, 629, 326–335. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, R.; Yang, B.; Li, T.; Tryk, D.; Fujishima, A.; Hashimoto, K.; Zhu, D. Binary cooperative complementary nanoscale interfacial materials. Pure Appl. Chem. 2000, 72, 73–81. [Google Scholar] [CrossRef]

- Lu, Y. Temperature Dependent Anti-Icing Performance of the Microstructure Surface: Wettability Change and Ice Nucleation. Coatings 2023, 13, 1485. [Google Scholar] [CrossRef]

- Koch, B.M.; Amirfazli, A.; Elliott, J.A. Modeling and measurement of contact angle hysteresis on textured high-contact-angle surfaces. J. Phys. Chem. C 2014, 118, 18554–18563. [Google Scholar] [CrossRef]

- Blake, T.; Fernández-Toledano, J.; De Coninck, J. A possible way to extract the dynamic contact angle at the molecular scale from that measured experimentally. J. Colloid Interface Sci. 2023, 629, 660–669. [Google Scholar] [CrossRef]

- Kumar, P.; Harvie, D.J. Contact Angle Hysteresis on Rough Surfaces Part II: Energy Dissipation via Microscale Interface Dynamics. arXiv 2023, arXiv:2303.09149. [Google Scholar]

- Iliev, S.; Pesheva, N.; Iliev, P. Contact angle hysteresis on random self-affine rough surfaces in Wenzel’s wetting regime: Numerical study. Phys. Rev. E 2023, 107, 24802. [Google Scholar] [CrossRef]

- Ford, R.; Furmidge, C. Studies at phase interfaces: II. The stabilization of water-in-oil emulsions using oil-soluble emulsifiers. J. Colloid Interface Sci. 1966, 22, 331–341. [Google Scholar] [CrossRef]

- Furmidge, C. Studies at phase interfaces. I. The sliding of liquid drops on solid surfaces and a theory for spray retention. J. Colloid Sci. 1962, 17, 309–324. [Google Scholar]

- Chen, W.; Fadeev, A.Y.; Hsieh, M.C.; Öner, D.; Youngblood, J.; McCarthy, T.J. Ultrahydrophobic and ultralyophobic surfaces: Some comments and examples. Langmuir 1999, 15, 3395–3399. [Google Scholar] [CrossRef]

- Mao-Gang, G.; Yuan-Yue, L.; Xiao-Liang, X. A new model for the formation of contact angle and contact angle hysteresis. Chin. Phys. B 2010, 19, 106801. [Google Scholar] [CrossRef]

- Young, T., III. An essay on the cohesion of fluids. Philos. Trans. R. Soc. Lond. 1805, 95, 65–87. [Google Scholar]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Bhushan, B. Bioinspired structured surfaces. Langmuir 2012, 28, 1698–1714. [Google Scholar] [CrossRef] [PubMed]

- Bhushan, B.; Jung, Y.C.; Koch, K. Micro-, nano-and hierarchical structures for superhydrophobicity, self-cleaning and low adhesion. Philosophical Transactions of the Royal Society A: Mathematical. Phys. Eng. Sci. 2009, 367, 1631–1672. [Google Scholar]

- Myronyuk, O.; Baklan, D.; Vasilyev, G.S.; Rodin, A.M.; Vanagas, E. Wetting patterns of liquid-repellent femtosecond laser textured aluminum surfaces. Coatings 2022, 12, 1852. [Google Scholar] [CrossRef]

- Ran, C.; Ding, G.; Liu, W.; Deng, Y.; Hou, W. Wetting on nanoporous alumina surface: Transition between Wenzel and Cassie states controlled by surface structure. Langmuir 2008, 24, 9952–9955. [Google Scholar] [CrossRef] [PubMed]

- Cassie, A.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Milne, A.J.B.; Amirfazli, A. The Cassie equation: How it is meant to be used. Adv. Colloid Interface Sci. 2012, 170, 48–55. [Google Scholar] [CrossRef]

- Cai, T.-M.; Jia, Z.-H.; Yang, H.-N.; Wang, G. Investigation of Cassie-Wenzel wetting transitions on microstructured surfaces. Colloid Polym. Sci. 2016, 294, 833–840. [Google Scholar] [CrossRef]

- Murakami, D.; Jinnai, H.; Takahara, A. Wetting transition from the Cassie–Baxter state to the Wenzel state on textured polymer surfaces. Langmuir 2014, 30, 2061–2067. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Patterned nonadhesive surfaces: Superhydrophobicity and wetting regime transitions. Langmuir 2008, 24, 1525–1533. [Google Scholar] [CrossRef] [PubMed]

- Jung, Y.C.; Bhushan, B. Dynamic effects of bouncing water droplets on superhydrophobic surfaces. Langmuir 2008, 24, 6262–6269. [Google Scholar] [CrossRef] [PubMed]

- Nosonovsky, M.; Bhushan, B. Energy transitions in superhydrophobicity: Low adhesion, easy flow and bouncing. J. Phys. Condens. Matter 2008, 20, 395005. [Google Scholar] [CrossRef]

- Krupenkin, T.N.; Taylor, J.A.; Schneider, T.M.; Yang, S. From rolling ball to complete wetting: The dynamic tuning of liquids on nanostructured surfaces. Langmuir 2004, 20, 3824–3827. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Feng, L.; Jin, M.; Zhai, J.; Jiang, L.; Zhu, D. Reversible super-hydrophobicity to super-hydrophilicity transition of aligned ZnO nanorod films. J. Am. Chem. Soc. 2004, 126, 62–63. [Google Scholar] [CrossRef] [PubMed]

- Bormashenko, E.; Pogreb, R.; Whyman, G.; Erlich, M. Cassie—Wenzel wetting transition in vibrating drops deposited on rough surfaces: Is the dynamic cassie—Wenzel wetting transition a 2d or 1d affair? Langmuir 2007, 23, 6501–6503. [Google Scholar] [CrossRef] [PubMed]

- Lafuma, A.; Quéré, D. Superhydrophobic states. Nat. Mater. 2003, 2, 457–460. [Google Scholar] [CrossRef]

- Extrand, C.W. Model for contact angles and hysteresis on rough and ultraphobic surfaces. Langmuir 2002, 18, 7991–7999. [Google Scholar] [CrossRef]

- Patankar, N.A. Transition between superhydrophobic states on rough surfaces. Langmuir 2004, 20, 7097–7102. [Google Scholar] [CrossRef]

- Gao, N.; Yan, Y. Modeling superhydrophobic contact angles and wetting transition. J. Bionic Eng. 2009, 6, 335–340. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Stochastic model for metastable wetting of roughness-induced superhydrophobic surfaces. Microsyst. Technol. 2006, 12, 231–237. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Roughness optimization for biomimetic superhydrophobic surfaces. Microsyst. Technol. 2005, 11, 535–549. [Google Scholar] [CrossRef]

- Ishino, C.; Okumura, K. Nucleation scenarios for wetting transition on textured surfaces: The effect of contact angle hysteresis. EPL (Europhys. Lett.) 2006, 76, 464. [Google Scholar] [CrossRef][Green Version]

- Bormashenko, E.; Bormashenko, Y.; Stein, T.; Whyman, G.; Pogreb, R.; Barkay, Z. Environmental scanning electron microscopy study of the fine structure of the triple line and Cassie—Wenzel wetting transition for sessile drops deposited on rough polymer substrates. Langmuir 2007, 23, 4378–4382. [Google Scholar] [CrossRef]

- Bhushan, B.; Jung, Y.C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci. 2011, 56, 1–108. [Google Scholar] [CrossRef]

- Quan, Y.-Y.; Chen, Z.; Lai, Y.; Huang, Z.-S.; Li, H. Recent advances in fabricating durable superhydrophobic surfaces: A review in the aspects of structures and materials. Mater. Chem. Front. 2021, 5, 1655–1682. [Google Scholar] [CrossRef]

- Parvate, S.; Dixit, P.; Chattopadhyay, S. Superhydrophobic surfaces: Insights from theory and experiment. J. Phys. Chem. B 2020, 124, 1323–1360. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhou, H.; Huang, J.; Guo, Z. Review on the recent development of durable superhydrophobic materials for practical applications. Nanoscale 2021, 13, 11734–11764. [Google Scholar] [CrossRef]

- Wang, D.; Sun, Q.; Hokkanen, M.J.; Zhang, C.; Lin, F.-Y.; Liu, Q.; Zhu, S.-P.; Zhou, T.; Chang, Q.; He, B. Design of robust superhydrophobic surfaces. Nature 2020, 582, 55–59. [Google Scholar] [CrossRef]

- Li, J.; Du, F.; Liu, X.; Jiang, Z.; Ren, L. Superhydrophobicity of Bionic Alumina Surfaces Fabricated by Hard Anodizing. J. Bionic Eng. 2011, 8, 369–374. [Google Scholar] [CrossRef]

- Zhao, D.; Tian, Q.; Wang, M.; Jin, Y. Study on the Hydrophobic Property of Shark-Skin-Inspired Micro-Riblets. J. Bionic Eng. 2014, 11, 296–302. [Google Scholar] [CrossRef]

- Najafian, H.; Manteghi, F.; Beshkar, F.; Salavati-Niasari, M. Efficient degradation of azo dye pollutants on ZnBi38O58 nanostructures under visible-light irradiation. Sep. Purif. Technol. 2018, 195, 30–36. [Google Scholar] [CrossRef]

- Sun, X.; Yang, S.; Xue, B.; Huo, K.; Li, X.; Tian, Y.; Liao, X.; Xie, L.; Qin, S.; Xu, K. Super-hydrophobic poly (lactic acid) by controlling the hierarchical structure and polymorphic transformation. Chem. Eng. J. 2020, 397, 125297. [Google Scholar] [CrossRef]

- Wang, X.; He, Y.; Liu, X.; Zhu, J. Synthesis of hierarchical flower-like particles and its application as super-hydrophobic coating. Powder Technol. 2017, 319, 408–414. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, D.; Liu, Z.; Yuan, S.; Wang, X.; Wang, H.; Wang, J. Fabrication of mechanically stable UV-curing superhydrophobic coating by interfacial strengthening strategy. J. Alloys Compd. 2021, 886, 161156. [Google Scholar] [CrossRef]

- Shi, L.; Hu, J.; Lin, X.; Fang, L.; Wu, F.; Xie, J.; Meng, F. A robust superhydrophobic PPS-PTFE/SiO2 composite coating on AZ31 Mg alloy with excellent wear and corrosion resistance properties. J. Alloys Compd. 2017, 721, 157–163. [Google Scholar] [CrossRef]

- Yu, Z.; Zhou, C.; Liu, R.; Zhang, Q.; Gong, J.; Tao, D.; Ji, Z. Fabrication of superhydrophobic surface with enhanced corrosion resistance on H62 brass substrate. Colloids Surf. A Physicochem. Eng. Asp. 2020, 589, 124475. [Google Scholar] [CrossRef]

- Peng, K.; Hu, J.; Yan, Y.; Wu, Y.; Fang, H.; Xu, Y.; Lee, S.; Zhu, J. Fabrication of single-crystalline silicon nanowires by scratching a silicon surface with catalytic metal particles. Adv. Funct. Mater. 2006, 16, 387–394. [Google Scholar] [CrossRef]

- Werner, J.H.; Dassow, R.; Rinke, T.; Köhler, J.; Bergmann, R. From polycrystalline to single crystalline silicon on glass. Thin Solid Film. 2001, 383, 95–100. [Google Scholar] [CrossRef]

- Nositschka, W.; Beneking, C.; Voigt, O.; Kurz, H. Texturisation of multicrystalline silicon wafers for solar cells by reactive ion etching through colloidal masks. Sol. Energy Mater. Sol. Cells 2003, 76, 155–166. [Google Scholar] [CrossRef]

- Macdonald, D.; Cuevas, A.; Kerr, M.J.; Samundsett, C.; Ruby, D.; Winderbaum, S.; Leo, A. Texturing industrial multicrystalline silicon solar cells. Sol. Energy 2004, 76, 277–283. [Google Scholar] [CrossRef]

- Niinobe, D.; Morikawa, H.; Hiza, S.; Sato, T.; Matsuno, S.; Fujioka, H.; Katsura, T.; Okamoto, T.; Hamamoto, S.; Ishihara, T. Large-size multi-crystalline silicon solar cells with honeycomb textured surface and point-contacted rear toward industrial production. Sol. Energy Mater. Sol. Cells 2011, 95, 49–52. [Google Scholar] [CrossRef]

- Chang, Z.; Sun, Y.; Xu, J.; Zong, X.; Tang, Q.; Guo, L.; Ren, L.; Cheng, W.-H. Hydrophobic nanostructures fabricated by ferric nitrate etching method on single crystalline silicon surface. Colloids Surf. A Physicochem. Eng. Asp. 2019, 583, 123999. [Google Scholar] [CrossRef]

- Kamal, S.A.A.; Ritikos, R.; Rahman, S.A. Wetting behaviour of carbon nitride nanostructures grown by plasma enhanced chemical vapour deposition technique. Appl. Surf. Sci. 2015, 328, 146–153. [Google Scholar] [CrossRef]

- Kamal, S.A.A.; Ritikos, R.; Rahman, S.A. Enhancement of self-cleaning properties and durability of super-hydrophobic carbon nitride nanostructures by post-annealing treatment. Surf. Coat. Technol. 2021, 409, 126912. [Google Scholar] [CrossRef]

- Fan, G.; Li, F. Effect of sodium borohydride on growth process of controlled flower-like nanostructured Cu2O/CuO films and their hydrophobic property. Chem. Eng. J. 2011, 167, 388–396. [Google Scholar] [CrossRef]

- Yin, Y.; Alivisatos, A.P. Colloidal nanocrystal synthesis and the organic–inorganic interface. Nature 2005, 437, 664–670. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Lieber, C.M. Lieber, Nanocrystals branch out. Nat. Mater. 2003, 2, 355–356. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L. Self-assembled nanoarchitectures of polar nanobelts/nanowires. J. Mater. Chem. 2005, 15, 1021–1024. [Google Scholar] [CrossRef]

- Burda, C.; Chen, X.; Narayanan, R.; El-Sayed, M.A. Chemistry and properties of nanocrystals of different shapes. Chem. Rev. 2005, 105, 1025–1102. [Google Scholar] [CrossRef]

- Xia, Y.; Yang, P.; Sun, Y.; Wu, Y.; Mayers, B.; Gates, B.; Yin, Y.; Kim, F.; Yan, H. One-dimensional nanostructures: Synthesis; characterization; applications. Adv. Mater. 2003, 15, 353–389. [Google Scholar] [CrossRef]

- Rhodes, K.H.; Davis, S.A.; Caruso, F.; Zhang, B.; Mann, S. Hierarchical assembly of zeolite nanoparticles into ordered macroporous monoliths using core—Shell building blocks. Chem. Mater. 2000, 12, 2832–2834. [Google Scholar] [CrossRef]

- Kim, F.; Kwan, S.; Akana, J.; Yang, P. Langmuir—Blodgett nanorod assembly. J. Am. Chem. Soc. 2001, 123, 4360–4361. [Google Scholar] [CrossRef]

- Fan, X.; Meng, X.M.; Zhang, X.H.; Shi, W.S.; Zhang, W.J.; Zapien, J.A.; Lee, C.S.; Lee, S.T. Dart-Shaped Tricrystal ZnS Nanoribbons. Angew. Chem. 2006, 118, 2630–2633. [Google Scholar] [CrossRef]

- Tiwari, J.N.; Tiwari, R.N.; Kim, K.S. Zero-dimensional, one-dimensional, two-dimensional and three-dimensional nanostructured materials for advanced electrochemical energy devices. Prog. Mater. Sci. 2012, 57, 724–803. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, M. Synthesis, characterization, and hydrophobic properties of Bi2S3 hierarchical nanostructures. Mater. Res. Bull. 2011, 46, 555–562. [Google Scholar] [CrossRef]

- Park, B.; Hwang, W. A facile fabrication method for corrosion-resistant micro/nanostructures on stainless steel surfaces with tunable wettability. Scr. Mater. 2016, 113, 118–121. [Google Scholar] [CrossRef]

- Ryu, J.; Kim, K.; Park, J.; Hwang, B.G.; Ko, Y.; Kim, H.; Han, J.; Seo, E.; Park, Y.; Lee, S.J. Nearly perfect durable superhydrophobic surfaces fabricated by a simple one-step plasma treatment. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Shen, H.; Qiu, J. Fabrication of biomimetic robust self-cleaning superhydrophobic wood with canna-leaf-like micro/nanostructure through morph-genetic method improved water-, UV-, and corrosion resistance properties. J. Mol. Struct. 2020, 1219, 128616. [Google Scholar] [CrossRef]

- Meng, A.; Tian, W.; Wang, Y.; Zhang, M.; Li, Z.; Li, Q.; Tan, S. Wicker-like SiC@graphene multidimensional nanostructures and their robust stable super-hydrophobic property against harsh conditions for self-cleaning application. Mater. Charact. 2021, 179, 111389. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Z.; Zhang, M.; Meng, A. Super-hydrophobic surfaces of SiO2-coated SiC nanowires: Fabrication, mechanism and ultraviolet-durable super-hydrophobicity. J. Colloid Interface Sci. 2015, 444, 33–37. [Google Scholar] [CrossRef]

- Chen, H.; Zheng, X.; Jiang, Q.; Li, X. Hydrophobic Modified Nanosized Crosslinked Polymer Microspheres. Asian J. Chem. 2014, 26, 5412–5414. [Google Scholar] [CrossRef]

- Haas, K.-H.; Rose, K. Hybrid inorganic/organic polymers with nanoscale building blocks: Precursors, processing, properties and applications. Rev. Adv. Mater. Sci. 2003, 5, 47–52. [Google Scholar]

- Ponnupandian, S.; Chakrabarty, A.; Mondal, P.; Hoogenboom, R.; Lowe, A.B.; Singha, N.K. POSS and fluorine containing nanostructured block copolymer; Synthesis via RAFT polymerization and its application as hydrophobic coating material. Eur. Polym. J. 2020, 131, 109679. [Google Scholar] [CrossRef]

- Sabbah, A.; Vandeparre, H.; Brau, F.; Damman, P. Self-Cleaning Surfaces Prepared By Microstructuring System. Phys. Procedia 2011, 21, 193–197. [Google Scholar] [CrossRef][Green Version]

- Leese, H.; Bhurtun, V.; Lee, K.P.; Mattia, D. Wetting behaviour of hydrophilic and hydrophobic nanostructured porous anodic alumina. Colloids Surf. A Physicochem. Eng. Asp. 2013, 420, 53–58. [Google Scholar] [CrossRef]

- He, R.; Liu, S.; Wang, R.; Fu, T.; Zhang, R.; Zhang, Q.; Zhou, Y. In situ modification of melamine sponge by MgAl-LDH with super-hydrophobicity and excellent harsh environment tolerance for high flux emulsion separation. Sep. Purif. Technol. 2022, 291, 120916. [Google Scholar] [CrossRef]

- Zhao, J.; Deng, Y.; Dai, M.; Wu, Y.; Ali, I.; Peng, C. Preparation of super-hydrophobic/super-oleophilic quartz sand filter for the application in oil-water separation. J. Water Process Eng. 2022, 46, 102561. [Google Scholar] [CrossRef]

- Lv, C.; Liao, X.; Zou, F.; Tang, W.; Xing, S.; Li, G. Generating porous polymer microspheres with cellular surface via a gas-diffusion confined scCO2 foaming technology to endow the super-hydrophobic coating with hierarchical roughness. Chem. Eng. J. 2022, 442, 136192. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; You, J.; Yu, P.; Li, X.; Xue, G.; Chen, H.; Xu, X.; van Agtmaal, S.; Alvarez, P.J.J. Hazardous waste dewatering and dry mass reduction through hydrophobic modification by a facile one-pot, alkali-assisted hydrothermal reaction. Water Res. 2019, 155, 225–232. [Google Scholar] [CrossRef]

- Wang, G.; Song, D.; Qiao, Y.; Cheng, J.; Liu, H.; Jiang, J.; Ma, A.; Ma, X. Developing super-hydrophobic and corrosion-resistant coating on magnesium-lithium alloy via one-step hydrothermal processing. J. Magnes. Alloys 2021, 11, 1422–1439. [Google Scholar] [CrossRef]

- Wang, G.; Jiang, J.; Qiao, Y.; Gu, L.; Klu, E.E.; Gong, X.; Ma, A.; Song, D. Enhanced super-hydrophobicity and corrosion resistance of the one-step hydrothermal synthesized coating on the Mg-9Li alloy: Role of the solid-solution treated substrate. J. Alloys Compd. 2022, 921, 166044. [Google Scholar] [CrossRef]

- Mezzourh, H.; Moumen, S.B.; Amjoud, M.; Mezzane, D.; El Amraoui, Y.; Marbati, B.; Lahmar, A.; Jouiad, M.; El Marssi, M. Effect of growth time on structural and surface properties of TiO2 nanostructures deposited by single-step hydrothermal method. Mater. Today Proc. 2022, 51, 2053–2058. [Google Scholar] [CrossRef]

- Li, M.; Su, Y.; Hu, J.; Yao, L.; Wei, H.; Yang, Z.; Zhang, Y. Hierarchically porous micro/nanostructured copper surfaces with enhanced antireflection and hydrophobicity. Appl. Surf. Sci. 2016, 361, 11–17. [Google Scholar] [CrossRef]

- Barthwal, S.; Lee, B.; Lim, S.-H. Fabrication of robust and durable slippery anti-icing coating on textured superhydrophobic aluminum surfaces with infused silicone oil. Appl. Surf. Sci. 2019, 496, 143677. [Google Scholar] [CrossRef]

- Tan, X.; Zhang, Y.; Liu, X.; Xi, S.; Yan, Z.; Liu, Z.; Shi, T.; Liao, G. Employing micro pyramidal holes and porous nanostructures for enhancing the durability of lubricant-infused surfaces in anti-icing. Surf. Coat. Technol. 2021, 405, 126568. [Google Scholar] [CrossRef]

- Yang, L.; Shen, X.; Yang, Q.; Liu, J.; Wu, W.; Li, D.; Du, J.; Zhang, B.; Fan, S. Fabrication of biomimetic anisotropic super-hydrophobic surface with rice leaf-like structures by femtosecond laser. Opt. Mater. 2021, 112, 110740. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, P.; Zhang, L.; Liu, H.; Jiang, Y.; Zhang, D.; Han, Z.; Jiang, L. Continuous directional water transport on the peristome surface of Nepenthes alata. Nature 2016, 532, 85–89. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, K.; Yao, W.; Liu, J.; Han, Z.; Ren, L. Bioinspired structured superhydrophobic and superoleophilic stainless steel mesh for efficient oil-water separation. Colloids Surf. A Physicochem. Eng. Asp. 2016, 500, 54–63. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Wang, G.; Huo, J.; Kong, H.; Wang, W.; Wang, D.; Song, Z. A facile one-step approach to superhydrophilic silica film with hierarchical structure using fluoroalkylsilane. Colloids Surf. A Physicochem. Eng. Asp. 2018, 539, 109–115. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, W.; Su, B.-L. Superhydrophobic surfaces: From natural to biomimetic to functional. J. Colloid Interface Sci. 2011, 353, 335–355. [Google Scholar] [CrossRef] [PubMed]

- Hancock, M.J.; Sekeroglu, K.; Demirel, M.C. Bioinspired directional surfaces for adhesion, wetting, and transport. Adv. Funct. Mater. 2012, 22, 2223–2234. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; Liang, X.; Cotton, I.; Emersic, C. Suppression of surface charge on micro-and nano-structured superhydrophobic silicone rubber. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1095–1102. [Google Scholar] [CrossRef]

- Wang, G.; Zhou, J.; Wang, M.; Zhang, Y.; Zhang, Y.; He, Q. A superhydrophobic surface with aging resistance, excellent mechanical restorablity and droplet bounce properties. Soft Matter 2020, 16, 5514–5524. [Google Scholar] [CrossRef] [PubMed]

- Ogbonna, V.E.; Popoola, P.I.; Popoola, O.M.; Adeosun, S.O. A comparative study on the failure analysis of field failed high voltage composite insulator core rods and recommendation of composite insulators: A review. Eng. Fail. Anal. 2022, 138, 106369. [Google Scholar] [CrossRef]

- Francis, U.U.; Philip, A.N. Degradation of epoxy reinforced Banana fibers and eggshell particles hybrid composite high-voltage insulators via accelerated UV aging processes. Chem. Data Collect. 2022, 38, 100842. [Google Scholar] [CrossRef]

- Ibrahim, M.E.; Selim, F.; Abd-Elhady, A.M. Partial discharge performance improvement of covered conductor (CC)/high voltage insulator based electrical distribution systems. Electr. Power Syst. Res. 2022, 202, 107601. [Google Scholar] [CrossRef]

- Salem, A.A.; Abd-Rahman, R.; Ishak, M.T.B.; Lau, K.Y.; Abdul-Malek, Z.; Al-ameri, S.; Al-Gailani, S.A.; Ghoneim, S.S. Influence of contamination distribution in characterizing the flashover phenomenon on outdoor insulator. Ain Shams Eng. J. 2023, 14, 102249. [Google Scholar] [CrossRef]

- Li, Y.; Jin, H.; Nie, S.; Zhang, P.; Gao, N. Dynamic behavior of water droplets and flashover characteristics on a superhydrophobic silicone rubber surface. Appl. Phys. Lett. 2017, 110, 201602. [Google Scholar] [CrossRef]

- Lei, S.; Wang, F.; Fang, X.; Ou, J.; Li, W. Icing behavior of water droplets impinging on cold superhydrophobic surface. Surf. Coat. Technol. 2019, 363, 362–368. [Google Scholar] [CrossRef]

- Peng, W.; Gou, X.; Qin, H.; Zhao, M.; Zhao, X.; Guo, Z. Creation of a multifunctional superhydrophobic coating for composite insulators. Chem. Eng. J. 2018, 352, 774–781. [Google Scholar] [CrossRef]

- Peng, W.; Gou, X.; Qin, H.; Zhao, M.; Zhao, X.; Guo, Z. Robust Mg (OH) 2/epoxy resin superhydrophobic coating applied to composite insulators. Appl. Surf. Sci. 2019, 466, 126–132. [Google Scholar] [CrossRef]

- Chen, L.; Guo, F.; Yang, T.; Hu, T.; Bennett, P.; Yang, Q.; Liu, D. Aging characteristics and self-healing properties of laser-textured superhydrophobic silicone rubber for composite insulators. Polym. Degrad. Stab. 2021, 192, 109693. [Google Scholar] [CrossRef]

- Wang, G.; Li, A.; Li, K.; Zhao, Y.; Ma, Y.; He, Q. A fluorine-free superhydrophobic silicone rubber surface has excellent self-cleaning and bouncing properties. J. Colloid Interface Sci. 2021, 588, 175–183. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Wang, G.; Ma, Y.; Zhao, C.; Zhang, F.; He, Q.; Zhang, F. Study on preparation and properties of superhydrophobic surface of RTV silicone rubber. J. Mater. Res. Technol. 2021, 11, 135–143. [Google Scholar] [CrossRef]

- Boinovich, L.; Emelyanenko, A.M.; Pashinin, A.S. Analysis of long-term durability of superhydrophobic properties under continuous contact with water. ACS Appl. Mater. Interfaces 2010, 2, 1754–1758. [Google Scholar] [CrossRef]

- Chen, J.; Dou, R.; Cui, D.; Zhang, Q.; Zhang, Y.; Xu, F.; Zhou, X.; Wang, J.; Song, Y.; Jiang, L. Robust prototypical anti-icing coatings with a self-lubricating liquid water layer between ice and substrate. ACS Appl. Mater. Interfaces 2013, 5, 4026–4030. [Google Scholar] [CrossRef]

- Pike, W. Extreme warm frontal icing on 25 February 1994 causes an aircraft accident near Uttoxeter. Meteorol. Appl. 1995, 2, 273–279. [Google Scholar] [CrossRef]

- Wenxuan, Y.; Yuan, Y.; Guoyong, L.; Bing, Z.; Rongkai, Y. The anti-icing/frosting aluminum surface with hydrangea-like micro/nano structure prepared by chemical etching. Mater. Lett. 2018, 226, 4–7. [Google Scholar] [CrossRef]

- Kraj, A.G.; Bibeau, E.L. Phases of icing on wind turbine blades characterized by ice accumulation. Renew. Energy 2010, 35, 966–972. [Google Scholar] [CrossRef]

- Momen, G.; Jafari, R.; Farzaneh, M. Ice repellency behaviour of superhydrophobic surfaces: Effects of atmospheric icing conditions and surface roughness. Appl. Surf. Sci. 2015, 349, 211–218. [Google Scholar] [CrossRef]

- Kong, L.; Li, Y.; Kong, X.; Ji, Z.; Wang, X.; Zhang, X. A novel flexible and fluoride-free superhydrophobic thermal energy storage coating for photothermal energy conversion. Compos. Part B Eng. 2022, 232, 109588. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Yang, J.; Yue, Y.; Zhang, H. Fabrication of superhydrophobic surface on stainless steel by two-step chemical etching. Chem. Phys. Lett. 2022, 797, 139567. [Google Scholar] [CrossRef]

- Zhu, P.; Zhu, L.; Ge, F.; Wang, G.; Zeng, Z. Sprayable superhydrophobic coating with high mechanical/chemical robustness and anti-corrosion. Surf. Coat. Technol. 2022, 443, 128609. [Google Scholar] [CrossRef]

- Hellstén, P.P.; Salminen, J.M.; Jørgensen, K.S.; Nystén, T.H. Use of potassium formate in road winter deicing can reduce groundwater deterioration. Environ. Sci. Technol. 2005, 39, 5095–5100. [Google Scholar] [CrossRef] [PubMed]

- Yin, X.; Yang, K.; Zhang, H.; Xiong, B.; Duan, M.; Wang, M.; Hao, Y. Important Explorations on Surface Corrosion of the Copper Coins Sourced from the Qing Dynasty. Scanning 2022, 2022, 1647217. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Shen, Y.; Tao, J.; Luo, X.; Jin, M.; Xie, Y.; Li, Z.; Guo, S. Facilely constructing micro-nanostructure superhydrophobic aluminum surface with robust ice-phobicity and corrosion resistance. Surf. Coat. Technol. 2017, 329, 224–231. [Google Scholar] [CrossRef]

- Zhou, H.; Jing, X.; Guo, Z. Excellent fog droplets collector via an extremely stable hybrid hydrophobic-hydrophilic surface and Janus copper foam integrative system with hierarchical micro/nanostructures. J. Colloid Interface Sci. 2020, 561, 730–740. [Google Scholar] [CrossRef]

- Shen, Y.; Wu, Y.; Tao, J.; Zhu, C.; Chen, H.; Wu, Z.; Xie, Y. Spraying fabrication of durable and transparent coatings for anti-icing application: Dynamic water repellency, icing delay, and ice adhesion. ACS Appl. Mater. Interfaces 2018, 11, 3590–3598. [Google Scholar] [CrossRef]

- Xiong, J.; Sarkar, D.K.; Chen, X.-G. Superhydrophobic honeycomb-like cobalt stearate thin films on aluminum with excellent anti-corrosion properties. Appl. Surf. Sci. 2017, 407, 361–370. [Google Scholar] [CrossRef]

- Ishizaki, T.; Saito, N. Rapid formation of a superhydrophobic surface on a magnesium alloy coated with a cerium oxide film by a simple immersion process at room temperature and its chemical stability. Langmuir 2010, 26, 9749–9755. [Google Scholar] [CrossRef] [PubMed]

- Ishizaki, T.; Masuda, Y.; Sakamoto, M. Corrosion resistance and durability of superhydrophobic surface formed on magnesium alloy coated with nanostructured cerium oxide film and fluoroalkylsilane molecules in corrosive NaCl aqueous solution. Langmuir 2011, 27, 4780–4788. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Zhang, D.; Qiu, R.; Hou, B. Super-hydrophobic film prepared on zinc as corrosion barrier. Corros. Sci. 2011, 53, 2080–2086. [Google Scholar] [CrossRef]

- Liu, T.; Yin, Y.; Chen, S.; Chang, X.; Cheng, S. Super-hydrophobic surfaces improve corrosion resistance of copper in seawater. Electrochim. Acta 2007, 52, 3709–3713. [Google Scholar] [CrossRef]

- Ishizaki, T.; Sakamoto, M. Facile formation of biomimetic color-tuned superhydrophobic magnesium alloy with corrosion resistance. Langmuir 2011, 27, 2375–2381. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, D.; Liu, Q.; Yin, X.; Zhang, Y.; Jing, X.; Zhang, M. Fabrication of hydrophobic surface with hierarchical structure on Mg alloy and its corrosion resistance. Electrochim. Acta 2010, 55, 6897–6906. [Google Scholar] [CrossRef]

- Liang, J.; Hu, Y.; Wu, Y.; Chen, H. Facile formation of superhydrophobic silica-based surface on aluminum substrate with tetraethylorthosilicate and vinyltriethoxysilane as co-precursor and its corrosion resistant performance in corrosive NaCl aqueous solution. Surf. Coat. Technol. 2014, 240, 145–153. [Google Scholar] [CrossRef]

- Zheng, S.; Li, C.; Fu, Q.; Xiang, T.; Hu, W.; Wang, J.; Ding, S.; Liu, P.; Chen, Z. Fabrication of a micro-nanostructured superhydrophobic aluminum surface with excellent corrosion resistance and anti-icing performance. Rsc Adv. 2016, 6, 79389–79400. [Google Scholar] [CrossRef]

- Seckler, D.W. World Water Demand and Supply, 1990 to 2025: Scenarios and Issues; International Water Management Institute (IWMI): Colombo, Sri Lanka, 1998; Volume 19. [Google Scholar]

- Seckler, D.; Barker, R.; Amarasinghe, U. Water scarcity in the twenty-first century. Int. J. Water Resour. Dev. 1999, 15, 29–42. [Google Scholar] [CrossRef]

- Chakraborti, R.K.; Kaur, J.; Kaur, H. Water shortage challenges and a way forward in India. J. -Am. Water Work. Assoc. 2019, 111, 42–49. [Google Scholar] [CrossRef]

- Zheng, Y.; Bai, H.; Huang, Z.; Tian, X.; Nie, F.-Q.; Zhao, Y.; Zhai, J.; Jiang, L. Directional water collection on wetted spider silk. Nature 2010, 463, 640–643. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.-L.; Song, Y.-Y.; Zhang, X.; Zhang, Z.-Q.; Cheng, G.-G.; Liu, Y.; Lv, G.-J.; Ding, J.-N. Research progress of bionic fog collection surfaces based on special structures from natural organisms. RSC Adv. 2023, 13, 27839–27864. [Google Scholar] [CrossRef] [PubMed]

- Song, D.; Bhushan, B. Optimization of bioinspired triangular patterns for water condensation and transport. Philos. Trans. R. Soc. A 2019, 377, 20190127. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; He, Y.; Yang, S.; Ben, S.; Cao, M.; Li, K.; Liu, K.; Jiang, L. Magnetically induced fog harvesting via flexible conical arrays. Adv. Funct. Mater. 2015, 25, 5967–5971. [Google Scholar] [CrossRef]

- Song, K.; Kim, G.; Oh, S.; Lim, H. Enhanced water collection through a periodic array of tiny holes in dropwise condensation. Appl. Phys. Lett. 2018, 112, 71602. [Google Scholar] [CrossRef]

- Zhong, L.; Zhu, H.; Wu, Y.; Guo, Z. Understanding how surface chemistry and topography enhance fog harvesting based on the superwetting surface with patterned hemispherical bulges. J. Colloid Interface Sci. 2018, 525, 234–242. [Google Scholar] [CrossRef] [PubMed]

- Andrews, H.; Eccles, E.; Schofield, W.; Badyal, J. Three-dimensional hierarchical structures for fog harvesting. Langmuir 2011, 27, 3798–3802. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Yu, L.; Zhang, Z.; Wu, S.; Li, G.; Wu, P.; Hu, Y.; Li, J.; Chu, J.; Wu, D. Biomimetic surfaces with anisotropic sliding wetting by energy-modulation femtosecond laser irradiation for enhanced water collection. RSC Adv. 2017, 7, 11170–11179. [Google Scholar] [CrossRef]

- Lu, Y. Superior lubrication properties of biomimetic surfaces with hierarchical structure. Tribol. Int. 2018, 119, 131–142. [Google Scholar] [CrossRef]

- Zhao, Y.; Su, Y.; Hou, X.; Hong, M. Directional sliding of water: Biomimetic snake scale surfaces. Opto-Electron. Adv. 2021, 4, 21000801–21000812. [Google Scholar] [CrossRef]

- Stratakis, E.; Bonse, J.; Heitz, J.; Siegel, J.; Tsibidis, G.D.; Skoulas, E.; Papadopoulos, A.; Mimidis, A.; Joel, A.C.; Comanns, P.; et al. Laser engineering of biomimetic surfaces. Mater. Sci. Eng. R Rep. 2020, 141, 100562. [Google Scholar] [CrossRef]

- Niu, Z.; Zhao, Y.; Sun, W.; Shi, S.; Gong, Y. Biomimetic surface modification of polypropylene by surface chain transfer reaction based on mussel-inspired adhesion technology and thiol chemistry. Appl. Surf. Sci. 2016, 386, 41–50. [Google Scholar] [CrossRef]

- He, B.; Du, Y.; Wang, B.; Wang, X.; Ye, Q.; Liu, S. Grafting embedded poly(ionic liquid) brushes on biomimetic sharklet resin surface for anti-biofouling applications. Prog. Org. Coat. 2021, 157, 106298. [Google Scholar] [CrossRef]

- Zhao, S.; Du, H.; Ma, Z.; Xiao, G.; Liu, J.; Jiang, Y.; Hu, S.; Zhao, H.; Wen, C.; Ren, L. Efficient fabrication of ternary coupling biomimetic superhydrophobic surfaces with superior performance of anti-wetting and self-cleaning by a simple two-step method. Mater. Des. 2022, 223, 111145. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Y.; Jiang, H.; Zhang, Y.; Han, Z.; Ren, L. Biomimetic super hydrophobic structured graphene on stainless steel surface by laser processing and transfer technology. Surf. Coat. Technol. 2017, 328, 152–160. [Google Scholar] [CrossRef]

- Hwang, J.-J.; Wu, C.-Y.; Hung, Y.-H.; Li, M.-X.; Luo, K.-H.; Jia, H.-W.; Balitaan, J.N.I.; Lin, S.-R.; Yeh, J.-M. Biomimetic PMMA coating surface and its application on inhibition of bacterial attachment and anti-biofilm performance. Surf. Interfaces 2023, 36, 102548. [Google Scholar] [CrossRef]

- Zhang, H.; Gan, J.; Wu, Y.; Wu, Z. Biomimetic high water adhesion superhydrophobic surface via UV nanoimprint lithography. Appl. Surf. Sci. 2023, 633, 157610. [Google Scholar] [CrossRef]

- Wang, Z.; Han, L.; Zhou, Y.; Cai, J.; Sun, S.; Ma, J.; Wang, W.; Li, X.; Ma, L. The combination of a 3D-Printed porous Ti–6Al–4V alloy scaffold and stem cell sheet technology for the construction of biomimetic engineered bone at an ectopic site. Mater. Today Bio 2022, 16, 100433. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Deng, J.; Yue, H.; Ge, D.; Zou, X. Wear performance of electrohydrodynamically atomized WS2 coatings deposited on biomimetic shark-skin textured surfaces. Tribol. Int. 2019, 134, 240–251. [Google Scholar] [CrossRef]

- Deng, W.; Liu, Y.; Rui, Y.; Lu, G.; Liu, J. Construction of superhydrophobic surfaces via dual-scale modified particles and digital light processing 3D printing techniques. Prog. Org. Coat. 2023, 181, 107570. [Google Scholar] [CrossRef]

- Li, G.; Tan, L.; Ren, L.; Zheng, A.; Li, Y.; He, Z.; Wang, K.; Han, Z.; Liu, Q.; Wu, W.; et al. Biomimetic 4D printing of dome-shaped dynamic mechanical metamaterials. J. Mater. Res. Technol. 2023, 24, 4047–4059. [Google Scholar] [CrossRef]

- Pugliese, R.; Graziosi, S. Biomimetic scaffolds using triply periodic minimal surface-based porous structures for biomedical applications. SLAS Technol. 2023, 28, 165–182. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Zhang, X.; Dai, J.; Yu, D.; Ji, M.; Chen, M. Biomimetic microtextured surfaces to improve tribological and antibacterial behaviors of 3Y-TZP ceramics. J. Mater. Res. Technol. 2023, 23, 1360–1374. [Google Scholar] [CrossRef]

- Ismail, M.F.; Azmi, W.H.; Mamat, R.; Ali, H.M. Thermal and Tribological Properties Enhancement of PVE Lubricant Modified with SiO2 and TiO2 Nanoparticles Additive. Nanomaterials 2023, 13, 42. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.; Gu, Y.; Chang, J.; Wang, C. Recent Patents on Friction and Wear Tester. Recent Pat. Eng. 2023, 17, 86–102. [Google Scholar] [CrossRef]

- Afonso, I.S.; Nobrega, G.; Lima, R.; Gomes, J.R.; Ribeiro, J.E. Conventional and Recent Advances of Vegetable Oils as Metalworking Fluids (MWFs): A Review. Lubricants 2023, 11, 160. [Google Scholar] [CrossRef]

- Xu, X.; Guo, P.; Tiong, L.C.O.; Zuo, X.; Li, X.; Lee, K.-R.; Cui, P.; Ke, P.; Wang, A. Role of dimple textured surface on tribological properties of Ti/Al-codoped diamond-like carbon films. Thin Solid Film. 2020, 708, 138136. [Google Scholar] [CrossRef]

- Tong, J.; Liu, S.; Peng, R.; Sun, H.; Jiang, S. Development of a micro/nano composite super-hydrophobic silicon surface with nail-shaped texture/dual self-assembly monolayers and its wetting behavior. Appl. Surf. Sci. 2021, 544, 148803. [Google Scholar] [CrossRef]

- Hamilton, D.B.; Walowit, J.A.; Allen, C.M. A Theory of Lubrication by Microirregularities. J. Basic Eng. 1966, 88, 177–185. [Google Scholar] [CrossRef]

- Gyawali, G.; Joshi, B.; Tripathi, K.; Kim, S.-H.; Lee, S.W. Effect of microtexturing on tribological performance of Ni/Ni–SiC composite coatings. Surf. Eng. 2015, 31, 701–707. [Google Scholar] [CrossRef]

- Vlădescu, S.-C.; Medina, S.; Olver, A.V.; Pegg, I.G.; Reddyhoff, T. The transient friction response of a laser-textured, reciprocating contact to the entrainment of individual pockets. Tribol. Lett. 2016, 62, 19. [Google Scholar] [CrossRef]

- Xu, D.; Wu, W.; Malhotra, R.; Chen, J.; Lu, B.; Cao, J. Mechanism investigation for the influence of tool rotation and laser surface texturing (LST) on formability in single point incremental forming. Int. J. Mach. Tools Manuf. 2013, 73, 37–46. [Google Scholar] [CrossRef]

- Nakano, M.; Korenaga, A.; Korenaga, A.; Miyake, K.; Murakami, T.; Ando, Y.; Usami, H.; Sasaki, S. Applying micro-texture to cast iron surfaces to reduce the friction coefficient under lubricated conditions. Tribol. Lett. 2007, 28, 131–137. [Google Scholar] [CrossRef]

- Maldonado-Cortés, D.; Peña-Parás, L.; Barrios-Saldaña, V.; Cruz-Bañuelos, J.S.; Adamiak, M. Synergistic effect on the tribological properties of tool steel through the use of laser surface texturing channels and nanoparticles. Wear 2019, 426–427, 1354–1361. [Google Scholar] [CrossRef]

- Fleming, R.A.; Zou, M. The effects of confined core volume on the mechanical behavior of Al/a-Si core-shell nanostructures. Acta Mater. 2017, 128, 149–159. [Google Scholar] [CrossRef]

- Steck, J.G.; Afshar-Mohajer, M.; Sun, Q.; Meng, X.; Zou, M. Fabrication and tribological characterization of deformation-resistant nano-textured surfaces produced by two-photon lithography and atomic layer deposition. Tribol. Int. 2019, 132, 75–84. [Google Scholar] [CrossRef]

- Qian, M.; Xu, X.; Qin, Z.; Yan, S. Silicon carbide whiskers enhance mechanical and anti-wear properties of PA6 towards potential applications in aerospace and automobile fields. Compos. Part B Eng. 2019, 175, 107096. [Google Scholar] [CrossRef]

- Suarez, S.; Rosenkranz, A.; Gachot, C.; Mücklich, F. Enhanced tribological properties of MWCNT/Ni bulk composites–Influence of processing on friction and wear behaviour. Carbon 2014, 66, 164–171. [Google Scholar] [CrossRef]

- Reinert, L.; Suárez, S.; Rosenkranz, A. Tribo-mechanisms of carbon nanotubes: Friction and wear behavior of CNT-reinforced nickel matrix composites and CNT-coated bulk nickel. Lubricants 2016, 4, 11. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.; Pan, Z. Wear resistance enhancement of electroless nanocomposite coatings via incorporation of alumina nanoparticles prepared by milling. Mater. Des. 2013, 47, 443–448. [Google Scholar] [CrossRef]

- Gu, D.; Zhang, H.; Dai, D.; Xia, M.; Hong, C.; Poprawe, R. Laser additive manufacturing of nano-TiC reinforced Ni-based nanocomposites with tailored microstructure and performance. Compos. Part B Eng. 2019, 163, 585–597. [Google Scholar] [CrossRef]

- Alizadeh, M.; Safaei, H. Characterization of Ni-Cu matrix, Al2O3 reinforced nano-composite coatings prepared by electrodeposition. Appl. Surf. Sci. 2018, 456, 195–203. [Google Scholar] [CrossRef]

- Yang, K.; Shi, X.; Zou, J.; Shen, Q.; Zhai, W.; Huang, Y. The study of the preparation and tribological behavior of TiAl matrix composites containing 1 wt% multi-walled carbon nanotubes. RSC Adv. 2016, 6, 29334–29341. [Google Scholar] [CrossRef]

- Deore, H.A.; Mishra, J.; Rao, A.G.; Mehtani, H.; Hiwarkar, V.D. Effect of filler material and post process ageing treatment on microstructure, mechanical properties and wear behaviour of friction stir processed AA 7075 surface composites. Surf. Coat. Technol. 2019, 374, 52–64. [Google Scholar] [CrossRef]

- Huang, S.J.; Abbas, A.; Ballóková, B. Effect of CNT on microstructure, dry sliding wear and compressive mechanical properties of AZ61 magnesium alloy. J. Mater. Res. Technol. 2019, 8, 4273–4286. [Google Scholar] [CrossRef]

- Chen, W.X.; Li, F.; Han, G.; Xia, J.B.; Wang, L.Y.; Tu, J.P.; Xu, Z.D. Tribological behavior of carbon-nanotube-filled PTFE composites. Tribol. Lett. 2003, 15, 275–278. [Google Scholar] [CrossRef]

- Wu, H.; Zhu, L.N.; Yue, W.; Fu, Z.Q.; Kang, J.J. Wear-resistant and hydrophobic characteristics of PTFE/CF composite coatings. Prog. Org. Coat. 2019, 128, 90–98. [Google Scholar] [CrossRef]

- Shi, Y.J.; Feng, X.; Wang, H.Y.; Lu, X.H. The effect of surface modification on the friction and wear behavior of carbon nanofiber-filled PTFE composites. Wear 2008, 264, 934–939. [Google Scholar] [CrossRef]

- Baghdadchi, A.; Movahedi, M. Consumable pin-friction stir spot welding of Al-Mg-Si alloy via pre-created hole and refilling: Microstructure evolution, defects, and shear/tensile failure load. Proceedings of the Institution of Mechanical Engineers. Part C J. Mech. Eng. Sci. 2023, 237, 3861–3870. [Google Scholar] [CrossRef]

- Dawari, C.K.; Haq, I.; Mönkkönen, K.; Suvanto, M.; Saarinen, J.J. Reduced sliding friction on flat and microstructured metal injection molded (MIM) WC-Co hard metals with MoS2 composite lubricants. Tribol. Int. 2021, 160, 107020. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Shen, Q. Enhancing tribological performance by anodizing micro-textured surfaces with nano-MoS2 coatings prepared on aluminum-silicon alloys. Tribol. Int. 2018, 122, 84–95. [Google Scholar] [CrossRef]

- Li, X.; Deng, J.; Zhang, L.; Liu, Y.; Yue, H.; Duan, R.; Ge, D. Effect of surface textures and electrohydrodynamically atomized WS2 films on the friction and wear properties of ZrO2 coatings. Ceram. Int. 2019, 45, 1020–1030. [Google Scholar] [CrossRef]

- Shi, Z.; Shum, P.; Wasy, A.; Zhou, Z.; Li, L.K.-Y. Tribological performance of few layer graphene on textured M2 steel surfaces. Surf. Coat. Technol. 2016, 296, 164–170. [Google Scholar] [CrossRef]

- Xing, Y.; Wu, Z.; Yang, J.; Wang, X.; Liu, L. LIPSS combined with ALD MoS2 nano-coatings for enhancing surface friction and hydrophobic performances. Surf. Coat. Technol. 2020, 385, 125396. [Google Scholar] [CrossRef]

- Lu, G.; Shi, X.; Liu, X.; Zhou, H.; Chen, Y.; Yang, Z.; Huang, Y. Tribological performance of functionally gradient structure of graphene nanoplatelets reinforced Ni3Al metal matrix composites prepared by laser melting deposition. Wear 2019, 428–429, 417–429. [Google Scholar] [CrossRef]

- Liu, Q.-S.; Liu, X.-B.; Wang, G.; Liu, Y.-F.; Meng, Y.; Zhang, S.-H. Effect of Cu content on microstructure evolution and tribological behaviors of Ni60 composite coatings on 45# steel by laser cladding. Opt. Laser Technol. 2022, 156, 108549. [Google Scholar]

- Wu, H.Y.; Gu, Z.B.; Lei, Y.; Li, Q.F.; Gong, C.J.; Shao, S.F.; Rao, W.F. Effects of Pt cylinder arrays on macro-tribological properties of graphene and the SiO2/Si substrate. Wear 2015, 332–333, 1314–1321. [Google Scholar] [CrossRef]

- Chen, S.; Qian, G.; Yang, L. Precise control of surface texture on carbon film by ion etching through filter: Optimization of texture size for improving tribological behavior. Surf. Coat. Technol. 2019, 362, 105–112. [Google Scholar] [CrossRef]

- Ovchinnikov, S.; Kalashnikov, M. Structure and tribological properties of gradient-layered coatings (Ti, Al, Si, Cr, Mo, S) O, N. Surf. Coat. Technol. 2021, 408, 126807. [Google Scholar] [CrossRef]

- Wu, G.; Xu, C.; Xiao, G.; Yi, M.; Chen, Z. Structure design of Al2O3/TiC/CaF2 multicomponent gradient self-lubricating ceramic composite and its tribological behaviors. Ceram. Int. 2018, 44, 5550–5563. [Google Scholar] [CrossRef]

- Naebe, M.; Shirvanimoghaddam, K. Functionally graded materials: A review of fabrication and properties. Appl. Mater. Today 2016, 5, 223–245. [Google Scholar] [CrossRef]

- Carroll, B.E.; Otis, R.A.; Borgonia, J.P.; Suh, J.-O.; Dillon, R.P.; Shapiro, A.A.; Hofmann, D.C.; Liu, Z.-K.; Beese, A.M. Functionally graded material of 304L stainless steel and inconel 625 fabricated by directed energy deposition: Characterization and thermodynamic modeling. Acta Mater. 2016, 108, 46–54. [Google Scholar] [CrossRef]

- Fakhrabadi, E.A.; Stickel, J.J.; Liberatore, M.W. Frictional contacts between individual woody biomass particles under wet and dry conditions. Powder Technol. 2022, 408, 117719. [Google Scholar] [CrossRef]

- Tikanmäki, M.; Sainio, P. Experiments on friction of dry and wet ice. Cold Reg. Sci. Technol. 2020, 172, 102990. [Google Scholar] [CrossRef]

- Hamilton, D.; Walowit, J.; Allen, C. A Theory of Lubrication by Micro-irregularities. In Proceedings of the ASME-ASLE Lubrication Conference; 1966. [Google Scholar]

- Sreejith, P.; Ngoi, B. Dry machining: Machining of the future. J. Mater. Process. Technol. 2000, 101, 287–291. [Google Scholar] [CrossRef]

- Costa, H.; Hutchings, I. Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol. Int. 2007, 40, 1227–1238. [Google Scholar] [CrossRef]

- Zhou, L.; Kato, K.; Umehara, N.; Miyake, Y. Nanometre scale island-type texture with controllable height and area ratio formed by ion-beam etching on hard-disk head sliders. Nanotechnology 1999, 10, 363. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Wu, B.; Qin, D.; Hu, J.; Liu, Y. Experimental data mining research on factors influencing friction coefficient of wet clutch. J. Tribol. 2021, 143, 121802. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Wang, Y.; Fu, Y. Fabrication of friction-reducing texture surface by selective laser melting of ink-printed (SLM-IP) copper (Cu) nanoparticles(NPs). Appl. Surf. Sci. 2017, 396, 659–664. [Google Scholar] [CrossRef]

- Wang, M.; Wang, X.; Liu, J.; Wei, J.; Shen, Z.; Wang, Y. 3-Dimensional ink printing of friction-reducing surface textures from copper nanoparticles. Surf. Coat. Technol. 2019, 364, 57–62. [Google Scholar] [CrossRef]

- Zhou, L.; Fu, Y.; Yin, T.; Tian, X.; Qi, L. Building the silicon carbide nanowire network on the surface of carbon fibers: Enhanced interfacial adhesion and high-performance wear resistance. Ceram. Int. 2019, 45, 22571–22577. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene–A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Vail, J.R.; Burris, D.L.; Sawyer, W.G. Multifunctionality of single-walled carbon nanotube–polytetrafluoroethylene nanocomposites. Wear 2009, 267, 619–624. [Google Scholar] [CrossRef]

- Kumar, R.M.; Sharma, S.K.; Kumar, B.V.M.; Lahiri, D. Effects of carbon nanotube aspect ratio on strengthening and tribological behavior of ultra high molecular weight polyethylene composite. Compos. Part A Appl. Sci. Manuf. 2015, 76, 62–72. [Google Scholar] [CrossRef]

- Otitoju, T.A.; Okoye, P.U.; Chen, G.; Li, Y.; Okoye, M.O.; Li, S. Advanced ceramic components: Materials; fabrication; applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- Candelario, V.M.; Moreno, R.; Guiberteau, F.; Ortiz, A.L. Enhancing the sliding-wear resistance of SiC nanostructured ceramics by adding carbon nanotubes. J. Eur. Ceram. Soc. 2016, 36, 3083–3089. [Google Scholar] [CrossRef]

- Jung, Y.C.; Bhushan, B. Contact angle; adhesion, and friction properties of micro- and nanopatterned polymers for superhydrophobicity. Nanotechnol. Nanotechnol. 2006, 17, 4970. [Google Scholar] [CrossRef]

- Amiri, M.; Khonsari, M.M. On the thermodynamics of friction and wear—A review. Entropy 2010, 12, 1021–1049. [Google Scholar] [CrossRef]

- Scharf, T.; Prasad, S. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Jin, B.; Zhao, J.; He, Y.; Chen, G.; Li, Y.; Zhang, C.; Luo, J. High-quality ultra-flat reduced graphene oxide nanosheets with super-robust lubrication performances. Chem. Eng. J. 2022, 438, 135620. [Google Scholar] [CrossRef]

- Chhattal, M.; Kaihuan, Y.; Ali, S.; Zambrano, D.F.; Rosenkranz, A.; Grützmacher, P.G.; Gong, Z.; Zhang, J. Solid Lubrication Performance of Ti2CTx Coatings with Reduced Friction and Extended Durability. Tribol. Int. 2024, 194, 109535. [Google Scholar] [CrossRef]

- Erdemir, A.; Ramirez, G.; Eryilmaz, O.L.; Narayanan, B.; Liao, Y.; Kamath, G.; Sankaranarayanan, S.K. Carbon-based tribofilms from lubricating oils. Nature 2016, 536, 67–71. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Xue, Y.; Qiang, L.; Gao, K.; Liu, Q.; Yang, B.; Liang, A.; Zhang, J. Assembling of carbon nanotubes film responding to significant reduction wear and friction on steel surface. Appl. Nanosci. 2017, 7, 835–842. [Google Scholar] [CrossRef]

- Ahmad, H.; Tamil, T. High responsivity, self-powered carbon–zinc oxide hybrid thin film based photodetector. Appl. Nanosci. 2018, 8, 1755–1765. [Google Scholar] [CrossRef]

- Scagliotti, M.; Salvato, M.; De Crescenzi, M.; Boscardin, M.; Castrucci, P. Influence of the contact geometry on single-walled carbon nanotube/Si photodetector response. Appl. Nanosci. 2018, 8, 1053–1058. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Erdemir, A.; Donnet, C. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D Appl. Phys. 2006, 39, R311. [Google Scholar] [CrossRef]

- Charitidis, C. Nanomechanical and nanotribological properties of carbon-based thin films: A review. Int. J. Refract. Met. Hard Mater. 2010, 28, 51–70. [Google Scholar] [CrossRef]

- Bewilogua, K.; Hofmann, D. History of diamond-like carbon films—From first experiments to worldwide applications. Surf. Coat. Technol. 2014, 242, 214–225. [Google Scholar] [CrossRef]

- Argibay, N.; Babuska, T.; Curry, J.; Dugger, M.; Lu, P.; Adams, D.; Nation, B.; Doyle, B.; Pham, M.; Pimentel, A. In-situ tribochemical formation of self-lubricating diamond-like carbon films. Carbon 2018, 138, 61–68. [Google Scholar] [CrossRef]

- Arcieri, E.V.; Baragetti, S. Impact of DLC Coating Deposition on the Fatigue Strength of Al-7075-T6 Aluminum Alloy. J. Mater. Sci. Technol. Res. 2023, 10, 12–18. [Google Scholar] [CrossRef]

- Song, R.; Chen, S.; Liu, Z.; Huo, C.; Chen, Q. Effect of W-doping on the structure and properties of DLC films prepared by combining physical and chemical vapor deposition. Diam. Relat. Mater. 2023, 132, 109687. [Google Scholar] [CrossRef]

- Rawian, N.A.M.; Akasaka, H.; Liza, S.; Fukuda, K.; Zulkifli, N.A.; Tahir, N.A.M.; Yaakob, Y. Surface and tribological characterization of anodic aluminum oxide coating containing diamond-like carbon flakes. Diam. Relat. Mater. 2023, 132, 109674. [Google Scholar] [CrossRef]

- Cao, Z.; Zhao, W.; Liang, A.; Zhang, J. A general engineering applicable superlubricity: Hydrogenated amorphous carbon film containing nano diamond particles. Adv. Mater. Interfaces 2017, 4, 1601224. [Google Scholar] [CrossRef]

- Wang, Z.; Gong, Z.; Zhang, B.; Wang, Y.; Gao, K.; Zhang, J.; Liu, G. Heating induced nanostructure and superlubricity evolution of fullerene-like hydrogenated carbon films. Solid State Sci. 2019, 90, 29–33. [Google Scholar] [CrossRef]

- Gong, Z.; Jia, X.; Ma, W.; Zhang, B.; Zhang, J. Hierarchical structure graphitic-like/MoS2 film as superlubricity material. Appl. Surf. Sci. 2017, 413, 381–386. [Google Scholar] [CrossRef]

- Li, R.; Yang, X.; Hou, D.; Wang, Y.; Zhang, J. Superlubricity of carbon nanostructural films enhanced by graphene nanoscrolls. Mater. Lett. 2020, 271, 127748. [Google Scholar] [CrossRef]

- Martin, J.-M. Superlubricity of molybdenum disulfide. In Superlubricity; Elsevier: Amsterdam, The Netherlands, 2007; pp. 207–225. [Google Scholar]

- Chhowalla, M.; Amaratunga, G.A. Thin films of fullerene-like MoS2 nanoparticles with ultra-low friction and wear. Nature 2000, 407, 164–167. [Google Scholar] [CrossRef]

- Jiang, J.-W.; Park, H.S. Mechanical properties of MoS2/graphene heterostructures. Appl. Phys. Lett. 2014, 105, 33108. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, J.; Grey, F.; Liu, J.Z.; Liu, Y.; Wang, Y.; Yang, Y.; Cheng, Y.; Zheng, Q. Observation of microscale superlubricity in graphite. Phys. Rev. Lett. 2012, 108, 205503. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, J. Superlubricity of carbon nanostructures. Carbon 2020, 158, 1–23. [Google Scholar] [CrossRef]

- Nurmi, H.A.; Yu, C.; Toptunov, D.; Ras, R.H.A.; Jokinen, V. Superhydrophobic Lubrication: Gas–Liquid Bilayer Reduces the Friction Between Two Solids. Adv. Mater. Interfaces 2022, 9, 2102132. [Google Scholar] [CrossRef]

- Urbakh, M.; Klafter, J.; Gourdon, D.; Israelachvili, J. The nonlinear nature of friction. Nature 2004, 430, 525–528. [Google Scholar] [CrossRef] [PubMed]

- Koster, D.A.; Croquette, V.; Dekker, C.; Shuman, S.; Dekker, N.H. Friction and torque govern the relaxation of DNA supercoils by eukaryotic topoisomerase IB. Nature 2005, 434, 671–674. [Google Scholar] [CrossRef] [PubMed]

- Bowden, F.P.; Bowden, F.P.; Tabor, D. The Friction and Lubrication of Solids; Oxford University Press: Oxford, UK, 2001; Volume 1. [Google Scholar]

- Alazemi, A.A.; Dysart, A.D.; Phuah, X.L.; Pol, V.G.; Sadeghi, F. MoS2 nanolayer coated carbon spheres as an oil additive for enhanced tribological performance. Carbon 2016, 110, 367–377. [Google Scholar] [CrossRef]

- Liu, S.; Gao, Q.; Hou, K.; Li, Z.; Wang, J.; Yang, S. Solvent-free covalent MXene nanofluid: A new lubricant combining the characteristics of solid and liquid lubricants. Chem. Eng. J. 2023, 462, 142238. [Google Scholar] [CrossRef]

- Ahmed, A.; Masjuki, H.; Varman, M.; Kalam, M.; Habibullah, M.; Al Mahmud, K. An overview of geometrical parameters of surface texturing for piston/cylinder assembly and mechanical seals. Meccanica 2016, 51, 9–23. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M. Numerical optimization of texture shape for parallel surfaces under unidirectional and bidirectional sliding. Tribol. Int. 2015, 82, 1–11. [Google Scholar] [CrossRef]

- Kligerman, Y.; Etsion, I.; Shinkarenko, A. Improving tribological performance of piston rings by partial surface texturing. J. Trib. 2005, 127, 632–638. [Google Scholar] [CrossRef]

- Borghi, A.; Gualtieri, E.; Marchetto, D.; Moretti, L.; Valeri, S. Tribological effects of surface texturing on nitriding steel for high-performance engine applications. Wear 2008, 265, 1046–1051. [Google Scholar] [CrossRef]

- Pillari, L.K.; Lessoway, K.; Bichler, L. Reciprocating dry sliding friction and wear behavior of B319 aluminum alloy-graphene composites. Tribol. Int. 2024, 192, 109334. [Google Scholar] [CrossRef]

- Guo, W.; Bai, Q.; Deng, K.; Dou, Y.; Wang, T.; Wang, H. Comparison of lubrication mechanism and friction behavior of graphene on stainless steel substrate at different scales. Appl. Surf. Sci. 2024, 649, 159192. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, Y.; Han, F.; Wang, D.; Zhang, S. Multilayer graphene for reducing friction and wear in water-based sand cleaning liquid. Wear 2021, 470, 203619. [Google Scholar] [CrossRef]

- Flamina, A.; Raghavendra, R.; Gupta, A.; Subramaniam, A. Hydrogen storage in Nickel dispersed boron doped reduced graphene oxide. Appl. Surf. Sci. Adv. 2023, 13, 100371. [Google Scholar] [CrossRef]

- Siochi, E.J.; Harrison, J.S. Structural nanocomposites for aerospace applications. MRS Bull. 2015, 40, 829–835. [Google Scholar] [CrossRef]

- Dumitrica, T.; Hua, M.; Yakobson, B.I. Symmetry-, time-, and temperature-dependent strength of carbon nanotubes. Proc. Natl. Acad. Sci. USA 2006, 103, 6105–6109. [Google Scholar] [CrossRef] [PubMed]

- Jin, L.; Bower, C.; Zhou, O. Alignment of carbon nanotubes in a polymer matrix by mechanical stretching. Appl. Phys. Lett. 1998, 73, 1197–1199. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Li, J.; Luo, J. Investigation of superlubricity achieved by polyalkylene glycol aqueous solutions. Adv. Mater. Interfaces 2016, 3, 1600531. [Google Scholar] [CrossRef]