A CFD Study of Particulate Deposition on Dimple-Type Flue Walls of Coal-Fired Power Plants

Abstract

1. Introduction

2. Materials and Methods

2.1. Continuous Phase

2.2. Discrete Phase Model

2.3. Stochastic Turbulent Model

2.4. Particle Deposition Efficiency

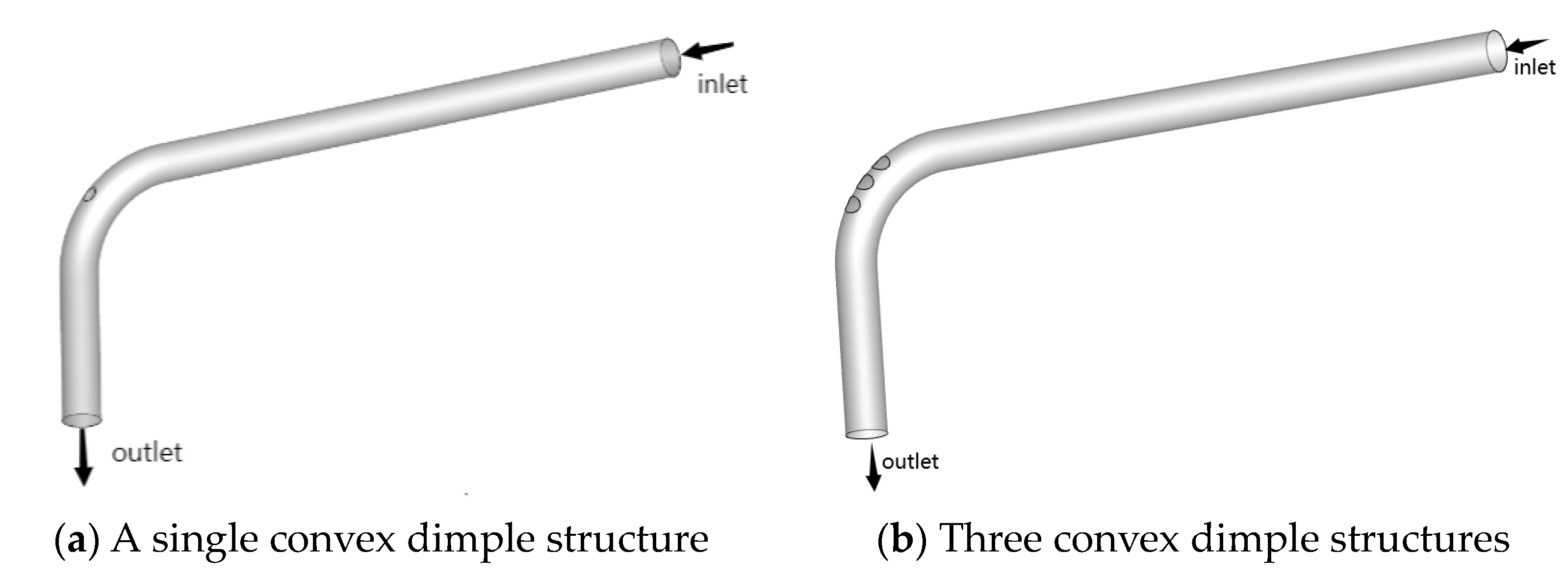

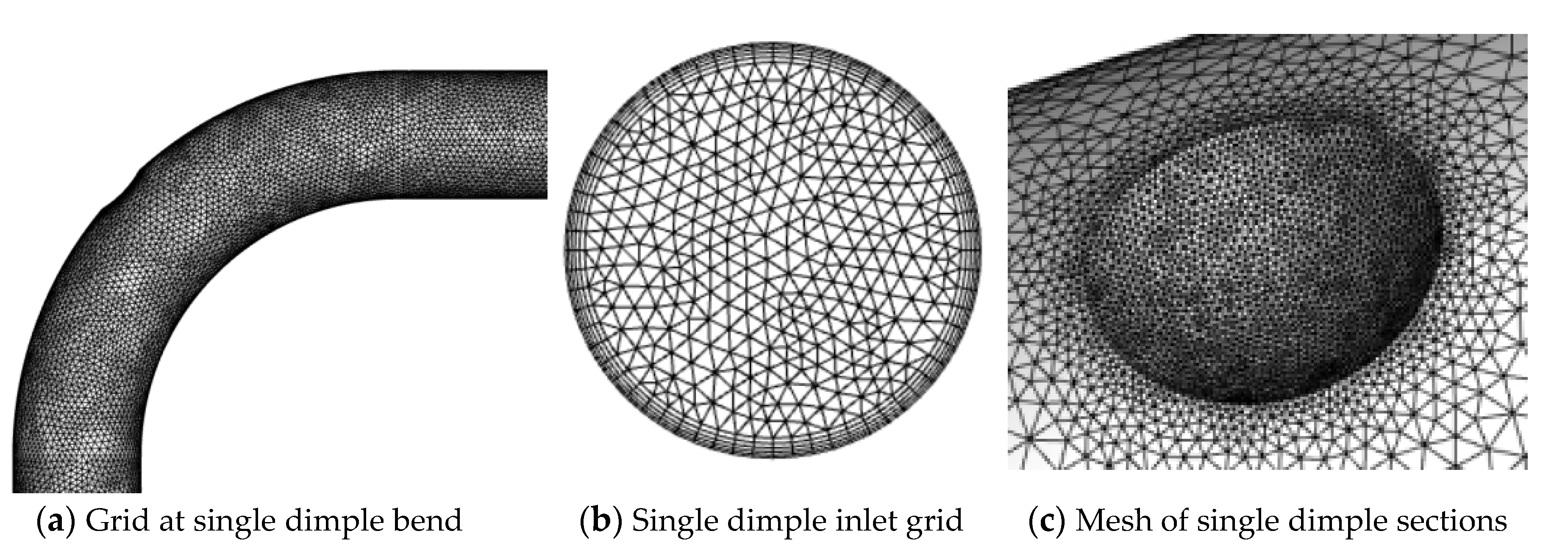

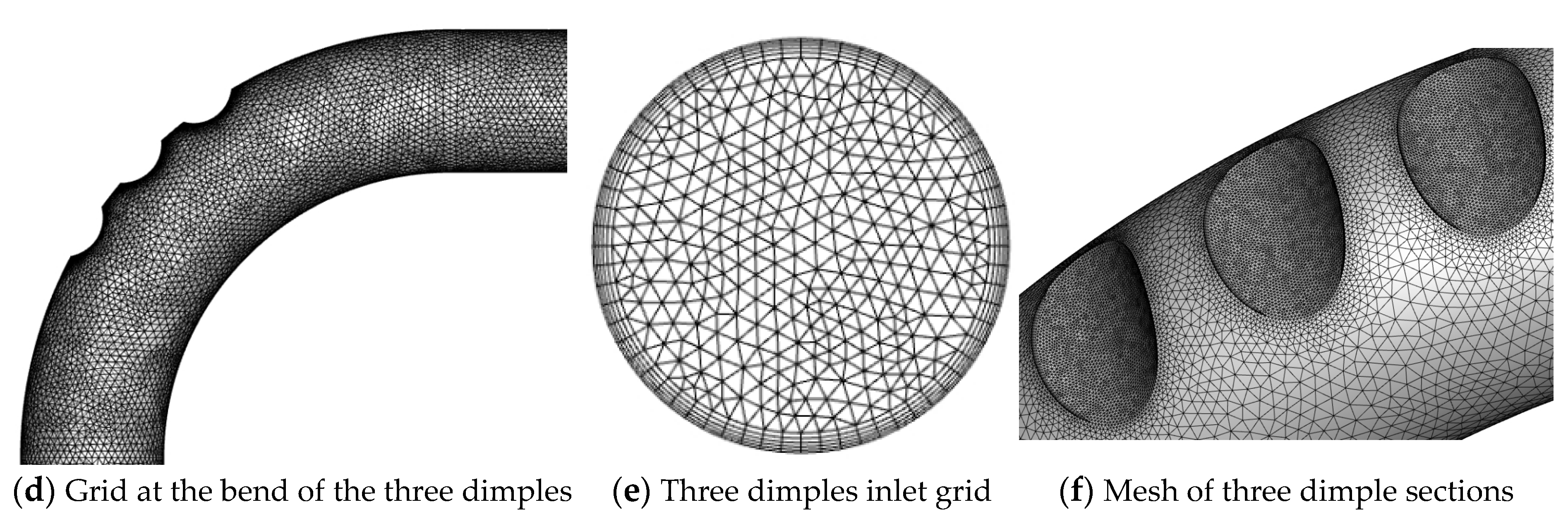

3. Case Description

4. Results

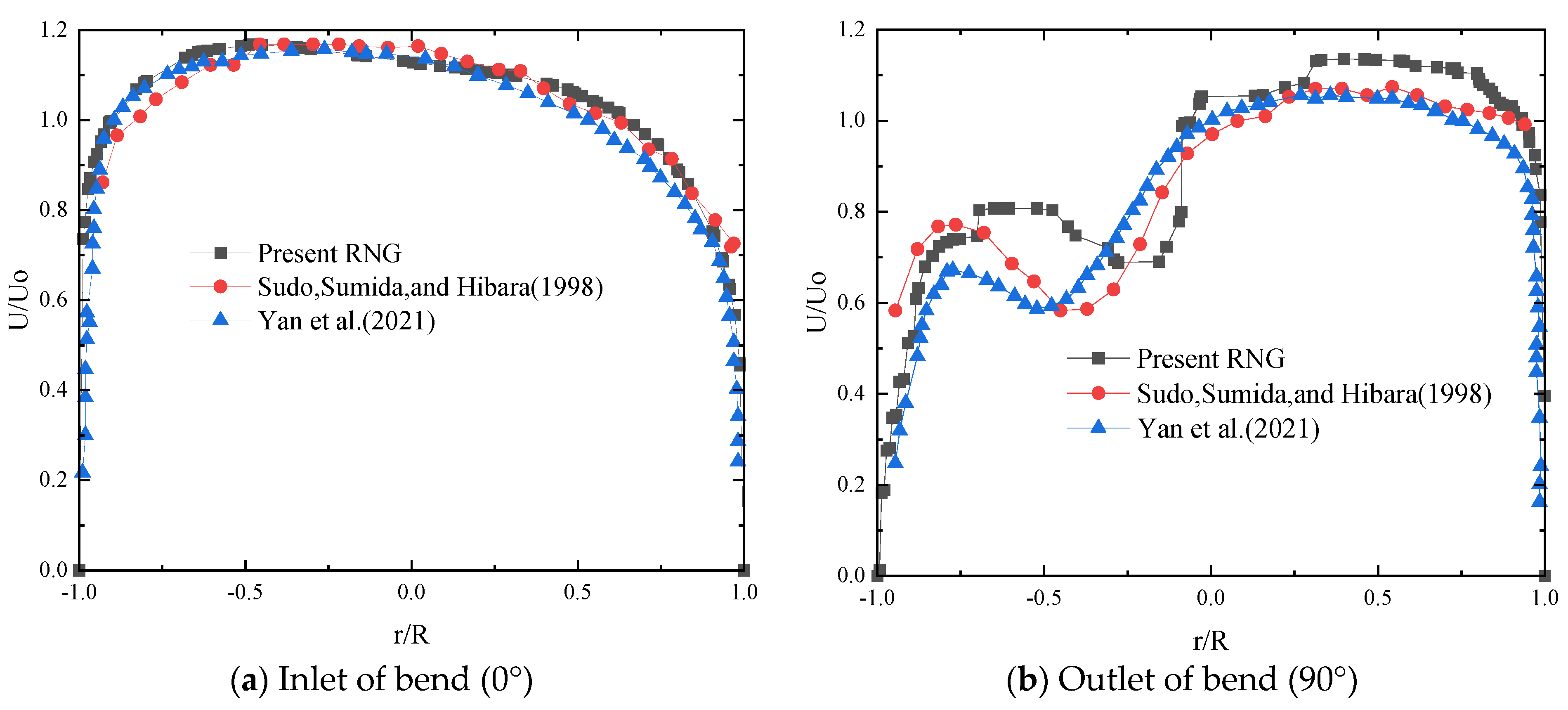

4.1. Numerical Validation

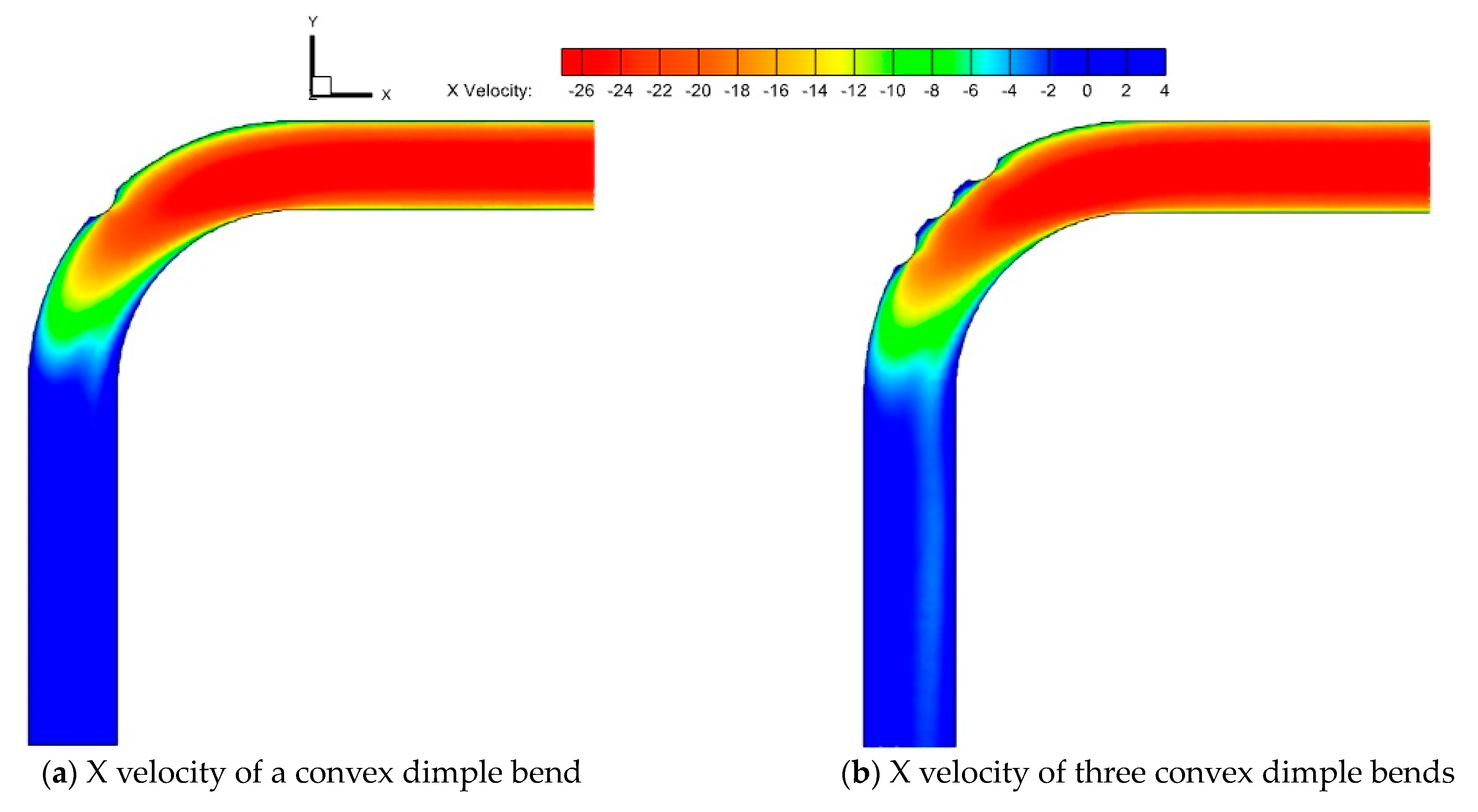

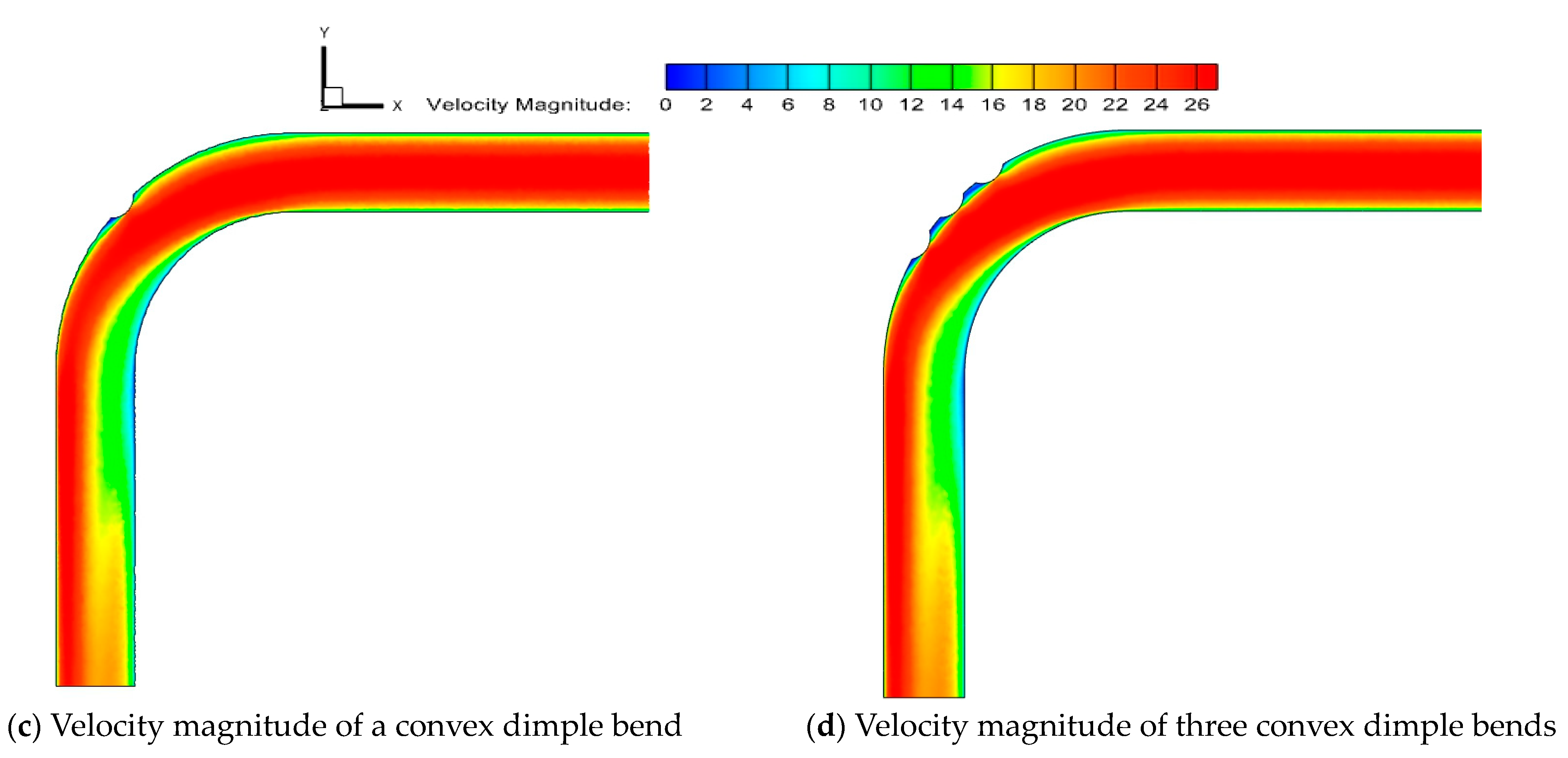

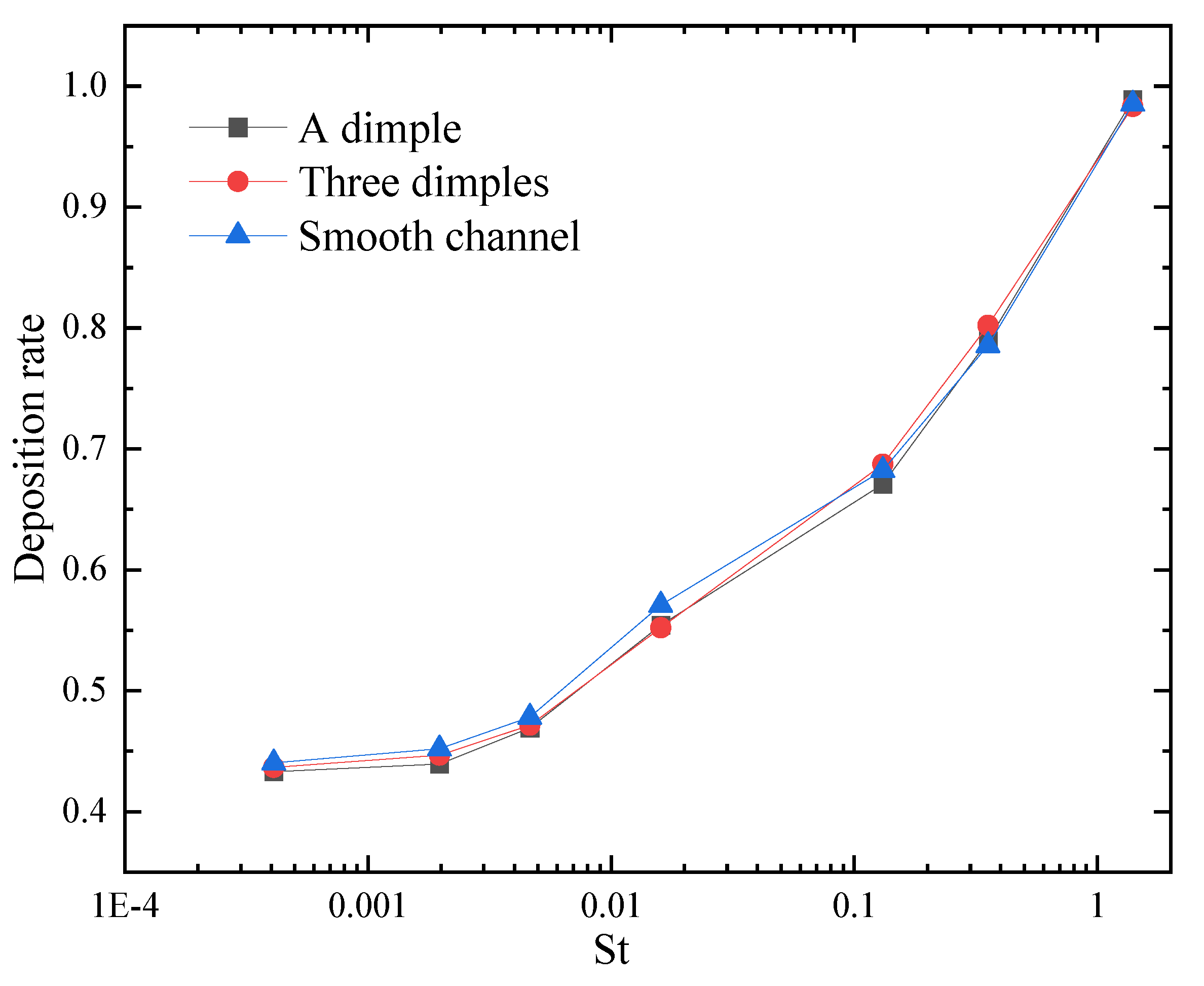

4.2. Analysis of Turbulent Flow Field

4.3. Particle Deposition Rate Analysis

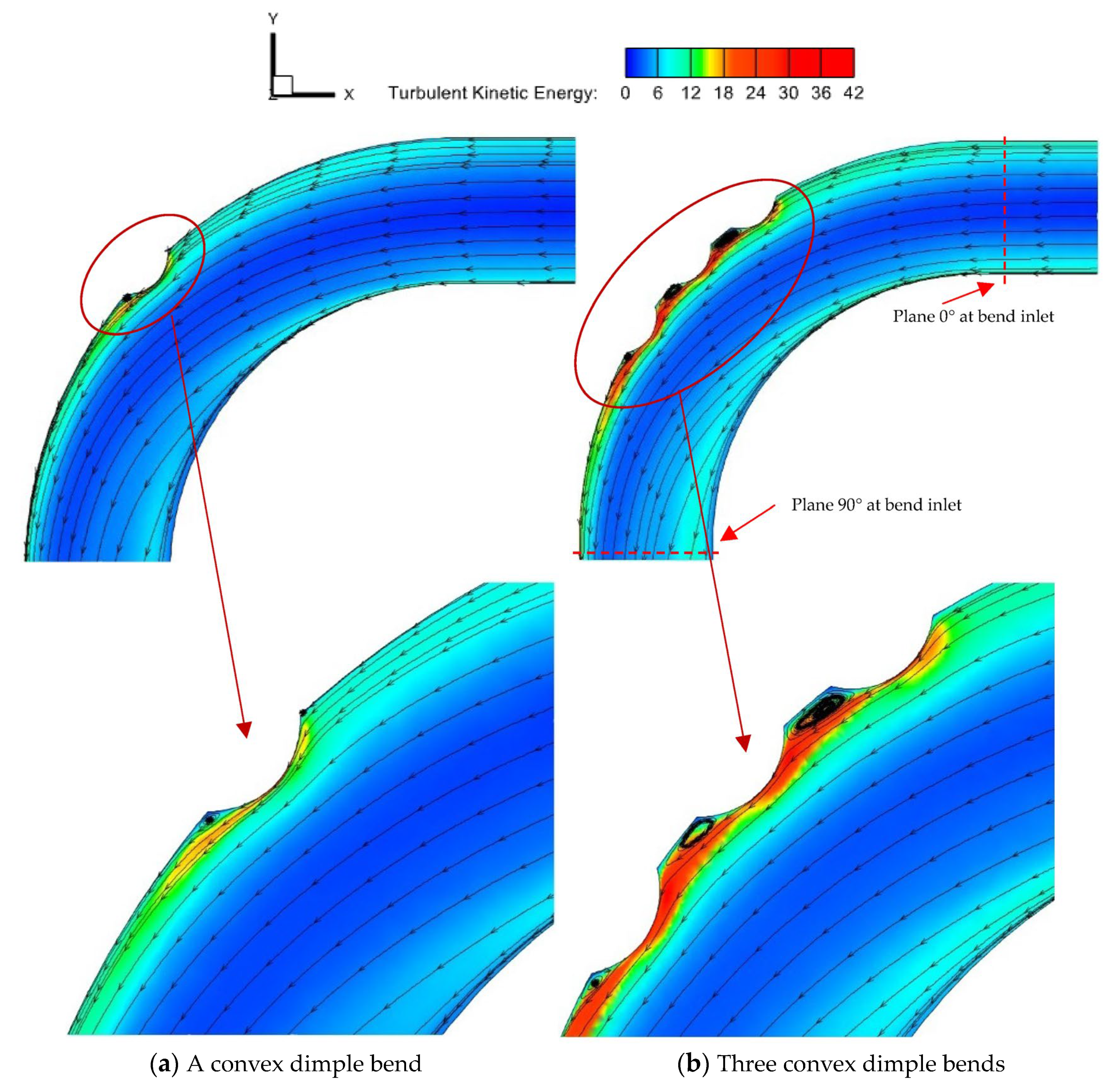

4.3.1. Effect of Stokes Number on Particle Deposition

4.3.2. Effect of Different Convex Dimple Numbers on Particle Deposition

5. Conclusions

- (1)

- The presence of convex dimple structures can have an impact on the flow field in the bend channel as well as on the particle deposition characteristics. In this case, for particles with small St, it will encourage their deposition inside the convex dimple cavity. And for particles with larger St, this leads to more particles being deposited on the windward side of the convex dimple.

- (2)

- As the number of convex dimples increases, the TKE value near the convex dimple will increase significantly. At the same time, a higher temperature gradient will exist near the channel wall. These reasons will promote particle deposition. The presence of vortex clusters between the two convex dimples allows fewer particles to be deposited there. An increase in the number of convex dimples does not significantly reduce the rate of particle deposition.

- (3)

- Particle deposition in the bend is influenced by a different St, and as the St increases, the rate of particle deposition increases. As the St increases, the particle diameter increases, and the inertial force of the particles increases. The concentration of particles deposited in the curved portion of the bend is more pronounced.

- (4)

- A special convex dimple-type structure is added to the bend portion of the elbow, which effectively reduces the deposition of some particles. When applied in the tail flue of a coal-fired power plant, it can improve the operating efficiency of the equipment and reduce energy consumption. In future studies, User-Defined Functions (UDFs) will be used to bring the deposition of particles closer to reality. In addition, inter-particle collisions are important for regions where particles are highly aggregated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Cunningham correction factor | |

| drag coefficient | |

| diameter of dust particle (μm) | |

| channel diameter (m) | |

| thermophoretic coefficient | |

| Brownian force (N) | |

| trailing force (N) | |

| Saffman’s lift (N) | |

| thermophoretic force (N) | |

| gravitational acceleration (m/s2) | |

| the turbulent kinetic energy from mean velocity gradient (kg/(m·s3)) | |

| turbulent kinetic energy (m2/s2) | |

| turbulence length scales in two-layer models (m) | |

| average pressure (Pa) | |

| relative Reynolds number | |

| modulus of the average strain rate tensor (s−1) | |

| average strain rate tensor (s−1) | |

| spectral intensity of a Gaussian white noise random process | |

| Lagrangian integration time | |

| velocity vector of particles (m/s) | |

| time-averaged velocity of air (m/s) | |

| average flow rate (m/s) | |

| kinetic viscosity (m2/s) | |

| position vector of particles (m) | |

| air density (kg/m3) | |

| particle density (kg/m3) | |

| random number with a normal distribution | |

| mean free range of air | |

| time scale | |

| particle relaxation time | |

| system response time | |

| effective power viscosity (kg/(m·s)) | |

| turbulent viscosity | |

| dynamic turbulent viscosity in the viscous region |

References

- Yang, F. Analysis of the demand prospect of coal products in China’s power industry. China Coal 2020, 46, 22–31. [Google Scholar] [CrossRef]

- Qi, Y. Analysis on the Current Situation and Future Trend of Energy Development in China. Inn. Mong. Coal Econ. 2019, 14, 1–2+11. [Google Scholar] [CrossRef]

- Zhu, F.; Zhang, J.; Xu, Z. Current Situation and Predicament of China’s Industrial Flue Gas Treatment and Relevant Suggestions. China Environ. Prot. Ind. 2020, 10, 13–16. [Google Scholar]

- Yan, Y.; Zhao, Y.; Yao, J.; Wang, C.-H. Investigation of particle transport by a turbulent flow through a 90° bend pipe with electrostatic effects. Powder Technol. 2021, 394, 547–561. [Google Scholar] [CrossRef]

- Han, Z.; Xu, Z.; Yu, X. CFD modeling for prediction of particulate fouling of heat transfer surface in turbulent flow. Int. J. Heat Mass Transf. 2019, 144, 118428. [Google Scholar] [CrossRef]

- Sippola, M.R.; Nazaroff, W.W. Particle Deposition in Ventilation Ducts: Connectors, Bends and Developing Turbulent Flow. Aerosol Sci. Technol. 2005, 39, 139–150. [Google Scholar] [CrossRef]

- Sun, K.; Lu, L.; Jiang, H.; Jin, H. Experimental Study of Solid Particle Deposition in 90° Ventilated Bends of Rectangular Cross Section with Turbulent Flow. Aerosol Sci. Technol. 2013, 47, 115–124. [Google Scholar] [CrossRef]

- Hong, W.; Wang, X. Numerical study on particle deposition in rough channels with large-scale irregular roughness. Korean J. Chem. Eng. 2018, 35, 1517–1524. [Google Scholar] [CrossRef]

- Tu, Z.; Cao, X. Simulation of Aerosol Deposition in the Micro-channel under Turbulent Flow. Nucl. Sci. Eng. 2021, 41, 1260–1267. [Google Scholar]

- Farahani, B.; Jadidi, M.; Moghtadernejad, S. Compressibility and Rarefaction Effects on Particle Dynamics and Heat Transfer in Aerosol Deposition Process. Coatings 2022, 12, 1578. [Google Scholar] [CrossRef]

- Hong, W.; Wang, X.; Zheng, J. Numerical study on particle deposition in rough channels with different structure parameters of rough elements. Adv. Powder Technol. 2018, 29, 2895–2903. [Google Scholar] [CrossRef]

- Han, Z.; Xu, Z.; Yu, X.; Sun, A.; Li, Y. Numerical simulation of ash particles deposition in rectangular heat exchange channel. Int. J. Heat Mass Transf. 2019, 136, 767–776. [Google Scholar] [CrossRef]

- Cong, X.C.; Yang, G.S.; Qu, J.H.; Zhao, J.J. A model for evaluating the particle penetration efficiency in a ninety-degree bend with a circular-cross section in laminar and turbulent flow regions. Powder Technol. 2017, 305, 771–781. [Google Scholar] [CrossRef]

- Han, Z.; Lu, H. Numerical simulation of turbulent flow and particle deposition in heat transfer channels with concave dimples. Appl. Therm. Eng. 2023, 230, 120672. [Google Scholar] [CrossRef]

- Lu, H.; Ma, T.; Lu, L. Deposition characteristics of particles in inclined heat exchange channel with surface ribs. Int. J. Heat Mass Transf. 2020, 161, 120289. [Google Scholar] [CrossRef]

- Lu, H.; Wang, Y.; Li, H.; Zhao, W. Numerical Simulation of Turbulent Structure and Particle Deposition in a Three-Dimensional Heat Transfer Pipe with Corrugation. Energies 2024, 17, 321. [Google Scholar] [CrossRef]

- Han, Z.; Lu, H.; Zhao, W.; Wang, Z.; Xiao, Z. Numerical simulation study of particle deposition and heat transfer characteristics in heat transfer pipeswith dimpled dimple surface. Energy Environ. Prot. 2023, 37, 201–208. [Google Scholar] [CrossRef]

- Lu, H.; Han, Z.; Li, H.; Chang, X.; Dong, L.; Fan, M.; Kong, D.; Jing, X. Simulation of Turbulent Flow Structure and Particle Deposition in a Three-Dimensional Heat Transfer Duct with Convex Dimples. Coatings 2023, 13, 900. [Google Scholar] [CrossRef]

- Arsalanloo, A.; Abbasalizadeh, M. Numerical study on deposition of particles in a 90° bend in the presence of swirling flow using Eulerian-Lagrangian method. Powder Technol. 2017, 320, 285–294. [Google Scholar] [CrossRef]

- Erraghroughi, F.Z.; Bah, A.; El Maakoul, A.; Abdellah, A.B. Numerical assessment of particle deposition reduction in turbulent bend pipe flow with a rib insertion. Int. J. Heat Fluid Flow 2024, 106, 109290. [Google Scholar] [CrossRef]

- Pui, D.Y.H.; Romay-Novas, F.; Liu, B.Y.H. Experimental Study of Particle Deposition in Bends of Circular Cross Section. Aerosol Sci. Technol. 1987, 7, 301–315. [Google Scholar] [CrossRef]

- Ladino, A.; Duque-Daza, C.A.; Lain, S. Effect of walls with large scale roughness in deposition efficiency for 90-degree square bend configurations. J. Aerosol Sci. 2023, 167, 106093. [Google Scholar] [CrossRef]

- Hongtao, L.; Li, Z. Prediction of particle deposition characteristic in 90° square bend: Square bend particle deposition characteristic. Appl. Therm. Eng. 2011, 31, 3402–3409. [Google Scholar] [CrossRef]

- Yakhot, V.; Orszag, S.A.; Thangam, S.; Gatski, T.B.; Speziale, C.G. Development of turbulence models for shear flows by a double expansion technique. Phys. Fluids A Fluid Dyn. 1992, 4, 1510–1520. [Google Scholar] [CrossRef]

- Kim, J.; Yadav, M.; Kim, S. Characteristics of Secondary Flow Induced by 90-Degree Elbow in Turbulent Pipe Flow. Eng. Appl. Comput. Fluid Mech. 2014, 8, 229–239. [Google Scholar] [CrossRef]

- Yin, Z.-Q.; Li, X.-F.; Bao, F.-B.; Tu, C.-X.; Gao, X.-Y. Thermophoresis and Brownian Motion Effects on Nanoparticle Deposition Inside a 90° Square Bend Tube. Aerosol Air Qual. Res. 2018, 18, 1746–1755. [Google Scholar] [CrossRef]

- Lu, H.; Lu, L. Numerical investigation on particle deposition enhancement in duct air flow by ribbed wall. Build. Environ. 2015, 85, 61–72. [Google Scholar] [CrossRef]

- Lu, H.; Lu, L.; Jiang, Y. Numerical simulation of particle deposition in duct air flows with uniform, expanding or contracting cross-section. Energy Build. 2016, 128, 867–875. [Google Scholar] [CrossRef]

- Lu, H.; Lu, L.; Jiang, Y. Numerical study of monodispersed particle deposition rates in variable-section ducts with different expanding or contracting ratios. Appl. Therm. Eng. 2017, 110, 150–161. [Google Scholar] [CrossRef]

- Sudo, K.; Sumida, M.; Hibara, H. Experimental investigation on turbulent flow in a circular-sectioned 90-degree bend. Exp. Fluids 1998, 25, 42–49. [Google Scholar] [CrossRef]

- Zhang, P.; Roberts, R.M.; Bénard, A. Computational guidelines and an empirical model for particle deposition in curved pipes using an Eulerian-Lagrangian approach. J. Aerosol Sci. 2012, 53, 1–20. [Google Scholar] [CrossRef]

- Guo, J.; Chen, Z.; Shen, B.; Wang, J.; Yang, L. Numerical study on characteristics of particle deposition efficiency on different walls of 90° square bend. Powder Technol. 2020, 364, 572–583. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hua, D.; Chang, X.; Liao, M.; Han, Z.; Lu, H. A CFD Study of Particulate Deposition on Dimple-Type Flue Walls of Coal-Fired Power Plants. Coatings 2024, 14, 526. https://doi.org/10.3390/coatings14050526

Hua D, Chang X, Liao M, Han Z, Lu H. A CFD Study of Particulate Deposition on Dimple-Type Flue Walls of Coal-Fired Power Plants. Coatings. 2024; 14(5):526. https://doi.org/10.3390/coatings14050526

Chicago/Turabian StyleHua, Dong, Xiqiang Chang, Mengke Liao, Zunshi Han, and Hao Lu. 2024. "A CFD Study of Particulate Deposition on Dimple-Type Flue Walls of Coal-Fired Power Plants" Coatings 14, no. 5: 526. https://doi.org/10.3390/coatings14050526

APA StyleHua, D., Chang, X., Liao, M., Han, Z., & Lu, H. (2024). A CFD Study of Particulate Deposition on Dimple-Type Flue Walls of Coal-Fired Power Plants. Coatings, 14(5), 526. https://doi.org/10.3390/coatings14050526