Brazing Temperature Effects on the Microstructure and Mechanical Properties of Ti-45Al-8Nb Joints Using TiZrCuNi Amorphous Interlayer

Abstract

1. Introduction

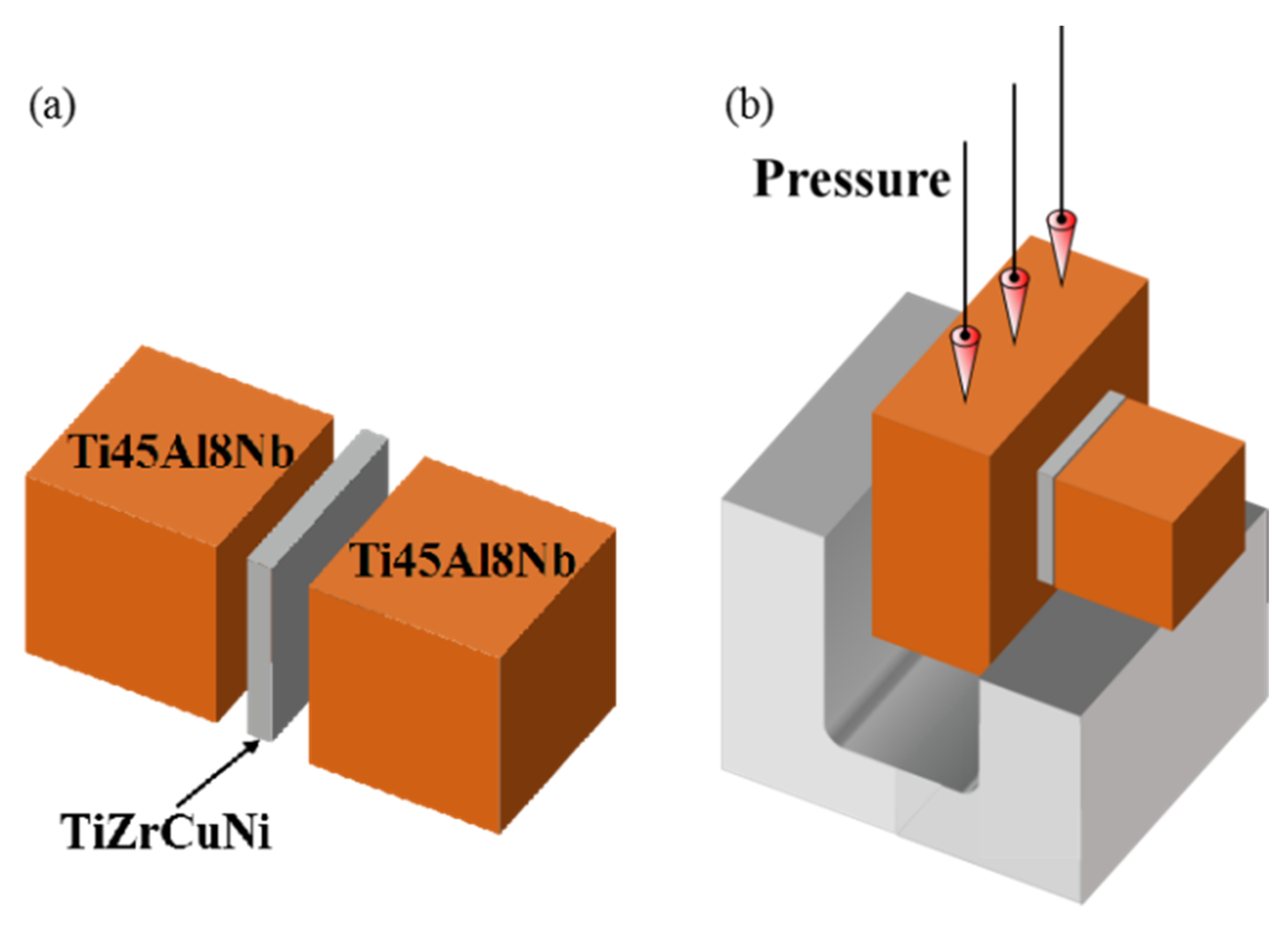

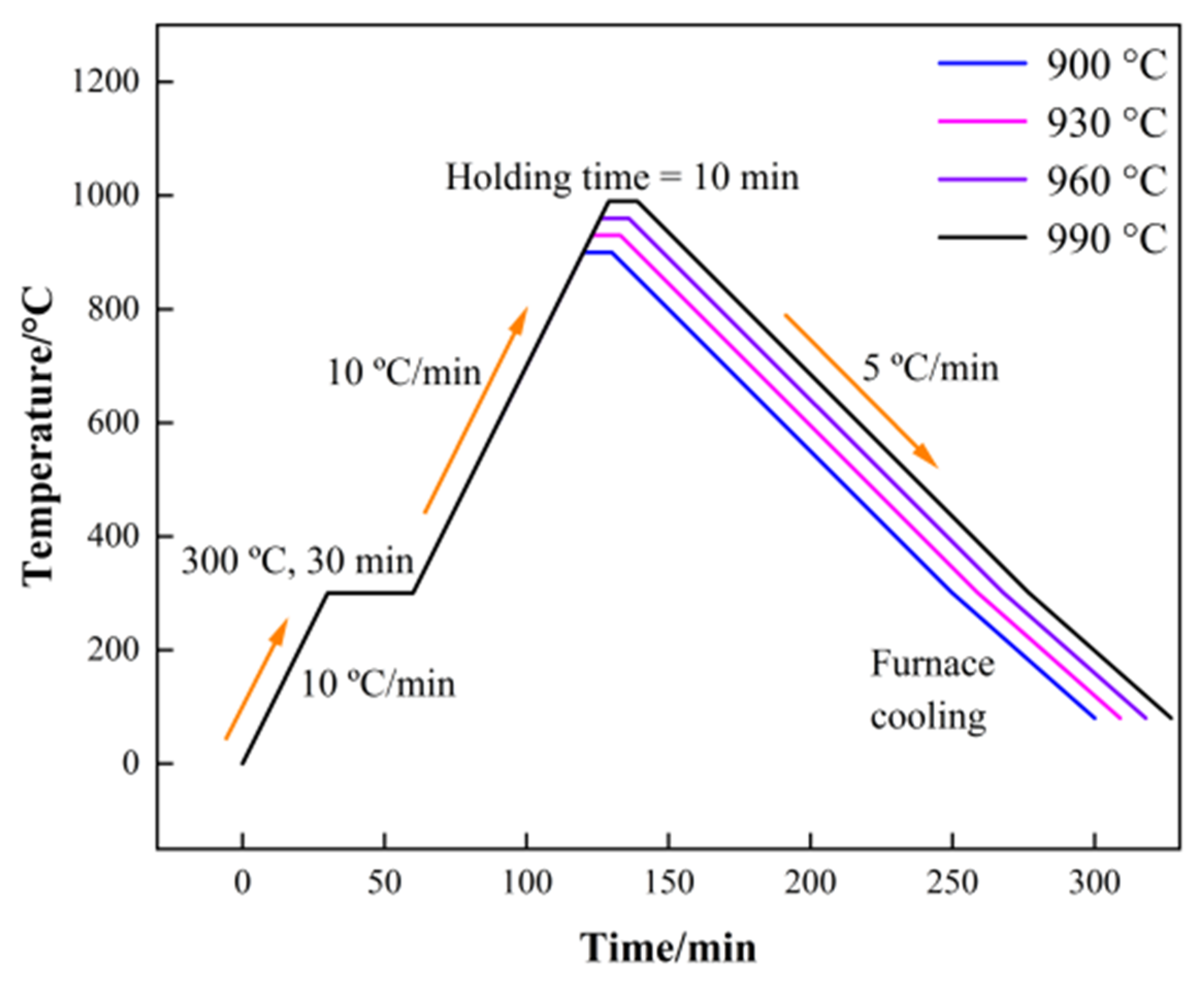

2. Materials and Methods

3. Results and Discussion

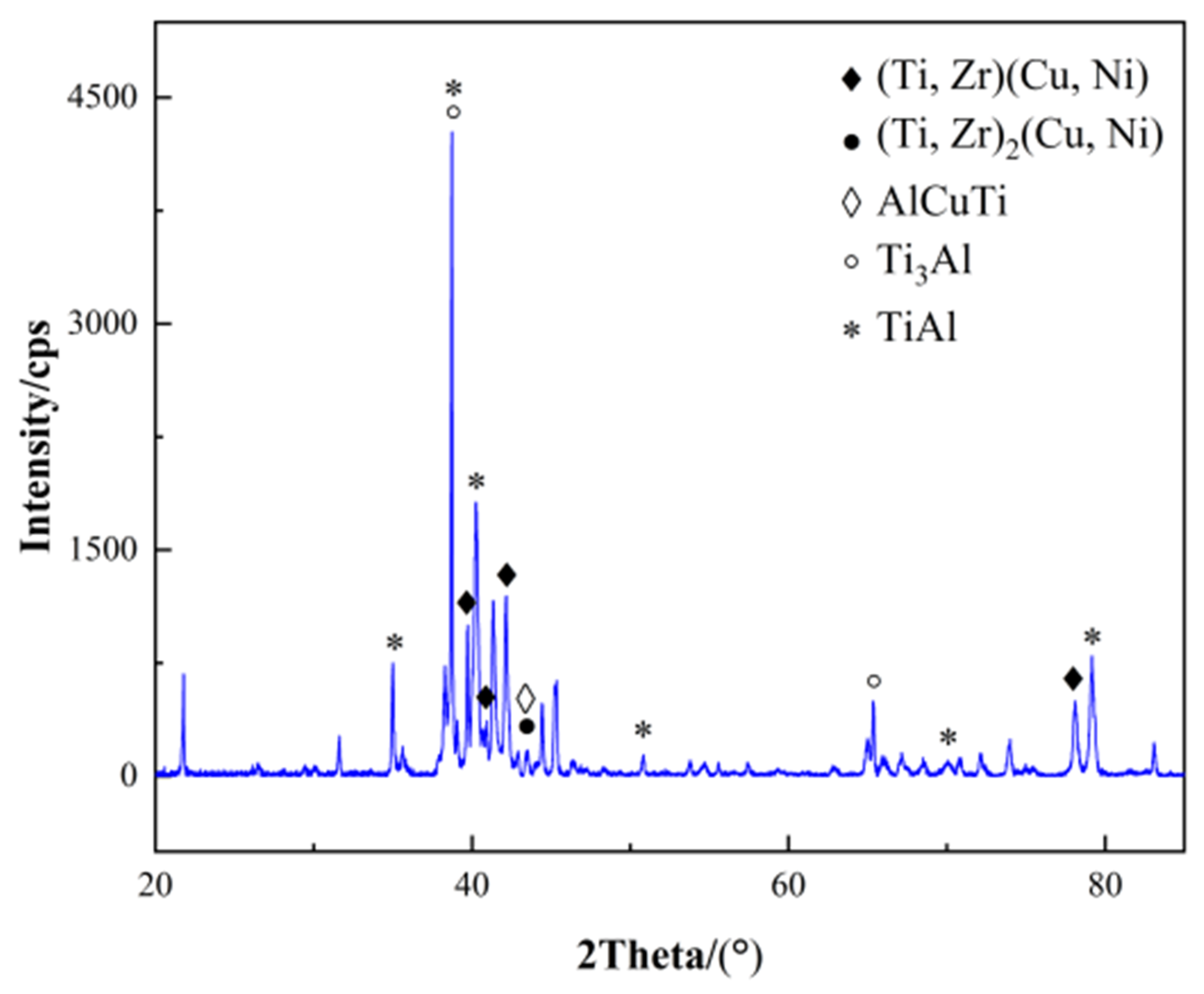

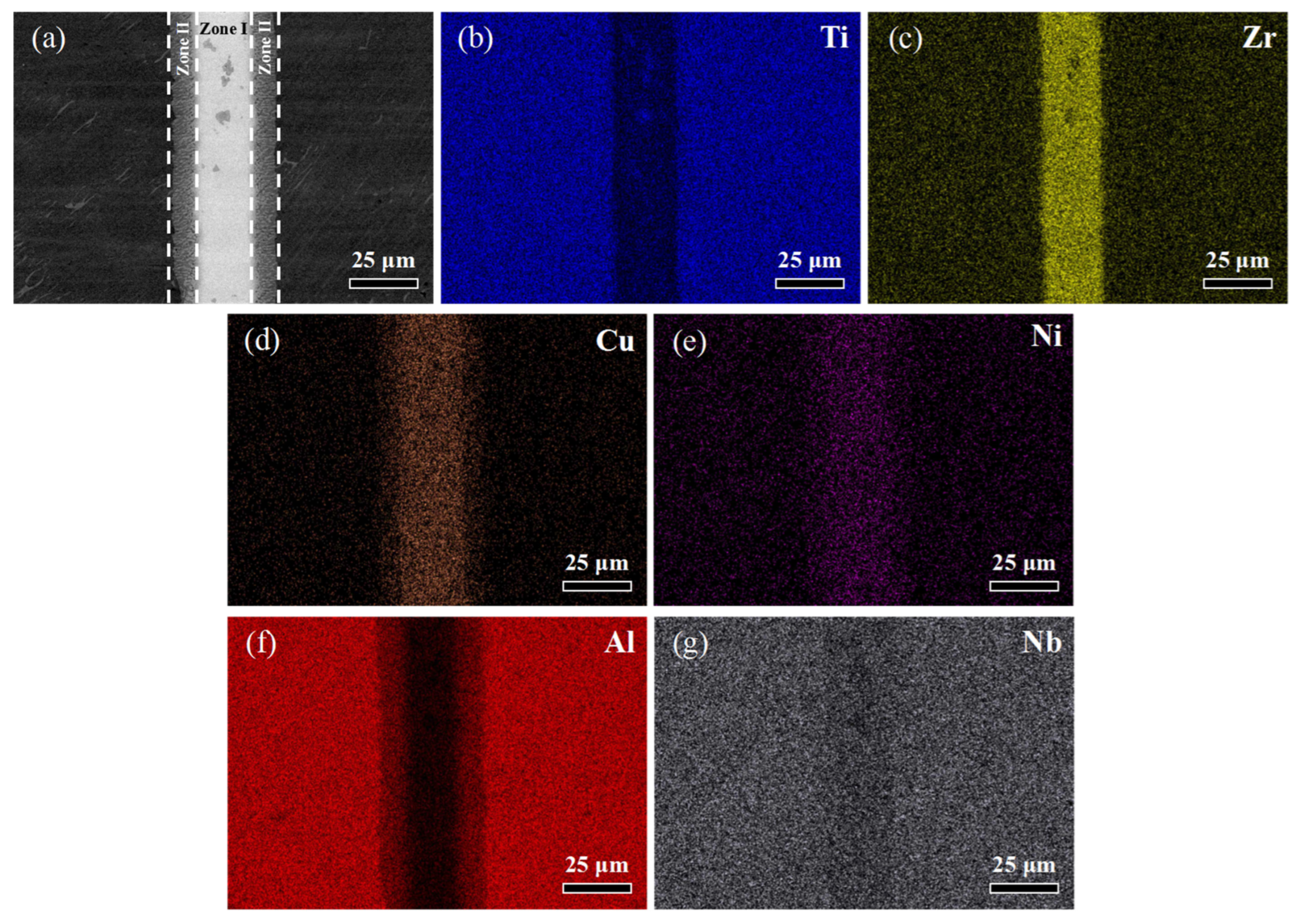

3.1. Typical Microstructure of the Ti-45Al-8Nb Joint

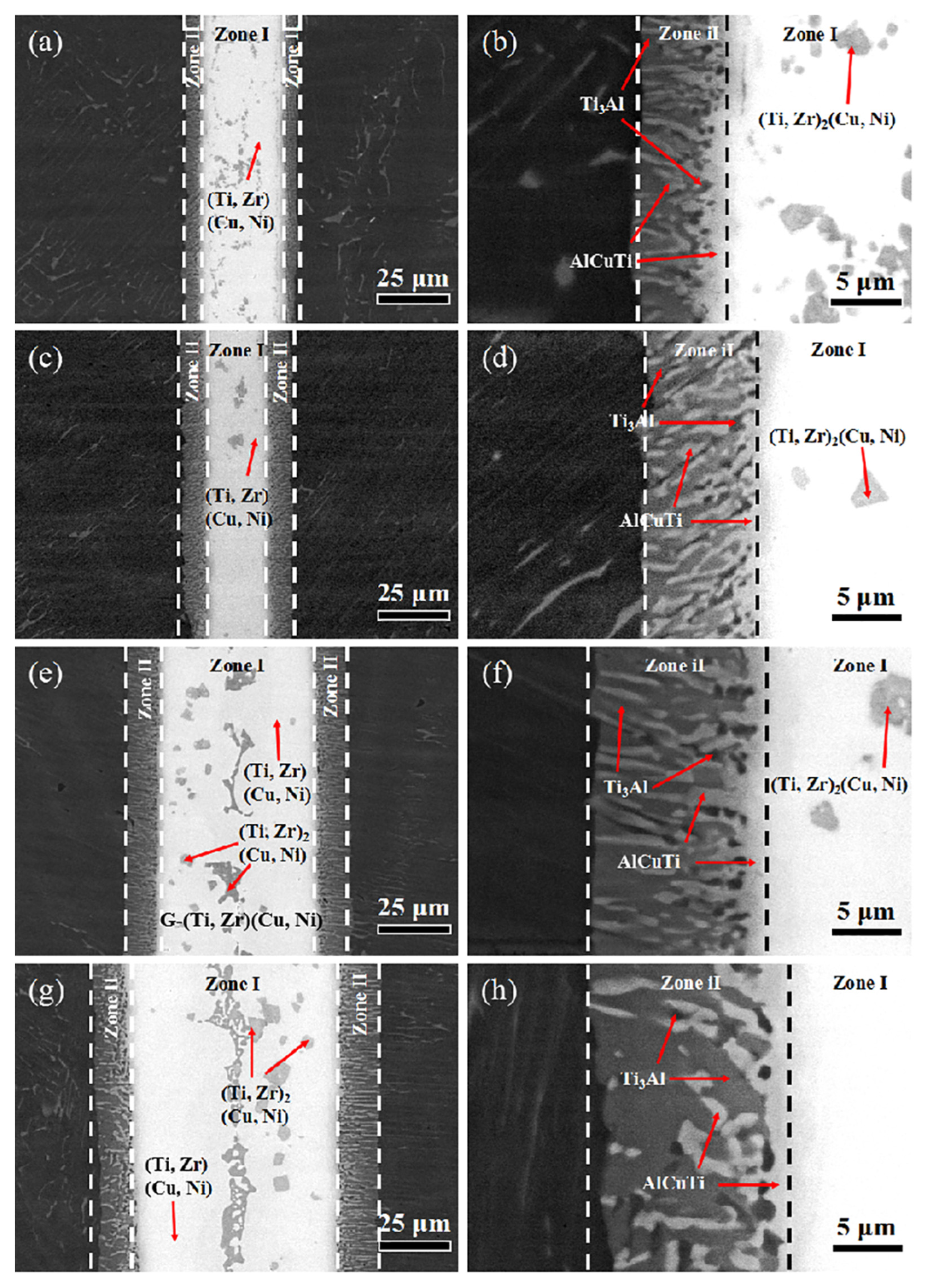

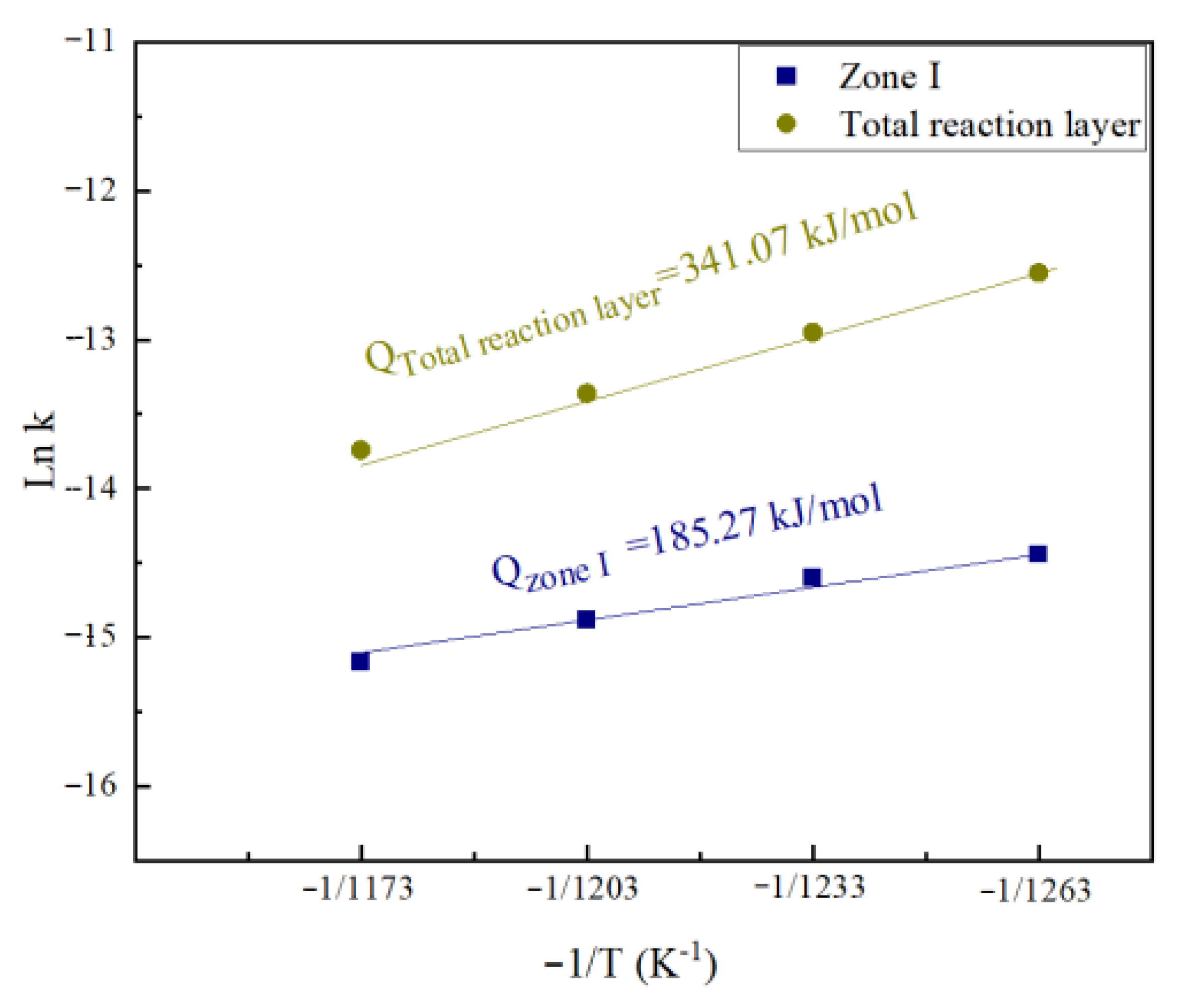

3.2. Effect of Brazing Temperature on the Microstructure of Ti-45Al-8Nb Joints

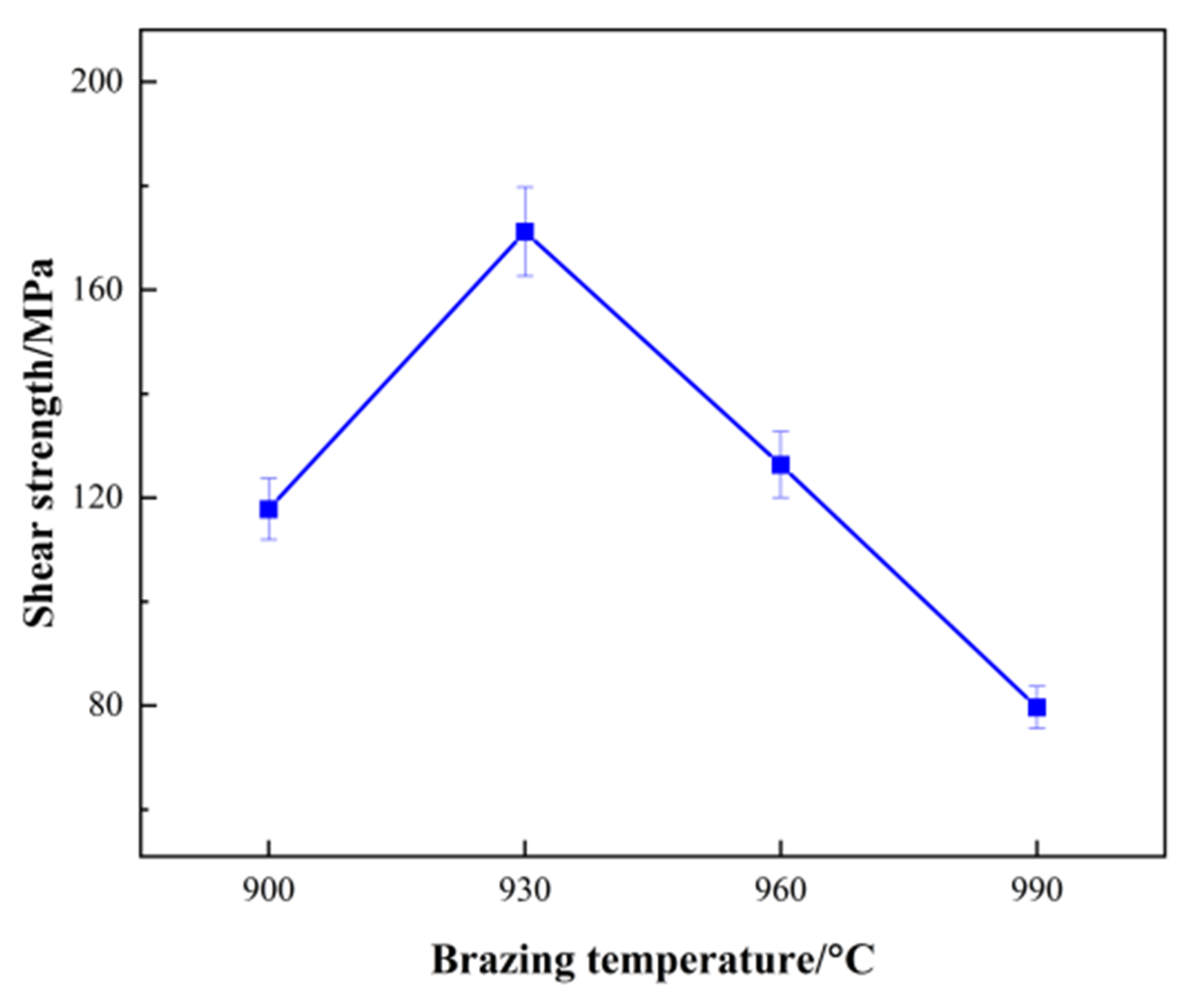

3.3. Effect of Brazing Temperature on the Mechanical Properties of Ti-45Al-8Nb Joints

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Riedlsperger, F.; Wojcik, T.; Buzolin, R.; Zuderstorfer, G.; Speicher, M.; Sommitsch, C.; Sonderegger, B. Microstructural insights into creep of Ni-based alloy 617 at 700 °C provided by electron microscopy and modelling. Mater. Charact. 2023, 198, 112720. [Google Scholar] [CrossRef]

- Chen, K.J.; Lin, H.M. Effects of niobium carbide additions on Ni-based superalloys: A Study on microstructures and cutting-wear characteristics through plasma-transferred-arc-assisted deposition. Coatings 2024, 14, 167. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Zhang, L.; Long, W.; Du, D.; Fan, Z.; Jiang, C.; Jin, X. A novel diamond/AlSi composite coating on Ti-6Al-4V subStrate made by ultrasonic-assisted brazing. Coatings 2023, 13, 1596. [Google Scholar] [CrossRef]

- Ren, H.S.; Xiong, H.P.; Chen, B.; Pang, S.J.; Chen, B.Q.; Ye, L. Vacuum brazing of Ti3Al-based alloy to TiAl using TiZrCuNi(Co) fillers. J. Mater. Process. Technol. 2015, 224, 26–32. [Google Scholar] [CrossRef]

- Dong, D.; Xu, H.T.; Zhu, D.D.; Wang, G.; He, Q.; Lin, J.P. Microstructure and mechanical properties of TiC/Ti matrix composites and Ti–48Al–2Cr–2Nb alloy joints brazed with Ti–28Ni eutectic filler alloy. Arch. Civ. Mech. Eng. 2019, 19, 1259–1267. [Google Scholar] [CrossRef]

- Ren, X.Y.; Ren, H.S.; Shang, Y.L.; Xiong, H.P.; Zhang, K.; Zheng, J.H.; Liu, D.; Lin, J.G.; Jiang, J. Microstructure evolution and mechanical properties of Ti2AlNb/TiAl brazed joint using newly-developed Ti-Ni-Nb-Zr filler alloy. Prog. Nat. Sci. 2020, 30, 410–416. [Google Scholar] [CrossRef]

- Chang, C.; Yang, J. The constitutive equation-based recrystallization mechanism of Ti-6Al-4V alloy during superplastic forming. Coatings 2024, 14, 122. [Google Scholar] [CrossRef]

- Ye, P.H.; Li, X.W.; Wu, H.; Miao, K.S.; Wu, H.; Li, R.G.; Liu, C.L.; Huang, C.X.; Fang, W.B.; Fan, G.H. A bicomponent TiAl alloy with superior compressive strength-ductility synergy prepared by powder metallurgy. Mater. Sci. Eng. A 2023, 884, 145511. [Google Scholar] [CrossRef]

- Zhu, D.D.; Yan, J.F.; Jin, Y.L.; Dong, D.; Wang, X.H.; Ma, T.F. Pressure-induced excellent corrosion resistance of Ti-45Al-8Nb alloy. Mater. Lett. 2024, 355, 135446. [Google Scholar] [CrossRef]

- Cui, S.; Tian, F.; Zhang, S.; Cai, H.; Yu, Y. Numerical simulation and mechanical properties of 6063/6082 dissimilar joints by laser welding. Coatings 2023, 13, 2049. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chen, S.Y. Infrared brazing of TiAl intermetallic using pure silver. Intermetallics 2004, 12, 929–936. [Google Scholar] [CrossRef]

- Cai, X.L.; Li, Q.; Li, H.M.; Xu, G.B.; Yu, H.B. Microstructure evolution and formation mechanism of γ-TiAl/Ni-based superalloy laser-welded joint with Ti/V/Cu filler metals. Mater. Lett. 2023, 333, 133647. [Google Scholar] [CrossRef]

- Cao, H.Y.; Li, H.L.; Wang, D.; Xia, H.B.; Han, K.; Wang, Z.Y.; Zhu, Q.; Liu, D. Dissimilar joining of TC4 and SiCp/6092Al matrix composite by laser lap welding technology. Mater. Lett. 2023, 351, 135069. [Google Scholar] [CrossRef]

- Dong, D.; Shi, K.Q.; Zhu, D.D.; Liang, Y.F.; Wang, X.H.; Wei, Z.J.; Lin, J.P. Microstructure evolution and mechanical properties of high Nb-TiAl alloy/GH4169 joints brazed using CuTiZrNi amorphous filler alloy. Intermetallics 2021, 139, 107351. [Google Scholar] [CrossRef]

- Wang, Z.W.; Liu, M.; Zhang, H.; Xie, G.M.; Xue, P.; Wu, L.H.; Zhang, Z.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y. Welding behavior of an ultrahigh-strength quenching and partitioning steel by fusion and solid-state welding methods. J. Mater. Res. Technol. 2022, 17, 1289–1301. [Google Scholar] [CrossRef]

- Zhou, J.F.; Zhou, D.W.; Liu, J.S. Effect of oscillating laser beam on the interface and mechanical properties of Ti/Al fusion welding joint. J. Mater. Res. Technol. 2022, 19, 1993–2007. [Google Scholar] [CrossRef]

- Fan, J.F.; Li, X.Q.; Pan, C.L.; Zhu, Z.C.; Wang, X.C.; Qu, S.G.; Yang, C.; Hou, J.B. Microstructure evolution and mechanical properties of pulse high current diffusion bonding γ-TiAl alloy to Ti2AlNb alloy. Intermetallics 2023, 163, 108044. [Google Scholar] [CrossRef]

- Du, S.G.; Wang, S.L.; Ding, K. A novel method of friction-diffusion welding between TiAl alloy and GH3039 high temperature alloy. J. Manuf. Process. 2020, 56, 688–696. [Google Scholar] [CrossRef]

- Sun, Z.; Zhu, X.X.; Chen, H.Z.; Zhang, L.X. Brazing of TiAl and Ti2AlNb alloys using high-entropy braze fillers. Mater. Charact. 2022, 186, 111814. [Google Scholar] [CrossRef]

- Song, X.G.; Ben, B.Y.; Hu, S.P.; Feng, J.C.; Tang, D.Y. Vacuum brazing high Nb-containing TiAl alloy to Ti60 alloy using Ti-28Ni eutectic brazing alloy. J. Alloys Compd. 2017, 692, 485–491. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chen, S.Y. Infrared brazing of TiAl intermetallic using BAg-8 braze alloy. Acta Mater. 2003, 51, 1991–2004. [Google Scholar] [CrossRef]

- Li, Y.L.; Liu, W.; Sekulic, D.P.; He, P. Reactive wetting of AgCuTi filler metal on the TiAl-based alloy substrate. Appl. Surf. Sci. 2012, 259, 343–348. [Google Scholar] [CrossRef]

- Zhu, D.D.; Tang, F.H.; Dong, D.; Wang, X.H.; Ma, T.F. Phase formation and nanohardness of Ti-48Al-2Cr-2Nb-1.5C alloy by melt spinning: The effect of cooling rates. Vacuum 2024, 13, 112985. [Google Scholar] [CrossRef]

- Dong, H.G.; Yang, Z.L.; Wang, Z.R.; Deng, D.W.; Dong, C. CuTiNiZrV amorphous alloy foils for vacuum brazing of TiAl alloy to 40Cr steel. J. Mater. Sci. Technol. 2015, 31, 217–222. [Google Scholar] [CrossRef]

- Li, L.; Li, X.Q.; Hu, K.; He, B.L.; Man, H. Brazeability evaluation of Ti-Zr-Cu-Ni-Co-Mo filler for vacuum brazing TiAl-based alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 754–763. [Google Scholar] [CrossRef]

- Feng, G.J.; Wei, Y.; Hu, B.X.; Wang, Y.F.; Deng, D.A.; Yang, X.X. Vacuum diffusion bonding of Ti2AlNb alloy and TC4 alloy. Trans. Nonferrous Met. Soc. China 2021, 31, 2677–2686. [Google Scholar] [CrossRef]

- Song, X.G.; Cao, J.; Liu, Y.Z.; Feng, J.C. Brazing high Nb containing TiAl alloy using TiNi-Nb eutectic braze alloy. Intermetallics 2012, 22, 136–141. [Google Scholar] [CrossRef]

- Xia, Y.Q.; Dong, H.G.; Hao, X.H.; Li, P.; Li, S. Vacuum brazing of Ti6Al4V alloy to 316L stainless steel using a Ti-Cu-based amorphous filler metal. J. Mater. Process. Technol. 2019, 269, 35–44. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Jing, Y.J.; Jiang, J. Predicting the hardness and solute distribution during brazing of Ti-6Al-4V with TiZrCuNi filler metals. Mater. Sci. Eng. A 2018, 712, 122–126. [Google Scholar] [CrossRef]

- Yuan, L.; Xiong, J.T.; Du, Y.J.; Wang, Y.; Shi, J.M.; Li, J.L. Effects of pure Ti or Zr powder on microstructure and mechanical properties of Ti6Al4V and Ti2AlNb joints brazed with TiZrCuNi. Mater. Sci. Eng. A 2020, 788, 139602. [Google Scholar] [CrossRef]

| Phase | Al | Zr | Ni | Cu | Ti | Nb | Possible Phase |

|---|---|---|---|---|---|---|---|

| A | 7.04 | 12.98 | 10.22 | 39.38 | 28.38 | 1.99 | (Ti, Zr)(Cu, Ni) |

| B | 2.45 | 7.24 | 13.97 | 26.15 | 48.62 | 1.57 | (Ti, Zr)2(Cu, Ni) |

| C | 24.81 | 4.52 | 10.42 | 28.49 | 26.84 | 4.93 | AlCuTi |

| D | 31.93 | 2.07 | 5.96 | 22.7 | 32.56 | 4.78 | AlCuTi |

| E | 31.29 | 1.54 | 2.20 | 5.12 | 52.74 | 7.12 | Ti3Al |

| F | 25.91 | 1.48 | 3.62 | 9.45 | 54.41 | 5.12 | Ti3Al |

| G | 7.01 | 10.16 | 7.36 | 37.03 | 37.16 | 1.27 | (Ti, Zr)(Cu, Ni) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Xu, T.; Wu, Y.; Chen, X.; Yang, X. Brazing Temperature Effects on the Microstructure and Mechanical Properties of Ti-45Al-8Nb Joints Using TiZrCuNi Amorphous Interlayer. Coatings 2024, 14, 300. https://doi.org/10.3390/coatings14030300

Wang S, Xu T, Wu Y, Chen X, Yang X. Brazing Temperature Effects on the Microstructure and Mechanical Properties of Ti-45Al-8Nb Joints Using TiZrCuNi Amorphous Interlayer. Coatings. 2024; 14(3):300. https://doi.org/10.3390/coatings14030300

Chicago/Turabian StyleWang, Sheng, Tianle Xu, Yingchen Wu, Xiguo Chen, and Xiaohong Yang. 2024. "Brazing Temperature Effects on the Microstructure and Mechanical Properties of Ti-45Al-8Nb Joints Using TiZrCuNi Amorphous Interlayer" Coatings 14, no. 3: 300. https://doi.org/10.3390/coatings14030300

APA StyleWang, S., Xu, T., Wu, Y., Chen, X., & Yang, X. (2024). Brazing Temperature Effects on the Microstructure and Mechanical Properties of Ti-45Al-8Nb Joints Using TiZrCuNi Amorphous Interlayer. Coatings, 14(3), 300. https://doi.org/10.3390/coatings14030300