Effect of Spark Plasma Sintering Temperature on the Microstructure and Thermophysical Properties of High-Silicon–Aluminum Composites

Abstract

1. Introduction

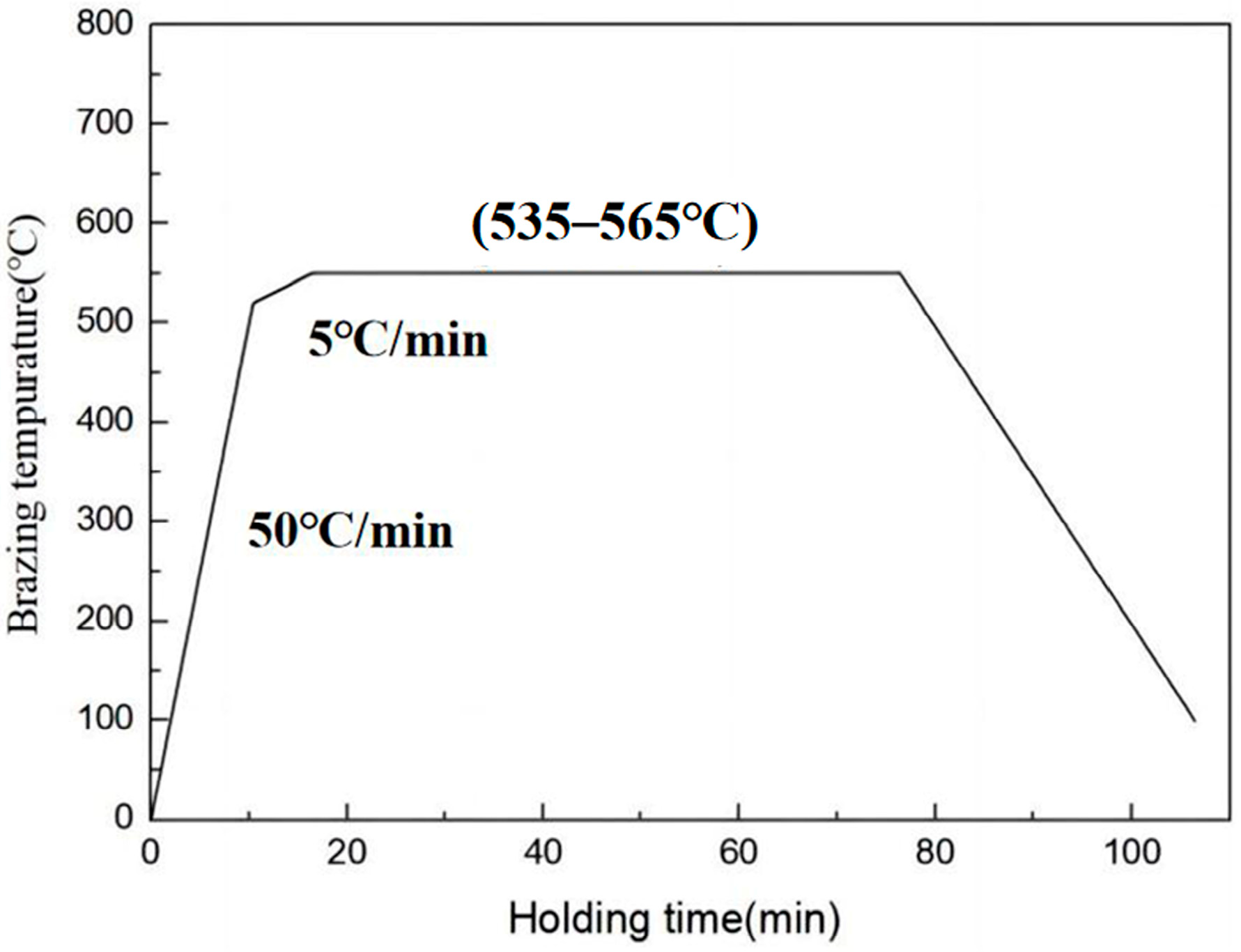

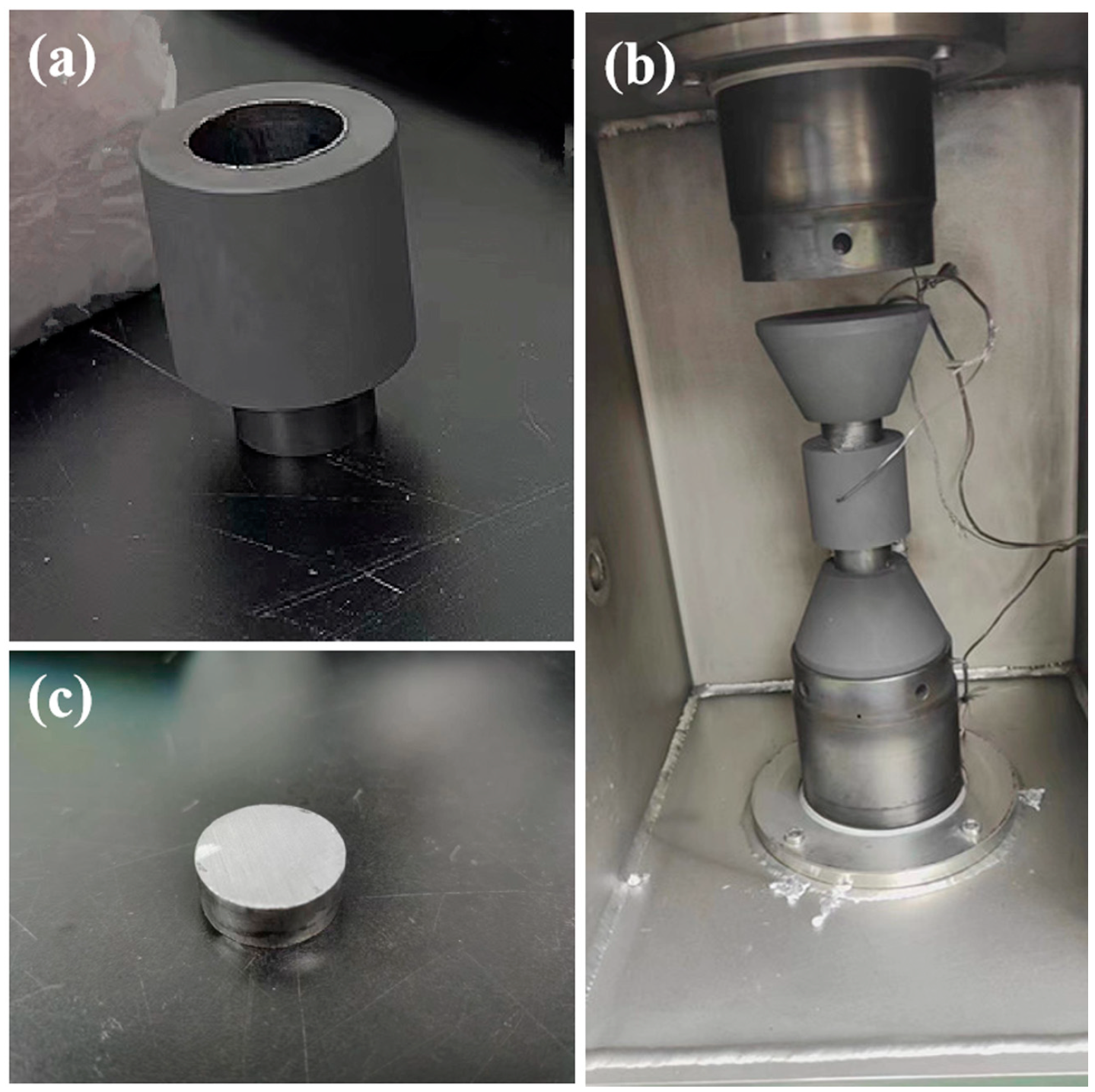

2. Materials and Methods

3. Results and Discussion

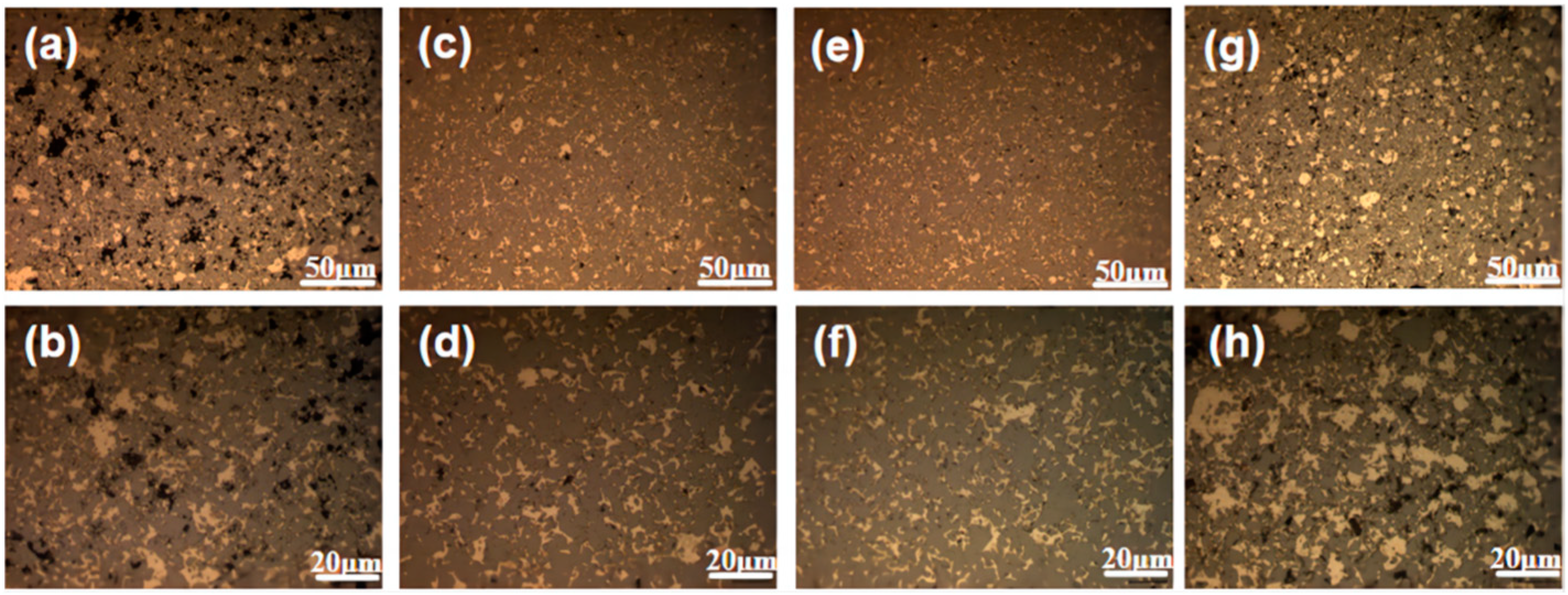

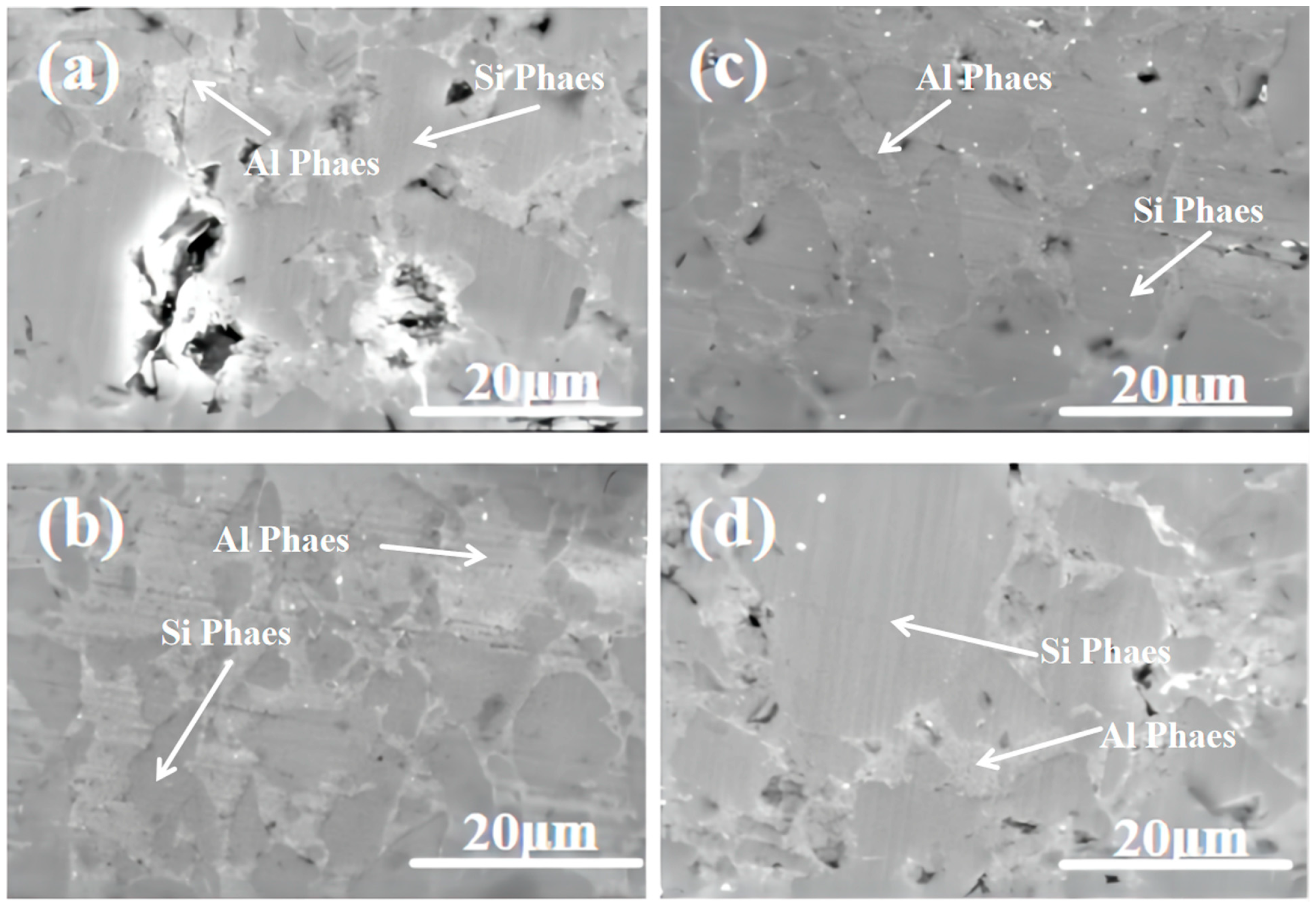

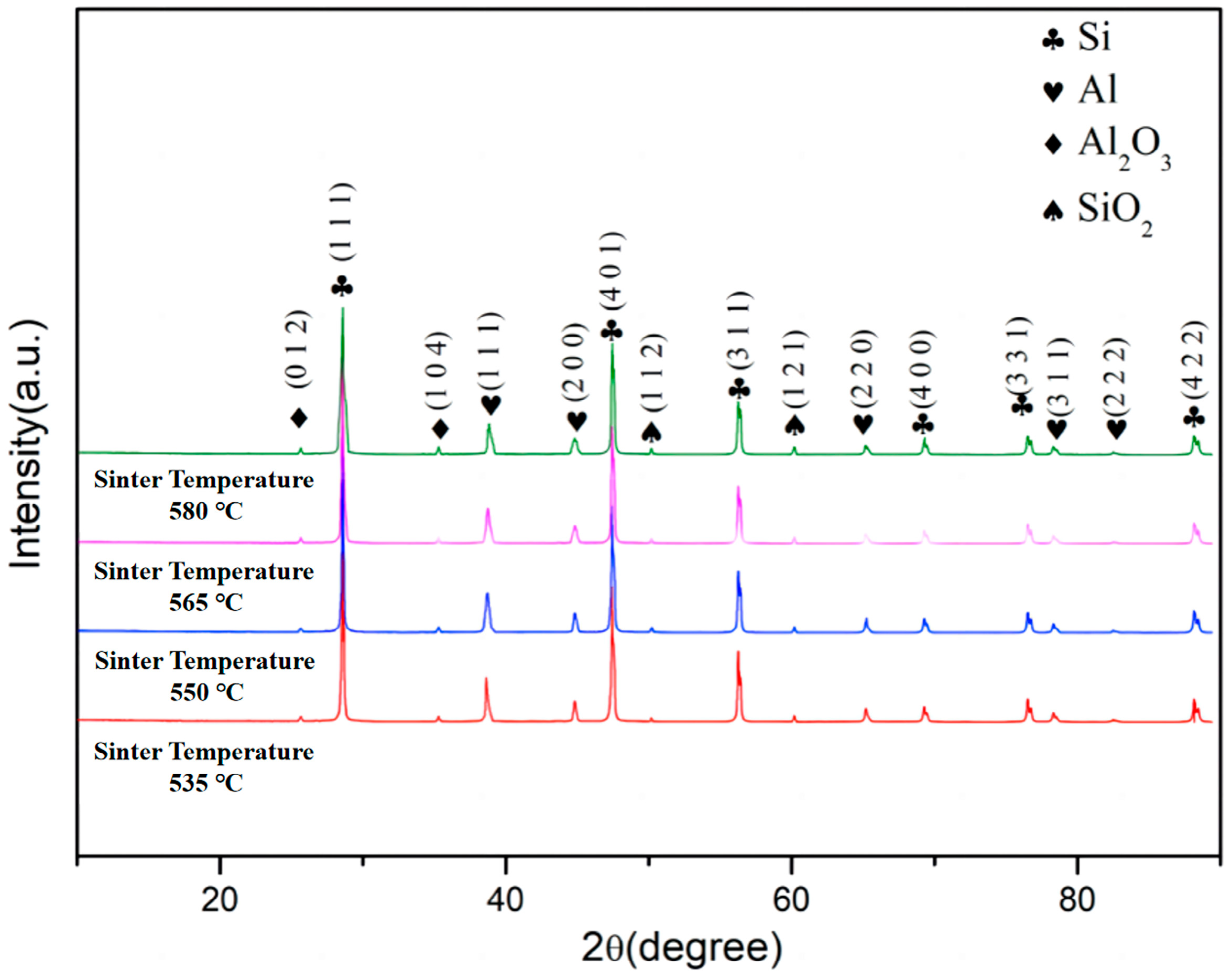

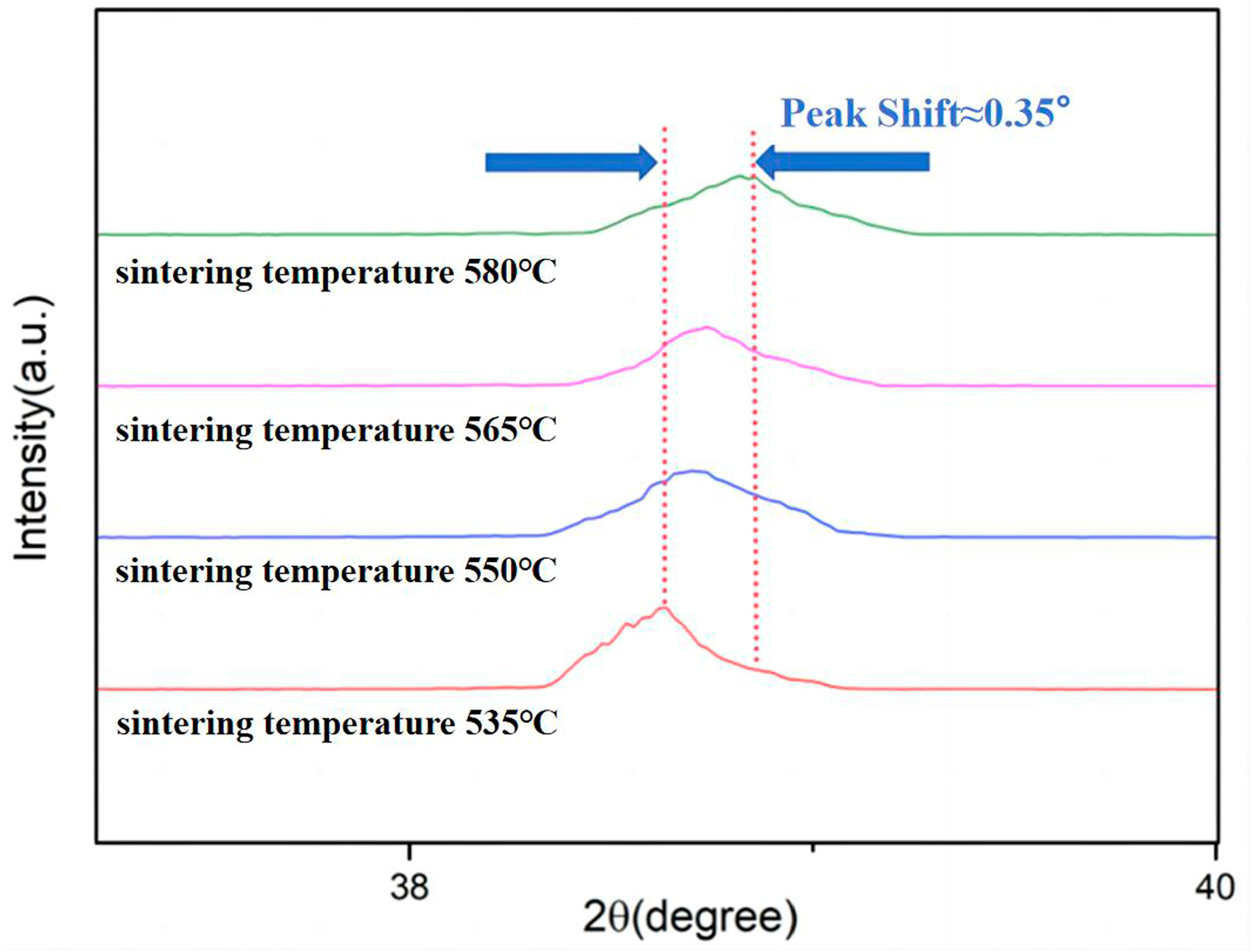

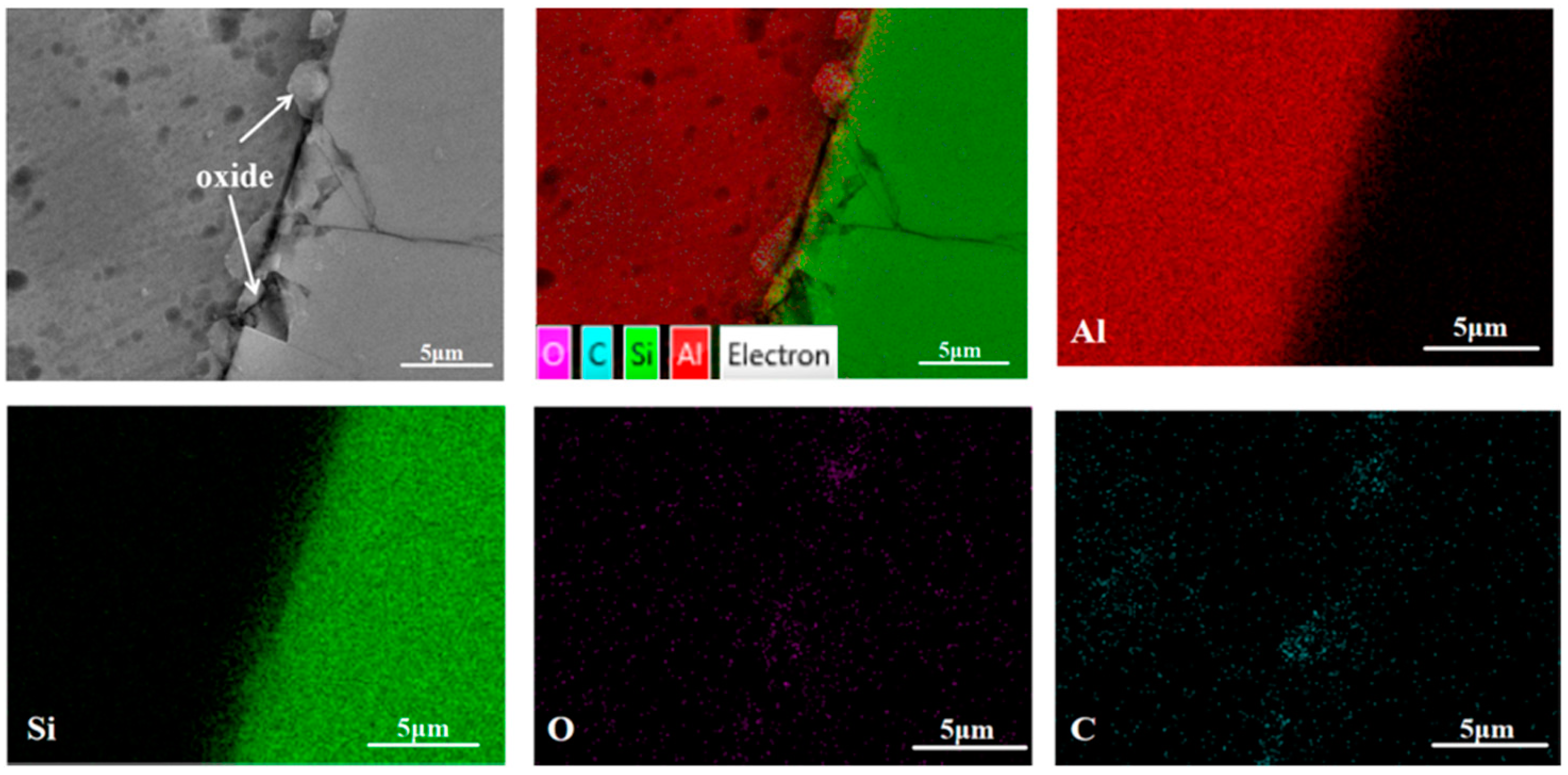

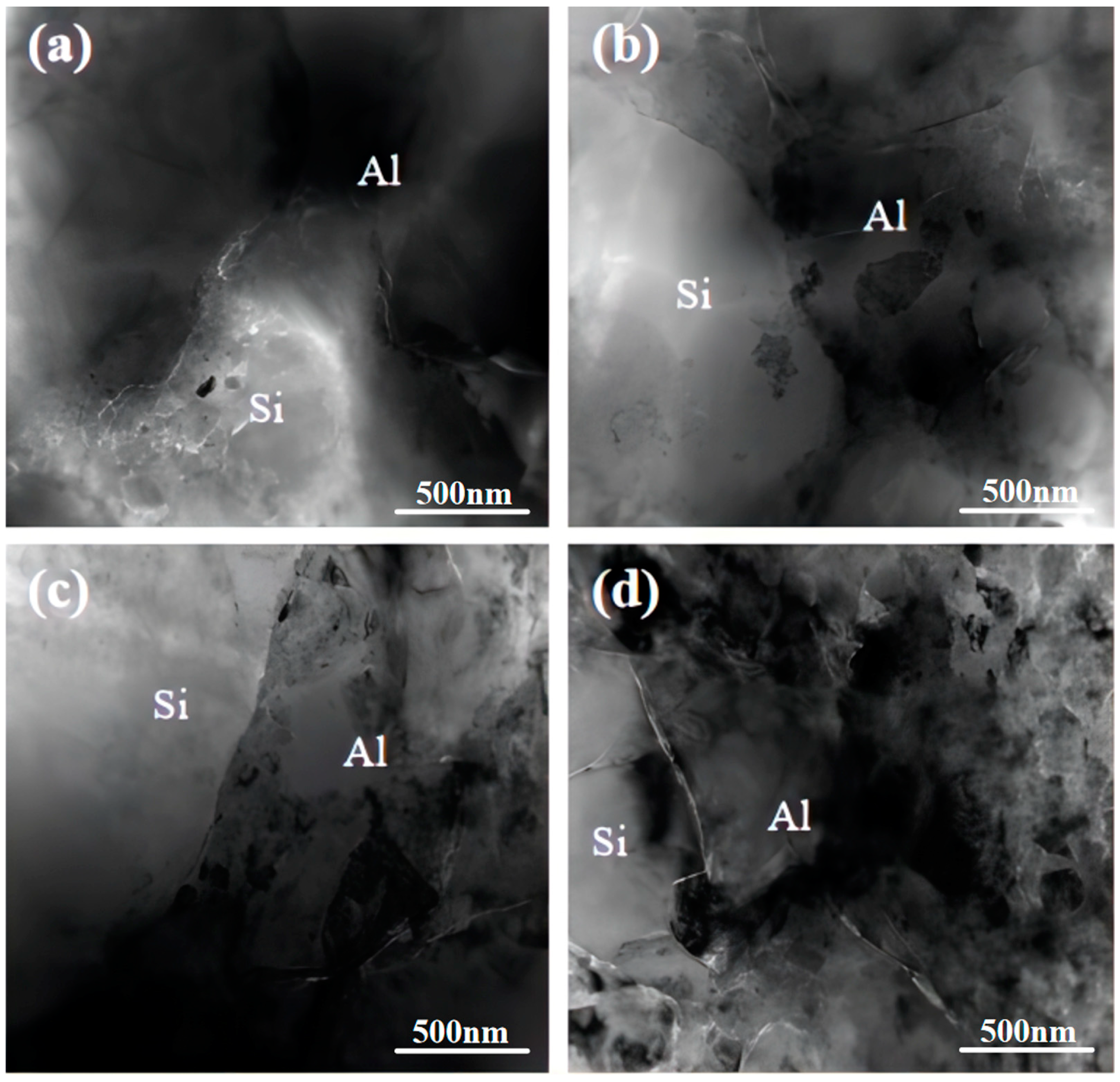

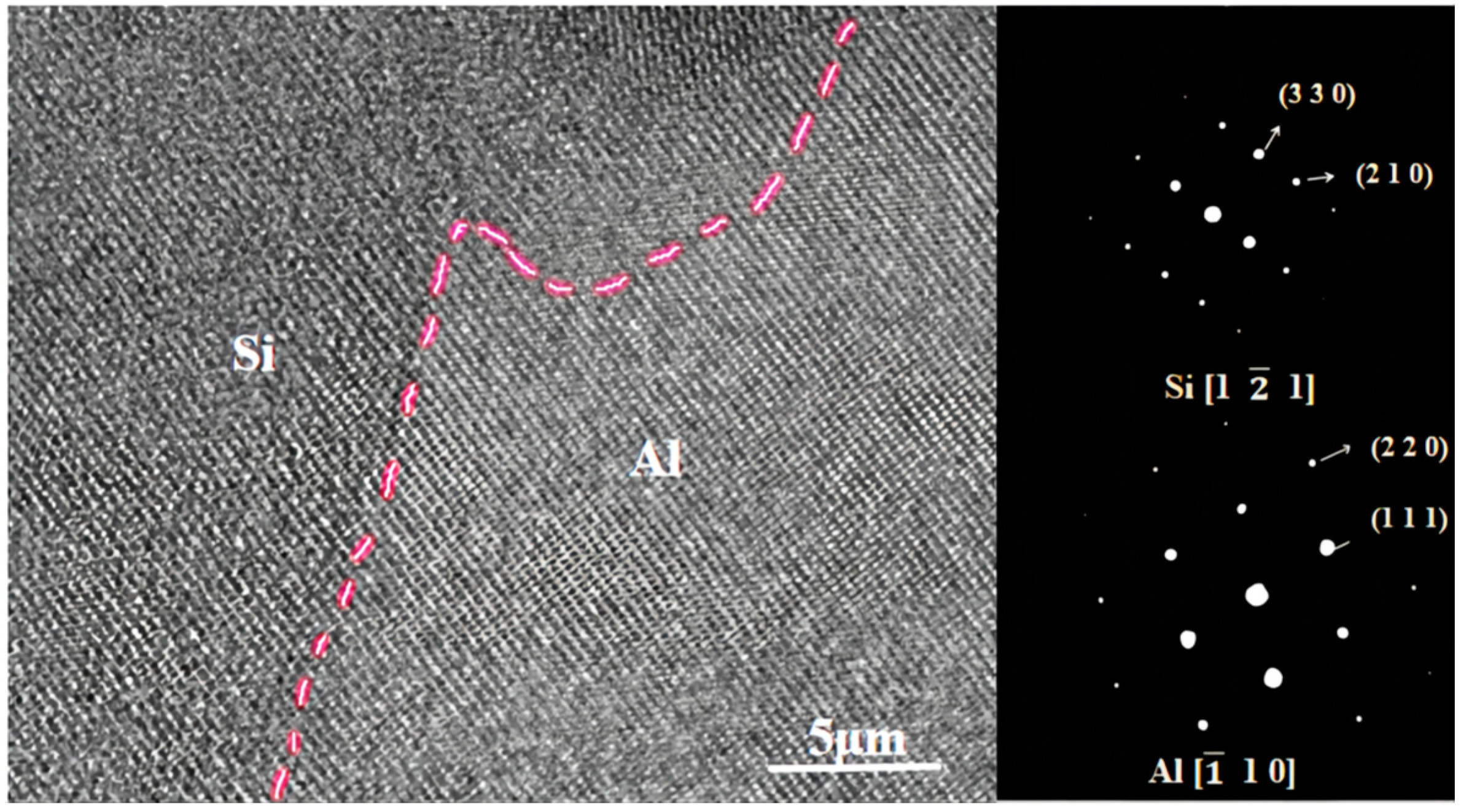

3.1. Influence of Sintering Temperature on the Material Structure and Interface

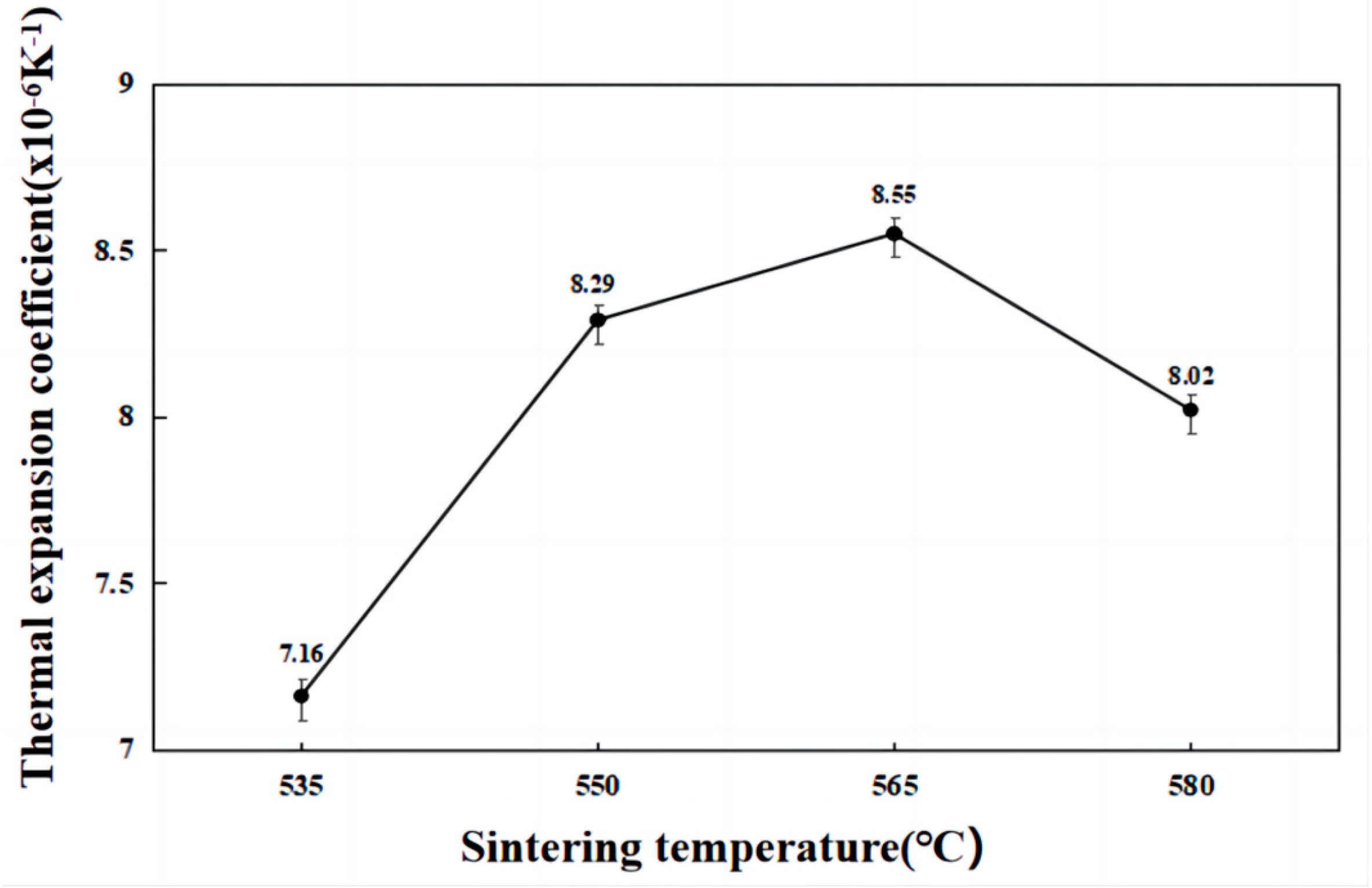

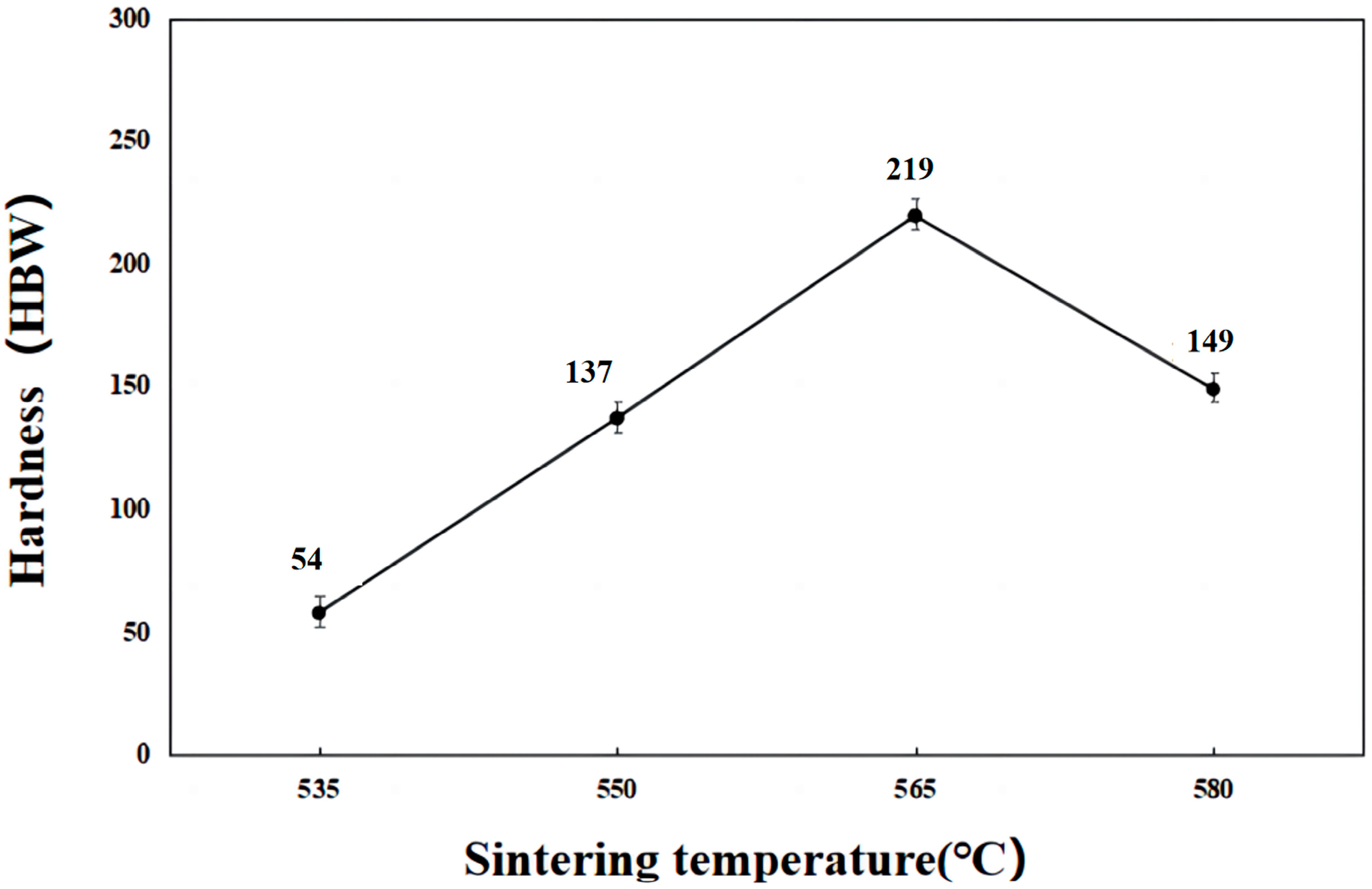

3.2. Influence of Sintering Temperature on Material Properties

4. Conclusions

- (1)

- In the discharge plasma sintering process, the sintering temperature is a critical parameter. Within a certain range, increasing the temperature and extending the sintering time can effectively enhance the material’s wettability. This enables full particle rearrangement and dissolution–precipitation processes, ultimately improving the microstructural properties of the materials;

- (2)

- The material achieves its most compact microstructure and the smallest number of pores at a sintering temperature of 565 °C;

- (3)

- At a sintering temperature of 565 °C, the material exhibited a thermal expansion coefficient of 8.55 × 10−⁶ K−1, a high thermal conductivity of 134.6 W/m·K, a density and relative density of 2.415 g/cm3 and 97.75%, respectively, and a high hardness of 219 HBW. These characteristics represent the best overall performance, meeting the requirements of electronic packaging materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Feng, C.P.; Yang, L.Y.; Yang, J.; Bai, L.; Bao, R.Y.; Liu, Z.Y.; Yang, W. Recent advances in polymer-based thermal interface materials for thermal management: A mini-review. Compos. Commun. 2020, 22, 100528. [Google Scholar] [CrossRef]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Li, R.; Yang, X.; Li, J.; Shen, Y.; Zhang, L.; Lu, R.; Zhang, T. Review on polymer composites with high thermal conductivity and low dielectric properties for electronic packaging. Mater. Today Phys. 2022, 22, 100594. [Google Scholar] [CrossRef]

- Yu, K.; Li, S.J.; Chen, L.S. Microstructure characterization and thermal properties of hypereutectic Si-Al alloy for electronic packaging applications. Trans. Nonferrous Met. Soc. China 2012, 6, 1412–1417. [Google Scholar] [CrossRef]

- Wang, F.; Xiong, B.; Zhang, Y.; Zhu, B.; Liu, H.; Wei, Y. Microstructure, thermo-physical and mechanical properties of spray-deposited Si–30Al alloy for electronic packaging application. Mater. Charact. 2008, 10, 1455–1457. [Google Scholar] [CrossRef]

- Jun, F.A.N.G.; Zhong, Y.H.; Xia, M.K.; Zhang, F.W. Mechanical and thermo-physical properties of rapidly solidified Al50SiCu(Mg) alloys for thermal management application. Trans. Nonferrous Met. Soc. China 2021, 31, 586–594. [Google Scholar]

- Zhang, W.; Ding, D.; Gao, P. High volume fraction Si particle-reinforced aluminium matrix composites fabricated by a filtration squeeze casting route. Mater. Des. 2016, 90, 834–838. [Google Scholar] [CrossRef]

- Raghukiran, N.; Kumar, R. Effect of scandium addition on the microstructure, mechanical and wear properties of the spray formed hypereutectic aluminum–silicon alloys. Mater. Sci. Eng. A 2015, 641, 138–147. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Wei, S.H.; Fan, J.Z.; Ma, Z.L.; Zuo, T. Mechanical Properties of a Low-thermal-expansion Aluminum/Silicon Composite Produced by Powder Metallurgy. J. Mater. Sci. Technol. 2014, 30, 417–422. [Google Scholar] [CrossRef]

- Jia, Q.J.; Liu, J.Y.; Li, Y.X.; Wang, W.S. Microstructure and properties of electronic packaging box with high silicon aluminum-base alloy by semi-solid thixoforming. Trans. Nonferrous Met. Soc. China 2013, 23, 80–85. [Google Scholar] [CrossRef]

- Caiju, L.; Jidong, Z.; Xinkun, Z.; Bingbing, S.; Hailin, T.; Jie, L.; Mengchun, X. Preparation of pure Aluminum nanocrystalline materials by High energy ball milling. Powder Metall. 2006, 24, 457–459. [Google Scholar]

- Saraswat, E.; Maharana, H.S.; Murty, S.N.; Shekhar, S.; Kar, K.K.; Ramkumar, J.; Mondal, K. Fabrication of Al-Si controlled expansion alloys by unique combination of pressureless sintering and hot forging. Adv. Powder Technol. Int. J. Soc. Powder Technol. Jpn. 2020, 31, 2820–2832. [Google Scholar] [CrossRef]

- Almubarak, A.A. The Effects of Heat on Electronic Components. Int. J. Eng. Res. Appl. 2017, 7, 52–57. [Google Scholar] [CrossRef]

- Lee, H.S.; Jeon, K.Y.; Kim, H.Y.; Hong, S.H. Fabrication process and thermal properties of SiCp/Al metal matrix composites for electronic packaging applications. J. Mater. Sci. 2000, 35, 6231–6236. [Google Scholar] [CrossRef]

- Wan, Y.J.; Li, G.; Yao, Y.M.; Zeng, X.L.; Zhu, P.L.; Sun, R. Recent advances in polymer-based electronic packaging materials. Compos. Commun. 2020, 19, 154–167. [Google Scholar] [CrossRef]

- Dai, H.A.; Liu, X.F. Refinement performance and mechanism of an Al-50Si alloy. Mater. Charact. 2008, 59, 1559–1563. [Google Scholar] [CrossRef]

- Liu, Z.; Liang, J.; Su, S.; Zhang, C.; Li, J.; Yang, M.; Wang, D. Preparation of defect-free alumina insulation film using layer-by-layer electrohydrodynamic jet deposition for high temperature applications. Ceram. Int. 2021, 47, 14498–14505. [Google Scholar] [CrossRef]

- Li, Y.X.; Liu, J.Y.; Wang, W.S.; Liu, G.Q. Microstructures and properties of Al-45%Si alloy prepared by liquid-solid separation process and spray deposition. Trans. Nonferrous Met. Soc. China 2013, 23, 970–976. [Google Scholar] [CrossRef]

- Alves, S.J.F.; de Sousa, M.M.S.; de Araújo, E.R.; Filho, F.A.; dos Santos, M.J.; de Araújo Filho, O.O. Processing of Metal Matrix AA2124 Aluminium Alloy Composites Reinforced by Alumina and Silicon Carbide by Powder Metallurgy Techniques. Mater. Sci. Forum 2014, 802, 84–89. [Google Scholar] [CrossRef]

- Wei, L.; Zhenhua, C.; Ding, C.; Cang, F.; Canrang, W. Thermal fatigue behavior of Al–Si/SiCp composite synthesized by spray deposition. J. Alloys Compd. 2010, 504 (Suppl. S1), S522–S526. [Google Scholar] [CrossRef]

- Qiu, T.; Wu, M.; Du, Z.; Chen, G.; Zhang, L.; Qu, X. Microstructure evolution and densification behaviour of powder metallurgy Al-Cu-Mg-Si alloy. Powder Metall. 2020, 63, 54–63. [Google Scholar] [CrossRef]

- Etter, T.; Papakyriacou, M.; Schulz, P.; Uggowitzer, P.J. Physical properties of graphite/aluminium composites produced by gas pressure infiltration method. Carbon 2003, 41, 1017–1024. [Google Scholar] [CrossRef]

- Yu, K.; Li, C.; Wang, R.; Yang, J. Production and Properties of a Spray Formed 70%Si-Al. Mater. Trans. 2008, 49, 685–687. [Google Scholar] [CrossRef]

- Lee, J.I.; Hong, T.W.; Kim, I.H.; Ur, S.C.; Lee, Y.G.; Ryu, S.L. Synthesis and Evaluations of Microstructure Properties on Al-(50, 60, 70 mass%)Si Systems by Mechanical Alloying. Mater. Sci. Forum 2004, 449, 249–252. [Google Scholar] [CrossRef]

- Fan, X.; Ni, N.; Wang, X.; Hao, W.; Guo, F.; Zhao, X. Mechanically isotropic alumina prepared by spark plasma sintering: The role of pyrolytic carbon and multilayer graphene. J. Eur. Ceram. Soc. 2021, 41, 4242–4251. [Google Scholar] [CrossRef]

- Rousselle, M.; Ansart, F.; de Beauvoir, T.H.; Fradet, G.; Estournès, C. Phase evolution and sinterability of lanthanum phosphate-towards a below 600 °C Spark Plasma Sintering. J. Eur. Ceram. Soc. 2021, 41, 7261–7268. [Google Scholar] [CrossRef]

- Lee, J.H.; Oh, I.H.; Jang, J.H.; Kim, J.H.; Hong, S.K.; Park, H.K. Effect of Mechanical Alloying on the Microstructural Evolution of Al60Cr30Si10 Alloys Processed by Spark Plasma Sintering. Met. Mater. Int. 2020, 27, 1147–1154. [Google Scholar] [CrossRef]

- Vidyasagar, C.S.; Karunakar, D.B. Effect of spark plasma sintering and reinforcements on the formation of ultra-fine and nanograins in AA2024-TiB2-Y hybrid composites. Prog. Nat. Sci. Mater. Int. 2022, 32, 79–86. [Google Scholar] [CrossRef]

- Zhang, X.; Qin, Y.; Jin, J. High-efficiency and energy-conservation grinding technology using a special ceramic-medium stirred mill: A pilot-scale study. Powder Technol. 2022, 396, 354–365. [Google Scholar] [CrossRef]

| Element | Purity (wt. %) | Median Particle Size (µm) |

|---|---|---|

| Al | ≥99.5 | 25 |

| Si | ≥99.5 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, Z.; Wang, Z.; Li, Y.; Li, R. Effect of Spark Plasma Sintering Temperature on the Microstructure and Thermophysical Properties of High-Silicon–Aluminum Composites. Coatings 2024, 14, 299. https://doi.org/10.3390/coatings14030299

Kong Z, Wang Z, Li Y, Li R. Effect of Spark Plasma Sintering Temperature on the Microstructure and Thermophysical Properties of High-Silicon–Aluminum Composites. Coatings. 2024; 14(3):299. https://doi.org/10.3390/coatings14030299

Chicago/Turabian StyleKong, Zhaoyang, Zhipeng Wang, Yingmin Li, and Runxia Li. 2024. "Effect of Spark Plasma Sintering Temperature on the Microstructure and Thermophysical Properties of High-Silicon–Aluminum Composites" Coatings 14, no. 3: 299. https://doi.org/10.3390/coatings14030299

APA StyleKong, Z., Wang, Z., Li, Y., & Li, R. (2024). Effect of Spark Plasma Sintering Temperature on the Microstructure and Thermophysical Properties of High-Silicon–Aluminum Composites. Coatings, 14(3), 299. https://doi.org/10.3390/coatings14030299