Microstructure and Mechanical Properties of Electrically Assisted Brazing Joints of Dissimilar Aluminum and Steel Alloys

Abstract

1. Introduction

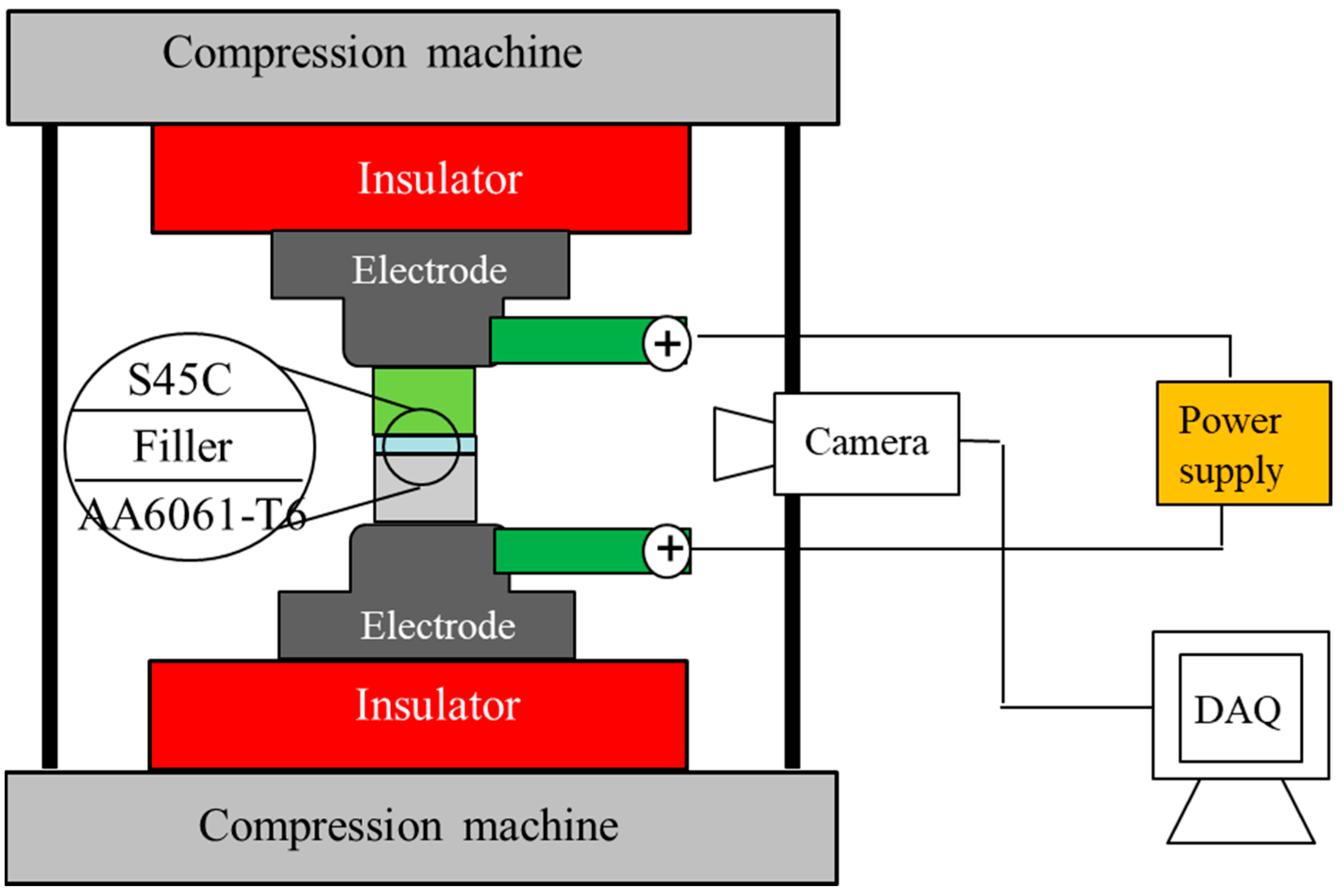

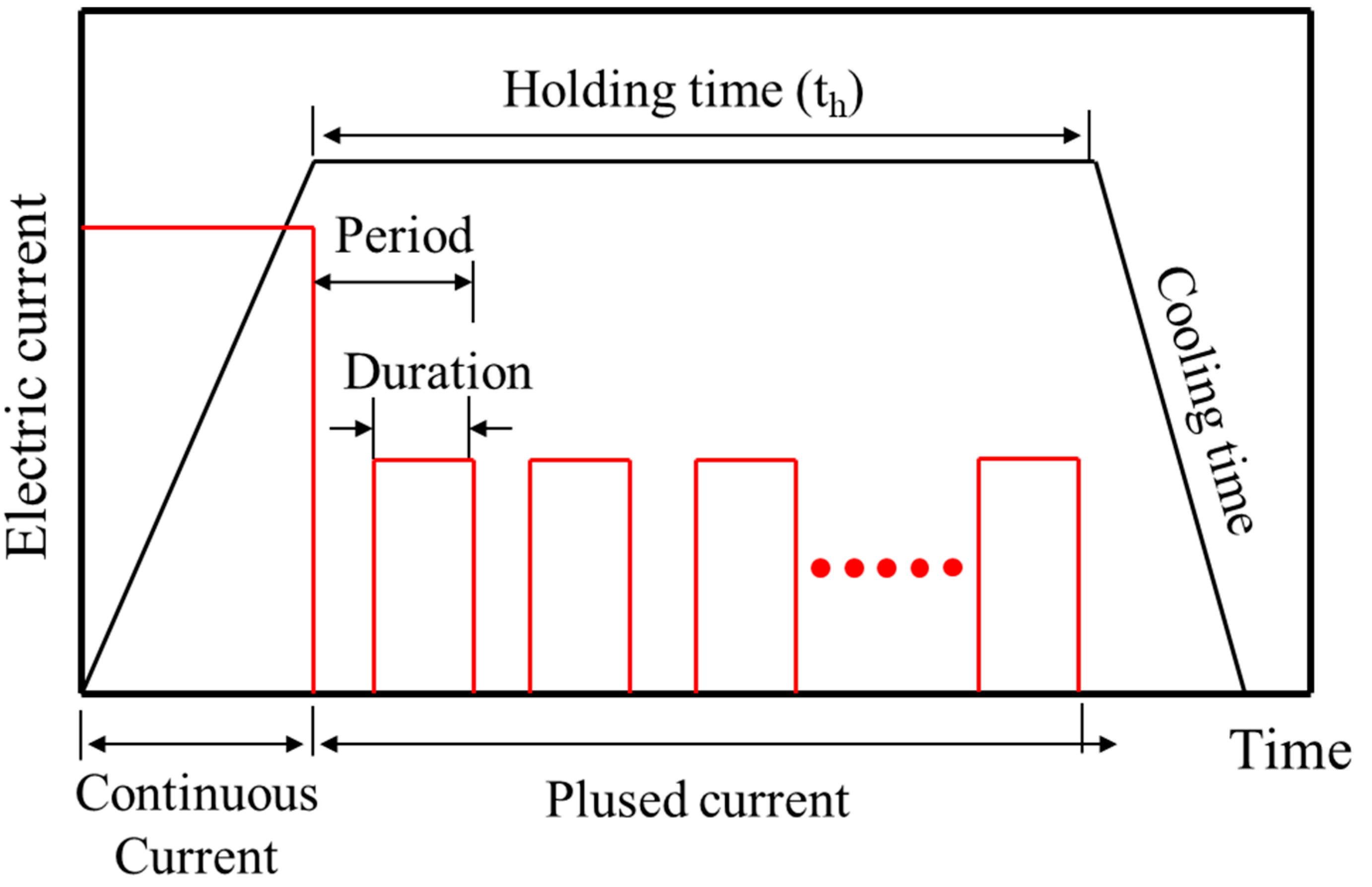

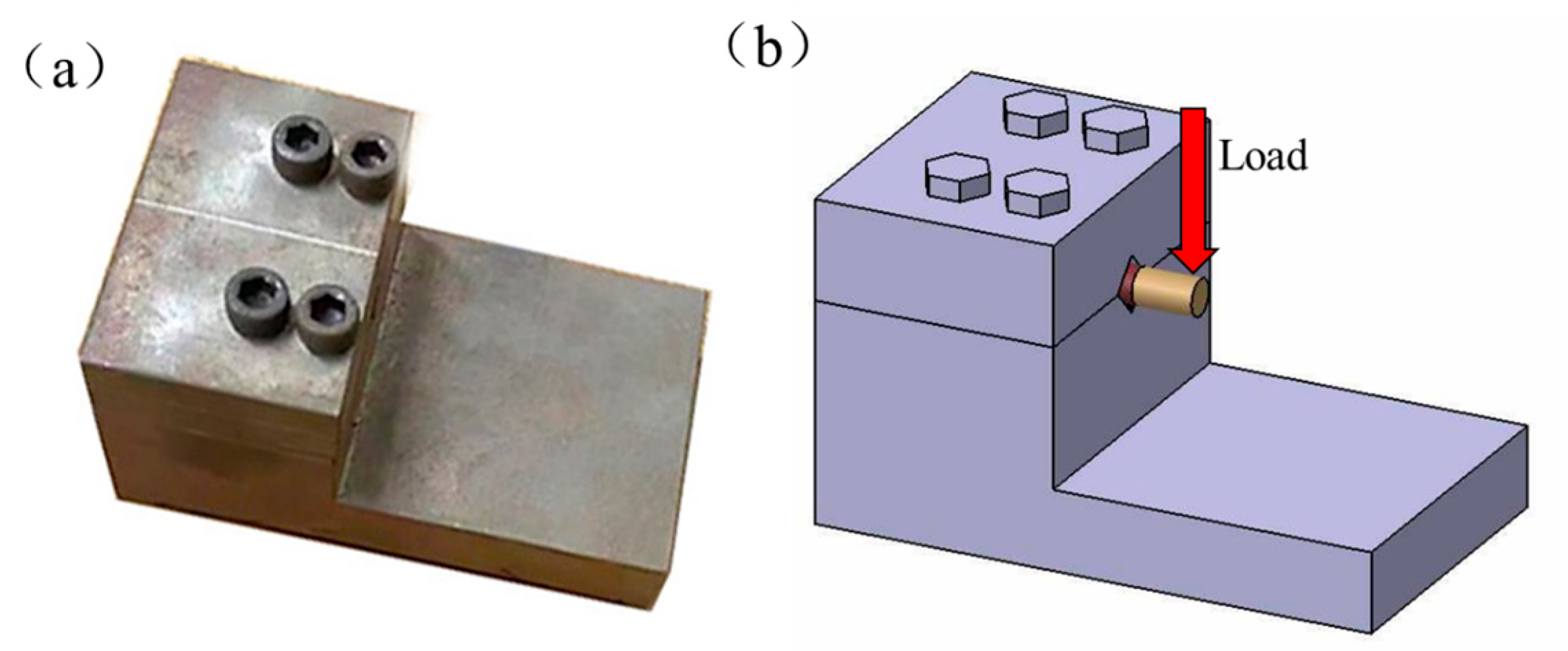

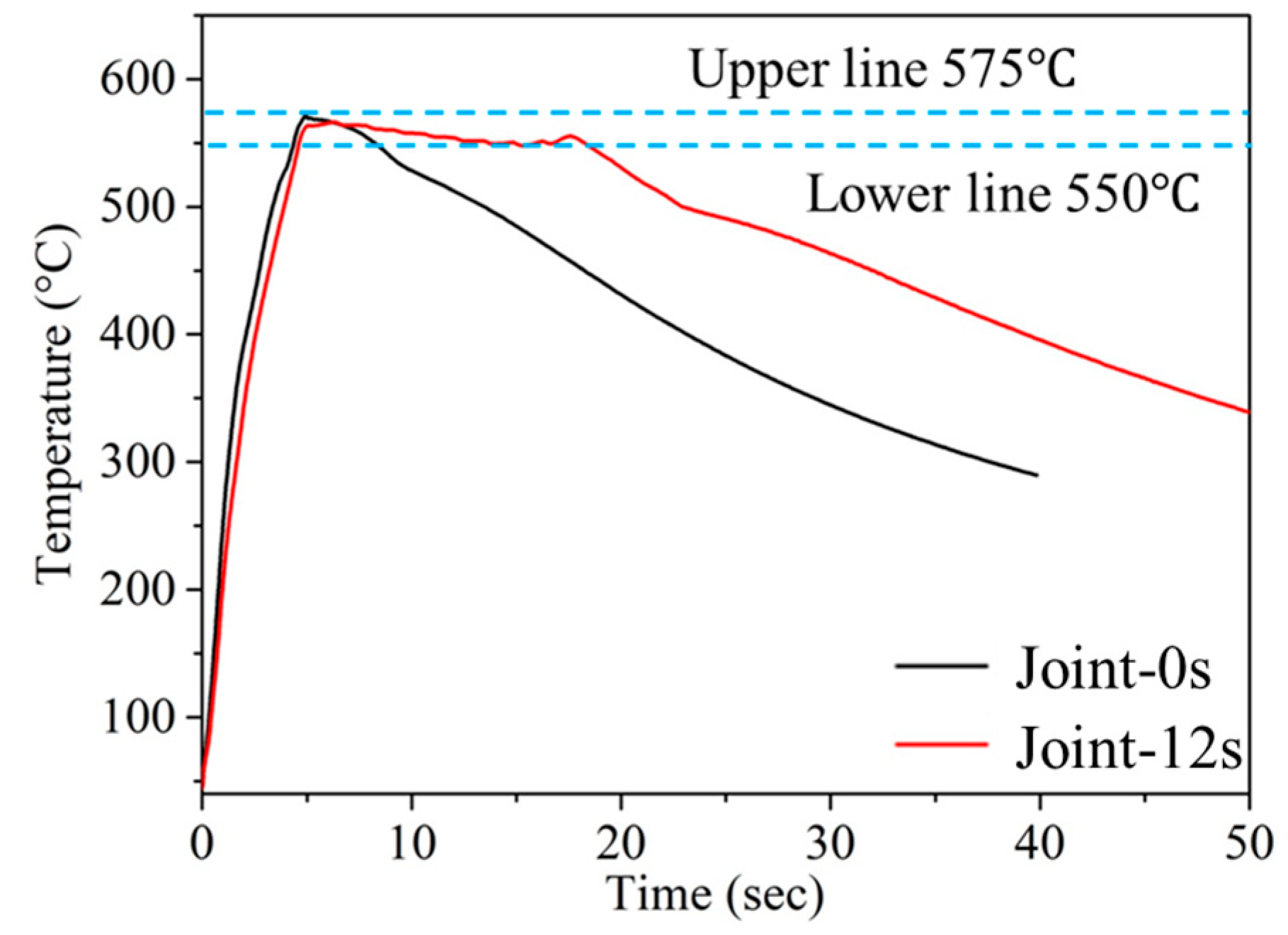

2. Experimental Process

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Song, J.L.; Lin, S.B.; Yang, C.L.; Fan, C. Effects of Si additions on intermetallic compound layer of aluminum–steel TIG welding–brazing joint. J. Alloys Compd. 2009, 488, 31–40. [Google Scholar] [CrossRef]

- Nasiri, A.M.; Li, L.; Kim, S.H.; Zhou, Y.; Weckman, D.C.; Nguyen, T.C. Microstructure and Properties of Laser Brazed Magnesium to Coated Steel. Weld. J. 2011, 90, 212–219. [Google Scholar]

- Qiu, R.F.; Iwamoto, C.; Satonaka, S. The influence of reaction layer on the strength of aluminum/steel joint welded by resistance spot welding. Mater. Charact. 2009, 60, 156–159. [Google Scholar] [CrossRef]

- Hokamoto, K.; Nakata, K.; Moria, A.; Tsuda, S.; Tsumura, T.; Inoue, A. Dissimilar material welding of rapidly solidified foil and stainless steel plate using underwater explosive welding technique. J. Alloys Compd. 2009, 472, 507–511. [Google Scholar] [CrossRef]

- Liu, X.; Lan, S.H.; Ni, J. Analysis of process parameters effects on friction stir welding of dissimilar aluminum alloy to advanced high strength steel. Mater. Design 2014, 59, 50–62. [Google Scholar] [CrossRef]

- Ogura, T.; Saito, Y.; Nishida, T.; Nishida, H.; Yoshida, T.; Omichi, N.; Fujimoto, M.; Hirose, A. Partitioning evaluation of mechanical properties and the interfacial microstructure in a friction stir welded aluminum alloy/stainless steel lap joint. Scr. Mater. 2012, 66, 531–534. [Google Scholar] [CrossRef]

- Das, H.; Jana, S.S.; Pal, T.K.; De, A. Numerical and Experimental Investigation on Friction Stir Lap Welding of Aluminum to Steel. Sci. Technol. Weld. Join. 2014, 19, 69–75. [Google Scholar] [CrossRef]

- Acarer, M.; Demir, B. An investigation of mechanical and metallurgical properties of explosive welded aluminum–dual phase steel. Mater. Lett. 2008, 62, 4158–4160. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Huang, J.H.; Cheng, Z.; Zheng, Y.; Chi, H.; Li, P.; Chen, S. Study on MIG-TIG double-sided arc welding-brazing of aluminum and stainless steel. Mater. Lett. 2016, 172, 146–148. [Google Scholar] [CrossRef]

- Lin, S.B.; Song, J.L.; Yang, C.L.; Fan, C.L.; Zhang, D.W. Brazability of dissimilar metals tungsten inert gas butt welding–brazing between aluminum alloy and stainless steel with Al–Cu filler metal. Mater. Design 2010, 31, 2637–2642. [Google Scholar] [CrossRef]

- Findik, F. Recent developments in explosive welding. Mater. Design 2011, 32, 1081–1093. [Google Scholar] [CrossRef]

- Milani, A.M.; Paidar, M.; Khodabandeh, A.; Nategh, S. Influence of filler wire and wire feed speed on metallurgical and mechanical properties of MIG welding-brazing of automotive galvanized steel/5754 aluminum alloy in a lap joint configuration. Int. J. Adv. Manuf. Tech. 2016, 09, 1495–1506. [Google Scholar] [CrossRef]

- Yang, J.; Oliveira, J.P.; Li, Y.; Tan, C.; Gao, C.; Zhao, Y.; Yu, Z. Laser techniques for dissimilar joining of aluminum alloys to steels: A critical review. J. Mater. Process. Technol. 2022, 301, 117443. [Google Scholar] [CrossRef]

- Liu, P.; Li, Y.J.; Wang, J.; Guo, J.S. Investigation of interfacial structure of Mg/Al vacuum diffusion-bonded joint. Vacuum 2006, 80, 395–399. [Google Scholar]

- Yang, J.L.; Xue, S.B.; Xue, P.; Lv, Z.P.; Long, W.; Zhang, G.; Zhang, Q.; He, P. Development of Zn–15Al–xZr filler metals for Brazing 6061 aluminum alloy to stainless steel. Mater. Sci. Eng. A 2016, 651, 425–434. [Google Scholar] [CrossRef]

- Dong, H.; Hu, W.; Duan, Y.; Wang, X.; Dong, C. Dissimilar metal joining of aluminum alloy to galvanized steel with Al–Si, Al–Cu, Al–Si–Cu and Zn–Al filler wires. J. Mater. Process. Technol. 2012, 212, 458–464. [Google Scholar] [CrossRef]

- Qin, G.L.; Ji, Y.; Ma, H.; Ao, Z.Y. Effect of modified flux on MIG arc brazing-fusion welding of aluminum alloy to steel butt joint. J. Mater. Process. Technol. 2017, 245, 115–121. [Google Scholar] [CrossRef]

- Mathieu, A.; Pontevicci, S.; Viala, J.; Cicala, E.; Matteï, S.; Grevey, D. Laser brazing of a steel/aluminium assembly with hot filler wire (88% Al, 12% Si). Mater. Sci. Eng. A 2006, 435–436, 19–28. [Google Scholar] [CrossRef]

- Luu, V.T.; Dinh, T.K.A.; Das, H.; Kim, J.-R.; Hong, S.-T.; Sung, H.-M.; Han, H.N. Diffusion Enhancement during Electrically Assisted Brazing of Ferritic Stainless Steel Alloys. Int. J. Precis. Eng. Manuf. Technol. 2018, 5, 613–621. [Google Scholar] [CrossRef]

- Liu, S.Y.; Suzumura, A.; Ikeshoji, T.; Yamazaki, T. Brazing of Stainless Steel to Various Aluminum Alloys in Air. JSME Int. J. Series A 2005, 48, 420–425. [Google Scholar] [CrossRef]

- Yu, J.; Ge, F.; Yu, G.; Zhang, H.; Fan, Y.; Su, Z.; Gao, J. Feasibility study of thermo-compensated resistance brazing welding of 6061 aluminum alloy to 304 stainless steel. J. Mater. Res. Technol. 2023, 23, 6200–6215. [Google Scholar] [CrossRef]

- Zhang, S.; Gao, K.; Hong, S.T.; Ahn, H.; Choi, Y.; Lee, S.; Han, H.N. Electrically assisted solid state lap joining of dissimilar steel S45C and aluminum 6061-T6 alloy. J. Mater. Res. Technol. 2021, 12, 271–282. [Google Scholar] [CrossRef]

- Gao, K.; Zhang, S.; Mondal, M.; Basak, S.; Hong, S.T.; Shim, H. Friction Stir Spot Butt Welding of Dissimilar S45C Steel and 6061-T6 Aluminum Alloy. Metals 2021, 11, 1252. [Google Scholar] [CrossRef]

- Tanaka, K.; Kumagai, M.; Yoshida, H. Dissimilar joining of aluminum alloy and steel sheets by friction stir spot welding. J. Jpn. Inst. Light. Met. 2006, 56, 317–322. [Google Scholar] [CrossRef]

- Zandsalimi, S.; Heidarzadeh, A.; Saeid, T. Dissimilar friction-stir welding of 430 stainless steel and 6061 aluminum alloy: Microstructure and mechanical properties of the joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2018, 233, 1791–1801. [Google Scholar] [CrossRef]

- Fereiduni, E.; Movahedi, M.; Kokabi, A.H. Aluminum/steel joints made by an alternative friction stir spot welding process. J. Mater. Process. Technol. 2015, 224, 1–10. [Google Scholar] [CrossRef]

- Bozzi, S.; Helbert-Etter, A.L.; Baudin, T.; Criqui, B.; Kerbiguet, J.G. Intermetallic compounds in Al 6016/IF-steel friction stir spot welds. Mater. Sci. Eng. A 2010, 527, 4505–4509. [Google Scholar] [CrossRef]

- Li, Y.F.; Hong, S.T.; Choi, H.; Han, H. Solid-state dissimilar joining of stainless steel 316L and Inconel 718 alloys by electrically assisted pressure joining. Mater. Charact. 2019, 154, 161–168. [Google Scholar] [CrossRef]

- Arghavani, M.R.; Kokabi, A.H. Role of zinc layer in resistance spot welding of aluminum to steel. Mater. Design 2016, 102, 106–114. [Google Scholar] [CrossRef]

- Pourali, M.; Abdollah-zadeh, A.; Saeid, T.; Kargar, F. Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminum friction stir welds. J. Alloys Compd. 2017, 715, 1–8. [Google Scholar] [CrossRef]

| Fe | Al | Ni | Mn | Cu | Si | P | C | S | Zn | Ti | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S45C | Bal. | -- | 0.2 | 0.6 | 0.25 | 0.15 | 0.03 | 0.42 | 0.035 | -- | -- |

| AA6061-T6 | 0.7 | Bal. | -- | 0.15 | 0.15 | 0.4 | -- | -- | -- | 0.25 | 0.25 |

| Al718 filler | -- | Bal. | -- | -- | -- | 12 | -- | -- | -- | -- | -- |

| Step | Current Duration (s) | Current Intensity (kA) | Pulse Period (s) | Total Time (s) |

|---|---|---|---|---|

| Continuous current | 5 | 3.8 | 0 | 5 |

| Pulsed current | 1.1 | 1.65 | 1.5 | 12 |

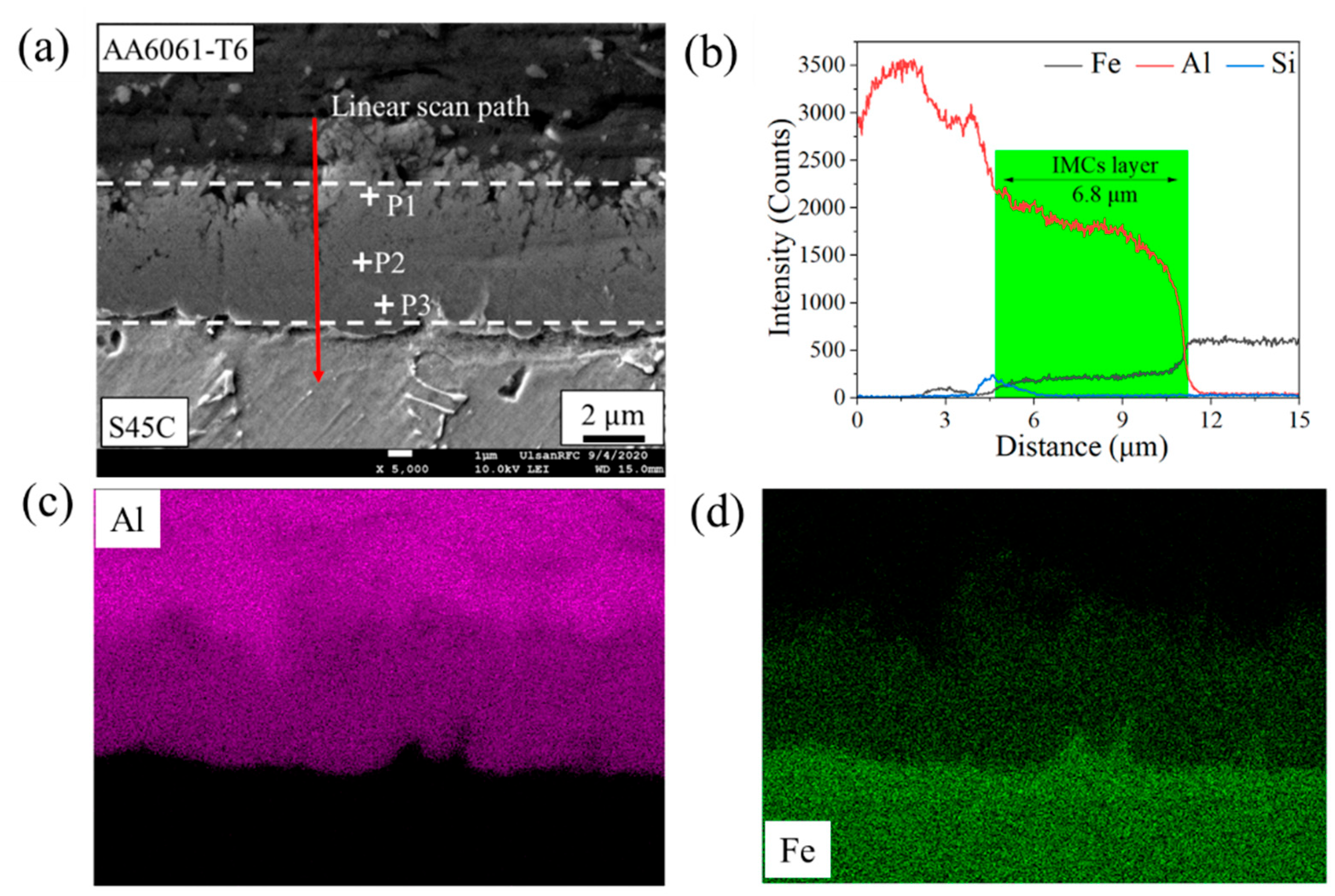

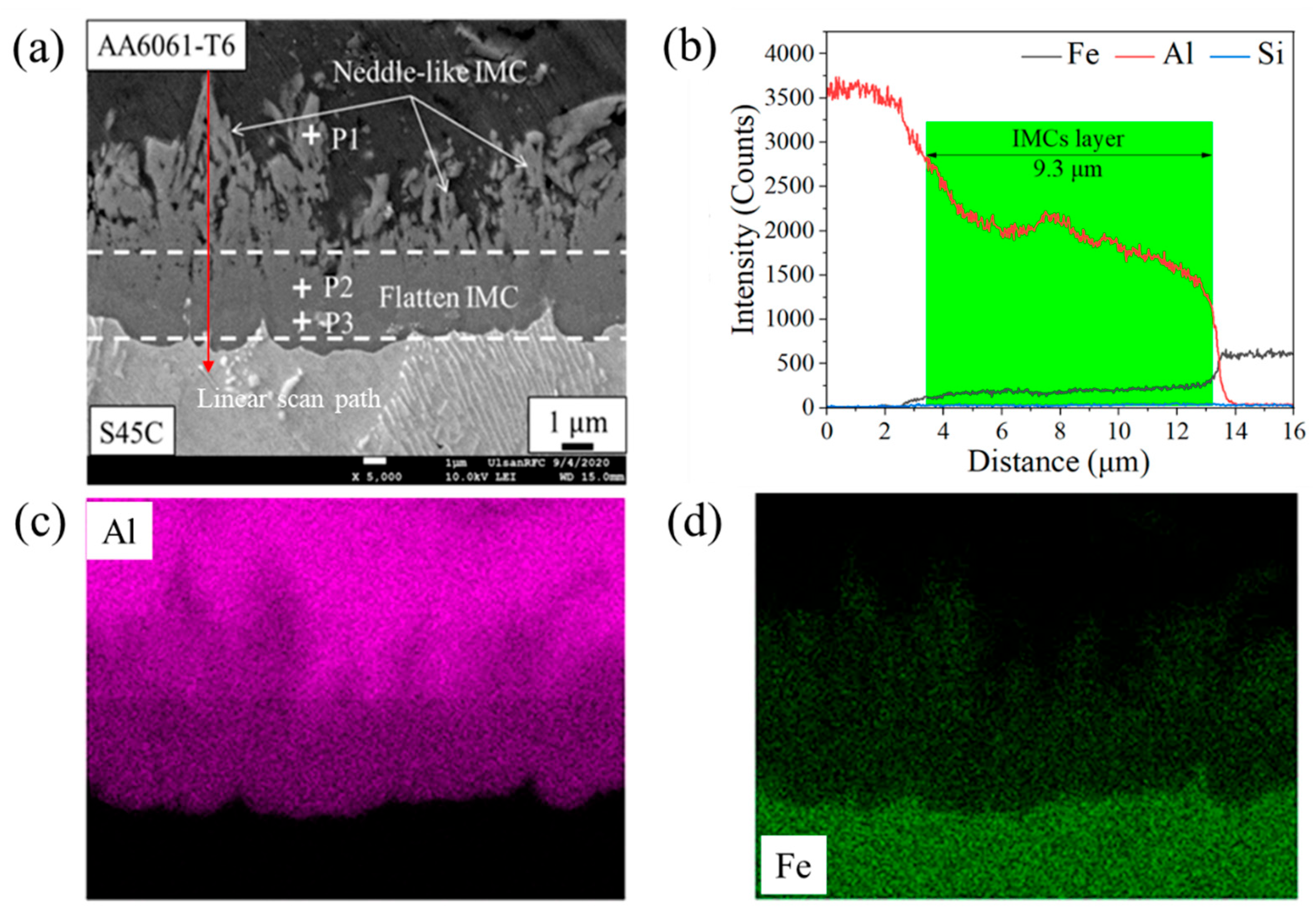

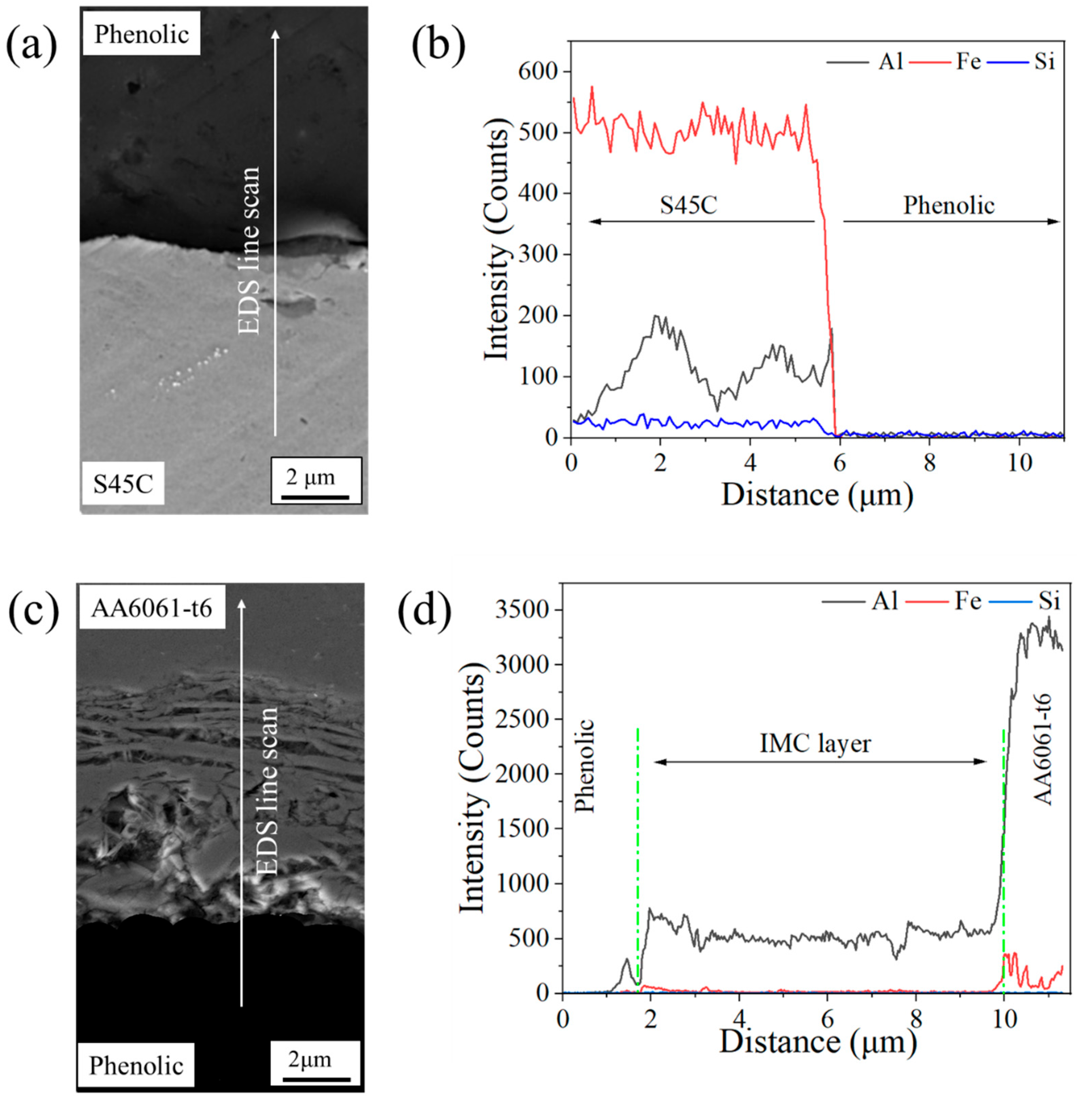

| Joining Condition | Location | Compositions (at.%) | Possible Phase | ||

|---|---|---|---|---|---|

| Al | Fe | Si | |||

| Joint-0s | P1 | 76.65 | 21.61 | 1.74 | FeAl3, FeAl2 |

| P2 | 73.72 | 24.04 | 2.24 | FeAl3, FeAl2 | |

| P3 | 62.13 | 36.69 | 1.18 | Fe2Al5 | |

| Joint-12s | P1 | 72.66 | 26.21 | 1.13 | FeAl3, FeAl2 |

| P2 | 58.72 | 40.04 | 1.24 | Fe2Al5 | |

| P3 | 50.25 | 47.96 | 1.79 | FeAl | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, K.; Liu, G.; Sun, X.; Wang, Y. Microstructure and Mechanical Properties of Electrically Assisted Brazing Joints of Dissimilar Aluminum and Steel Alloys. Coatings 2024, 14, 213. https://doi.org/10.3390/coatings14020213

Gao K, Liu G, Sun X, Wang Y. Microstructure and Mechanical Properties of Electrically Assisted Brazing Joints of Dissimilar Aluminum and Steel Alloys. Coatings. 2024; 14(2):213. https://doi.org/10.3390/coatings14020213

Chicago/Turabian StyleGao, Kun, Guiqi Liu, Xiaojun Sun, and Yu Wang. 2024. "Microstructure and Mechanical Properties of Electrically Assisted Brazing Joints of Dissimilar Aluminum and Steel Alloys" Coatings 14, no. 2: 213. https://doi.org/10.3390/coatings14020213

APA StyleGao, K., Liu, G., Sun, X., & Wang, Y. (2024). Microstructure and Mechanical Properties of Electrically Assisted Brazing Joints of Dissimilar Aluminum and Steel Alloys. Coatings, 14(2), 213. https://doi.org/10.3390/coatings14020213