Experimental and Simulation Studies on Thermal Shock of Multilayer Thermal Barrier Coatings with an Intermediate Transition Layer at 1500 °C

Abstract

1. Introduction

2. Experiments and Numerical Models

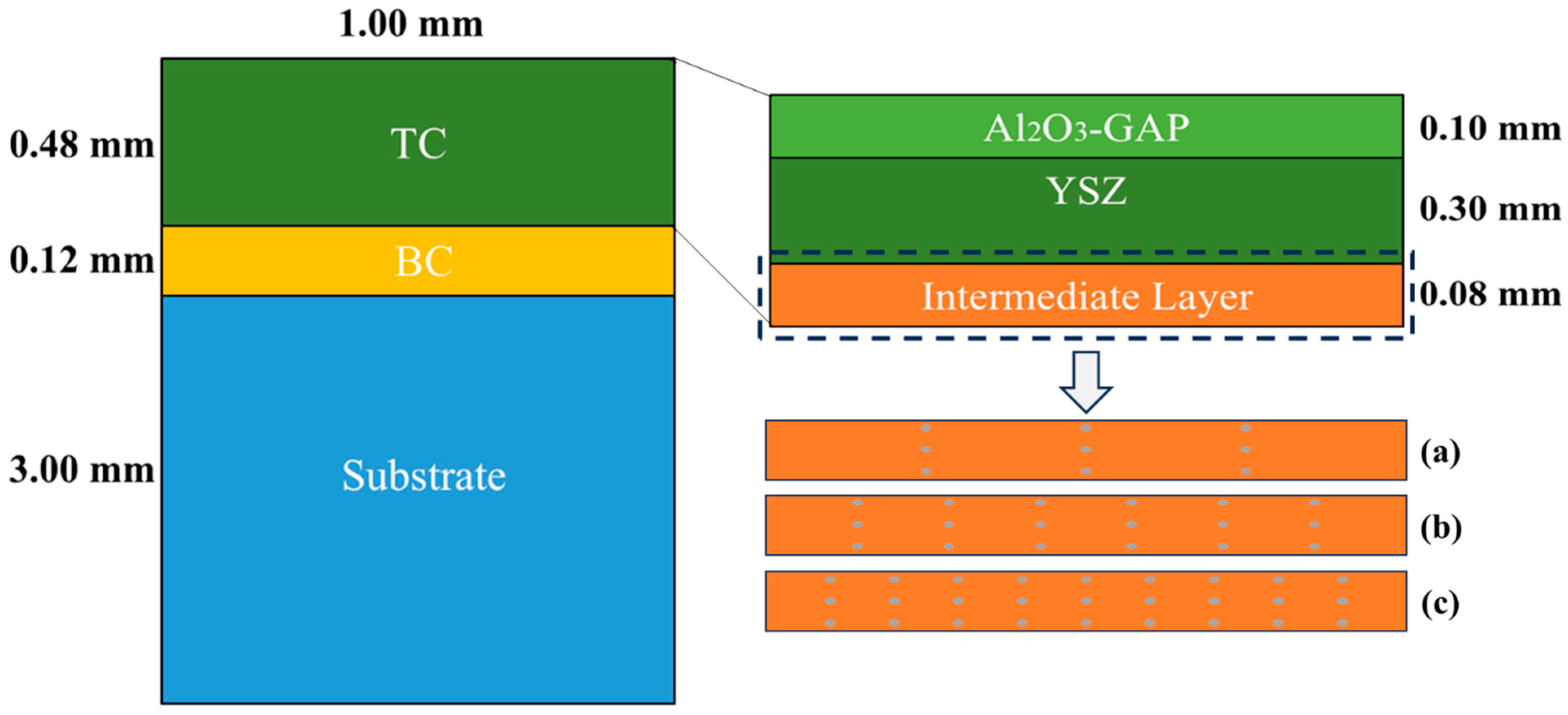

2.1. Coating Preparation

2.2. Thermal Shock Test

2.3. Characterization

2.4. Finite Element Analysis

3. Result and Discussion

3.1. Experiment Characterization

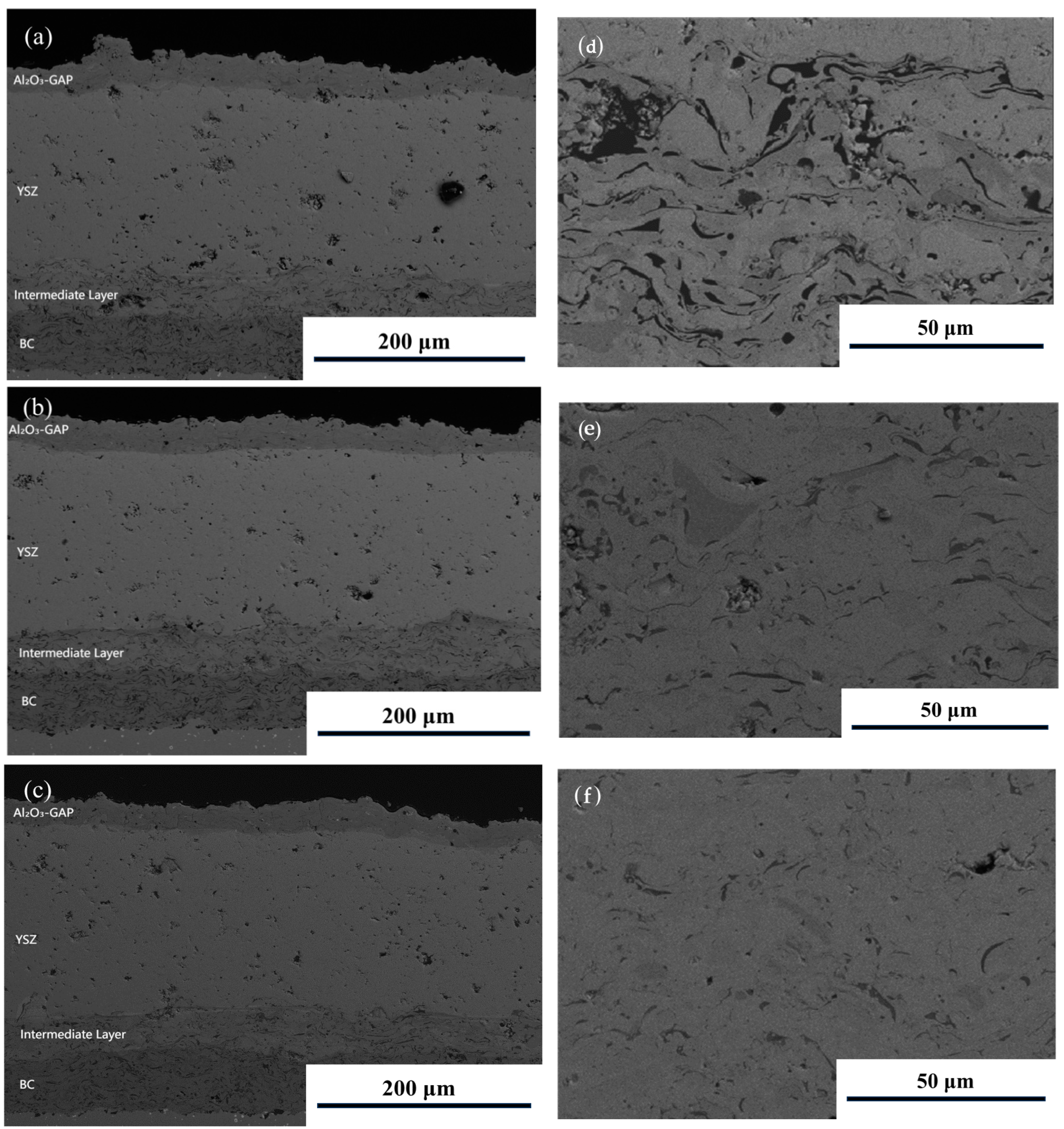

3.1.1. Microscopic Morphology of Sprayed Coatings

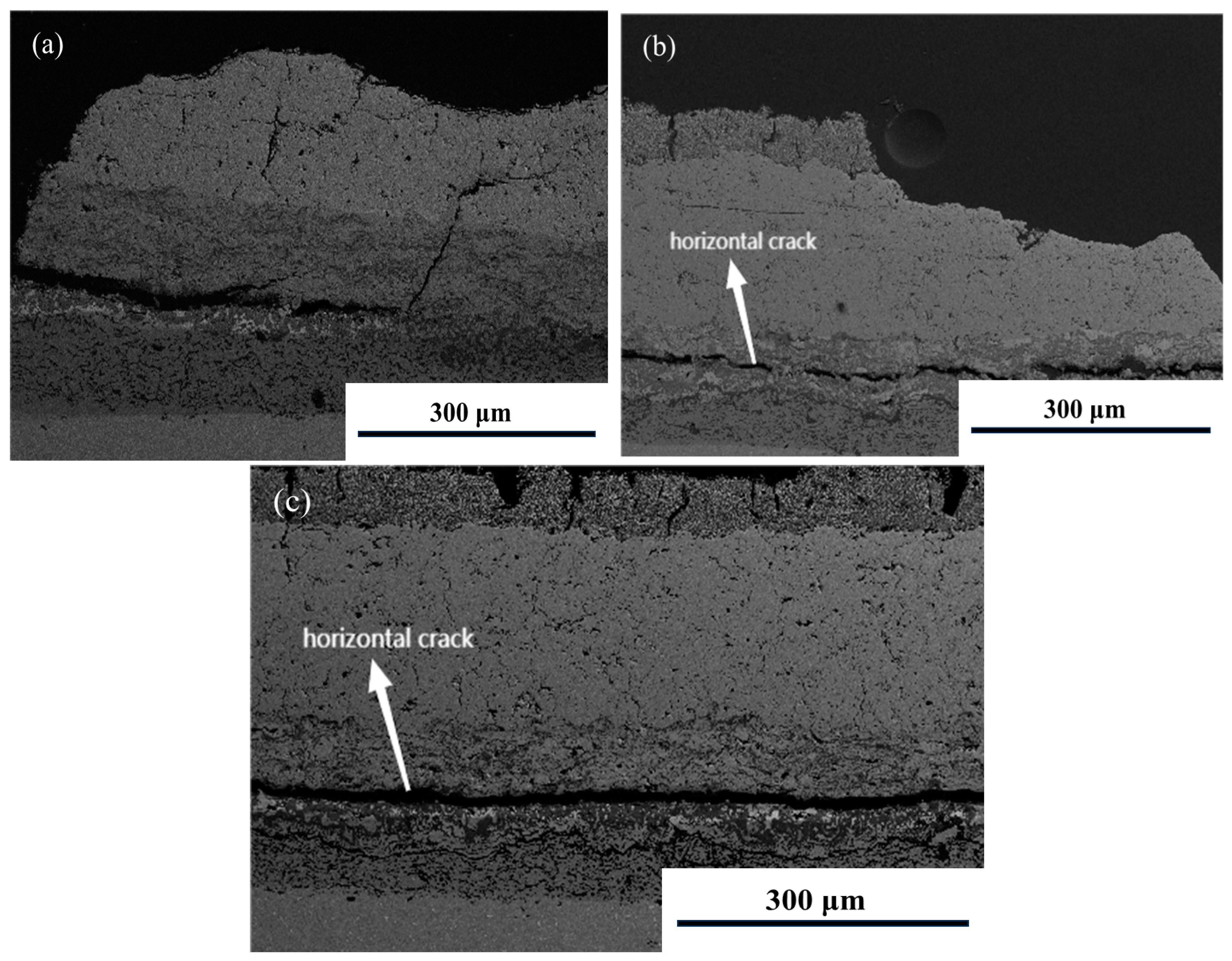

3.1.2. Thermal Shock Resistance

3.2. Simulation of Thermal Stress and Temperature Distributions of AYIB Coatings

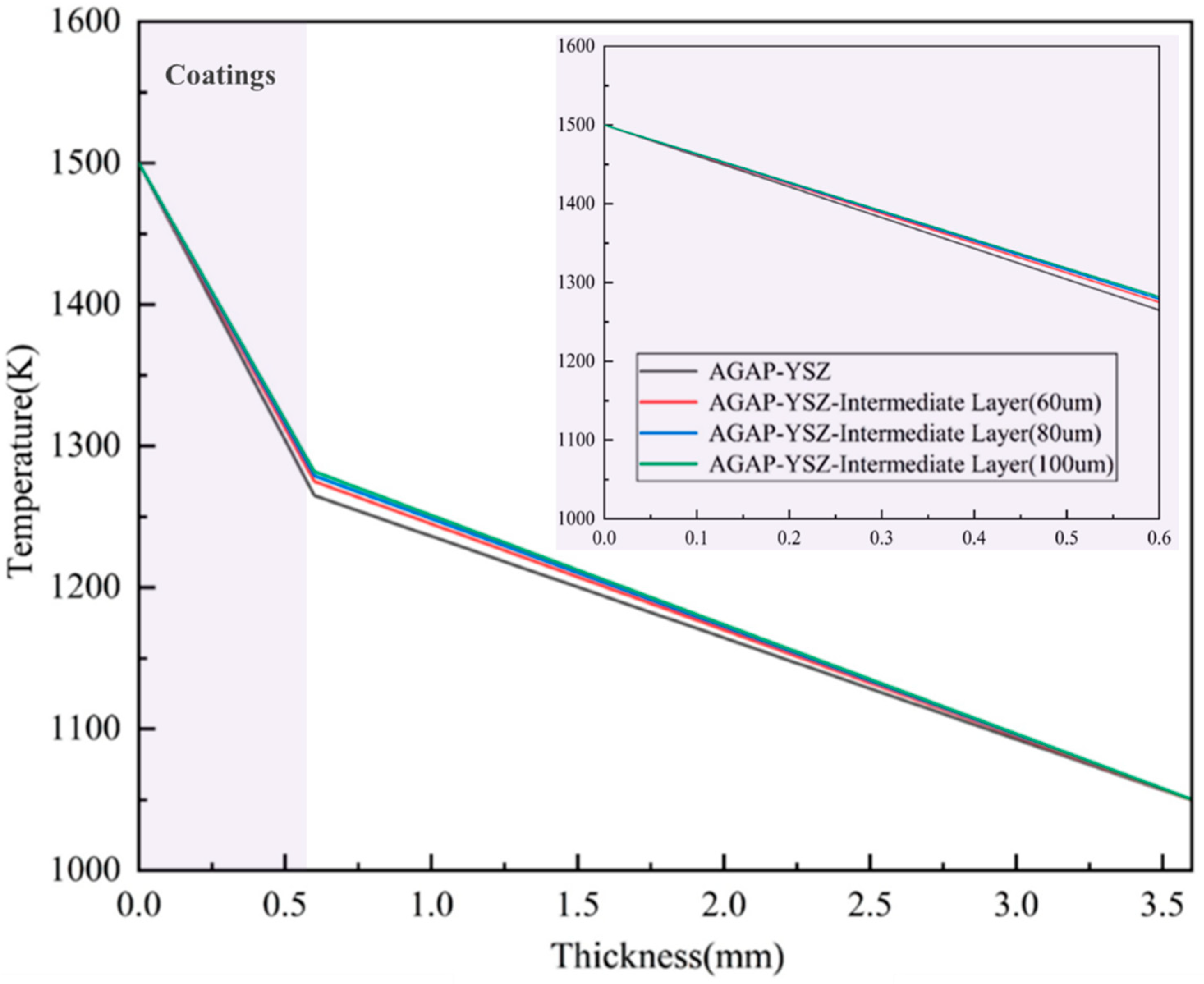

3.2.1. Temperature Distributions of AYIB Coatings

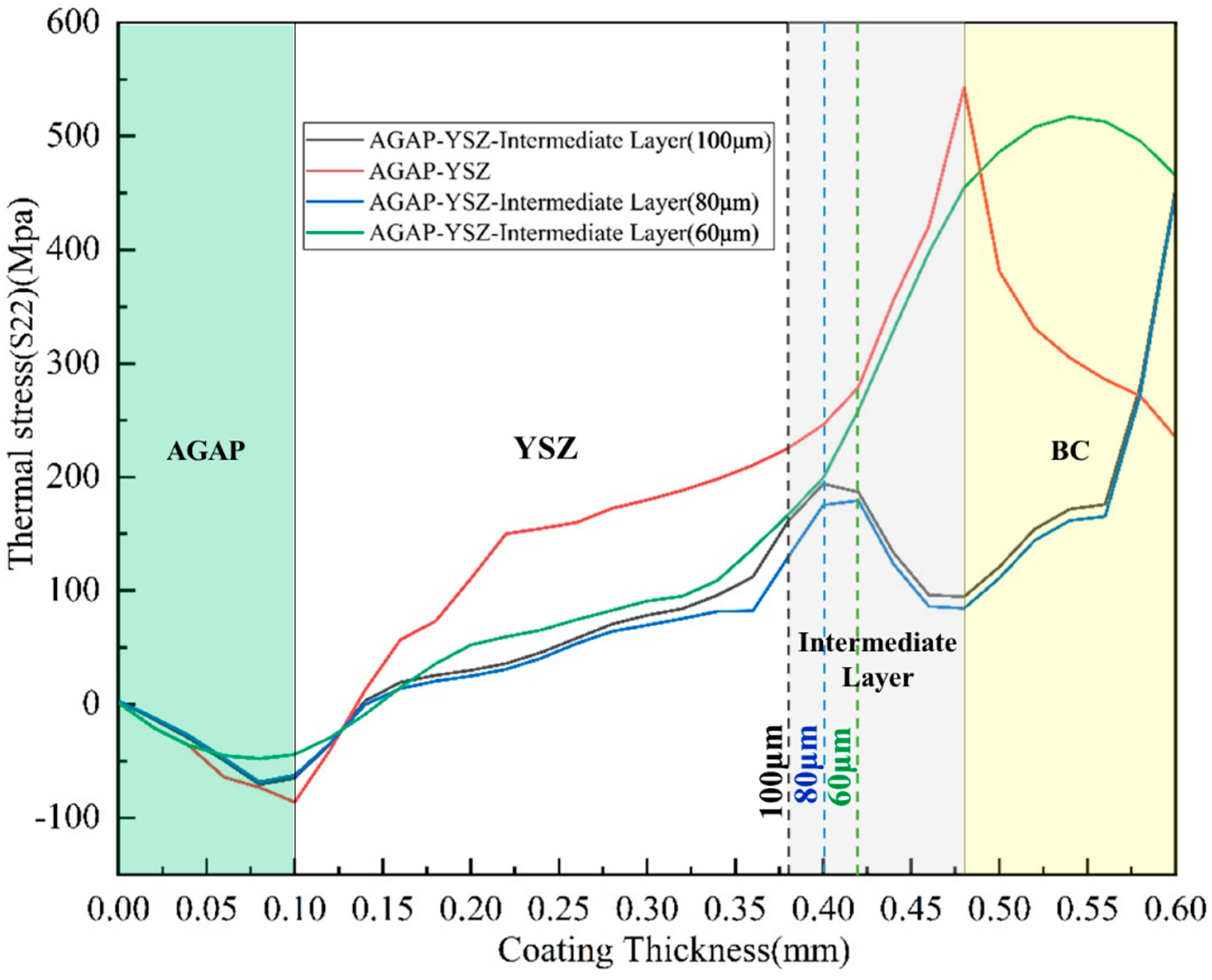

3.2.2. Thermal Stress Distribution of AYIB Coatings

3.3. Simulation of Thermal Stress and Temperature Distributions of AYI(E)B Coatings

3.3.1. Temperature Distributions of AYI(E)B Coatings

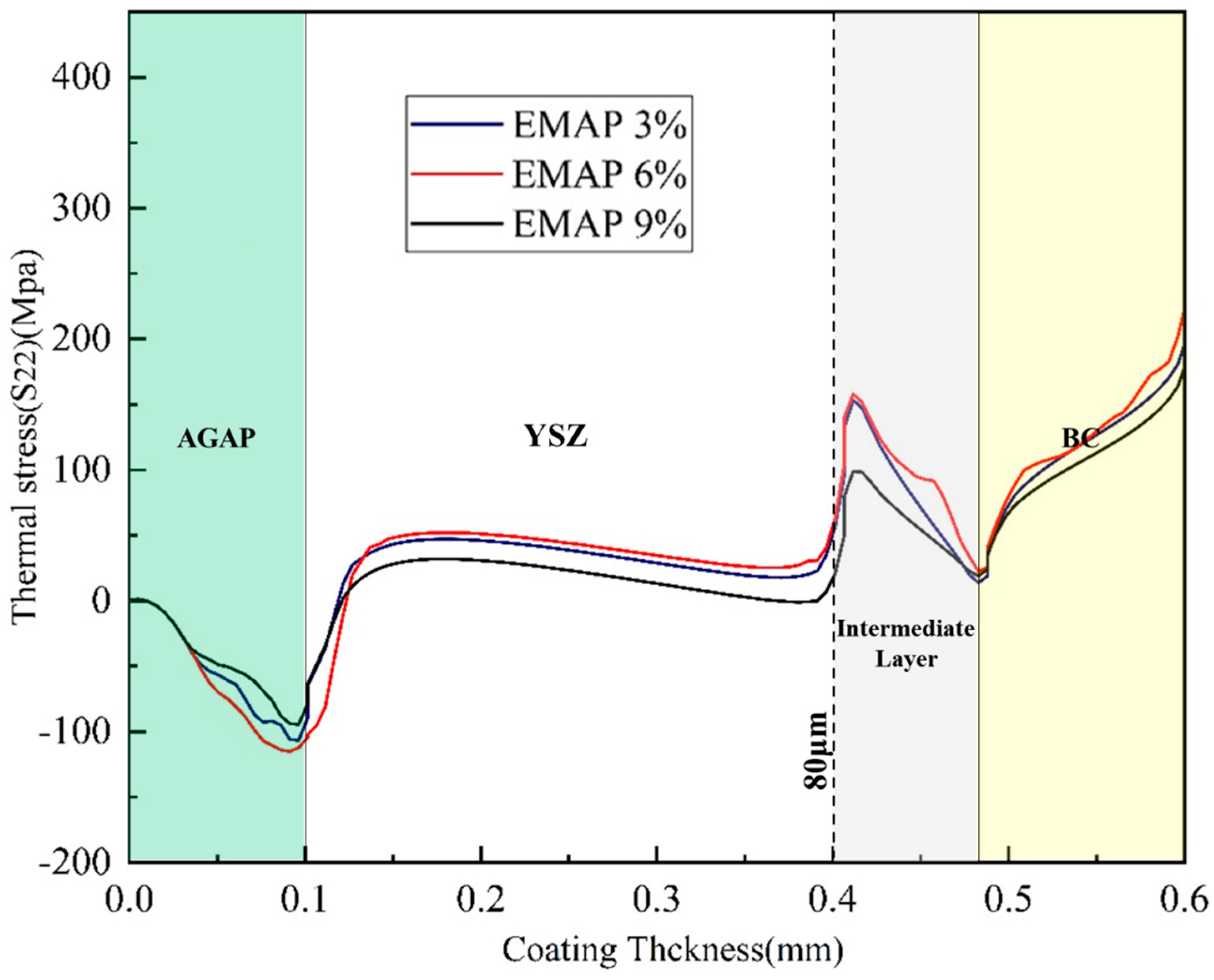

3.3.2. Thermal Stress Distribution of AYI(E)B Coatings

4. Conclusions

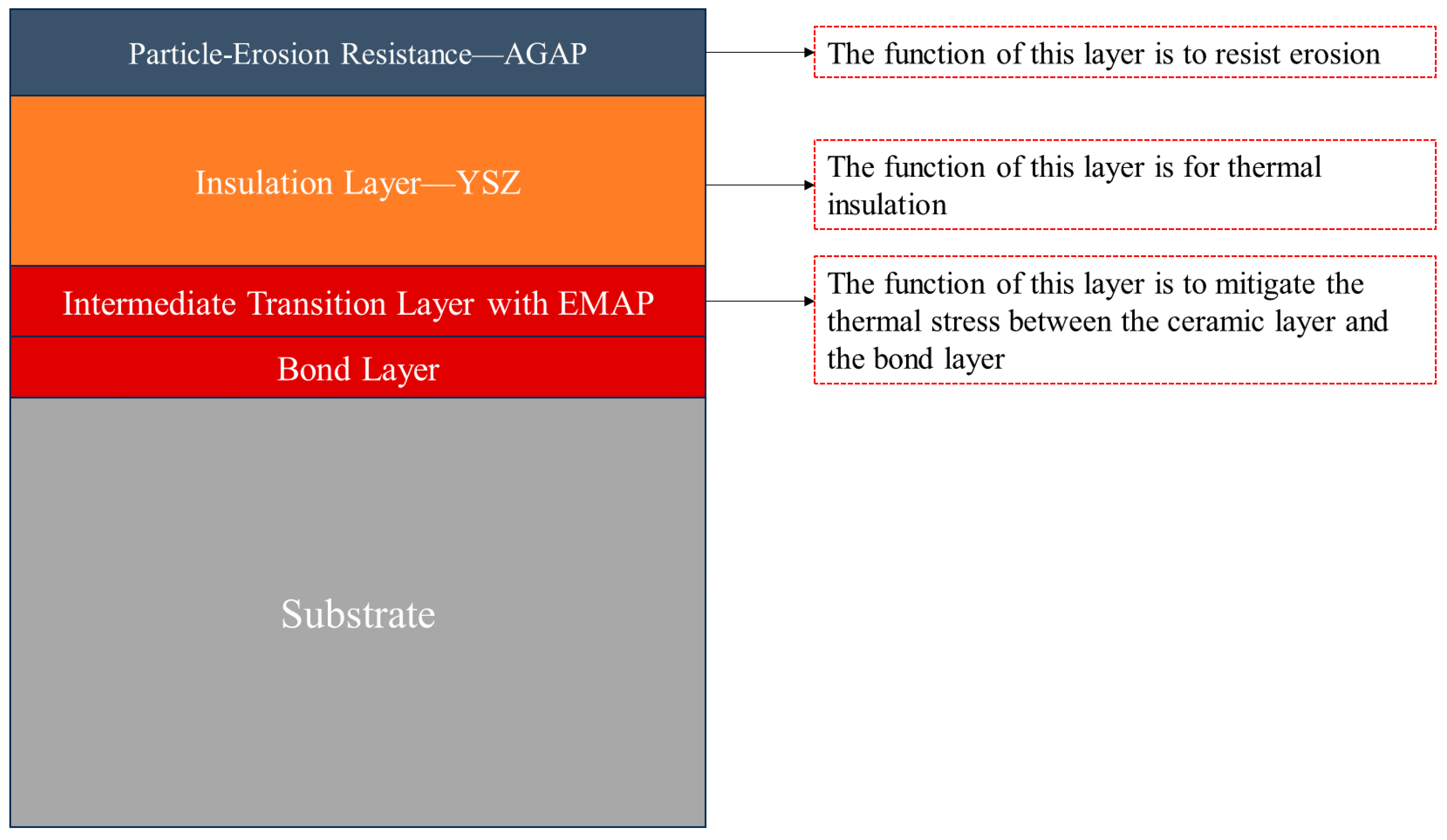

- By analyzing the results of the flame thermal shock experiments on the AYIB coating system at 1500 °C, the coating’s failure mode changes due to the introduction of the intermediate transition layer, and the location of crack generation moves from the interface between the BC layer and the ceramic layer to the interior of the intermediate transition layer.

- The thermal insulation performance of the coating decreases slightly due to the introduction of the intermediate transition layer. For the AYB system, the temperature of the substrate surface is 1275 °C in a high-temperature environment of 1500 °C. After the introduction of the intermediate transition layers of 60 μm, 80 μm, and 100 μm, the temperatures of the substrate surface are 1283 °C, 1287 °C, and 1294 °C, respectively.

- Compared with the AYB coating system without an intermediate transition layer, the thermal mismatch stresses caused by thermal expansion mismatch in the high-temperature thermal shock experiments are significantly alleviated by adding different thicknesses of the intermediate transition layer in the AYIB coating system. When the thickness of the intermediate transition layer is 80 μm and 100 μm, the maximum thermal stresses are 457.1 MPa and 478.1 MPa, respectively, 15.78% and 12.12% are reduced.

- The coatings’ strain tolerance and thermal insulation properties were significantly improved by introducing the EMAP structure in the intermediate transition layer. When the contents of second-phase embedded particles were 3%, 6%, and 9%, respectively, the maximum thermal stresses inside the coatings were 150.39 MPa, 146.85 MPa, and 99.01 MPa. The temperatures on the substrate surface were 1203 °C, 1193 °C, and 1183 °C, respectively. The increase in the second-phase particle content effectively relieves the thermal stress inside the coating and enhances the thermal insulation performance of the coating system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, H.; Guo, Y.; Xue, Z.; Gong, S.; Xu, H. Overview of thermal barrier coatings for advanced gas turbine engine. In Thermal Barrier Coatings; Woodhead Publishing: Cambridge, UK, 2023; pp. 1–20. [Google Scholar]

- Cao, X.Q.; Vassen, R.; Stoever, D. Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 2004, 24, 1–10. [Google Scholar] [CrossRef]

- Clarke, D.R.; Oechsner, M.; Padture, N.P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012, 37, 891–898. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Feuerstein, A.; Knapp, J.; Taylor, T.; Ashary, A.; Bolcavage, A.; Hitchman, N. Technical and Economical Aspects of Current Thermal Barrier Coating Systems for Gas Turbine Engines by Thermal Spray and EBPVD: A Review. J. Therm. Spray Technol. 2008, 17, 199–213. [Google Scholar] [CrossRef]

- Wright, P.K.; Evans, A.G. Mechanisms governing the performance of thermal barrier coatings. Curr. Opin. Solid State Mater. Sci. 1999, 4, 255–265. [Google Scholar] [CrossRef]

- Dong, H.; Liang, X.; Wang, Z.; Luo, N.; Zhang, J.; Zhan, Y.; Zhang, X. Enhancing the performances of EB-PVD TBCs via overlayer Al-modification. Surf. Coat. Technol. 2023, 473, 130001. [Google Scholar] [CrossRef]

- Fang, H.J.; Wang, W.Z.; Yang, Z.N.; Yang, T.; Wang, Y.H.; Huang, J.B.; Ye, D.D. Phase stability, thermal shock behavior and CMAS corrosion resistance of Yb2O3-Y2O3 co-stabilized zirconia thermal barrier coatings prepared by atmospheric plasma spraying. Surf. Coat. Technol. 2021, 427, 127864. [Google Scholar] [CrossRef]

- Kulkarni, A.; Vaidya, A.; Goland, A.; Sampath, S.; Herman, H. Processing effects on porosity-property correlations in plasma sprayed yttria-stabilized zirconia coatings. Mater. Sci. Eng. A 2003, 359, 100–111. [Google Scholar] [CrossRef]

- Li, G.R.; Yang, G.J.; Li, C.X.; Li, C.J. Sintering characteristics of plasma-sprayed TBCs: Experimental analysis and an overall modelling. Ceram. Int. 2018, 44, 2982–2990. [Google Scholar] [CrossRef]

- Trice, R.W.; Su, Y.J.; Mawdsley, J.R.; Faber, K.T.; De Arellano-López, A.R.; Wang, H.; Porter, W.D. Effect of heat treatment on phase stability, microstructure, and thermal conductivity of plasma-sprayed YSZ. J. Mater. Sci. 2002, 37, 2359–2365. [Google Scholar] [CrossRef]

- Lashmi, P.; Ananthapadmanabhan, P.; Unnikrishnan, G.; Aruna, S. Present status and future prospects of plasma sprayed multilayered thermal barrier coating systems. J. Eur. Ceram. Soc. 2020, 40, 2731–2745. [Google Scholar] [CrossRef]

- Vaßen, R.; Jarligo, M.O.; Steinke, T.; Mack, D.E.; Stöver, D. Overview on advanced thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 938–942. [Google Scholar] [CrossRef]

- Fang, H.J.; Wang, W.Z.; Huang, J.B.; Li, Y.J.; Ye, D.D. Corrosion behavior and thermos-physical properties of a promising Yb2O3 and Y2O3 co-stabilized ZrO2 ceramic for thermal barrier coatings subject to calcium-magnesium-aluminum-silicate (CMAS) deposition: Experiments and first-principles calculation. Corros. Sci. 2021, 182, 109230. [Google Scholar] [CrossRef]

- McPherson, R. A review of microstructure and properties of plasma sprayed ceramic coatings. Surf. Coat. Technol. 1989, 40, 173–181. [Google Scholar] [CrossRef]

- Li, C.; Wang, W. Quantitative characterization of lamellar microstructure of plasma-sprayed ceramic coatings through visualization of void distribution. Mater. Eng. A 2004, 386, 10–19. [Google Scholar] [CrossRef]

- Allen, A.; Ilavsky, J.; Long, G.; Wallace, J.; Berndt, C.; Herman, H. Microstructural characterization of yttria-stabilized zirconia plasma-sprayed deposits using multiple small-angle neutron scattering. Acta Mater. 2001, 49, 1661–1675. [Google Scholar] [CrossRef]

- Antou, G.; Montavon, G.; Hlawka, F.; Cornet, A.; Coddet, C.; Machi, F. Evaluation of modifications induced on pore network and structure of partially stabilized zirconia manufactured by hybrid plasma spray process. Surf. Coat. Technol. 2004, 180, 627–632. [Google Scholar] [CrossRef]

- Fauchais, P.; Vardelle, M.; Goutier, S. Latest Researches Advances of Plasma Spraying: From Splat to Coating Formation. J. Therm. Spray Technol. 2016, 25, 1534–1553. [Google Scholar] [CrossRef]

- Kulkarni, A.A.; Goland, A.; Herman, H.; Allen, A.J.; Ilavsky, J.; Long, G.G.; Johnson, C.A.; Ruud, J.A. Microstructure–Property Correlations in Industrial Thermal Barrier Coatings. J. Am. Ceram. Soc. 2004, 87, 1294–1300. [Google Scholar] [CrossRef]

- Fleck, N.; Cocks, A.; Lampenscherf, S. Thermal shock resistance of air plasma sprayed thermal barrier coatings. J. Eur. Ceram. Soc. 2014, 34, 2687–2694. [Google Scholar] [CrossRef]

- Heveran, C.M.; Xu, J.; Sarin, V.K.; Basu, S.N. Simulation of stresses in TBC–EBC coating systems for ceramic components in gas turbines. Surf. Coat. Technol. 2013, 235, 354–360. [Google Scholar] [CrossRef]

- Levi, C.G. Emerging materials and processes for thermal barrier systems. Curr. Opin. Solid State Mater. Sci. 2004, 8, 77–91. [Google Scholar] [CrossRef]

- Ozgurluk, Y.; Gulec, A.; Ozkan, D.; Binal, G.; Karaoglanli, A.C. Structural characteristics, oxidation performance and failure mechanism of thermal barrier coatings fabricated by atmospheric plasma spraying and detonation gun spraying. Eng. Fail. Anal. 2023, 152, 107499. [Google Scholar] [CrossRef]

- Scrivani, A.; Rizzi, G.; Berndt, C.C. Enhanced thick thermal barrier coatings that exhibit varying porosity. Mater. Sci. Eng. A 2008, 476, 1–7. [Google Scholar] [CrossRef]

- Tao, S.; Yang, J.; Shao, F.; Zhao, H.; Zhong, X.; Zhuang, Y.; Sheng, J.; Ni, J.; Li, Q.; Tao, S. Atmospheric plasma sprayed thick thermal barrier coatings: Microstructure, thermal shock behaviors and failure mechanism. Eng. Fail. Anal. 2021, 131, 105819. [Google Scholar] [CrossRef]

- Liu, K.; Tang, J.; Bai, Y.; Yang, Q.; Wang, Y.; Kang, Y.; Zhao, L.; Zhang, P.; Han, Z. Particle in-flight behavior and its influence on the microstructure and mechanical property of plasma sprayed La2Ce2O7 thermal barrier coatings. Mater. Sci. Eng. A 2015, 625, 177–185. [Google Scholar] [CrossRef]

- Liu, L.; Wang, S.; Zhang, B.; Jiang, G.; Liu, H.; Yang, J.; Wang, J.; Liu, W. Present status and prospects of nanostructured thermal barrier coatings and their performance improvement strategies: A review. J. Manuf. Process. 2023, 97, 12–34. [Google Scholar] [CrossRef]

- Pakseresht, A.; Sharifianjazi, F.; Esmaeilkhanian, A.; Bazli, L.; Nafchi, M.R.; Bazli, M.; Kirubaharan, K. Failure mechanisms and structure tailoring of YSZ and new candidates for thermal barrier coatings: A systematic review. Mater. Des. 2022, 222, 111044. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, W.; Deng, S.; Fang, H.; Yang, T.; Wang, L. Thermal Shock Behavior and Particle Erosion Resistance of Toughened GZ Coatings Prepared by Atmospheric Plasma Spraying. Coatings 2021, 11, 1477. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, K.; Wang, W.; Yang, T.; Fang, H.; Qiang, L.; Zhang, X.; Zhang, C. Investigation of Thermal Shock Behavior of Multilayer Thermal Barrier Coatings with Superior Erosion Resistance Prepared by Atmospheric Plasma Spraying. Coatings 2022, 12, 804. [Google Scholar] [CrossRef]

- Yang, T.; Wang, W.; Huang, J.; Wang, L.; Yang, Z.; Fang, H.; Ye, D. Thermal Shock Resistance and Bonding Strength of Novel-Structured Thermal Barrier Coatings with Different Microstructure. J. Therm. Spray Technol. 2022, 31, 1540–1555. [Google Scholar] [CrossRef]

- Yang, T.; Wang, W.; Tang, Z.; Liu, Y.; Li, K. Structural optimization for porous thermal barrier coating and analysis of thermomechanical properties by experimental and computational investigation. Surf. Coat. Technol. 2023, 458, 129347. [Google Scholar] [CrossRef]

- Yedida, V.S.; Vasudev, H. A review on the development of thermal barrier coatings by using thermal spray techniques. Mater. Today Proc. 2022, 50, 1458–1464. [Google Scholar] [CrossRef]

- Song, J.-B.; Wang, L.-S.; Dong, H.; Yao, J.-T. Long lifespan thermal barrier coatings overview: Materials, manufacturing, failure mechanisms, and multiscale structural design. Ceram. Int. 2022, 49, 1–23. [Google Scholar] [CrossRef]

- Huang, J.; Wang, W.; Lu, X.; Liu, S.; Li, C. Influence of Lamellar Interface Morphology on Cracking Resistance of Plasma-Sprayed YSZ Coatings. Coatings 2018, 8, 187. [Google Scholar] [CrossRef]

- Kim, D.-J.; Shin, I.-H.; Koo, J.-M.; Seok, C.-S.; Lee, T.-W. Failure mechanisms of coin-type plasma-sprayed thermal barrier coatings with thermal fatigue. Surf. Coat. Technol. 2010, 205, S451–S458. [Google Scholar] [CrossRef]

- Yang, T.; Wang, W.; Tang, Z.; Liu, Y.; Li, K.; Liu, W.; Zhang, W.; Ye, D. CMAS infiltration behavior of atmospheric plasma-sprayed thermal barrier coating with tailored pore structures. Ceram. Int. 2023, 50, 7218–7229. [Google Scholar] [CrossRef]

- Cai, Z.; Zhang, Z.; Liu, Y.; Zhao, X.; Wang, W. Numerical Study on Effect of Non-uniform CMAS Penetration on TGO Growth and Interface Stress Behavior of APS TBCs. Chin. J. Mech. Eng. 2021, 34, 128. [Google Scholar] [CrossRef]

- Abbas, R.A.; Ajeel, S.A.; Bash, M.A.A.; Kadhim, M.J. Effect of plasma spray distance on the features and hardness reliability of YSZ thermal barrier coating. Mater. Today Proc. 2021, 42, 2553–2560. [Google Scholar] [CrossRef]

- Jamali, H.; Mozafarinia, R.; Razavi, R.S.; Ahmadi-Pidani, R. Comparison of thermal shock resistances of plasma-sprayed nanostructured and conventional yttria stabilized zirconia thermal barrier coatings. Ceram. Int. 2012, 38, 6705–6712. [Google Scholar] [CrossRef]

- Wu, J.; Guo, H.-B.; Zhou, L.; Wang, L.; Gong, S.-K. Microstructure and Thermal Properties of Plasma Sprayed Thermal Barrier Coatings from Nanostructured YSZ. J. Therm. Spray Technol. 2010, 19, 1186–1194. [Google Scholar] [CrossRef]

- Li, K.; Wang, W.; Yang, S.; Liu, Y.; Yang, T. First-principles calculations and thermal-mechanical experimental studies on middle-entropy rare-earth disilicates. Ceram. Int. 2024, 50, 22290–22305. [Google Scholar] [CrossRef]

- Li, K.; Wang, W.; Yang, T.; Liu, Y. Simulation of 1500 °C Thermal Shock for Novel Structural Thermal/Environmental Barrier Coatings System. Coatings 2023, 13, 96. [Google Scholar] [CrossRef]

- Huang, J.B.; Wang, W.Z.; Li, Y.J.; Fang, H.J.; Ye, D.D.; Zhang, X.C.; Tu, S.T. Improve durability of plasma-sprayed thermal barrier coatings by decreasing sintering-induced stiffening in ceramic coatings. J. Eur. Ceram. Soc. 2020, 40, 1433–1442. [Google Scholar] [CrossRef]

- Huang, J.B.; Wang, W.Z.; Li, Y.J.; Fang, H.J.; Ye, D.D.; Zhang, X.C.; Tu, S.T. A novel strategy to control the microstructure of plasma-sprayed YSZ thermal barrier coatings. Surf. Coat. Technol. 2020, 402, 126304. [Google Scholar] [CrossRef]

| Parameter | BC | YSZ | Intermediate Layer of A | Intermediate Layer of B | Intermediate Layer of C | AGAP |

|---|---|---|---|---|---|---|

| Current, A | 550 | 600 | 550 | 575 | 600 | 650 |

| Voltage, V | 68.5 | 67.2 | 68.5 | 67.9 | 67.2 | 67 |

| Primary gas flow rate, Ar, L/min | 50 | 50 | 50 | 45 | 50 | 40 |

| Carrier gas flow rate,, L/min | 8 | 9 | 8 | 8.5 | 9 | 9 |

| Spray distance, mm | 120 | 90 | 120 | 105 | 90 | 120 |

| Travers speed of gun, mm/s | 900 | 500 | 900 | 700 | 500 | 900 |

| Powder feeding rate, % | 10 | 20 | 10 | 15 | 20 | 20 |

| Thickness, μm | 120 | 300 | 80 | 80 | 80 | 100 |

| Temperature (°C) | Elastic Modulus (109 Pa) | Coefficient of Thermal Expansion (10−6 °C−1) | Density (103 kg/m3) | Thermal Conductivity (W/m·°C) | Thermal Capacity (J/kg·°C) | Poisson Rate |

|---|---|---|---|---|---|---|

| 20 | 120 | 12.7 | 6.69 | 3.5 | 425 | 0.2 |

| 200 | 13.2 | 4.345 | 0.2 | |||

| 400 | 13.5 | 5.34 | 0.21 | |||

| 600 | 14.1 | 6.575 | 0.21 | |||

| 800 | 15.2 | 7.83 | 0.22 | |||

| 1000 | 16.2 | 8.67 | 0.23 | |||

| 1100 | 16.7 | 9.06 | 0.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Yang, S.; Li, K.; Wang, W.; Liu, Y.; Yang, T. Experimental and Simulation Studies on Thermal Shock of Multilayer Thermal Barrier Coatings with an Intermediate Transition Layer at 1500 °C. Coatings 2024, 14, 1614. https://doi.org/10.3390/coatings14121614

Liu P, Yang S, Li K, Wang W, Liu Y, Yang T. Experimental and Simulation Studies on Thermal Shock of Multilayer Thermal Barrier Coatings with an Intermediate Transition Layer at 1500 °C. Coatings. 2024; 14(12):1614. https://doi.org/10.3390/coatings14121614

Chicago/Turabian StyleLiu, Pengpeng, Shilong Yang, Kaibin Li, Weize Wang, Yangguang Liu, and Ting Yang. 2024. "Experimental and Simulation Studies on Thermal Shock of Multilayer Thermal Barrier Coatings with an Intermediate Transition Layer at 1500 °C" Coatings 14, no. 12: 1614. https://doi.org/10.3390/coatings14121614

APA StyleLiu, P., Yang, S., Li, K., Wang, W., Liu, Y., & Yang, T. (2024). Experimental and Simulation Studies on Thermal Shock of Multilayer Thermal Barrier Coatings with an Intermediate Transition Layer at 1500 °C. Coatings, 14(12), 1614. https://doi.org/10.3390/coatings14121614