Modification of Microstructure and Properties of Cold-Sprayed AlSi10Mg+TiB2 Composite by Friction Stir Process

Abstract

1. Introduction

2. Experimental Details

2.1. CS Deposition

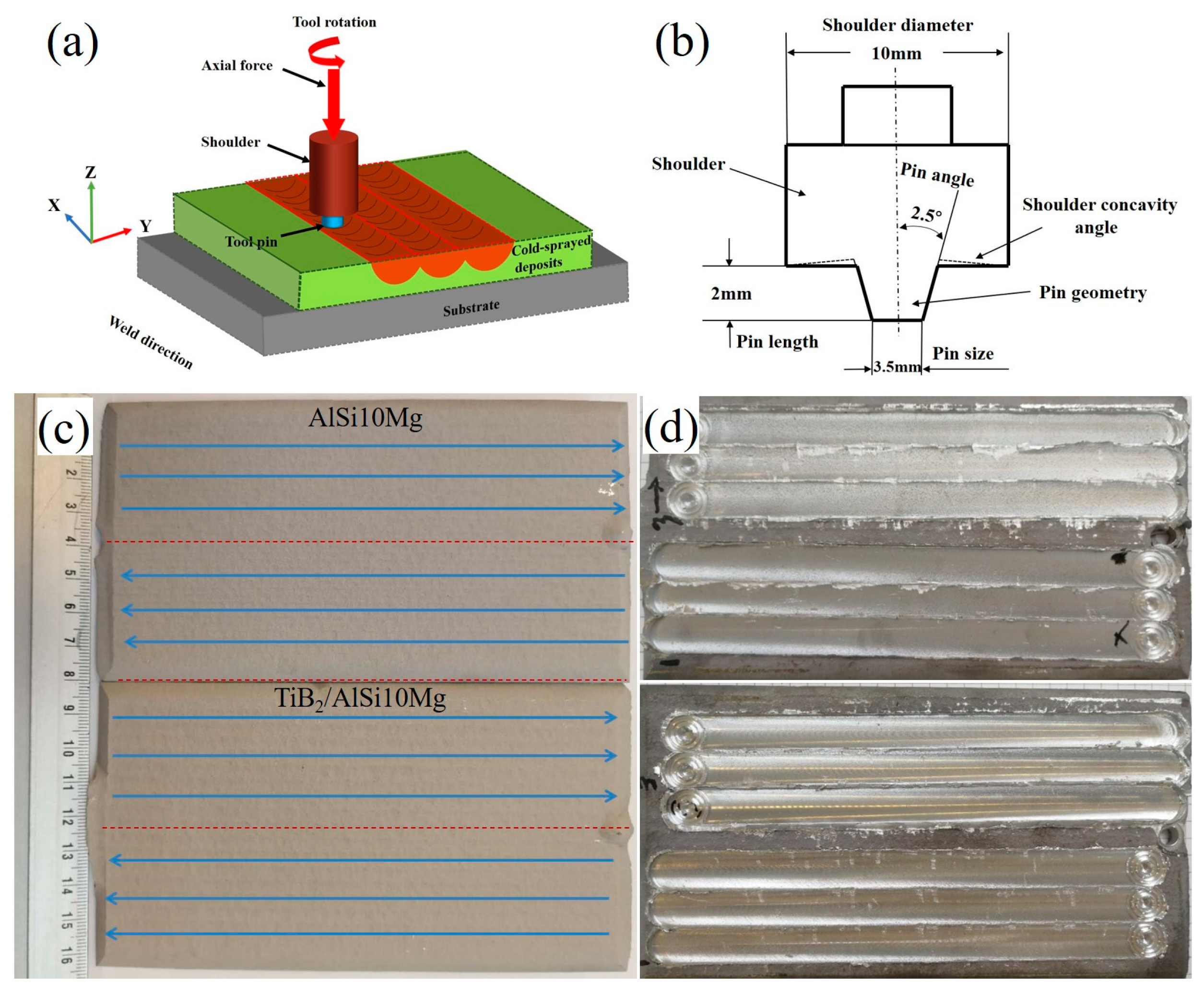

2.2. Post-FSP Treatment

2.3. Microstructure Characterization

2.4. Microhardness and Tribological Test

3. Results and Discussion

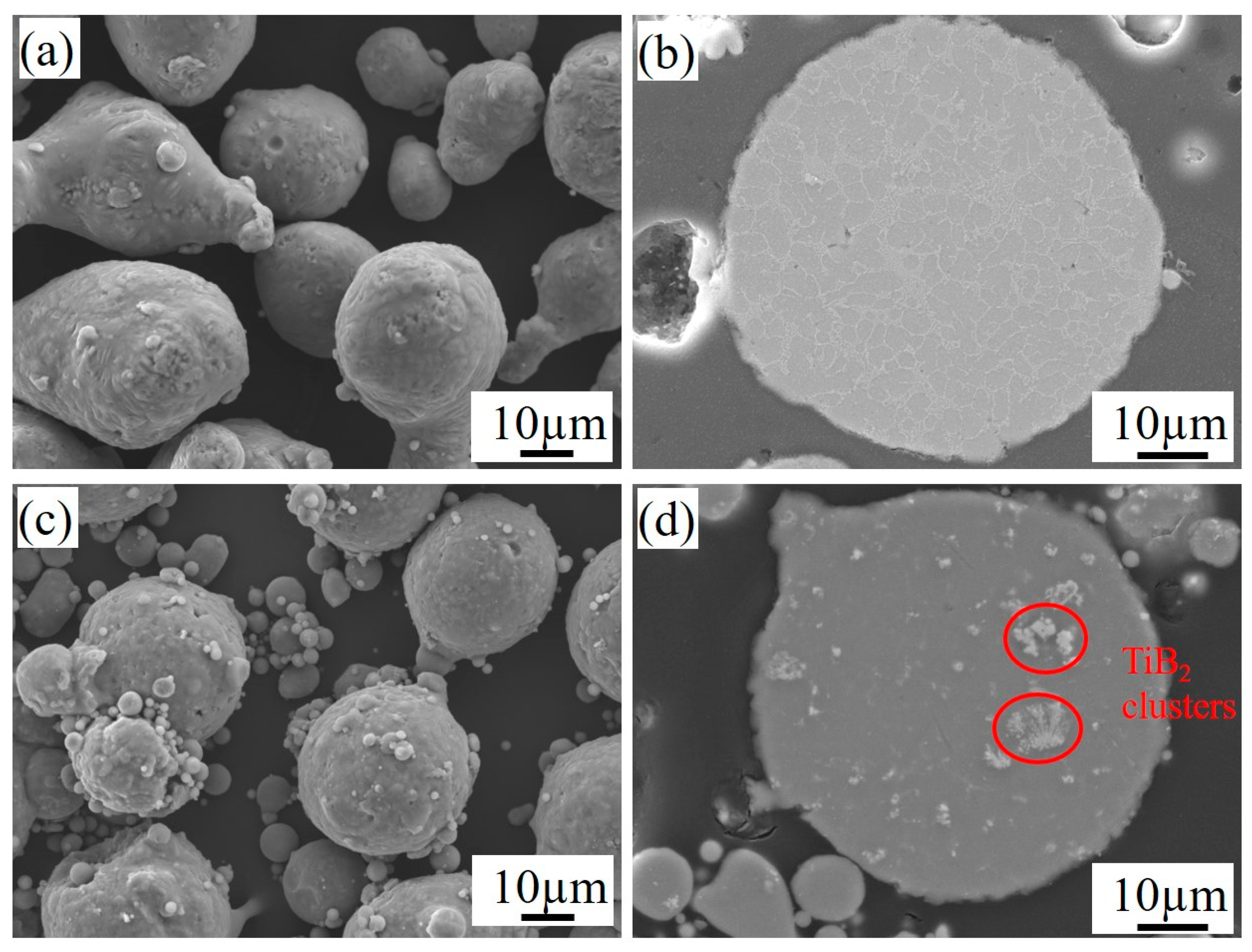

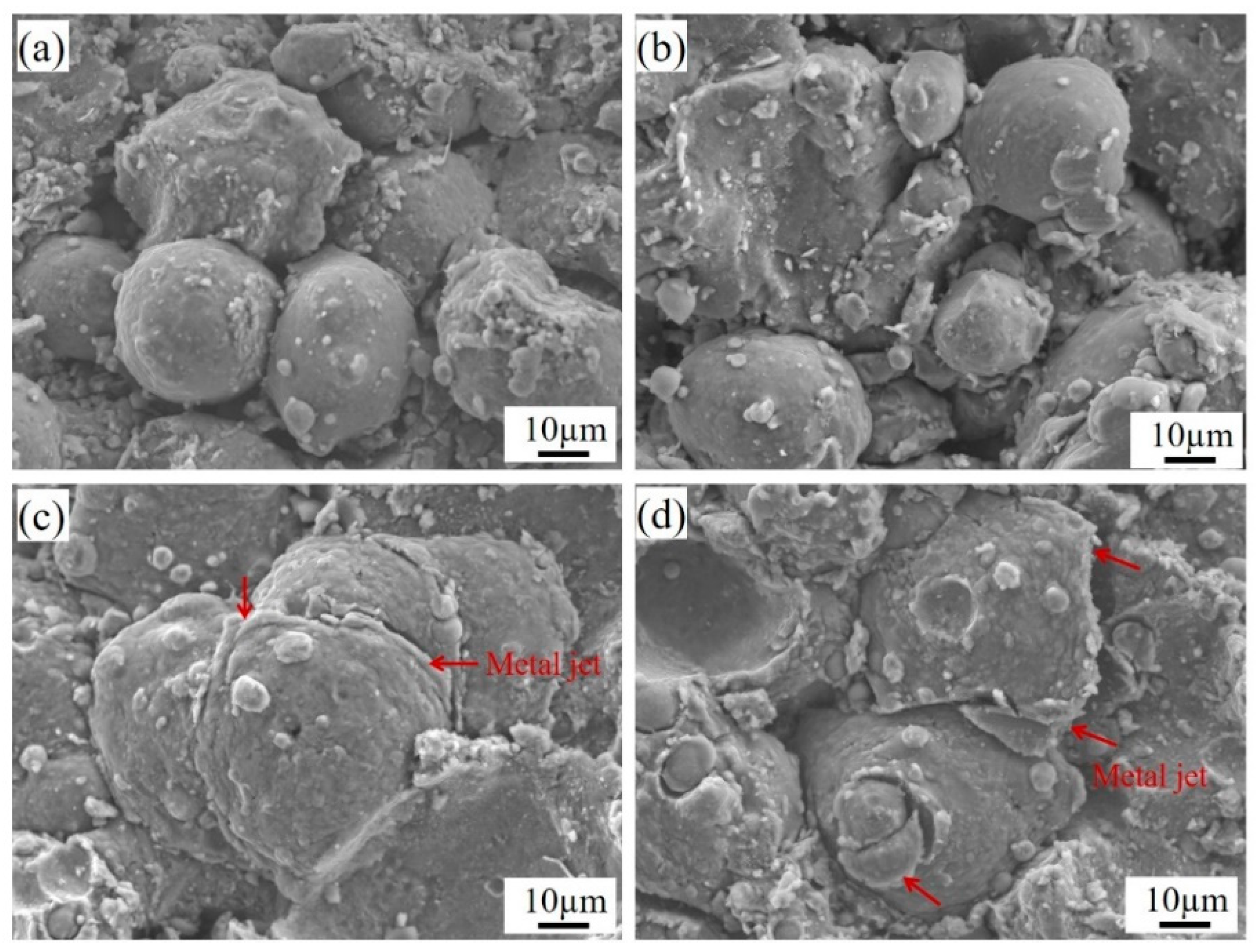

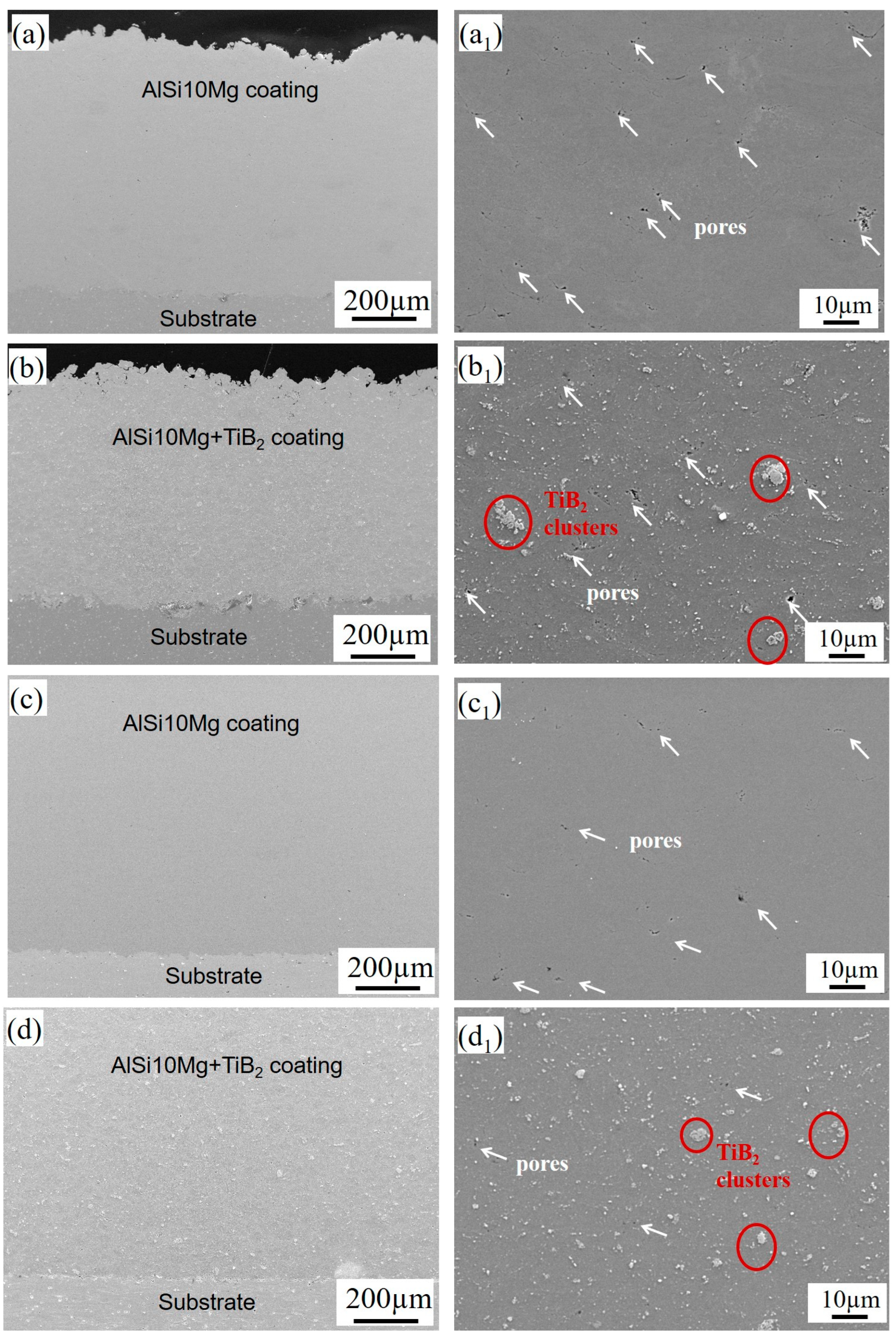

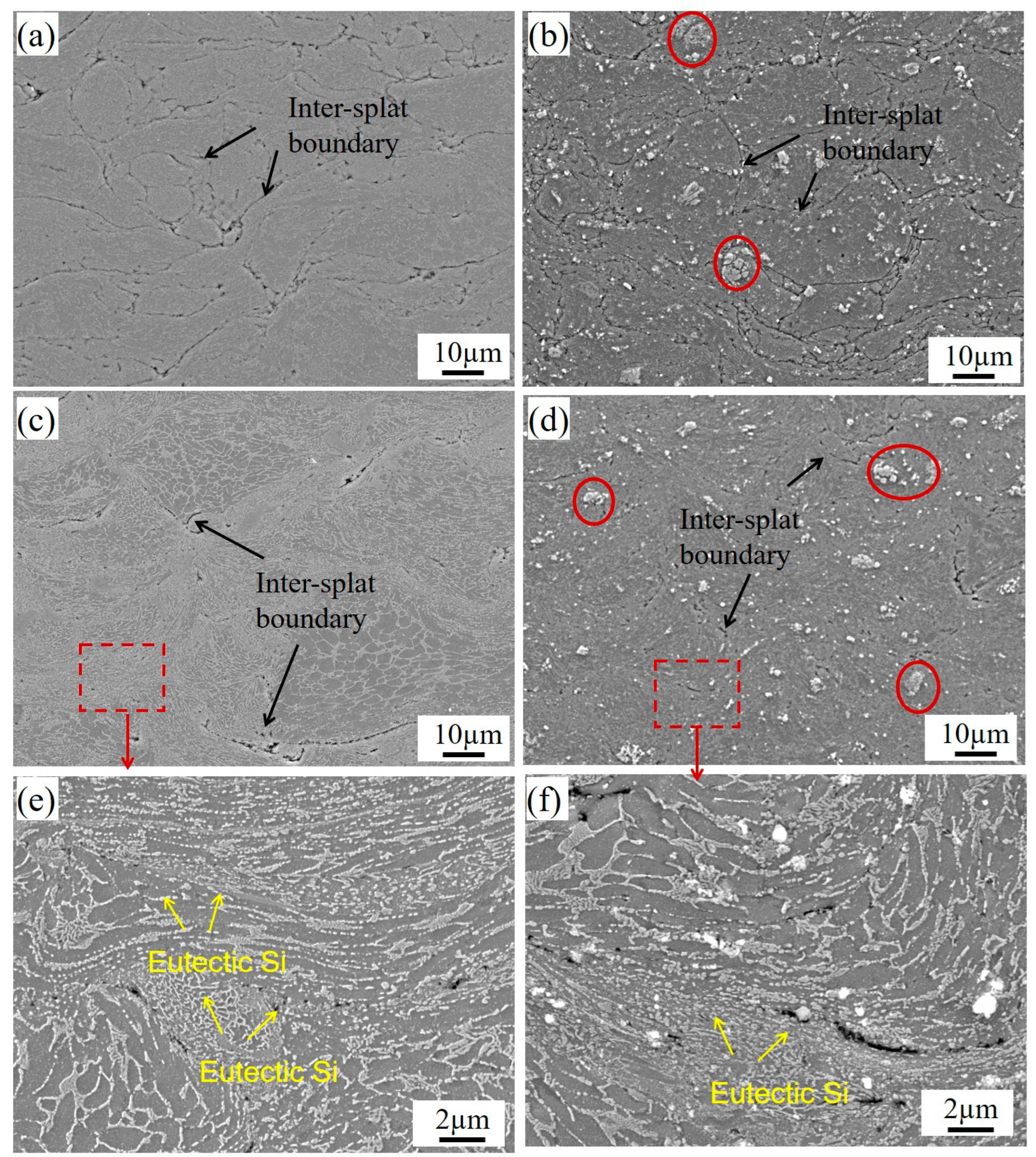

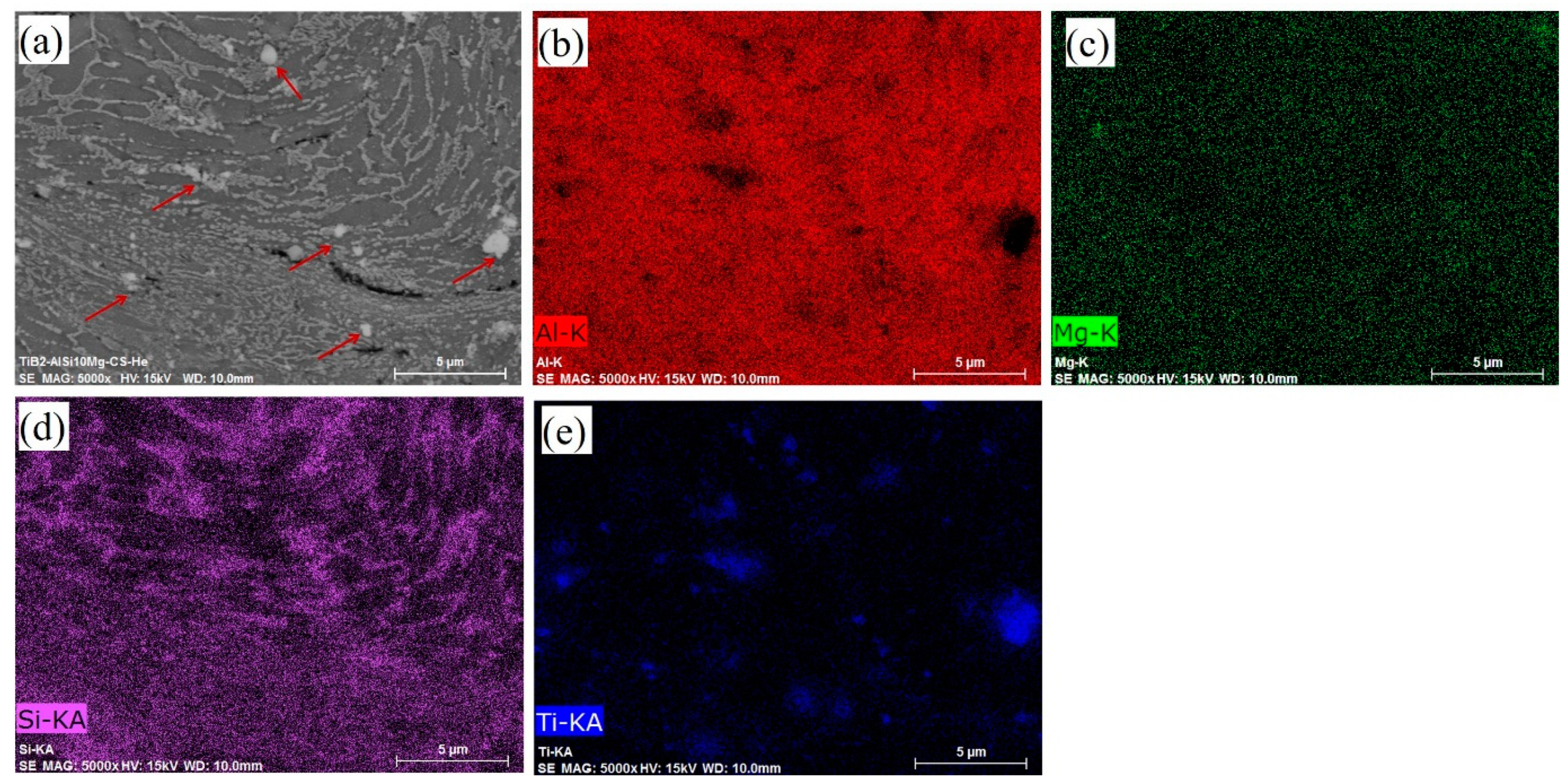

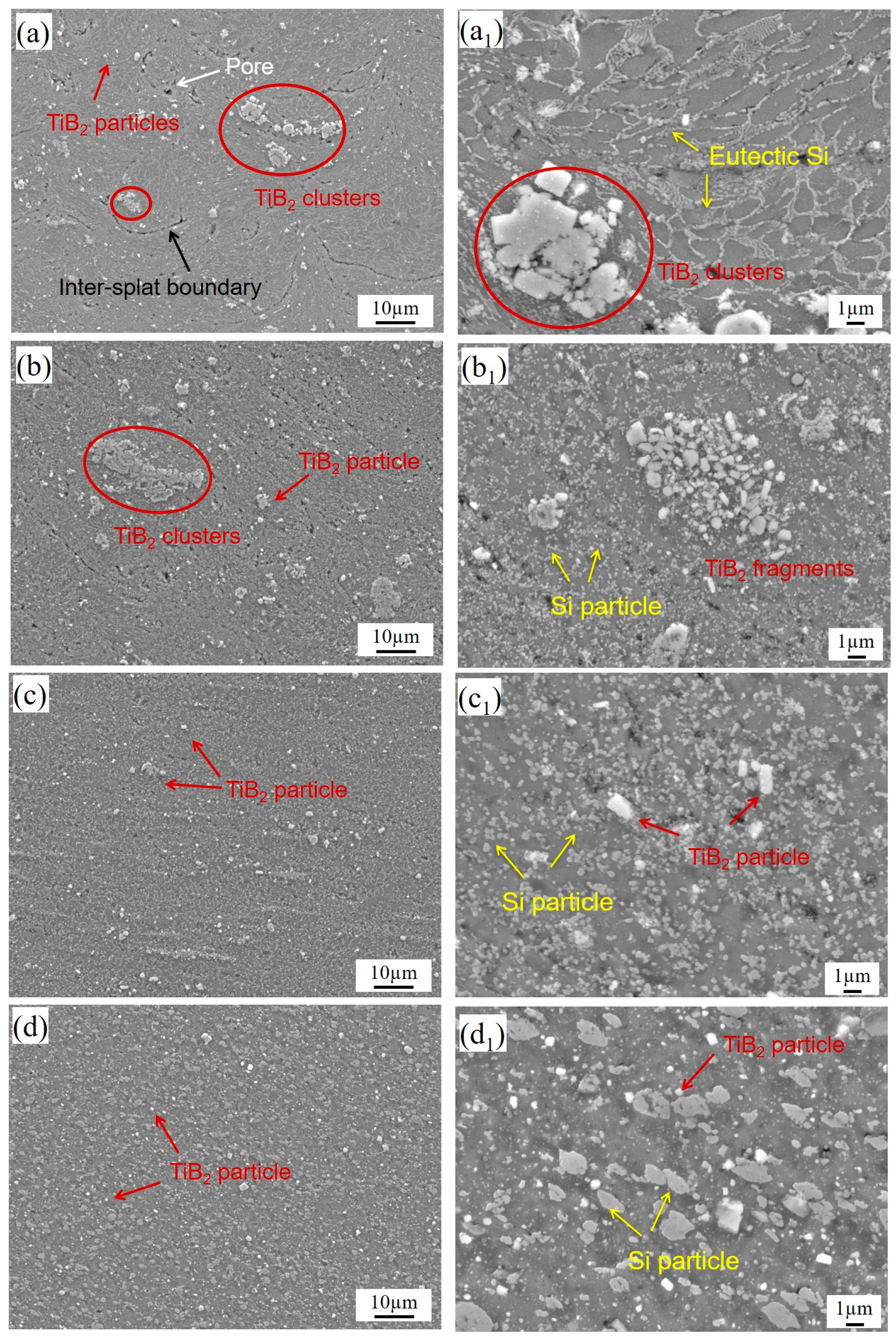

3.1. Microstructure Characterization of As-Deposited Deposits

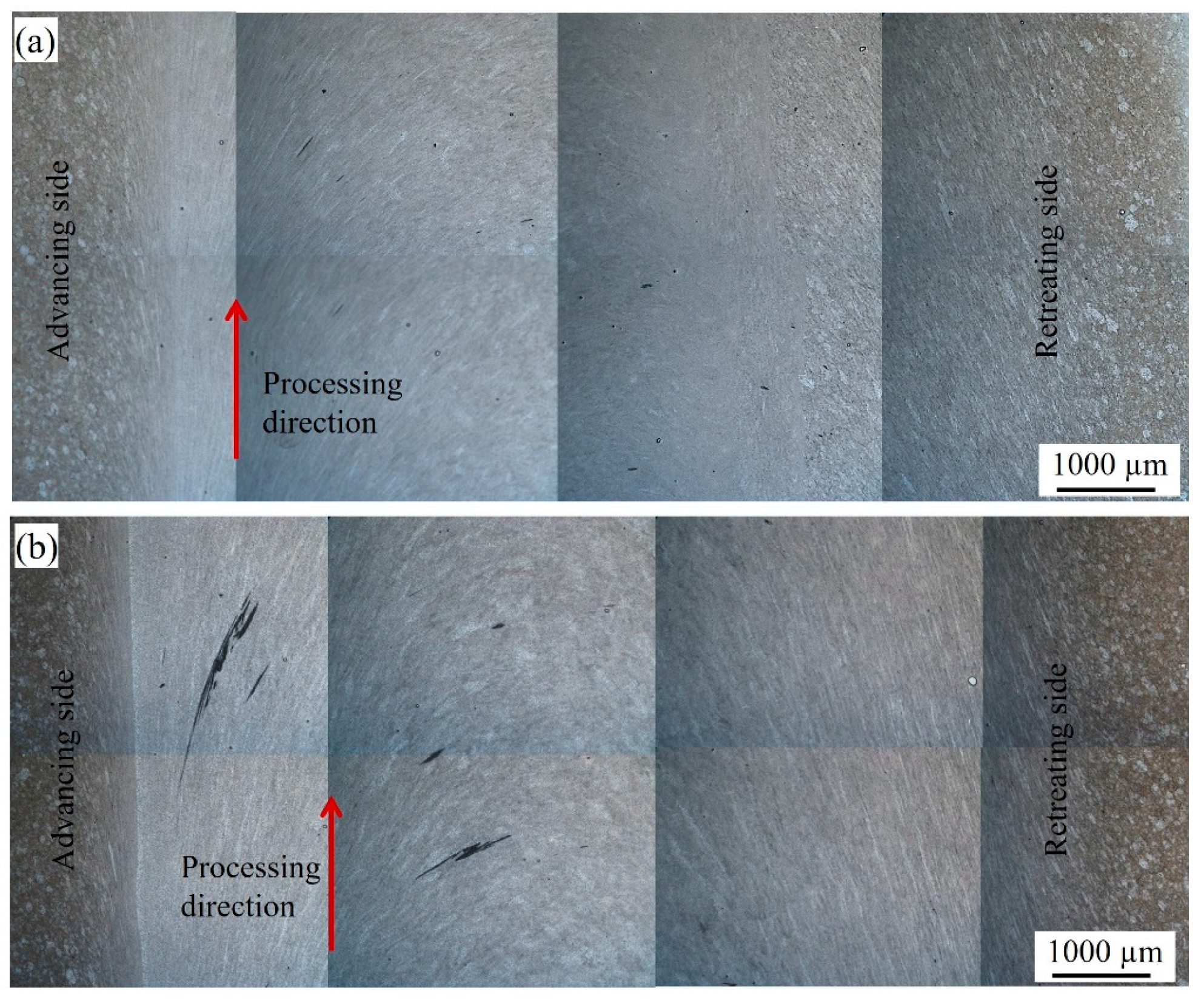

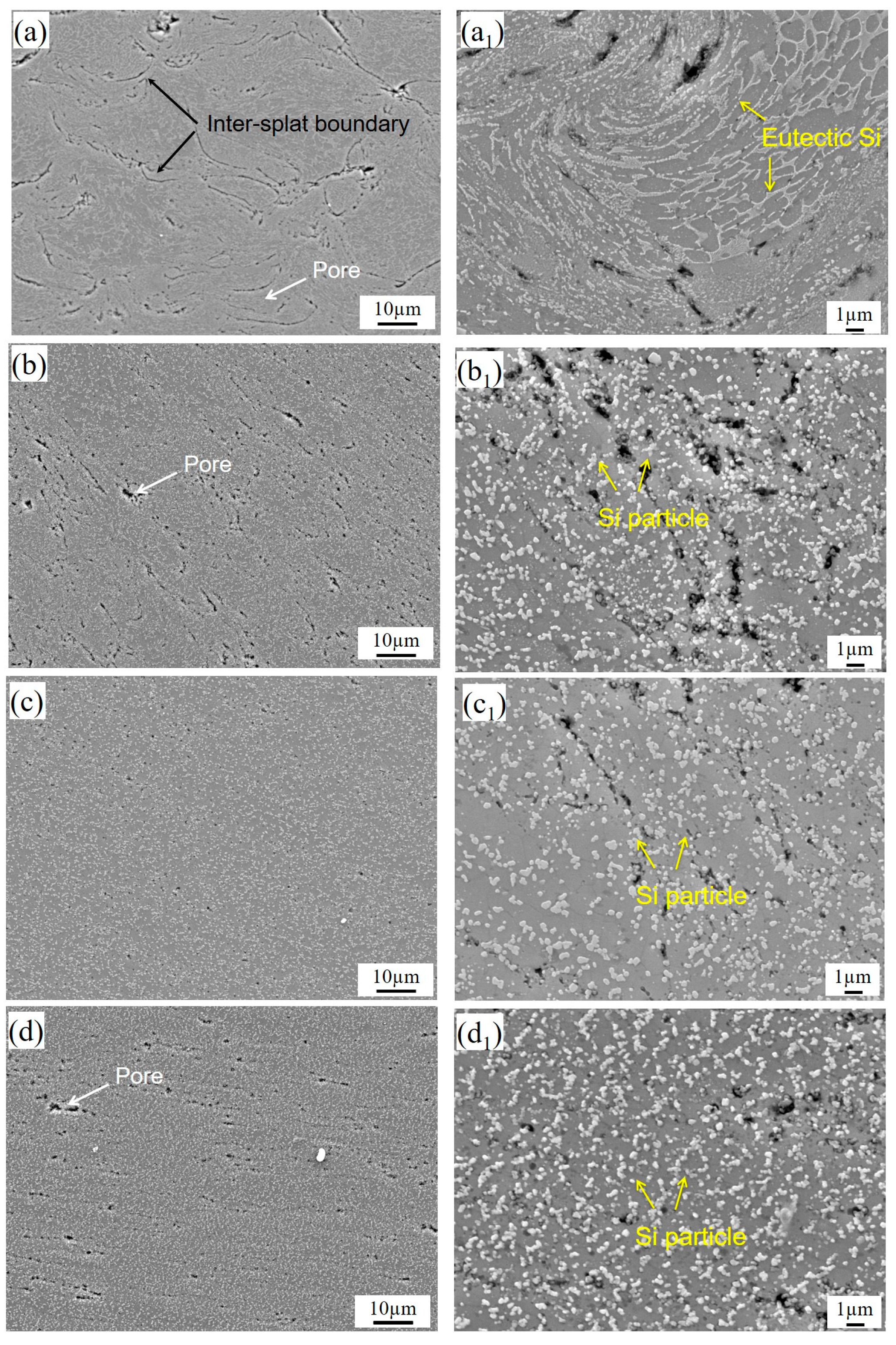

3.2. Microstructure Characterization After Post-FSP Treatment

3.3. Microhardness Evolution

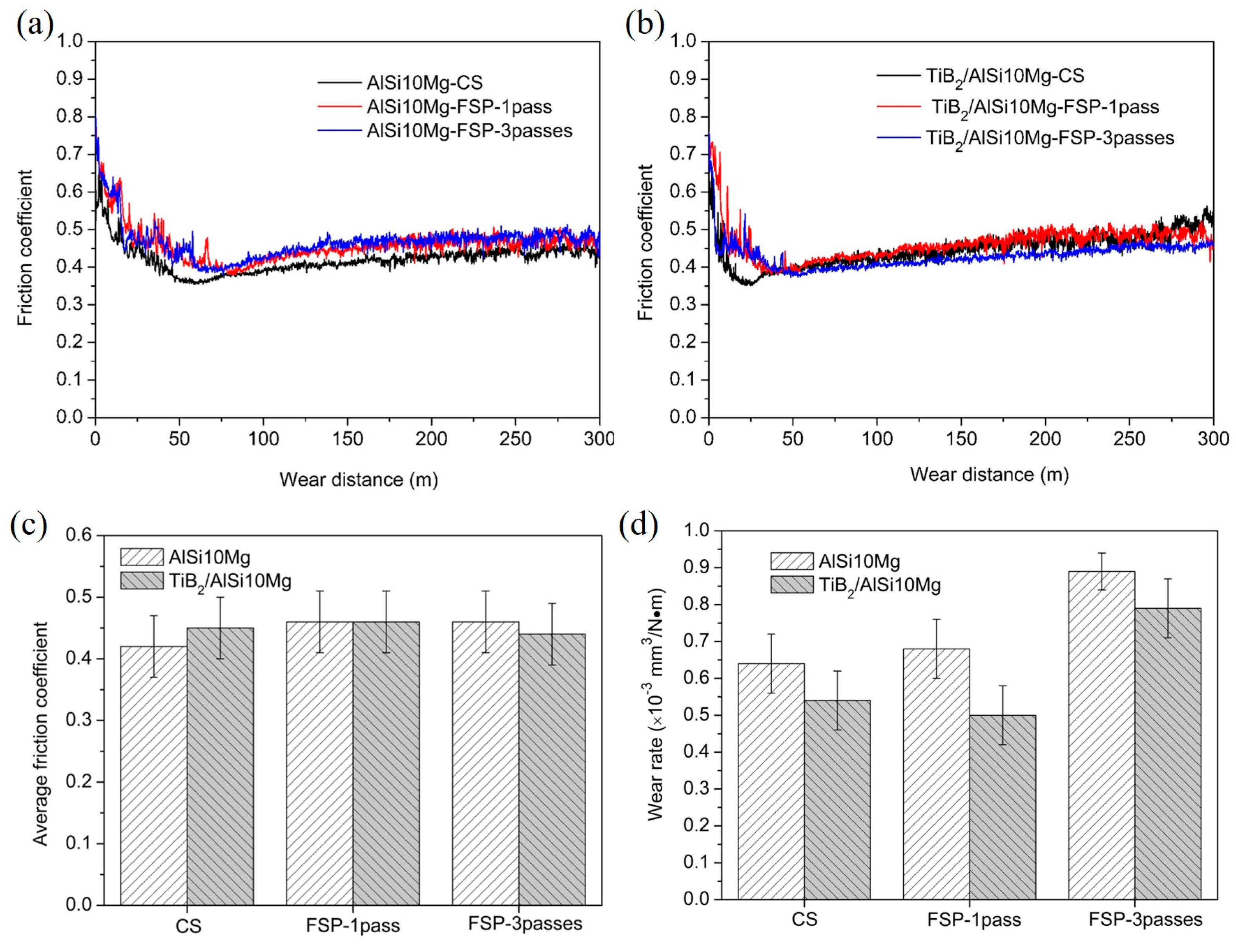

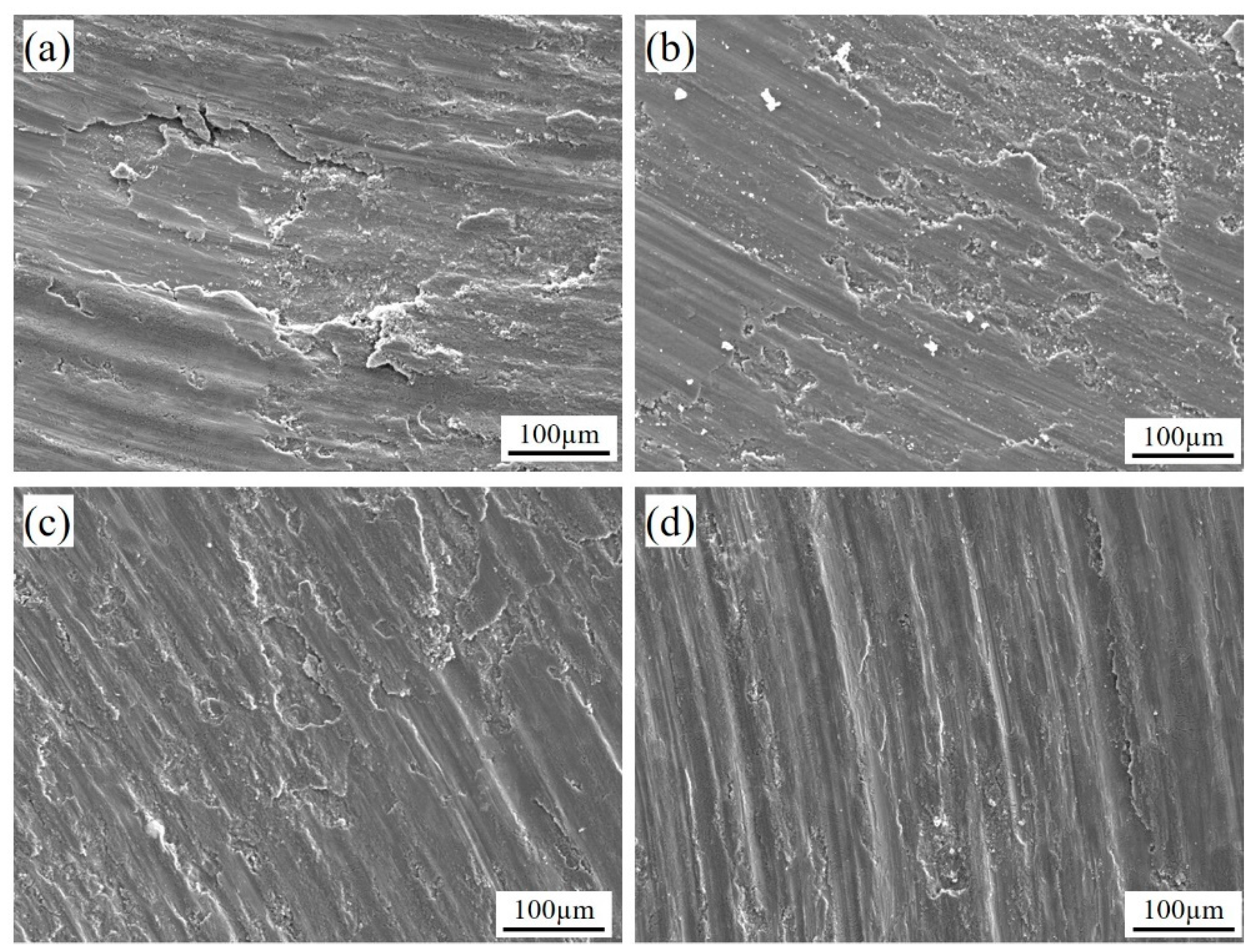

3.4. Wear Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, W.; Yang, K.; Yin, S.; Yang, X.; Xu, Y.; Lupoi, R. Solid-state additive manufacturing and repairing by cold spraying: A review. J. Mater. Sci. Technol. 2018, 34, 440–457. [Google Scholar] [CrossRef]

- Schmidt, T.; Gärtner, F.; Assadi, H.; Kreye, H. Development of a generalized parameter window for cold spray deposition. Acta Mater. 2006, 54, 729–742. [Google Scholar] [CrossRef]

- Zou, Y. Cold Spray Additive Manufacturing: Microstructure Evolution and Bonding Features. Acc. Mater. Res. 2021, 2, 1071–1081. [Google Scholar] [CrossRef]

- Assadi, H.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Bonding mechanism in cold gas spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

- Klinkov, S.V.; Kosarev, V.F.; Rein, M. Cold spray deposition: Significance of particle impact phenomena. Aerosp. Sci. Technol. 2005, 9, 582–591. [Google Scholar] [CrossRef]

- Dewar, M.P.; McDonald, A.G.; Gerlich, A.P. Interfacial heating during low-pressure cold-gas dynamic spraying of aluminum coatings. J. Mater. Sci. 2011, 47, 184–198. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gärtner, F.; Klassen, T. Cold spraying—A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef]

- Yin, S.; Fan, N.; Huang, C.; Xie, Y.; Zhang, C.; Lupoi, R.; Li, W. Towards high-strength cold spray additive manufactured metals: Methods, mechanisms, and properties. J. Mater. Sci. Technol. 2024, 170, 47–64. [Google Scholar] [CrossRef]

- Borchers, C.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Microstructural bonding features of cold sprayed face centered cubic metals. J. Appl. Phys. 2004, 96, 4288–4292. [Google Scholar] [CrossRef]

- Grujicic, M.; Saylor, J.R.; Beasley, D.E.; DeRosset, W.S.; Helfritch, D. Computational analysis of the interfacial bonding between feed-powder particles and the substrate in the cold-gas dynamic-spray process. Appl. Surf. Sci. 2003, 219, 211–227. [Google Scholar] [CrossRef]

- Xie, Y.; Yin, S.; Chen, C.; Planche, M.-P.; Liao, H.; Lupoi, R. New insights into the coating/substrate interfacial bonding mechanism in cold spray. Scr. Mater. 2016, 125, 1–4. [Google Scholar] [CrossRef]

- Cavaliere, P.; Silvello, A. Fatigue behaviour of cold sprayed metals and alloys: Critical review. Surf. Eng. 2016, 32, 631–640. [Google Scholar] [CrossRef]

- Maharjan, N.; Ramesh, T.; Pham, D.Q.; Zhai, W.; Ang, A.; Zhou, W. Post-processing of cold sprayed Ti6Al4V coating by laser shock peening. J. Mater. Process. Technol. 2024, 330, 118461. [Google Scholar] [CrossRef]

- Judas, J.; Zapletal, J.; Adam, O.; Řehořek, L.; Jan, V. Microstructural stability and precipitate evolution of thermally treated 7075 aluminum alloy fabricated by cold spray. Mater. Charact. 2024, 216, 114259. [Google Scholar] [CrossRef]

- Kromer, S.C.R.; Verdy, C.; Gojon, S.; Liao, H. Laser surface texturing to enhance adhesion bond strength of spray coatings—Cold spraying, wire-arc spraying, and atmospheric plasma spraying. Surf. Coat. Technol. 2018, 352, 642–653. [Google Scholar] [CrossRef]

- Shtansky, D.V.; Batenina, I.V.; Yadroitsev, I.A.; Ryashin, N.S.; Kiryukhantsev-Korneev, P.V.; Kudryashov, A.E.; Sheveyko, A.N.; Zhitnyak, I.Y.; Gloushankova, N.A.; Smurov, I.Y.; et al. A new combined approach to metal-ceramic implants with controllable surface topography, chemistry, blind porosity, and wettability. Surf. Coat. Technol. 2012, 208, 14–23. [Google Scholar] [CrossRef]

- Wang, W.; Han, P.; Wang, Y.; Zhang, T.; Peng, P.; Qiao, K.; Wang, Z.; Liu, Z.; Wang, K. High-performance bulk pure Al prepared through cold spray-friction stir processing composite additive manufacturing. J. Mater. Res. Technol. 2020, 9, 9073–9079. [Google Scholar] [CrossRef]

- Liu, Z.-H.; Han, P.; Wang, W.; Guan, X.-H.; Wang, Z.; Fang, Y.; Qiao, K.; Ye, D.-M.; Cai, J.; Xie, Y.-C.; et al. Microstructure; mechanical properties, and corrosion behavior of 6061Al alloy prepared by cold spray-friction stir processing composite additive manufacturing. Trans. Nonferrous Met. Soc. China 2023, 33, 3250–3265. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, J.; Li, X.; Wang, Y.; Ni, D.; Zhang, X.; Xu, J.; Li, M. Improving the mechanical properties and electrical conductivity of cold-sprayed Cu-Ti3SiC2 composite by friction stir processing. Compos. Part A Appl. Sci. Manuf. 2023, 173, 107698. [Google Scholar] [CrossRef]

- Hodder, K.J.; Izadi, H.; McDonald, A.G.; Gerlich, A.P. Fabrication of aluminum–alumina metal matrix composites via cold gas dynamic spraying at low pressure followed by friction stir processing. Mater. Sci. Eng. A 2012, 556, 114–121. [Google Scholar] [CrossRef]

- Yu, M.; Suo, X.K.; Li, W.Y.; Wang, Y.Y.; Liao, H.L. Microstructure, mechanical property and wear performance of cold sprayed Al5056/SiCp composite coatings: Effect of reinforcement content. Appl. Surf. Sci. 2014, 289, 188–196. [Google Scholar] [CrossRef]

- Yang, X.; Li, W.; Yu, S.; Xu, Y.; Hu, K.; Zhao, Y. Electrochemical characterization and microstructure of cold sprayed AA5083/Al2O3 composite coatings. J. Mater. Sci. Technol. 2020, 59, 117–128. [Google Scholar] [CrossRef]

- Xie, X.; Chen, C.; Chen, Z.; Addad, A.; Xie, Y.; Wu, H.; Verdy, C.; Wang, Y.; Wang, J.; Ren, Z.; et al. Effect of annealing treatment on microstructure and mechanical properties of cold sprayed TiB2/AlSi10Mg composites. Surf. Interfaces 2021, 26, 101341. [Google Scholar] [CrossRef]

- Xie, X.; Ma, Y.; Chen, C.; Ji, G.; Verdy, C.; Wu, H.; Chen, Z.; Yuan, S.; Normand, B.; Yin, S.; et al. Cold spray additive manufacturing of metal matrix composites (MMCs) using a novel nano-TiB2-reinforced 7075Al powder. J. Alloys Compd. 2020, 819, 152962. [Google Scholar] [CrossRef]

- Alidokht, S.; Manimunda, P.; Vo, P.; Yue, S.; Chromik, R. Cold spray deposition of a Ni-WC composite coating and its dry sliding wear behavior. Surf. Coat. Technol. 2016, 308, 424–434. [Google Scholar] [CrossRef]

- Luo, X.-T.; Wei, Y.-K.; Wang, Y.; Li, C.-J. Microstructure and mechanical property of Ti and Ti6Al4V prepared by an in-situ shot peening assisted cold spraying. Mater. Des. 2015, 85, 527–533. [Google Scholar] [CrossRef]

- Xie, X.; Chen, C.; Xie, Y.; Ren, Z.; Aubry, E.; Ji, G.; Liao, H. A novel approach for fabricating Ni-coated FeSiAl soft magnetic composite via cold spraying. J. Alloys Compd. 2018, 749, 523–533. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C. Effect of friction stir welding on microtructuer of 7075 Aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Rajan, H.M.; Dinaharan, I.; Ramabalan, S.; Akinlabi, E. Influence of friction stir processing on microstructure and properties of AA7075/TiB2 in situ composite. J. Alloys Compd. 2016, 657, 250–260. [Google Scholar] [CrossRef]

- Yang, K.; Li, W.; Niu, P.; Yang, X.; Xu, Y. Cold sprayed AA2024/Al2O3 metal matrix composites improved by friction stir processing: Microstructure characterization, mechanical performance and strengthening mechanisms. J. Alloys Compd. 2018, 736, 115–123. [Google Scholar] [CrossRef]

- Mishra, R.S.; McFadden, S.X.; Mara, N.A.; Mukherjee, A.K. High strain rate superplasticity in a friction stir processed 7075 Al alloy. Scr. Mater. 1999, 42, 163–168. [Google Scholar] [CrossRef]

| Conditions | Nozzle | Propelling Gas | Carrier Gas | Gas Pressure (MPa) | Gas Temperature (°C) | CS System |

|---|---|---|---|---|---|---|

| CT1 | SiC-1 | Air | Ar | 3.0 | 470 | CGT-3000 |

| CT2 | PBI-3 | He | He | 1.8 | 320 | LERMPS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, Y.; Xie, X.; Li, R. Modification of Microstructure and Properties of Cold-Sprayed AlSi10Mg+TiB2 Composite by Friction Stir Process. Coatings 2024, 14, 1509. https://doi.org/10.3390/coatings14121509

Jing Y, Xie X, Li R. Modification of Microstructure and Properties of Cold-Sprayed AlSi10Mg+TiB2 Composite by Friction Stir Process. Coatings. 2024; 14(12):1509. https://doi.org/10.3390/coatings14121509

Chicago/Turabian StyleJing, Yufei, Xinliang Xie, and Rengeng Li. 2024. "Modification of Microstructure and Properties of Cold-Sprayed AlSi10Mg+TiB2 Composite by Friction Stir Process" Coatings 14, no. 12: 1509. https://doi.org/10.3390/coatings14121509

APA StyleJing, Y., Xie, X., & Li, R. (2024). Modification of Microstructure and Properties of Cold-Sprayed AlSi10Mg+TiB2 Composite by Friction Stir Process. Coatings, 14(12), 1509. https://doi.org/10.3390/coatings14121509