The Interfacial Reaction Traits of (Al63Cu25Fe12)99Ce1 Quasicrystal-Enhanced Aluminum Matrix Composites Produced by Means of Hot Pressing

Abstract

1. Introduction

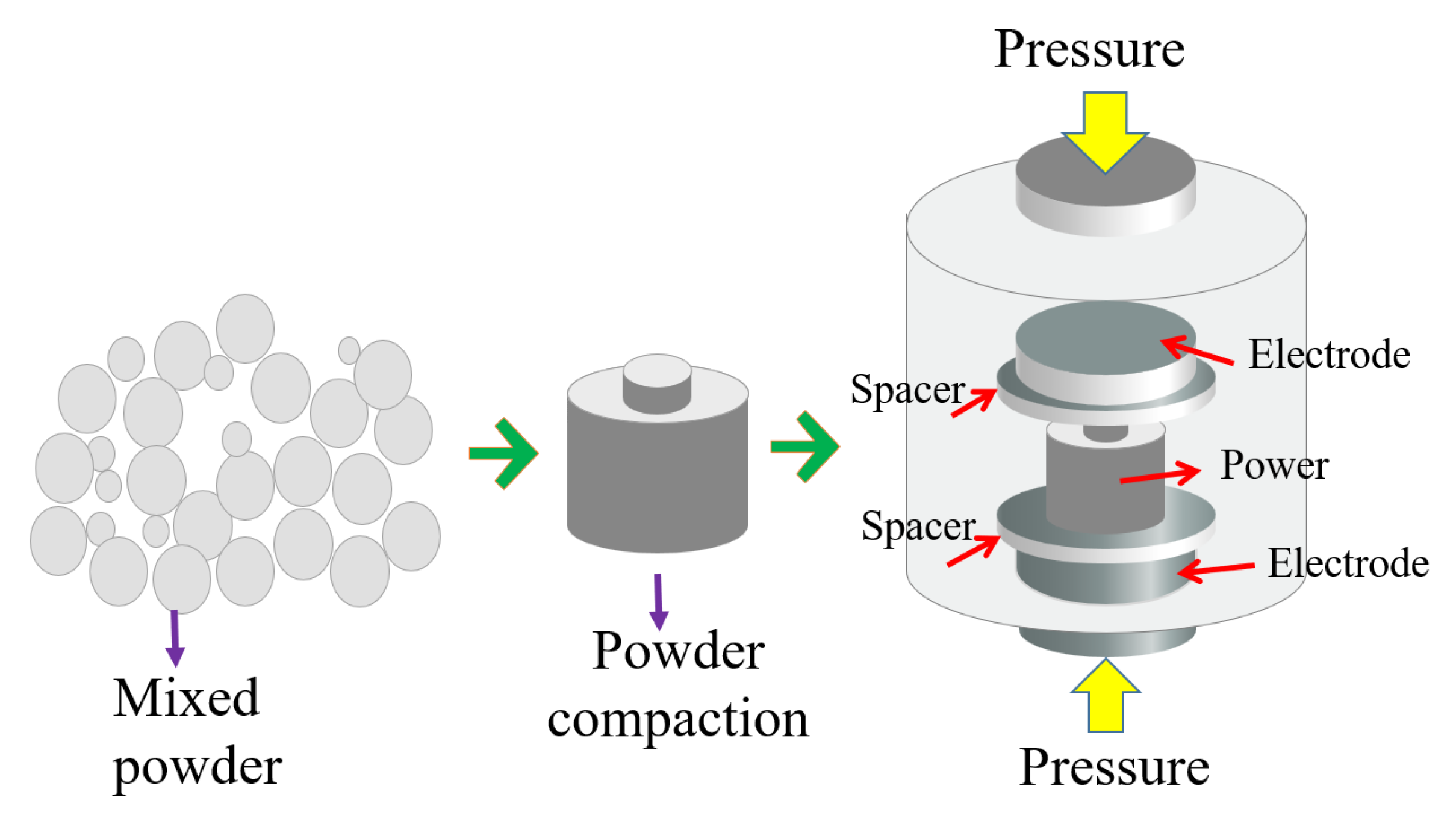

2. Experimental

2.1. Selection of Raw Substances

2.2. Material Characterization Methods

3. Results

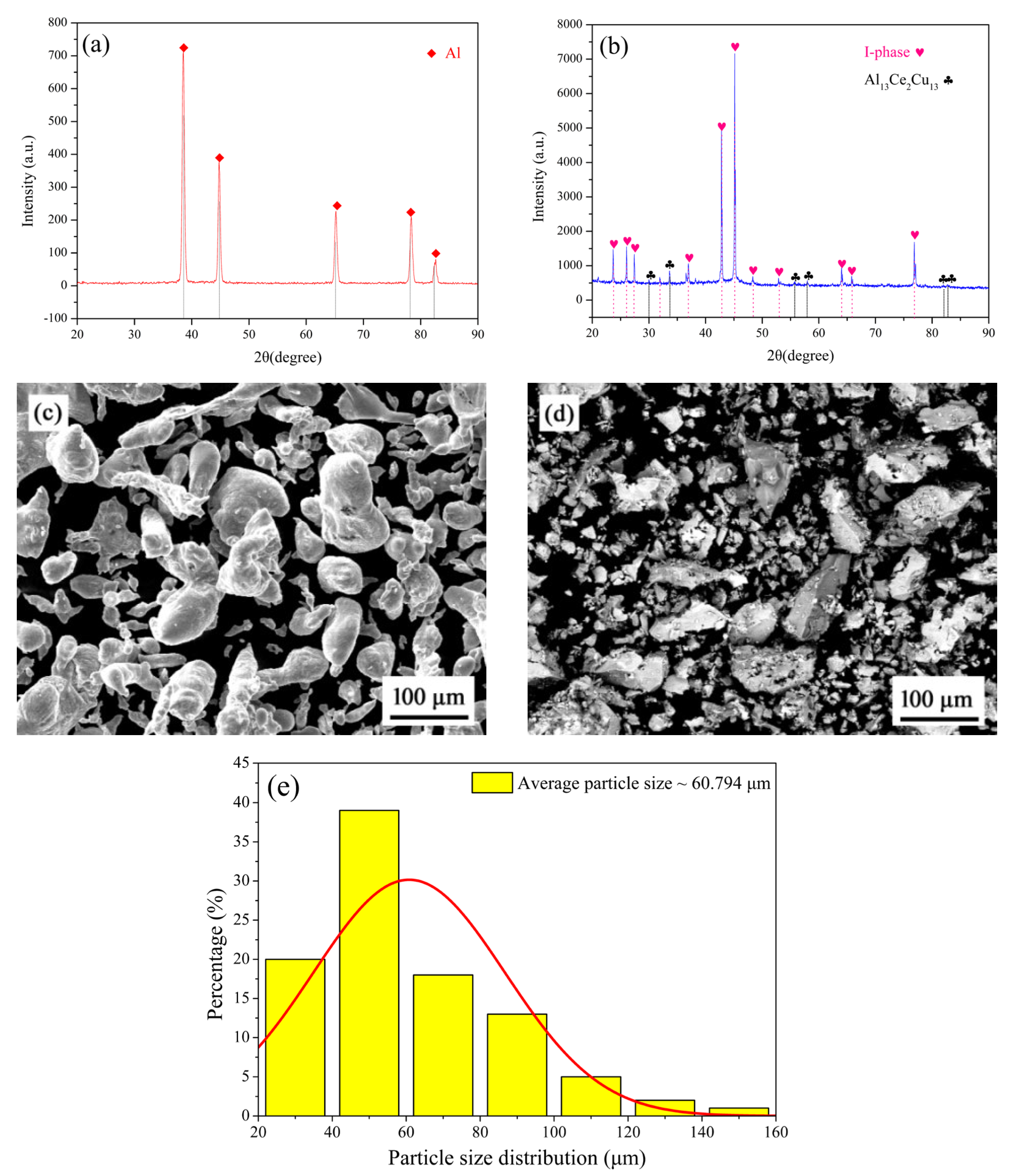

3.1. XRD Characterization

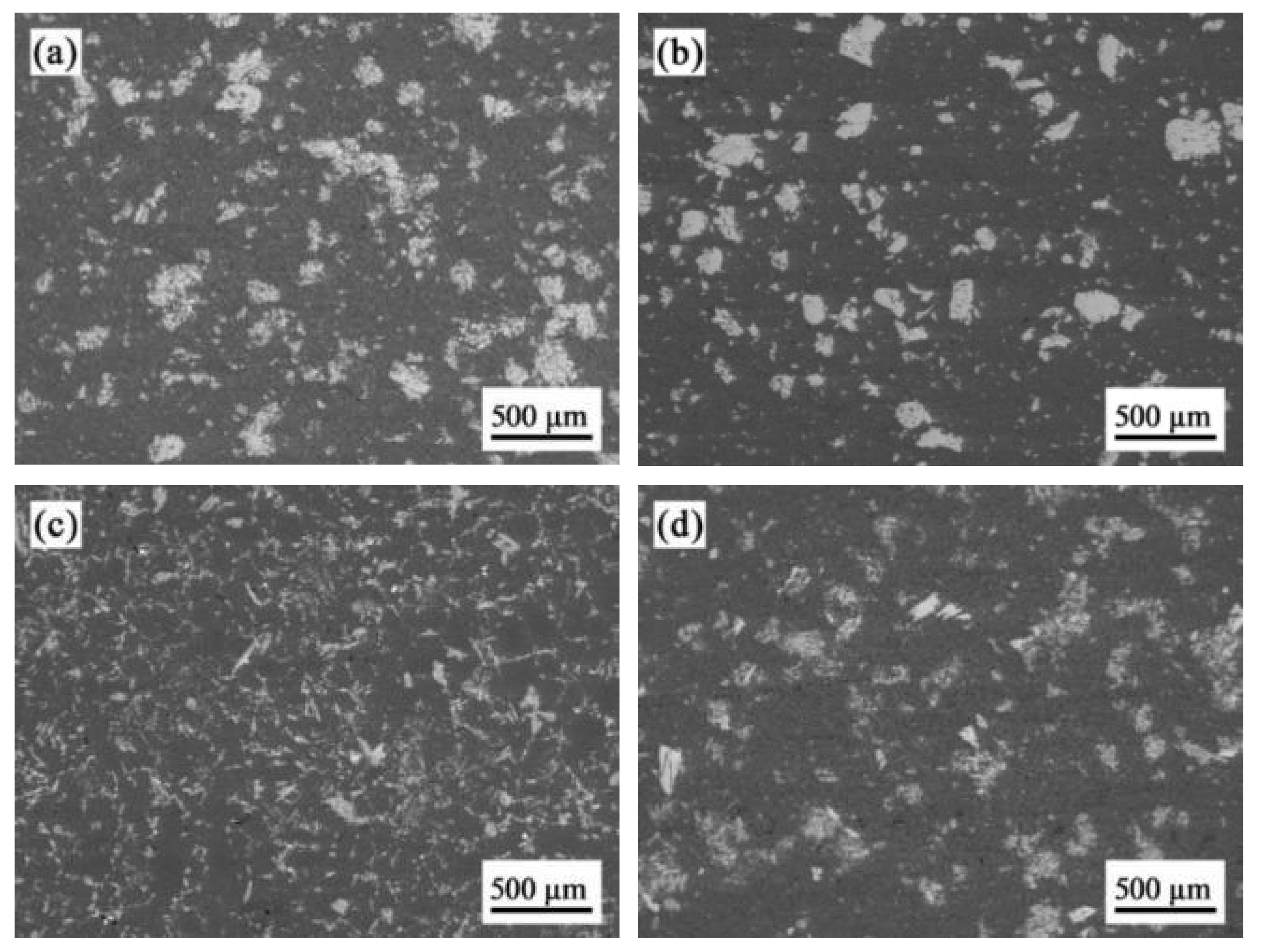

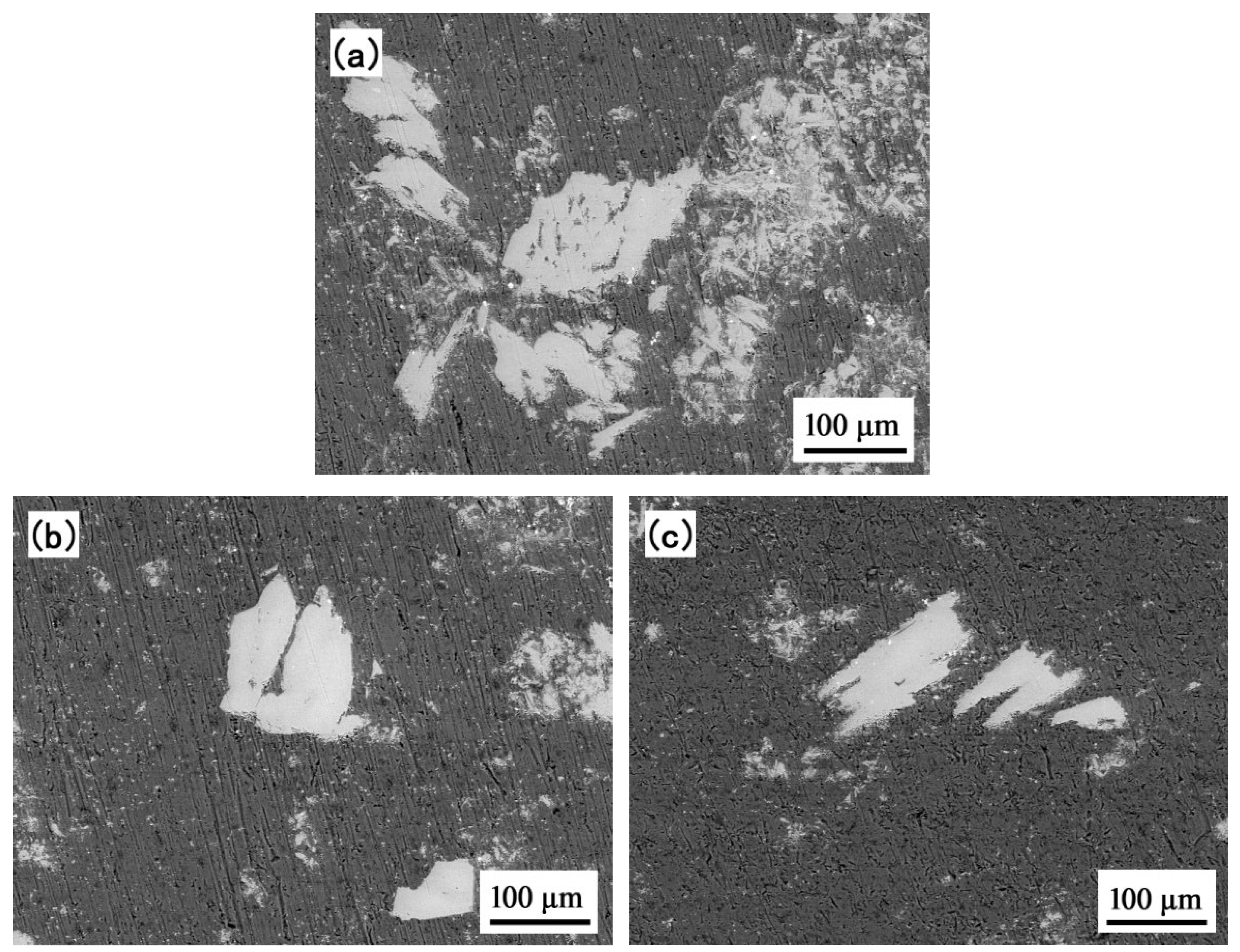

3.2. Microstructure Analysis of Al-20IQC

3.3. Diffusion Dynamics Analysis of the Hot Pressing Process

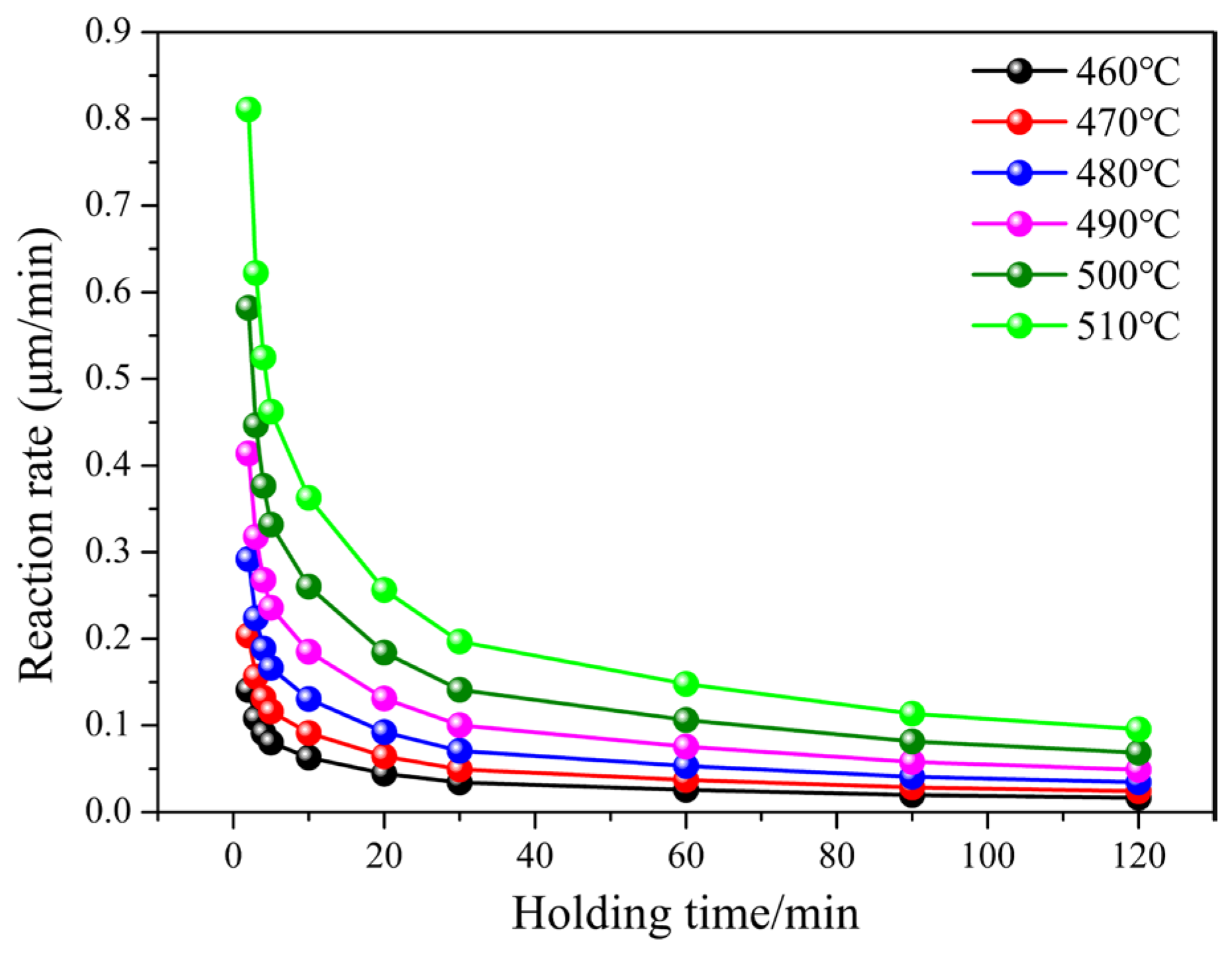

3.4. Densification Tests

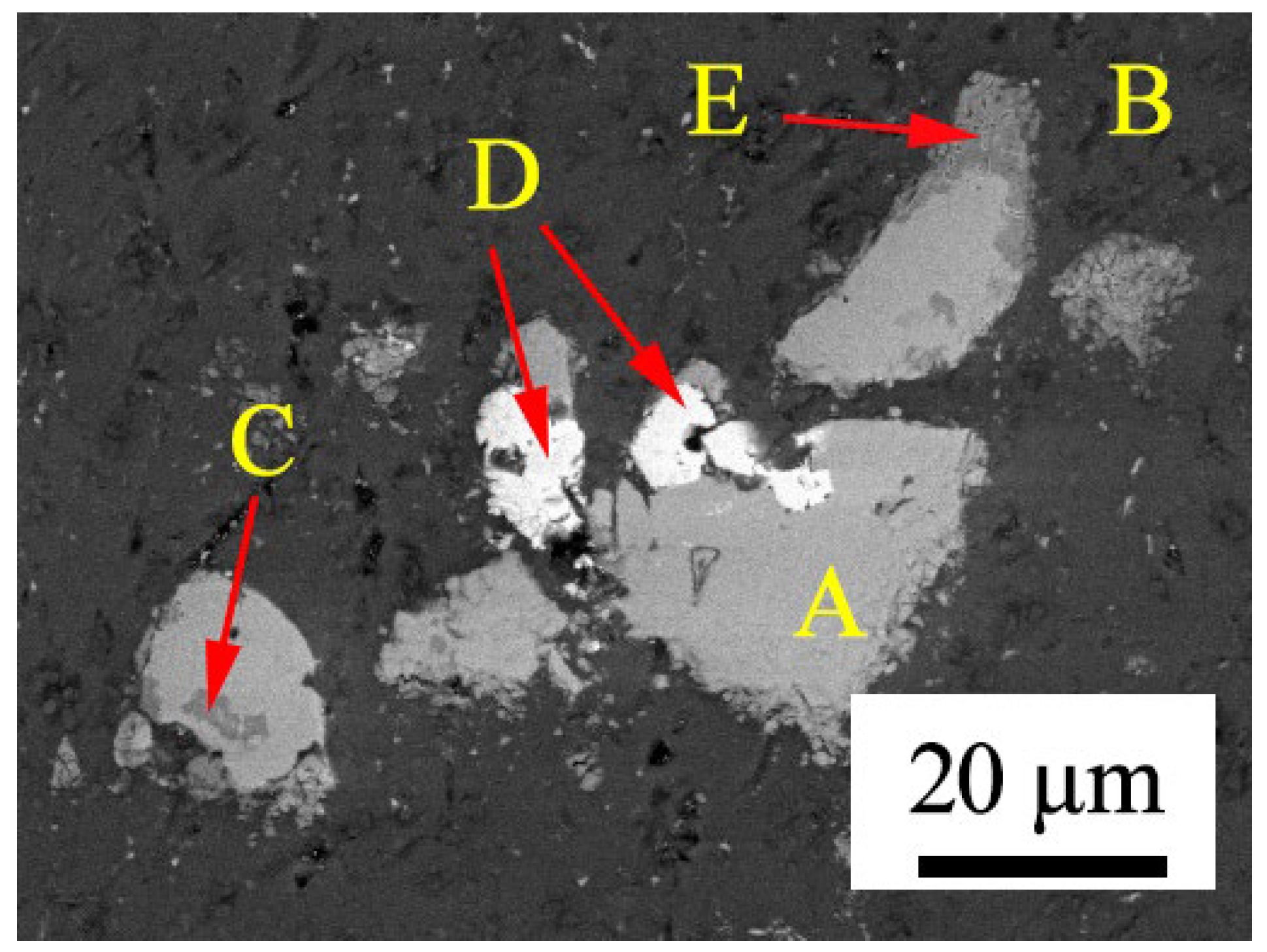

3.5. Energy Spectrum Analysis

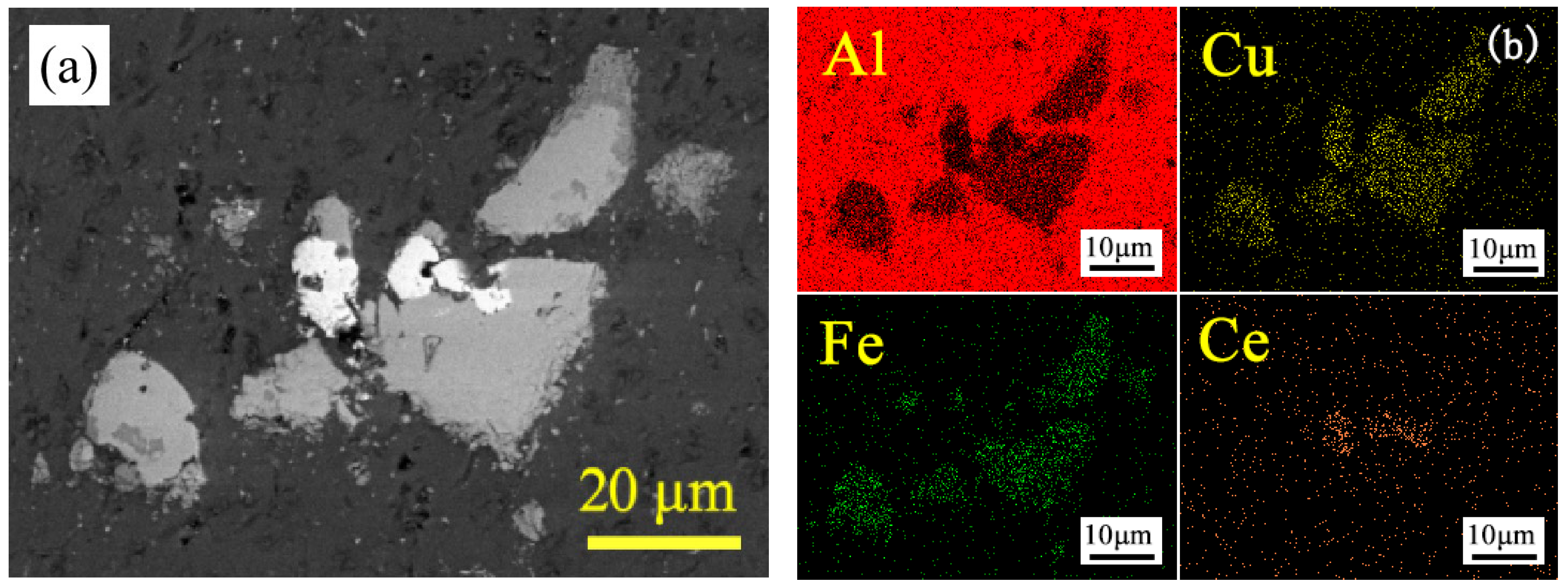

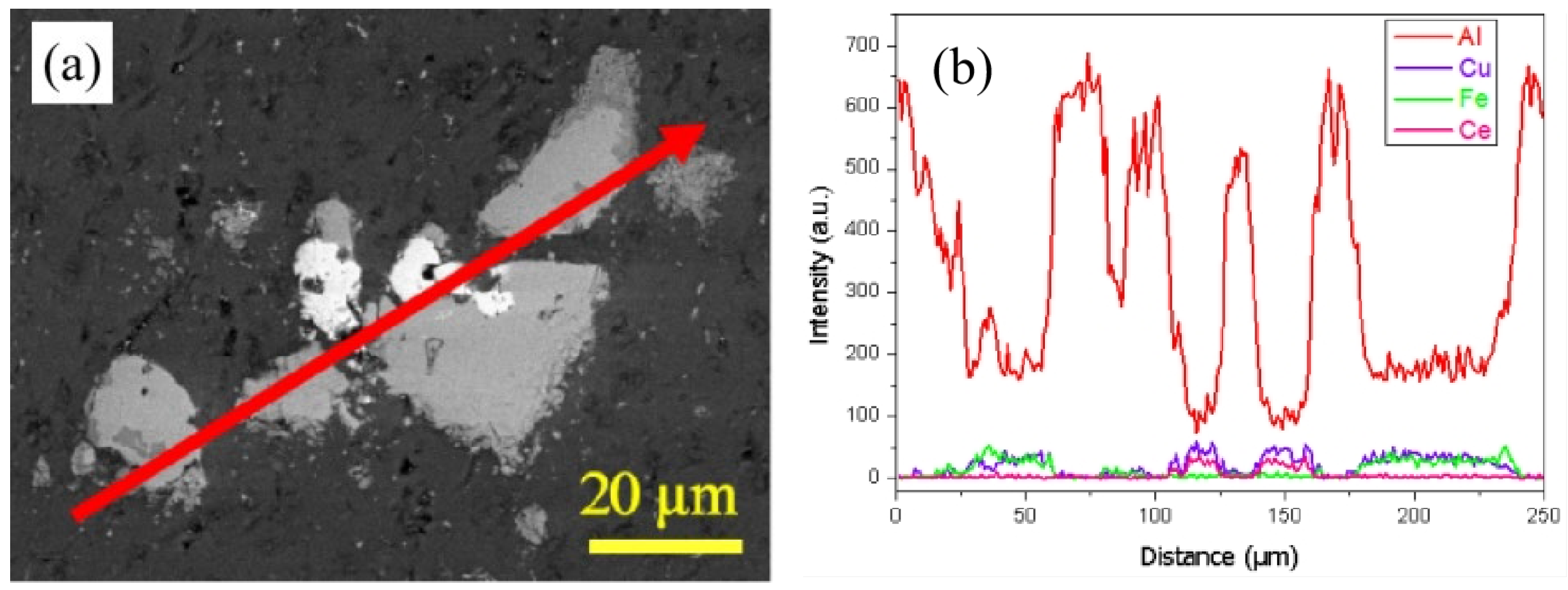

3.6. Analysis of the Surface Distribution and Line Scanning Distribution of Al-20IQC

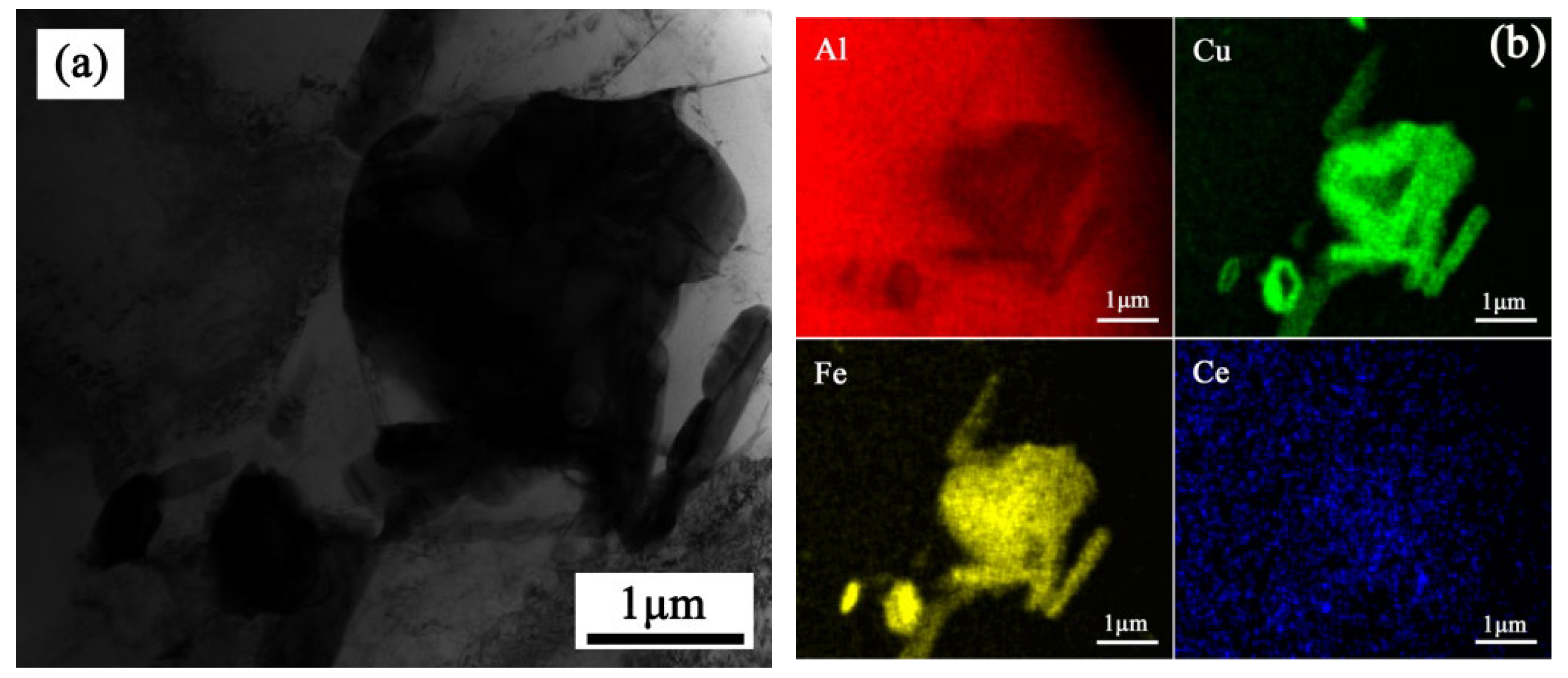

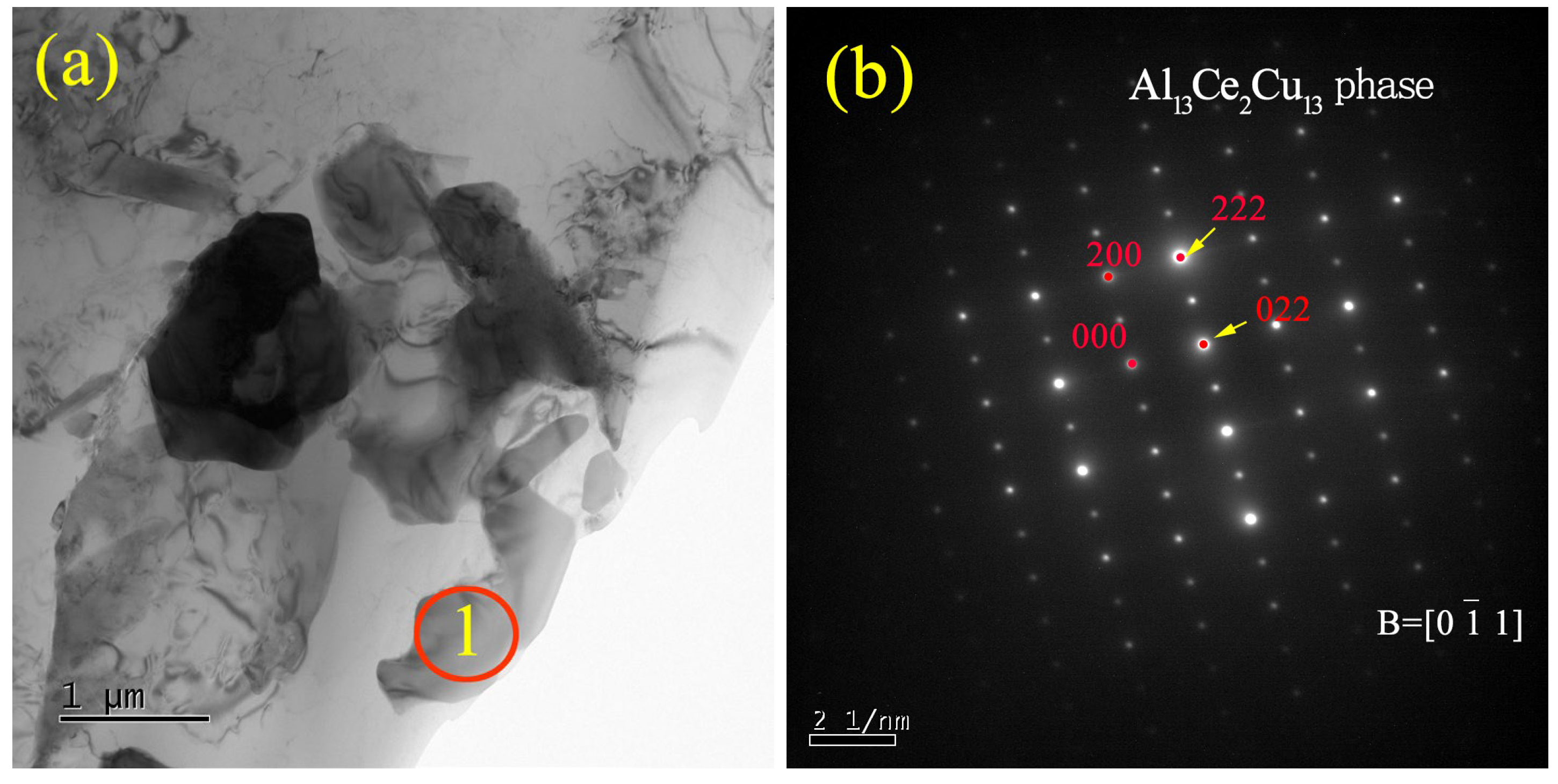

3.7. Transmission Electron Microscopy Analysis

3.8. Mechanical Performances

4. Discussion

5. Conclusions

- When the sintering temperature is 490 °C for 30 min, the interface between the composite matrix and reinforcement is clear, and the interface integrity is good. During hot pressing sintering, chemical diffusion occurs between the I-phase and aluminum matrix, forming part of the Al7Cu2Fe phase, AlFe phase, and AlCu phase. Due to the uniform and fine distribution of these phases, the overall properties of the alloy are obviously enhanced;

- When the holding time increases, the compactness of the composite first increases and then decreases again. After holding at 490 °C for 30 min, the compactness of the composite reaches the maximum, which is about 98.89%;

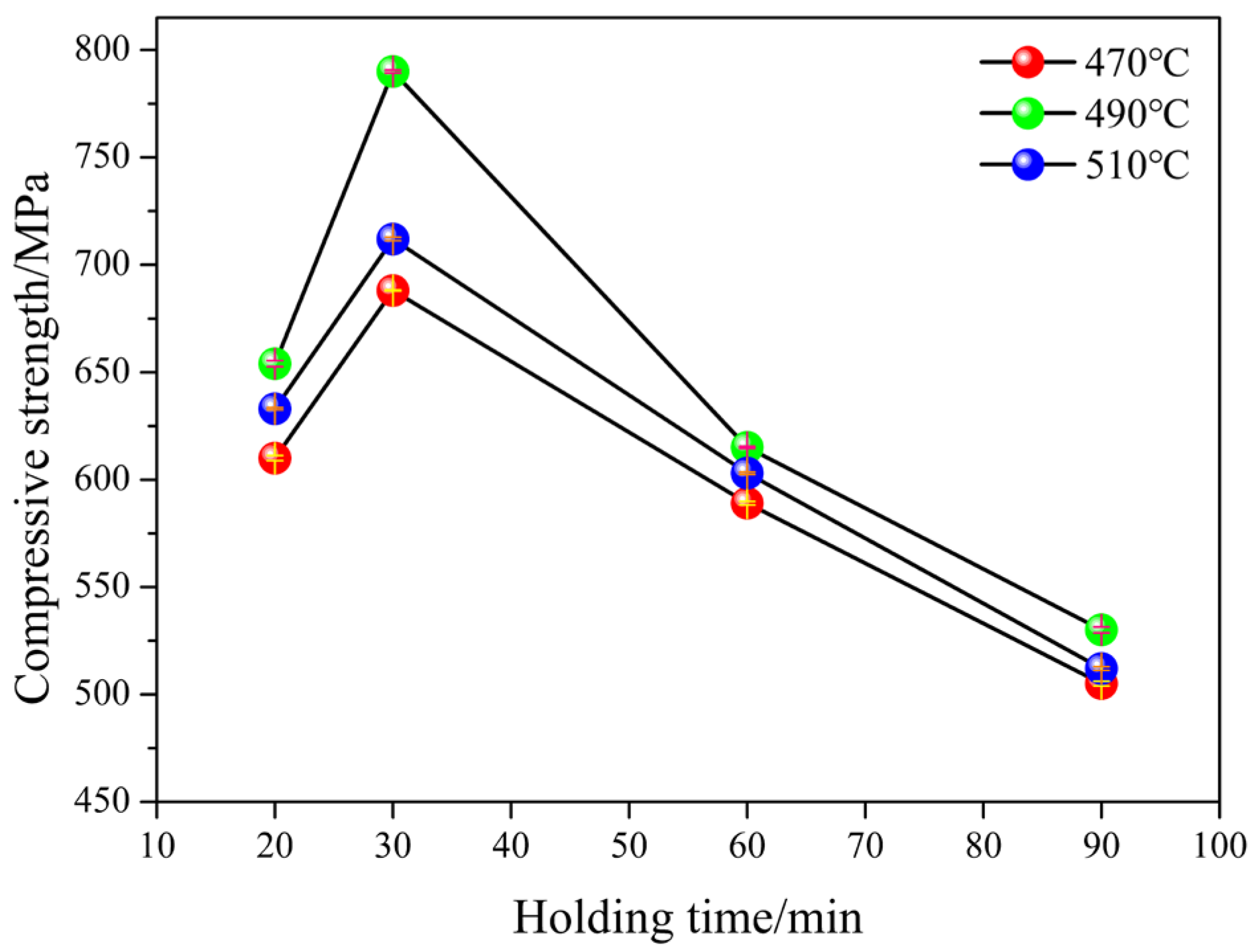

- As sintering temperature increases, the composite shows a first increase and later decrease trend of compressive strength. Following 30 min holding under 490 °C, there is a dense reinforcement particles-matrix combination, accompanied by integrated reinforcement under even distribution within the matrix. Moreover, the composite has the highest compressive strength at around 790 MPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bhowmik, A.; Sen, B.; Beemkumar, N.; Chohan, J.S.; Bains, P.S.; Singh, G.; Kumar, A.V. Development and wear resistivity performance of SiC and TiB2 particles reinforced novel aluminium matrix composites. Results Eng. 2024, 24, 102981. [Google Scholar] [CrossRef]

- Senthil, R.; Mohanavel, V. Effect of aluminium nitride (AlN) particles addition on mechanical and tribological properties of aluminium matrix composites. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Sun, X.; Xie, Y.; Meng, X.; Mao, D.; Zhang, Z.; Wang, J.; Ma, X.; Wang, N.; Huang, Y. Tailoring high-entropy oxides to ameliorate interfacial mismatch of aluminum-matrix composites towards superior strength-ductility balance. Mater. Sci. Eng. A 2024, 909, 146813. [Google Scholar] [CrossRef]

- Anirudh, V.; Vigneshwaran, M.; Vijay, E.; Pramod, R.; Kumar, G.V. Influence of Titanium Diboride and Graphite Reinforcement on Al6061 Alloy. Mater. Today Proc. 2018, 5, 25341–25349. [Google Scholar] [CrossRef]

- Singla, D.; Amulya, K.; Murtaza, Q. CNT Reinforced Aluminium Matrix Composite-A Review. Mater. Today Proc. 2015, 2, 2886–2895. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Elanchezhian, C.; Jaivignesh, M.; Rajesh, S.; Parswajinan, C.; Ghias, A.S. Evaluation of mechanical properties of aluminium alloy–alumina–boron carbide metal matrix composites. Mater. Des. 2014, 58, 332–338. [Google Scholar] [CrossRef]

- Koli, D.; Agnihotri, G.; Purohit, R. Advanced Aluminium Matrix Composites: The Critical Need of Automotive and Aerospace Engineering Fields. Mater. Today Proc. 2015, 2, 3032–3041. [Google Scholar] [CrossRef]

- Xavior, M.A.; Kumar, H.G.P. Processing and Characterization Techniques of Graphene Reinforced Metal Matrix Composites (GRMMC); A Review. Mater. Today Proc. 2017, 4 Pt A, 3334–3341. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, W. A review on aluminum matrix composites’ characteristics and applications for automotive sector. Heliyon 2024, 10, e38576. [Google Scholar] [CrossRef]

- Demuynck, M.; Erauw, J.; Van der Biest, O.; Delannay, F.; Cambier, F. Densification of alumina by SPS and HP: A comparative study. J. Eur. Ceram. Soc. 2012, 32, 1957–1964. [Google Scholar] [CrossRef]

- Aravindan, M.K.; Balamurugan, K.; Murali, G. Effect of reinforcement of AL-6063 with SiC on mechanical behavior and microstructure of metal matrix composites. Carbon Sci. Technol. 2014, 6, 388–394. [Google Scholar]

- Llorca, J.; Needleman, A.; Suresh, S. An analysis of the effects of matrix void growth on deformation and ductility in metal-ceramic composites. Acta Metall. Mater. 1991, 39, 2317–2335. [Google Scholar] [CrossRef]

- Texier, M.; Proult, A.; Bonneville, J.; Rabier, J.; Baluc, N.; Cordier, P. Microstructure of icosahedral Al-Pd-Mn quasicrystals deformed at room temperature in an anisotropic confining medium. Philos. Mag. Lett. 2002, 82, 659–669. [Google Scholar] [CrossRef]

- Lee, K.; Dai, W.; Naugle, D.; Liang, H. Effects of Microstructure of Quasicrystal Alloys on Their Mechanical and Tribological Performance. J. Tribol. 2018, 140, 051605. [Google Scholar] [CrossRef]

- Kim, Y.K.; Kim, W.T.; Kim, D.H. Quasicrystal-reinforced Mg alloys. Sci. Technol. Adv. Mater. 2014, 15, 024801. [Google Scholar]

- Tsai, A.; Aoki, K.; Inoue, A.; Masumoto, T. Synthesis of stable quasicrystalline particle-dispersed Al base composite alloys. J. Mater. Res. 1993, 8, 5–7. [Google Scholar] [CrossRef]

- Ying, Y.; Guan, Z.; Wang, X.; Wang, G.; Yan, W. Room temperature tensile creep behavior of Mg-6Zn-0.4Mn-0.3Al-0.2Ca (wt%) alloy containing icosahedral quasicrystals. Mater. Today Commun. 2024, 39, 108602. [Google Scholar] [CrossRef]

- Zhang, L.; Ai, T.; Tian, X.; Dai, S. An efficient removal mechanism for different hydrophilic antibiotics from aquatic environments by Cu–Al–Fe–Cr quasicrystals††Electronic supplementary information (ESI) available. RSC Adv. 2022, 12, 9995–10004. [Google Scholar] [CrossRef]

- Polozhentsev, O.E.; Kozakov, A.T.; Vlasenko, V.G.; Bryleva, M.A.; Kubrin, S.P.; Soldatov, A.V. The local atomic and electronic structure of quasicrystal i-Al65Cu23Fe12 powder. Mater. Today Commun. 2024, 39, 108747. [Google Scholar] [CrossRef]

- Shadangi, Y.; Sharma, S.; Shivam, V.; Basu, J.; Chattopadhyay, K.; Majumdar, B.; Mukhopadhyay, N.K. Fabrication of Al–Cu–Fe quasicrystal reinforced 6082 aluminium matrix nanocomposites through mechanical milling and spark plasma sintering. J. Alloys Compd. 2020, 828, 154258. [Google Scholar] [CrossRef]

- Silveira, A.D.; Silva, L.P.M.E.; Oliveira, T.C.D.; Castro, M.M.; Figueiredo, R.B.; Bolfarini, C.; Botta, W.J.; Wolf, W. Al-matrix composites reinforced with quasicrystals consolidated at room temperature using HPT. Mater. Lett. 2022, 317, 132107. [Google Scholar] [CrossRef]

- Wolf, W.; Bolfarini, C.; Kiminami, C.S.; Botta, W.J. Fabrication of Al-matrix composite reinforced with quasicrystals using conventional metallurgical fabrication methods. Scr. Mater. 2019, 173, 21–25. [Google Scholar] [CrossRef]

- Kang, N.; Fu, Y.; Coddet, P.; Guelorget, B.; Liao, H.; Coddet, C. On the microstructure, hardness and wear behavior of Al-Fe-Cr quasicrystal reinforced Al matrix composite prepared by selective laser melting. Mater. Des. 2017, 132, 105–111. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.; Wang, L.; Li, J. Interfacial reaction kinetics of (Al63Cu25Fe12)99Ce1 quasicrystal reinforced 6061 aluminum matrix composites. J. Alloys Compd. 2023, 955, 170261. [Google Scholar] [CrossRef]

- Yavas, B.; Li, M.; Hung, C.J.; Hebert, R.J.; Alpay, S.P.; Aindow, M. Transformations in laser track microstructures for a quasicrystal-reinforced Al-Cu-Fe-Cr alloy. Mater. Charact. 2024, 217, 114345. [Google Scholar] [CrossRef]

- Ali, F.; Scudino, S.; Liu, G.; Srivastava, V.C.; Mukhopadhyay, N.K.; Khoshkhoo, M.S.; Prashanth, K.G.; Uhlenwinkel, V.; Calin, M.; Eckert, J. Modeling the strengthening effect of Al–Cu–Fe quasicrystalline particles in Al-based metal matrix composites. J. Alloys Compd. 2012, 536, S130–S133. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.; Ma, Z.; Duan, H.; Zhang, J.; Tao, D.; Li, J. Effect of the addition of cerium on the microstructure evolution and thermal expansion properties of cast Al-Cu-Fe alloy. Mater. Res. Express 2021, 8, 036503. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.; Duan, H.; Ma, Z.; Tao, D.; Li, J. Effect of heat treatment on microstructure and thermal expansion properties of as cast (Al63Cu25Fe12)99Ce1 alloy. Kov. Mater.-Met. Mater. 2021, 59, 367–377. [Google Scholar] [CrossRef]

- Joseph, A.; Gauthier-Brunet, V.; Monchoux, J.P.; Joulain, A.; Brisset, F.; Tromas, C.; Douin, J.; Pettinari, F.; Bonneville, J.; Dubois, S. Formation processes of the ω-Al70Cu20Fe10 phase synthesized by SPS technique. J. Alloys Compd. 2016, 699, 1157–1165. [Google Scholar] [CrossRef]

- Parsamehr, H.; Yang, C.L.; Liu, W.T.; Chen, S.W.; Chang, S.Y.; Chen, L.J.; Tsai, A.P.; Lai, C.H. Direct observation of growth and stability of Al-Cu-Fe quasicrystal thin films. Acta Mater. 2019, 174, 1–8. [Google Scholar] [CrossRef]

- Saâdi, N.; Harmelin, M.; Faudot, F.; Legendre, B. Enthalpy of formation of the Al0.63Cu0.25Fe0.12 icosahedral phase. J. Non-Cryst. Solids 1993, 153–154, 500–503. [Google Scholar] [CrossRef]

- Zhang, L.; Schneider, J.; Lück, R. Phase transformations and phase stability of the AlCuFe alloys with low-Fe content. Intermetallics 2005, 13, 1195–1206. [Google Scholar] [CrossRef]

- Fedorov, G.B.; Shevchuk, Y.A.; Khasaev, T.O. Growth kinetics of the intermetallic coating in mutual diffusion in systems of aluminium with titanium and titanium-zirconium alloys. Fiz. I Khimiya Obarabotki Mater. 1990, 24, 53–56. [Google Scholar]

- Luo, J.G.; Acoff, V.L. Using cold roll bonding and annealing to process Ti/Al multi-layered composites from elemental foils. Mater. Sci. Eng. A 2004, 379, 164–172. [Google Scholar] [CrossRef]

- Inoue, A.; Kimura, H. High-strength aluminum alloys containing nanoquasicrystalline particles. Mater. Sci. Eng. A 2000, 286, 1–10. [Google Scholar] [CrossRef]

- Lloyd, D.J. Particle reinforced aluminium and magnesium matrix composites. Int. Mater. Rev. 1994, 39, 1–23. [Google Scholar] [CrossRef]

- Scudino, S.; Liu, G.; Sakaliyska, M.; Surreddi, K.B.; Eckert, J. Powder metallurgy of Al-based metal matrix composites reinforced with β-Al3Mg2 intermetallic particles: Analysis and modeling of mechanical properties. Acta Mater. 2009, 57, 4529–4538. [Google Scholar] [CrossRef]

- Nardone, V.C.; Prewo, K.M. On the strength of discontinuous silicon carbide reinforced aluminum composites. Scr. Metall. 1986, 20, 43–48. [Google Scholar] [CrossRef]

- Andersen, S.I.; Lilholt, H.; Pedersen, O.B. Mechanical and physical behaviour of metallic and ceramic composites. In Proceedings of the 9th Risø International Symposium on Metallurgy and Materials Science, Roskilde, Denmark, 5–9 September 1988. [Google Scholar]

- Miller, W.S.; Humphreys, F.J. Strengthening mechanisms in particulate metal-matrix composites. Scr. Metall. Mater. 1991, 25, 2623–2626. [Google Scholar] [CrossRef]

- Hansen, N. The effect of grain size and strain on the tensile flow stress of aluminium at room temperature. Acta Metall. 1977, 25, 863–869. [Google Scholar] [CrossRef]

- Scudino, S.; Liu, G.; Prashanth, K.G.; Bartusch, B.; Surreddi, K.B.; Murty, B.S.; Eckert, J. Mechanical properties of Al-based metal matrix composites reinforced with Zr-based glassy particles produced by powder metallurgy. Acta Mater. 2009, 57, 2029–2039. [Google Scholar] [CrossRef]

- Arsenault, R.J.; Wang, L.; Feng, C.R. Strengthening of composites due to microstructural changes in the matrix. Acta Metall. Mater. 1991, 39, 47–57. [Google Scholar] [CrossRef]

- Brown, L.M.; Stobbs, W.M. The work-hardening of copper-silica v. equilibrium plastic relaxation by secondary dislocations. Philos. Mag. J. Theor. Exp. Appl. Phys. 1976, 34, 351–372. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: {III} Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

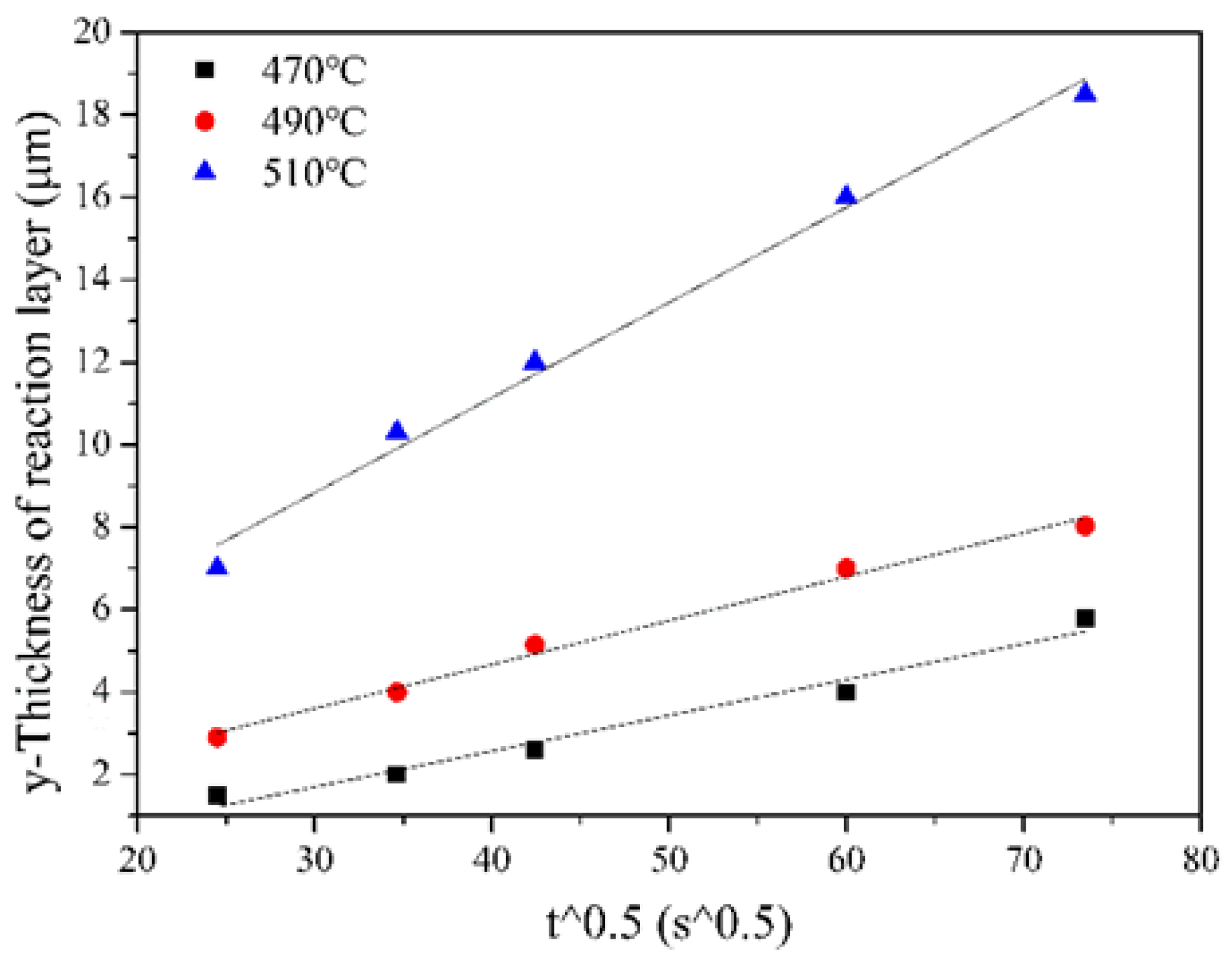

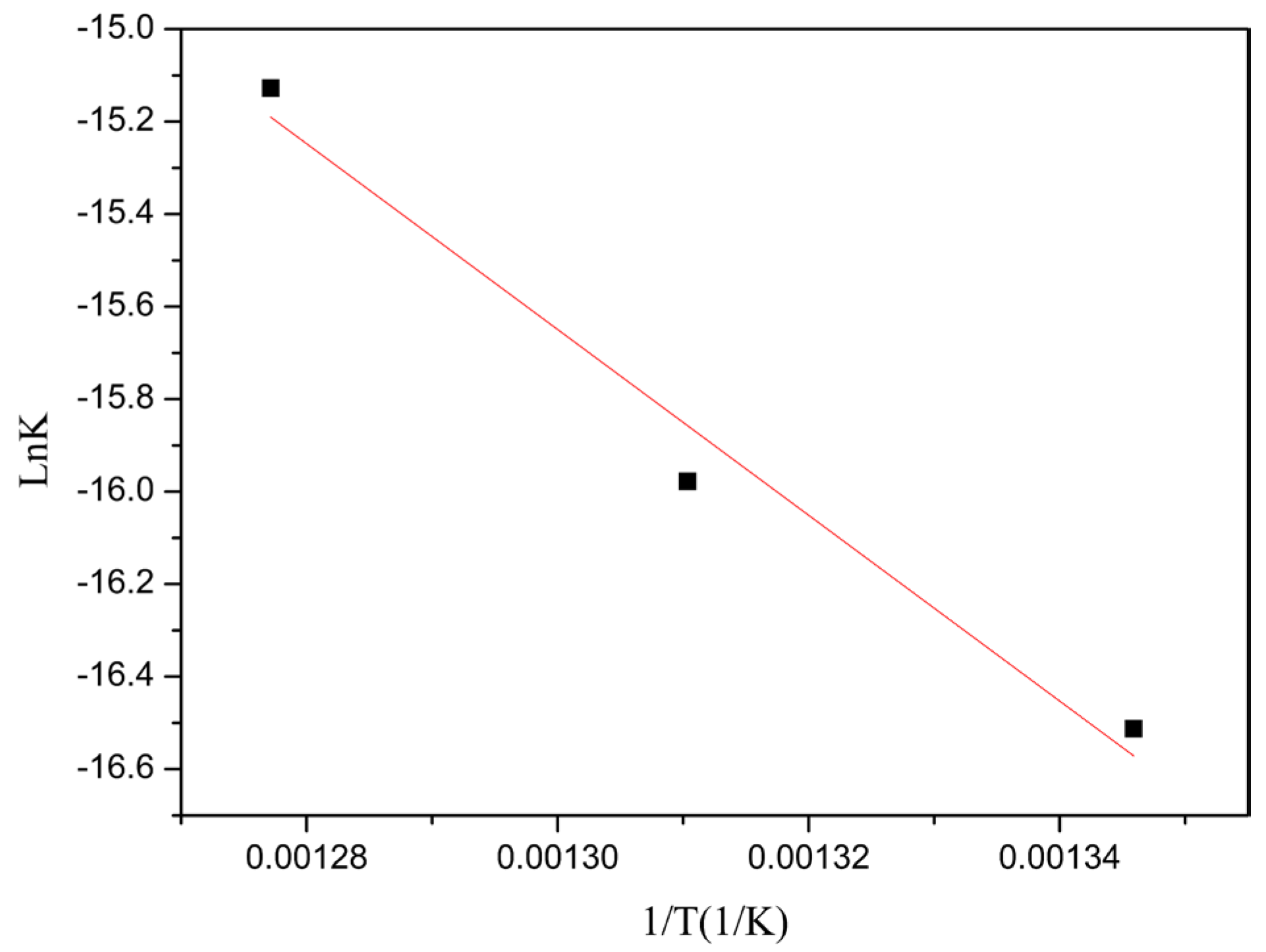

| Temperature (°C) | 470 | 470 | 470 | 470 | 470 | 490 | 490 | 490 | 490 | 490 | 510 | 510 | 510 | 510 | 510 |

| Time (min) | 10 | 20 | 30 | 60 | 90 | 10 | 20 | 30 | 60 | 90 | 10 | 20 | 30 | 60 | 90 |

| Reaction Layer Thickness (µm) | 1.5 | 2 | 2.6 | 4 | 5.78 | 2.9 | 4 | 5.15 | 7 | 8.03 | 7 | 10.3 | 12 | 16 | 18.5 |

| Elemental Composition of Phases in Al-20IQC Composite HPS at 490 °C | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| HPS Temperature | Region | Al | Fe | Cu | Ce | ||||

| wt% | at% | wt% | at% | wt% | at% | wt% | at% | ||

| 490 °C | A | 47.1 | 66.75 | 17.05 | 11.68 | 31.85 | 21.57 | ||

| B | 96.71 | 98.57 | 3.29 | 1.43 | |||||

| C | 31.73 | 49.12 | 67.43 | 50.33 | 0.84 | 0.55 | |||

| D | 24.49 | 47.18 | 55.51 | 45.41 | 20 | 7.42 | |||

| E | 49.95 | 69.26 | 15.6 | 10.45 | 34.45 | 20.28 | |||

| Compressive Strength | Sintering Temperature | 20 min | 30 min | 60 min | 90 min |

|---|---|---|---|---|---|

| σbc (MPa) | 470 °C | 610 ± 1.2 | 688 ± 0.2 | 589 ± 0.8 | 505 ± 1.1 |

| 490 °C | 654 ± 1.42 | 790 ± 0.68 | 615 ± 0.44 | 530 ± 1.38 | |

| 510 °C | 633 ± 0.5 | 712 ± 0.8 | 603 ± 0.6 | 512 ± 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Yang, Z. The Interfacial Reaction Traits of (Al63Cu25Fe12)99Ce1 Quasicrystal-Enhanced Aluminum Matrix Composites Produced by Means of Hot Pressing. Coatings 2024, 14, 1411. https://doi.org/10.3390/coatings14111411

Wang J, Yang Z. The Interfacial Reaction Traits of (Al63Cu25Fe12)99Ce1 Quasicrystal-Enhanced Aluminum Matrix Composites Produced by Means of Hot Pressing. Coatings. 2024; 14(11):1411. https://doi.org/10.3390/coatings14111411

Chicago/Turabian StyleWang, Juan, and Zhong Yang. 2024. "The Interfacial Reaction Traits of (Al63Cu25Fe12)99Ce1 Quasicrystal-Enhanced Aluminum Matrix Composites Produced by Means of Hot Pressing" Coatings 14, no. 11: 1411. https://doi.org/10.3390/coatings14111411

APA StyleWang, J., & Yang, Z. (2024). The Interfacial Reaction Traits of (Al63Cu25Fe12)99Ce1 Quasicrystal-Enhanced Aluminum Matrix Composites Produced by Means of Hot Pressing. Coatings, 14(11), 1411. https://doi.org/10.3390/coatings14111411