Study on the Adhesion Performance of Biochar-Modified Asphalt Based on Surface Free Energy and Atomic Force Microscopy

Abstract

1. Introduction

2. Surface Free Energy Theory (SFE)

3. Materials and Test Methods

3.1. Materials

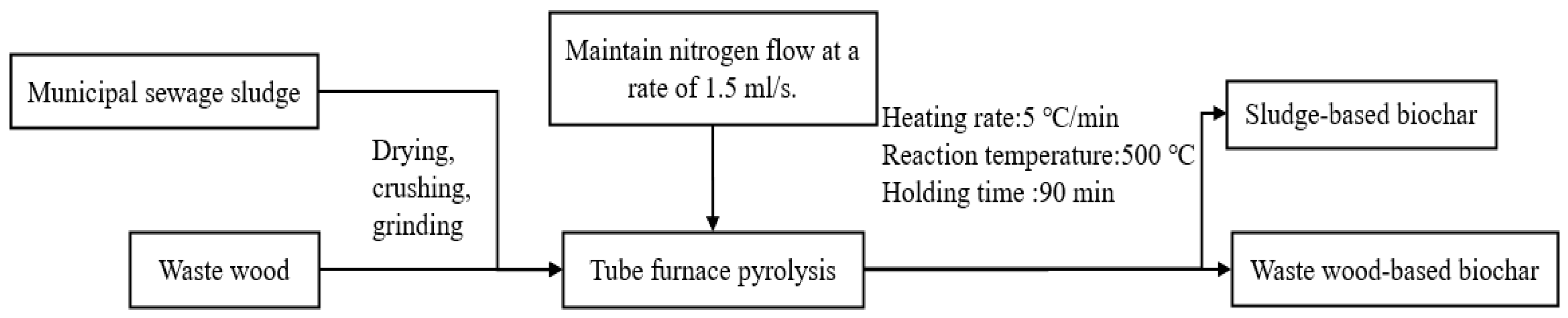

3.1.1. Biochar

3.1.2. Asphalt

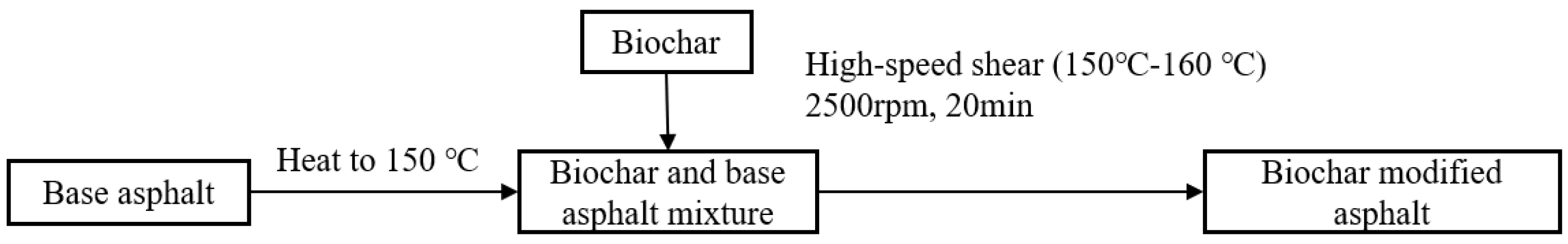

3.1.3. Biochar-Modified Asphalt

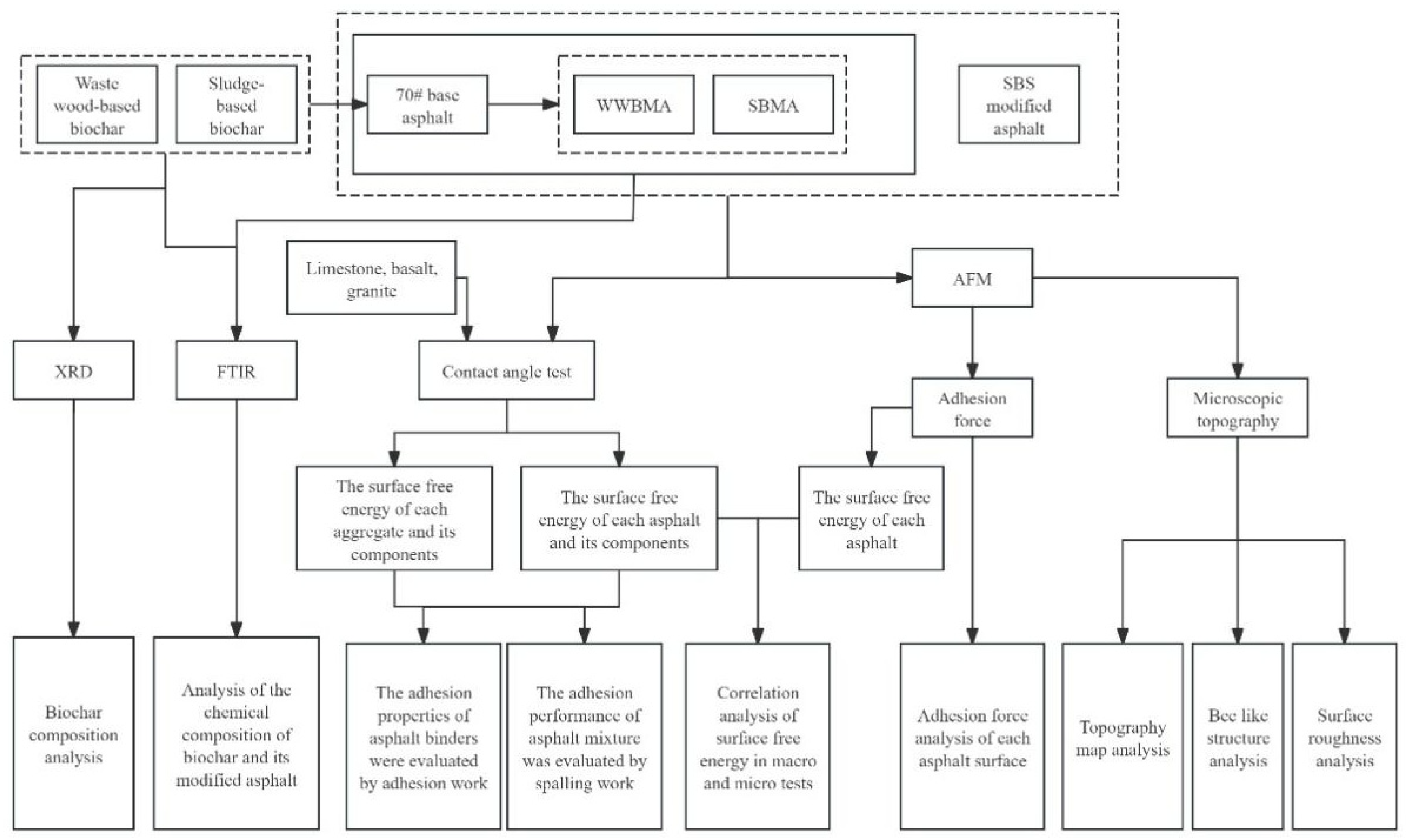

3.2. Test Methods

3.2.1. Fourier Transform Infrared Spectroscopy (FTIR)

3.2.2. X-Ray Diffraction Analysis (XRD)

3.2.3. Atomic Force Microscopy Test (AFM)

- Bee Area Ratio

- 2.

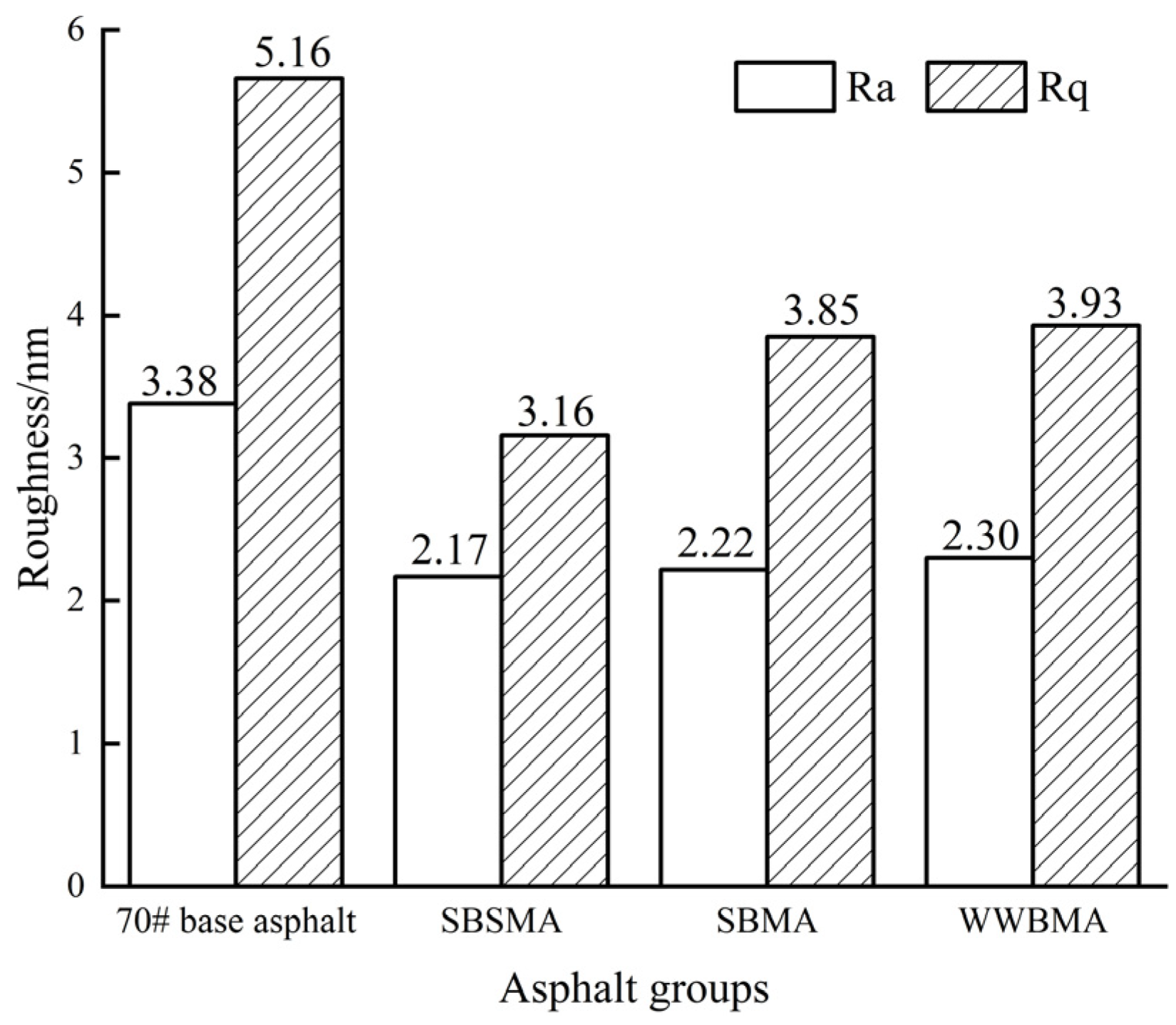

- Surface Roughness

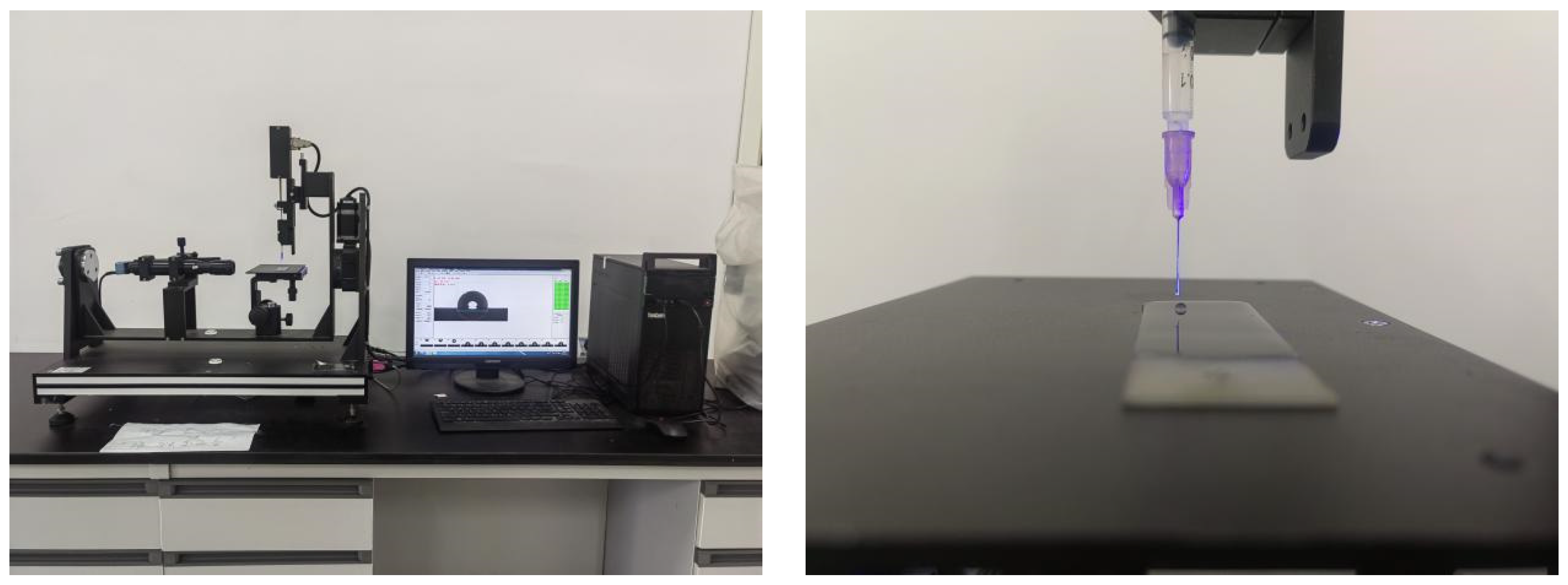

3.2.4. Contact Angle Test

4. Results and Discussion

4.1. Basic Properties of Biochar

4.1.1. FTIR

4.1.2. XRD

4.2. Microstructural Analysis of Biochar-Modified Asphalt

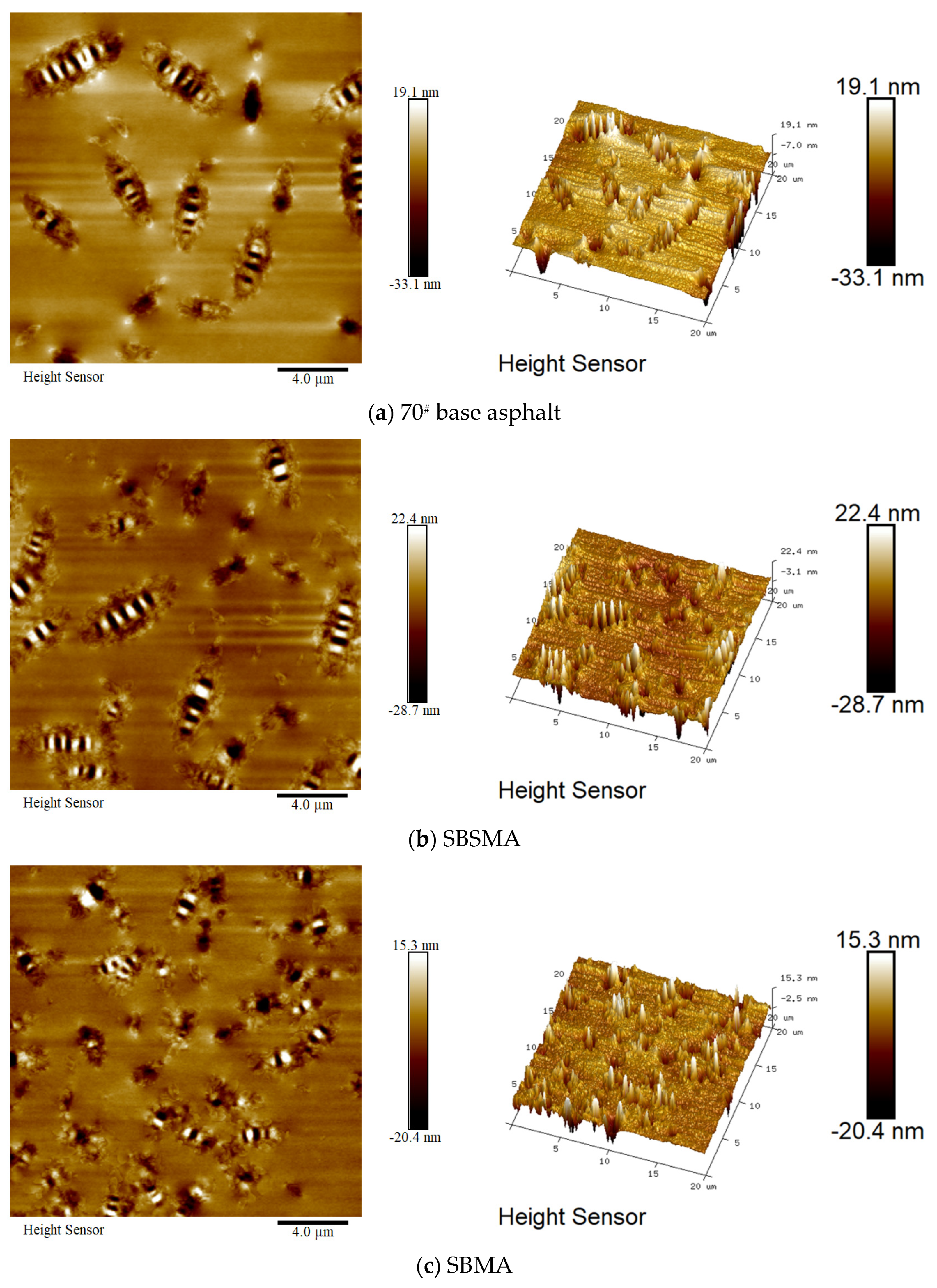

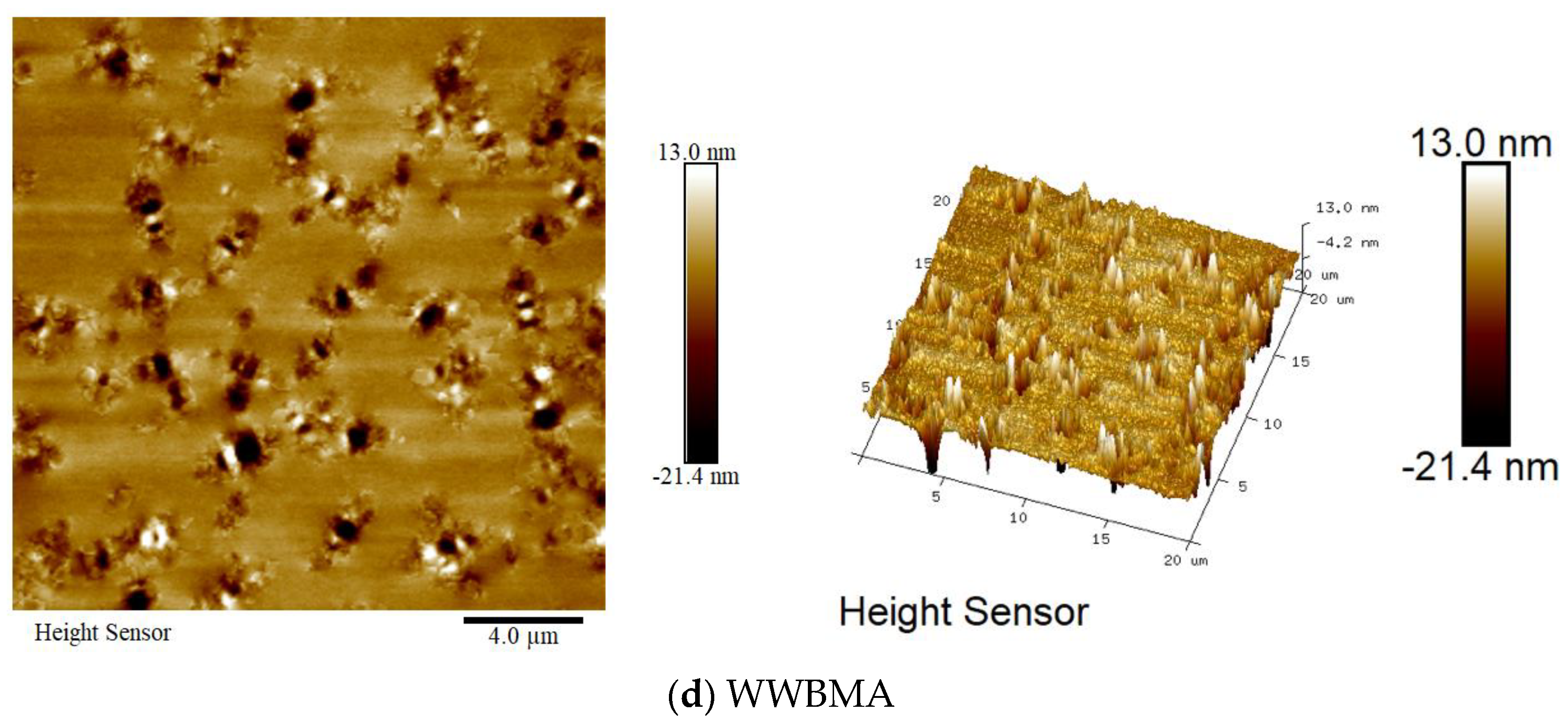

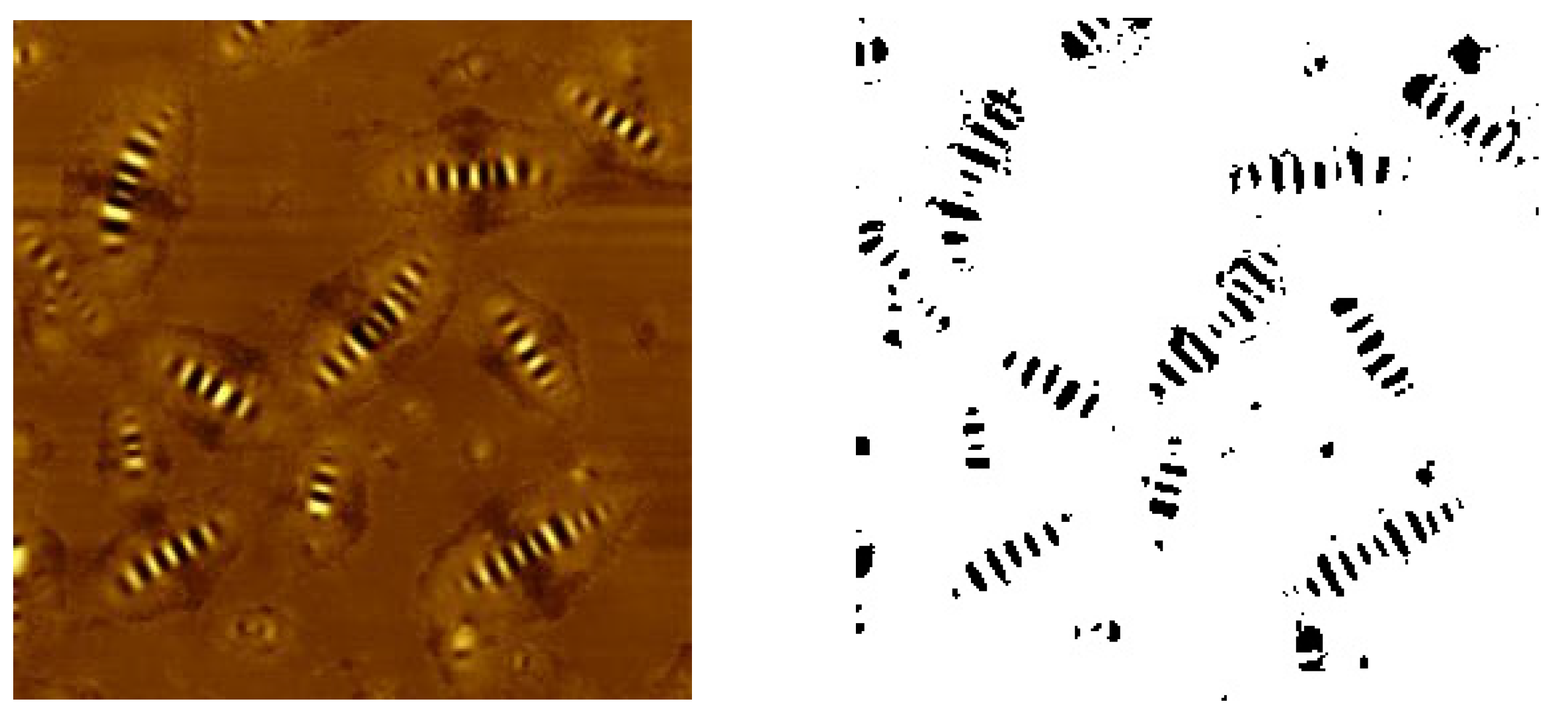

4.2.1. Morphological Analysis

4.2.2. Bee Structure Area Ratio

4.2.3. Surface Roughness

4.3. Micro-Adhesion Performance Analysis of BMA

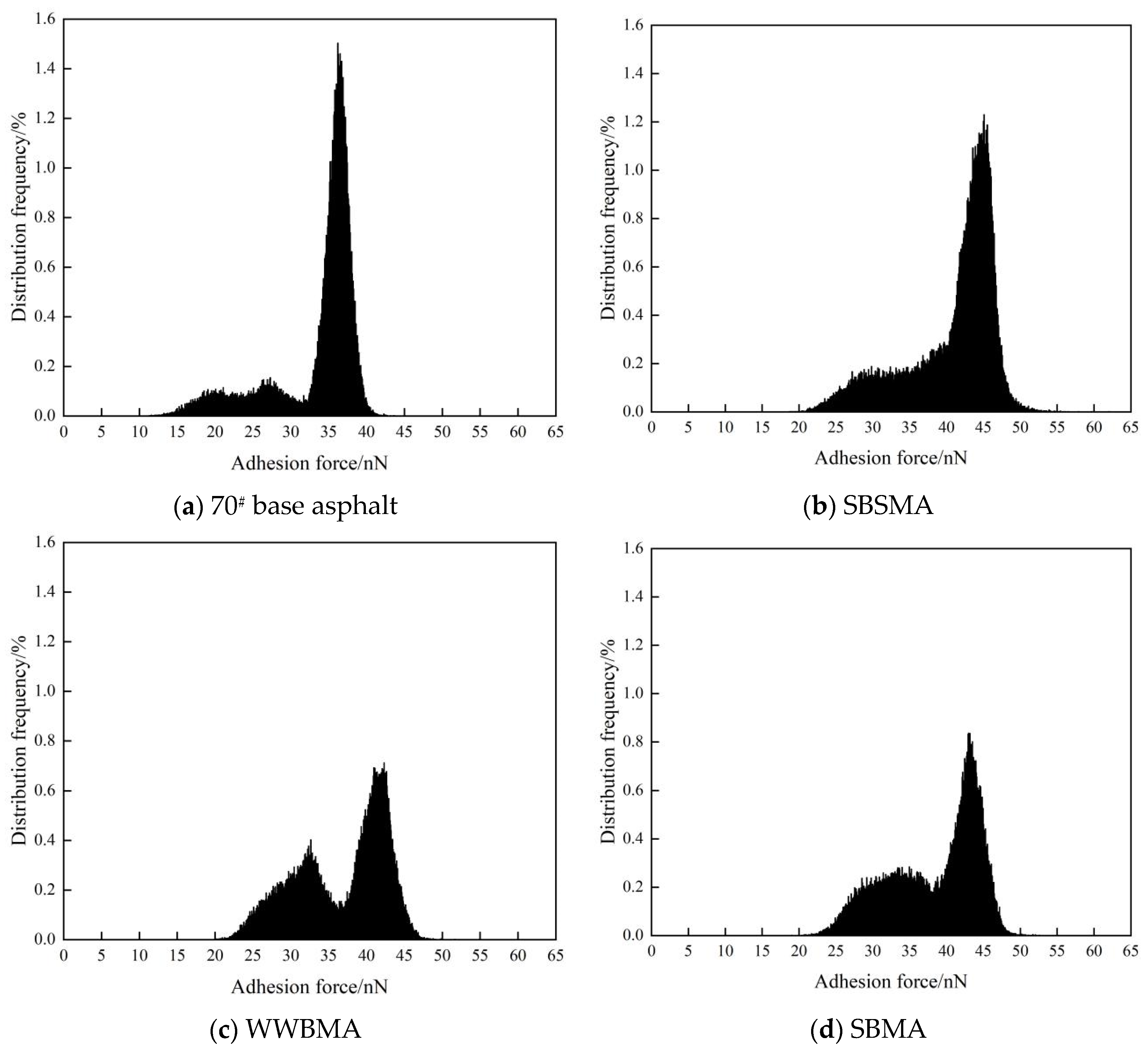

4.3.1. Adhesion Force of Asphalt Based on AFM Testing

4.3.2. Asphalt SFE Based on AFM Testing

4.3.3. Correlation Analysis of Macro/Micro SFE of Asphalt

4.4. Analysis of Macroscopic Adhesion of Biochar-Modified Asphalt

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviation | Variables | ||

| SFE | Surface free energy | γ | Surface free energy |

| AFM | Atomic force microscopy | γLW | Non-polar dispersion component |

| AFM-QNM | AFM-quantitative nano-mechanics | γAB | Polar acid-base component |

| DMT | Derjaguin–Muller–Toporov | γ+ | Polar acid component |

| JKR | Johnson–Kendall–Roberts | γ− | Polar base component |

| SBSMA | SBS-modified asphalt | Was | Adhesion work |

| BMA | Biochar-modified asphalt | Waωs | Peel work |

| SBMA | Sludge-based biochar-modified asphalt | ||

| WWBMA | Waste wood-based biochar-modified asphalt | ||

| DSC | Differential scanning calorimetry | ||

| FTIR | Fourier transform infrared spectroscopy | ||

| XRD | X-ray diffraction analysis |

References

- Xing, L.; Xiujuan, H.; Fengde, T. Analysis of sludge generation, treatment, disposal status, and economic trends in typical cities of china. Environ. Prot. Circ. Econ. 2021, 41, 88–93. [Google Scholar] [CrossRef]

- Li-ping, B.; Hongtao, Q.; Ya-ping, F.; Ping, L. Nutrient contents and heavy metal pollutions in composted sewage sludge from different municipal wastewater treatment plants in beijing region. Environ. Sci. 2014, 35, 4648–4654. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Ye, P. Laboratory evaluation of asphalt cement and mixture modified by bio-char produced through fast pyrolysis. In Pavement Materials, Structures, and Performance; ASCE: Reston, VA, USA, 2014; pp. 140–149. [Google Scholar]

- Zhang, R.; Wang, H.; Ji, J.; Wang, H. Viscoelastic properties, rutting resistance, and fatigue resistance of waste wood-based biochar-modified asphalt. Coatings 2022, 12, 89. [Google Scholar] [CrossRef]

- Walters, R.; Begum, S.A.; Fini, E.H.; Abu-Lebdeh, T.M. Investigating bio-char as flow modifier and water treatment agent for sustainable pavement design. Am. J. Eng. Appl. 2015, 8, 138–146. [Google Scholar] [CrossRef]

- Jäger, A.; Lackner, R.; Eisenmenger-Sittner, C.; Blab, R. Identification of four material phases in bitumen by atomic force microscopy. Road Mater. Pavement Des. 2004, 5, 9–24. [Google Scholar] [CrossRef]

- Wu, S.-p.; Zhu, G.-j.; Chen, Z.; Liu, Z.-f. Laboratory research on rheological behavior and characterization of ultraviolet aged asphalt. J. Cent. South Univ. Technol. 2008, 15, 369–373. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, H.; Yu, J. Effect of aging on morphology of organo-montmorillonite modified bitumen by atomic force microscopy. J. Microsc. 2011, 242, 37–45. [Google Scholar] [CrossRef]

- Lyne, Å.L.; Wallqvist, V.; Rutland, M.W.; Claesson, P.; Birgisson, B. Surface wrinkling: The phenomenon causing bees in bitumen. J. Mater. Sci. 2013, 48, 6970–6976. [Google Scholar] [CrossRef]

- Jun, Y.; Minghui, G.; Troy, P.; Jianming, W.; Xiaoting, W. Study on micro-structures of asphalt by using atomic force microscopy. Acta Pet. Sin. (Pet. Process. Sect.) 2015, 31, 959–965. [Google Scholar] [CrossRef]

- Pauli, A.; Grimes, R.; Beemer, A.; Turner, T.; Branthaver, J. Morphology of asphalts, asphalt fractions and model wax-doped asphalts studied by atomic force microscopy. Int. J. Pavement Eng. 2011, 12, 291–309. [Google Scholar] [CrossRef]

- Das, P.K.; Kringos, N.; Wallqvist, V.; Birgisson, B. Micromechanical investigation of phase separation in bitumen by combining atomic force microscopy with differential scanning calorimetry results. Road Mater. Pavement Des. 2013, 14, 25–37. [Google Scholar] [CrossRef]

- Das, P.K.; Kringos, N.; Birgisson, B. Microscale investigation of thin film surface ageing of bitumen. J. Microsc. 2014, 254, 95–107. [Google Scholar] [CrossRef] [PubMed]

- Xiaoyi, P. Asphalt and Aggregate Adhesion Characteristics Analysis Based on the Principle of AFM and the Surface Energy. Master’s Dissertation, Harbin Institute of Technology, Harbin, China, 2015. [Google Scholar]

- Ben, L.; Ju-nan, S.; Peng-cheng, S. Nano-scale microscopic characteristics and functional groups of aged asphalt. J. Highw. Transp. Res. Dev. 2016, 33, 6–13. [Google Scholar] [CrossRef]

- Lyne, Å.; Wallqvist, V.; Birgisson, B. Adhesive surface characteristics of bitumen binders investigated by Atomic Force Microscopy. Fuel 2013, 113, 248–256. [Google Scholar] [CrossRef]

- Van Oss, C.J. Interfacial Forces in Aqueous Media; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Van Oss, C.; Giese, R. Surface modification of clays and related materials. J. Dispersion Sci. Technol. 2003, 24, 363–376. [Google Scholar] [CrossRef]

- Della Volpe, C.; Siboni, S. Some reflections on acid-base solid surface free energy theories. J. Colloid Interface Sci. 1997, 195, 121–136. [Google Scholar] [CrossRef]

- Della Volpe, C.; Siboni, S. Acid-base surface free energies of solids and the definition of scales in the Good-van Oss-Chaudhury theory. In Proceedings of the International Symposium on Apparent and Microscopic Contact Angles in Conjunction with the 216th American-Chemical-Society Meeting, Boston, MA, USA, 24–27 August 1998; pp. 171–208. [Google Scholar]

- Yingying, D.; Xiaomin, L.; Zhijie, Y.; Dingbang, W. Adhesion and water stability of pegenerated asphalt based on surface free energy. J. Mater. Sci. Eng. 2020, 38, 648–653. [Google Scholar] [CrossRef]

- Gan, X.; Zhang, W. Application of biochar from crop straw in asphalt modification. PLoS ONE 2021, 16, e0247390. [Google Scholar] [CrossRef] [PubMed]

- Zhen, Y. Study on Multi-Scale Behavioral Characteristics of Asphalt before and after Aging. Master’s Dissertation, South China University of Technology, Guangzhou, China, 2018. [Google Scholar]

- Wu-ping, R.; Shan-shan, Z.; Hai-lin, Z.; Ling, L.; Yu, Z. Stability of asphalt mortar from pyrolysis residue of oil sludge modified with hydrated lime based on rheological properties. China J. Highw. Transp. 2023, 36, 107–119. [Google Scholar] [CrossRef]

- Qingfu, Z.; Zhi-min, W.; Bao-guo, C.; Gui-feng, L.; Ji, Z. Analysis of XRD spectral structure and carbonization of the biochar preparation. Spectrosc. Spectral Anal. 2016, 36, 3355–3359. [Google Scholar] [CrossRef]

- Loeber, L.; Sutton, O.; Morel, J.; Valleton, J.M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 1996, 182, 32–39. [Google Scholar] [CrossRef]

- Minda, R. Study on Modification Mechanism and Micro-Properties of Poly-Phosphoric Acid Modified Asphalt Considering Aging Performance Base on AFM. Master’s Dissertation, Inner Mongolia University of Technology, Inner Mongolia, China, 2018. [Google Scholar]

- Lageng, S.; Gaochao, W.; Er-hu, Y. Research on surface energy of asphalt based on atomic force microscope. J. China Foreign Highw. 2018, 38, 287–289. [Google Scholar] [CrossRef]

- Young, T.; Monclus, M.; Burnett, T.; Broughton, W.; Ogin, S.; Smith, P. The use of the peak force TM quantitative nanomechanical mapping AFM-based method for high-resolution Young’s modulus measurement of polymers. Meas. Sci. Technol. 2011, 22, 125703. [Google Scholar] [CrossRef]

- Little, D.N.; Bhasin, A. Using Surface Energy Measurements to Select Materials for Asphalt Pavement; Transportation Research Board: Washington, DC, USA, 2007. [Google Scholar]

- Yunqing, G.; Licheng, D.; Ze, Y.; Xu, Z. Research on misalignment fault diagnosis method for rotating machinery based on pearson correlation coefficient. New Technol. New Prod. China 2022, 48–50. [Google Scholar] [CrossRef]

- Cheng, D. Surface Free Energy of Asphalt-Aggregate System and Performance Analysis of Asphalt Concrete Based on Surface Free Energy; Texas A&M University: College Station, TX, USA, 2002. [Google Scholar]

- Wei, J. Study on Surface Free Energy of Asphalt, Aggregate and Moisture Diffusion in Asphalt. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2008. [Google Scholar]

- Zhu, J.; Zhang, K.; Liu, K.; Shi, X. Adhesion characteristics of graphene oxide modified asphalt unveiled by surface free energy and AFM-scanned micro-morphology. Constr. Build. Mater. 2020, 244, 118404. [Google Scholar] [CrossRef]

| Types | Appearance | Particle Size/μm | Moisture Content/% | Carbon Content/% |

|---|---|---|---|---|

| Sludge-based biochar | Powder form | <75 | 4.2 | 24.15 |

| Waste wood-based biochar | Powder form | <75 | 5.8 | 74.84 |

| Technical Specifications | 70# Base Asphalt | Technical Requirements | SBSMA | Technical Requirements | Testing Methods | |

|---|---|---|---|---|---|---|

| Penetration/0.1 mm | 69 | 60~80 | 48 | 30~60 | T0604 | |

| Softening point/°C | 48.0 | ≥46 | 90 | ≥60 | T0606 | |

| Ductility at 15 °C/cm | >100 | ≥100 | —— | —— | T0605 | |

| Ductility at 5 °C/cm | —— | —— | 27 | ≥20 | T0605 | |

| Flash point/°C | 294 | ≥260 | 281 | ≥260 | T0611 | |

| Dynamic viscosity at 60 °C/(Pa·s) | 195 | ≥180 | —— | —— | T0620 | |

| Rotational viscosity at 135 °C/(Pa·s) | —— | —— | 1.47 | ≤3 | T0620 | |

| Density at 15 °C/(g·cm−3) | 1.018 | Measured records | 1.030 | Measured records | T0603 | |

| After TFOT * test (163 °C, 5 h) | Mass change/% | −0.04 | ±0.8 | −0.01 | ±1.0 | T0609 |

| Penetration ratio/% | 65.7 | ≥61 | 77 | ≥65 | T0609T0604 | |

| Ductility at 15 °C/cm | 10 | ≥4 | —— | —— | T0609T0605 | |

| Ductility at 5 °C/cm | —— | —— | 17 | ≥15 | T0609T0605 | |

| Testing Liquids | |||||

|---|---|---|---|---|---|

| Distilled water (H2O) | 72.8 | 21.8 | 51.0 | 25.5 | 25.5 |

| Glycero (C3H8O3) | 64.0 | 34.0 | 30.0 | 3.92 | 57.4 |

| Formamide (CH3NO) | 58.0 | 39.0 | 19.0 | 2.28 | 39.6 |

| Types of Asphalt | 70# Base Asphalt | SBSMA | WWBMA | SBMA |

|---|---|---|---|---|

| Adhesion strength/nN | 33.61 | 40.80 | 36.72 | 38.41 |

| Asphalt Type | Adhesion Force/nN | Adhesion Work/(mJ/m2) | SFE/(mJ/m2) |

|---|---|---|---|

| 70# base asphalt | 33.61 | 445.77 | 24.84 |

| SBSMA | 40.80 | 541.13 | 36.60 |

| WWBMA | 36.72 | 487.01 | 29.65 |

| SBMA | 38.41 | 509.43 | 32.44 |

| Types of Asphalt | 70# Base Asphalt | SBSMA | WWBMA | SBMA |

|---|---|---|---|---|

| Distilled Water | 97.52 | 103.30 | 100.65 | 102.59 |

| Glycerol | 87.36 | 89.98 | 88.98 | 89.43 |

| Formamide | 80.43 | 78.17 | 79.06 | 78.59 |

| Types of Asphalt | 70# Base Asphalt | SBSMA | WWBMA | SBMA |

|---|---|---|---|---|

| 24.94 | 36.73 | 29.54 | 32.81 | |

| 24.46 | 36.15 | 29.29 | 32.43 | |

| 0.48 | 0.58 | 0.25 | 0.38 | |

| 2.07 | 0.29 | 1.00 | 0.44 | |

| 0.03 | 0.28 | 0.02 | 0.08 |

| Aggregate Type | Granite | Limestone | Basalt |

|---|---|---|---|

| Distilled water | 69.5 | 70.6 | 73.3 |

| Glycerol | 58.1 | 54.8 | 59.5 |

| Formamide | 45.6 | 37.4 | 44.2 |

| Aggregate Type | Granite | Limestone | Basalt |

|---|---|---|---|

| 46.10 | 57.54 | 52.46 | |

| 42.49 | 56.59 | 51.74 | |

| 3.61 | 0.95 | 0.72 | |

| 9.25 | 5.65 | 5.86 | |

| 0.35 | 0.04 | 0.02 |

| Types of Asphalt | 70# Base Asphalt | SBSMA | SBMA | WWBMA | |

|---|---|---|---|---|---|

| Granite | 67.19 | 82.31 | 76.79 | 72.51 | |

| Limestone | 75.77 | 93.25 | 87.32 | 82.42 | |

| Basalt | 72.38 | 89.28 | 83.53 | 78.77 | |

| Granite | −55.55 | −67.26 | −64.57 | −60.57 | |

| Limestone | −64.09 | −78.38 | −75.51 | −70.85 | |

| Basalt | −63.71 | −77.56 | −74.82 | −70.25 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Xu, L.; Chen, X.; Li, W.; Li, Y.; Wang, H.; Liu, K. Study on the Adhesion Performance of Biochar-Modified Asphalt Based on Surface Free Energy and Atomic Force Microscopy. Coatings 2024, 14, 1390. https://doi.org/10.3390/coatings14111390

Li Q, Xu L, Chen X, Li W, Li Y, Wang H, Liu K. Study on the Adhesion Performance of Biochar-Modified Asphalt Based on Surface Free Energy and Atomic Force Microscopy. Coatings. 2024; 14(11):1390. https://doi.org/10.3390/coatings14111390

Chicago/Turabian StyleLi, Quan, Le Xu, Xing Chen, Wen Li, Yongwei Li, Hanqing Wang, and Kefei Liu. 2024. "Study on the Adhesion Performance of Biochar-Modified Asphalt Based on Surface Free Energy and Atomic Force Microscopy" Coatings 14, no. 11: 1390. https://doi.org/10.3390/coatings14111390

APA StyleLi, Q., Xu, L., Chen, X., Li, W., Li, Y., Wang, H., & Liu, K. (2024). Study on the Adhesion Performance of Biochar-Modified Asphalt Based on Surface Free Energy and Atomic Force Microscopy. Coatings, 14(11), 1390. https://doi.org/10.3390/coatings14111390