Performance of Drying Oil Modified Chinese Lacquer and Its Gilding Effect

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Modification of Chinese Raw Lacquer

2.3. Determination of Drying Time

2.4. Viscosity and Leveling Property

2.5. FTIR Investigation of Modified Chinese Lacquer

2.6. Evaluation of Gold Leafing Effect

2.6.1. Roughness

2.6.2. Glossiness

2.6.3. Color Measurement

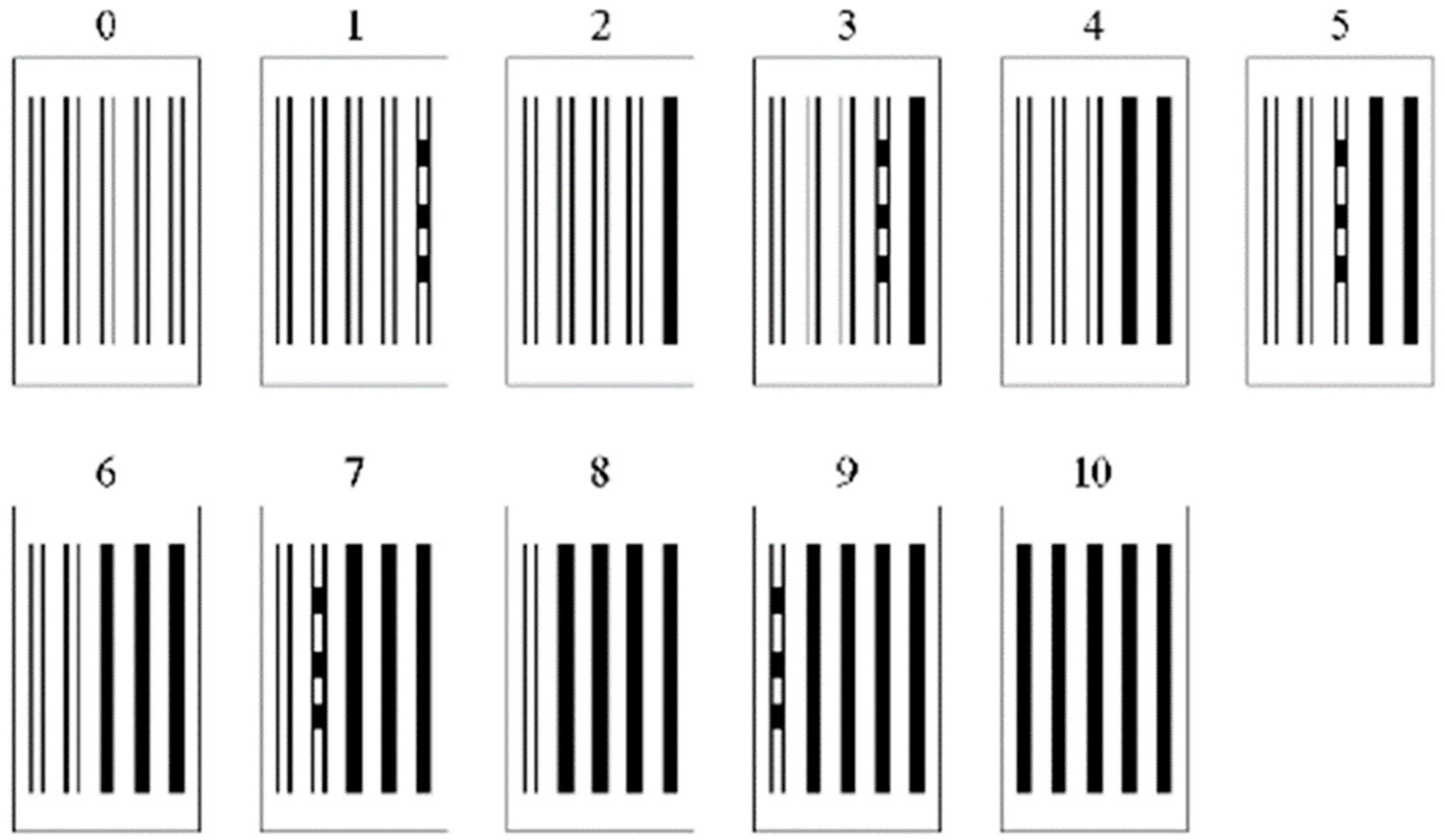

2.6.4. Adhesion

2.7. Statistical Analysis

3. Results

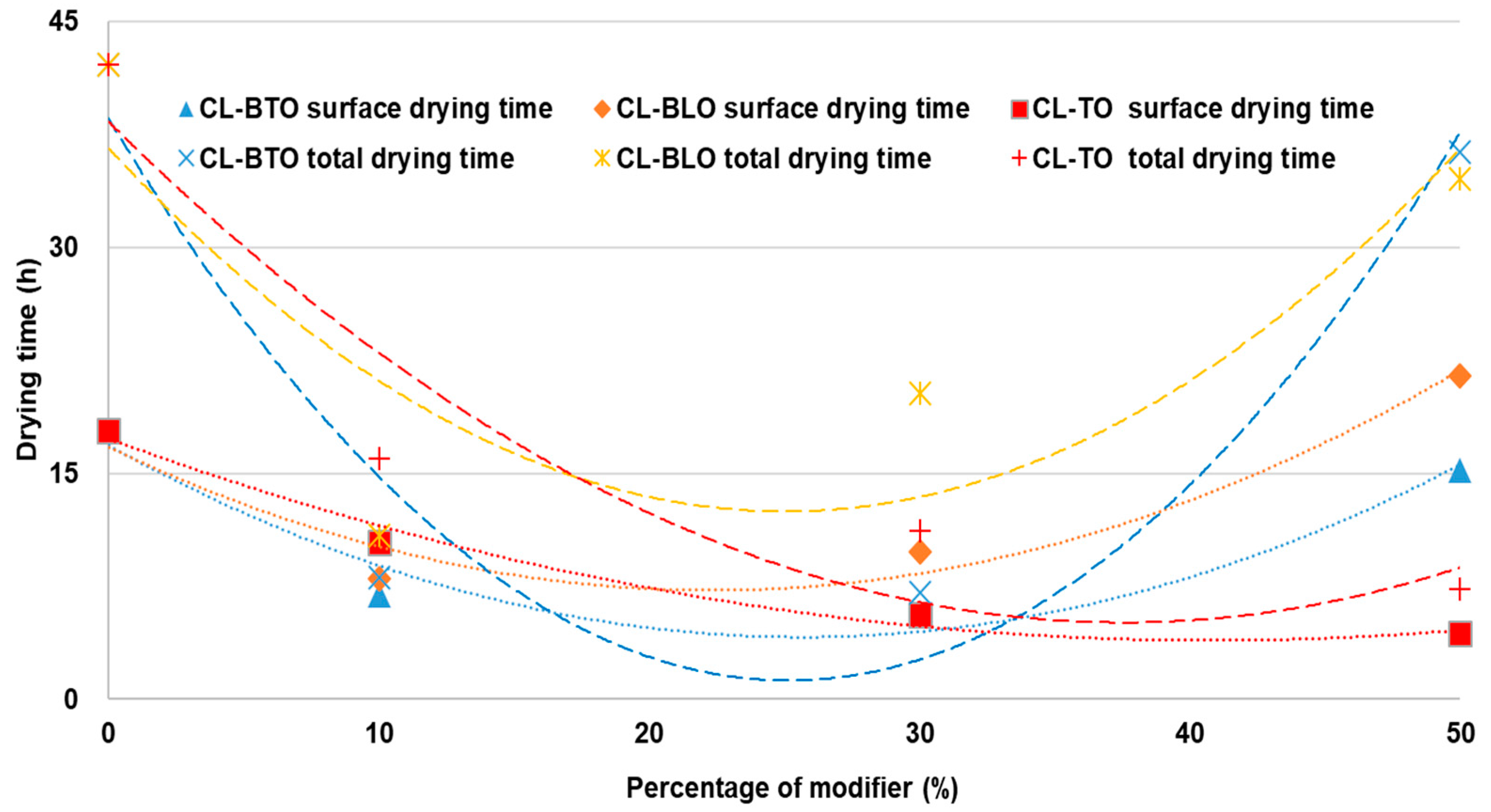

3.1. Determination of Drying Time

3.2. Viscosity and Leveling Property

3.3. FTIR Investigation of Modified Chinese Lacquer

3.4. Evaluation of Gold Leafing Effect

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dunkle, S.E.; Craig, J.R.; Rimstidt, J.D.; Lusardi, W.R. Romarchite, hydroromarchite and abhurite formed during the corrosion of pewter artifacts from the Queen Anne’s Revenge (1718). Can. Mineral. 2003, 41, 659–669. [Google Scholar] [CrossRef][Green Version]

- Duran, A.; Perez-Rodriguez, J.L.; Jimenez de Haro, M.C.; Herrera, L.K.; Justo, A. Degradation of gold and false golds used as gildings in the cultural heritage of Andalusia, Spain. J. Cult. Herit. 2008, 9, 184–188. [Google Scholar] [CrossRef]

- Tian, X.; Ma, Q.; Zheng, M.; Li, Z. Gold Leaf Corrosion in Moisture Acid Atmosphere at Ambient Temperature. Rare Met. Mater. Eng. 2014, 43, 2637–2642. [Google Scholar]

- Huang, H.; Xu, G.; Liu, X. Study on the Purity of Gold Leaf in a SO2 Atmosphere at Ambient Temperature. Materials 2021, 14, 2425. [Google Scholar] [CrossRef]

- Bunker, E.C. Gold in the Ancient Chinese World: A Cultural Puzzle. Artibus Asiae. 1993, 53, 27–50. [Google Scholar] [CrossRef]

- Ciarlo, L.; Chiari, M.; Galassi, M.C.; Ferretti, M.; Sideras-Haddad, E.; Zucchiatti, A.; Castagnotto, E. Practices and Rules of 16th Century Genoese Gilding: Exploring Gold Leaf Thickness and Caratage through X-ray and Ion Beam Techniques. Heritage 2024, 7, 3630–3642. [Google Scholar] [CrossRef]

- Körber, U.; Schilling, M.R.; Dias, C.B.; Dias, L. Simplified Chinese lacquer techniques and Nanban style decoration on Luso-Asian objects from the late sixteenth or early seventeenth centuries. Stud. Conserv. 2016, 61 (Suppl. S3), 68–84. [Google Scholar] [CrossRef][Green Version]

- Bonaduce, I.; Colombini, M.P.; Diring, S. Identification of garlic in old gildings by gas chromatography–mass spectrometry. J. Chromatogr. A 2006, 1107, 226–232. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, B.; Jiang, L.; Wu, J.; Sun, G. Natural lacquer was used as a coating and an adhesive 8000 years ago, by early humans at Kuahuqiao, determined by ELISA. J. Archaeol. Sci. 2018, 100, 80–87. [Google Scholar] [CrossRef]

- Berger, G. Gilding and Gold Leaf: The History and Process of Gold Leaf Gilding; Crowood Press: London, UK, 2010. [Google Scholar]

- Schilling, M.R.; Heginbotham, A.; Chang, J.; Chasen, J. Highlights of Chinese Lacquer Research at the Getty. In Research on Early Chinese Lacquer Buddhas; Archetype Publications Ltd.: London, UK, 2023. [Google Scholar]

- Schilling, M.R.; Khanjian, H.; Chang, J.; Heginbotham, A.; Schellmann, N. Chinese lacquer: Much more than Chinese lacquer. Stud. Conserv. 2014, 59 (Suppl. S1), S131–S133. [Google Scholar] [CrossRef]

- Wei, S.; Pintus, V.; Pitthard, V.; Schreiner, M. Analytical characterization of lacquer objects excavated from a Chu tomb in China. J. Archaeol. Sci. 2011, 38, 2667–2674. [Google Scholar] [CrossRef]

- Fu, Y.; Xiao, Q.; Zong, S.; Wei, S. Characterization and quantitation study of ancient lacquer objects by NIR spectroscopy and THM-Py-GC/MS. J. Cult. Herit. 2020, 46, 95–101. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, G.; Zhang, G.; Ma, C. Rapid curing and self-stratifying lacquer coating with antifouling and anticorrosive properties. Chem. Eng. J. 2021, 421, 129755. [Google Scholar] [CrossRef]

- Zheng, B.; Bai, W.; Chen, J.; Jian, R.; Yang, K.; Lin, Q.; Xu, Y. Inorganic salts as effective additive for adjusting the curing of natural oriental lacquer. Prog. Org. Coat. 2021, 161, 106494. [Google Scholar] [CrossRef]

- Han, J.; Webb, M.; Hao, X.; Khanjian, H.; Schilling, M.R. Surface appearance and morphology changes of Asian lacquer due to artificial aging: Impacts of traditional additives. J. Cult. Herit. 2023, 63, 249–262. [Google Scholar] [CrossRef]

- Xiao, Q.; Cao, Y.; Tan, H.; Feng, Q.; Gu, X.; Lyu, J.; Xiao, H.; Chen, M.; Chen, Y. Preparation and properties of Chinese lacquer modified by methylolureas. J. Renew. Mater 2023, 11, 14. [Google Scholar] [CrossRef]

- Chalier, P.; Martinez-Lopez, B.; Lacour, M.A.; Rigou, P. Extraction of turpentine essential oil from Pinus pinaster ait: Comparison of yield and composition between conventional-or microwave assisted-hydro-distillation and vacuum distillation. Sustain. Chem. Pharm. 2024, 41, 101702. [Google Scholar] [CrossRef]

- Humar, M.; Lesar, B. Efficacy of linseed-and tung-oil-treated wood against wood-decay fungi and water uptake. Int. Biodeterior. Biodegrad. 2013, 85, 223–227. [Google Scholar] [CrossRef]

- Mercier, B.; Prost, J.; Prost, M. The Essential Oil of Turpentine and Its Major Volatile Fraction (α- and β-Pinenes): A Review. Int. J. Occup. Med. Environ. Health 2009, 22, 331–342. [Google Scholar] [CrossRef]

- Pagliaro, M.; Fabiano-Tixier, A.-S.; Ciriminna, R. Limonene as a Natural Product Extraction Solvent. Green Chem. 2023, 25, 6108–6119. [Google Scholar] [CrossRef]

- Yu, H.; Yu, P.; Luo, Y. Renewable Low-Viscosity Dielectrics Based on Vegetable Oil Methyl Esters. J. Electr. Eng. Technol. 2017, 12, 820–829. [Google Scholar] [CrossRef]

- GB/T 1728-2020; Determination of Drying Time of Coating and Putty Films. Standardization Administration of China: Beijing, China, 2020.

- GB/T 1723-93; Determination of Viscosity of Coatings. Standardization Administration of China: Beijing, China, 1993.

- JB/T 3998-1999; Test Method for Leveling Characteristics of Paints by Draw-Down Method. Standardization Administration of China: Beijing, China, 1999.

- Zhang, F. Chinese lacquer painting technology. In Lacquer Painting Technology Lacquer Painting Technology and Lacquer Protection in China; Sun, L., Shen, X., Eds.; Science Press: Beijing, China, 2010; Volume 445–462. [Google Scholar]

- GB/T1031-1995; Surface Roughness Parameters and Their Values. Standardization Administration of China: Beijing, China, 1995.

- GB/T 9286-2021; Paints and Varnishes—Cross-Cut Test. Standardization Administration of China: Beijing, China, 2021.

- Zhang, H.; Feng, X.; Wu, Y.; Wu, Z. Factors influencing the properties of UV-cured self-matting film. Prog. Org. Coat. 2024, 189, 108241. [Google Scholar] [CrossRef]

- Yan, X.; Chang, Y. Investigation of waterborne thermochromic topcoat film with color-changing microcapsules on Chinese fir surface. Prog. Org. Coat. 2019, 136, 105262. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Y.; Zhang, X.; Sun, X.; Yang, L.; Shen, Z. Preparation of hard carbon from cellulose under the assistance of water-in-salt ZnCl2 on dissolution and carbonization. Ind. Crops Prod. 2024, 220, 119231. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, X.; Wu, Y.; Wu, Z. Self-matting waterborne polyurethane acrylate wood coating by 222 nm far-UVC irradiation in ambient air. Prog. Org. Coat. 2024, 189, 108305. [Google Scholar] [CrossRef]

- Chang, Y.; Yan, X.; Wu, Z. Application and prospect of self-healing microcapsules in surface coating of wood. Colloid Interface Sci. Commun. 2023, 56, 100736. [Google Scholar] [CrossRef]

- Lang, S.; Zhou, Q. Synthesis and characterization of poly (urea-formaldehyde) microcapsules containing linseed oil for self-healing coating development. Prog. Org. Coat. 2017, 105, 99–110. [Google Scholar] [CrossRef]

- Vogl, O. Oriental lacquer, poison ivy, and drying oils. J. of Polym. Sci. Part A Polym. Chem. 2000, 38, 4327–4335. [Google Scholar] [CrossRef]

- Bonanni, F.; Publications, G. Techniques of chinese lacquer. Am. J. Transplant. 2009, 13, 811–814. [Google Scholar]

| Adhesion Grade | Illustration | Schematic Diagram |

|---|---|---|

| 0 | The edges of the cuts are completely smooth, and none of the squares in the lattice have detached. |  |

| 1 | Small flakes of the coating have detached at the intersections of the cuts, affecting no more than 5% of the cross-cut area. |  |

| 2 | The coating has flaked along the edges and/or at the intersections of the cuts, affecting a cross-cut area greater than 5% but not exceeding 15%. |  |

| 3 | The coating has flaked along the edges of the cuts, either partly or wholly in large ribbons, and/or it has flaked partly or wholly on different parts of the squares, affecting a cross-cut area greater than 15% but not exceeding 35%. |  |

| 4 | The coating has flaked along the edges of the cuts in large ribbons, and/or some squares have detached partly or wholly, affecting a cross-cut area greater than 35% but not exceeding 65%. |  |

| 5 | The coating exhibits flaking to an extent that exceeds the criteria of classification 4 and cannot be classified. |  |

| CL | CL-BTO | CL-BLO | CL-TO | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 30% | 50% | 10% | 30% | 50% | 10% | 30% | 50% | ||

| Viscosity (mPa·s) | 12,860 | 12,020 | 11,220 | 10,040 | 12,600 | 11,740 | 9060 | 4950 | 2620 | 1140 |

| Leveling grade | 1 | 2–3 | 2–3 | 4–5 | 1 | 2 | 2 | 6–7 | 8–10 | 9–10 |

| Visual aspect |  |  |  |  |  |  |  |  |  |  |

| Roughness 1 | Glossiness(%) | Color Changes | Adhesion | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Ra (μm) | Rq (μm) | Rt (μm) | ΔL | Δa | Δb | ΔE | |||

| CL | 1.348 | 1.648 | 8.778 | 45.78 | - | - | - | 0 | 3 |

| Oil type | |||||||||

| BTO | 0.522 b | 0.667 b | 5.191 c | 52.15 c | −2.35 a | 4.65 a | 11.59 a | 13.00 a | 2.83 a |

| BLO | 1.091 a | 1.329 a | 8.590 b | 57.91 b | −1.51 a | 3.46 b | 10.84 a | 11.53 a | 2.92 a |

| TO | 1.290 a | 1.627 a | 11.658 a | 62.36 a | −1.24 a | 3.39 b | 6.41 b | 9.14 b | 2.75 a |

| Oil addition amount | |||||||||

| 10% | 0.653 b | 0.822 b | 5.919 b | 46.98 c | −2.94 a | 4.14 a | 8.62 a | 11.14 ab | 2.67 a |

| 30% | 1.239 a | 1.538 a | 10.251 a | 61.07 b | −1.84 a | 4.16 a | 9.14 a | 12.21 a | 2.83 a |

| 50% | 1.011 a | 1.263 a | 9.270 a | 64.37 a | −3.09 a | 3.19 b | 11.08 a | 10.33 b | 3.00 a |

| p Values 2 | |||||||||

| Oil type | <0.0001 | <0.0001 | <0.0001 | <0.0001 | 0.262 | <0.0001 | 0.001 | <0.0001 | 0.857 |

| Oil addition amount | <0.0001 | <0.0001 | 0.001 | <0.0001 | 0.003 | 0.005 | 0.161 | 0.058 | 0.545 |

| Oil type × Oil addition amount 3 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | 0.006 | 0.006 | 0.022 | 0.001 | 0.551 |

| Drying Time | Modified CL | Fitting Formula | R2 |

|---|---|---|---|

| Surface drying | CL-BTO | y = 0.0193x2 − 0.992x + 16.842 | 0.9395 |

| CL-BLO | y = 0.0191x2 − 0.8523x + 16.735 | 0.9357 | |

| CL-TO | y = 0.008x2 − 0.6562x + 17.284 | 0.9812 | |

| Total drying | CL-BTO | y = 0.059x2 − 2.9673x + 38.543 | 0.9227 |

| CL-BLO | y = 0.0386x2 − 1.9312x + 36.598 | 0.6815 | |

| CL-TO | y = 0.0236x2 − 1.7711x + 38.339 | 0.8813 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhang, C.; Wang, W.; Liu, X. Performance of Drying Oil Modified Chinese Lacquer and Its Gilding Effect. Coatings 2024, 14, 1379. https://doi.org/10.3390/coatings14111379

Wang Q, Zhang C, Wang W, Liu X. Performance of Drying Oil Modified Chinese Lacquer and Its Gilding Effect. Coatings. 2024; 14(11):1379. https://doi.org/10.3390/coatings14111379

Chicago/Turabian StyleWang, Qiuyi, Changjun Zhang, Wei Wang, and Xinyou Liu. 2024. "Performance of Drying Oil Modified Chinese Lacquer and Its Gilding Effect" Coatings 14, no. 11: 1379. https://doi.org/10.3390/coatings14111379

APA StyleWang, Q., Zhang, C., Wang, W., & Liu, X. (2024). Performance of Drying Oil Modified Chinese Lacquer and Its Gilding Effect. Coatings, 14(11), 1379. https://doi.org/10.3390/coatings14111379