Improving Hydrophobicity and Water Vapor Barrier Properties in Paper Using Cellulose Nanofiber-Stabilized Cocoa Butter and PLA Emulsions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Pickering Emulsions Stabilized with CNF

2.3. Particle Size Distribution

2.4. Rheological Behavior

2.5. Coatings Application

2.6. Field Emission Scanning Electron Microscopy (FESEM)

2.7. Contact Angle Measurements

2.8. Water Vapor Transmisión Rate (WVTR)

3. Results and Discussion

3.1. Pickering Emulsion Stability

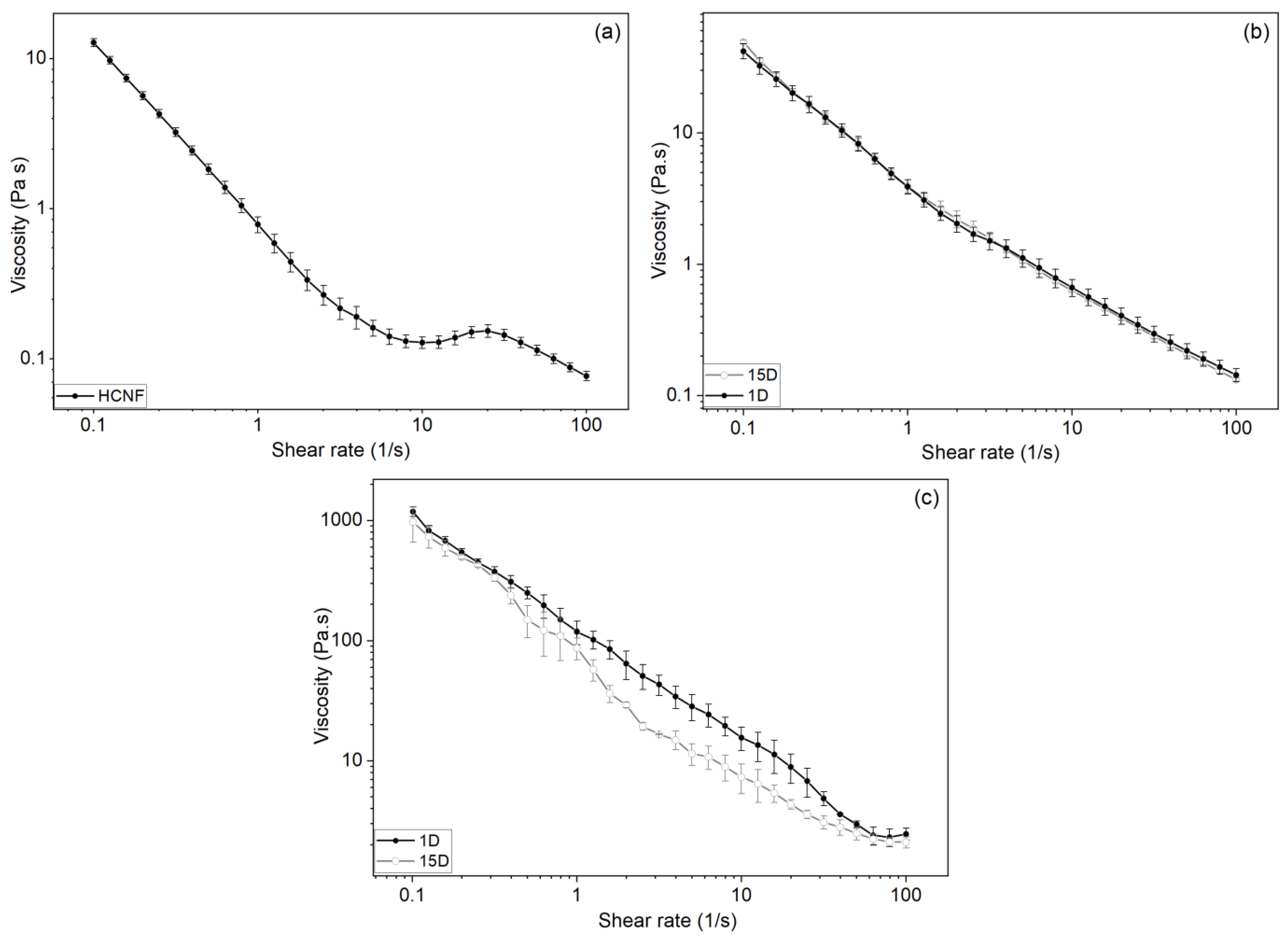

3.2. Rheological Behavior

3.3. Coating Processing

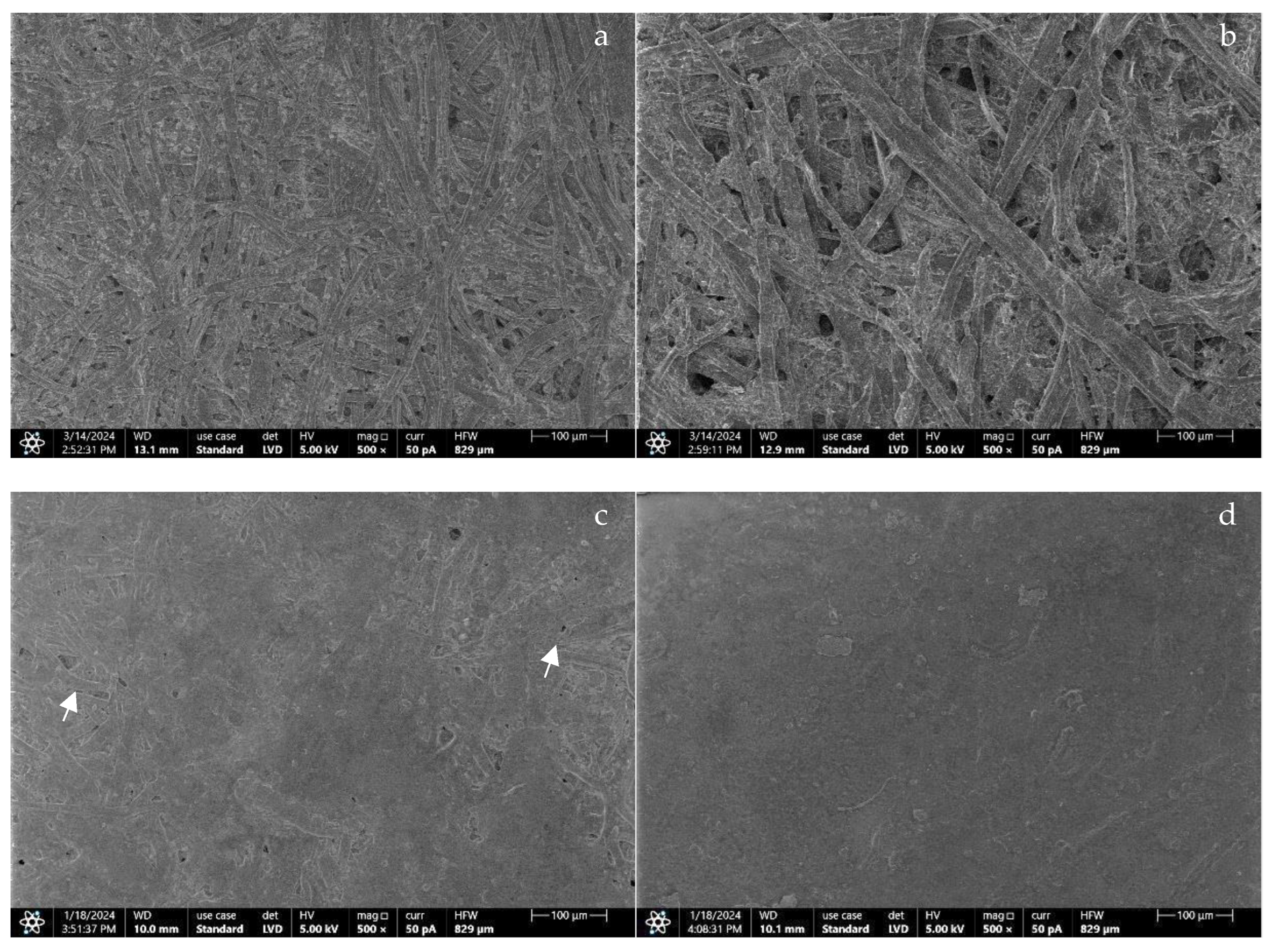

3.4. Scanning Electron Microscopy (FE-SEM)

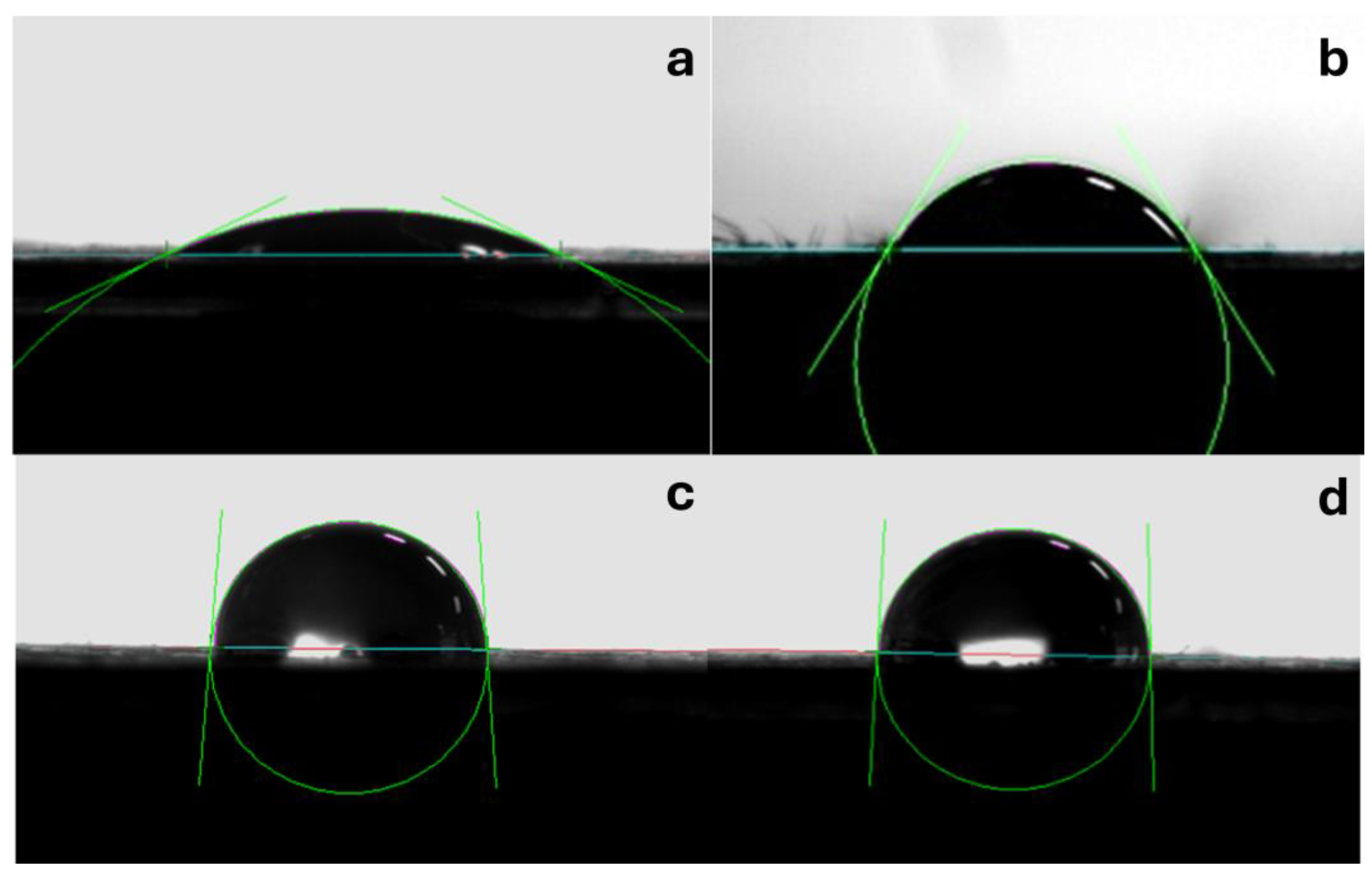

3.5. Contact Angle

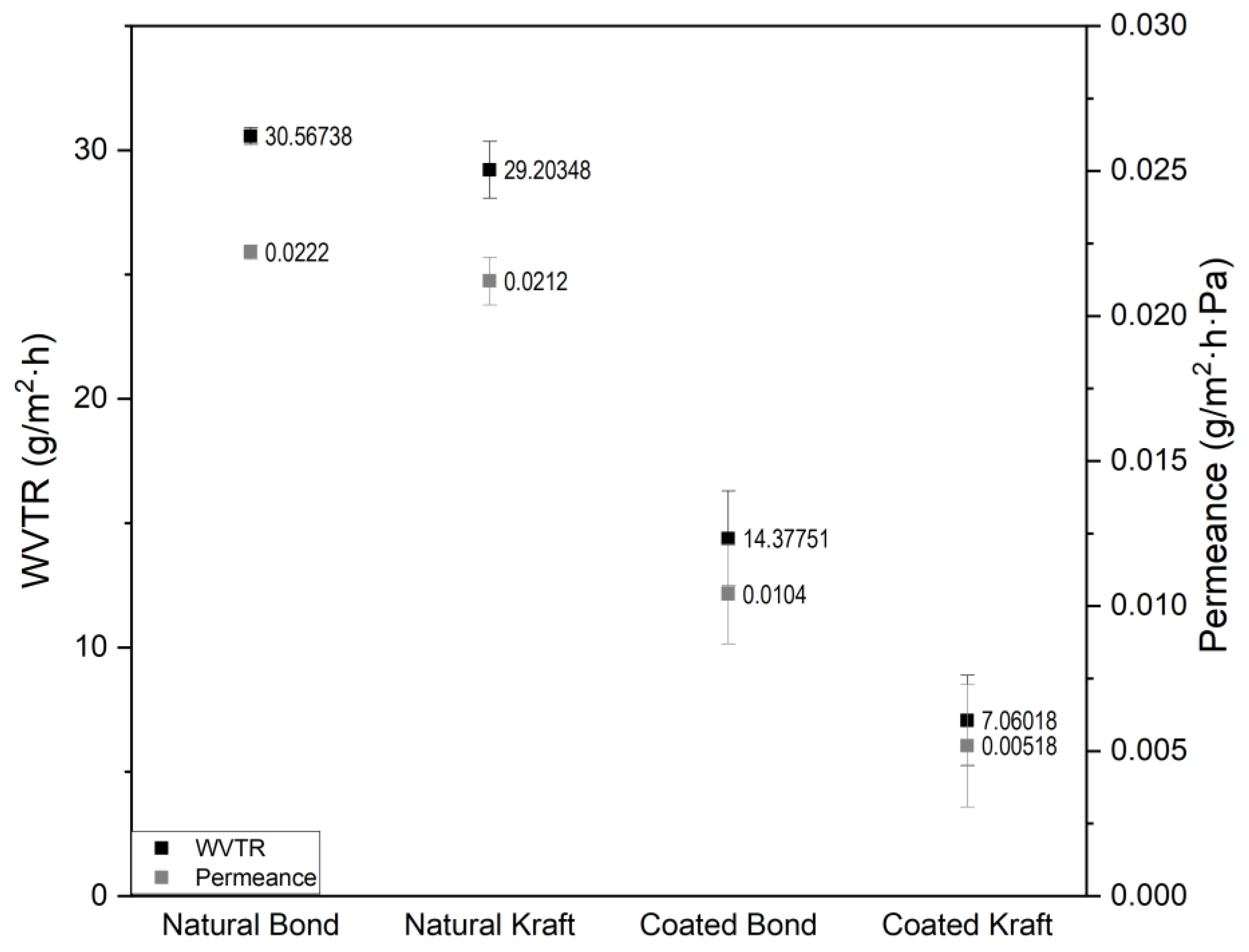

3.6. Water Vapor Permeability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raheem, D. Use and Production of Paper Packaging for Food. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Park, J.M. Paper and paperboard packaging. In Handbook of Food Science, Technology, and Engineering—4 Volume Set; Elsevier: Amsterdam, The Netherlands, 2012; pp. 178–239. [Google Scholar] [CrossRef]

- Asgher, M.; Qamar, S.A.; Bilal, M.; Iqbal, H.M. Bio-based active food packaging materials: Sustainable alternative to conventional petrochemical-based packaging materials. Food Res. Int. 2020, 137, 109625. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.-A.; Gregersen, W.; Männle, F.; Brachet, P. Effects of hydrophobic polyhedral oligomeric silsesquioxane coating on water vapour barrier and water resistance properties of paperboard. J. Sol-Gel Sci. Technol. 2014, 69, 237–249. [Google Scholar] [CrossRef]

- Mendes, A.C.; Pedersen, G.A. Perspectives on sustainable food packaging:– is bio-based plastics a solution? Trends Food Sci. Technol. 2021, 112, 839–846. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Mahmud, J.; Sarmast, E.; Shankar, S.; Lacroix, M. Advantages of nanotechnology developments in active food packaging. Food Res. Int. 2022, 154, 111023. [Google Scholar] [CrossRef]

- Pereira, A.L.S.; Nascimento, D.M.D.; Filho, M.d.S.M.S.; Morais, J.P.S.; Vasconcelos, N.F.; Feitosa, J.P.; Brígida, A.I.S.; Rosa, M.d.F. Improvement of polyvinyl alcohol properties by adding nanocrystalline cellulose isolated from banana pseudostems. Carbohydr. Polym. 2014, 112, 165–172. [Google Scholar] [CrossRef]

- Hassan, E.A.; Hassan, M.L.; Abou-Zeid, R.E.; El-Wakil, N.A. Novel nanofibrillated cellulose/chitosan nanoparticles nanocomposites films and their use for paper coating. Ind. Crop. Prod. 2016, 93, 219–226. [Google Scholar] [CrossRef]

- Mousavi, S.M.M.; Afra, E.; Tajvidi, M.; Bousfield, D.W.; Dehghani-Firouzabadi, M. Cellulose nanofiber/carboxymethyl cellulose blends as an efficient coating to improve the structure and barrier properties of paperboard. Cellulose 2017, 24, 3001–3014. [Google Scholar] [CrossRef]

- He, Y.; Li, H.; Fei, X.; Peng, L. Carboxymethyl cellulose/cellulose nanocrystals immobilized silver nanoparticles as an effective coating to improve barrier and antibacterial properties of paper for food packaging applications. Carbohydr. Polym. 2021, 252, 117156. [Google Scholar] [CrossRef]

- Pérez Mejía, J.A. El Fique: Su Taxonomía, Cultivo y Tecnología; SIDALC: Turrialba, Costa Rica, 1974. [Google Scholar]

- Zhang, W.; Xiao, H.; Qian, L. Enhanced water vapour barrier and grease resistance of paper bilayer-coated with chitosan and beeswax. Carbohydr. Polym. 2014, 101, 401–406. [Google Scholar] [CrossRef]

- Song, Z.; Xiao, H.; Zhao, Y. Hydrophobic-modified nano-cellulose fiber/PLA biodegradable composites for lowering water vapor transmission rate (WVTR) of paper. Carbohydr. Polym. 2014, 111, 442–448. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Chen, X.; Wang, H. Fabrication of water/oil-resistant paper by nanocellulose stabilized Pickering emulsion and chitosan. Int. J. Biol. Macromol. 2024, 275, 133609. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Hortal, M.; Jordá-Beneyto, M.; Rosa, E.; Lara-Lledo, M.; Lorente, I. ZnO-PLA nanocomposite coated paper for antimicrobial packaging application. LWT 2017, 78, 250–257. [Google Scholar] [CrossRef]

- Pretula, J.; Slomkowski, S.; Penczek, S. Polylactides—Methods of synthesis and characterization. Adv. Drug Deliv. Rev. 2016, 107, 3–16. [Google Scholar] [CrossRef]

- Adibi, A.; Trinh, B.M.; Mekonnen, T.H. Recent progress in sustainable barrier paper coating for food packaging applications. Prog. Org. Coat. 2023, 181, 107566. [Google Scholar] [CrossRef]

- Belletti, G.; Buoso, S.; Ricci, L.; Guillem-Ortiz, A.; Aragón-Gutiérrez, A.; Bortolini, O.; Bertoldo, M. Preparations of Poly(lactic acid) Dispersions in Water for Coating Applications. Polymers 2021, 13, 2767. [Google Scholar] [CrossRef]

- Devi, L.S.; Kalita, S.; Mukherjee, A.; Kumar, S. Carnauba wax-based composite films and coatings: Recent advancement in prolonging postharvest shelf-life of fruits and vegetables. Trends Food Sci. Technol. 2022, 129, 296–305. [Google Scholar] [CrossRef]

- Pearly, C.; Zhi, Q.; Ashok, K.; Abdul, K. An Overview of Cocoa Butter: Novel Excipients for Oral Tablets. Int. J. Pharm. Res. 2021, 13. [Google Scholar] [CrossRef]

- O’loughlin, J.; Doherty, D.; Herward, B.; McGleenan, C.; Mahmud, M.; Bhagabati, P.; Boland, A.N.; Freeland, B.; Rochfort, K.D.; Kelleher, S.M.; et al. The Potential of Bio-Based Polylactic Acid (PLA) as an Alternative in Reusable Food Containers: A Review. Sustainability 2023, 15, 15312. [Google Scholar] [CrossRef]

- Zuluaga, R.; Putaux, J.L.; Cruz, J.; Vélez, J.; Mondragon, I.; Gañán, P. Cellulose microfibrils from banana rachis: Effect of alkaline treatments on structural and morphological features. Carbohydr. Polym. 2008, 76, 51–59. [Google Scholar] [CrossRef]

- Velásquez-Cock, J.; Gañán, P.; Posada, P.; Castro, C.; Serpa, A.; Gómez, H.C.; Putaux, J.-L.; Zuluaga, R. Influence of combined mechanical treatments on the morphology and structure of cellulose nanofibrils: Thermal and mechanical properties of the resulting films. Ind. Crop. Prod. 2016, 85, 1–10. [Google Scholar] [CrossRef]

- Kmetty, A.; Litauszki, K. Development of Poly (Lactide Acid) Foams with Thermally Expandable Microspheres. Polymers 2020, 12, 463. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Hegyesi, N.; Zhang, Y.; Mao, Z.; Feng, X.; Wang, B.; Pukánszky, B.; Sui, X. Poly(lactic acid)/lignin blends prepared with the Pickering emulsion template method. Eur. Polym. J. 2019, 110, 378–384. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhong, M.; Xiang, H.; Ding, Y.; Wang, Y.; Shi, Y.; Yang, G.; Tang, B.; Tam, K.C.; Zhou, G. Antibacterial polylactic acid fabricated via Pickering emulsion approach with polyethyleneimine and polydopamine modified cellulose nanocrystals as emulsion stabilizers. Int. J. Biol. Macromol. 2023, 253, 127263. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, Z.; Fu, S.; Meng, L.; Liu, Y.; Chen, F.; Wang, K.; Fu, Q. Fabrication of PLA/CNC/CNT conductive composites for high electromagnetic interference shielding based on Pickering emulsions method. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105558. [Google Scholar] [CrossRef]

- Hindle, S.; Povey, M.J.; Smith, K. Kinetics of Crystallization in n-Hexadecane and Cocoa Butter Oil-in-Water Emulsions Accounting for Droplet Collision-Mediated Nucleation. J. Colloid Interface Sci. 2000, 232, 370–380. [Google Scholar] [CrossRef]

- Li, L.; Chen, Y.; Yu, T.; Wang, N.; Wang, C.; Wang, H. Preparation of polylactic acid/TEMPO-oxidized bacterial cellulose nanocomposites for 3D printing via Pickering emulsion approach. Compos. Commun. 2019, 16, 162–167. [Google Scholar] [CrossRef]

- Keowmaneechai, E.; McClements, D.J. Influence of EDTA and Citrate on Physicochemical Properties of Whey Protein-Stabilized Oil-in-Water Emulsions Containing CaCl2. J. Agric. Food Chem. 2002, 50, 7145–7153. [Google Scholar] [CrossRef]

- ISO Standard No. 13320:2020; Particle size analysis — Laser diffraction methods. International Organization for Standardization: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/69111.html (accessed on 10 October 2024).

- Frank, D.G.; John, L.H.; Fred, B.P. The Lipid Handbook, 2nd ed.; Chapman & Hall Chemical Database: London, UK, 1994; Available online: https://books.google.com.co/books?id=m9J9pTDZEGEC (accessed on 10 October 2024).

- Niskanen, I.; Suopajärvi, T.; Liimatainen, H.; Fabritius, T.; Heikkilä, R.; Thungström, G. Determining the complex refractive index of cellulose nanocrystals by combination of Beer-Lambert and immersion matching methods. J. Quant. Spectrosc. Radiat. Transf. 2019, 235, 1–6. [Google Scholar] [CrossRef]

- Simões, S.; Sanchez, C.C.; Santos, A.J.; Figueira, D.; Prista, C.; Raymundo, A. Impact of Grass Pea Sweet Miso Incorporation in Vegan Emulsions: Rheological, Nutritional and Bioactive Properties. Foods 2023, 12, 1362. [Google Scholar] [CrossRef]

- Velásquez-Cock, J.; Serpa, A.M.; Gómez-Hoyos, C.; Gañán, P.; Romero-Sáez, M.; Vélez, L.M.; Correa-Hincapié, N.; Zuluaga, R. Influence of a Non-Ionic Surfactant in the Microstructure and Rheology of a Pickering Emulsion Stabilized by Cellulose Nanofibrils. Polymers 2021, 13, 3625. [Google Scholar] [CrossRef] [PubMed]

- Chungsiriporn, J.; Khunthongkaew, P.; Wongnoipla, Y.; Sopajarn, A.; Karrila, S.; Iewkittayakorn, J. Fibrous packaging paper made of oil palm fiber with beeswax-chitosan solution to improve water resistance. Ind. Crop. Prod. 2022, 177, 114541. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Wang, B.; Sui, X.; Zhong, Y.; Zhang, L.; Mao, Z.; Xu, H. Cellulose nanofibril-reinforced biodegradable polymer composites obtained via a Pickering emulsion approach. Cellulose 2017, 24, 3313–3322. [Google Scholar] [CrossRef]

- ASTM D7490-08; Standard Test Method for Measurement of the Surface Tension of Solid Coatings, Substrates and Pigments using Contact Angle Measurements. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Kape, A.; Ruick, B.; Drusch, S. Characterisation of the work of adhesion of food grade coating materials on a maltodextrin model surface. Chem. Eng. Res. Des. 2016, 110, 152–159. [Google Scholar] [CrossRef]

- Vargaftik, N.B.; Volkov, B.N.; Voljak, L.D. International Tables of the Surface Tension of Water. J. Phys. Chem. Ref. Data 1983, 12, 817–820. [Google Scholar] [CrossRef]

- ASTM E96/E96M-10; Standard Test Methods for Water Vapor Transmission of Materials. ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- Goi, Y.; Fujisawa, S.; Saito, T.; Yamane, K.; Kuroda, K.; Isogai, A. Dual Functions of TEMPO-Oxidized Cellulose Nanofibers in Oil-in-Water Emulsions: A Pickering Emulsifier and a Unique Dispersion Stabilizer. Langmuir 2019, 35, 10920–10926. [Google Scholar] [CrossRef]

- Han, Y.; Chen, R.; Ma, Z.; Wang, Q.; Wang, X.; Li, Y.; Sun, G. Stabilization of Pickering emulsions via synergistic interfacial interactions between cellulose nanofibrils and nanocrystals. Food Chem. 2022, 395, 133603. [Google Scholar] [CrossRef]

- Hoyos, C.G.; Botero, L.D.; Flórez-Caro, A.; Velásquez-Cock, J.A.; Zuluaga, R. Nanocellulose from Cocoa Shell in Pickering Emulsions of Cocoa Butter in Water: Effect of Isolation and Concentration on Its Stability and Rheological Properties. Polymers 2023, 15, 4157. [Google Scholar] [CrossRef]

- Silva, C.E.; Tam, K.C.; Bernardes, J.S.; Loh, W. Double stabilization mechanism of O/W Pickering emulsions using cationic nanofibrillated cellulose. J. Colloid Interface Sci. 2020, 574, 207–216. [Google Scholar] [CrossRef]

- Sharma, N.; Madan, P.; Lin, S. Effect of process and formulation variables on the preparation of parenteral paclitaxel-loaded biodegradable polymeric nanoparticles: A co-surfactant study. Asian J. Pharm. Sci. 2016, 11, 404–416. [Google Scholar] [CrossRef]

- Roland, H.S.; Katharina, L.; Daniel, C. Recent Advances in the Emulsion Solvent Evaporation Technique for the Preparation of Nanoparticles and Nanocapsules; Springer: Cham, Switzerland, 2013; pp. 329–344. [Google Scholar] [CrossRef]

- Gómez Hoyos, C.; Mazo Márquez, P.; Penagos Vélez, L.; Serpa Guerra, A.; Eceiza, A.; Urbina, L.; Velásquez-Cock, J.; Gañán Rojo, P.; Vélez Acosta, L.; Zuluaga, R. Cocoa shell: An industrial by-product for the preparation of suspensions of holocellulose nanofibers and fat. Cellulose 2020, 27, 10873–10884. [Google Scholar] [CrossRef]

- Whitby, C.P.; Wanless, E.J. Controlling Pickering Emulsion Destabilisation: A Route to Fabricating New Materials by Phase Inversion. Materials 2016, 9, 626. [Google Scholar] [CrossRef] [PubMed]

- Whitby, C.P.; Lotte, L.; Lang, C. Structure of concentrated oil-in-water Pickering emulsions. Soft Matter 2012, 8, 7784–7789. [Google Scholar] [CrossRef]

- Saarikoski, E.; Saarinen, T.; Salmela, J.; Seppälä, J. Flocculated flow of microfibrillated cellulose water suspensions: An imaging approach for characterisation of rheological behaviour. Cellulose 2012, 19, 647–659. [Google Scholar] [CrossRef]

- Karppinen, A.; Saarinen, T.; Salmela, J.; Laukkanen, A.; Nuopponen, M.; Seppälä, J. Flocculation of microfibrillated cellulose in shear flow. Cellulose 2012, 19, 1807–1819. [Google Scholar] [CrossRef]

- Michel, S.; Joachim, S.; Patrice, M.; Patrick, G. Rheological investigation of complex micro and nanofibrillated cellulose (MNFC) suspensions: Discussion of flow curves and gel stability. TAPPI J. 2016, 15, 405–416. [Google Scholar]

- Lasseuguette, E.; Roux, D.; Nishiyama, Y. Rheological properties of microfibrillar suspension of TEMPO-oxidized pulp. Cellulose 2008, 15, 425–433. [Google Scholar] [CrossRef]

- Charani, P.R.; Dehghani-Firouzabadi, M.; Afra, E.; Blademo, Å.; Naderi, A.; Lindström, T. Production of microfibrillated cellulose from unbleached kraft pulp of Kenaf and Scotch Pine and its effect on the properties of hardwood kraft: Microfibrillated cellulose paper. Cellulose 2013, 20, 2559–2567. [Google Scholar] [CrossRef]

- Nazari, B.; Bousfield, D.W. Cellulose nanofibers influence on properties and processing of paperboard coatings. Nord. Pulp Pap. Res. J. 2016, 31, 511–520. [Google Scholar] [CrossRef]

- Mezger, T. The Rheology Handbook; Walter de Gruyter GmbH: Berlin, Germany, 2020. [Google Scholar] [CrossRef]

- Ye, F.; Miao, M.; Cui, S.W.; Jiang, B.; Jin, Z.; Li, X. Characterisations of oil-in-water Pickering emulsion stabilized hydrophobic phytoglycogen nanoparticles. Food Hydrocoll. 2018, 76, 78–87. [Google Scholar] [CrossRef]

- Nasrolahi, S.; Sadeghizadeh-Yazdi, J.; Ehrampoush, M.H.; Madadizadeh, F.; Khalili, E. Evaluation of rheological and optical properties plus stability of beverage cloud emulsions prepared with corn oil, gum rosin, and modified starch. Food Sci. Nutr. 2023, 11, 806–816. [Google Scholar] [CrossRef] [PubMed]

- Lin, Q.; Shang, M.; Li, X.; Sang, S.; Chen, L.; Long, J.; Jiao, A.; Ji, H.; Qiu, C.; Jin, Z. Rheology and 3D printing characteristics of heat-inducible pea protein-carrageenan-glycyrrhizic acid emulsions as edible inks. Food Hydrocoll. 2024, 147, 109347. [Google Scholar] [CrossRef]

- Torres, L.G.; Iturbe, R.; Snowden, M.J.; Chowdhry, B.Z.; Leharne, S.A. Preparation of o/w emulsions stabilized by solid particles and their characterization by oscillatory rheology. Colloids Surf. A Physicochem. Eng. Asp. 2007, 302, 439–448. [Google Scholar] [CrossRef]

- Izidoro, D.R.; Scheer, A.P.; Sierakowski, M.-R.; Haminiuk, C.W. Influence of green banana pulp on the rheological behaviour and chemical characteristics of emulsions (mayonnaises). LWT 2008, 41, 1018–1028. [Google Scholar] [CrossRef]

- Stephan, F.K.; Peter, M.S. Liquid Film Coating: Scientific Principles and Their Technological Implications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Pal, J.; Wu, D.; Hakkarainen, M.; Srivastava, R.K. The viscoelastic interaction between dispersed and continuous phase of PCL/HA-PVA oil-in-water emulsion uncovers the theoretical and experimental basis for fiber formation during emulsion electrospinning. Eur. Polym. J. 2017, 96, 44–54. [Google Scholar] [CrossRef]

- Liu, X.; Qi, X.; Guan, Y.; He, Y.; Li, S.; Liu, H.; Zhou, L.; Wei, C.; Yu, C.; Chen, Y. Transparent and strong polymer nanocomposites generated from Pickering emulsion gels stabilized by cellulose nanofibrils. Carbohydr. Polym. 2019, 224, 115202. [Google Scholar] [CrossRef]

- Li, S.; Zhou, C.; He, Y.; Liu, H.; Zhou, L.; Yu, C.; Wei, C.; Wang, C. Novel Nanocellulose/Polymer Composite Aerogel as Solid-State Fluorescence Probe by Pickering Emulsion Route. Macromol. Mater. Eng. 2020, 305, 2000467. [Google Scholar] [CrossRef]

- Michael, A.R. Crystallization of Fats and Fatty Acids in Edible Oils and Structure Determination. In Fatty Acids; Chemistry, Synthesis, and Applications; Elsevier: Amsterdam, The Netherlands, 2017; pp. 541–559. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, X.; Gonzalez, A.J.P.; Huang, Q. Kafirin nanoparticles-stabilized Pickering emulsions: Microstructure and rheological behavior. Food Hydrocoll. 2016, 54, 30–39. [Google Scholar] [CrossRef]

- Dai, L.; Sun, C.; Wei, Y.; Mao, L.; Gao, Y. Characterization of Pickering emulsion gels stabilized by zein/gum arabic complex colloidal nanoparticles. Food Hydrocoll. 2018, 74, 239–248. [Google Scholar] [CrossRef]

- Li, X.-M.; Xie, Q.-T.; Zhu, J.; Pan, Y.; Meng, R.; Zhang, B.; Chen, H.-Q.; Jin, Z.-Y. Chitosan hydrochloride/carboxymethyl starch complex nanogels as novel Pickering stabilizers: Physical stability and rheological properties. Food Hydrocoll. 2019, 93, 215–225. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Tayeb, P.; Joyce, M.; Tyagi, P.; Kehoe, M.; Dimic-Misic, K.; Pal, L. Rheology of nanocellulose-rich aqueous suspensions: A Review. BioResources 2017, 12, 9556–9661. [Google Scholar] [CrossRef]

- Espino-Pérez, E.; Bras, J.; Ducruet, V.; Guinault, A.; Dufresne, A.; Domenek, S. Influence of chemical surface modification of cellulose nanowhiskers on thermal, mechanical, and barrier properties of poly(lactide) based bionanocomposites. Eur. Polym. J. 2013, 49, 3144–3154. [Google Scholar] [CrossRef]

- Sundar, N.; Kumar, A.; Pavithra, A.; Ghosh, S. Studies on Semi-crystalline Poly Lactic Acid (PLA) as a Hydrophobic Coating Material on Kraft Paper for Imparting Barrier Properties in Coated Abrasive Applications. Prog. Org. Coat. 2020, 145, 105682. [Google Scholar] [CrossRef]

- Inthamat, P.; Karbowiak, T.; Tongdeesoontorn, W.; Siripatrawan, U. Biodegradable active coating from chitosan/astaxanthin crosslinked with genipin to improve water resistance, moisture and oxygen barrier and mechanical properties of Kraft paper. Int. J. Biol. Macromol. 2024, 254, 127816. [Google Scholar] [CrossRef] [PubMed]

- Saba, N.; Mohammad, F.; Pervaiz, M.; Jawaid, M.; Alothman, O.; Sain, M. Mechanical, morphological and structural properties of cellulose nanofibers reinforced epoxy composites. Int. J. Biol. Macromol. 2017, 97, 190–200. [Google Scholar] [CrossRef]

- Niska, A.; Małachowska, E. Influence of coating grammage on the utility properties of coated papers. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2021, 113, 5–12. [Google Scholar] [CrossRef]

- Mousavi, S.M.M.; Afra, E.; Tajvidi, M.; Bousfield, D.W.; Dehghani-Firouzabadi, M. Application of cellulose nanofibril (CNF) as coating on paperboard at moderate solids content and high coating speed using blade coater. Prog. Org. Coat. 2018, 122, 207–218. [Google Scholar] [CrossRef]

- Pydimalla, M.; Reddy, K. Effect of Pulping, Bleaching and Refining Process on Fibers for Paper Making—A Review. Int. J. Eng. Res. Technol. 2020, 9, 310–316. [Google Scholar]

- Syverud, K.; Stenius, P. Strength and barrier properties of MFC films. Cellulose 2008, 16, 75–85. [Google Scholar] [CrossRef]

- Ramallo, L.A.; Albani, O.A. Prediction and Determination of Water Uptake in Packaged Yerba Mate. Food Sci. Technol. Int. 2004, 10, 35–40. [Google Scholar] [CrossRef]

| Sample | D90 (μm) | D50 (μm) | D10 (μm) | Polydispersion Index (a.u.) |

|---|---|---|---|---|

| CNF suspension | 60.80 ± 2.25 a | 20.60 ± 0.60 a | 5.53 ± 0.19 a | 2.68 ± 0.08 a |

| CNF/PLA-1D | 156.00 ± 7.72 b | 64.10 ± 1.99 b | 7.04 ± 0.15 b | 2.32 ± 0.07 b |

| CNF/PLA-15D | 137.00 ± 3.07 c | 41.40 ± 0.74 c | 9.63 ± 0.35 c | 3.08 ± 0.04 c |

| CNF/CB-1D | 26.30 ± 0.87 d | 13.30 ± 0.40 d | 4.43 ± 0.07 d | 1.64 ± 0.03 d |

| CNF/CB-15D | 58.70 ± 2.87 e | 16.40 ± 0.22 e | 4.06 ± 0.03 e | 3.33 ± 0.12 e |

| Sample Name | Yield Stress T0 (Pa) | k-Values (Pa·s)n | Values n | R-Values2 |

|---|---|---|---|---|

| CNF | 0.78 ± 0.08 a | 0.12 ± 0.01 a | 0.90 ± 0.01 a | 0.95 |

| CNF/PLA-1D | 5.17 ± 0.74 b | 0.52 ± 0.07 a | 0.64 ± 0.01 b | 0.96 |

| CNF/PLA-15D | 3.91 ± 0.32 b | 0.45 ± 0.01 a | 0.68 ± 0.03 b | 0.97 |

| CNF/CB-1D | 118.67 ± 23.49 b | 6.81 ± 0.70 b | 0.55 ± 0.05 c | 0.45 |

| CNF/CB-15D | 24.60 ± 2.02 e | 3.35 ± 0.09 c | 0.78 ± 0.04 d | 0.97 |

| Paper | Thickness (mm) | Grammage (g/m2) | Coating Weight (g/m2) |

|---|---|---|---|

| Natural Bond | 0.090 ± 0.005 a | 67.306 ± 2.325 c | NA |

| Kraft natural | 0.148 ± 0.007 b | 90.120 ± 1.272 d | NA |

| Coated Bond | 0.099 ± 0.0008 a | 87.657 ± 3.599 a | 17.472 ± 2.451 a |

| Coated Kraft | 0.155 ± 0.006 b | 116.185 ± 4.002 b | 25.944 ± 2.807 b |

| Paper | Theta @ 5 s (°) | Theta @ 55 s (°) | WA @ 5 s (mN/m) | WA @ 55 s (mN/m) |

|---|---|---|---|---|

| Natural Bond | 53.40 ± 8.37 a | 26.87 ± 6.33 b | 114.47 ± 10.64 a | 135.82 ± 4.72 a |

| Natural Kraft | 97.27 ± 1.30 a | 50.77 ± 4.15 b | 62.89 ± 1.99 a | 117.40 ± 4.83 a |

| Coated Bond | 86.93 ± 0.82 a | 82.67 ± 4.03 a | 75.84 ± 1.26 a | 81.15 ± 6.12 a |

| Coated Kraft | 88.47 ± 1.94 a | 87.30 ±1.69 a | 73.92 ± 2.99 a | 75.38 ± 2.59 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Argel-Pérez, S.; Velásquez-Cock, J.; Zuluaga, R.; Gómez-Hoyos, C. Improving Hydrophobicity and Water Vapor Barrier Properties in Paper Using Cellulose Nanofiber-Stabilized Cocoa Butter and PLA Emulsions. Coatings 2024, 14, 1310. https://doi.org/10.3390/coatings14101310

Argel-Pérez S, Velásquez-Cock J, Zuluaga R, Gómez-Hoyos C. Improving Hydrophobicity and Water Vapor Barrier Properties in Paper Using Cellulose Nanofiber-Stabilized Cocoa Butter and PLA Emulsions. Coatings. 2024; 14(10):1310. https://doi.org/10.3390/coatings14101310

Chicago/Turabian StyleArgel-Pérez, Shaydier, Jorge Velásquez-Cock, Robin Zuluaga, and Catalina Gómez-Hoyos. 2024. "Improving Hydrophobicity and Water Vapor Barrier Properties in Paper Using Cellulose Nanofiber-Stabilized Cocoa Butter and PLA Emulsions" Coatings 14, no. 10: 1310. https://doi.org/10.3390/coatings14101310

APA StyleArgel-Pérez, S., Velásquez-Cock, J., Zuluaga, R., & Gómez-Hoyos, C. (2024). Improving Hydrophobicity and Water Vapor Barrier Properties in Paper Using Cellulose Nanofiber-Stabilized Cocoa Butter and PLA Emulsions. Coatings, 14(10), 1310. https://doi.org/10.3390/coatings14101310