Effect of Trace Bismuth on Deformation Behavior of Ultrahigh-Purity Copper during Hot Compression

Abstract

1. Introduction

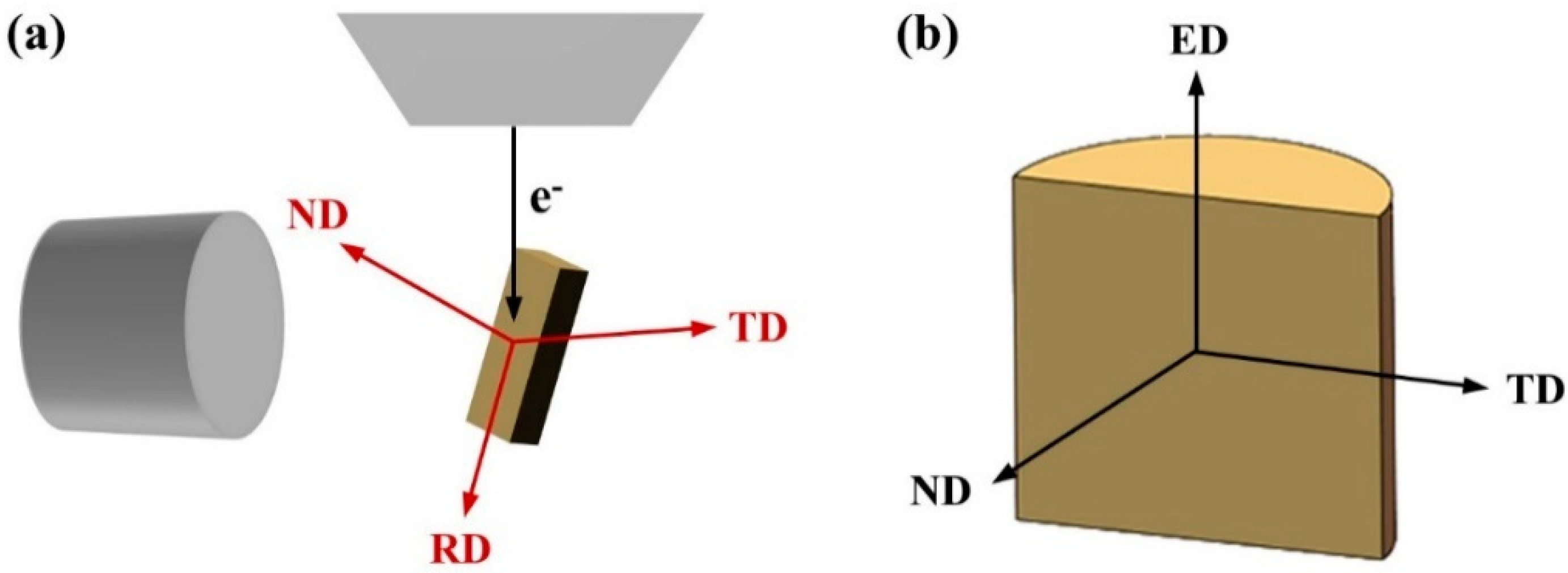

2. Materials and Methods

3. Results and Discussion

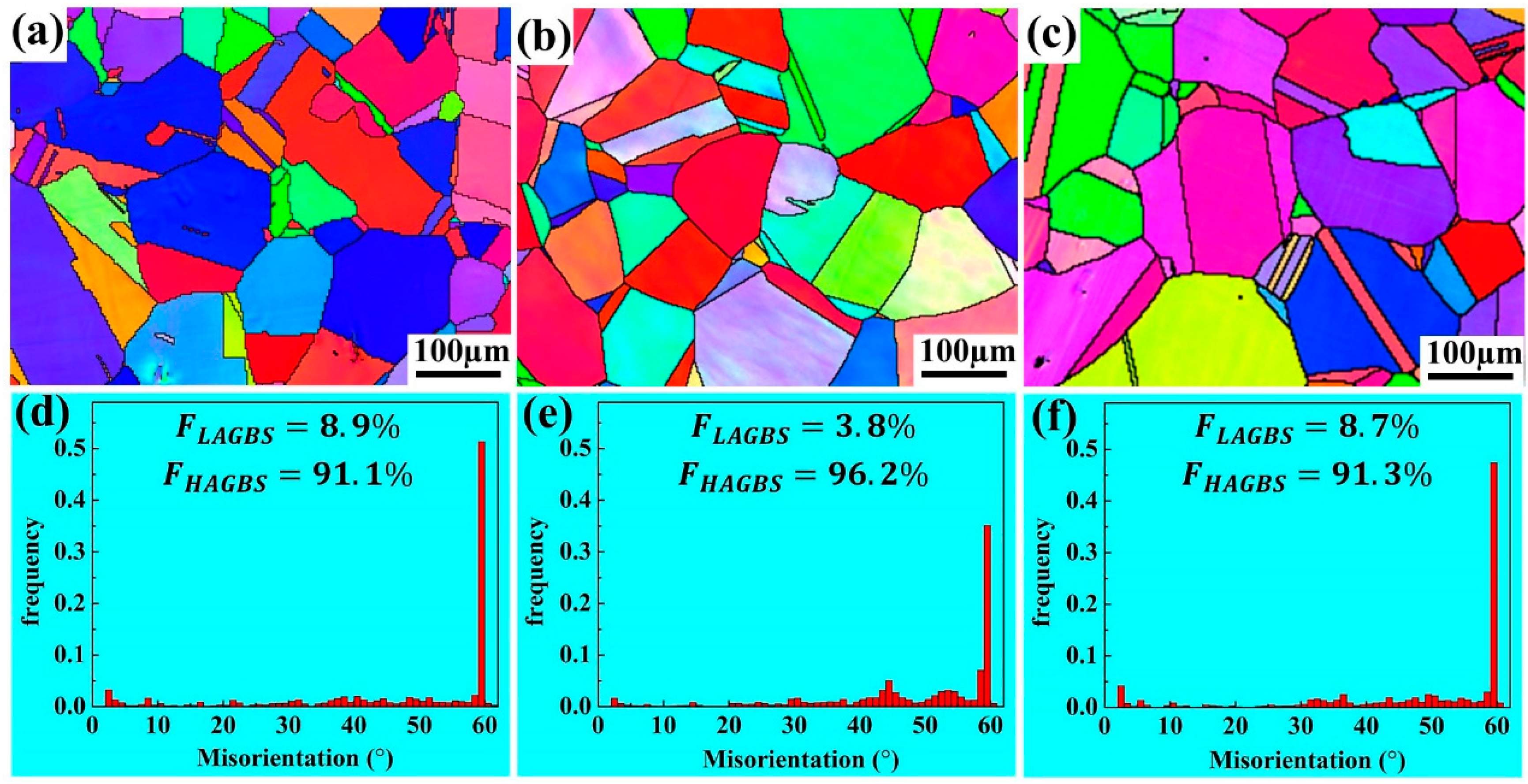

3.1. Initial Microstructure

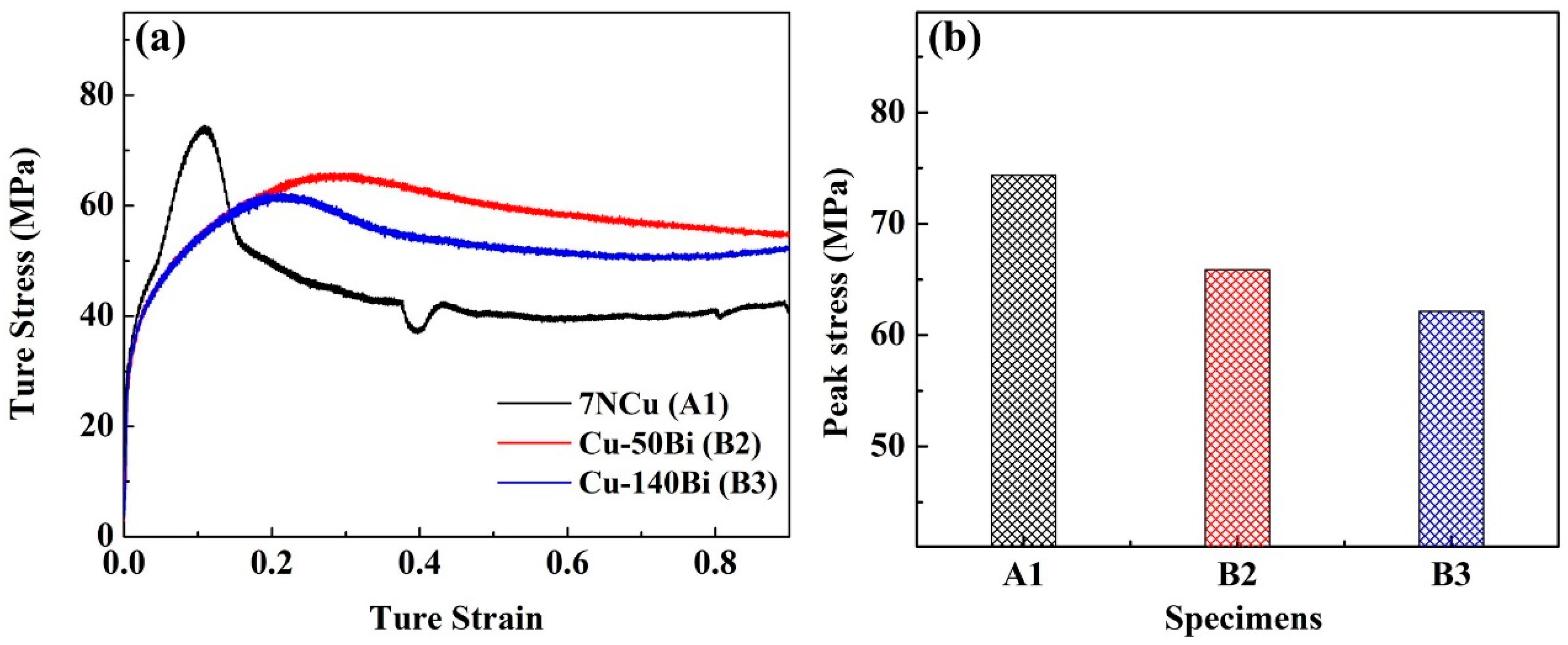

3.2. True Stress–Strain Curves

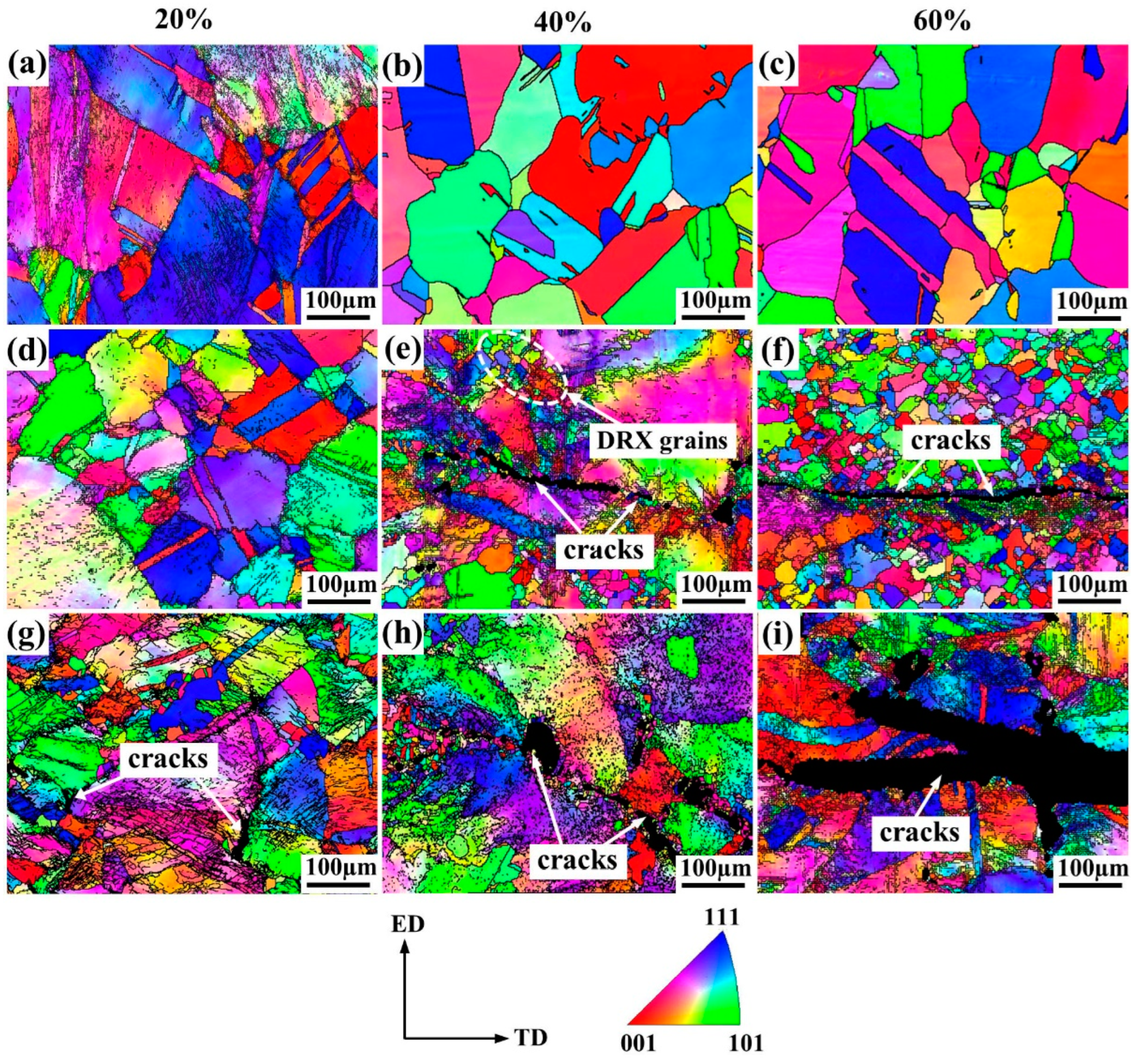

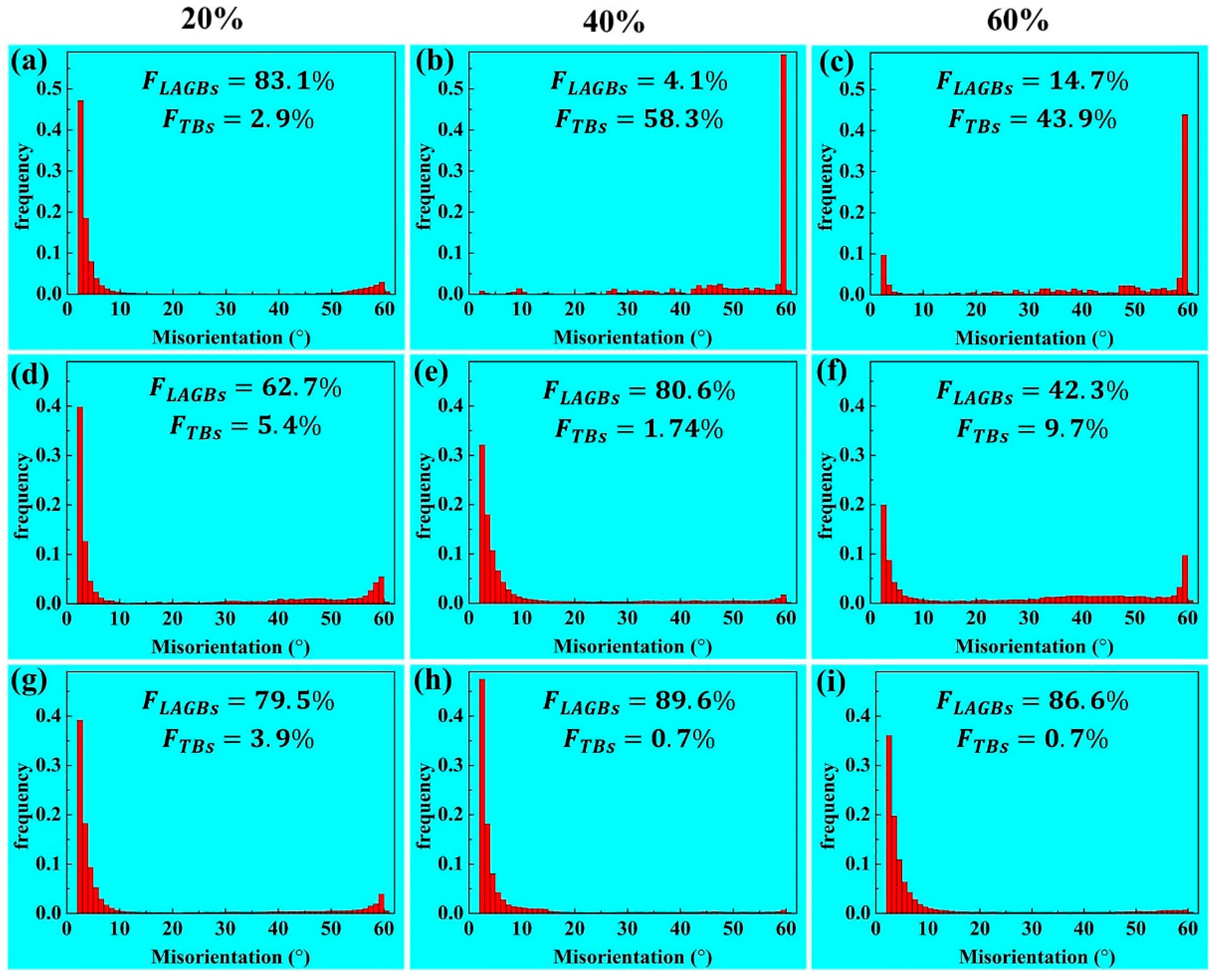

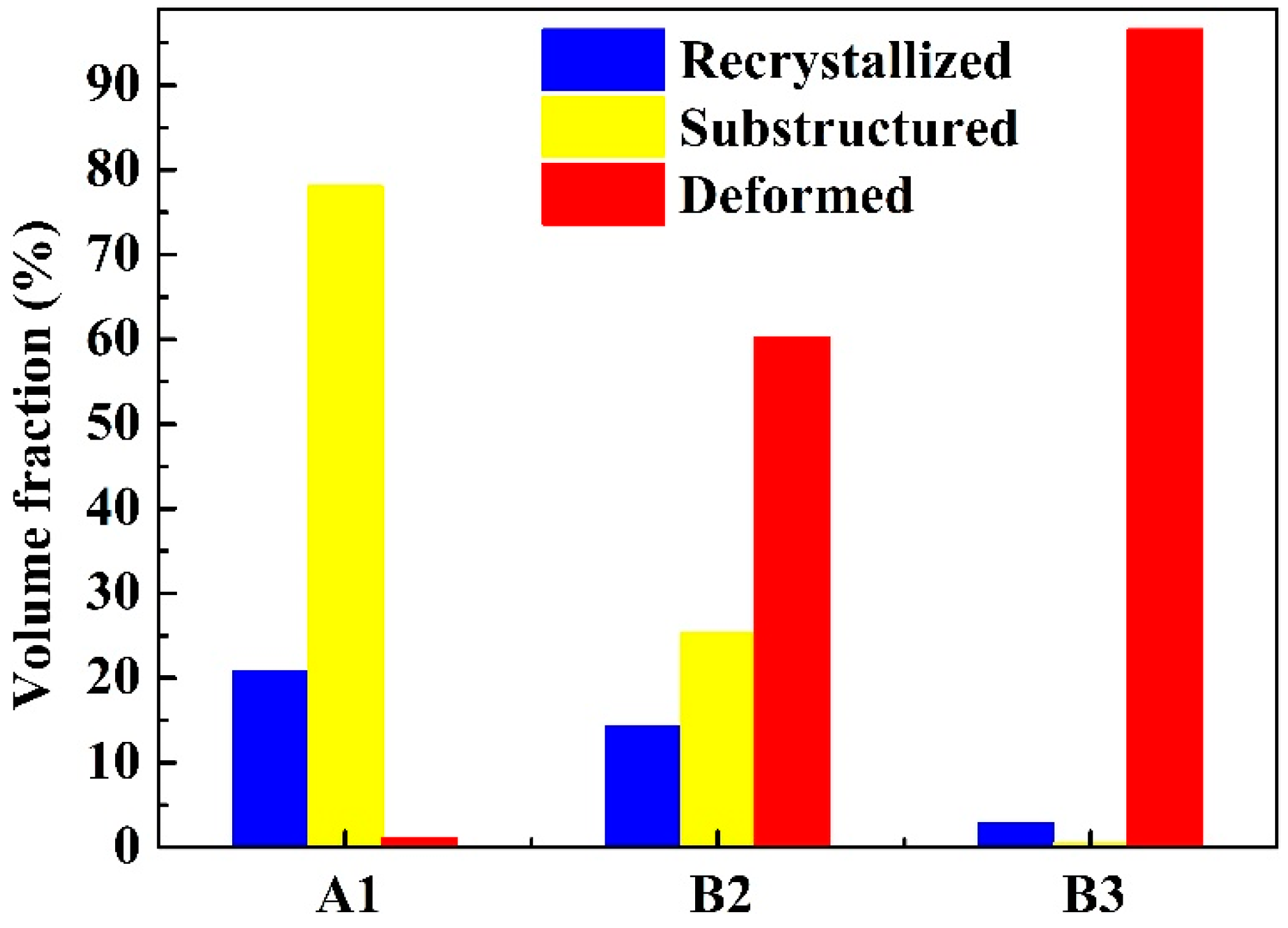

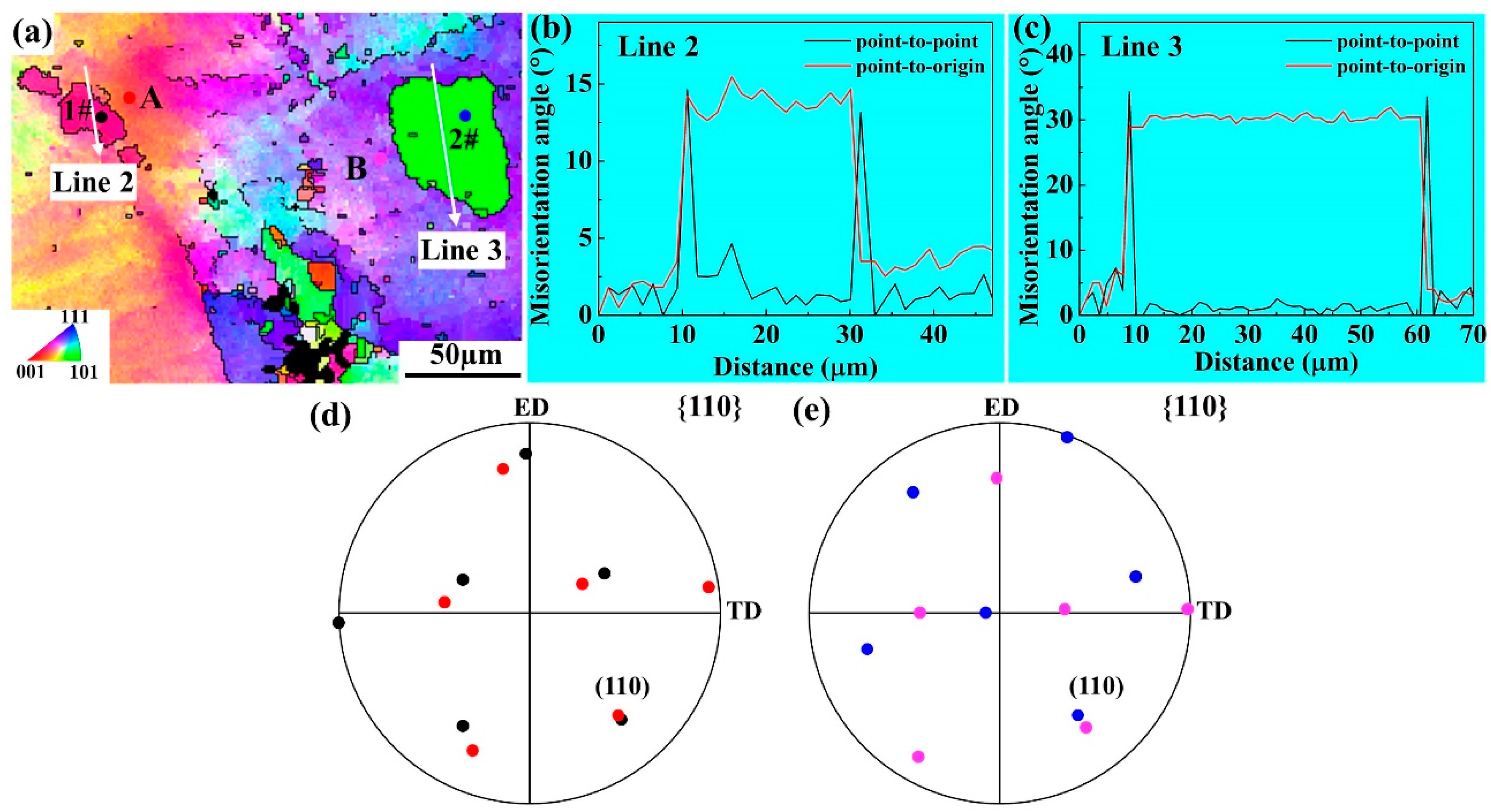

3.3. Microstructure Evolution

3.4. Dynamic Recrystallization

4. Conclusions

- (1)

- The peak stress of the ultrahigh-purity copper gradually decreases from 74.37 MPa to 62.13 MPa with increasing Bi content, which is due to the segregation of Bi at GBs.

- (2)

- During the hot compression process, trace Bi impurities induce severe intergranular embrittlement of the ultrahigh-purity copper. And the microstructure of B3 copper with 140 ppm Bi content does not undergo obvious refinement, which results from the inhibition of the DRX grain nucleation.

- (3)

- With the increase in strain, the primary deformation mechanism of ultrahigh-purity copper transforms from the dislocation slip to twinning, while the dislocation slip dominates the entire compression process for both Bi-containing coppers.

- (4)

- The addition of trace Bi impurities can inhibit the DRX process of ultrahigh-purity copper and transform its DRX mechanism from DDRX to the coexistence of DDRX and CDRX.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.C.; Gao, D.; Xiang, H.F.; Feng, X.Y.; Yu, Y. Research progress on copper-based current collector for lithium metal batteries. Energy Fuels 2021, 35, 12921–12937. [Google Scholar] [CrossRef]

- Phiri, T.C.; Singh, P.; Nikoloski, A.N. The potential for copper slag waste as a resource for a circular economy: A review–Part I. Miner. Eng. 2022, 180, 107474. [Google Scholar] [CrossRef]

- Li, Z.D.; Lin, C.G.; Cui, S. Development of research and application of copper alloys with high strength and high conductivity. Adv. Mater. Res. 2014, 1053, 61–68. [Google Scholar] [CrossRef]

- Duscher, G.; Chisholm, M.F.; Alber, U.; Rühle, M. Bismuth-induced embrittlement of copper grain boundaries. Nat. Mater. 2004, 3, 621–626. [Google Scholar] [CrossRef] [PubMed]

- Otto, F.; Frenzel, J.; Eggeler, G. On the influence of small quantities of Bi and Sb on the evolution of microstructure during swaging and heat treatments in copper. J. Alloys Compd. 2011, 509, 4073–4080. [Google Scholar] [CrossRef]

- Gao, Y.M.; Liu, Y.; Feng, K.J.; Ma, J.Q.; Miao, Y.J.; Xu, B.R.; Pan, K.M.; Akiyoshi, O.; Wang, G.X.; Zhang, K.K.; et al. Emerging WS2/WSe2@graphene nanocomposites: Synthesis and electrochemical energy storage applications. Rare Metals. 2024, 43, 1–19. [Google Scholar] [CrossRef]

- He, H.W.; Zhao, H.Y.; Guo, F.; Xu, G.C. Bi layer formation at the anode interface in Cu/Sn-58Bi/Cu solder joints with high current density. J. Mater. Sci. Technol. 2012, 28, 46–52. [Google Scholar] [CrossRef]

- Schusteritsch, G.; Kühne, T.D.; Guo, Z.X.; Kaxiras, E. The effect of Ag, Pb and Bi impurities on grain boundary sliding and intergranular decohesion in copper. Philos. Mag. 2016, 96, 2868–2886. [Google Scholar] [CrossRef]

- Xu, B.R.; Li, Q.A.; Liu, Y.; Wang, G.B.; Zhang, Z.H.; Ren, F.Z. Urea-induced interfacial engineering enabling highly reversible aqueous zinc-ion battery. Rare Metals 2024, 43, 1599–1609. [Google Scholar] [CrossRef]

- Keast, V.J.; Williams, D.B. Quantitative compositional mapping of Bi segregation to grain boundaries in Cu. Acta Mater. 1999, 47, 3999–4008. [Google Scholar] [CrossRef]

- Alber, U.; Müllejans, H.; Rühle, M. Bismuth segregation at copper grain boundaries. Acta Mater. 1999, 47, 4047–4060. [Google Scholar] [CrossRef]

- Baumann, S.F.; Williams, D.B. A STEM/X-ray microanalytical study of the equilibrium segregation of bismuth in copper. J. Microsc. 1981, 123, 299–305. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, K.J.; Han, J.M.; Wang, F.; Xing, Y.B.; Tao, F.; Li, H.M.; Xu, B.R.; Ji, J.T.; Li, H.X. Regulation of Zn2+ solvation shell by a novel N-methylacetamide based eutectic electrolyte toward high-performance zinc-ion batteries. J. Mater. Sci. Technol. 2025, 211, 53–61. [Google Scholar] [CrossRef]

- Keast, V.J.; La Fontaine, A.; du Plessis, J. Variability in the segregation of bismuth between grain boundaries in copper. Acta Mater. 2007, 55, 5149–5155. [Google Scholar] [CrossRef]

- Laporte, V.; Mortensen, A. Intermediate temperature embrittlement of copper alloys. Int. Mater. Rev. 2013, 54, 94–116. [Google Scholar] [CrossRef]

- Gavin, S.A.; Billingham, J.; Chubb, J.P.; Hancock, P. Effect of trace impurities on hot ductility of as-cast cupronickel alloys. Met. Technol. 1978, 5, 397–401. [Google Scholar] [CrossRef]

- Powell, B.D.; Mykura, H. The segregation of bismuth to grain boundaries in copper-bismuth alloys. Acta Met. 1973, 21, 1151–1156. [Google Scholar] [CrossRef]

- Joshi, A.; Stein, D.F. Auger spectroscopic analysis of bismuth segregated to grain boundaries in copper. J. Inst. Met. 1971, 99, 178–181. [Google Scholar]

- Powell, B.D.; Woodruff, D.P. Anisotropy in grain boundary segregation in copper-bismuth alloys. Philos. Mag. 1976, 34, 169–176. [Google Scholar] [CrossRef]

- Kosinova, A.; Straumal, B.B.; Kilmametov, A.R.; Rabkin, E. The effect of bismuth on microstructure evolution of ultrafine grained copper. Mater. Lett. 2017, 199, 156–159. [Google Scholar] [CrossRef]

- Hua, Y.X.; Liu, H.T.; Song, K.X.; Peng, X.W.; Zhang, C.M.; Zhou, Y.J.; Huang, T.; Guo, X.H.; Mi, X.J.; Wang, Q.S. Trace Ce addition for inhibiting Bi segregation induced embrittlement in ultrahigh-purity copper. Mater. Charact. 2022, 194, 112352. [Google Scholar] [CrossRef]

- Hua, Y.X.; Song, K.X.; Liu, H.T.; Wang, J.W.; Zhang, C.M.; Zhou, Y.J.; Pang, B.; Song, J.T.; He, J.L.; Zhao, H.L. Role of grain boundary character on Bi segregation-induced embrittlement in ultrahigh-purity copper. J. Mater. Sci. Technol. 2023, 159, 52–61. [Google Scholar] [CrossRef]

- GB/T 5121.27-2008; Methods for Chemical Analysis of Copper and Copper Alloys–Part 27: The Inductively Coupled Plasma Atomic Emission Spectromertric Method. General Administration of Quality Supervision, Inspection and Quarantine of the People‘s Republic of China: Beijing, China, 2008.

- Luo, J.; Cheng, H.K.; Asl, K.M.; Kiely, C.J.; Harmer, M.P. The role of a bilayer interfacial phase on liquid metal embrittlement. Science 2011, 333, 1730–1733. [Google Scholar] [CrossRef] [PubMed]

- Wade, C.A.; MacLaren, I.; Vinci, R.P.; Watanabe, M. The role of grain boundary dislocations in the segregation-induced grain boundary embrittlement of copper by bismuth. Microsc. Microanal. 2016, 22, 1264–1265. [Google Scholar] [CrossRef][Green Version]

- Keast, V.J.; Bruley, J.; Rez, P.; Maclaren, J.M.; Williams, D.B. Chemistry and bonding changes associated with the segregation of Bi to grain boundaries in Cu. Acta Mater. 1998, 46, 481–490. [Google Scholar] [CrossRef]

- Song, K.X.; Hua, Y.X.; Liu, H.T.; Zhang, Y.M.; Zhang, C.M.; Zhou, Y.J.; Huang, T. Effect of Trace Cerium Addition on the Hot Deformation Behavior of Ultrahigh-Purity Copper Containing Sulfur in a ppm Concentration. Trans. Nonferr. Met. Soc. China 2024. Available online: http://kns.cnki.net/kcms/detail/43.1239.TG.20240426.1825.014.html (accessed on 4 August 2024).

- Rouxel, B.; Cayron, C.; Bornand, J.; Sanders, P.; Logé, R.E. Micro-addition of Fe in highly alloyed Cu-Ti alloys to improve both formability and strength. Mater. Des. 2022, 213, 110340. [Google Scholar] [CrossRef]

- Zhang, F.J.; Hu, H.Y.; Hu, J.J.; Yang, X.; Li, M.; Chen, Y.X.; Ma, C.P.; Guo, N. Microstructure and defects of rectangular Cu-Ag wires fabricated by the continuous extrusion forming process. Can. Met. Q. 2024, 63, 46–57. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Z.; Pan, D.Q.; Li, D.X.; Luo, Z.Q.; Zhang, D.T.; Yang, C.; Zhang, W.W. Effect of Si and Ti on dynamic recrystallization of high-performance Cu-15Ni-8Sn alloy during hot deformation. Trans. Nonferr. Met. Soc. China 2019, 29, 2556–2565. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Saeid, T.; Klemm, V.; Chabok, A.; Pei, Y.T. Effect of stacking fault energy on the restoration mechanisms and mechanical properties of friction stir welded copper alloys. Mater. Des. 2019, 162, 185–197. [Google Scholar] [CrossRef]

- Deshpande, A.; Tofangchi, A.; Hsu, K. Microstructure evolution of Al6061 and copper during ultrasonic energy assisted compression. Mater. Charact. 2019, 153, 240–250. [Google Scholar] [CrossRef]

- Primig, S.; Clemens, H.; Knabl, W.; Lorich, A.; Stickler, R. Orientation dependent recovery and recrystallization behavior of hot-rolled molybdenum. Int. J. Refract. Met. Hard Mater. 2015, 48, 179–186. [Google Scholar] [CrossRef]

- Primig, S.; Leitner, H.; Knabl, W.; Lorich, A.; Stickler, R. Static recrystallization of molybdenum after deformation below 0.5*TM(K). Met. Mater. Trans. A 2012, 43, 4806–4818. [Google Scholar] [CrossRef]

- Primig, S.; Leitner, H.; Knabl, W.; Lorich, A.; Clemens, H.; Stickler, R. Textural evolution during dynamic recovery and static recrystallization of molybdenum. Met. Mater. Trans. A 2012, 43, 4794–4805. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Hua, Y.; Li, W.; Hou, Z.; Dong, J.; Liu, Y. Effect of Trace Bismuth on Deformation Behavior of Ultrahigh-Purity Copper during Hot Compression. Coatings 2024, 14, 1261. https://doi.org/10.3390/coatings14101261

Liu H, Hua Y, Li W, Hou Z, Dong J, Liu Y. Effect of Trace Bismuth on Deformation Behavior of Ultrahigh-Purity Copper during Hot Compression. Coatings. 2024; 14(10):1261. https://doi.org/10.3390/coatings14101261

Chicago/Turabian StyleLiu, Haitao, Yunxiao Hua, Weiqiang Li, Zhenguo Hou, Jincan Dong, and Yong Liu. 2024. "Effect of Trace Bismuth on Deformation Behavior of Ultrahigh-Purity Copper during Hot Compression" Coatings 14, no. 10: 1261. https://doi.org/10.3390/coatings14101261

APA StyleLiu, H., Hua, Y., Li, W., Hou, Z., Dong, J., & Liu, Y. (2024). Effect of Trace Bismuth on Deformation Behavior of Ultrahigh-Purity Copper during Hot Compression. Coatings, 14(10), 1261. https://doi.org/10.3390/coatings14101261