Abstract

Wind turbines in cold and humid regions face significant icing challenges. Heating is considered an efficient strategy to prevent ice accretion over the turbine’s blade surface. An ice protection system is required to minimize freezing of the runback water at the back of the blade and the melting state of the ice on the blade; the law of re-freezing of the runback water is necessary for the design of wind turbine de-icing systems. In this paper, a wind tunnel test was conducted to investigate the de-icing process of a static heated blade under various rime icing conditions. Ice shapes of different thicknesses were obtained by spraying water at 5 m/s, 10 m/s, and 15 m/s. The spray system was turned off and different heating fluxes were applied to heat the blade. The de-icing state and total energy consumption were explored. When de-icing occurred in a short freezing time, the ice layer became thin, and runback water flowed out (pattern I). With an increase in freezing time at a low wind speed, the melting ice induced by the dominant action of inertial force moved backward due to the reduction in adhesion between the ice and blade surface (pattern II). As wind speed increased, it exhibited various de-icing states, including refreezing at the trailing edge (pattern III) and ice shedding (pattern IV). The total energy consumption of ice melting decreased as the heat flux increased and the ice melting time shortened. At 5 m/s, when the heat flux was q = 14 kW/m2, the energy consumption at EA at tδ = 1 min, 5 min, and 7 min were 0.33 kJ, 0.55 kJ, and 0.61 kJ, respectively. At 10 m/s, when the heat flux was q = 14 kW/m2, the energy consumption at EA at tδ = 1 min, 3 min, and 5 min were 0.77 kJ, 0.81 kJ, and 0.80 kJ, respectively. Excessive heat flow density increased the risk of the return water freezing; thus, the reference de-icing heat fluxes of 5 m/s and 10 m/s were 10 kW/m2 and 12 kW/m2, respectively. This paper provides an effective reference for wind turbine de-icing.

1. Introduction

Wind energy is a renewable energy source that is being actively developed in the world. The development and use of wind energy have far-reaching implications for optimizing the traditional energy structure and reducing global carbon emissions. According to the “Statistical Review of World Energy” published by British Petroleum Global, global wind power installation in 2021 added 93.1 GW to the cumulative installed capacity of 824.9 GW, representing an increase of 13% compared to the previous year [1]. In recent years, wind power generation in cold regions has been 1% higher than that in other regions due to higher air density [2,3]. Installed capacity has also been rising. By the end of 2015, the global wind power generation in cold climates was approximately 127 GW. However, wind turbines in cold regions suffer from severe icing problems, with 72%, 94%, and 19% of wind turbines affected by icing events in North America, Europe, and Asia, respectively [4]. Ice accretion on wind turbine blades can change their aerodynamic shape, affecting their aerodynamic characteristics and causing power losses in wind turbines [5,6,7,8]. Ice accretion on the blades affects their load distribution and shortens the wind turbine’s life [9]. The wind turbines usually stop working during severe ice accretion to avoid mechanical damage. The downtime may last days or weeks, causing economic losses to wind farm operators [10]. For wind turbines in more extreme icing conditions, the estimated loss of annual total energy production (AEP) is about 17% [11]. Ice accretion on the blades can also cause some safety hazards [12]. With the growing icing problem of wind turbines in cold climates, there is an urgent need to develop innovative solutions to mitigate wind turbine blade icing.

Currently, icing mitigation methods for wind turbine blades are generally divided into anti-icing and de-icing systems [13]. Anti-icing prevents ice from being generated on the blades’ surfaces. De-icing refers to removing ice accretion until it reaches a certain amount. Ice mitigation methods are divided into passive and active methods, based on whether additional energy is required [14]. The passive method requires no additional energy consumption. It mainly employs coatings with anti-icing characteristics [15,16,17,18,19] or chemical solutions that lower the freezing point, changing the blade surface properties to mitigate ice accretion [20]. However, the passive method does not achieve the desired de-icing effect when the ice has already adhered to the surface.

Active methods mainly include mechanical actuation and heating methods. Mechanical actuation methods mainly use force to break the adhesion between the ice and the component’s surface. Consequently, the ice structure is destroyed by vibration or motion, which include expansion tube methods (e.g., the inflatable belt and airbag methods), electrical pulse methods [21], and ultrasonic methods [22,23,24]. Heating methods, such as hot air, microwave, and electro-thermal heating, are employed to maintain the temperature above 0 °C for anti/de-icing. Among the various active and passive anti-/de-icing methods, the heating method is considered an efficient strategy for preventing ice accretion over the turbine’s blade surface.

In addition, ice protection systems are required to minimize the runback water freezing at the rear of the blade. During anti-icing, the ice interface generated by the impact of evaporated supercooled water droplets can be used to prevent the runback water from refreezing. The evaporation mode consumes a lot of energy and is not suitable for wind turbines. De-icing systems have lower power costs than anti-icing systems because they must protect icing areas only within ice impact limits. In addition, because the icing acts as an insulator, the de-icing system is not subjected to the high level of convective cooling encountered by anti-icing systems. However, the de-icing state is relatively complex and affected by ambient temperature, wind speed, ice shape, ice thickness, heating power, and the centrifugal force generated by the blade’s rotation. The ambient conditions affect the efficiency of ice mitigation techniques [25]. Shu et al. [26,27] proposed a numerical method to determine the critical de-icing power through fluid and temperature fields. Xu et al. [28] numerically investigated the anti-icing energy demand of a blade airfoil for wind turbines under various icing conditions. The authors found that the maximum heat flux demanded for anti-icing increases by 2717 W/m2 and 745 W/m2 for 253 K and 268 K, respectively, as the wind speed rises (6–14 m/s). Roberge et al. [29] explored the relationship between a wind turbine’s standstill time, wind speed, and ambient temperature at a wind farm in eastern Canada. The authors developed a method to indicate whether a certain ice protection system can be efficient based on wind speed and ambient temperature. Xu et al. [30] conducted static and rotational experiments on a surface-mounted continuous laminate model blade made of carbon fiber. The authors measured the surface temperature of the electrically heated model blade under various conditions of input voltages, rotational speeds, and air temperatures. Stoyanov et al. [31] proposed a method that considers accumulated ice mass, net energy losses, and financial breakeven points to compare and evaluate two ice mitigation strategies: tip-speed ratio derating and electro-thermal anti-icing. The finding revealed that derating reduced the accumulated ice mass and daily power loss by up to 23% and 37% for a 1 h extreme icing event. Anti-icing was identified as the preferred strategy when ambient temperatures were above −5 °C, and the system cost was no higher than 2% of the turbine’s capital. Gezt et al. [32] designed an efficient anti-icing system for wind turbines by combining modeling and experimental testing. Experimental tests showed that accumulated ice needs to reach a certain minimum thickness to break away at a given available power. The results indicated that de-icing a typical 1.5 MW wind turbine requires four sections along the blade span, each covering 17.8% of the span, providing a power density of 2.48 W/in2 (0.385 W/cm2). Hann et al. [33] conducted experiments to show that the energy efficiency of the electro-thermal anti-icing system for fixed-wing UAVs depends on the selected IPS method. In order to determine the most energy-efficient operating mode, the parameters of de-icing times were studied. The results show that systems with longer cycle durations led to higher efficiencies. Additionally, de-icing with barriers was better than anti-icing and de-icing systems without barriers. Fakorede et al. [34] carried out anti-icing tests on the NACA 0012 airfoil with heaters at the International Wind Tunnel Laboratory, characterized the relationship between anti-icing energy and ambient wind speed, and used the law to estimate the anti-icing energy consumption of full-scale wind turbines under certain assumptions.

The above studies have conducted fine explorations of ice protection systems. However, in de-icing systems, the melting state of ice on the blade and re-freezing of the runback water are very important aspects in the design of wind turbine de-icing systems. The de-icing state plays an important role in assessing the thermal efficiency during thermal de-icing of wind turbine blades. Moreover, the effects of different parameters on the de-icing state have not been well described.

In this paper, the de-icing process of rime ice by electric heating under −16 °C was studied. Different heat fluxes were applied under three wind speeds of 5 m/s, 10 m/s and 15 m/s with different ice thicknesses, and the de-icing state and freezing of runback water were observed, with the aim of exploring the laws of the de-icing process and provide a basic theory for the design of a heated de-icing system. The main contributions of this paper are as follows:

- (a)

- the de-icing process on the blade section with electro-thermal elements in rime ice conditions was characterized under different wind speed, input power, and ice thickness conditions;

- (b)

- the surface temperature during the de-icing process was obtained under different conditions;

- (c)

- the energy consumption changes were observed under the same degree of ice melting under different heat fluxes.

2. Experimental Method

2.1. Setup

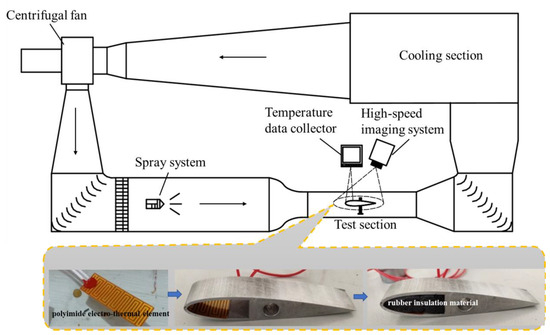

The experimental study was conducted in the reflux icing wind tunnel at the Wind Energy Laboratory of Northeast Agricultural University. As shown in Figure 1, the icing wind tunnel comprises a cooling section, centrifugal fan, spray system, and test section. The cross-section of the wind tunnel test section is a rectangle measuring 250 mm × 250 mm. The evaporator was installed in the cooling section to cool the air, and the nozzle was installed in the stable section to eject tiny droplets. These droplets formed subcooled droplets during the flight and were impinged with the test model in the test section. The designed maximum wind speed was 20 m/s. The ambient temperature was −20–0 °C, the liquid water content (LWC) was 0.5–1.5 g/m3, and the supercooled water droplets’ medium volume diameter (MVD) was 66 μm.

Figure 1.

Schematic of reflux icing wind tunnel.

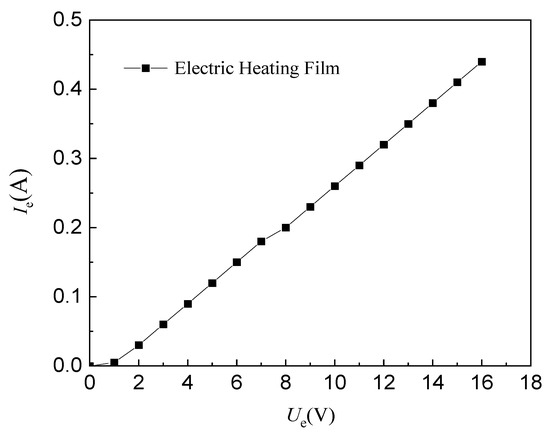

Aluminum was selected as the blade material, due to its known thermophysical parameters, to explore the heat transfer performance in de-icing. A test blade section with an NACA0018 airfoil, a chord of 100 mm, and a thickness of 20 mm was used. The first 1/3 segment of the model was hollow, with a wall thickness of 2 mm. The electro-thermal elements were attached to the inside wall of the blade. Then, the gap was filled with thermal insulation material to prevent heat transfer to the inside, and the model was installed horizontally in the wind tunnel. The commercially available polyimide electro-thermal elements, with a mature process, were chosen as the experimental heating elements. These elements were wrapped with polyimide material, good insulation in the outer layer, and metal alloy as the heating wire. The size of the electro-thermal elements is 49 mm × 19 mm, and the rated voltage and Powert were 12 V and 24 W, respectively. Figure 2 and Table 1 shows the volt-ampere characteristics and specific parameters of the electro-thermal elements, respectively. Ie and Ue were the current and voltage of electro-thermal elements respectively. In Figure 2, it can be seen that the volt-ampere characteristic curve of the heating element is linear, indicating that the resistance of the conductor is constant and does not change with the voltage or current. As the voltage increases, the current also increases correspondingly, but the proportional relationship between them remains constant. The heating element is a linear element. A DC-regulated power supply provides the power, while the voltage and current are used to calculate the power during the test.

Figure 2.

Volt-ampere characteristics of electro-thermal element.

Table 1.

Electro-thermal element parameters.

2.2. Data Acquisition

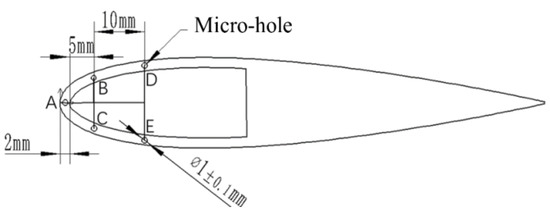

Micro-holes of 1 mm diameter were drilled in the wall (about 0.5 mm from the surface) to obtain the temperature of the blade surface during de-icing without damaging its aerodynamic characteristics. The distribution positions of micro-holes A, B, C, D and E were shown in Figure 3. In addition, the K-type thermocouples were welded into the holes. The hole voids were filled with thermal conductive silica gel to reduce the effect of air thermal resistance on heat transfer.

Figure 3.

The distribution of the temperature measurement holes.

2.3. Experimental Procedure

The test temperature was set at −16 °C to investigate the de-icing process of the blade under rime ice conditions. The heat flux q, which was set by adjusting the supply voltage, represents the power per unit area of the electro-thermal elements. The temperature and wind speed were first set, and the wind tunnel reached a stable state after running for some time. Then, the spray system was turned on to cause icing on the leading blade edge; the icing thickness was controlled by adjusting the spray time. The spray system was turned off during de-icing because the effect of supercooled water droplets in the atmosphere on the de-icing process was neglected. When the temperature reached a stable state, the heating system was turned on for the de-icing.

The heat flux was set to an integer value in the range of 1 kW/m2 to 10 kW/m2 during de-icing, and the surface temperature of the blade was obtained. The heat flux maintaining the blade surface temperature above 0 °C was selected as the experimental parameter. The mass of ice accumulation on the blade surface was controlled by controlling the spraying time. The amount of ice accumulated simultaneously at a wind speed of 5 m/s was lower than at other wind speeds. Therefore, the spraying time at 5 m/s wind speed was increased. The melting ice shapes, and surface temperature variations, were recorded for different ice thicknesses. The de-icing heat flux, the incoming wind speed, and the variations were studied, as shown in Table 2. The shape of the ice and its accretion rates depend on the atmospheric temperature, liquid water content, impact velocity, water droplet size and accretion time. The test was conducted when rime ice formed on the blade surface at −16 °C. According to the working wind speed range of the wind turbine, which is 3–20 m/s, three wind speeds of 5 m/s, 10 m/s, and 15 m/s were selected as the test conditions.

Table 2.

Test conditions.

2.4. Uncertainty Analysis

In this study, the accuracy of the K-type thermocouple was ±0.5 °C. The uncertainties of the voltage and current were ±0.1 V and ±0.01 A, respectively. The uncertainty of the power may be calculated by [35]:

Based on Equation (1), the obtained uncertainties of the power measurements are ±0.108–0.187 W for the heat flux of 6–18 kW/m2.

3. Results and Discussion

3.1. Ice-Melting Shapes under Different Conditions

Figure 4 shows the photos and shapes of transient ice accretion on the blade at the different wind speeds in the initial state. The ice profile curve of the blade’s leading edge develops from circular to angular from 5 m/s to 15 m/s. At 5 m/s, the overall ice accretion color is white. When the wind speed increases to 10 m/s and 15 m/s, the ice accretion near the blades is white, and the ice accretion leading edge is opaque. Under the same spraying time conditions, ice accretion is lowest at a wind speed of 5 m/s and highest at a wind speed of 10 m/s.

Figure 4.

The effect of wind speed on the transient ice accretion in the initial state.

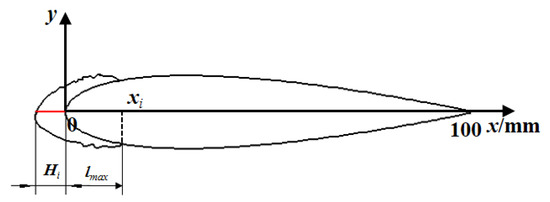

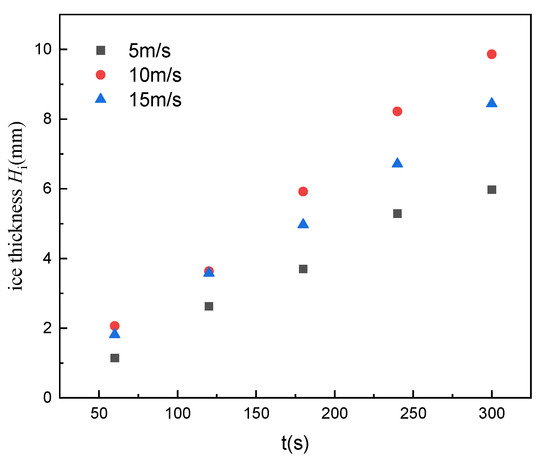

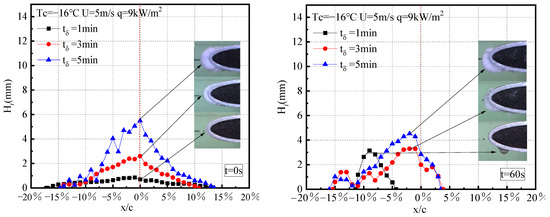

As shown in Figure 5, the ice distribution characteristics of the blade surface were quantitatively analyzed during de-icing, where xi was defined as the absolute value of the horizontal coordinate of any point on the airfoil surface. The maximum thickness of the ice sheet was denoted by Himax. Parameter xi of the intersection between the ice profile and the wing surface is the runback water’s maximum overflow distance (lmax). As shown in Figure 6, the relationship between the icing thickness Hi and the time is approximately linear under different wind speeds, in which the growth rate of 15 m/s was less than that of 10 m/s. This may be due to the higher wind speed at 15 m/s; some of the droplets were carried away by the air flow and did not adhere to the blade’s surface.

Figure 5.

Schematic diagram of ice layer parameters.

Figure 6.

The ice thickness with time under different wind speeds.

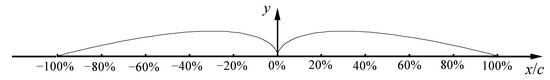

Figure 7 shows the relative position of the blade’s chord length. The horizontal axis is positive for the upper and negative for the lower airfoil side. Parameter c is the airfoil chord length, and x/c is the relative position of the airfoil’s chord length.

Figure 7.

Relative position of blade’s chord length.

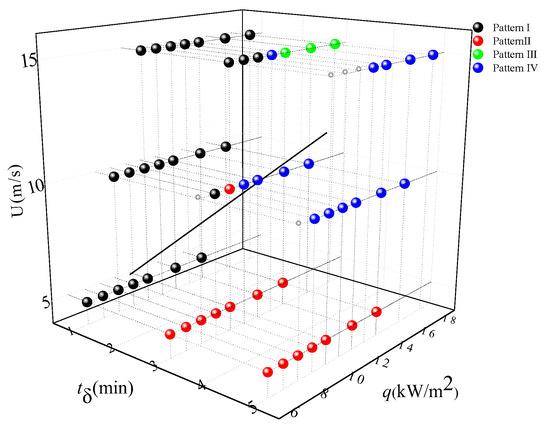

Different de-icing states were obtained by applying different heat fluxes to the iced blades with different wind speeds and icing times. The de-icing states were divided into four categories.

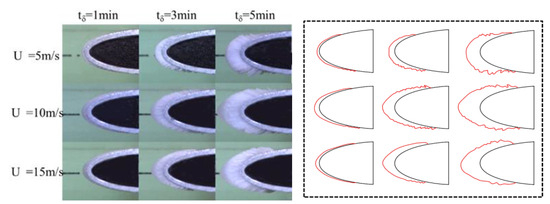

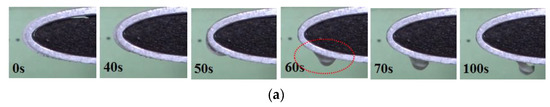

The de-icing patterns are shown in Figure 8. When de-icing is performed over a short freezing time (tδ = 1 min), the runback water flows along the airfoil surface due to the inertial force. The runback water drips as droplets (Figure 9a) at low wind speeds (U = 5 m/s), forms inclined transparent icicles, and then falls (Figure 9b) at medium wind speeds (U = 10 m/s) and freezes during the flow. Ice accumulation forms, adhering to the blade leading edge (Figure 9c) at high wind speeds (U = 15 m/s). When de-icing occurs in a short freezing time, the ice layer becomes thin, and the runback water flows out (pattern I). With an increase in the freezing time at a low wind speed (5 m/s), the melting ice induced by the dominant action of inertial force moves backward due to the reduction in adhesion between the ice and the blade’s surface (pattern II). At medium wind speeds (U = 10 m/s), a thin water film is formed between the ice accretion and the blade, leading to ice shedding due to decreased adhesion (pattern IV). At a high wind speed (U = 15 m/s), the runback water flows to the blade’s trailing edge under the action of inertia, freezing to form ice again (pattern III). The de-icing patterns under different test conditions are shown in Table 3.

Figure 8.

Distribution of de-icing patterns under different conditions.

Figure 9.

Pattern I during the electro-thermal de-icing process: (a) Tc = −16 °C U = 5 m/s q = 9 kW/m2 tδ = 1 min; (b) Tc = −16 °C U = 10 m/s q = 9 kW/m2 tδ = 1 min; and (c) Tc = −16 °C U = 15 m/s q = 10 kW/m2 tδ = 1 min.

Table 3.

De-icing patterns under different test conditions (“×” means that the ice accumulation has not obviously changed).

The four modes are described in detail below.

Pattern I (Figure 9): the runback water freezes on the blade’s leading edge. This de-icing pattern appeared at three wind speeds at the short freezing time (1 min). The ice accumulation always adheres to the airfoil’s leading edge. The runback water flows out and backward along the airfoil surface under the wind speed. The de-icing effect is improved at low and medium wind speeds. However, at high wind speeds, ice accretion formed by the runback water will affect the aerodynamic characteristics of the blade again.

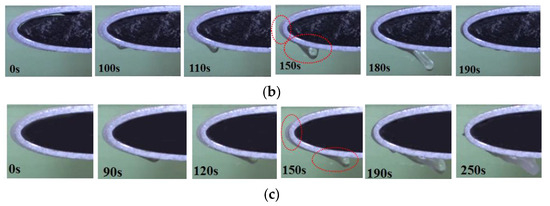

Pattern II (Figure 10): the runback water moves with the melting ice. This pattern is mainly concentrated at tδ = 3–7 min at 5 m/s as the ice accretion thickness reaches a certain amount. Once the ice accumulation near the blade surface melts, the runback water penetrates the ice layer, forming a semi-melting state of ice accretion that slides backward along the airfoil surface caused by the inertial force.

Figure 10.

Pattern II during the electro-thermal de-icing process: (a) Tc = −16 °C U = 10 m/s q = 10 kW/m2 tδ = 3 min; (b) Tc = −16 °C U = 5 m/s q = 14 kW/m2 tδ = 7 min; and (c) Tc = −16 °C U = 5 m/s q = 9 kW/m2 tδ = 3 min.

Three phenomena are found as follows. The water moves to the unheated area to be frozen again, as shown in Figure 10a; ice sheds due to the effect of the wind speed, as shown in Figure 10b; the water flows out to form a water column under the blade due to the melting ice, as shown in Figure 10c.

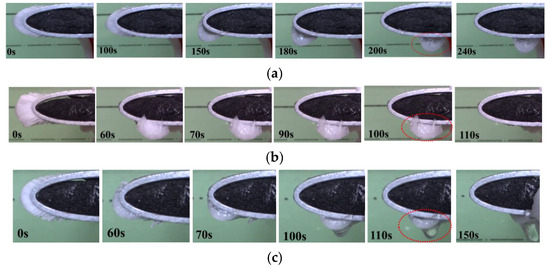

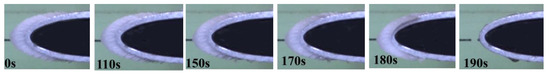

Pattern III (Figure 11): the runback water freezes to the blade’s trailing edge. This pattern appears under q = 14–18 kW/m2, tδ = 3 min, and U = 15 m/s. A part of the water flows to the trailing edge of the blade (t = 50 s), and a part of the ice sheds under the wind speed due to the melting ice. The water forms quickly at the high heat flux and moves backward at a high wind speed, leading to secondary freezing.

Figure 11.

Pattern III during the electro-thermal de-icing process. Tc = −16 °C U = 15 m/s q = 18 kW/m2 tδ = 3 min.

Pattern IV (Figure 12): no runback water is formed. This pattern appears under U = 10 m/s, tδ = 3–5 min or U = 15 m/s, tδ = 5 min. No visible water flows once the ice layer near the blade surface melts. The ice sheds as a whole due to the inertial force.

Figure 12.

Pattern IV during the electro-thermal de-icing process. Tc = −16 °C U = 10 m/s q = 9 kW/m2 tδ = 3 min.

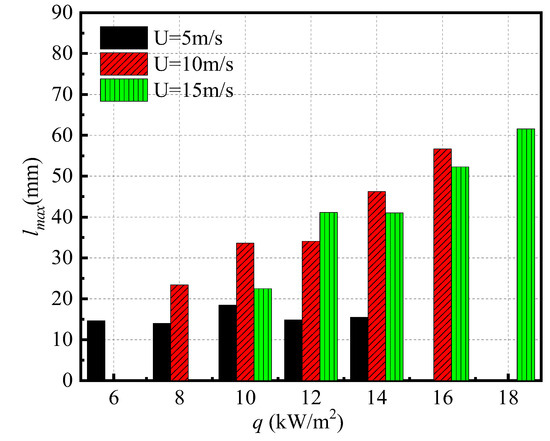

Figure 13 shows the flow distance of runback water in pattern I. The flow distance increases with wind speed. The flow distance is not noticeably affected by the heat flux at 5 m/s, but increases with the heat flux at 10 m/s and 15 m/s. In summary, the thermal ice protection system increases energy consumption for thin ice accretion and does not achieve the desired result.

Figure 13.

Overflow distance of the runback water in pattern I.

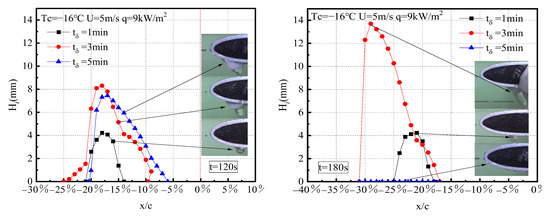

Figure 14 shows the profiles and photos of ice accretion in pattern II. When the ice starts to melt, the ice thickness increases with melting degrees. Moreover, the ice moves to the lower side of the blade as a whole, and the contact area between the ice and the blade’s surface gradually decreases. The areas with less ice are the first to melt completely. After moving to a position below the blade, the melting ice does not move backward, and the sliding position of the melting ice is unaffected by the amount of ice. A water column is formed under the accumulated ice with the outflow of the runback water.

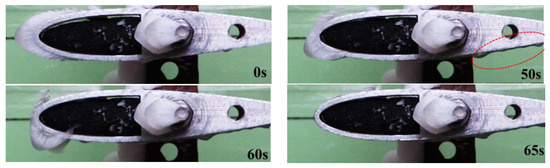

Figure 14.

Profiles and images of the ice accretion in pattern II.

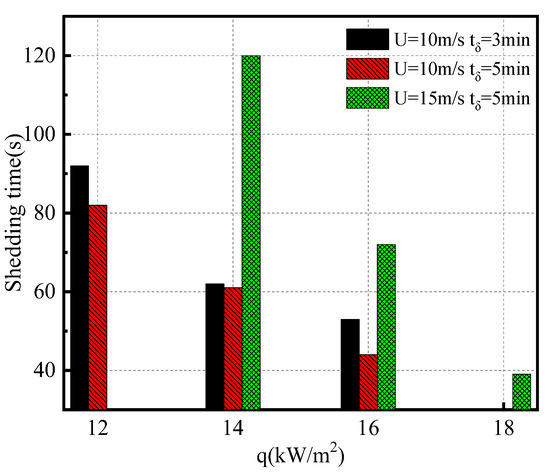

Figure 8 demonstrates that pattern IV is mainly generated at 10 m/s and 15 m/s. Figure 15 shows the change of the ice accretion shedding time at different heat fluxes in pattern IV. The ice shedding time decreases with increased heat flux under various conditions. At 10 m/s, the shedding time of thicker ice is shorter due to the greater gravity of those with larger ice volumes under the same wind speed. Ice accretion takes longer to shed with increasing wind speeds when the ice accretion time is the same. The reason for this may be that the lower airspeeds lead to lower heat convection and thus more efficient heating from the IPS, and the thin ice layer and large force effect are offset by high heat convection.

Figure 15.

Time of ice accumulation shedding in pattern IV.

3.2. Temperature and Total Energy Consumption during De-Icing

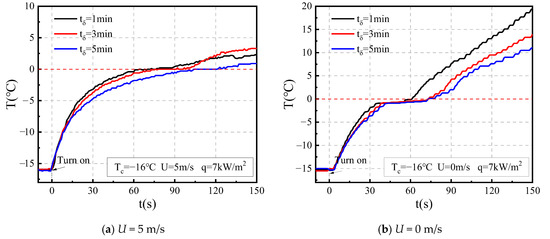

As shown in Figure 16, the blade’s surface point A temperatures are obtained for the different initial icing times during de-icing under U = 5 m/s, Tc = −16 °C, and q = 7 kW/m2. Point A of the blade is the leading-edge point of the airfoil. When the angle of attack is 0°, the surface of point A is attached by ice accumulation, and the change in ice accumulation will cause the temperature of point A to change. After heating, the temperature of the heating film is transmitted to point A, causing the temperature of point A to begin to rise. Due to the influence of convection, the rising rate gradually decreases. After reaching the ice freezing point of 0 °C, part of the heat flux acts as latent heat to melt the ice, and the temperature reaches a plateau. It can be seen from the figure that the temperature growth rate at different ice thicknesses for U = 0 m/s is higher than U = 5 m/s. The temperature increases once the heating is started. After reaching 0 °C, the temperature rate decreases as the ice melts. The rate increases again after some time at 0 °C. The rate of the temperature rise decreases with an increase in ice accumulation; the greater the ice accumulation, the more time it takes for the temperature to reach 0 °C. The time it takes to reach 0 °C at tδ = 1 min, tδ = 3 min, and tδ = 5 min is 64 s, 76 s, and 104 s, respectively. Lastly, the retention times of the temperature curve at 0 °C are 53 s, 49 s, and 70 s, respectively.

Figure 16.

Temperatures of the blade surface point A for the different times of ice accretion during the de-icing.

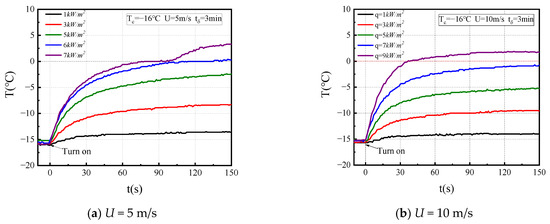

As shown in Figure 17, the temperatures of the blade surface at point A at the different heat flux and wind speeds are provided. The higher the heat flux, the greater the temperature rising rate. The results show that the critical heat flux for de-icing is when the heat flux makes the blade surface reach 0 °C. The heat flux is too low for de-icing when it cannot make the blade temperature reach 0 °C. If the temperature reaches above 0 °C, the rising rate decreases and continues to increase. Ice accumulation on the blade surface during this period starts to melt, and a gap appears between the ice and the blade surface. Due to the influence of convection, the rising rate gradually decreases. After reaching the ice freezing point of 0 °C, part of the heat flux acts as latent heat to melt the ice, and the temperature reaches a plateau. As a result of heat loss due to convection, the temperature rise rate gradually decreases until it drops to 0. The temperature no longer increases and remains constant, reaching a thermal equilibrium state. The critical heat fluxes (test conditions) for de-icing at wind speeds of 5 m/s and 10 m/s are 6 kW/m2 and 9 kW/m2, respectively. Therefore, the given heating heat flux must be greater than the critical de-icing heat flux to melt ice accretion.

Figure 17.

Temperatures of the blade surface at point A at different heat fluxes and wind speeds.

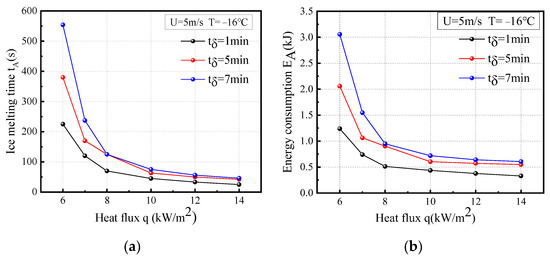

The time of ice melting at blade point A (denoted as tA) was regarded as the de-icing time in order to investigate the relationship between heat flux and the total energy consumption of de-icing under the same degree of ice melting. The energy that the electric heating film consumes at point A without ice is expressed as EA.

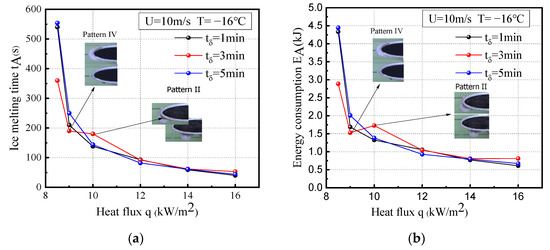

Figure 18 and Figure 19 show the changes in de-icing time tA (a) and total energy consumption EA (b) with heat flux q at wind speeds of 5 m/s and 10 m/s, respectively. The de-icing time and energy consumption decrease with an increase in heat flux. At the same time, the downward trend gradually slows down. The energy consumption of thin ice volume is relatively low at 5 m/s. When the heat flux is q = 6 kW/m2, the energy consumptions EA at tδ = 1 min, 5 min, and 7 min are 1.24 kJ, 2.06 kJ, and 3.06 kJ, respectively. The influence of ice volume on energy consumption is gradually weakened with an increase in heat flux. When the heat flux is q = 14 kW/m2, the energy consumptions EA at tδ = 1 min, 5 min, and 7 min are 0.33 kJ, 0.55 kJ, and 0.61 kJ, respectively. At 10 m/s, when the heat flux is q = 14 kW/m2, the energy consumptions EA at tδ = 1 min, 3 min, and 5 min are 0.77 kJ, 0.81 kJ, and 0.80 kJ. The impact of ice accumulation is not as large as the effect of heat flux, and it does not show obvious laws, but is affected by the de-icing mode. As shown in Figure 19b, pattern IV consumes less energy than pattern II. The reference de-icing heat fluxes of 5 m/s and 10 m/s are 10 kW/m2 and 12 kW/m2, respectively.

Figure 18.

De-icing time tA (a); and energy consumption EA (b) for different heat fluxes at U = 5 m/s.

Figure 19.

De-icing time tA (a); and energy consumption EA (b) for the different heat fluxes at U = 10 m/s.

4. Conclusions

In this paper, electro-thermal de-icing tests were carried out on a blade airfoil of an NACA0018 in a reflux ice wind tunnel under different icing conditions. The main conclusions from the study are as follows:

- When de-icing occurs during a short freezing time (1 min), the ice layer becomes thin, and runback water flows out;

- With an increase in freezing time (3–7 min), the melting ice induced by the dominant action of inertial force moves backward at a low wind speed (5 m/s) due to the reduction in adhesion between the ice and blade surface;

- As the wind speed increases (10–15 m/s), it exhibits various de-icing states, including refreezing to ice at the trailing edge and ice shedding;

- The total energy consumption of ice melting decreases as the heat flux increases and the ice melting time shortens. The reference de-icing heat fluxes of 5 m/s and 10 m/s are 10 kW/m2 and 12 kW/m2, respectively.

Author Contributions

Conceptualization, X.L., Y.L. and Z.X.; Formal analysis, X.L., Y.L. and Z.X.; Funding acquisition, Y.L.; Investigation, X.L. and H.C.; Methodology, X.L., X.L. and Z.X.; Supervision, Y.L.; Validation, Z.X. and Y.L.; Writing—original draft, X.L.; Writing—review and editing, X.L., F.F. and W.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (NSFC) [grant number 51976029] and the National Natural Science Foundation of China (NSFC) [grant number 52376170].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| LWC | Liquid Water Content, g/m3 |

| MVD | Medium Volume Droplet Diameter, μm |

| c | Chord length of airfoil, mm |

| EA | Total energy consumption, kJ |

| Hi | Maximum ice thickness, mm |

| Ie | Current, A |

| lmax | Flow distance of runback water, mm |

| q | Heat flux of electro-thermal elements, kW/m2 |

| tA | De-icing time, s |

| Tc | Wind tunnel temperature, °C |

| tδ | Time of ice accretion, min |

| U | Wind speed, m/s |

| Ue | Voltage, V |

| xi | Abscissa of the intersection between the ice profile and the wing surface |

References

- BP. BP Statistical Review of World Energy 2022 71st Edition. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html (accessed on 1 September 2023).

- Fortin, G.; Perron, J.; Ilinca, A. Behaviour and modeling of cup anemometers under Icing conditions. In Proceedings of the IWAIS 2005, Montreal, QC, Canada, 12–16 June 2005; pp. 1–6. [Google Scholar]

- Technical Research Centre of Finland (VTT). Cold Climate Wind Energy Showing Huge Potential. Science Daily (2013). Available online: https://www.sciencedaily.com/releases/2013/05/130528091611.htm (accessed on 1 September 2023).

- Lehtomäki, V.; Task, I.E.A.W. Wind Energy in Cold Climates Available Technologies-Report. Task 19, Tech. Rep., IEA 2018. 2018. Available online: https://www.researchgate.net/publication/305881044_IEA_Wind_Task_19_-_Available_Technologies_report_of_Wind_Energy_in_Cold_Climates (accessed on 1 September 2023).

- Gao, L.Y.; Hu, H. Wind turbine icing characteristics and icing-induced power losses to utility-scale wind turbines. Proc. Natl. Acad. Sci. USA 2021, 18, 42. [Google Scholar] [CrossRef] [PubMed]

- Jolin, N.; Bolduc, D.; Swytink-Binnema, N.; Rosso, G.; Godreau, C. Wind turbine blade ice accretion: A correlation with nacelle ice accretion. Cold Reg. Sci. Technol. 2018, 157, 235–241. [Google Scholar] [CrossRef]

- Li, Y.; Tagawa, K.; Feng, F.; Li, Q.; He, Q.B. A wind tunnel experimental study of icing on wind turbine blade airfoil. Energy Convers. Manag. 2014, 85, 591–595. [Google Scholar] [CrossRef]

- Jasinski, W.J.; Noe, S.C.; Selig, M.S.; Bragg, M.B. Wind turbine performance under icing conditions. J. Sol. Energy Eng. 1998, 120, 60–65. [Google Scholar] [CrossRef]

- Lamraoui, F.; Fortin, G.; Benoit, R.; Perron, J.; Masson, C. Atmospheric icing impact on wind turbine production. Cold Reg. Sci. Technol. 2014, 100, 36–49. [Google Scholar] [CrossRef]

- Gao, L.Y.; Tao, T.; Liu, Y.Q.; Hu, H. A field study of ice accretion and its effects on the power production of utility-scale wind turbines. Renew. Energy 2021, 167, 917–928. [Google Scholar] [CrossRef]

- Barber, S.; Wang, Y.; Jafari, S. The Impact of Ice Formation on Wind Turbine Performance and Aerodynamics. J. Sol. Energy Eng. 2011, 133, 1. [Google Scholar] [CrossRef]

- Drapalik, M.; Zajicek, L.; Purker, S. Ice aggregation and ice throw from small wind turbines. Cold Reg. Sci. Technol. 2021, 192, 103399. [Google Scholar] [CrossRef]

- Madi, E.; Pope, K.; Huang, W.M.; Iqbal, T. A review of integrating ice detection and mitigation for wind turbine blades. Renew. Sustain. Energy Rev. 2019, 103, 269–281. [Google Scholar] [CrossRef]

- Parent, O.; Ilinca, A. Anti-icing and de-icing techniques for wind turbines: Critical review. Cold Reg. Sci. Technol. 2011, 65, 88–96. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Y.; Li, Y. Superhydrophobic coating for blade surface ice-phobic properties of wind turbines: A review. Prog. Org. Coat. 2024, 187, 108145. [Google Scholar] [CrossRef]

- Khedir, K.R.; Kannarpady, G.K.; Ryerson, C.; Biris, A.S. An outlook on tunable superhydrophobic nanostructural surfaces and their possible impact on ice mitigation. Prog. Org. Coat. 2017, 112, 304–318. [Google Scholar] [CrossRef]

- Khadak, A.; Subeshan, B.; Asmatulu, R. Studies on de-icing and anti-icing of carbon fiber-reinforced composites for aircraft surfaces using commercial multifunctional permanent superhydrophobic coatings. J. Mater. Sci. 2021, 56, 3078–3094. [Google Scholar] [CrossRef]

- Xie, Z.T.; Wang, H.; Geng, Y.; Li, M.; Deng, Q.Y.; Tian, Y.; Chen, R.; Zhu, X.; Liao, Q. Carbon-based photothermal superhydrophobic materials with hierarchical structure enhances the anti-icing and photothermal de-icing properties. ACS Appl. Mater. Interfaces 2021, 13, 48308–48321. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Li, Y.; He, Z. Ice-phobic properties of mos2-loaded rice straw biogas residue biochar-based photothermal and anti-corrosion coating with low oxygen to carbon ratio. Biochar 2023, 5, 74. [Google Scholar] [CrossRef]

- Ma, L.Q.; Zhang, Z.C.; Gao, L.Y.; Hu, H. An exploratory study on using Slippery-Liquid-Infused-Porous-Surface (SLIPS) for wind turbine icing mitigation. Renew. Energy 2020, 162, 2344–2360. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Jiang, X.L. Design research and experimental verification of the electro-Impulse de-Icing system for wind turbine blades in the xuefeng mountain natural icing station. IEEE Access 2020, 8, 28915–28924. [Google Scholar] [CrossRef]

- Habibi, H.; Cheng, L.; Zheng, H.T.; Kappators, V.; Selcuk, C.; Gan, T.H. A dual de-icing system for wind turbine blades combining high-power ultrasonic guided waves and low-frequency forced vibrations. Renew. Energy 2015, 83, 859–870. [Google Scholar] [CrossRef]

- Yin, C.B.; Zhang, Z.D.; Wang, Z.J.; Gao, H. Numerical simulation and experimental validation of ultrasonic de-icing system for wind turbine blade. Appl. Acoust. 2016, 114, 19–26. [Google Scholar] [CrossRef]

- Daniliuk, V.; Xu, Y.M.; Liu, R.B.; He, T.P.; Wang, X. Ultrasonic de-icing of wind turbine blades: Performance comparison of perspective transducers. Renew. Energy 2020, 145, 2005–2018. [Google Scholar] [CrossRef]

- Fakorede, O.; Feger, Z.; Ibrahim, H.; Ilinca, A.; Perron, J.; Masson, C. Ice protection systems for wind turbines in cold climate: Characteristics, comparisons and analysis. Renew. Sustain. Energy Rev. 2016, 65, 662–675. [Google Scholar] [CrossRef]

- Shu, L.C.; Qiu, G.; Hu, Q.; Jiang, X.L.; McClure, G.; Yang, H. Numerical and field experimental investigation of wind turbine dynamic de-icing process. J. Wind Eng. Ind. Aerodyn. 2018, 175, 90–99. [Google Scholar] [CrossRef]

- Shu, L.C.; Qiu, G.; Hu, Q.; Jiang, X.L.; McClure, G.; Liu, Y.Q. Numerical and experimental investigation of threshold de-icing heat flux of wind turbine. J. Wind Eng. Ind. Aerodyn. 2018, 174, 296–302. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, T.; Li, X.J.; Li, Y. Effects of ambient temperature and wind speed on icing characteristics and anti-icing energy demand of a blade airfoil for wind turbine. Renew. Energy 2023, 217, 119135. [Google Scholar] [CrossRef]

- Roberge, P.; Lemay, J.; Ruel, J.; Begin-Drolet, A. Field analysis, modeling and characterization of wind turbine hot air ice protection systems. Cold Reg. Sci. Technol. 2019, 163, 19–26. [Google Scholar] [CrossRef]

- Xu, B.; Lu, F.; Song, G.B. Experimental study on anti-icing and deicing for model wind turbine blades with continuous carbon fiber sheets. J. Cold Reg. Eng. 2018, 32, 04017024. [Google Scholar] [CrossRef]

- Stoyanov, D.B.; Nixon, J.D.; Sarlak, H. Analysis of derating and anti-icing strategies for wind turbines in cold climates. Appl. Energy 2021, 288, 116610. [Google Scholar] [CrossRef]

- Getz, D.; Palacios, J. Design procedures and experimental verification of an electro-thermal deicing system for wind turbines. Wind Energy Sci. 2021, 6, 1291–1309. [Google Scholar] [CrossRef]

- Hann, R.; Enache, A.; MC, N. Experimental heat loads for electrothermal anti-icing and de-icing on UAVs. Aerospace 2021, 8, 83. [Google Scholar] [CrossRef]

- Fakorede, O.; Ibrahim, H.; Ilinca, A.; Perron, J. Experimental investigation of power requirements for wind turbines electrothermal anti-icing systems. In Wind Turbines-Design, Control and Applications; IntechOpen Limited: London, UK, 2016. [Google Scholar]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).