Numerical Simulation of the Residual Stress at the Interface between Thermal Barrier Coating and Nickel-Based Single-Crystal Superalloy Based on Crystal Plasticity Theory

Abstract

:1. Introduction

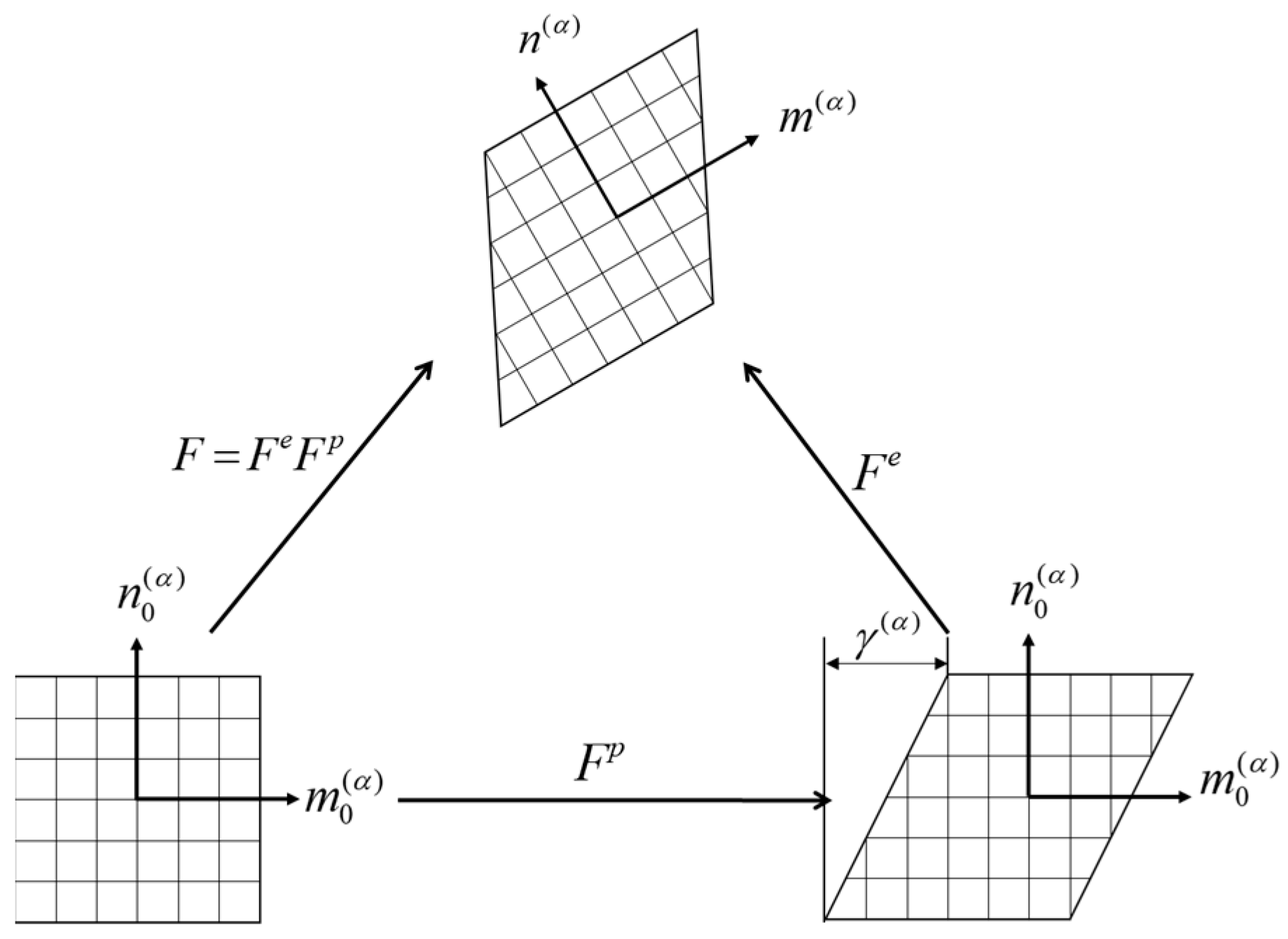

2. Finite Element Theory of Crystal Plasticity

2.1. Kinematic Equation

2.2. Hardening Criterion

3. Finite Element Model

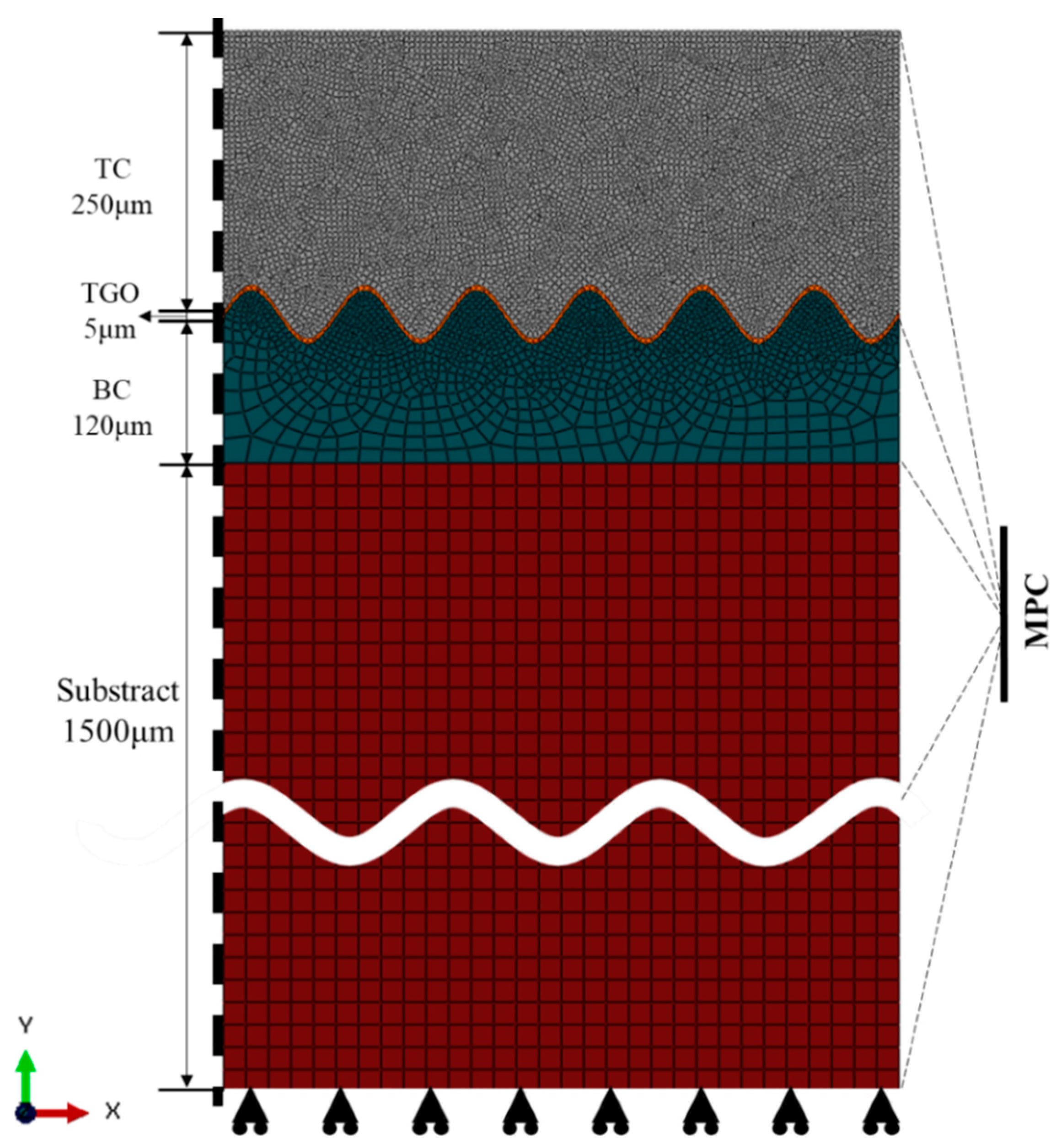

3.1. TBCs Model

3.1.1. Geometric Model

3.1.2. Material Parameters

3.1.3. Load and Boundary Conditions

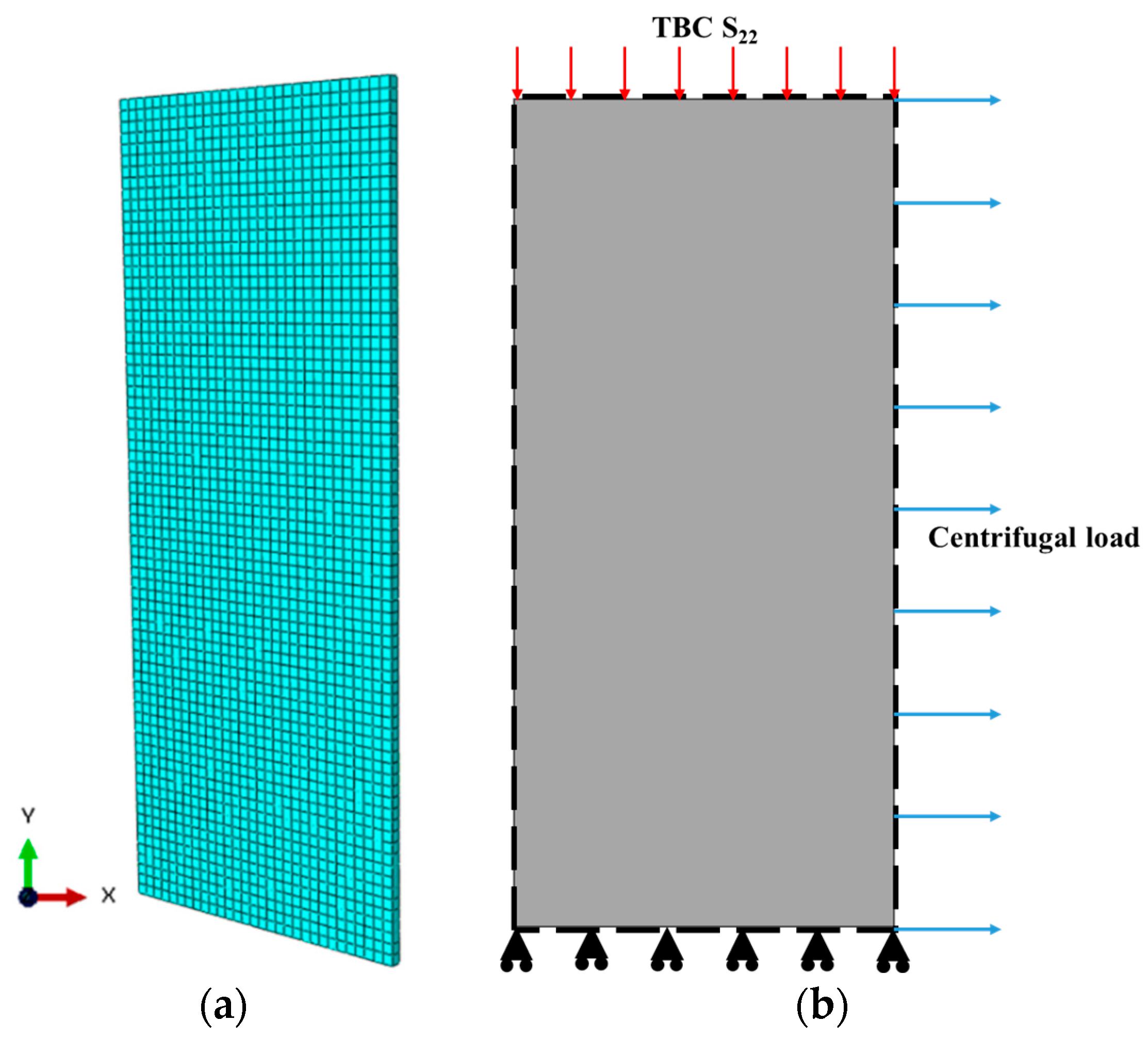

3.2. Crystal Plasticity Finite Element Model

3.2.1. Geometric Model

3.2.2. Crystal Plastic Material Parameters

3.2.3. Load and Boundary Conditions

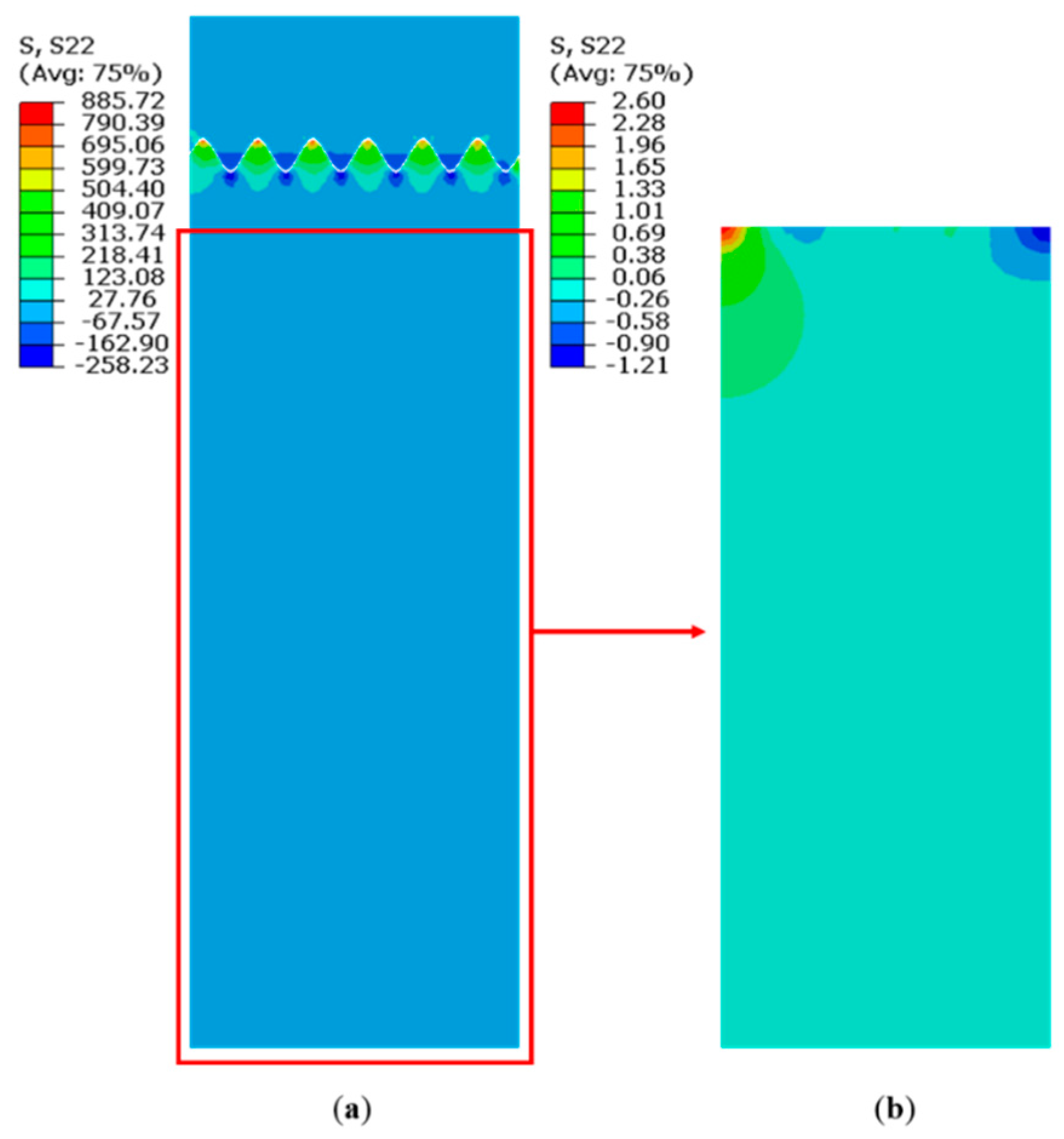

4. Results and Discussion

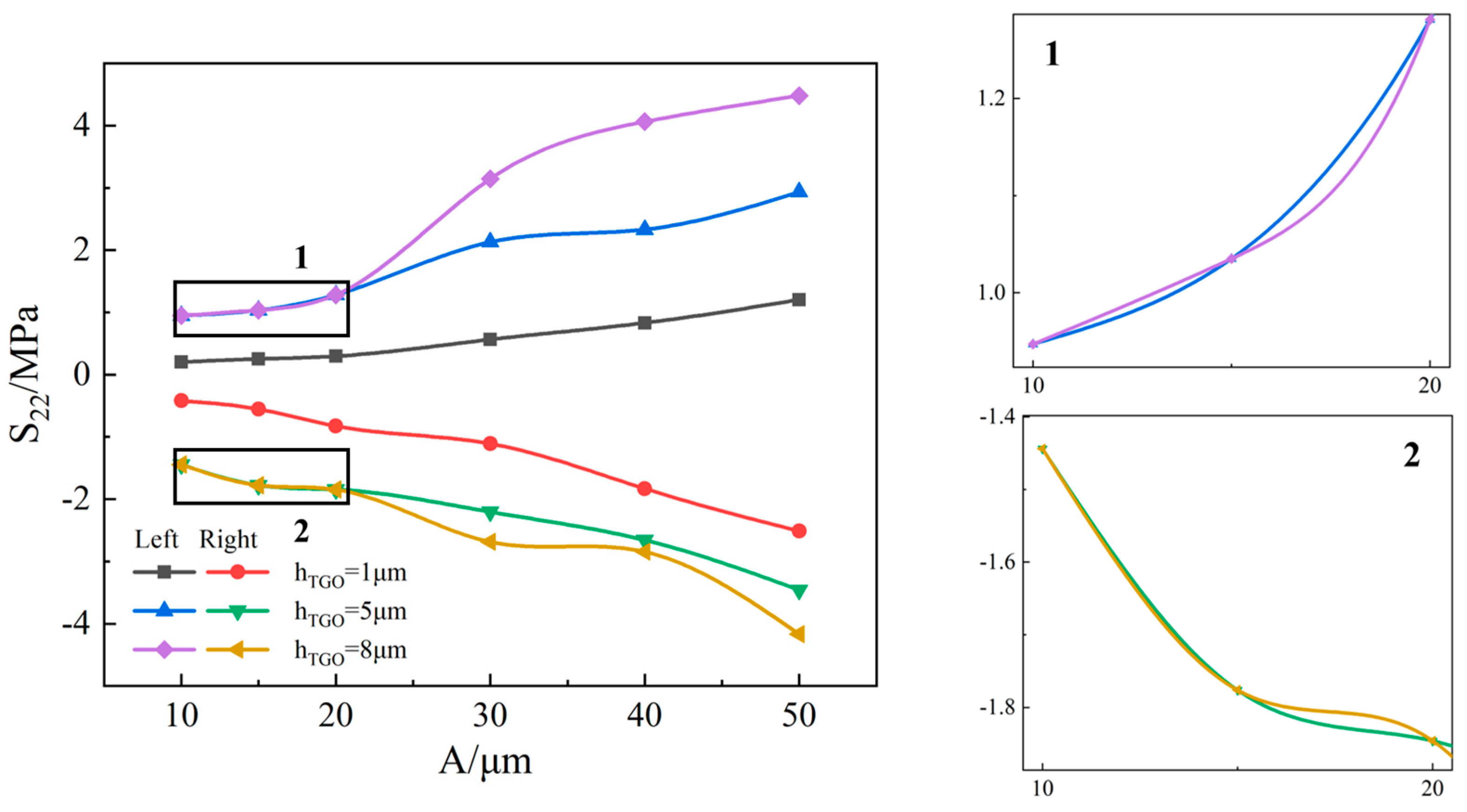

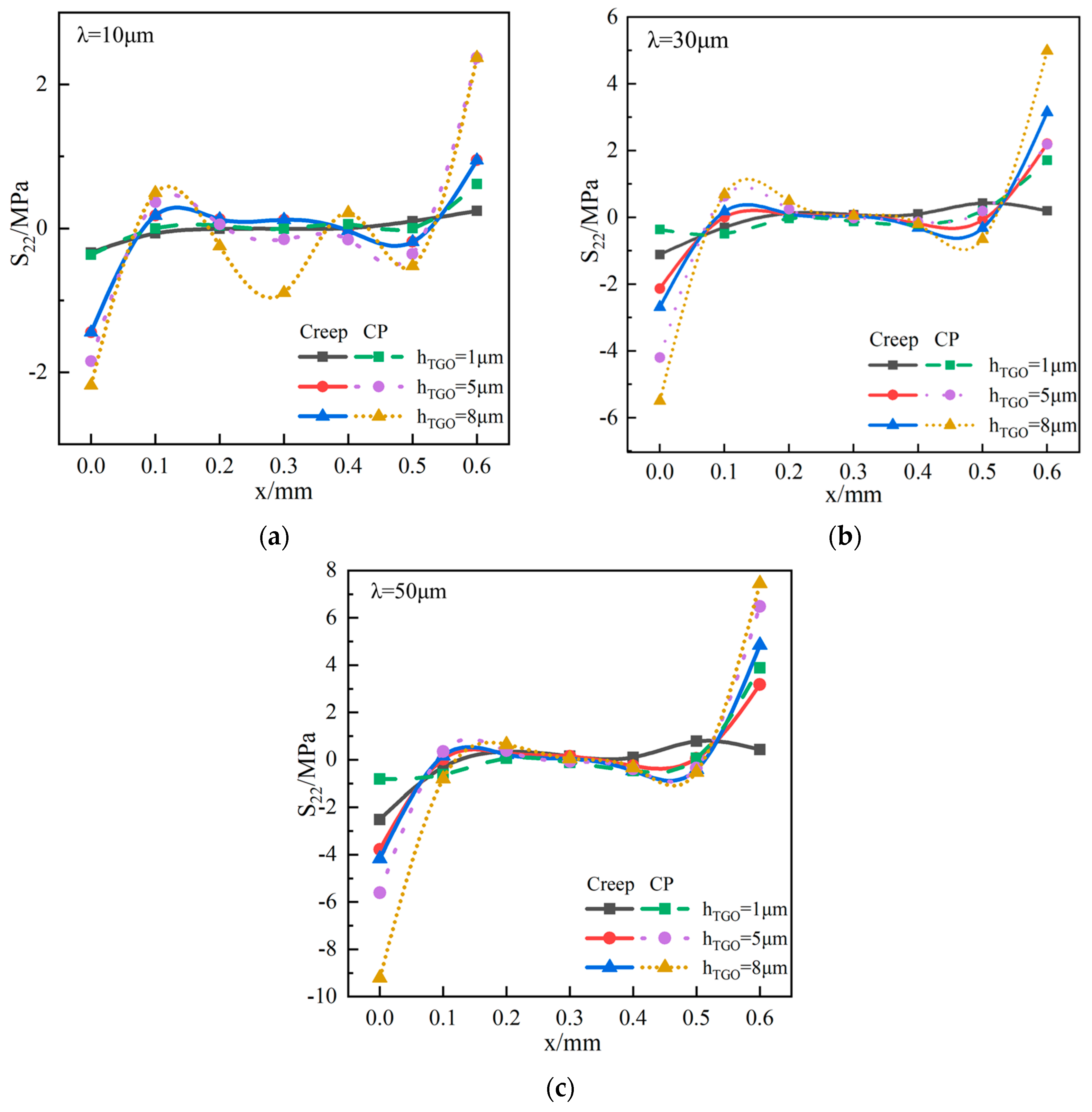

4.1. Influence of Interface Amplitude on Residual Stress of Substrate

4.2. Influence of Material Properties of Substrate

4.3. Influence of Different Orientations on Residual Stress of Substrate

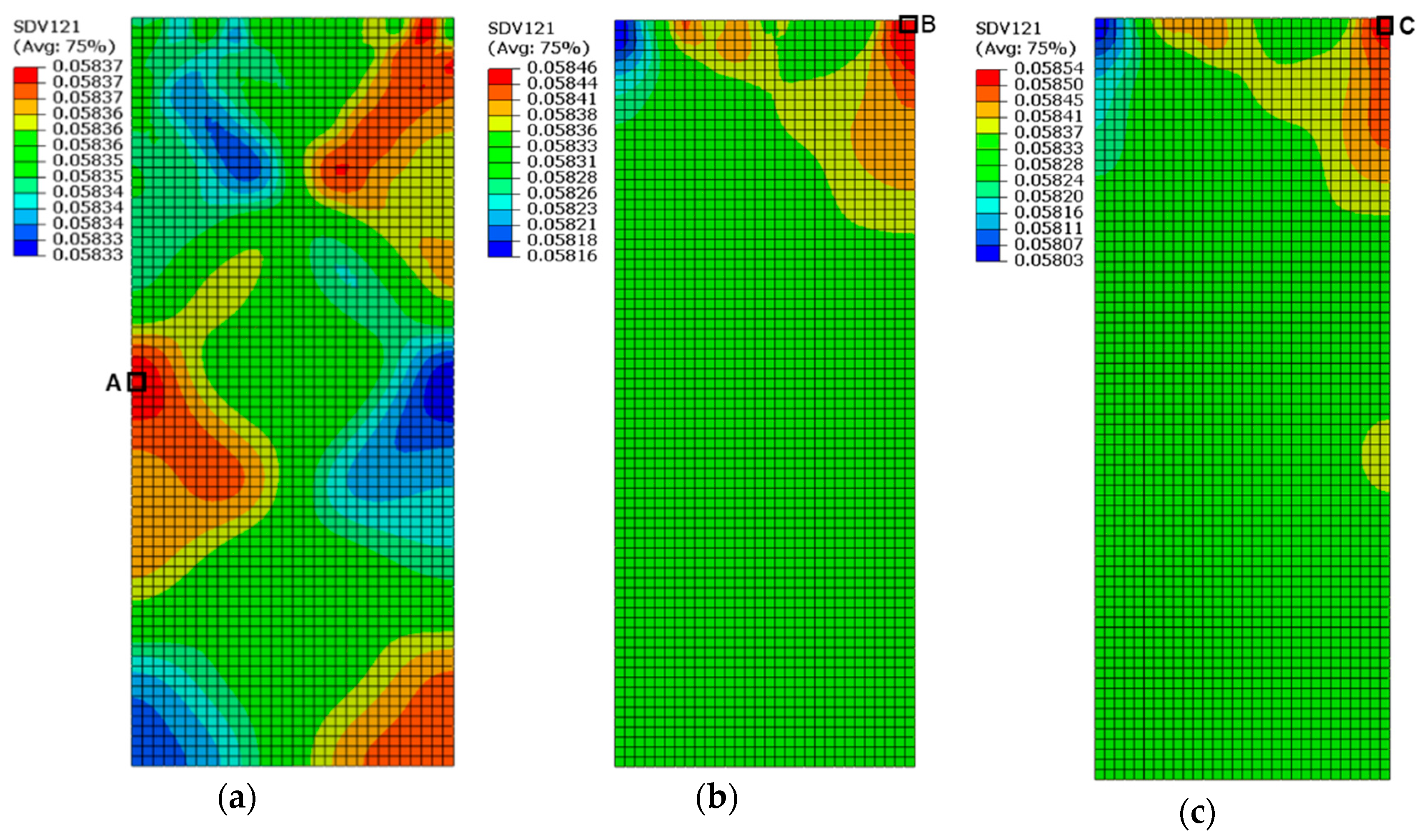

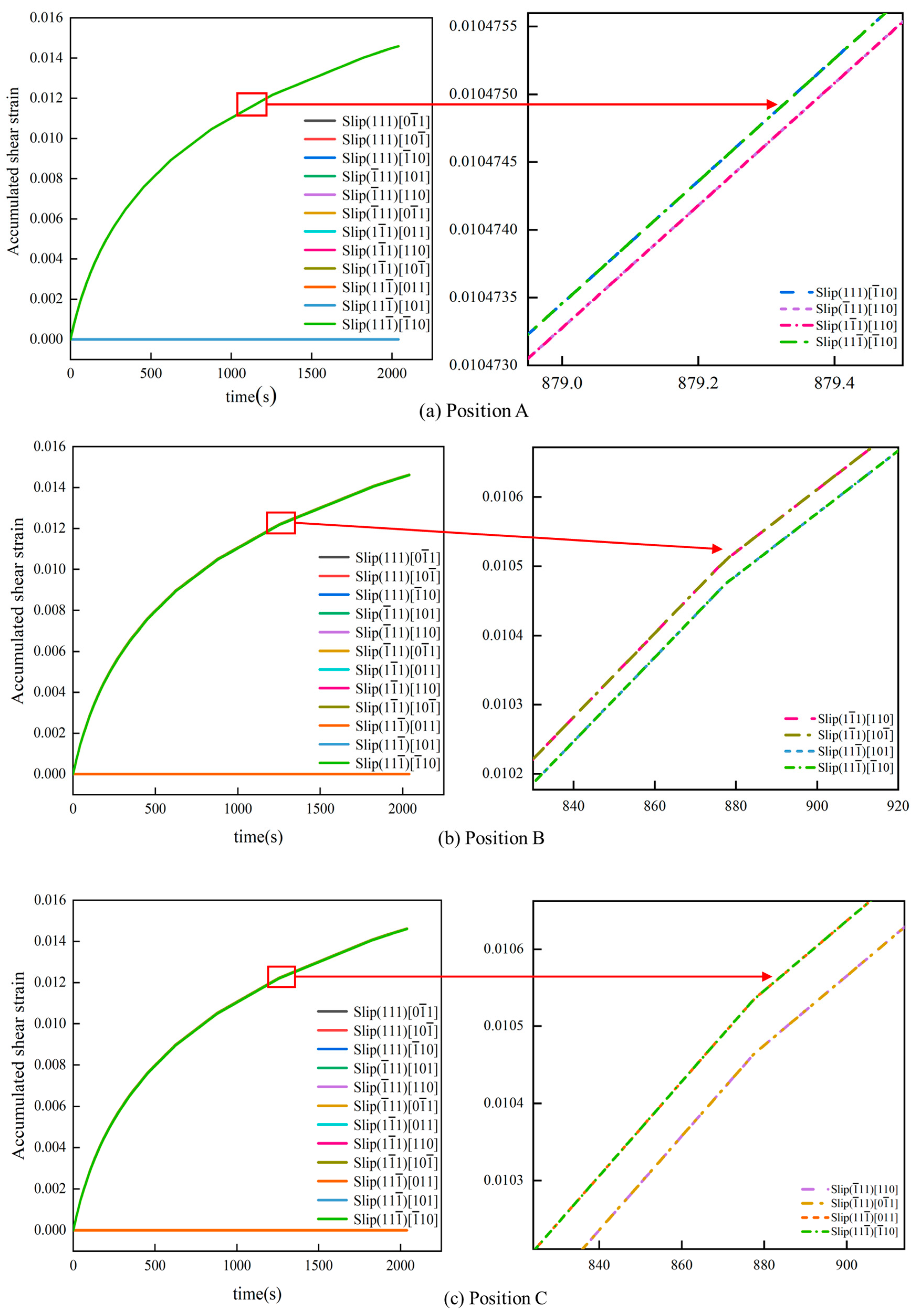

4.3.1. Activation of Slip Systems with Different Orientations

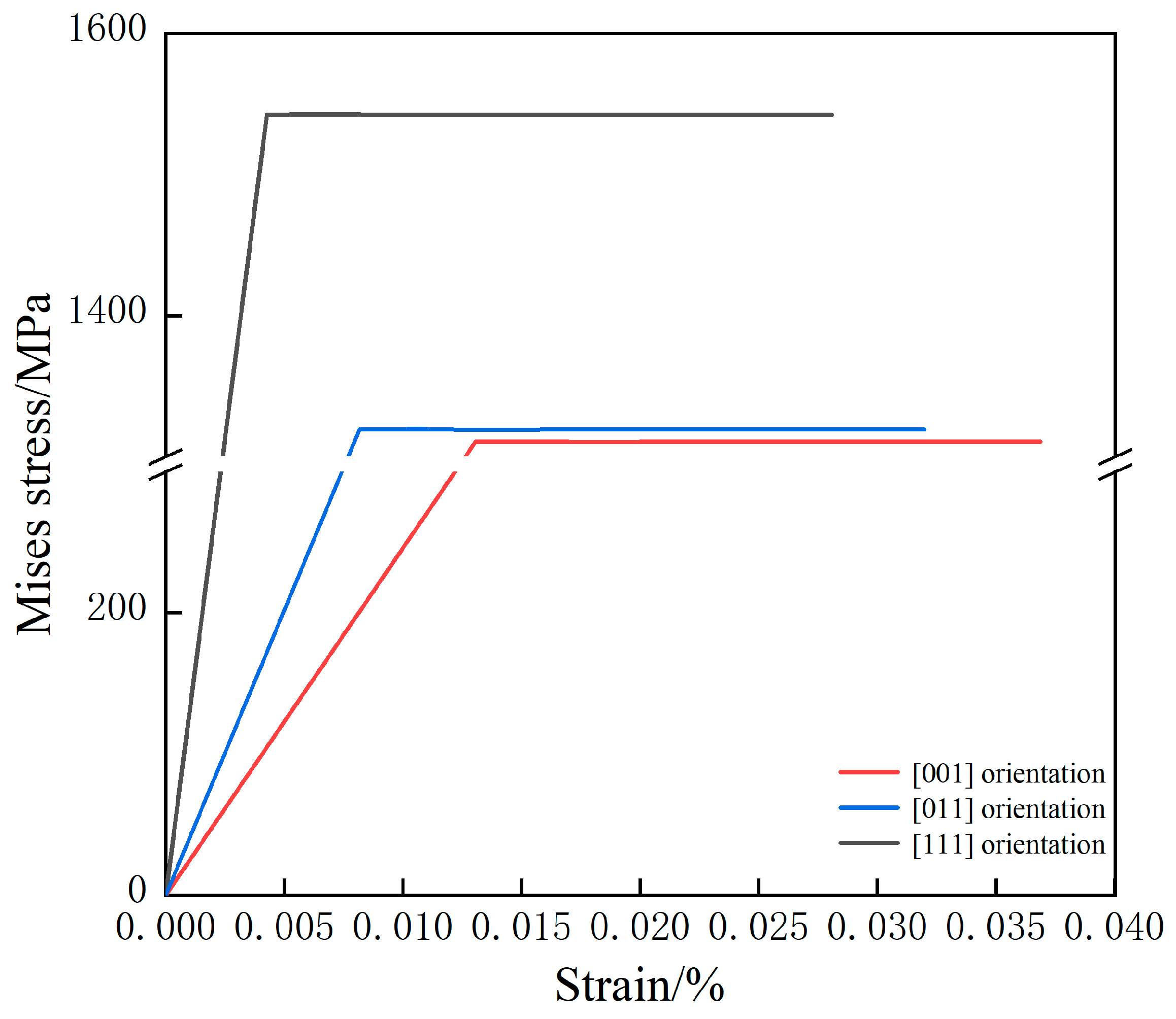

4.3.2. Yield Stress of Different Orientations

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nowotnik, A.; Kubiak, K.; Sieniawski, J.; Rokicki, P.; Pędrak, P.; Mrówka-Nowotnik, G. Development of Nickel Based Superalloys for Advanced Turbine Engines. Mater. Sci. Forum 2014, 783–786, 2491–2496. [Google Scholar] [CrossRef]

- Białas, M. Finite element analysis of stress distribution in thermal barrier coatings. Surf. Coat. Technol. 2008, 202, 6002–6010. [Google Scholar] [CrossRef]

- Khan, Z.; Fida, S.; Nisar, F.; Alam, N. Investigation of Intergranular Corrosion in 2nd stage gas turbine blades of an aircraft engine. Eng. Fail. Anal. 2016, 68, 197–209. [Google Scholar] [CrossRef]

- Yang, T.; Wang, W.Z.; Tang, Z.X.; Liu, Y.G.; Li, K.B.; Liu, W.; Zhang, W.K.; Ye, D.D. CMAS infiltration behavior of atmospheric plasma-sprayed thermal barrier coating with tailored pore structures. Ceram. Int. 2023; in press. [Google Scholar] [CrossRef]

- Najafizadeh, N.; Ghasempour-Mouziraji, M.; Hosseinzadeh, M.; Shirkharkolaei, E.M.; Bozorg, M.; Cavaliere, P. Thermal barrier ceramic coatings. In Advanced Ceramic Coatings; Gupta, R.K., Motallebzadeh, A., Kakooei, S., Nguyen, T.A., Behera, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 335–356. ISBN 9780323996594. [Google Scholar]

- Vaßen, R.; Jarligo, M.O.; Steinke, T.; Mack, D.E.; Stöver, D. Overview on advanced thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 938–942. [Google Scholar] [CrossRef]

- Padture, N.P. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.C.; Xu, B.S.; Wang, H.D.; Wu, Y.X. Effects of oxide thickness, Al2O3 interlayer and interface asperity on residual stresses in thermal barrier coatings. Mater. Des. 2006, 27, 989–996. [Google Scholar] [CrossRef]

- He, M.Y.; Hutchinson, J.W.; Evans, A.G. Simulation of stresses and delamination in a plasma-sprayed thermal barrier system upon thermal cycling. Mater. Sci. Eng. A 2003, 345, 172–178. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Cai, H.N. Stress states and crack behavior in plasma sprayed TBCs based on a novel lamellar structure model with real interface morphology. Ceram. Int. 2019, 45, 16948–16962. [Google Scholar] [CrossRef]

- Eriksson, R.; Sjöström, S.; Brodin, H.; Johansson, S.; Östergren, L.; Li, X.-H. TBC bond coat–top coat interface roughness: Influence on fatigue life and modelling aspects. Surf. Coat. Technol. 2013, 236, 230–238. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Baxevanakis, K.P.; Lu, S.; Zhao, L.G.; Bullough, C. Discrete crystal plasticity modelling of slip-controlled cyclic deformation and short crack growth under low cycle fatigue. Int. J. Fatigue 2021, 145, 106095. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Baxevanakis, K.P.; Zhao, L.G.; Bullough, C. Modelling short crack propagation in a single crystal nickel-based superalloy using crystal plasticity and XFEM. Int. J. Fatigue 2020, 136, 105594. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, L.; Jiang, R.; Bullough, C. Crystal plasticity finite-element modelling of cyclic deformation and crack initiation in a nickel-based single-crystal superalloy under low-cycle fatigue. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1769–1783. [Google Scholar] [CrossRef]

- Sun, S.; Li, L.; Yue, Z.; Yang, W.; Zhao, Z.; Cao, R.; Li, S. Experimental and numerical investigation on fretting fatigue behavior of Nickel-based single crystal superalloy at high temperature. Mech. Mater. 2020, 150, 103595. [Google Scholar] [CrossRef]

- Taylor, G.I. The mechanism of plastic deformation of crystals. Part I.—Theoretical. Proc. R. Soc. Lond. Ser. A Contain. Pap. A Math. Phys. Character 1934, 145, 362–387. [Google Scholar] [CrossRef]

- Hill, R. Generalized constitutive relations for incremental deformation of metal crystals by multislip. J. Mech. Phys. Solids 1966, 14, 95–102. [Google Scholar] [CrossRef]

- Hill, R.; Rice, J. Constitutive analysis of elastic-plastic crystals at arbitrary strain. J. Mech. Phys. Solids 1972, 20, 401–413. [Google Scholar] [CrossRef]

- Asaro, R.J.; Rice, J. Strain localization in ductile single crystals. J. Mech. Phys. Solids 1977, 25, 309–338. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.; Needleman, A. An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Huang, Y. A User-Material Subroutine Incroporating Single Crystal Plasticity in the ABAQUS Finite Element Program; Harvard University: Cambridge, UK, 1991. [Google Scholar]

- Pei, H.Q.; Yao, X.H.; Zhang, Y.M.; Yang, Y.Q.; Li, Z.; Wen, Z.X. The plastic strengthening effect after long-term endurance and fatigue verification of aero-engine turbine blade single crystal superalloy. Mech. Time-Depend. Mater. 2022, 26, 815–827. [Google Scholar] [CrossRef]

- Wang, J.; Liang, J.; Zhang, D.; Peng, Y.; Wen, Z. The effect of small orientation deviation from [001] to [011] on high-temperature creep properties of nickel-based single crystal. Int. J. Plast. 2023, 166, 103648. [Google Scholar] [CrossRef]

- Long, X.; Chong, K.; Su, Y.; Chang, C.; Zhao, L. Meso-scale low-cycle fatigue damage of polycrystalline nickel-based alloy by crystal plasticity finite element method. Int. J. Fatigue 2023, 175, 107778. [Google Scholar] [CrossRef]

- Gu, S.N.; Gao, H.S.; Wen, Z.X.; Li, Z.W.; Zhang, C.Z.; Yue, Z.F. Creep properties and life model of anisotropic Ni-based single crystal superalloys over a wide temperature range. Int. J. Mech. Sci. 2024, 261, 108674. [Google Scholar] [CrossRef]

- Hutchinson, J.W. Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. Lond. A Math. Phys. Sci. 1976, 348, 101–127. [Google Scholar]

- Li, Z.W.; Gao, H.S.; Wen, Z.X.; Yang, Y.Q.; Zhang, Y.M.; Ai, X.; Yue, Z.F. Microcrack initiation behavior around film cooling holes in a Ni-based single crystal: In situ observation and crystal plastic analysis. Mater. Sci. Eng. A 2020, 771, 138609. [Google Scholar] [CrossRef]

- Zhang, D.X.; He, J.Y.; Liang, J.W.; He, Z. Surface slip deformation characteristics of nickel-base single crystal thin plates with film cooling holes. IEEE Access 2020, 8, 75145–75153. [Google Scholar] [CrossRef]

- Han, X.N.; Li, K.D.; Deng, Y.; Zhang, M.Q.; Li, J.S. Research on the effect of micro-voids on the deformation behavior and crack initiation lifetime of titanium alloy under cyclic loading by crystal plasticity finite element method. J. Mater. Res. Technol. 2022, 22, 3218–3229. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. Material rate dependence and localized deformation in crystalline solids. Acta Metall. 1983, 31, 1951–1976. [Google Scholar] [CrossRef]

- Karanam, M.K.; Chinthapenta, V.R. Void growth and morphology evolution during ductile failure in an FCC single crystal. Contin. Mech. Thermodyn. 2021, 33, 497–513. [Google Scholar] [CrossRef]

- Liu, Y.G.; Wang, W.Z.; Wang, Y.H.; Fang, H.J.; Yang, T.; Li, K.B.; Zhang, C.C. Effect of CMAS attack behaviour on stress distribution in double-ceramic-layer thermal barrier coatings. Ceram. Int. 2022, 49, 13271–13288. [Google Scholar] [CrossRef]

- Yu, Q.M.; Zhou, H.L.; Wang, L.B. Influences of interface morphology and thermally grown oxide thickness on residual stress distribution in thermal barrier coating system. Ceram. Int. 2016, 42, 8338–8350. [Google Scholar] [CrossRef]

- Yuan, K.; Yu, Y.; Wen, J.-F. A study on the thermal cyclic behavior of thermal barrier coatings with different MCrAlY roughness. Vacuum 2017, 137, 72–80. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, N.; Xu, H. Comparison of thermal cycling behavior of plasma-sprayed nanostructured and traditional thermal barrier coatings. Mater. Sci. Eng. A 2007, 452–453, 569–574. [Google Scholar] [CrossRef]

- Standards Press of China. High Temperature Materials Branch of Chinese Society of Metals. In China Superalloys Handbook; Standards Press of China: Beijing, China, 2012; Volume 2, pp. 549–564. ISBN 978-7-5066-6237-6. [Google Scholar]

- Yu, Q.M.; He, Q. Effect of material properties on residual stress distribution in thermal barrier coatings. Ceram. Int. 2018, 44, 3371–3380. [Google Scholar] [CrossRef]

- Burov, A.; Fedorova, E. Modeling of interface failure in a thermal barrier coating system on Ni-based superalloys. Eng. Fail. Anal. 2021, 123, 105320. [Google Scholar] [CrossRef]

- Maniatty, A.; Dawson, P.; Lee, Y.S. A time integration algorithm for elasto-viscoplastic cubic crystals applied to modelling polycrystalline deformation. Int. J. Numer. Methods Eng. 1992, 35, 1565–1588. [Google Scholar] [CrossRef]

- Sauzay, M. Cubic elasticity and stress distribution at the free surface of polycrystals. Acta Mater. 2007, 55, 1193–1202. [Google Scholar] [CrossRef]

- Sun, S.; Li, L.; Yue, Z.; Yang, W.; He, K.; Li, S. Fretting fatigue failure behavior of Nickel-based single crystal superalloy dovetail specimen in contact with powder metallurgy pads at high temperature. Tribol. Int. 2020, 142, 105986. [Google Scholar] [CrossRef]

- Du, J.; Yu, G.; Jia, Y.; Liu, C.; Sui, Z.; Gao, X.; Wang, F.; Song, Y. Numerical study of residual stresses in environmental barrier coatings with random rough geometry interfaces. Ceram. Int. 2023, 49, 5748–5759. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, H.Z.; Zhang, X.; Zhang, K. A multiaxial probabilistic fatigue life prediction method for nickel-based single crystal turbine blade considering mean stress correction. Qual. Reliab. Eng. Int. 2023, 39, 1735–1755. [Google Scholar] [CrossRef]

| Materials | Temperature (°C) | E (GPa) | α (10−5 °C−1) | ρ (103 kg/m3) | k (W/m °C) | c (J/kg °C) | υ |

|---|---|---|---|---|---|---|---|

| DD6 | 25 | 132 | - | 8.8 | 6.70 | - | 0.30 |

| 700 | 107 | 13.5 | 8.8 | 20.20 | 566 | 0.32 | |

| 1100 | 68 | 15.8 | 8.8 | 28.95 | 704 | 0.34 | |

| NiCrAlY | 20 | 200 | 13.6 | 8.1 | 5.80 | 400 | 0.30 |

| 200 | 190 | 14.2 | 8.1 | 7.50 | 400 | 0.30 | |

| 400 | 175 | 14.6 | 8.1 | 9.50 | 400 | 0.31 | |

| 600 | 160 | 15.2 | 8.1 | 12.0 | 400 | 0.31 | |

| 800 | 145 | 16.1 | 8.1 | 14.5 | 400 | 0.32 | |

| 1000 | 120 | 17.2 | 8.1 | 16.2 | 400 | 0.33 | |

| 1100 | 110 | 17.6 | 8.1 | 17.0 | 400 | 0.33 | |

| YSZ | 20 | 48 | 9.0 | 5.6 | 1.20 | 450 | 0.10 |

| 200 | 47 | 9.2 | 5.6 | 1.19 | 450 | 0.10 | |

| 400 | 44 | 9.6 | 5.6 | 1.18 | 450 | 0.10 | |

| 600 | 40 | 10.1 | 5.6 | 1.15 | 450 | 0.11 | |

| 800 | 34 | 10.8 | 5.6 | 1.16 | 450 | 0.11 | |

| 1000 | 26 | 11.7 | 5.6 | 1.14 | 450 | 0.12 | |

| 1100 | 22 | 12.2 | 5.6 | 1.12 | 450 | 0.12 | |

| Al2O3 | 20 | 400 | 8.0 | 3.5 | 10.00 | 1000 | 0.23 |

| 200 | 390 | 8.2 | 3.5 | 7.79 | 1000 | 0.23 | |

| 400 | 380 | 8.4 | 3.5 | 6.03 | 1000 | 0.24 | |

| 600 | 370 | 8.7 | 3.5 | 5.07 | 1000 | 0.24 | |

| 800 | 355 | 9.0 | 3.5 | 4.41 | 1000 | 0.25 | |

| 1000 | 325 | 9.3 | 3.5 | 4.41 | 1000 | 0.25 | |

| 1100 | 320 | 9.6 | 3.5 | 4.00 | 1000 | 0.25 |

| n | t (°C) | ||

|---|---|---|---|

| TC [37] | 1.80 × 10−7 | 1.00 | 1000 |

| TGO [37] | 7.30 × 10−10 | 1.00 | 1000 |

| BC [37] | 6.54 × 10−19 | 4.75 | ≤600 |

| 2.20 × 10−12 | 2.99 | 700 | |

| 1.84 × 10−7 | 1.55 | 800 | |

| 2.15 × 10−8 | 2.45 | ≥850 | |

| DD6 [36] | 3.95 × 10−18 | 5.53 | 760 |

| 4.77 × 10−22 | 7.23 | 850 | |

| 1.31 × 10−19 | 5.53 | 950 |

| t/°C | 25 | 650 | 700 | 760 | 850 | 980 | 1070 | 1100 | |

|---|---|---|---|---|---|---|---|---|---|

| E/GPa | [001] | 131.5 | 107.5 | 107 | 105.5 | 98 | 80.5 | 69.5 | 67.5 |

| [011] | 231.5 | — | 184.5 | 187.5 | 137.5 | 145 | 130 | 121 | |

| [111] | 327 | — | 212 | 184.5 | 205 | 217.5 | 189 | 176.5 | |

| Cumulative Shear Strain | [001] | [011] | [111] |

|---|---|---|---|

| SDV109 | 2.025 × 10−23 | 0 | 0 |

| SDV110 | 4.440 × 10−13 | 1.150 × 10−25 | 0 |

| SDV111 | 1.459 × 10−2 | 1.157 × 10−25 | 0 |

| SDV112 | 4.558 × 10−13 | 1.157 × 10−25 | 0 |

| SDV113 | 1.460 × 10−2 | 1.150 × 10−25 | 1.464 × 10−2 |

| SDV114 | 1.968 × 10−23 | 0 | 1.464 × 10−2 |

| SDV115 | 1.968 × 10−23 | 0 | 0 |

| SDV116 | 1.460 × 10−2 | 1.465 × 10−2 | 0 |

| SDV117 | 4.558 × 10−13 | 1.465 × 10−2 | 0 |

| SDV118 | 2.205 × 10−23 | 0 | 1.475 × 10−2 |

| SDV119 | 4.440 × 10−13 | 1.462 × 10−2 | 0 |

| SDV120 | 1.459 × 10−2 | 1.462 × 10−2 | 1.475 × 10−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Wang, W.; Yang, T.; Liu, Y.; Liu, C.; Yang, X.; Zhang, X. Numerical Simulation of the Residual Stress at the Interface between Thermal Barrier Coating and Nickel-Based Single-Crystal Superalloy Based on Crystal Plasticity Theory. Coatings 2024, 14, 22. https://doi.org/10.3390/coatings14010022

Liu S, Wang W, Yang T, Liu Y, Liu C, Yang X, Zhang X. Numerical Simulation of the Residual Stress at the Interface between Thermal Barrier Coating and Nickel-Based Single-Crystal Superalloy Based on Crystal Plasticity Theory. Coatings. 2024; 14(1):22. https://doi.org/10.3390/coatings14010022

Chicago/Turabian StyleLiu, Shuainan, Weize Wang, Ting Yang, Yangguang Liu, Chen Liu, Xixi Yang, and Xiaoqin Zhang. 2024. "Numerical Simulation of the Residual Stress at the Interface between Thermal Barrier Coating and Nickel-Based Single-Crystal Superalloy Based on Crystal Plasticity Theory" Coatings 14, no. 1: 22. https://doi.org/10.3390/coatings14010022

APA StyleLiu, S., Wang, W., Yang, T., Liu, Y., Liu, C., Yang, X., & Zhang, X. (2024). Numerical Simulation of the Residual Stress at the Interface between Thermal Barrier Coating and Nickel-Based Single-Crystal Superalloy Based on Crystal Plasticity Theory. Coatings, 14(1), 22. https://doi.org/10.3390/coatings14010022