Evaluation of the Cyclic Fatigue Resistance of Tia Tornado Blue and Tia Tornado Gold in Curved Canals: In Vitro Study

Abstract

:1. Introduction

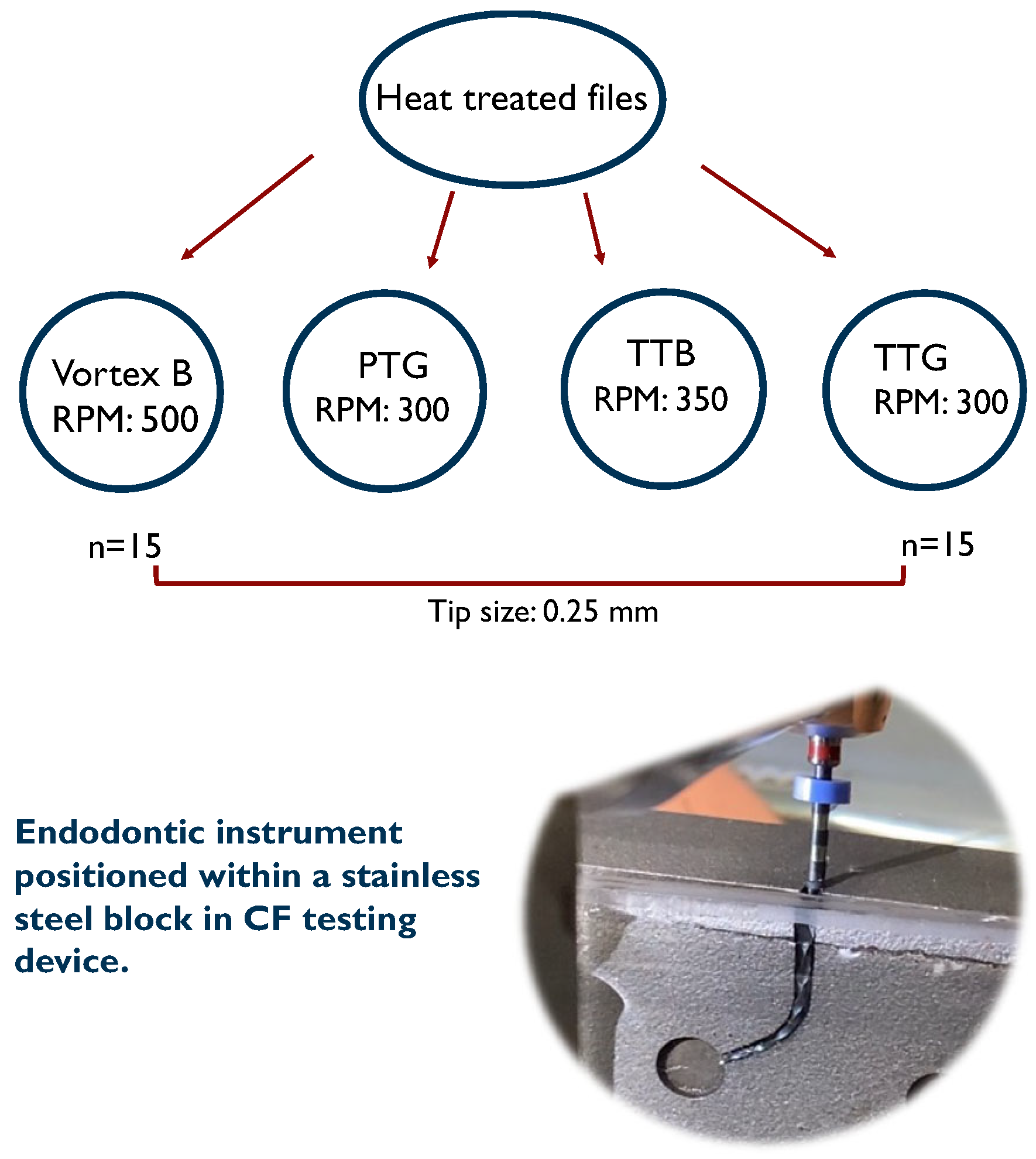

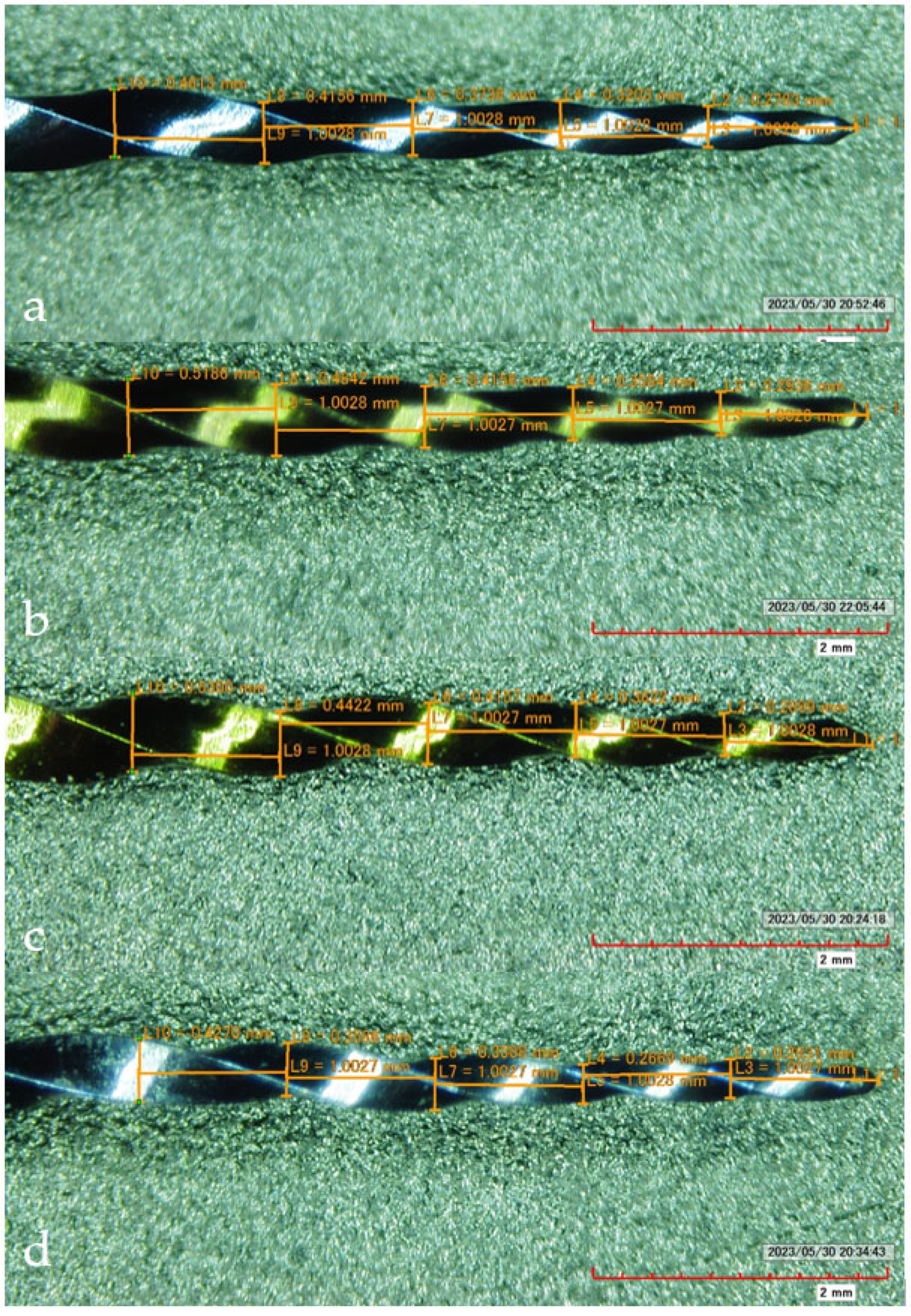

2. Materials and Methods

2.1. Preparation of Artificial Canals

2.2. Cyclic Fatigue Resistance Testing

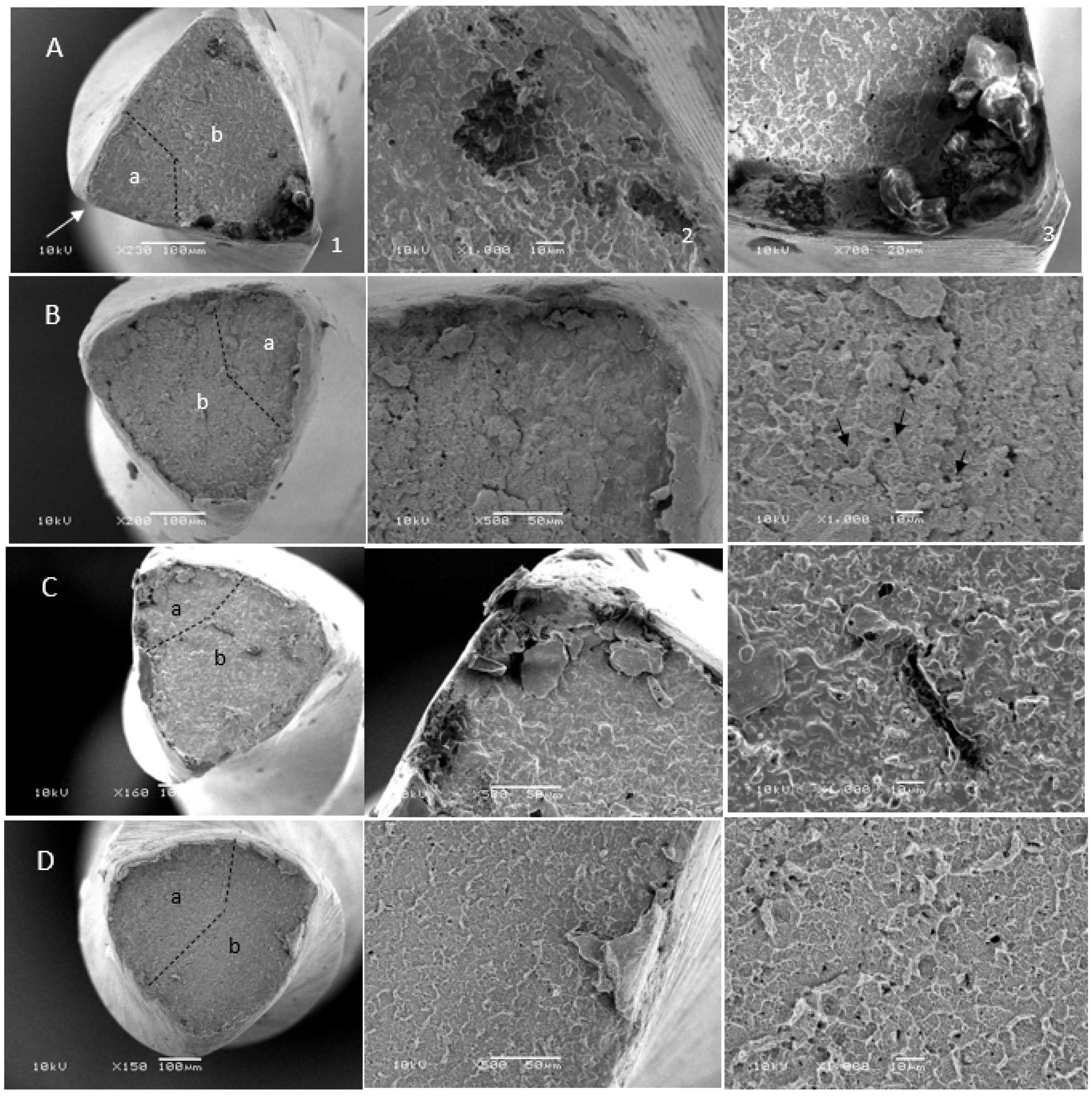

2.3. Scanning Electron Microscopy (SEM)

2.4. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Puleio, F.; Bellezza, U.; Torre, A.; Giordano, F.; Lo Giudice, G. Apical Transportation of Apical Foramen by Different NiTi Alloy Systems: A Systematic Review. Appl. Sci. 2023, 13, 10555. [Google Scholar] [CrossRef]

- Del Fabbro, M.; Afrashtehfar, K.I.; Corbella, S.; El-Kabbaney, A.; Perondi, I.; Taschieri, S. In Vivo and In Vitro Effectiveness of Rotary Nickel-Titanium vs. Manual Stainless Steel Instruments for Root Canal Therapy: Systematic Review and Meta-analysis. J. Evid. Based Dent. Pract. 2018, 18, 59–69. [Google Scholar] [CrossRef]

- Alfouzan, K.; Jamleh, A. Fracture of nickel titanium rotary instrument during root canal treatment and re-treatment: A 5-year retrospective study. Int. Endod. J. 2018, 51, 157–163. [Google Scholar] [CrossRef]

- Wang, N.N.; Ge, J.Y.; Xie, S.J.; Chen, G.; Zhu, M. Analysis of Mtwo rotary instrument separation during endodontic therapy: A retrospective clinical study. Cell Biochem. Biophys. 2014, 70, 1091–1095. [Google Scholar] [CrossRef] [PubMed]

- Pruett, J.P.; Clement, D.J.; Carnes, D.L., Jr. Cyclic fatigue testing of nickel-titanium endodontic instruments. J. Endod. 1997, 23, 77–85. [Google Scholar] [CrossRef] [PubMed]

- Parashos, P.; Linsuwanont, P.; Messer, H.H. A cleaning protocol for rotary nickel-titanium endodontic instruments. Aust. Dent. J. 2004, 49, 20–27. [Google Scholar] [CrossRef] [PubMed]

- Kuhn, G.; Tavernier, B.; Jordan, L. Influence of structure on nickel-titanium endodontic instruments failure. J. Endod. 2001, 27, 516–520. [Google Scholar] [CrossRef] [PubMed]

- Pereira, E.S.J.; Peixoto, I.F.C.; Viana, A.C.D.; Oliveira, I.I.; Gonzalez, B.M.; Buono, V.T.L.; Bahia, M.G.A. Physical and mechanical properties of a thermomechanically treated NiTi wire used in the manufacture of rotary endodontic instruments. Int. Endod. J. 2012, 45, 469–474. [Google Scholar] [CrossRef] [PubMed]

- Alapati, S.B.; Brantley, W.A.; Svec, T.A.; Powers, J.M.; Nusstein, J.M.; Daehn, G.S. SEM observations of nickel-titanium rotary endodontic instruments that fractured during clinical Use. J. Endod. 2005, 31, 40–43. [Google Scholar] [CrossRef] [PubMed]

- Topcuoglu, H.S.; Demirbuga, S.; Duzgun, S.; Topcuoglu, G. Cyclic fatigue resistance of new reciprocating files (Reciproc Blue, WaveOne Gold, and SmartTrack) in two different curved canals. J. Investig. Clin. Dent. 2018, 9, e12344. [Google Scholar] [CrossRef] [PubMed]

- Zubizarreta-Macho, Á.; Alonso-Ezpeleta, Ó.; Albaladejo Martínez, A.; Faus Matoses, V.; Caviedes Brucheli, J.; Agustín-Panadero, R.; Mena Álvarez, J.; Vizmanos Martínez-Berganza, F. Novel Electronic Device to Quantify the Cyclic Fatigue Resistance of Endodontic Reciprocating Files after Using and Sterilization. Appl. Sci. 2020, 10, 4962. [Google Scholar] [CrossRef]

- Hulsmann, M.; Donnermeyer, D.; Schafer, E. A critical appraisal of studies on cyclic fatigue resistance of engine-driven endodontic instruments. Int. Endod. J. 2019, 52, 1427–1445. [Google Scholar] [CrossRef] [PubMed]

- Baird, E.; Huang, X.; Liu, H.; Hieawy, A.; Ruse, N.D.; Wang, Z.; Haapasalo, M.; Shen, Y. A novel model to evaluate the fatigue resistance of NiTi instruments: Rotational and axial movement at body temperature. Aust. Endod. J. 2023, 49, 301–307. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Grande, N.M.; Cordaro, M.; Testarelli, L.; Gambarini, G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J. Endod. 2009, 35, 1469–1476. [Google Scholar] [CrossRef] [PubMed]

- Cheung, G.S.P.; Peng, B.; Bian, Z.; Shen, Y.; Darvell, B.W. Defects in ProTaper S1 instruments after clinical use: Fractographic examination. Int. Endod. J. 2005, 38, 802–809. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Zhou, H.; Campbell, L.; Wang, Z.; Wang, R.; Du, T.; Haapasalo, M. Fatigue and nanomechanical properties of K3XF nickel-titanium instruments. Int. Endod. J. 2014, 47, 1160–1167. [Google Scholar] [CrossRef] [PubMed]

- Gavini, G.; Santos, M.D.; Caldeira, C.L.; Machado, M.E.D.L.; Freire, L.G.; Iglecias, E.F.; Peters, O.A.; Candeiro, G.T.D.M. Nickel-titanium instruments in endodontics: A concise review of the state of the art. Braz. Oral Res. 2018, 32 (Suppl. S1), e67. [Google Scholar] [CrossRef] [PubMed]

- Gambarini, G.; Pongione, G.; Rizzo, F.; Testarelli, L.; Cavalleri, G.; Gerosa, R. Bending properties of nickel-titanium instruments: A comparative study. Minerva Stomatol. 2008, 57, 393–398. [Google Scholar]

- Larsen, C.M.; Watanabe, I.; Glickman, G.N.; He, J. Cyclic fatigue analysis of a new generation of nickel titanium rotary instruments. J. Endod. 2009, 35, 401–403. [Google Scholar] [CrossRef]

- Ataya, M.; Ha, J.H.; Kwak, S.W.; Abu-Tahun, I.H.; El Abed, R.; Kim, H.C. Mechanical Properties of Orifice Preflaring Nickel-titanium Rotary Instrument Heat Treated Using T-Wire Technology. J. Endod. 2018, 44, 1867–1871. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, H.M.; Zheng, Y.F.; Peng, B.; Haapasalo, M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J. Endod. 2013, 39, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Ye, J.; Gao, Y. Metallurgical characterization of M-Wire nickel-titanium shape memory alloy used for endodontic rotary instruments during low-cycle fatigue. J. Endod. 2012, 38, 105–107. [Google Scholar] [CrossRef] [PubMed]

- Yahata, Y.; Yoneyama, T.; Hayashi, Y.; Ebihara, A.; Doi, H.; Hanawa, T.; Suda, H. Effect of heat treatment on transformation temperatures and bending properties of nickel-titanium endodontic instruments. Int. Endod. J. 2009, 42, 621–626. [Google Scholar] [CrossRef] [PubMed]

- Elnaghy, A.M.; Elsaka, S.E. Mechanical properties of ProTaper Gold nickel-titanium rotary instruments. Int. Endod. J. 2016, 49, 1073–1078. [Google Scholar] [CrossRef] [PubMed]

- Hieawy, A.; Haapasalo, M.; Zhou, H.; Wang, Z.J.; Shen, Y. Phase Transformation Behavior and Resistance to Bending and Cyclic Fatigue of ProTaper Gold and ProTaper Universal Instruments. J. Endod. 2015, 41, 1134–1138. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Grande, N.M.; Cotti, E.; Testarelli, L.; Gambarini, G. Blue treatment enhances cyclic fatigue resistance of vortex nickel-titanium rotary files. J. Endod. 2014, 40, 1451–1453. [Google Scholar] [CrossRef] [PubMed]

- Hou, X.M.; Yang, Y.J.; Qian, J. Phase transformation behaviors and mechanical properties of NiTi endodontic files after gold heat treatment and blue heat treatment. J. Oral. Sci. 2020, 63, 8–13. [Google Scholar] [CrossRef] [PubMed]

- Alqedairi, A.; Alfawaz, H.; Bin Rabba, A.; Almutairi, A.; Alnafaiy, S.; Khan Mohammed, M. Failure Analysis and Reliability of Ni–Ti-Based Dental Rotary Files Subjected to Cyclic Fatigue. Metals 2018, 8, 36. [Google Scholar] [CrossRef]

- Mohammed, M.K.; Al-Ahmari, A.; Umer, U. Multiobjective optimization of Nd:YAG direct laser writing of microchannels for microfluidic applications. Int. J. Adv. Manuf. Technol. 2015, 81, 1363–1377. [Google Scholar] [CrossRef]

- Jamleh, A.; Alghaihab, A.; Alfadley, A.; Alfawaz, H.; Alqedairi, A.; Alfouzan, K. Cyclic Fatigue and Torsional Failure of EdgeTaper Platinum Endodontic Files at Simulated Body Temperature. J. Endod. 2019, 45, 611–614. [Google Scholar] [CrossRef]

- Alfawaz, H.; Alqedairi, A.; Alsharekh, H.; Almuzaini, E.; Alzahrani, S.; Jamleh, A. Effects of Sodium Hypochlorite Concentration and Temperature on the Cyclic Fatigue Resistance of Heat-treated Nickel-titanium Rotary Instruments. J. Endod. 2018, 44, 1563–1566. [Google Scholar] [CrossRef]

- Uygun, A.D.; Unal, M.; Falakaloglu, S.; Guven, Y. Comparison of the cyclic fatigue resistance of hyflex EDM, vortex blue, protaper gold, and onecurve nickel-Titanium instruments. Niger. J. Clin. Pract. 2020, 23, 41–45. [Google Scholar] [CrossRef]

- Ruiz-Sánchez, C.; Faus-Llácer, V.; Faus-Matoses, I.; Zubizarreta-Macho, Á.; Sauro, S.; Faus-Matoses, V. The Influence of NiTi Alloy on the Cyclic Fatigue Resistance of Endodontic Files. J. Clin. Med. 2020, 9, 3755. [Google Scholar] [CrossRef]

- Furlan, R.D.; Alcalde, M.P.; Duarte, M.A.; Bramante, C.M.; Piasecki, L.; Vivan, R.R. Cyclic and Torsional Fatigue Resistance of Seven Rotary Systems. Iran Endod. J. 2021, 16, 78–84. [Google Scholar]

- Alfawaz, H.; Alqedairi, A.; Alhamdan, M.; Alkhzim, N.; Alfarraj, S.; Jamleh, A. Effect of NaOCl and EDTA irrigating solutions on the cyclic fatigue resistance of EdgeTaper Platinum instruments. BMC Oral Health 2022, 22, 195. [Google Scholar] [CrossRef]

- McSpadden, J.T. Mastering Endodontic Instrumentation; Cloudland Institute: Chattanooga, TN, USA, 2007. [Google Scholar]

- Pereira, É.S.J.; Viana, A.C.D.; Buono, V.T.L.; Peters, O.A.; de Azevedo Bahia, M.G. Behavior of nickel-titanium instruments manufactured with different thermal treatments. J. Endod. 2015, 41, 67–71. [Google Scholar] [CrossRef] [PubMed]

| Instrument System | Mean (±SD) (NCF) | Outer Diameter at D5 (mm) | Surface Area at D5 (mm2) |

|---|---|---|---|

| VB | 1125.00 ± 174.83 a * | 1.9 | 0.22 |

| TTB | 117.93 ± 38.91 b | 2 | 0.19 |

| PTG | 831.60 ± 79.88 c | 2 | 0.23 |

| TTG | 542.80 ± 84.55 d | 1.4 | 0.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Allahem, Z.; Bendahmash, M.; Almeaither, R.; Alfawaz, H.; Alqedairi, A. Evaluation of the Cyclic Fatigue Resistance of Tia Tornado Blue and Tia Tornado Gold in Curved Canals: In Vitro Study. Coatings 2024, 14, 15. https://doi.org/10.3390/coatings14010015

Allahem Z, Bendahmash M, Almeaither R, Alfawaz H, Alqedairi A. Evaluation of the Cyclic Fatigue Resistance of Tia Tornado Blue and Tia Tornado Gold in Curved Canals: In Vitro Study. Coatings. 2024; 14(1):15. https://doi.org/10.3390/coatings14010015

Chicago/Turabian StyleAllahem, Ziyad, Mohammad Bendahmash, Reem Almeaither, Hussam Alfawaz, and Abdullah Alqedairi. 2024. "Evaluation of the Cyclic Fatigue Resistance of Tia Tornado Blue and Tia Tornado Gold in Curved Canals: In Vitro Study" Coatings 14, no. 1: 15. https://doi.org/10.3390/coatings14010015

APA StyleAllahem, Z., Bendahmash, M., Almeaither, R., Alfawaz, H., & Alqedairi, A. (2024). Evaluation of the Cyclic Fatigue Resistance of Tia Tornado Blue and Tia Tornado Gold in Curved Canals: In Vitro Study. Coatings, 14(1), 15. https://doi.org/10.3390/coatings14010015