High-Temperature Heat Treatment of Plasma Sprayed Ti–Si–C–Mo Coatings

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussions

4. Conclusions

- (1)

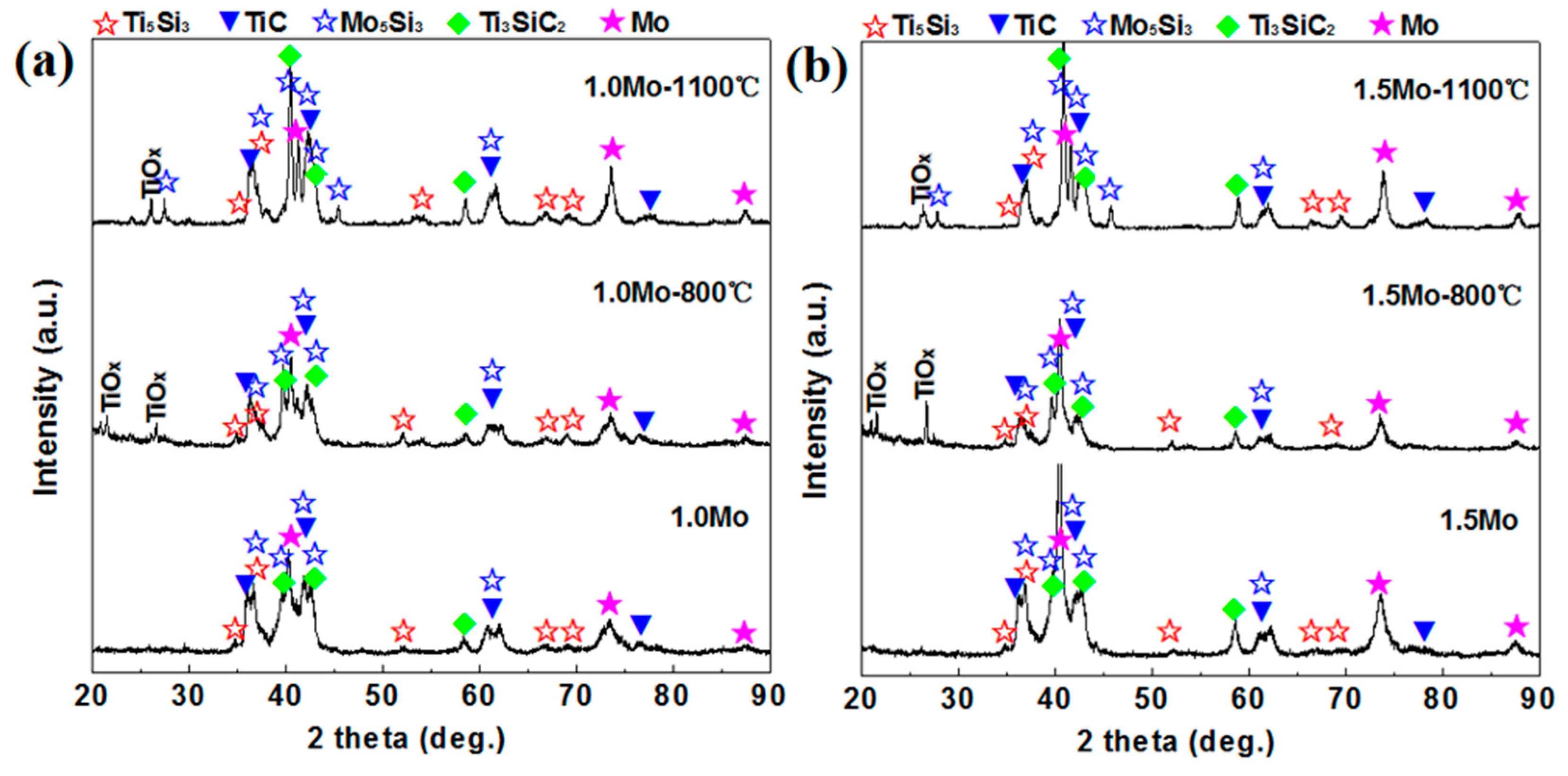

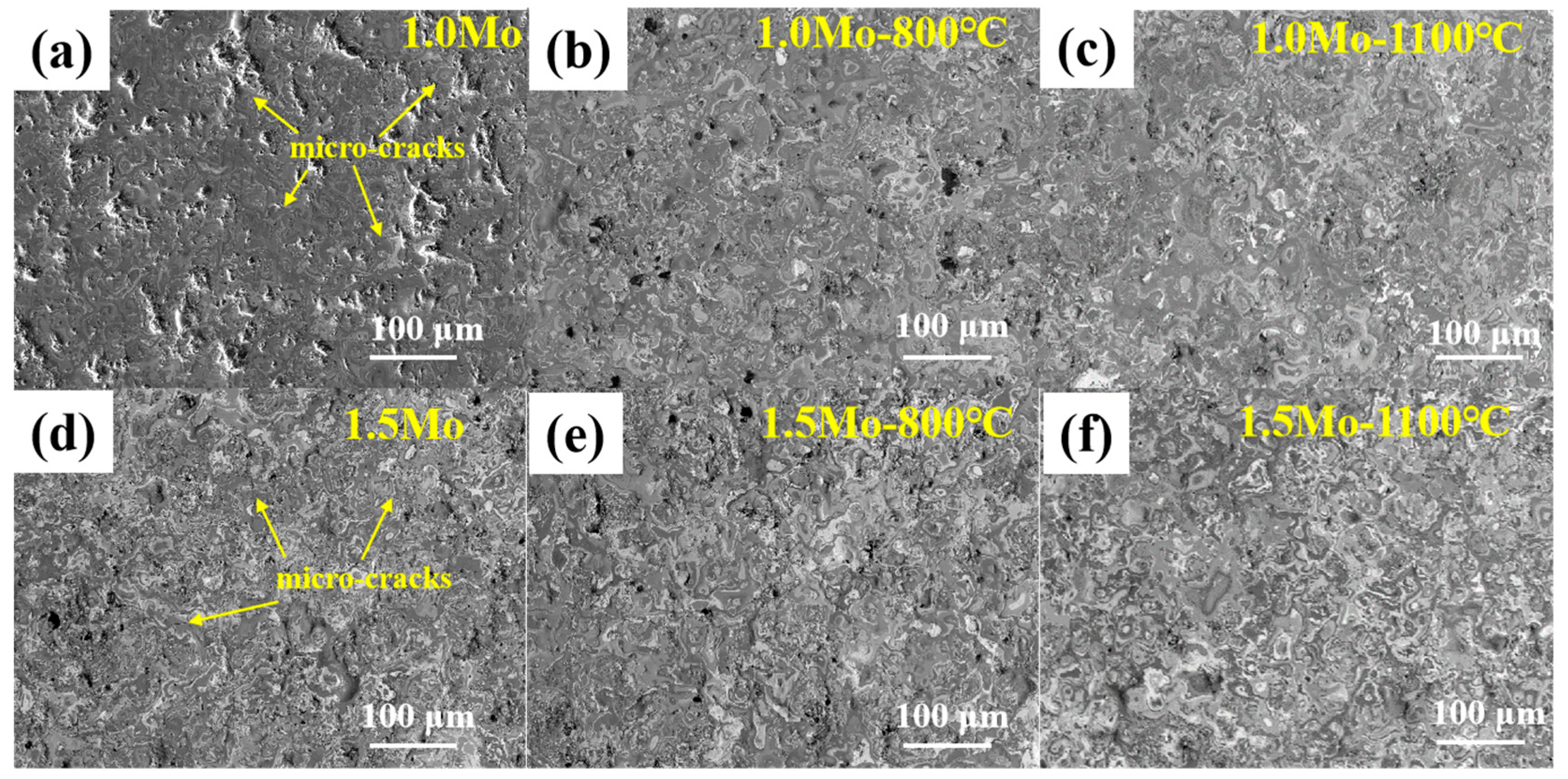

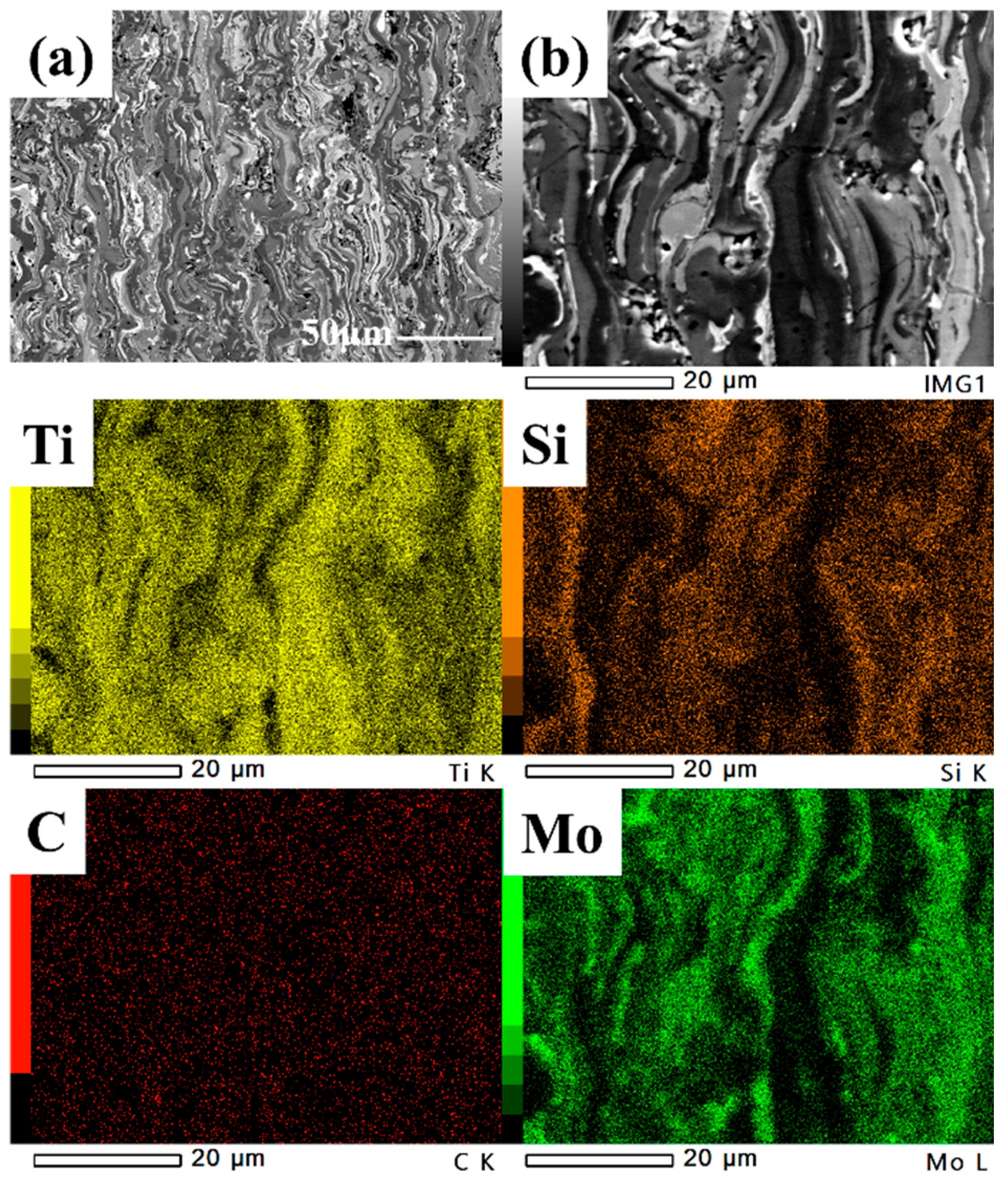

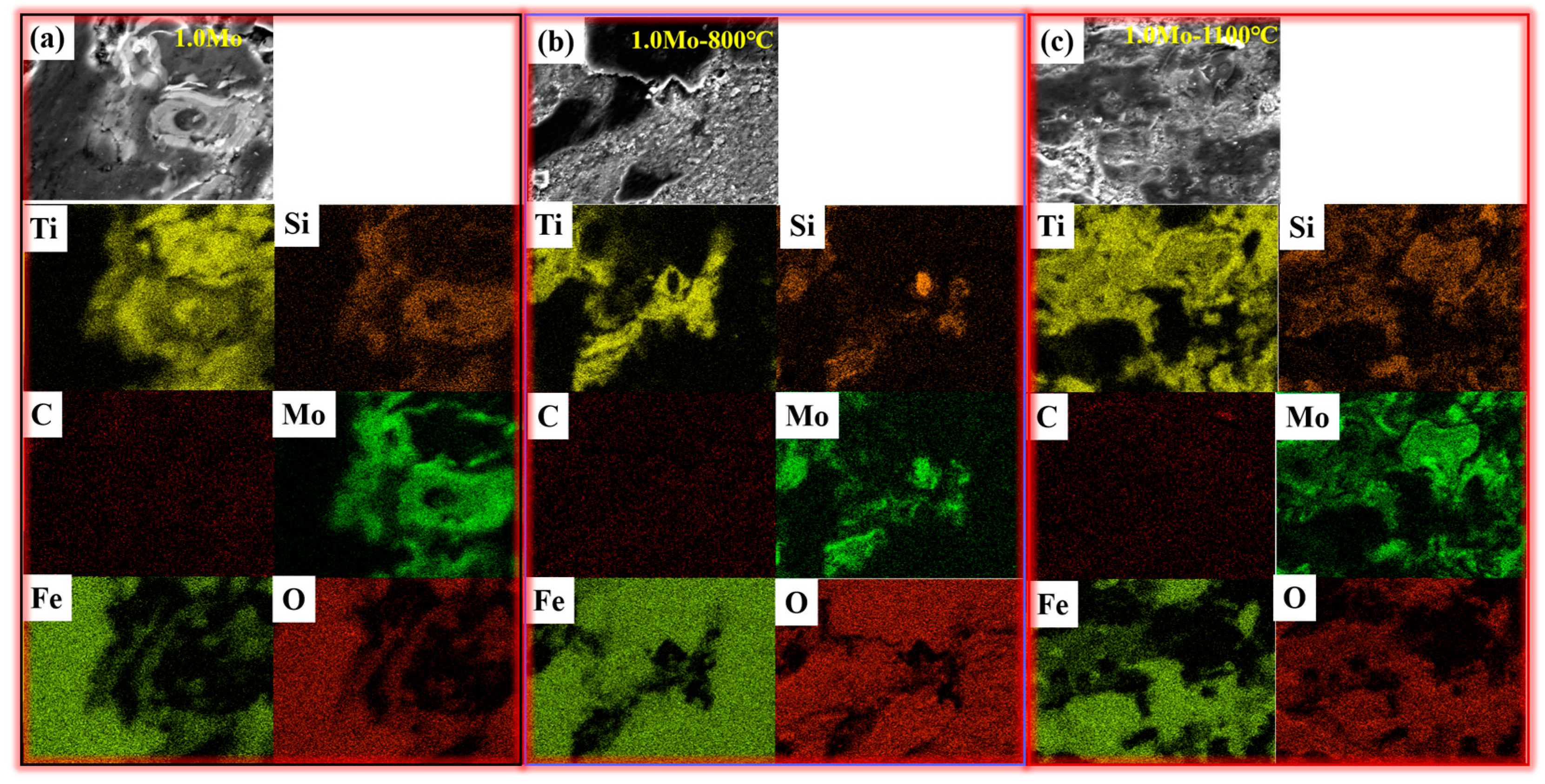

- Ti–Si–C–Mo coatings are composed of TiC, Ti3SiC2, Ti5Si3 and residual graphite. After heat treatment at 800 °C and 1100 °C, the Ti3SiC2 and Mo5Si3 phases increased, and the Ti/Si/C/Mo elements diffused during the heat treatment process to make the microstructure more uniform.

- (2)

- The average microhardness of the Ti–Si–C–1.0Mo coating is HV 1394. After heat treatment at 800 °C and 1100 °C, the microhardness reduced to HV 1187 and HV 1171, respectively. The average microhardness of the Ti–Si–C–1.5Mo coating is HV 1400. After heat treatment at 800 °C and 1100 °C, it reduced to HV 1209 and HV 1145. This decrease in microhardness was mainly due to the heat treatment reducing the internal stress in the coating and increasing the formation of the soft phase, Ti3SiC2.

- (3)

- The fracture toughness of the Ti–Si–C–1.0Mo coating is 3.35 MPa·m1/2. After heat treatment at 800 °C and 1100°C, it decreased to 3.303 MPa·m1/2 and 3.227 MPa·m1/2. The fracture toughness of the Ti–Si–C–1.5Mo coating was 2.93 MPa·m1/2. After heat treatment at 800 °C and 1100 °C, it increased to 3.362 MPa·m1/2 and 3.413 MPa·m1/2, respectively.

- (4)

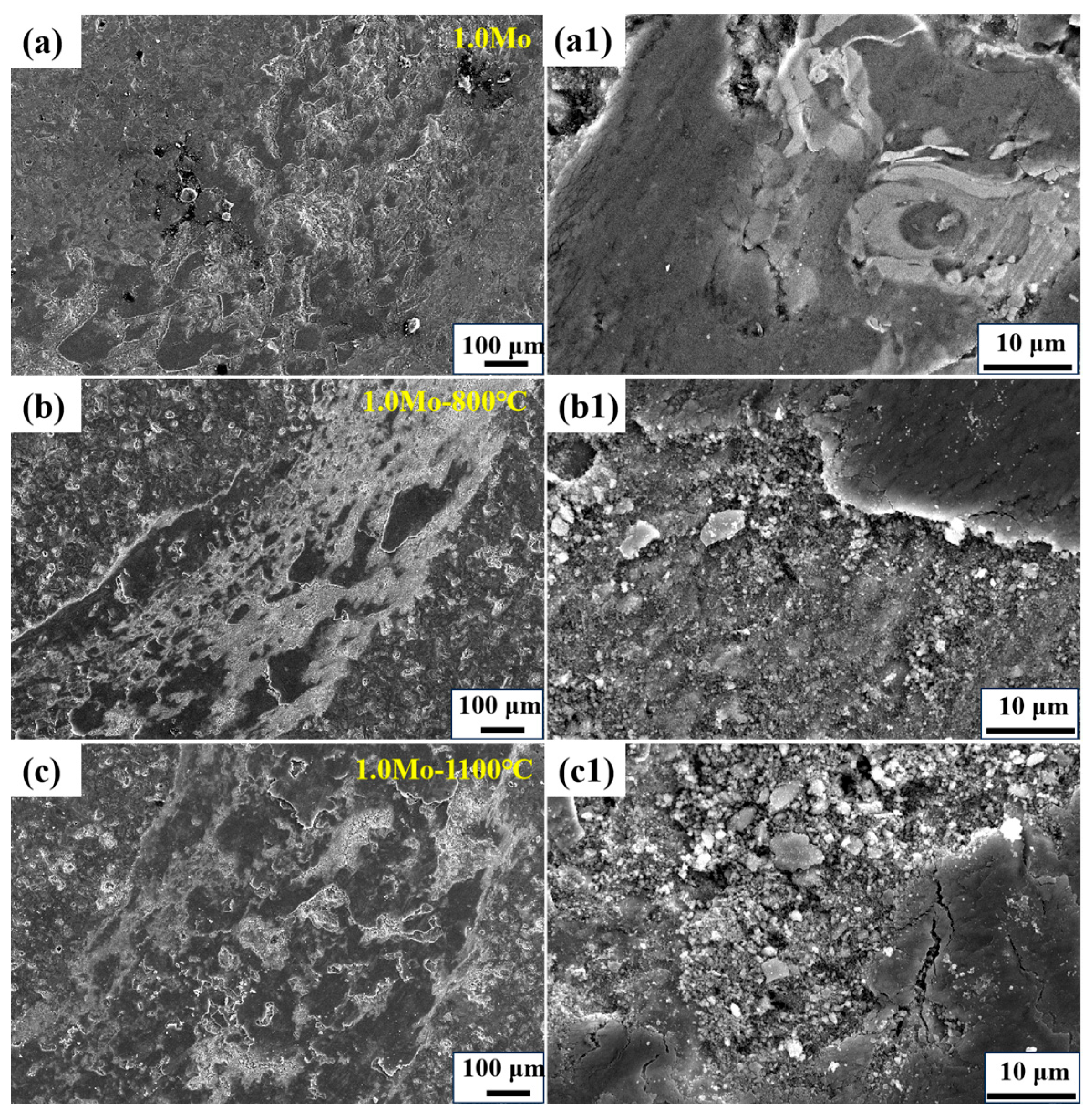

- The friction coefficient of Ti–Si–C–1.0/1.5Mo coatings before and after heat treatment was 0.4~0.6, the wear weight loss of the coating after heat treatment was first reduced and then increased, and the minimum wear weight loss occurred after heat treatment at 800 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Podgornik, B.; Sedlaček, M.; Batič, B.; Čekada, M. High temperature friction and galling properties of nanolayered (Cr,V)N coatings and effect of V content. Surf. Coat. Technol. 2023, 465, 129594. [Google Scholar] [CrossRef]

- Liu, Q.; Huang, S.; He, A. Composite ceramics thermal barrier coatings of yttria stabilized zirconia for aero-engines. J. Mater. Sci. Technol. 2019, 35, 2814–2823. [Google Scholar] [CrossRef]

- Shi, P.; Sun, H.; Yi, G.; Wang, W.; Wan, S.; Yu, Y.; Wang, Q. Tribological behavior and mechanical properties of thermal sprayed TiO2–ZnO and TiOx ceramic coatings. Ceram. Int. 2023, 49, 18662–18670. [Google Scholar] [CrossRef]

- Soković, M.; Mikuła, J.; Dobrzański, L.A.; Kopač, J.; Koseč, L.; Madejski, J.; Panjan, P.; Piech, A. Cutting properties of the Al2O3+SiC(w) based tool ceramic reinforced with the PVD and CVD wear resistant coatings. J. Mater. Process. Technol. 2005, 164–165, 924–929. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, X.; Ma, Z.; Liu, L.; Liu, Y. Investigation of the oxidation of plasma sprayed silicon coating. Mater. Chem. Phys. 2022, 280, 125762. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, F.Q.; Zhang, L.; Li, J.D.; Zhang, J.W. Microstructure evolution and high temperature corrosion behavior of FeCrBSi coatings prepared by laser cladding. Ceram. Int. 2020, 46, 17233–17242. [Google Scholar] [CrossRef]

- Liu, D.T.; Kong, D.J. Microstructure and electrochemical performance of plasma sprayed Fe45Mn35Co10Cr10 high−entropy alloy coating in different corrosive solutions. Intermetallics 2024, 165, 108154. [Google Scholar]

- Liu, G.; Wang, D.; Xing, Y.; Zhong, X.; Pan, W. Copper bonding silicon nitride substrate using atmosphere plasma spray. J. Eur. Ceram. Soc. 2023, 43, 3981–3987. [Google Scholar] [CrossRef]

- Zhao, P.; Zhu, J.; Yang, K.; Li, M.; Shao, G.; Lu, H.; Ma, Z.; Wang, H.; He, J. Outstanding wear resistance of plasma sprayed high-entropy monoboride composite coating by inducing phase structural cooperative mechanism. Appl. Surf. Sci. 2023, 616, 156516. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, W.; Fan, X.; Zhang, J.; Mao, W. Microstructure and mechanical properties of plasma-sprayed LaMgA111O19 thick ceramic coatings. Ceram. Int. 2021, 47, 22435–22446. [Google Scholar] [CrossRef]

- Hashemi, S.M.; Parvin, N.; Valefi, Z.; Alishahi, M. Comparative study on tribological and corrosion protection properties of plasma sprayed Cr2O3-YSZ-SiC ceramic coatings. Ceram. Int. 2019, 45, 21108–21119. [Google Scholar] [CrossRef]

- Sun, X.; Huang, J.; Ye, Z.; Yang, J.; Chen, S.; Zhao, X. Study on microstructure evolution and reaction mechanism of in-flight Ti–Si–C agglomerates during reactive plasma spraying using in situ water quenching. Ceram. Int. 2022, 48, 18866–18875. [Google Scholar] [CrossRef]

- Chu, Z.; Wei, F.; Zheng, X.; Zhang, C.; Yang, Y. Microstructure and properties of TiN/Fe-based amorphous composite coatings fabricated by reactive plasma spraying. J. Alloys Compd. 2019, 785, 206–213. [Google Scholar] [CrossRef]

- Tan, Z.; Luo, C.; Zhu, W.; Yang, L.; Zhou, Y.; Wu, Q. Reactive plasma spraying of supersaturated tungsten super-hard Ta-Hf-W-C solid solution coating. J. Eur. Ceram. Soc. 2021, 41, 6772–6777. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, K.; Zhou, Z.; Wang, G.; Zhang, X. Enhanced multi-scale nanomechanical deformation behavior in reactive plasma sprayed Fe-based amorphous/TiNx composite coating. J. Alloys Compd. 2023, 960, 171023. [Google Scholar] [CrossRef]

- Shao, Y.X.; Yang, Y.; Li, K.R.; Zhao, C.C.; Wang, Y.W.; Wang, X.Y. Reactive synthesis of ZrC-ZrSi2 composite coating by atmospheric plasma spraying. Surf. Coat. Technol. 2022, 450, 128976. [Google Scholar] [CrossRef]

- Sun, X.; Li, W.; Huang, J.; Yang, J.; Chen, S.; Zhao, X. Microstructure and properties of in-situ Ti5Si3-TiC composite coatings by reactive plasma spraying. Appl. Surf. Sci. 2020, 508, 145264. [Google Scholar] [CrossRef]

- Sun, X.; Li, W.; Huang, J.; Ye, Z.; Yang, J.; Chen, S.; Zhao, X. Effect of Si content on the microstructure and properties of Ti–Si–C composite coatings prepared by reactive plasma spraying. Ceram. Int. 2021, 47, 24438–24452. [Google Scholar] [CrossRef]

- Wang, X.-L.; Shao, Y.-X.; Guo, M.-Y.; Yang, Y.; Ma, Y.-D.; Cui, Y.-H.; Sun, W.-W.; Dong, Y.-C.; Yan, D.-R. Comparison of plasma sprayed NbB2-NbC coatings obtained by ex-situ and in-situ approaches. J. Eur. Ceram. Soc. 2021, 41, 5088–5099. [Google Scholar] [CrossRef]

- Cui, Y.-H.; Zhang, Q.; Shao, Y.-X.; Yang, Y.; Ma, Y.-D.; Sun, W.-W.; Wang, Y.-W.; Wang, X.-Y.; Dong, Y.-C. Microstructure and properties of in-situ ZrB2-ZrC composite coatings by plasma spraying. Surf. Coat. Technol. 2021, 409, 126846. [Google Scholar] [CrossRef]

- Wang, Y.-W.; Sun, X.-W.; Wang, L.; Yang, Y.; Ren, X.-X.; Ma, Y.-D.; Cui, Y.-H.; Sun, W.-W.; Wang, X.-Y.; Dong, Y.-C. Microstructure and properties of CrB2-Cr3C2 composite coatings prepared by plasma spraying. Surf. Coat. Technol. 2021, 425, 127693. [Google Scholar] [CrossRef]

- Tong, G.; Yu, L. Effect of Heat Treatment and Passivation on Corrosion Behavior of Electroless Ni-P Coating on 20# Steel in Simulated Soil Solution. Int. J. Electrochem. Sci. 2022, 17, 221247. [Google Scholar]

- Dong, H.; Guo, P.-F.; Han, Y.; Bai, R.-X.; Yang, Z.-C.; Zhang, S.-Q. Enhanced corrosion resistance of high speed laser-cladded Ni/316L alloy coating by heat treatment. J. Mater. Res. Technol. 2023, 24, 952–962. [Google Scholar] [CrossRef]

- Ghadami, F.; Sohi, M.H.; Ghadami, S. Effect of bond coat and post-heat treatment on the adhesion of air plasma sprayed WC-Co coatings. Surf. Coat. Technol. 2015, 261, 289–294. [Google Scholar] [CrossRef]

- Varis, T.; Lagerbom, J.; Suhonen, T.; Raami, L.; Terho, S.; Laurila, J.; Peura, P.; Vuoristo, P. Effect of heat treatments on the wear resistance of HVAF and HVOF sprayed tool steel coatings. Surf. Coat. Technol. 2023, 462, 129508. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, F.; Wang, L.; Yan, S.; He, J.; Yin, F. Effects of post-annealing on microstructure and mechanical properties of plasma sprayed Ti-Si-C composite coatings with Al addition. Surf. Coat. Technol. 2021, 416, 127164. [Google Scholar] [CrossRef]

- Zhao, H.; Hu, L.; Li, C.; Jiao, Q.; He, J.; Qin, Y.; Yin, F. Influence of metallic Cr addition on the phase structure and mechanical properties of plasma-sprayed Ti–Si–C coatings. Ceram. Int. 2021, 47, 17570–17579. [Google Scholar] [CrossRef]

- Li, S.; Fang, H.; Jiao, Q.; He, J.; Zhao, H.; Qin, Y.; Yin, F. Evolution of microstructure and mechanical performance of plasma-sprayed Ti–Cr–Si–C coatings annealed at 800 °C and 1100 °C. Vacuum 2022, 196, 110781. [Google Scholar] [CrossRef]

- Forn, A.; Picas, J.A.; Simón, M.J. Mechanical and tribological properties of Al–Si–Mo plasma-sprayed coatings. J. Mater. Process. Technol. 2003, 143–144, 52–57. [Google Scholar] [CrossRef]

- Jiao, Q.; Guo, F.; Li, C.; Zheng, G.; He, J.; Zhao, H.; Qin, Y.; Yin, F. Effects of Mo addition on tribological performance of plasma-sprayed Ti–Si–C coatings. Ceram. Int. 2020, 46, 12948–12954. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Y.; Tian, W.; Yan, D.-R.; Zhang, J.-X.; Wang, L. Influence of composite powders’ microstructure on the microstructure and properties of Al2O3–TiO2 coatings fabricated by plasma spraying. Mater. Des. 2015, 65, 814–822. [Google Scholar] [CrossRef]

- Li, W.; Yang, Y.; Liang, H.E.; Zhang, X.; Wang, Y.W.; Gou, J.F. Ablation resistance and mechanism of niobium carbide coatings fabricated by plasma spraying. Surf. Coat. Technol. 2023, 472, 129934. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Liu, J.; Zhao, H.; Qin, Y.; Fan, J. High-Temperature Heat Treatment of Plasma Sprayed Ti–Si–C–Mo Coatings. Coatings 2024, 14, 109. https://doi.org/10.3390/coatings14010109

He J, Liu J, Zhao H, Qin Y, Fan J. High-Temperature Heat Treatment of Plasma Sprayed Ti–Si–C–Mo Coatings. Coatings. 2024; 14(1):109. https://doi.org/10.3390/coatings14010109

Chicago/Turabian StyleHe, Jining, Jialin Liu, Hongjian Zhao, Yanfang Qin, and Jiawei Fan. 2024. "High-Temperature Heat Treatment of Plasma Sprayed Ti–Si–C–Mo Coatings" Coatings 14, no. 1: 109. https://doi.org/10.3390/coatings14010109

APA StyleHe, J., Liu, J., Zhao, H., Qin, Y., & Fan, J. (2024). High-Temperature Heat Treatment of Plasma Sprayed Ti–Si–C–Mo Coatings. Coatings, 14(1), 109. https://doi.org/10.3390/coatings14010109