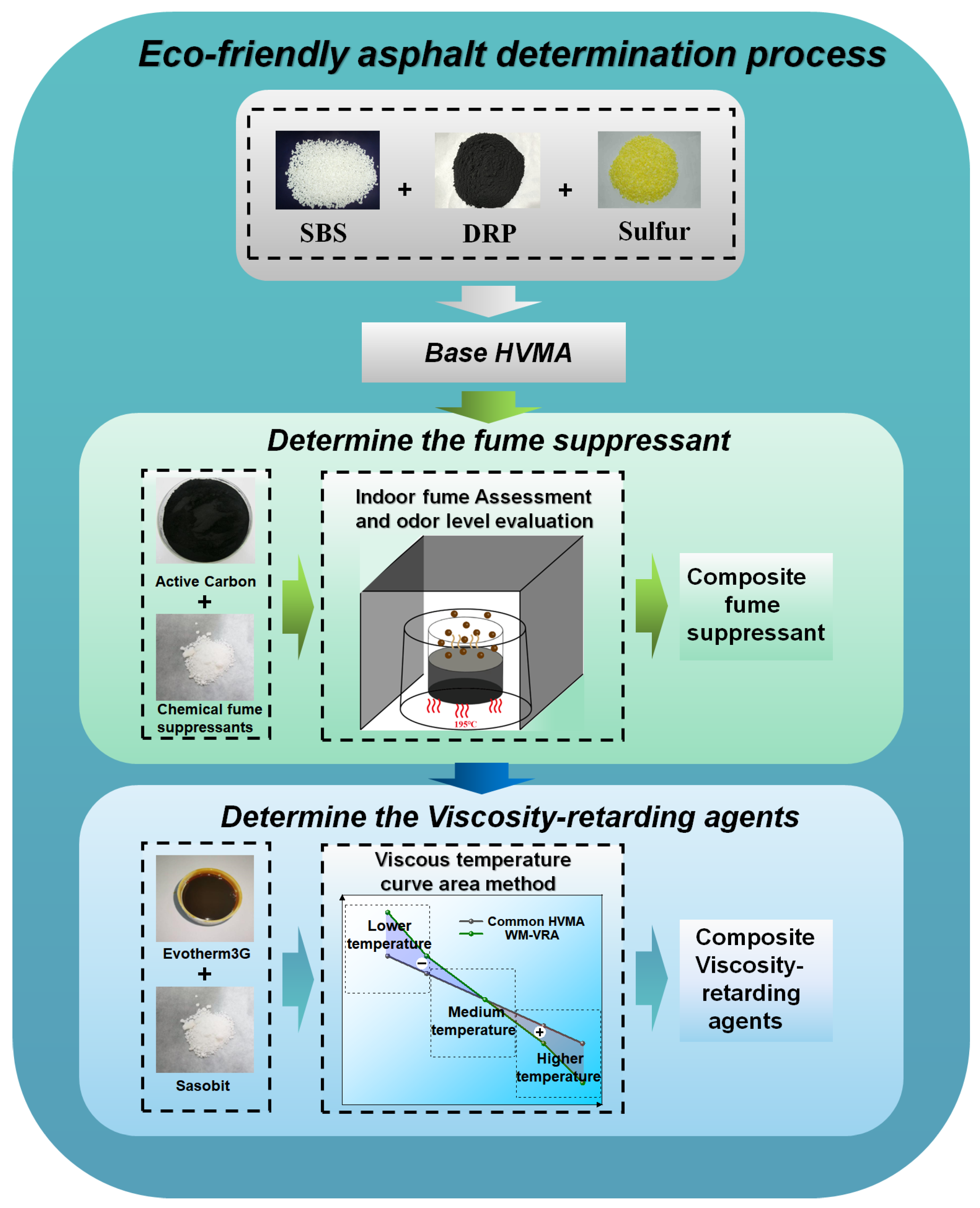

Evaluation of Fume Suppression, Viscosity-Retarding, and Rheological Properties of Eco-Friendly High-Viscosity Modified Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of the Modified Asphalt Samples

- (1)

- The base asphalt was heated to a temperature of 180~190 °C, SBS was then added and stirred for 10 min, followed by shearing for 15 min at a speed of 1000~3000 r/min. DRP was added in batches, stirred for 10 min, and sheared for 60 min at a speed of 4000~6000 r/min.

- (2)

- PPA and sulfur were added and sheared for 10 min at a speed of 4000~6000 r/min. Viscosity-retarding agents (VRAs) and antioxidants were then added and sheared for 10 min at a speed of 3000~5000 r/min. Finally, fume suppressant was added and sheared for 10 min at a speed of 4000~6000 r/min.

- (3)

- The temperature was lowered to a range of 170~180 °C, and a four-blade mixer operating at a speed of 600 r/min was used for low-speed stirring for 30 min to eliminate foaming. Subsequently, the mixture was taken out and placed in an oven at 170~180 °C for 30 min to undergo swelling and development.

- (4)

- Once the product was inspected and deemed qualified, it was certified as an eco-friendly HVMA and stored for insulation.

2.3. Experimental

2.3.1. Fluorescence Microscopy (FM) Observation

2.3.2. Indoor Fume Assessment

2.3.3. Odor-Level Evaluation

2.3.4. Viscosity Test Performed by Rotational Viscometer

2.3.5. Temperature Sweep (TS) Test

2.3.6. Shearing Rate Sweep Test

2.3.7. Multiple Stress Creep Recovery (MSCR) Analysis

2.3.8. Liner Amplitude Sweep (LAS) Test

2.3.9. Frequency Sweep (FS) Test

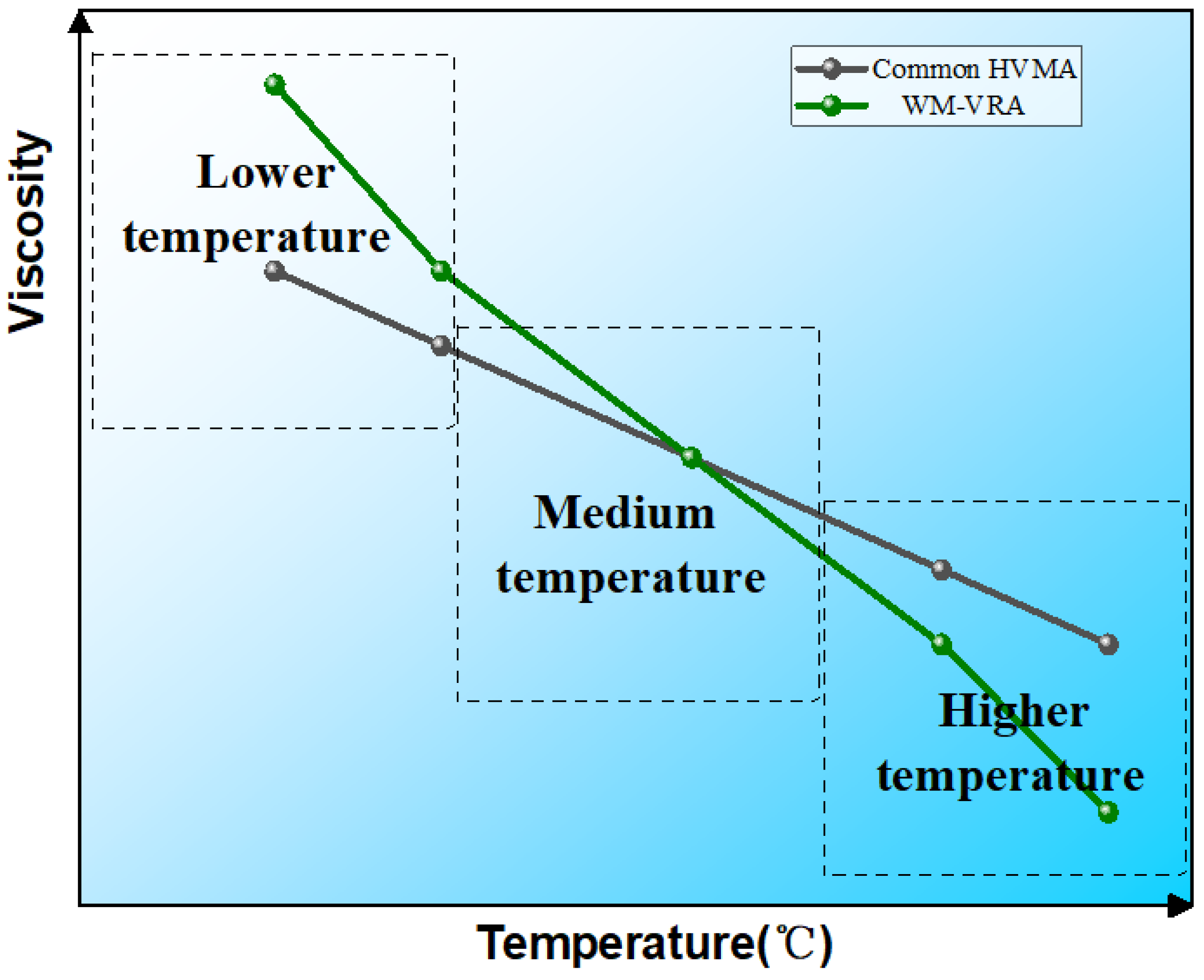

2.4. Evaluation Method

2.5. Test Process

3. Results and Discussion

3.1. Morphological Analysis

3.2. Fume-Suppressing Effect Evaluation

3.3. Energy-Saving Effect Evaluation

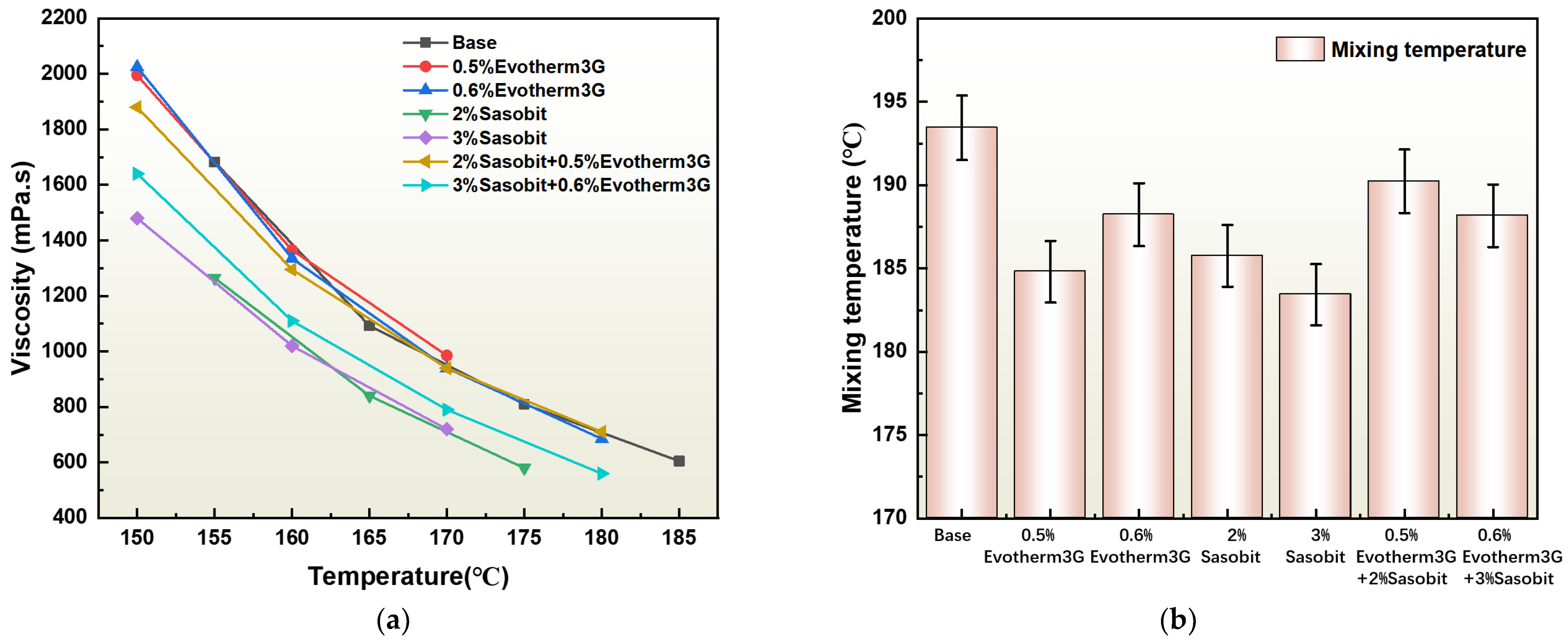

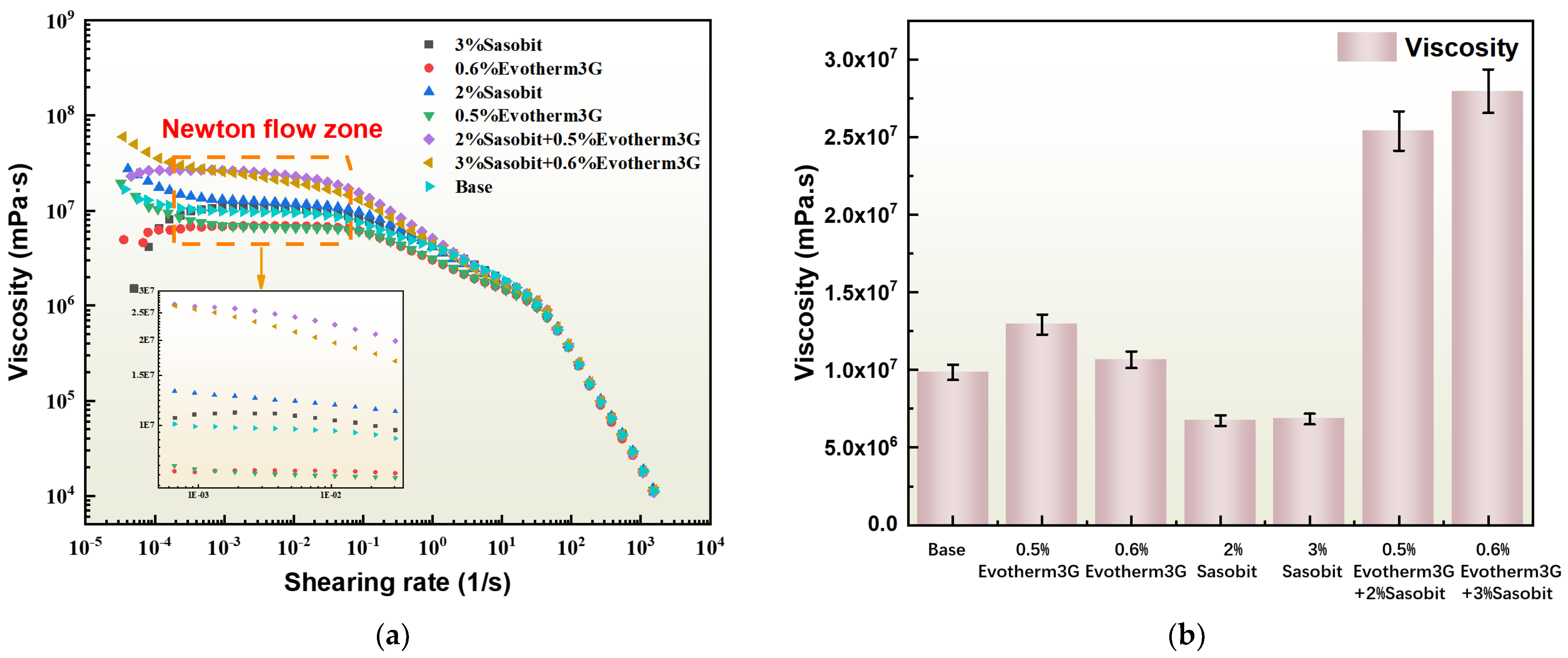

3.3.1. Rotational Viscosity Test Analysis

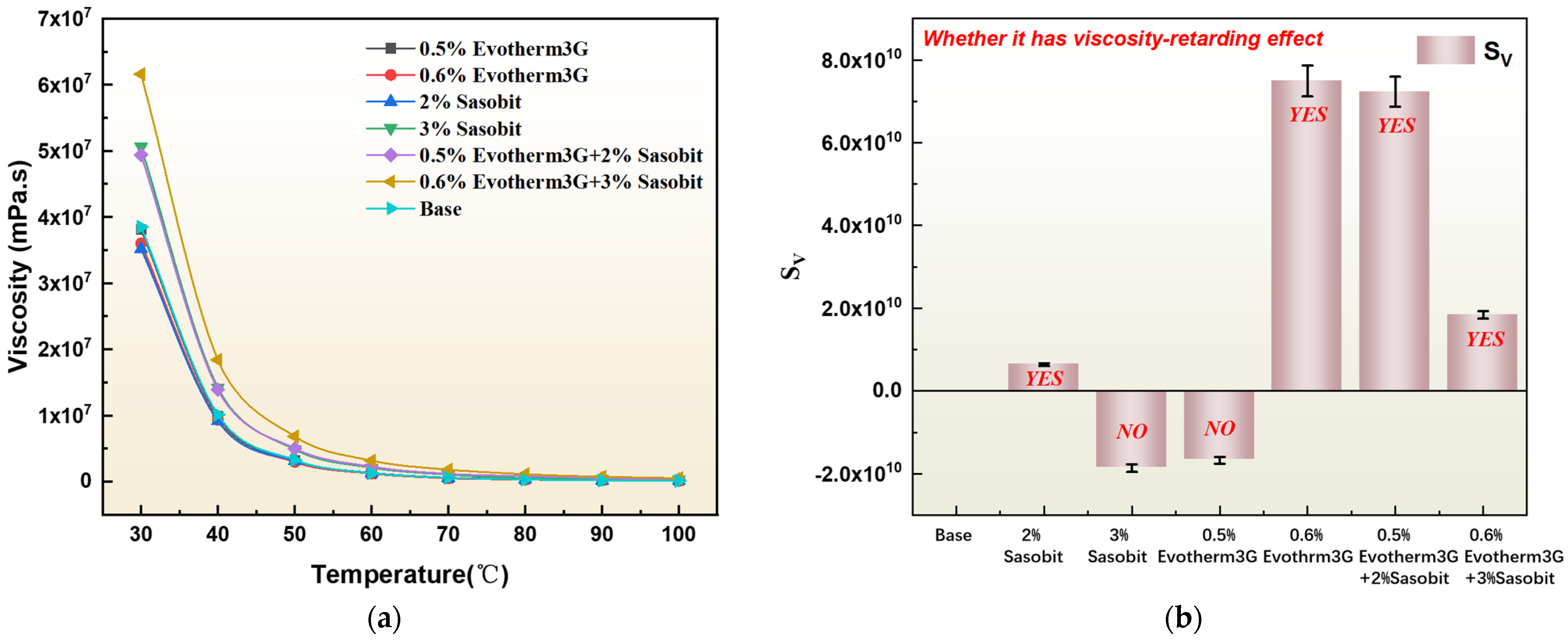

3.3.2. Evaluation of the Viscosity-Retarding Effect

3.4. Rheological Performance Characterization

3.4.1. Shearing Rate Sweep Test Analysis

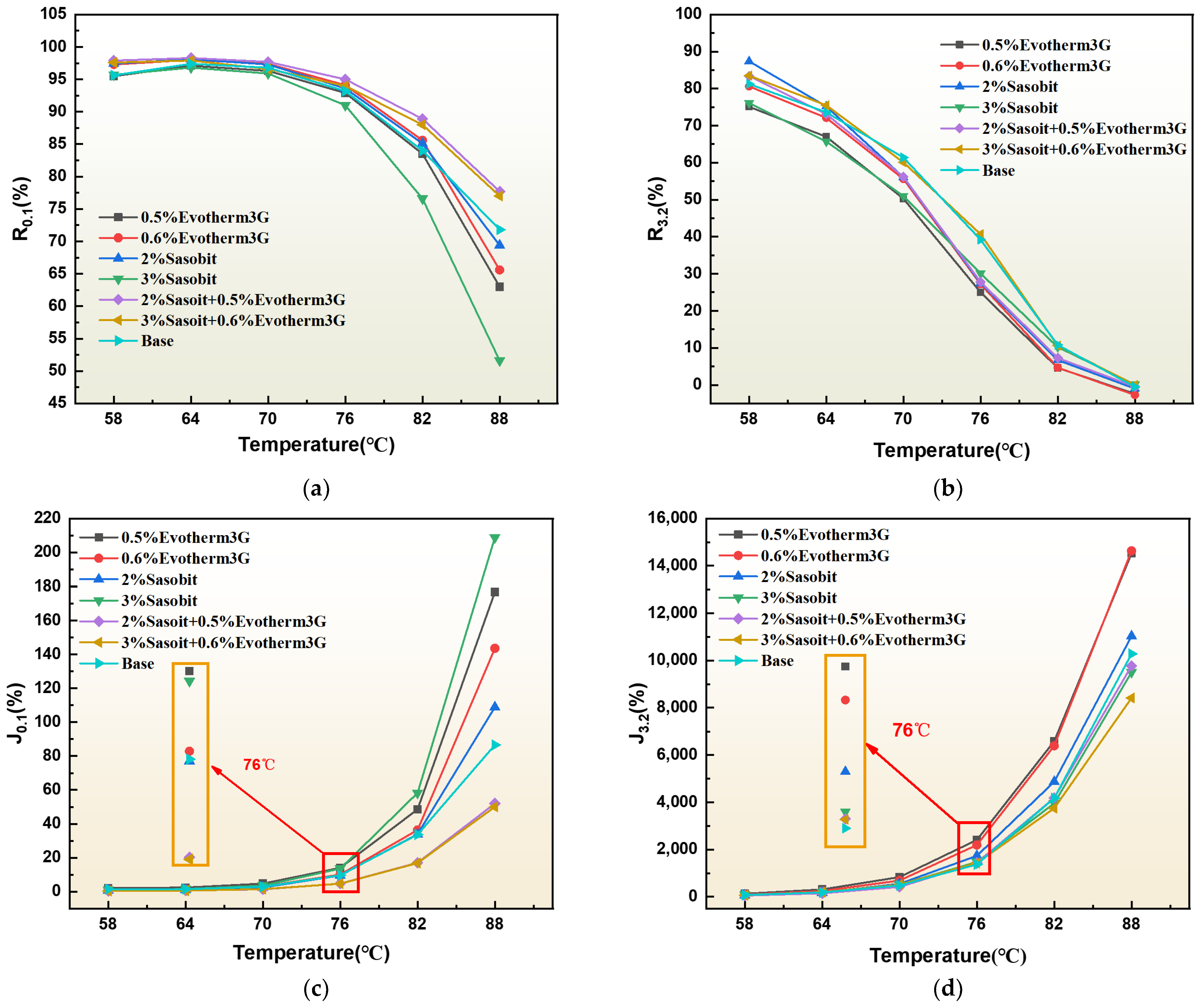

3.4.2. Multiple Stress Creep Recovery (MSCR) Analysis

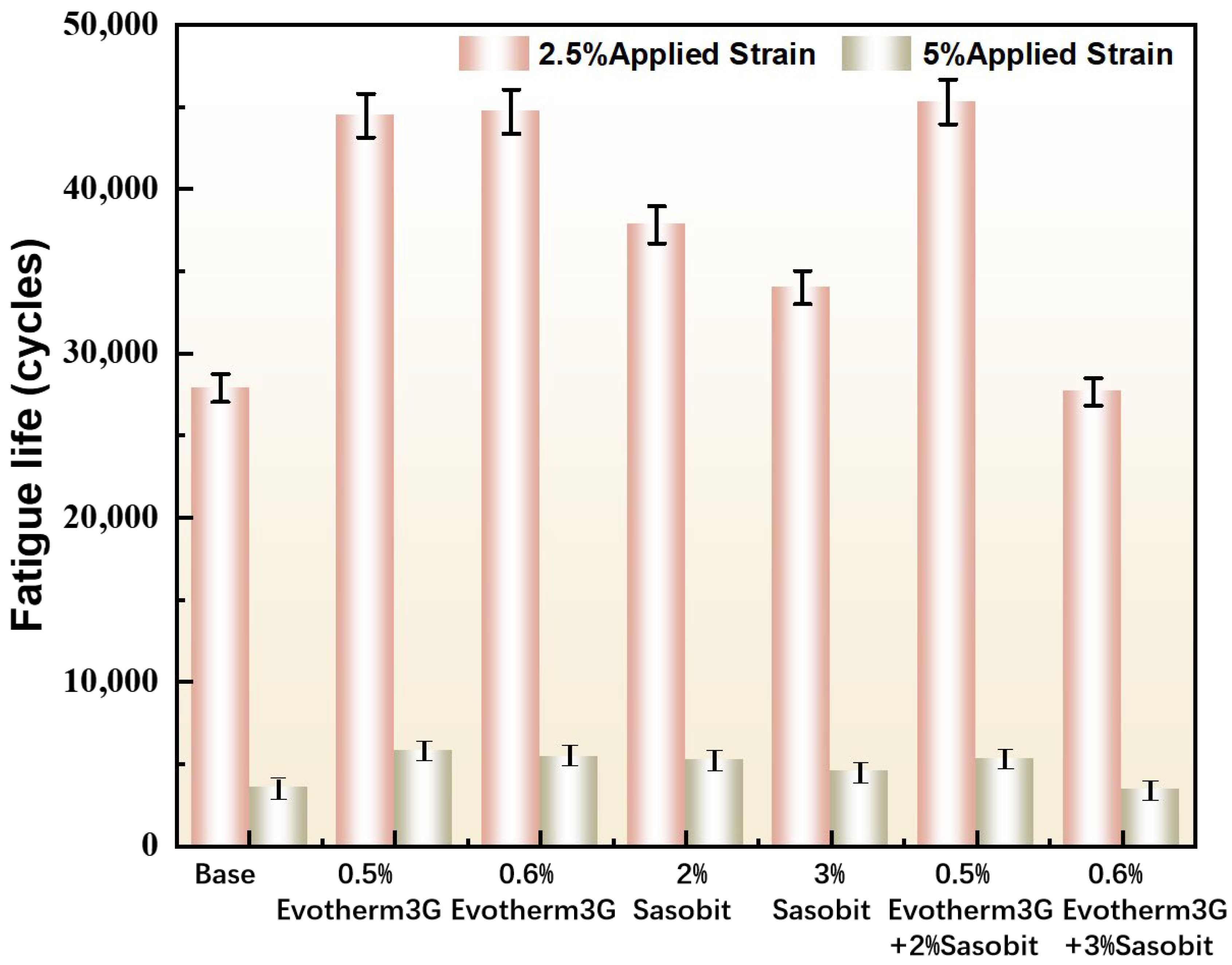

3.4.3. Analysis of Fatigue Life Prediction from LAS Test

3.4.4. Frequency Sweep Test Results

4. Conclusions and Outlook

- (1)

- According to the fume-suppressing effect and odor-level evaluation results, the fume suppression effect and odor level effect of the DRP-modified HVMA was superior to that of rubber-modified HVMA when different types of fume suppressants were added. Furthermore, the ranking in terms of fume suppression effects was: composite fume agent > activated carbon > chemical reaction fume suppressant. And the odor level of adding composite fume suppressants sharply decreased to level one, far lower than the level three of ordinary base HVMA. Ultimately, it was determined that the 1% composite fume suppressants was selected as the optimal fume suppression plan.

- (2)

- The mixing temperatures of different HVMAs were determined based on their viscosity–temperature curves. It was found that the addition of VRA could reduce the mixing temperature of HVMA to 4–10 °C. A novel method based on the integrated area of viscosity–temperature curve was proposed in this research to evaluate the viscosity-retarding effect of different VRAs. Finally, the HVMA containing with 0.6% Evotherm3G + 3% Sasobit VRAs had the optimal viscosity-retarding effect and lower mixing temperature, and was determined as the eco-friendly HVMA.

- (3)

- The morphological characteristics and rheological properties of various HVMAs were evaluated. After Sasobit/Evotherm3G was added, the network structure of the HVMA was not as apparent as that of the HVMA with a single component added, but a continuous spatial network structure still existed. The research results of ZSV, MSCR, and LAS indicated that the selected eco-friendly HVMA exhibited better high-temperature resistance compared to common HVMAs, and the fatigue life also met the performance requirements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, X.; Wang, G.; Rong, H.; Meng, Y.; Liu, X.; Liu, Y.; Peng, C. Review of fume-generation mechanism, test methods, and fume suppressants of asphalt materials. J. Clean. Prod. 2022, 347, 131240. [Google Scholar] [CrossRef]

- Cao, L.; Yang, C.; Li, A.; Wang, P.; Zhang, Y.; Dong, Z. Flue gas composition of waste rubber modified asphalt (WRMA) and effect of deodorants on hazardous constituents and WRMA. J. Hazard. Mater. 2021, 403, 123814. [Google Scholar] [CrossRef] [PubMed]

- Tang, N.; Zhang, Z.; Dong, R.; Zhu, H.; Huang, W. Emission behavior of crumb rubber modified asphalt in the production process. J. Clean. Prod. 2022, 340, 130850. [Google Scholar] [CrossRef]

- Li, H.; Jia, M.; Zhang, X.; Wang, Z.; Liu, Y.; Yang, J.; Yang, B.; Sun, Y.; Wang, H.; Ma, H. Laboratory investigation on fumes generated by different modified asphalt binders. Transp. Res. Part D Transp. Environ. 2023, 121, 103828. [Google Scholar] [CrossRef]

- Cui, P.; Schito, G.; Cui, Q. VOC emissions from asphalt pavement and health risks to construction workers. J. Clean. Prod. 2020, 244, 118757. [Google Scholar] [CrossRef]

- Xiu, M.; Wang, X.; Morawska, L.; Pass, D.; Beecroft, A.; Mueller, J.F.; Thai, P. Emissions of particulate matters, volatile organic compounds and polycyclic aromatic hydrocarbons from warm and hot asphalt mixes. J. Clean. Prod. 2020, 275, 123094. [Google Scholar] [CrossRef]

- Clark, C.R.; Burnett, D.M.; Parker, C.M.; Arp, E.W.; Swanson, M.S.; Minsavage, G.D.; Kriech, A.J.; Osborn, L.V.; Freeman, J.J.; Barter, R.A.; et al. Asphalt fume dermal carcinogenicity potential: I. dermal carcinogenicity evaluation of asphalt (bitumen) fume condensates. Regul. Toxicol. Pharmacol. 2011, 61, 9–16. [Google Scholar] [CrossRef]

- Bao, J.; Wang, H.; Cong, Y.; Wang, X.; Liu, S.; Wang, J.; Chen, M. Research progress of road asphalt smoke suppressant. Contemp. Chem. Ind. 2020, 49, 988–992. (In Chinese) [Google Scholar]

- Zhang, F.; Yu, J.; Wu, S. Effect of ageing on rheological properties of storage-stable SBS/sulfur-modified asphalts. J. Hazard. Mater. 2010, 182, 507–517. [Google Scholar] [CrossRef]

- Autelitano, F.; Garilli, E.; Pinalli, R.; Montepara, A.; Giuliani, F. The odour fingerprint of bitumen. Road Mater. Pavement Des. 2017, 18, 178–188. [Google Scholar] [CrossRef]

- Wang, M.; Li, P.; Nian, T.; Mao, Y. An overview of studies on the hazards, component analysis and suppression of fumes in asphalt and asphalt mixtures. Constr. Build. Mater. 2021, 289, 123185. [Google Scholar] [CrossRef]

- Mo, S.; Wang, Y.; Xiong, F.; Ai, C. Effects of asphalt source and mixing temperature on the generated asphalt fumes. J. Hazard. Mater. 2019, 371, 342–351. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; You, Z.; Perram, D.; Hand, D.; Ahmed, Z.; Wei, W.; Luo, S. Emission analysis of recycled tire rubber Modified Asphalt in hot and warm mix conditions. J. Hazard Mater. 2019, 365, 942–951. [Google Scholar] [CrossRef] [PubMed]

- Liang, M.; Ren, S.; Fan, W.; Wang, H.; Cui, W.; Zhao, P. Characterization of fume composition and rheological properties of asphalt with crumb rubber activated by microwave and TOR. Constr. Build. Mater. 2017, 154, 310–322. [Google Scholar] [CrossRef]

- Wang, F.; Li, N.; Hoff, I.; Wu, S.; Li, J.; Barbieri, D.M.; Zhang, L. Characteristics of VOCs generated during production and construction of an asphalt pavement. Transp. Res. Part D Transp. Environ. 2020, 87, 102517. [Google Scholar] [CrossRef]

- Gągol, M.; Boczkaj, G.; Haponiuk, J.; Formela, K. Investigation of volatile low molecular weight compounds formed during continuous reclaiming of ground tire rubber. Polym. Degrad. Stabil. 2015, 119, 113–120. [Google Scholar] [CrossRef]

- Cui, P.Q.; Wu, S.P.; Xiao, Y.; Zhang, H.H. Experimental study on the reduction of fumes emissions in asphalt by different additives. Mater. Res. Innov. 2015, 19, S158–S161. [Google Scholar] [CrossRef]

- Lv, Y.; Wu, S.; Li, N.; Cui, P.; Wang, H.; Amirkhanian, S.; Zhao, Z. Performance and VOCs emission inhibition of environmentally friendly rubber modified asphalt with UiO-66 MOFs. J. Clean. Prod. 2023, 385, 135633. [Google Scholar] [CrossRef]

- Li, H.; Feng, Z.; Liu, H.; Ahmed, A.T.; Zhang, M.; Zhao, G.; Guo, P.; Sheng, Y. Performance and inorganic fume emission reduction of desulfurized rubber powder/styrene–butadiene–styrene composite modified asphalt and its mixture. J. Clean. Prod. 2022, 364, 132690. [Google Scholar] [CrossRef]

- Cheraghian, G.; Falchetto, A.C.; You, Z.; Chen, S.; Kim, Y.S.; Westerhoff, J.; Moon, K.H.; Wistuba, M.P. Warm mix asphalt technology: An up to date review. J. Clean. Prod. 2020, 268, 122128. [Google Scholar] [CrossRef]

- Jamshidi, A.; Hamzah, M.O.; You, Z. Performance of Warm Mix Asphalt containing Sasobit®: State-of-the-art. Constr. Build. Mater. 2013, 38, 530–553. [Google Scholar] [CrossRef]

- Wan, Z.; Zheng, B.; Xie, X.; Yang, J.; Zhou, H.; Wan, R.S.; Wang, J.; Wang, J.; Luo, W.; Xue, R.; et al. Preparation method and performance test of Evotherm pre-wet treatment aluminum hydroxide type warm-mixed flame-retardant asphalt. Constr. Build. Mater. 2020, 262, 120618. [Google Scholar] [CrossRef]

- Valdes-Vidal, G.; Calabi-Floody, A.; Sanchez-Alonso, E. Performance evaluation of warm mix asphalt involving natural zeolite and reclaimed asphalt pavement (RAP) for sustainable pavement construction. Constr. Build. Mater. 2018, 174, 576–585. [Google Scholar] [CrossRef]

- Sukhija, M.; Saboo, N. A comprehensive review of warm mix asphalt mixtures-laboratory to field. Constr. Build. Mater. 2021, 274, 121781. [Google Scholar] [CrossRef]

- Duan, Y. Research of the Features and Mechanism of Retardable Viscosity’s Asphalt in Cold Region. Master’s Thesis, Chang’an University, Xi’an, China, 2013. (In Chinese). [Google Scholar]

- AASHTO T316; Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer. AASHTO: Washington, DC, USA, 2010.

- Sun, G.; Zhu, X.; Zhang, Q.; Yan, C.; Ning, W.; Wang, T. Oxidation and polymer degradation characteristics of high viscosity modified asphalts under various aging environments. Sci. Total Environ. 2022, 813, 152601. [Google Scholar] [CrossRef] [PubMed]

- Biro, S.; Gandhi, T.; Amirkhanian, S. Determination of zero shear viscosity of warm asphalt binders. Constr. Build. Mater. 2009, 23, 2080–2086. [Google Scholar] [CrossRef]

- AASHTO TP 70-1; Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). AASHTO: Washington, DC, USA, 2009.

- Huang, W.; Tang, N. Characterizing SBS modified asphalt with sulfur using multiple stress creep recovery test. Constr. Build. Mater. 2015, 93, 514–521. [Google Scholar] [CrossRef]

- AASHTO TP101-12; Standard Method of Test for Estimating Fatigue Tolerance of Asphalt Binders Using the Linear Amplitude Sweep. AASHTO: Washington, DC, USA, 2012.

- Asgharzadeh, S.; Tabatabaee, N.; Naderi, K.; Partl, M. An empirical model for modified bituminous binder master curves. Mater. Struct. 2012, 46, 1459–1471. [Google Scholar] [CrossRef]

- Asgharzadeh, S.; Tabatabaee, N.; Naderi, K.; Partl, M. Evaluation of rheological mastercurve models for bituminous binders. Mater. Struct. 2013, 48, 393–406. [Google Scholar] [CrossRef]

- Ingrassia, L.P.; Lu, X.; Canestrari, F.; Ferrotti, G. Tribological characterization of bituminous binders with Warm Mix Asphalt additives. Constr. Build. Mater. 2018, 172, 309–318. [Google Scholar] [CrossRef]

- Kassem, E.; Cucalon, L.G.; Masad, E.; Little, D. Effect of Warm Mix Additives on the Interfacial Bonding Characteristics of Asphalt Binders. Int. J. Pavement. Eng. 2018, 19, 1111–1124. [Google Scholar] [CrossRef]

| Strength | Grade |

|---|---|

| 0 | No odor |

| 1 | Can barely feel the odor |

| 2 | The odor is weak but can distinguish properties |

| 3 | Easy to feel the odor |

| 4 | Strong odor |

| 5 | An unbearable strong odor |

| Addictive | S1 | S2 | SG | SD | Retarding Viscosity Effect Presence (Yes/No) | Sv |

|---|---|---|---|---|---|---|

| Base | 0 | 0 | -- | -- | ||

| 0.5% Evotherm3G | No | -- | ||||

| 0.6% Evotherm3G | Yes | |||||

| 2% Sasobit | Yes | |||||

| 3% Sasobit | No | -- | ||||

| 2% Sasobit + 0.5% Evotherm3G | Yes | |||||

| 3% Sasobit + 0.6% Evotherm3G | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, W.; Sun, G.; Qiu, K.; Jiang, X.; Wang, C.; Zhao, R. Evaluation of Fume Suppression, Viscosity-Retarding, and Rheological Properties of Eco-Friendly High-Viscosity Modified Asphalt. Coatings 2023, 13, 1497. https://doi.org/10.3390/coatings13091497

Ning W, Sun G, Qiu K, Jiang X, Wang C, Zhao R. Evaluation of Fume Suppression, Viscosity-Retarding, and Rheological Properties of Eco-Friendly High-Viscosity Modified Asphalt. Coatings. 2023; 13(9):1497. https://doi.org/10.3390/coatings13091497

Chicago/Turabian StyleNing, Weidong, Guoqiang Sun, Kexin Qiu, Xulai Jiang, Chunze Wang, and Ruiqi Zhao. 2023. "Evaluation of Fume Suppression, Viscosity-Retarding, and Rheological Properties of Eco-Friendly High-Viscosity Modified Asphalt" Coatings 13, no. 9: 1497. https://doi.org/10.3390/coatings13091497

APA StyleNing, W., Sun, G., Qiu, K., Jiang, X., Wang, C., & Zhao, R. (2023). Evaluation of Fume Suppression, Viscosity-Retarding, and Rheological Properties of Eco-Friendly High-Viscosity Modified Asphalt. Coatings, 13(9), 1497. https://doi.org/10.3390/coatings13091497