Effect of Hafnium Addition on the Microstructure and Property Evolutions of ZrCN Coating Prepared via Physical Vapor Deposition

Abstract

1. Introduction

2. Experimental Section

2.1. Preparation of Zr(Hf)xCN Coatings

2.2. Characterization

3. Results and Discussion

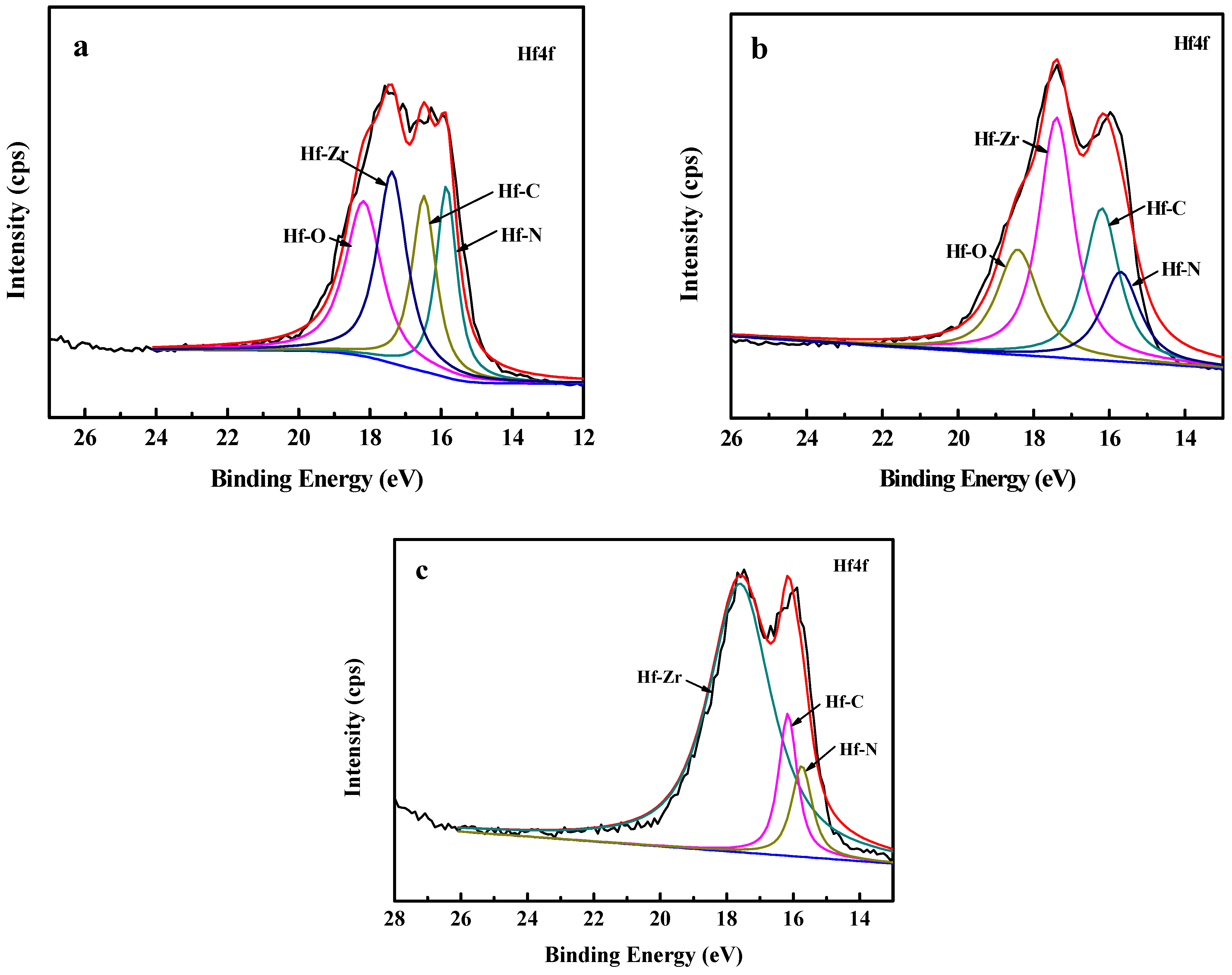

3.1. Elemental Composition and Chemical Bonds

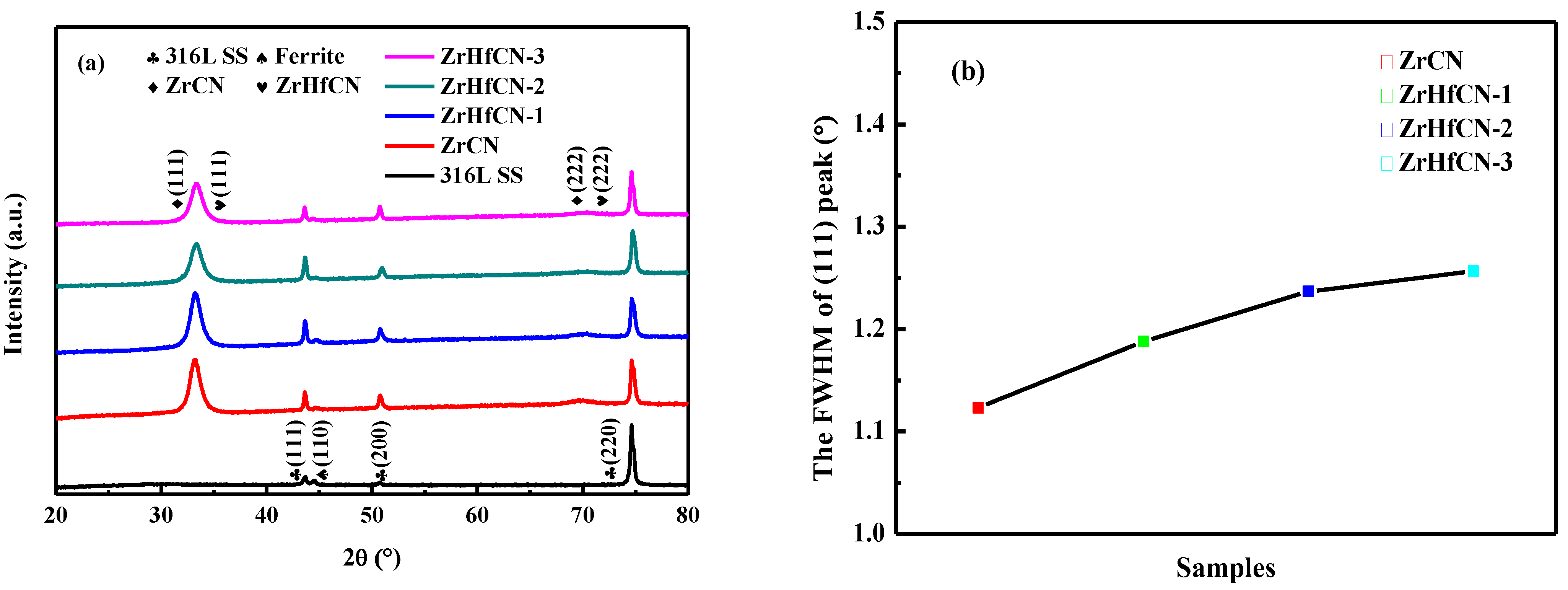

3.2. Microstructure Analysis

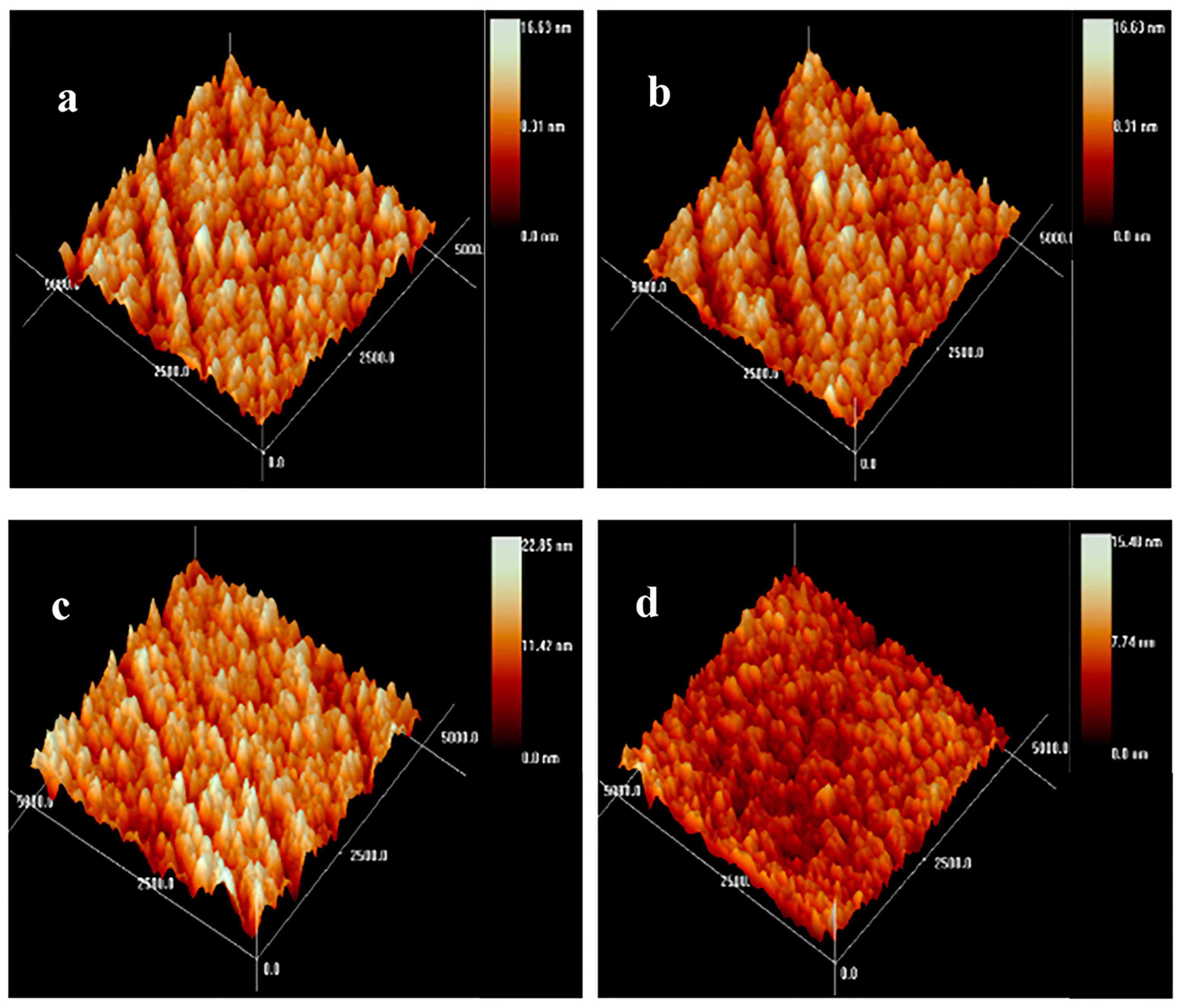

3.3. Morphology Analysis

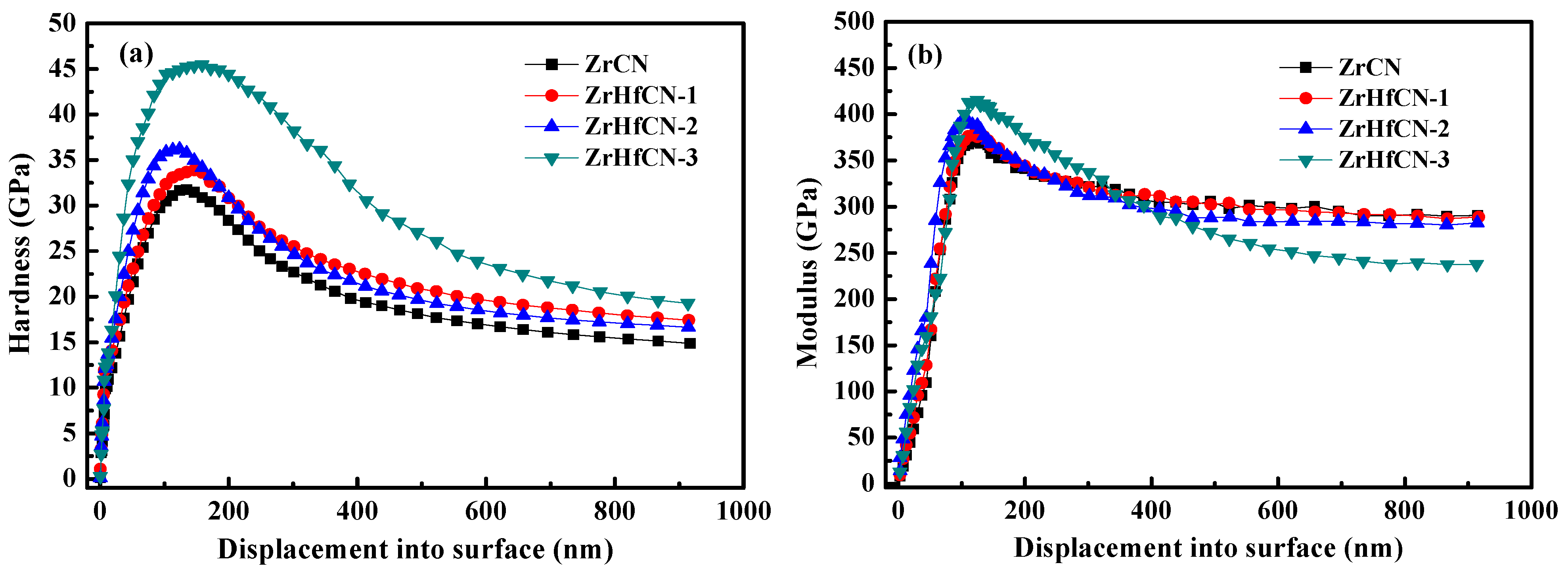

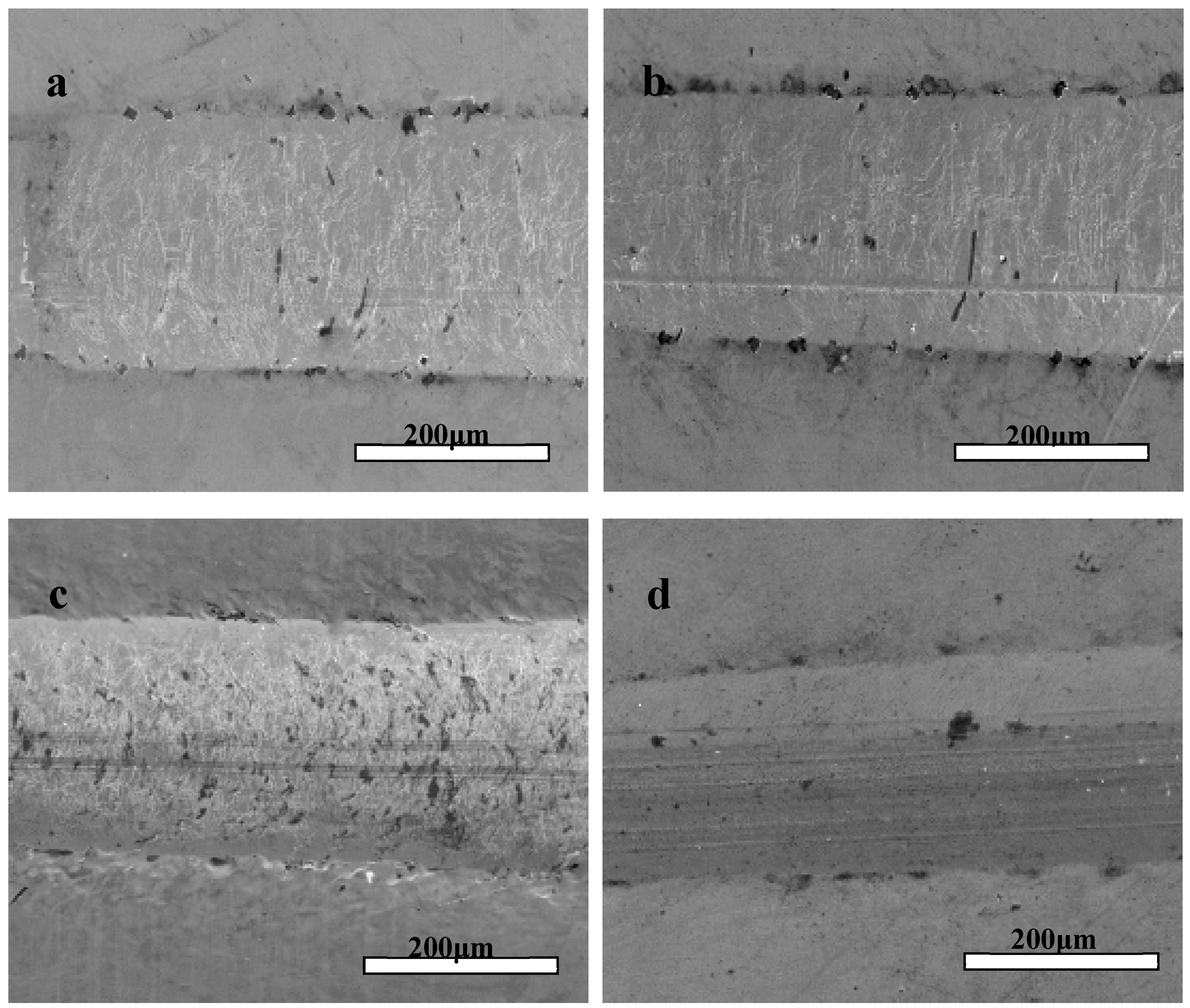

3.4. Mechanical Properties

3.5. Corrosion Resistance

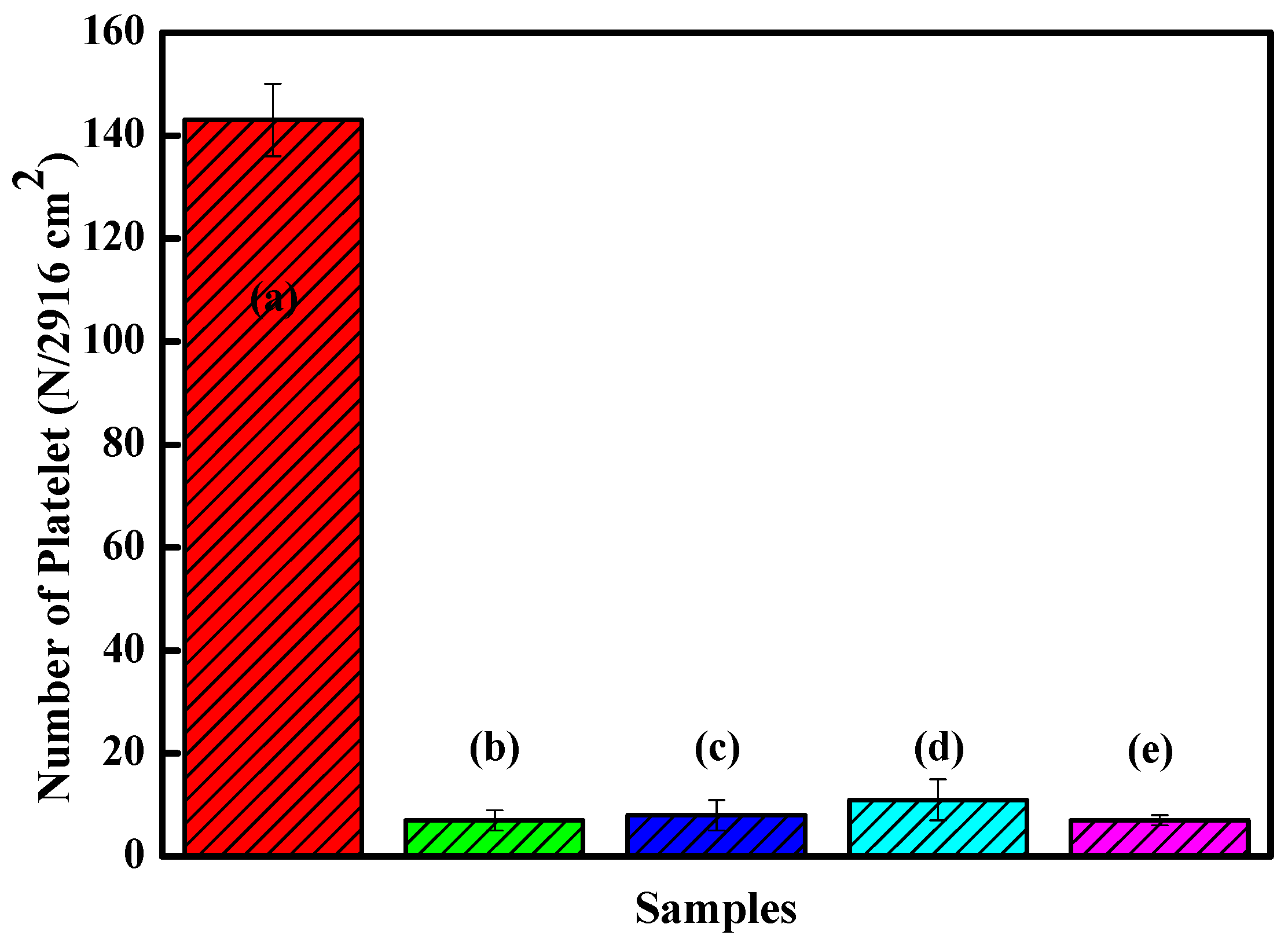

3.6. Surface Compatibility

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Park, J.B.; Kim, Y.K.; Park, J.B.; Bronzino, J.D. (Eds.) Biomaterials Principles and Applications; CRC Press: Boca Raton, FL, USA, 2003; pp. 1–20. [Google Scholar]

- Guo, D.; Chen, J.; Wen, L.; Wang, P.; Xu, S.; Cheng, J.; Wen, X.; Wang, S.; Huang, C.; Pi, P. A superhydrophobic polyacrylate film with good durability fabricated via spray coating. J. Mater. Sci. 2018, 53, 15390–15400. [Google Scholar] [CrossRef]

- Richards, B.T.; Zhao, H.; Wadley, H.N.G. Structure, composition, and defect control during plasma spray deposition of ytterbium silicate coatings. J. Mater. Sci. 2015, 50, 7939–7957. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, H.J.; Zhao, Z.H. Review of the biocompatibility of micro-arc oxidation coated titanium alloys. Mater. Design 2015, 85, 640–652. [Google Scholar] [CrossRef]

- Parsapour, A.; Khorasani, S.N.; Fathi, M.H. Effect of surface treatment and metallic coating on corrosion behavior and biocompatibility of surgical 316L stainless steel implant. J. Mater. Sci. Technol. 2012, 28, 125–131. [Google Scholar] [CrossRef]

- Penttila, S.; Toivonen, A.; Li, H.; Zheng, W.; Novotny, R. Effect of surface modification on the corrosion resistance of austenitic stainless steel 316L in supercritical water conditions. J. Supercrit. Fluids 2013, 81, 157–163. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Zhou, Z.; Li, L.K.-Y.; Yan, J. Electrochemical performance of TiCN coatings with low carbon concentration in simulated body fluid. Surf. Coat. Technol. 2014, 253, 199–204. [Google Scholar] [CrossRef]

- Gilewicz, A.; Chmielewska, P.; Murzynski, D.; Dobruchowska, E.; Warcholinski, B. Corrosion resistance of CrN and CrCN/CrN coatins deposited using cathodic arc evaporation in Ring’s and Hank’s solutions. Surf. Coat. Technol. 2016, 299, 7–14. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, X.; Ding, M.; Zheng, H.; Zhang, H.; Zhang, B.; Li, X.; Wu, G. Surface modification of biomedical AISI 316L stainless steel with zirconium carbonitride coatings. Appl. Surf. Sci. 2015, 340, 113–119. [Google Scholar] [CrossRef]

- Xie, Z.-H.; Shan, S. Nanocontainers-enhanced self-healing Ni coating for corrosion protection of Mg alloy. J. Mater. Sci. 2018, 53, 3744–3755. [Google Scholar] [CrossRef]

- Silva, E.; de Figueriredo, M.R.; Franz, R.; Galindo, R.E.; Palacio, C.; Espinosa, A.; Calderon, V.S.; Mitterer, C.; Carvalho, S. Structure-property relations in ZrCN coatings for tribological applications. Surf. Coat. Technol. 2010, 205, 2134–2141. [Google Scholar] [CrossRef]

- Larijani, M.M.; Zanjanbar, M.B.; Majdabadi, A. The effect of carbon fraction in Zr(C,N) films on the nano-structure properties and hardness. J. Alloys Compd. 2010, 492, 735–738. [Google Scholar] [CrossRef]

- Cotrut, C.M.; Braic, V.; Balaceanu, M.; Titorencu, I.; Braic, M.; Parau, A.C. Corrosion resistance, mechanical properties and biocompatibility of Hf-containing ZrCN coatings. Thin Solid Film. 2013, 538, 48–55. [Google Scholar] [CrossRef]

- Braic, M.; Balaceanu, M.; Vladescu, A.; Zoita, C.N.; Braic, V. Study of (Zr,Ti)CN, (Zr,Hf)CN and (Zr,Nb)CN films prepared by reactive magnetron sputtering. Thin Solid Film. 2011, 519, 4092–4096. [Google Scholar] [CrossRef]

- Negrila, C.-C.; Lazarescu, M.F.; Logofatu, C.; Cotirlan, C.; Ghita, R.V.; Frumosu, F.; Trupina, L. XPS Analysis of AuGeNi/Cleaved GaAs (110) interface. J. Cryst. Growth 2008, 310, 1576. [Google Scholar] [CrossRef]

- Zhao, J.P.; Chen, Y.; Tu, M. Improving blood-compatibility via surface heparin-immobilization based on a liquid crystalline matrix. Mater. Sci. Eng. C 2016, 58, 133–141. [Google Scholar] [CrossRef]

- Ferreri, I.; Henriques, M.; De Hosson, J.T.M.; Cavaleiro, A.; Carvalho, S. Nano-galvanic coupling for enhanced Af= release in ZrCN-Ag films: Antibacterial application. Surf. Coat. Technol. 2016, 298, 1–6. [Google Scholar]

- Zhou, F.Z.; Fu, K.H.; Liao, B.; Yu, J.; Yang, C.; Zhang, X. Effect of carbon content on nanostructural, mechanical and electrochemical characteristics of self-organized nc-ZrCN/a-CNx nanocomposite films. Appl. Surf. Sci. 2015, 327, 350–357. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, Y.; Chen, H.; Li, J.; Zhou, S.; Xue, Q. Influences of bias voltage on the microstructures and tribological performances of Cr-C-N coatings in seawater. Surf. Coat. Technol. 2015, 270, 305–313. [Google Scholar] [CrossRef]

- Sowjanya, V.; Bangera, K.V.; Shivakumar, G.K. Effect of substrate temperature and film thickness on the thermoelectric properties of In2Te3 thin films. J. Alloys Compd. 2017, 714, 224–229. [Google Scholar] [CrossRef]

- Braic, V.; Braic, M.; Balaceanu, M.; Vladescu, A.; Zoita, C.; Titorencu, I.; Jinga, V. (Zr, Ti)CN coatings as potential candidates for biomedical applications. Surf. Coat. Technol. 2011, 206, 604–609. [Google Scholar] [CrossRef]

- Lofaj, F.; Hviščová, P.; Zubko, P.; Kabátová, M. Mechanical and tribological properties of the high target utilization sputtering W-C coatings on different substrate. Int. J. Refract. Met. Hard Mater. 2017, 80, 305–314. [Google Scholar] [CrossRef]

- Tétard, F.; Djemia, P.; Angleraud, B.; Mubumbila, N.; Tessier, P.Y. Surface and bulk characterization of CNx thin film made by r.f. magnetron sputtering. Surf. Coat. Technol. 2002, 151–152, 184–188. [Google Scholar] [CrossRef]

- Vitelaru, C.; Balaceanu, M.; Parau, A.; Luculescu, C.R.; Vladescu, A. Investigation of nanostructured TiSiC-Zr and TiSiC-Cr hard coatings for industrial applications. Surf. Coat. Technol. 2014, 251, 21–28. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Luo, P.; Chen, W.Z.; Pan, S.R.; Chen, D.H. Hemocompatibility of ZnO thin films prepared by filtered cathodic vacuum are deposition. Vacuum 2013, 89, 220–224. [Google Scholar] [CrossRef]

- Kwok, S.C.H.; Ha, P.C.T.; Mckenzie, D.R.; Bilek, M.M.M.; Chu, P.K. Biocompatibility of calcium and phospuorus doped diamond-like films synthesized by plasma immersion ion implantation and deposition. Diam. Relat. Mater. 2006, 15, 893–897. [Google Scholar] [CrossRef]

- Viteri, V.S.; Barandika, G.; Peremarch, C.P.J. Development of Ti-C-N coatings with improved tribological behavior and antibacterial properties. J. Mech. Hehav. Biomed. 2016, 55, 75–86. [Google Scholar] [CrossRef]

- Zhang, P.R.; Liu, Z.Q. Enhancing surface integrity and corrosion resistance of laser cladded Cr-Ni alloys by hard turning and low plasticity burnishing. Appl. Surf. Sci. 2017, 409, 169–178. [Google Scholar] [CrossRef]

- Li, W.; Ming-hui, D.; Hong-sen, Z.; Bin, Z. Study on HfCxN1-x coatings deposited on biomedical AISI 316L by radio-frequency magnetron sputtering. J. Alloys Comp. 2018, 730, 219–227. [Google Scholar] [CrossRef]

- Khiabani, A.B.; Ebrahimi, S.; Yarmand, B. Highly corrosion protection properties of plasma electrolytic oxidized titanium usiong rGO nanosheets. Appl. Surf. Sci. 2019, 486, 153–165. [Google Scholar] [CrossRef]

- Hou, X.L.; Ren, Q.Y.; Yang, Y.; Cao, X.L.; Hu, J.; Zhang, C.; Deng, H.; Yu, D.; Li, K.; Lan, W. Effect of temperature on the electrochemical pitting corrosion behavior of 316L stainless steel in chloride-containing MDEA solution. J. Net. Gas. Sci. Eng. 2021, 86, 103718. [Google Scholar] [CrossRef]

| Samples | Element Content (%) | (C + N)/(Zr + Hf) | N/C | ||||

|---|---|---|---|---|---|---|---|

| Zr | Hf | C | N | O | |||

| ZrCN | 34.42 | - | 35.81 | 25.31 | 4.47 | 1.78 | 0.71 |

| ZrHfCN−1 | 26.34 | 2.75 | 39.84 | 26.91 | 4.17 | 2.20 | 0.66 |

| ZrHfCN−2 | 24.67 | 4.79 | 39.74 | 26.73 | 4.07 | 2.26 | 0.64 |

| ZrHfCN−3 | 22.03 | 7.33 | 41.83 | 25.69 | 3.22 | 2.30 | 0.61 |

| Samples | Thickness (μm) | Deposition Rate (nm/min) | Surface Roughness (nm) |

|---|---|---|---|

| ZrCN | 1.08 ± 0.03 | 9 | 3.86 ± 0.03 |

| ZrHfCN−1 | 1.18 ± 0.06 | 9.83 | 3.72 ± 0.07 |

| ZrHfCN−2 | 1.21 ± 0.02 | 10.08 | 3.67 ± 0.06 |

| ZrHfCN−3 | 1.28 ± 0.03 | 10.67 | 3.31 ± 0.05 |

| Samples | Hardness (GPa) | Modulus (GPa) | H/E | H3/E2 (GPa) | Lc (N) |

|---|---|---|---|---|---|

| ZrCN | 31.03 ± 0.4 | 359.58 ± 1.5 | 0.0863 | 0.2311 | 42 ± 1.3 |

| ZrHfCN−1 | 34.05 ± 0.5 | 366.72 ± 1.9 | 0.0929 | 0.3022 | 43.1 ± 0.8 |

| ZrHfCN−2 | 36.82 ± 0.3 | 370.09 ± 1.4 | 0.0995 | 0.3644 | 44.8 ± 1.8 |

| ZrHfCN−3 | 41.94 ± 0.1 | 381.28 ± 1.6 | 0.1099 | 0.5075 | 45.7 ± 1.2 |

| Samples | Icorr (A/cm2) | Ecorr (V) | P (E−10) |

|---|---|---|---|

| 316L SS | 4.19 × 10−12 | −0.202 | - |

| ZrCN | 1.72 × 10−14 | −0.098 | 0.97 |

| ZrHfCN−1 | 2.26 × 10−14 | −0.096 | 0.03 |

| ZrHfCN−2 | 7.74 × 10−15 | −0.091 | 0.025 |

| ZrHfCN−3 | 6.54 × 1015 | −0.083 | 0.022 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Pei, D.; Deng, C.-Y.; Yang, H.-S.; Hu, Z.-N.; Zhao, J.-Y.; He, D.; Ding, M.-H.; Zhang, B.; Hu, L. Effect of Hafnium Addition on the Microstructure and Property Evolutions of ZrCN Coating Prepared via Physical Vapor Deposition. Coatings 2023, 13, 1408. https://doi.org/10.3390/coatings13081408

Wang L, Pei D, Deng C-Y, Yang H-S, Hu Z-N, Zhao J-Y, He D, Ding M-H, Zhang B, Hu L. Effect of Hafnium Addition on the Microstructure and Property Evolutions of ZrCN Coating Prepared via Physical Vapor Deposition. Coatings. 2023; 13(8):1408. https://doi.org/10.3390/coatings13081408

Chicago/Turabian StyleWang, Li, Di Pei, Chun-Yan Deng, Hai-Shi Yang, Zhao-Nan Hu, Jun-Yu Zhao, Dong He, Ming-Hui Ding, Bin Zhang, and Li Hu. 2023. "Effect of Hafnium Addition on the Microstructure and Property Evolutions of ZrCN Coating Prepared via Physical Vapor Deposition" Coatings 13, no. 8: 1408. https://doi.org/10.3390/coatings13081408

APA StyleWang, L., Pei, D., Deng, C.-Y., Yang, H.-S., Hu, Z.-N., Zhao, J.-Y., He, D., Ding, M.-H., Zhang, B., & Hu, L. (2023). Effect of Hafnium Addition on the Microstructure and Property Evolutions of ZrCN Coating Prepared via Physical Vapor Deposition. Coatings, 13(8), 1408. https://doi.org/10.3390/coatings13081408