An Evaluation of Asphalt Mixture Crack Resistance and Identification of Influential Factors

Abstract

:1. Introduction

2. Materials Preparation and Test Method

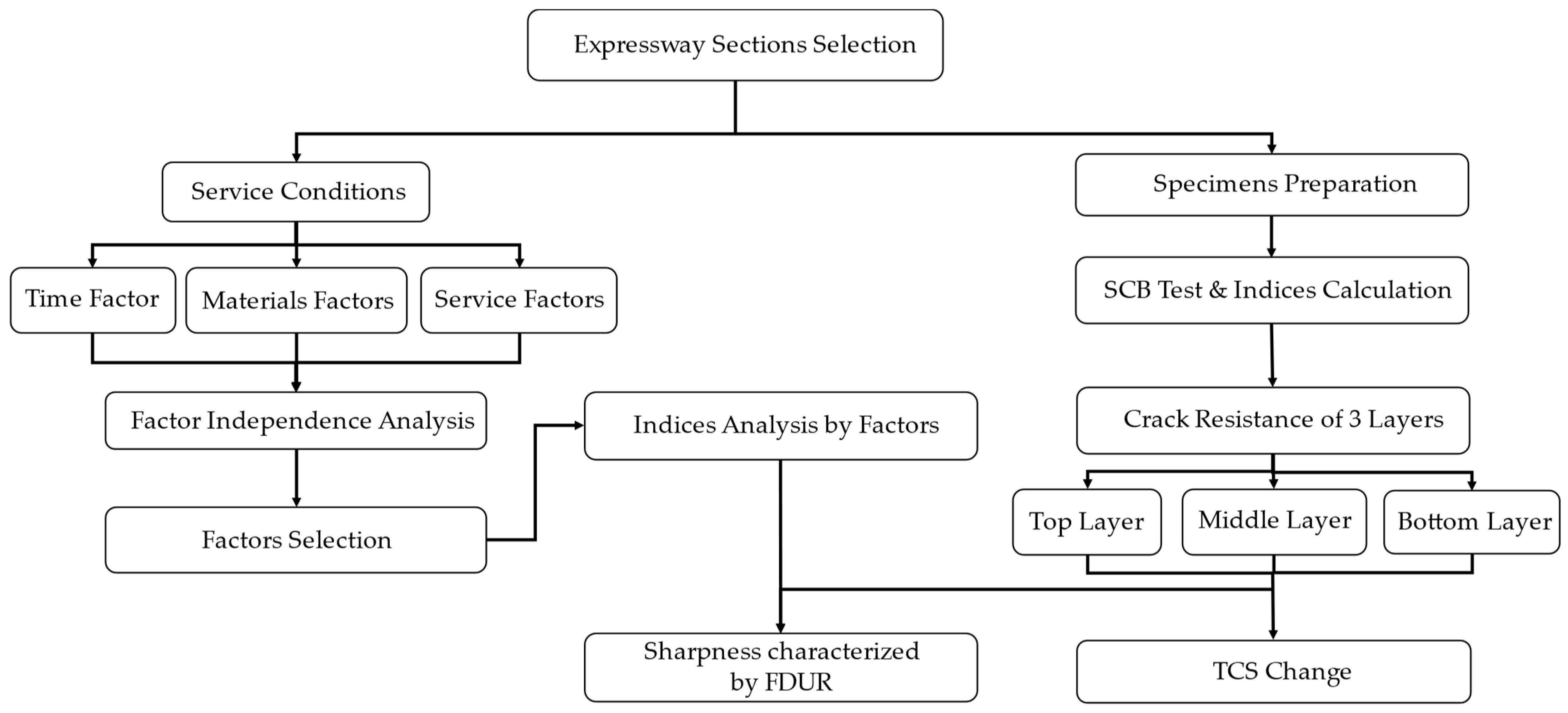

2.1. Pavement Section Selection and Factors Indentification

2.2. Specimens Preparation

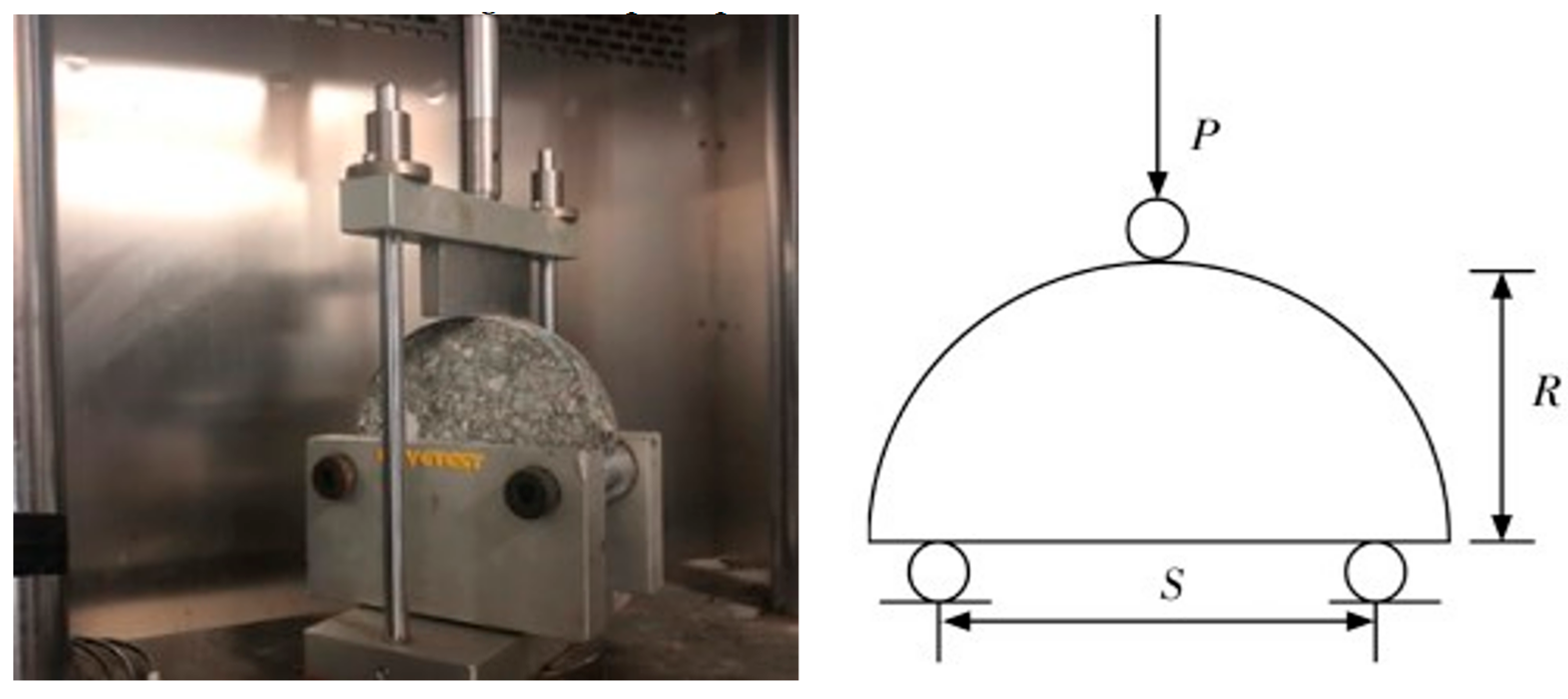

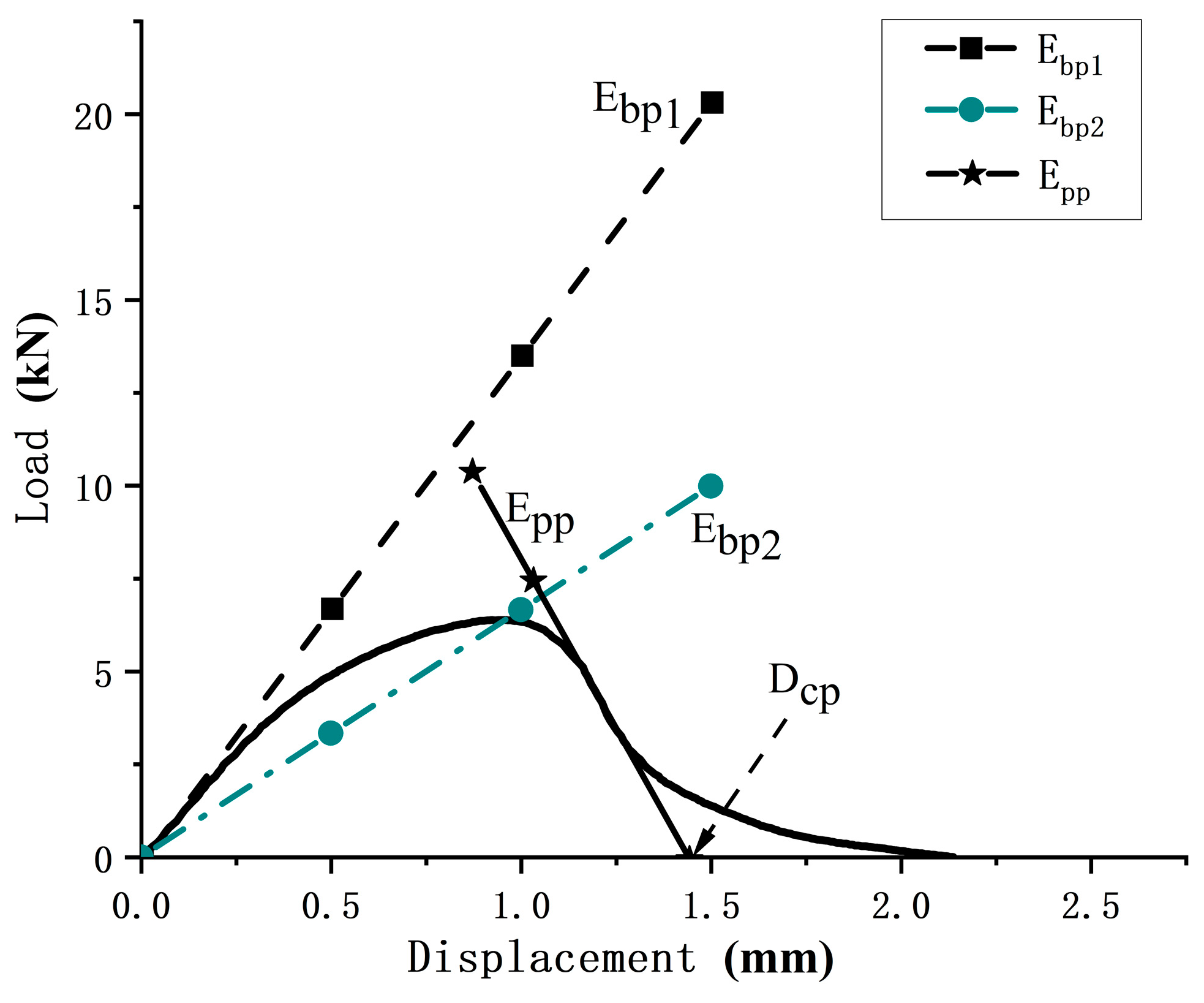

2.3. SCB Test and Indices

2.4. Significance Factors Analysis

3. Results and Discussion

3.1. Factor Independence Analysis

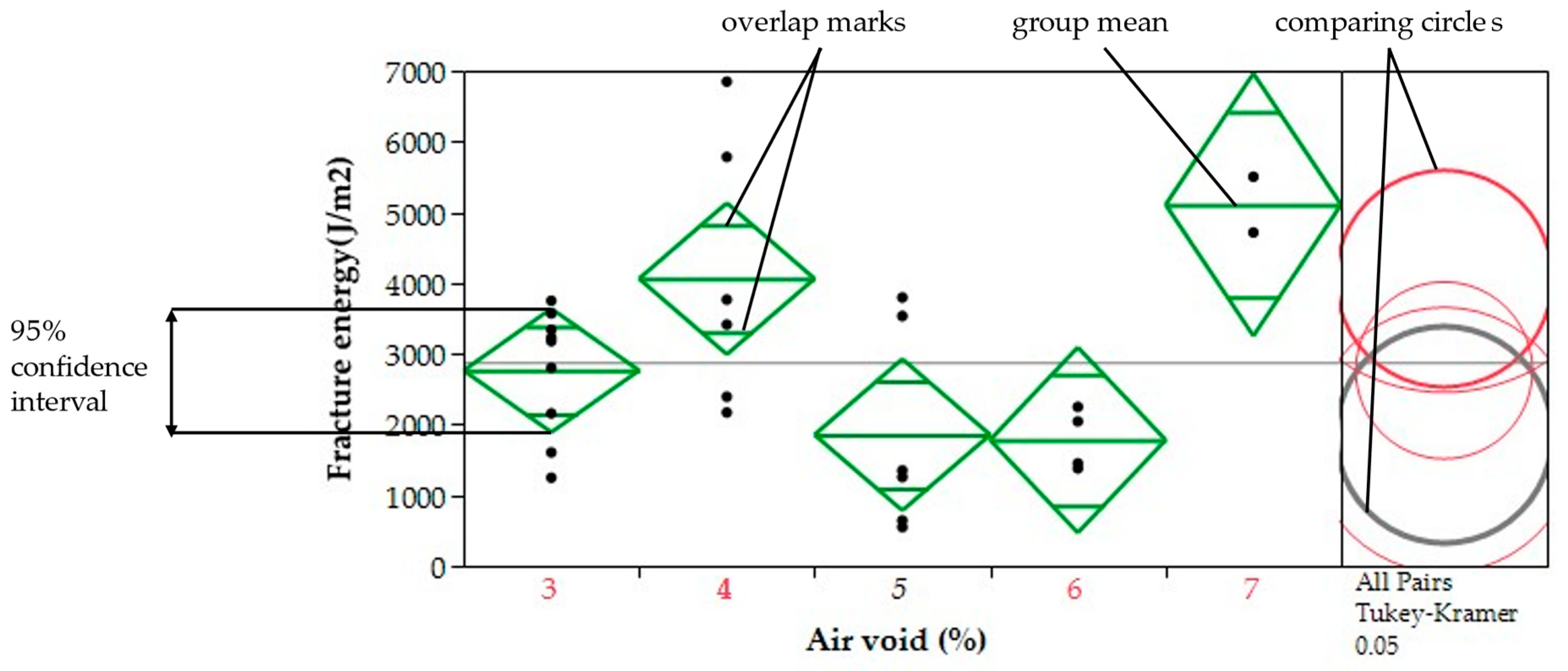

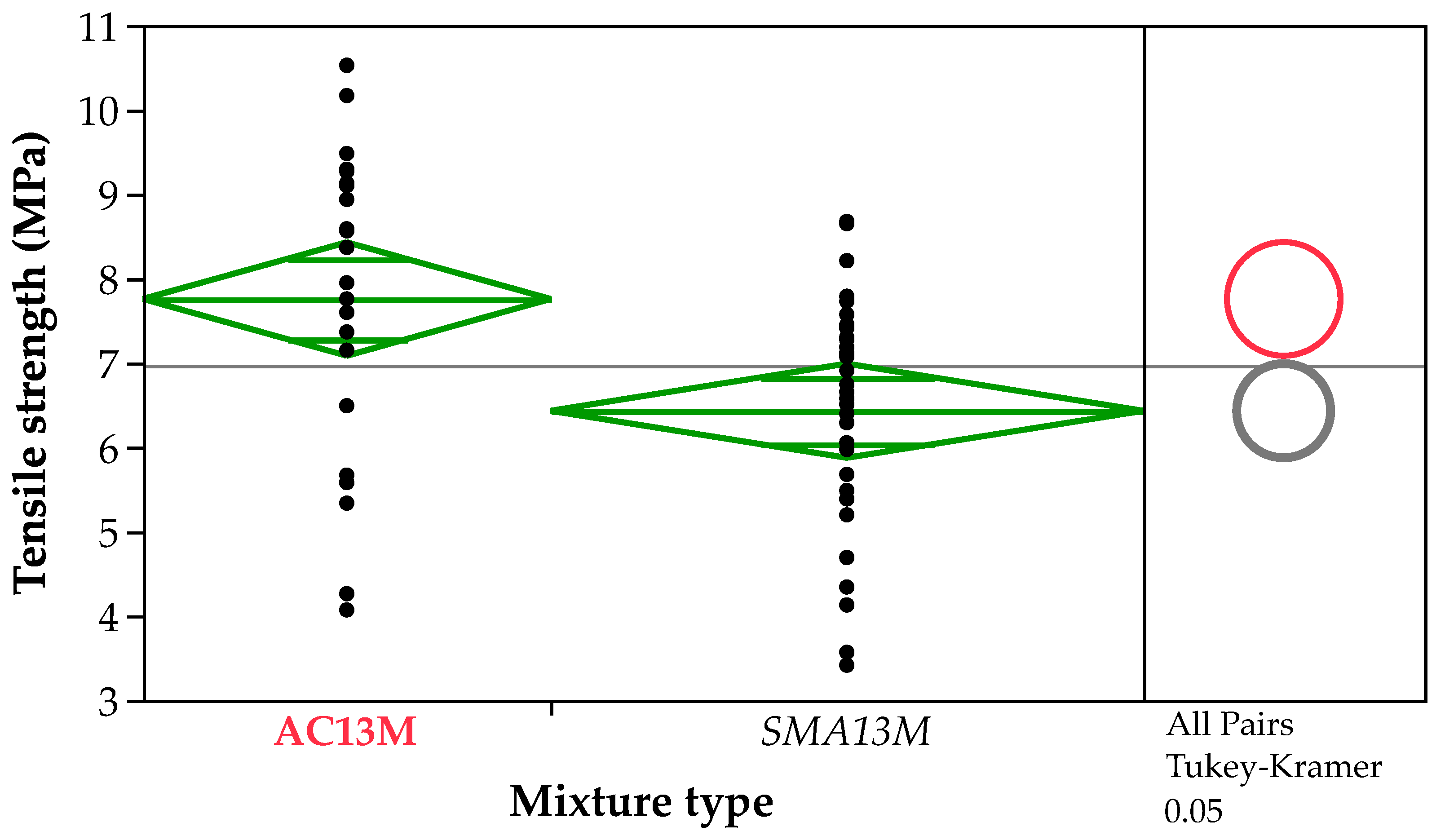

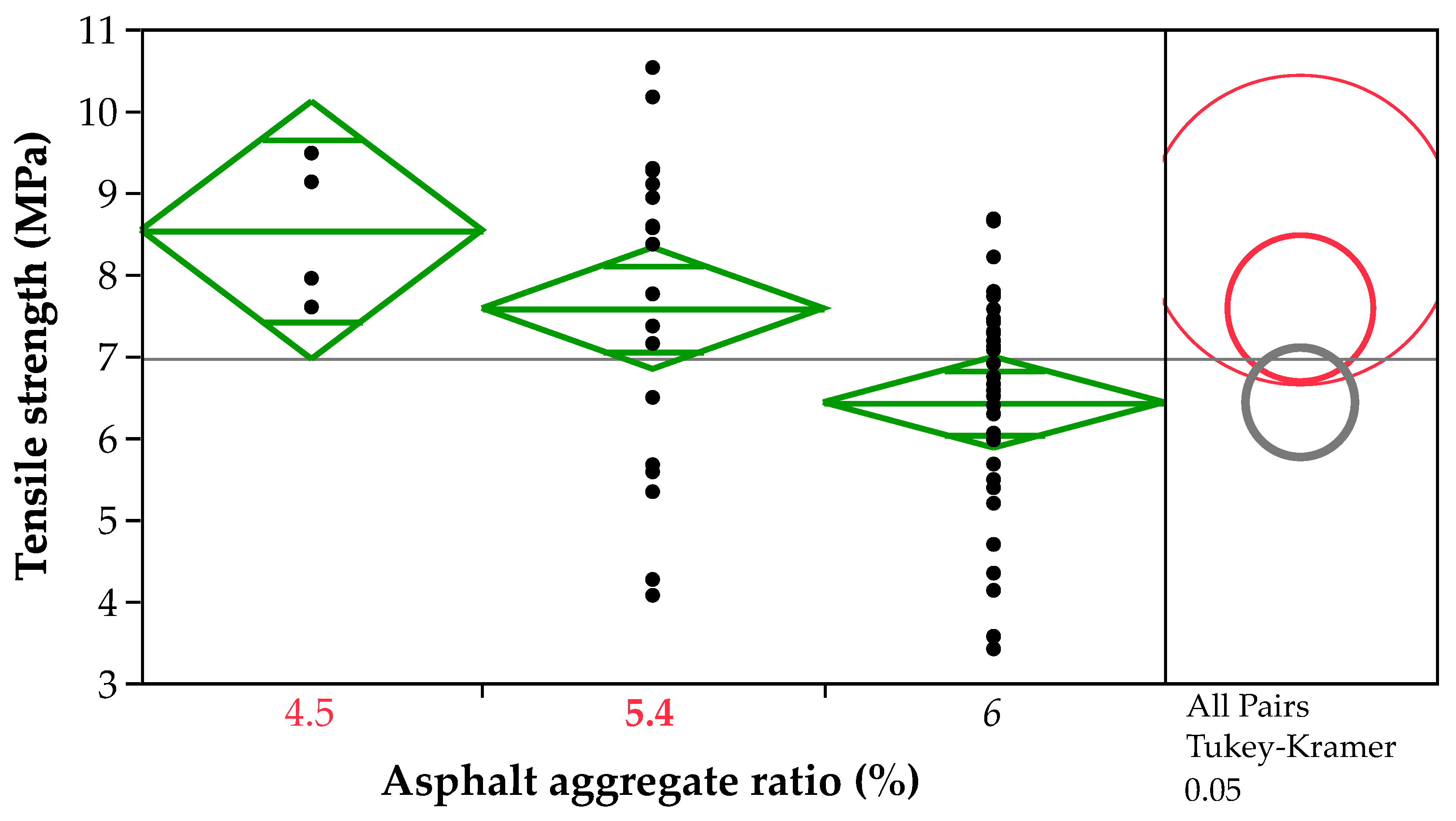

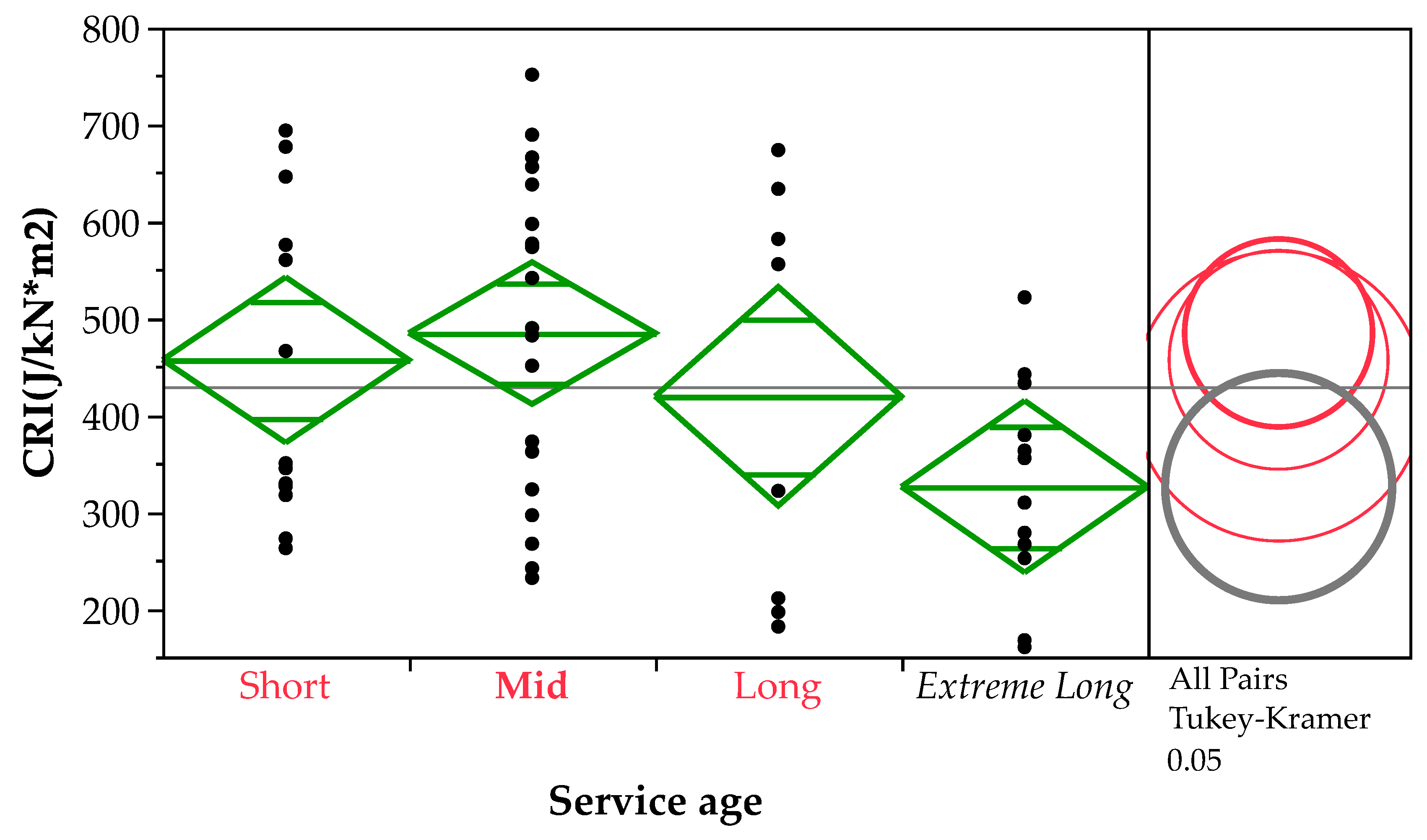

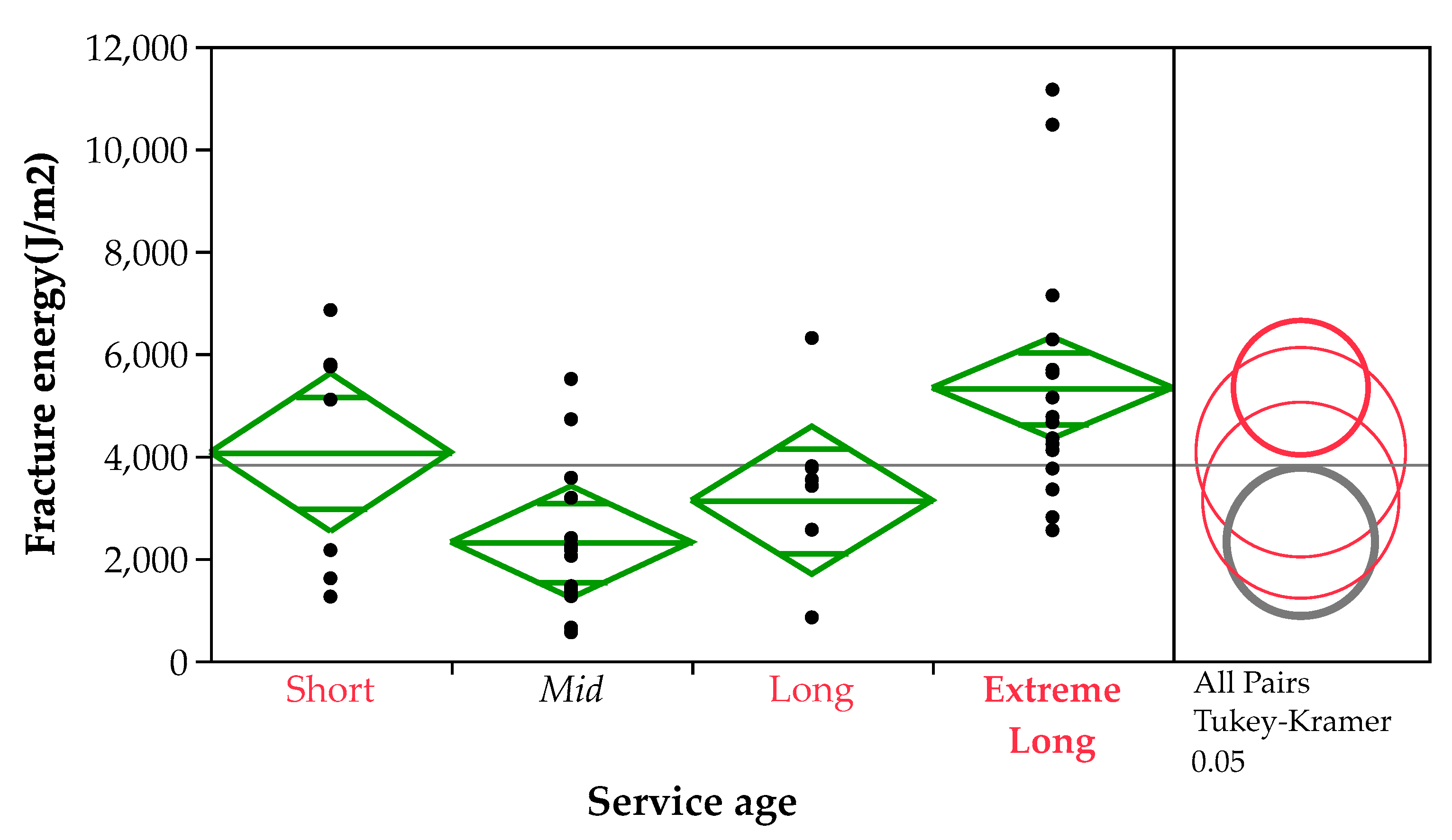

3.2. Indices Analysis Results by Factors

3.3. Crack-resistance performance on Three-Layer Specimens

3.3.1. Crack-resistance performance Change on Surface Layer Specimens

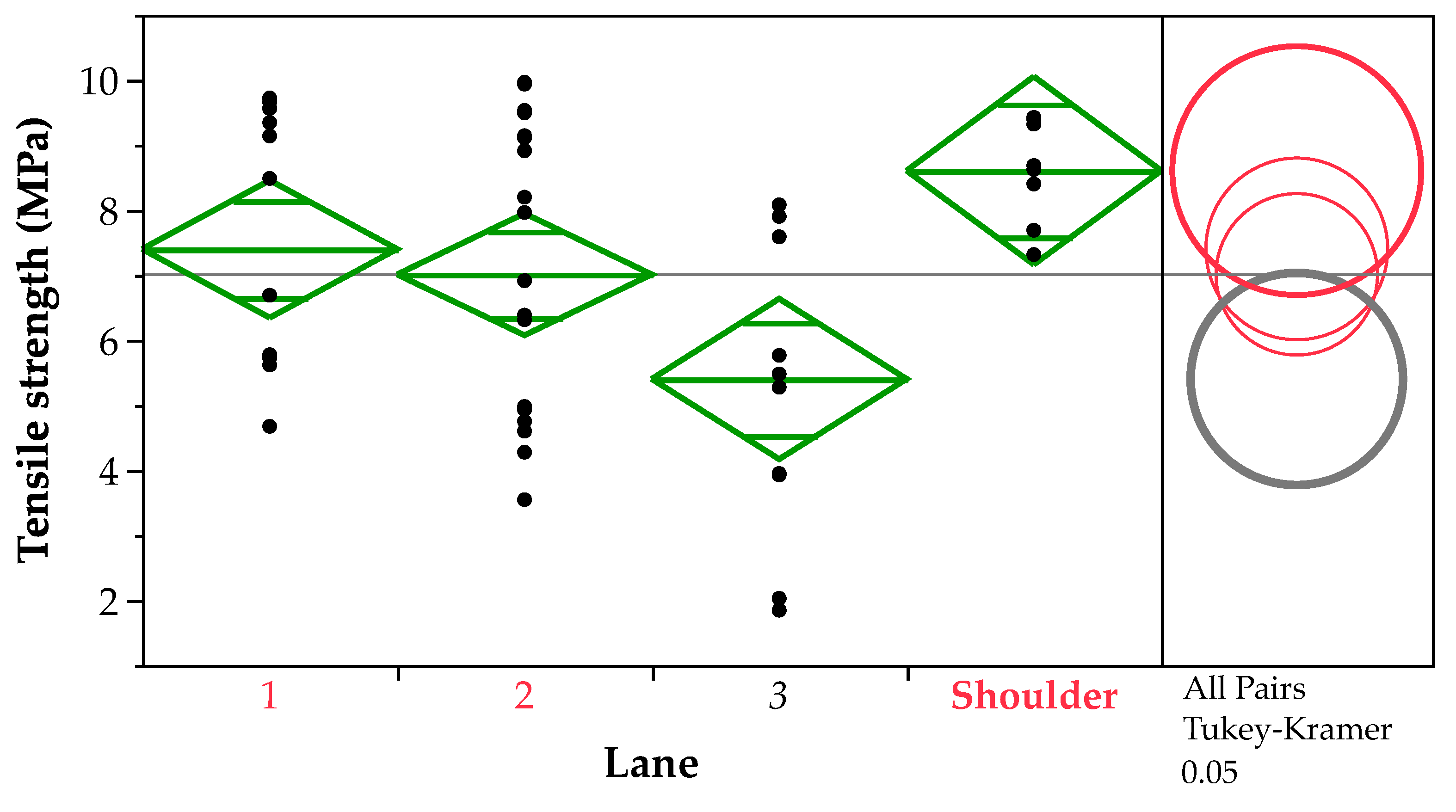

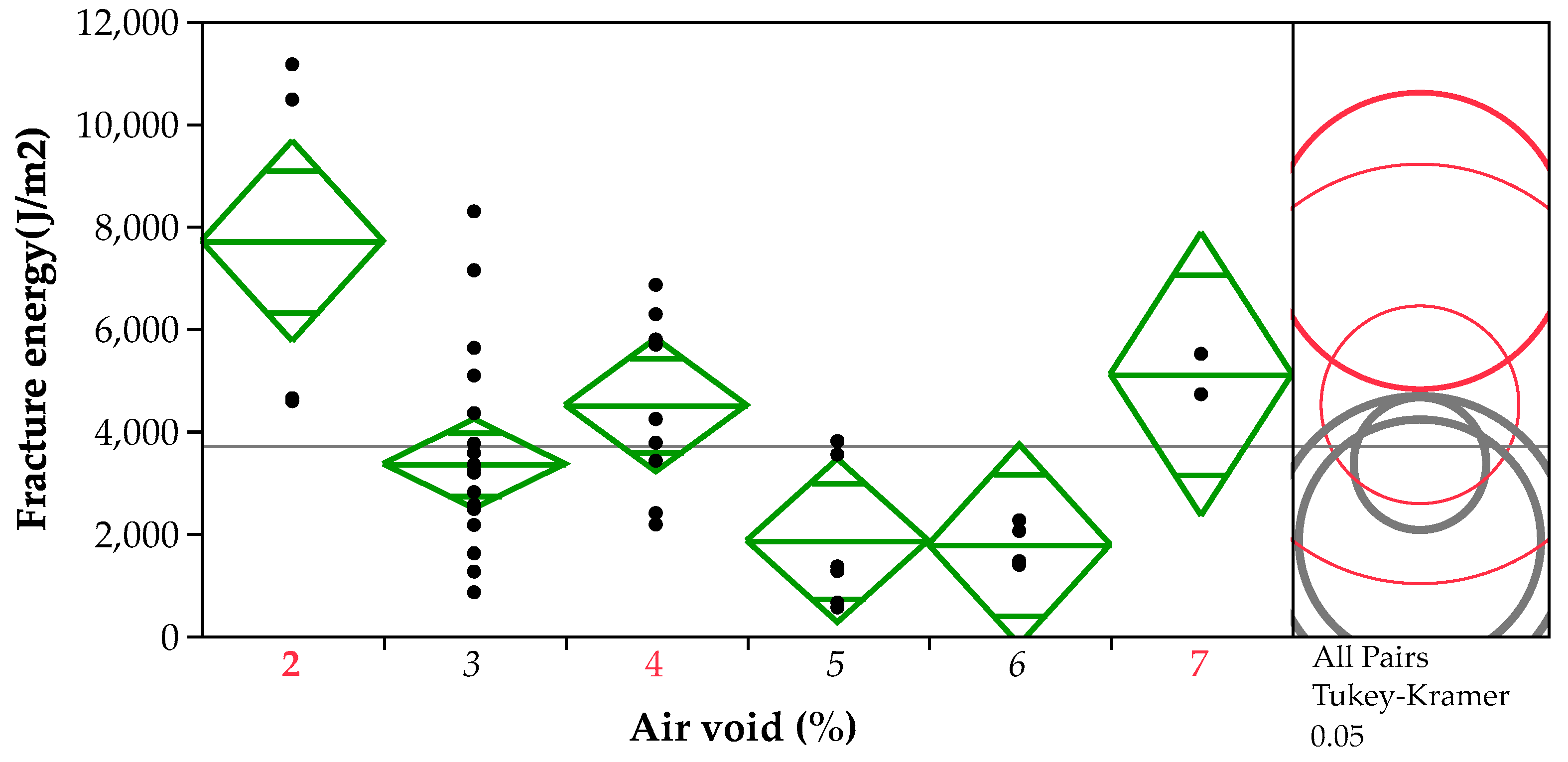

3.3.2. Crack-Resistance Performance Change in Middle-Layer Specimens

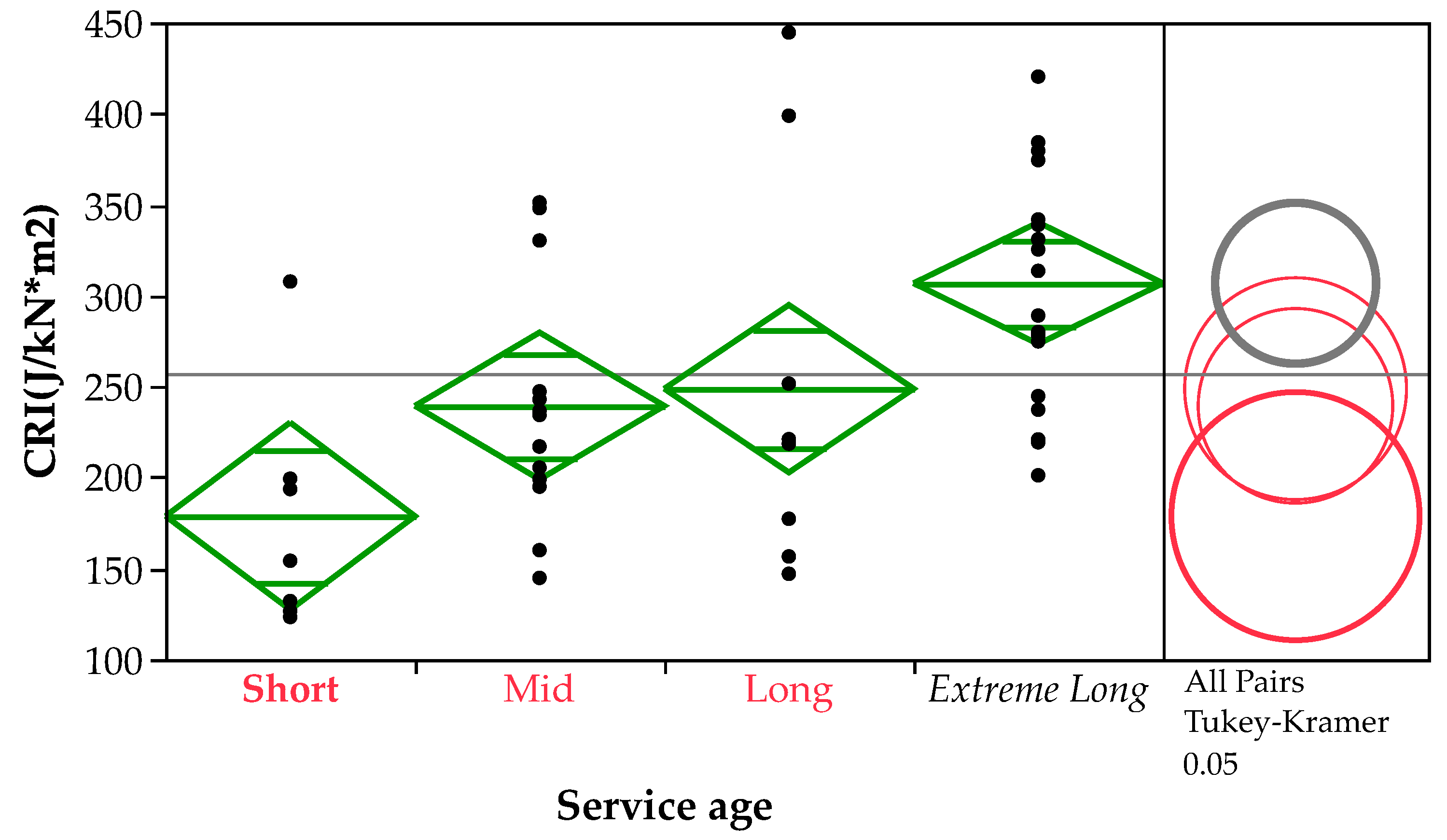

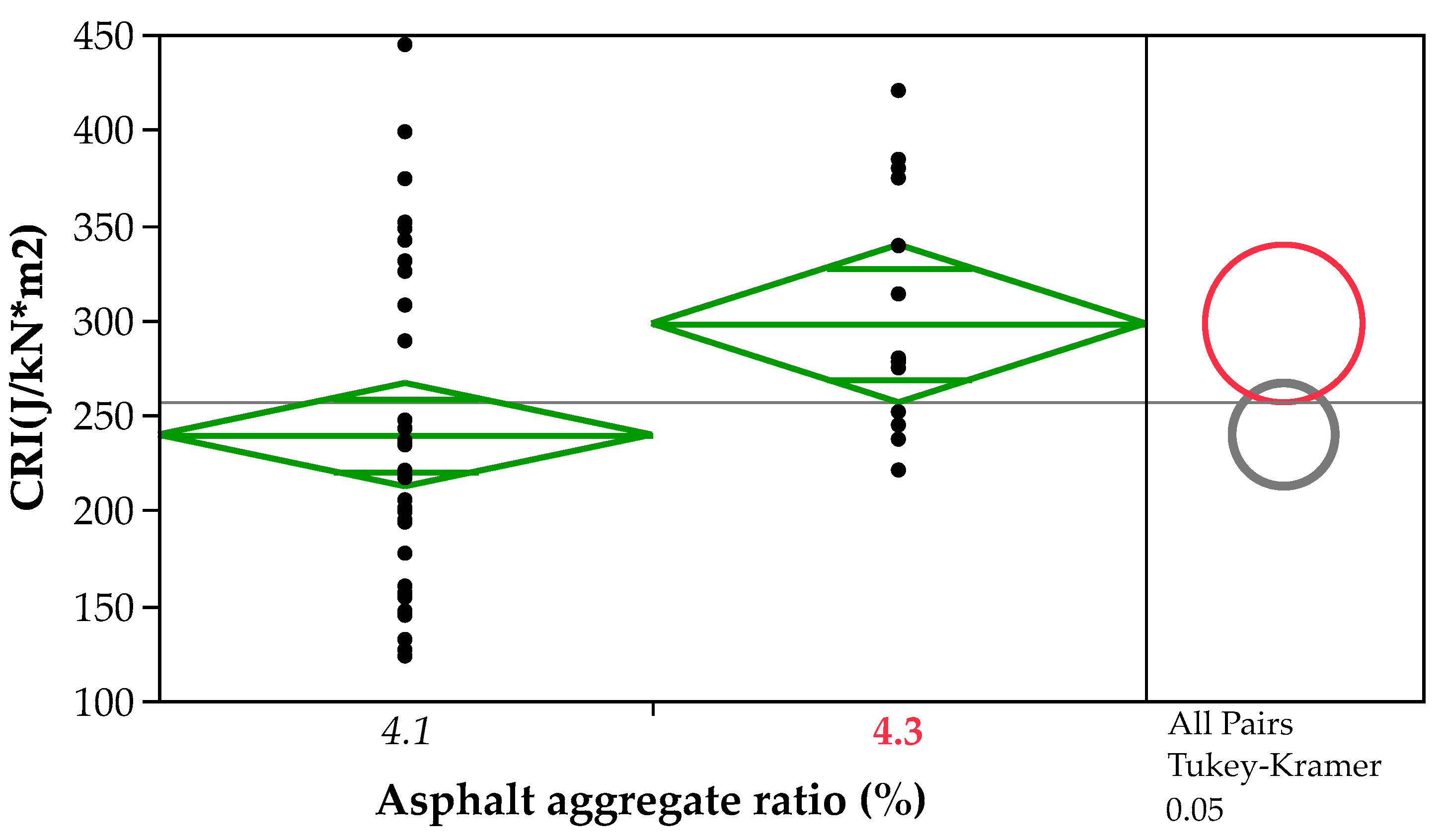

3.3.3. Crack Resistance Change on Bottom-Layer Specimens

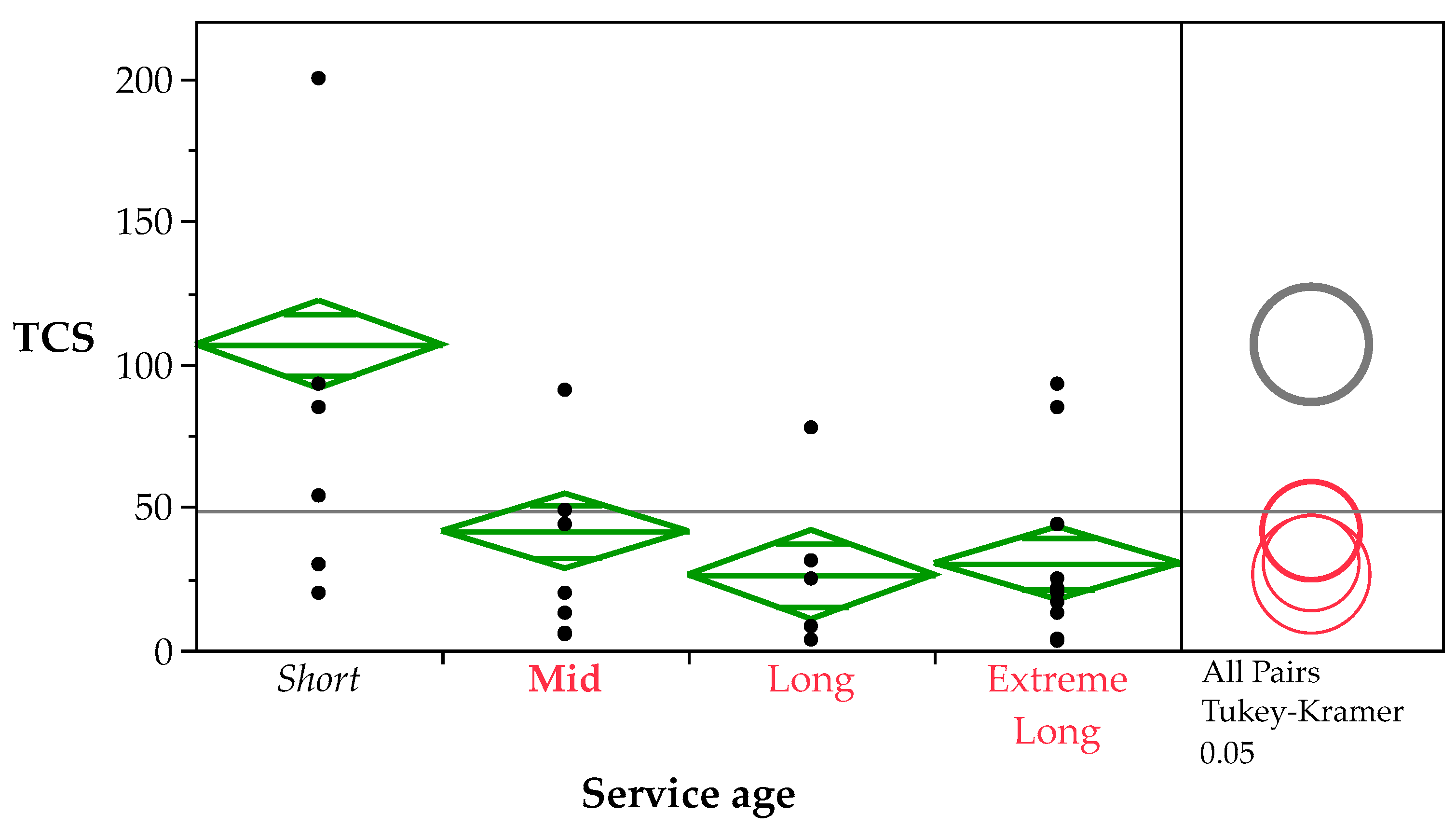

3.3.4. TCS Indicated by Fracture Indices of Mixture

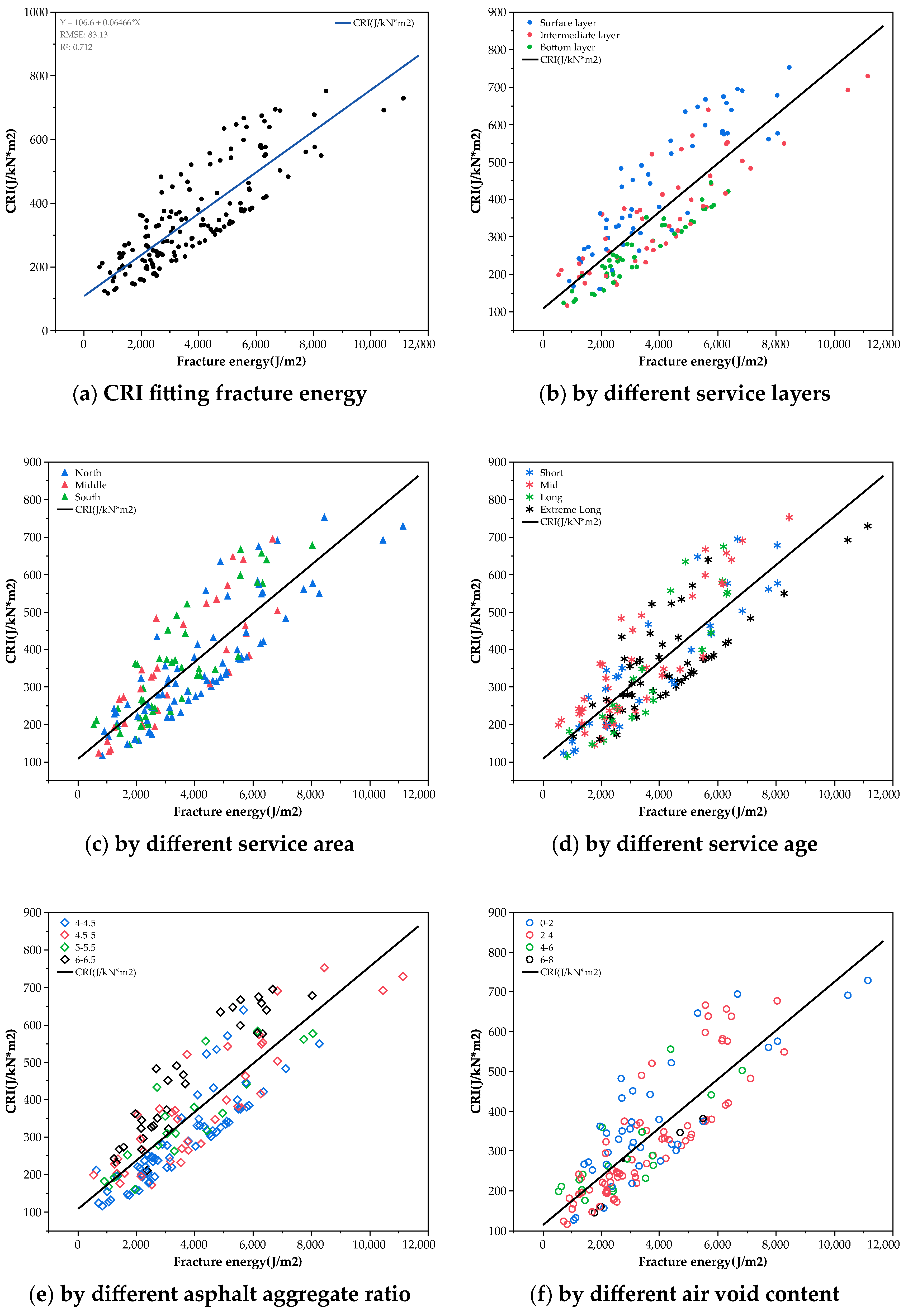

3.3.5. Correlation between CRI with Fracture Energy and Index FUDR Analysis

4. Conclusions

- Several representative expressway sections were selected and the SCB intermediate temperature fracture test was conducted. The factors independence analysis and different indices for different layers were applied. Service age and air void are independent factors for all three layers. The mixture type is a significant factor in relation to tensile strength on surface-layer specimens, lane is a significant factor to tensile strength on middle layers and the asphalt aggregate ratio is a significant factor to CRI on bottom layers.

- ANOVA and Tukey–Kramer comparison analysis of three layers was conducted and the indices of each layer and factors were analyzed. The most important factors affecting mixture crack resistance were one time factor (service age) and one material factor like air voids or the asphalt aggregate ratio. Only middle-layer specimens have another environmental factor lane, and lane 3 with the most truck loads has the lowest crack resistance of all lanes.

- For the surface layer, AC13M’s crack resistance is significantly larger than SMA13M’s, the crack resistance of 4.5% and 5% asphalt aggregate ratio specimens is significantly larger than that of the 6% ratio specimens, the crack resistance of extremely long service age specimens is significantly smaller than short, mid and long service age specimens. For the middle layer, the crack resistance of mid service age specimens is significantly smaller than the crack resistance of short, long and extremely long service age specimens. For the bottom layer, the crack resistance of 4.1% asphalt aggregate ratio specimens is significantly smaller than the crack resistance of 4.3% asphalt aggregate ratio specimens, while the crack resistance of extremely long service age specimens is significantly smaller than the crack resistance of short, mid and long service age specimens.

- Only the CRI index of the bottom-layer mixture has a significant relationship with TCS of the section from which the mixture was cored, while other mixture indices cannot represent the pavement transverse crack spacing of the section. The pavement sections with many transverse cracks may not have low crack-resistance mixtures.

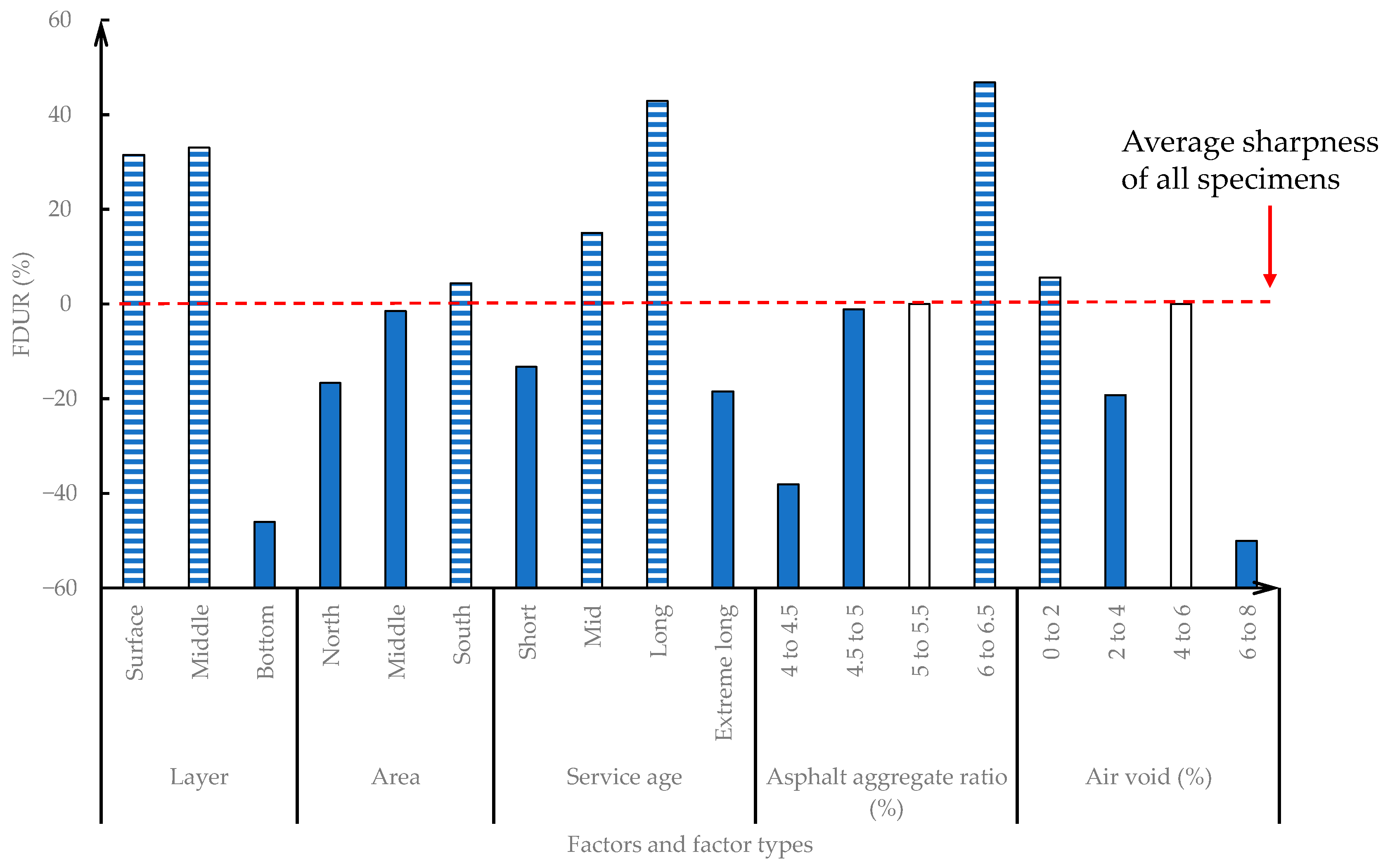

- The index FUDR and its absolute value absFUDR are promoted as an index for determining if a mixture of a certain factor type is softer or tougher than average on a statistical level. And this index is sensitive to many factors. The specimens with surface layer, middle layer, long service age or a 6% to 6.5% asphalt aggregate ratio are obviously softer than others and have an obviously flatter load–displacement curve on a statistical level.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, H.P.; Guo, Y.X.; Wu, M.Y.; Xiang, K.; Sun, S.R. Review on Structural Damage Rehabilitation and Performance Assessment of Asphalt Pavements. Rev. Adv. Mater. Sci. 2021, 60, 438–449. [Google Scholar] [CrossRef]

- Idris, I.I.; Sadek, H.; Hassan, M. State-of-the-Art Review of the Evaluation of Asphalt Mixtures’ Resistance to Reflective Cracking in Laboratory. J. Mater. Civ. Eng. 2020, 32, 03120004. [Google Scholar] [CrossRef]

- Gong, M.; Xiong, Z.; Chen, H.; Deng, C.; Chen, X.; Yang, J.; Zhu, H.; Hong, J. Evaluation on the Cracking Resistance of Semi-Flexible Pavement Mixture by Laboratory Research and Field Validation. Constr. Build. Mater. 2019, 207, 387–395. [Google Scholar] [CrossRef]

- Wu, S.; Wen, H.; Zhang, W.; Shen, S.; Mohammad, L.N.; Faheem, A.; Muhunthan, B. Field Performance of Top-down Fatigue Cracking for Warm Mix Asphalt Pavements. Int. J. Pavement Eng. 2019, 20, 33–43. [Google Scholar] [CrossRef]

- Zhou, L.; Ni, F.; Zhao, Y. Evaluation Method for Transverse Cracking in Asphalt Pavements on Freeways. Transp. Res. Rec. 2010, 2153, 97–105. [Google Scholar] [CrossRef]

- Canestrari, F.; Ingrassia, L.P.; Virgili, A. A Semi-Empirical Model for Top-down Cracking Depth Evolution in Thick Asphalt Pavements with Open-Graded Friction Courses. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 244–260. [Google Scholar] [CrossRef]

- Willis, J.R.; Taylor, A.J.; Nash, T.M. Laboratory and Field Evaluation of Florida Mixtures at the 2012 National Center for Asphalt Technology Pavement Test Track. Transp. Res. Rec. 2016, 2590, 65–73. [Google Scholar] [CrossRef]

- Saha, G.; Biligiri, K.P. Fracture Properties of Asphalt Mixtures Using Semi-Circular Bending Test: A State-of-the-Art Review and Future Research. Constr. Build. Mater. 2016, 105, 103–112. [Google Scholar] [CrossRef]

- Zaumanis, M.; Valters, A. Comparison of Two Low-Temperature Cracking Tests for Use in Performance-Based Asphalt Mixture Design. Int. J. Pavement Eng. 2020, 21, 1461–1469. [Google Scholar] [CrossRef]

- Du, H.; Ni, F.; Zhao, Y. Characterization of the Influence Factors of Low-Temperature Fracture Properties for Serving Asphalt Pavements Using Layer Core Samples. J. Transp. Eng. Part B Pavements 2021, 147, 04021016. [Google Scholar] [CrossRef]

- Seitllari, A.; Boz, I.; Habbouche, J.; Diefenderfer, S.D. Assessment of Cracking Performance Indices of Asphalt Mixtures at Intermediate Temperatures. Int. J. Pavement Eng. 2022, 23, 70–79. [Google Scholar] [CrossRef]

- Budziński, B.; Ratajczak, M.; Majer, S.; Wilmański, A. Influence of Bitumen Grade and Air Voids on Low-Temperature Cracking of Asphalt. Case Stud. Constr. Mater. 2023, 19, e02255. [Google Scholar] [CrossRef]

- Zhou, Z.; Gu, X.; Dong, Q.; Ni, F.; Jiang, Y. Low- and Intermediate-Temperature Behaviour of Polymer-Modified Asphalt Binders, Mastics, Fine Aggregate Matrices, and Mixtures with Reclaimed Asphalt Pavement Material. Road Mater. Pavement Des. 2020, 21, 1872–1901. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, Y.; Bahia, H.U. Comparison between SCB-IFIT, Un-Notched SCB-IFIT and IDEAL-CT for Measuring Cracking Resistance of Asphalt Mixtures. Constr. Build. Mater. 2020, 252, 119060. [Google Scholar] [CrossRef]

- Xu, D.; Ni, F.; Du, H.; Zhao, Z.; Wang, J.; Chen, S. Investigation of Factors Affecting the Intermediate-Temperature Cracking Resistance of In-Situ Asphalt Mixtures Based on Semi-Circular Bending Test. Coatings 2023, 13, 384. [Google Scholar] [CrossRef]

- Zhou, F.; Im, S.; Hu, S.; Newcomb, D.; Scullion, T. Selection and Preliminary Evaluation of Laboratory Cracking Tests for Routine Asphalt Mix Designs. Road Mater. Pavement Des. 2017, 18, 62–86. [Google Scholar] [CrossRef]

- Batioja-Alvarez, D.; Lee, J.; Haddock, J.E. Understanding the Illinois Flexibility Index Test (I-FIT) Using Indiana Asphalt Mixtures. Transp. Res. Rec. 2019, 2673, 337–346. [Google Scholar] [CrossRef]

- Zhou, Z.; Gu, X.; Ni, F.; Li, Q.; Ma, X. Cracking Resistance Characterization of Asphalt Concrete Containing Reclaimed Asphalt Pavement at Intermediate Temperatures. Transp. Res. Rec. 2017, 2633, 46–57. [Google Scholar] [CrossRef]

- Gao, L.; Li, H.; Xie, J.; Yu, Z.; Charmot, S. Evaluation of Pavement Performance for Reclaimed Asphalt Materials in Different Layers. Constr. Build. Mater. 2018, 159, 561–566. [Google Scholar] [CrossRef]

- Ding, H.; Gyasi, J.; Hesp, S.A.M.; Marks, P.; Nie, Y.; Somuah, M.; Tabib, S.; Tetteh, N.; Ubaid, I. Performance Grading of Extracted and Recovered Asphalt Cements. Constr. Build. Mater. 2018, 187, 996–1003. [Google Scholar] [CrossRef]

- Jaskula, P.; Szydlowski, C.; Stienss, M. Influence of Bitumen Type on Cracking Resistance of Asphalt Mixtures Used in Pavement Overlays. IOP Conf. Ser. Mater. Sci. Eng. 2018, 356, 012010. [Google Scholar] [CrossRef]

- Saeidi, H.; Aghayan, I. Investigating the Effects of Aging and Loading Rate on Low-Temperature Cracking Resistance of Core-Based Asphalt Samples Using Semi-Circular Bending Test. Constr. Build. Mater. 2016, 126, 682–690. [Google Scholar] [CrossRef]

- Dave, E.V.; Hoplin, C.; Helmer, B.; Dailey, J.; Van Deusen, D.; Geib, J.; Dai, S.; Johanneck, L. Effects of Mix Design and Fracture Energy on Transverse Cracking Performance of Asphalt Pavements in Minnesota. Transp. Res. Rec. 2016, 2576, 40–50. [Google Scholar] [CrossRef]

- Jiang, J.; Dong, Q.; Ni, F.; Zhao, Y. Effects of Loading Rate and Temperature on Cracking Resistance Characteristics of Asphalt Mixtures Using Nonnotched Semicircular Bending Tests. J. Test Eval. 2019, 47, 2649–2663. [Google Scholar] [CrossRef]

- Mirzaiyanrajeh, D.; Dave, E.V.; Sias, J.E.; Voels, J.; Dai, S. Effects of Laboratory Compacted Asphalt Mixtures Air-Void Variations on Fracture Properties at Low Temperatures. Adv. Civ. Eng. Mater. 2021, 10, 262–275. [Google Scholar] [CrossRef]

- Radeef, H.R.; Abdul Hassan, N.; Zainal Abidin, A.R.; Mahmud, M.Z.H.; Mohd Satar, M.K.I.; Mohd Warid, M.N.; Al Saffar, Z.H. Determining Fracture Energy in Asphalt Mixture: A Review. IOP Conf. Ser. Earth Env. Sci. 2021, 682, 012069. [Google Scholar] [CrossRef]

- Kaseer, F.; Yin, F.; Arámbula-Mercado, E.; Epps Martin, A.; Daniel, J.S.; Salari, S. Development of an Index to Evaluate the Cracking Potential of Asphalt Mixtures Using the Semi-Circular Bending Test. Constr. Build. Mater. 2018, 167, 286–298. [Google Scholar] [CrossRef]

- Das, B.P.; Siddagangaiah, A.K. Identification of Parameter to Assess Cracking Resistance of Asphalt Mixtures Subjected to Aging and Moisture Conditioning. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 293–304. [Google Scholar] [CrossRef]

- Haslett, K.E. Evaluation of Cracking Indices for Asphalt Mixtures Using SCB Tests at Different Temperatures and Loading Rates Evaluation of Cracking Indices for Asphalt Mixtures Using SCB Tests At Senior Honors Theses of Bachelor of Science; University of New Hampshire: Durham, UK, 2018; Available online: https://scholars.unh.edu/cgi/viewcontent.cgi?article=1385&context=honors (accessed on 3 July 2023).

- Zhou, F.; Newcomb, D.; Gurganus, C.; Banihashemrad, S.; Sakhaeifar, M.; Park, E.S.; Lytton, R.L. National Academies of Sciences, Engineering, and Medicine. In Field Validation of Laboratory Tests to Assess Cracking Resistance of Asphalt Mixtures: An Experimental Design; The National Academies Press: Washington, DC, USA, 2016. [Google Scholar] [CrossRef]

- Guo, R.; Zhou, F.; Nian, T. Indices Relation and Statistical Probability Analysis of Physical and Mechanical Performance of Asphalt Mixtures. Case Stud. Constr. Mater. 2022, 16, e01091. [Google Scholar] [CrossRef]

- Yang, Q.; Deng, Y. Evaluation of Cracking in Asphalt Pavement with Stabilized Base Course Based on Statistical Pattern Recognition. Int. J. Pavement Eng. 2019, 20, 417–424. [Google Scholar] [CrossRef]

- Du, H.; Ni, F.; Ma, X. Crack Resistance Evaluation for In-Service Asphalt Pavements by Using SCB Tests of Layer-Core Samples. J. Mater. Civ. Eng. 2021, 33, 04020418. [Google Scholar] [CrossRef]

| Section ID | Service Age (year) | Structure | Lane | TCS2 (m) |

|---|---|---|---|---|

| 1 RYDQ | 17 | 4 cm SMA13 + 6 cm AC20 + 8 cm AC25 + 36 cm CTB + 20 cm LFS | 1, 2, 3 | 44 |

| 2 TZDQ | 5 | 4 cm SMA13 + 6 cm AC20 + 8 cm AC25 + 38 cm CTB + 20 cm CTB | 2, shoulder | 200 |

| 3 TZDQ | 2 surface layers 9 others | 4 cm SMA13 + 6 cm AC20 + 8 cm AC25 + 38 cm CTB + 20 cm CTB | 3, shoulder | 21 |

| 4 XY1 | 4 | 4 cm SMA13 + 6 cm SUP20 + 8 cm SUP25 + 34 cm CTB + 20 cm LFTB | 2 | 30 |

| 5 XY2 | 17 | 4 cm AK13 + 6 cm AC20 + 8 cm AC25 + 34 cm CTB + 20 cm LFTB | 2 | 13 |

| 6 LL | 9 | 5 cm SMA13 + 6 cm SUP20 + 10 cm SUP25 + 38 cm CTB + 20 cm LFS | 2 | 5.4 |

| 7 JT | 14 | 4 cm SMA13 + 5 cm SUP20 + 7 cm SUP25 + 36 cm CTB + 20 cm LFS | 1, 2 | 31.3 |

| 8 YH1 | 15 | 4 cm SMA13 + 6 cm AC20 + 8 cm AC25 + 36 cm CTB + 20 cm LFS | 1 | 25 |

| 9 YH2 | 15 | 4 cm AK13 + 6 cm AC20 + 8 cm AC25 + 36 cm CTB + 20 cm LFS | 1, 3 | 8.3 |

| 10 QY | 17 | 4 cm AK13 + 6 cm AC20 + 8 cm AC25 + 36 cm CTB + 20 cm LFS | 1 | 25 |

| 11 FG | 17 | 4 cm AK13 + 6 cm AC20 + 8 cm AC25 + 38 cm CTB + 20 cm LFS | 1 | 3.9 |

| 13 LX2 | 18 | 4 cm AK13 + 6 cm AC20 + 8 cm AC25 + 36 cm LFTB + 20 cm LFS | 1, 2 | 16.8 |

| Factor | ESALs | Service Age (year) | Area | Mixture Type | Lane | Air Void (%) | Asphalt Aggregate Ratio (%) | Factor Selected |

|---|---|---|---|---|---|---|---|---|

| ESALs | \ | * | * | |||||

| Service age (year) | \ | * | * | √ | ||||

| Area | \ | * | * | * | * | |||

| Mixture type | \ | * | √ | |||||

| Lane | \ | |||||||

| Air Void (%) | \ | √ | ||||||

| Asphalt aggregate ratio (%) | \ | √ |

| Factor | ESALs | Service Age (year) | Area | Mixture Type | Lane | Air Void (%) | Asphalt Aggregate Ratio (%) | Factor Selected |

|---|---|---|---|---|---|---|---|---|

| ESALs | \ | * | * | * | * | * | ||

| Service age (year) | \ | * | * | √ | ||||

| Area | \ | * | * | |||||

| Mixture type | \ | * | * | |||||

| Lane | \ | * | √ | |||||

| Air Void (%) | \ | * | √ | |||||

| Asphalt aggregate ratio (%) | \ |

| Factor | ESALs | Service Age (year) | Area | Mixture Type | Lane | Air Void (%) | Asphalt Aggregate Ratio (%) | Factor Selected |

|---|---|---|---|---|---|---|---|---|

| ESALs | \ | * | * | * | * | |||

| Service age (year) | \ | * | * | * | √ | |||

| Area | \ | * | * | * | ||||

| Mixture type | \ | * | ||||||

| Lane | \ | |||||||

| Air Void (%) | \ | √ | ||||||

| Asphalt aggregate ratio (%) | \ | √ |

| Layer | Factor Selection | |||

|---|---|---|---|---|

| Surface | Service age | Mixture type | Air void | Asphalt aggregate ratio |

| Middle | Service age | Lane | Air void | |

| Bottom | Service age | Air void | Asphalt aggregate ratio | |

| Index | Factor | DF a | SS b | MS c | F-Value d | p-Value e | Significant Effect f |

|---|---|---|---|---|---|---|---|

| Tensile Strength | Service age | 1 | 0.65 | 0.65 | 0.2250 | 0.6373 | - |

| Mixture type | 1 | 22.88 | 22.88 | 9.26 | 0.0037 | ** | |

| Air void | 1 | 1.93 | 1.93 | 0.64 | 0.4273 | - | |

| Asphalt aggregate ratio | 1 | 15.11 | 15.11 | 5.76 | 0.0200 | * | |

| Fracture Energy | Service age | 1 | 3.22 × 107 | 3.22 × 107 | 8.62 | 0.0049 | ** |

| Mixture type | 1 | 1.85 × 106 | 1.85 × 106 | 0.4295 | 0.5151 | - | |

| Air void | 1 | 3.75 × 106 | 3.75 × 106 | 0.9398 | 0.3376 | - | |

| Asphalt aggregate ratio | 1 | 1.53 × 107 | 1.53 × 107 | 3.7627 | 0.0578 | - | |

| CRI | Service age | 1 | 1.82 × 105 | 1.82 × 105 | 7.3128 | 0.0092 | ** |

| Mixture type | 1 | 3.31 × 104 | 3.31 × 104 | 1.1918 | 0.2800 | - | |

| Air void | 1 | 5.52 × 104 | 5.52 × 104 | 2.2667 | 0.1393 | - | |

| Asphalt aggregate ratio | 1 | 2.22 × 104 | 2.22 × 104 | 0.7916 | 0.3777 | - |

| Index | Factor | DF a | SS b | MS c | F-Value d | p-Value e | Significant Effect f |

|---|---|---|---|---|---|---|---|

| Tensile Strength | Service age | 1 | 29.02 | 29.02 | 6.59 | 0.0133 | * |

| Lane | 3 | 51.10 | 17.03 | 4.12 | 0.0111 | * | |

| Air void | 1 | 9.12 | 9.12 | 1.6465 | 0.2063 | - | |

| Fracture Energy | Service age | 1 | 3.43 × 107 | 3.43 × 107 | 7.17 | 0.0099 | ** |

| Lane | 3 | 1.45 × 107 | 4.82 × 106 | 0.90 | 0.4504 | - | |

| Air void | 1 | 1.89 × 107 | 1.89 × 107 | 3.41 | 0.0715 | * | |

| CRI | Service age | 1 | 1.08 × 105 | 1.08 × 105 | 5.44 | 0.0237 | * |

| Lane | 3 | 2.52 × 104 | 8.40 × 103 | 0.37 | 0.7716 | - | |

| Air void | 1 | 3.38 × 104 | 3.38 × 104 | 1.68 | 0.2019 | - |

| Index | Factor | DF a | SS b | MS c | F-Value d | p-Value e | Significant Effect f |

|---|---|---|---|---|---|---|---|

| Tensile Strength | Service age | 1 | 27.53 | 27.53 | 17.19 | 0.0001 | *** |

| Air void | 1 | 1.68 | 1.68 | 0.83 | 0.37 | - | |

| Asphalt aggregate ratio | 1 | 3.12 | 3.12 | 1.48 | 0.2299 | - | |

| Fracture Energy | Service age grade | 1 | 3.58 × 107 | 3.58 × 107 | 23.58 | <0.0001 | *** |

| Air void | 1 | 5.31 × 106 | 5.31 × 106 | 2.95 | 0.0934 | - | |

| Asphalt aggregate ratio | 1 | 1.04 × 107 | 1.04 × 107 | 5.07 | 0.0290 | * | |

| CRI | Service age grade | 1 | 9.57 × 104 | 9.57 × 104 | 18.71 | <0.0001 | *** |

| Air void | 1 | 1.16 × 104 | 1.16 × 104 | 2.04 | 0.16 | - | |

| Asphalt aggregate ratio | 1 | 3.58 × 104 | 3.58 × 104 | 5.63 | 0.0217 | ** |

| Factor | Factor Type | Factor Percent (%) | Factor Count | FDUR (%) | absFDUR (%) |

|---|---|---|---|---|---|

| Layers | Surface | 34.4 | 54 | 31.5 | 31.5 |

| Middle | 33.8 | 53 | 33.0 | 33.0 | |

| Bottom | 31.8 | 50 | −46 | 46 | |

| Area | North | 49.7 | 78 | −16.7 | 16.7 |

| Middle | 21.0 | 33 | −1.5 | 1.5 | |

| South | 29.3 | 46 | 4.4 | 4.4 | |

| Service age (years) | Short | 18.5 | 29 | −13.3 | 13.3 |

| Mid | 29.3 | 46 | 15.0 | 15.0 | |

| Long | 17.8 | 28 | 42.9 | 42.9 | |

| Extremely long | 34.4 | 54 | −18.5 | 18.5 | |

| Asphalt aggregate ratio (%) | 4–4.5 | 42.7 | 67 | −38.1 | 38.1 |

| 4.5–5 | 26.1 | 41 | −1.2 | −1.2 | |

| 5–5.5 | 11.4 | 18 | 0 | 0 | |

| 5.5–6 | 0 | 0 | - | - | |

| 6–6.5 | 19.8 | 31 | 46.8 | 46.8 | |

| Air void (%) | 0–2 | 26.7 | 36 | 5.6 | 5.6 |

| 2–4 | 55.5 | 75 | −19.3 | 19.3 | |

| 4–6 | 14.8 | 20 | 0.0 | 0.0 | |

| 6–8 | 3.0 | 4 | −50 | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shu, L.; Ni, F.; Du, H.; Han, Y. An Evaluation of Asphalt Mixture Crack Resistance and Identification of Influential Factors. Coatings 2023, 13, 1382. https://doi.org/10.3390/coatings13081382

Shu L, Ni F, Du H, Han Y. An Evaluation of Asphalt Mixture Crack Resistance and Identification of Influential Factors. Coatings. 2023; 13(8):1382. https://doi.org/10.3390/coatings13081382

Chicago/Turabian StyleShu, Liheng, Fujian Ni, Hui Du, and Yajin Han. 2023. "An Evaluation of Asphalt Mixture Crack Resistance and Identification of Influential Factors" Coatings 13, no. 8: 1382. https://doi.org/10.3390/coatings13081382

APA StyleShu, L., Ni, F., Du, H., & Han, Y. (2023). An Evaluation of Asphalt Mixture Crack Resistance and Identification of Influential Factors. Coatings, 13(8), 1382. https://doi.org/10.3390/coatings13081382