Improvement of Microstructure and Sliding Wear Property of Cold-Sprayed FeAl Intermetallic Compound Coating by Annealing Treatment

Abstract

1. Introduction

2. Experimental Materials and Procedures

2.1. Materials

2.2. Coating Deposition and Annealing Treatment

2.3. Coating Characterization and Wear Test

3. Results and Discussion

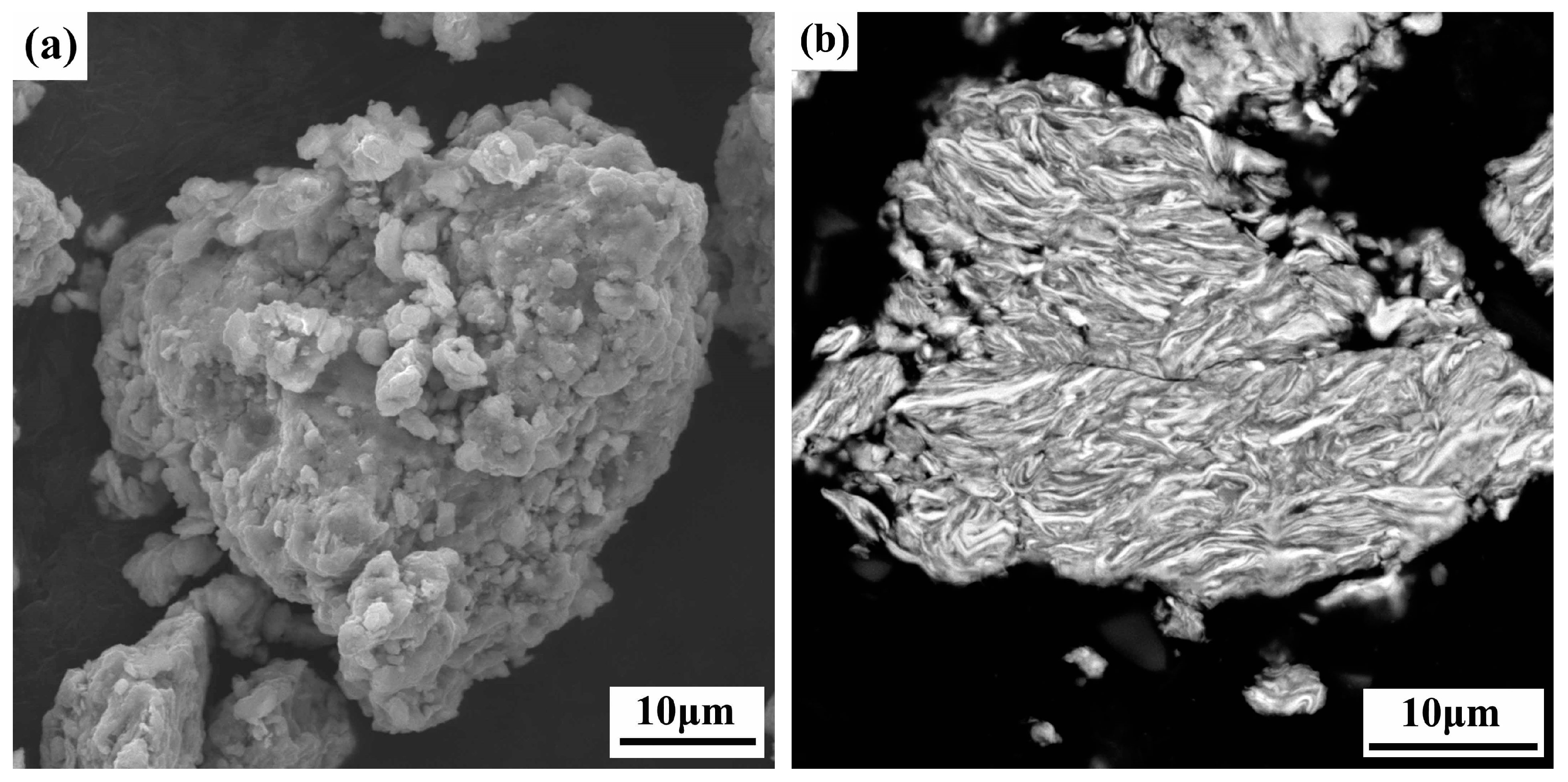

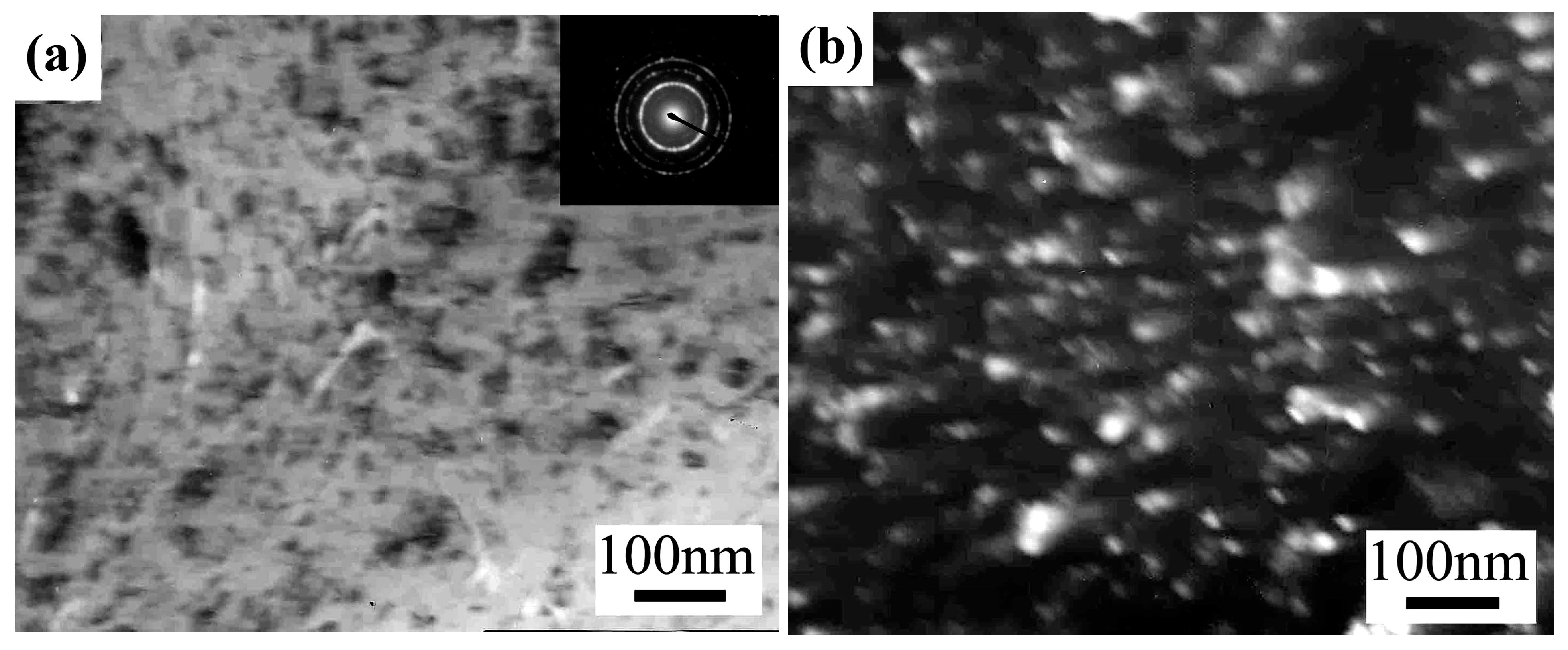

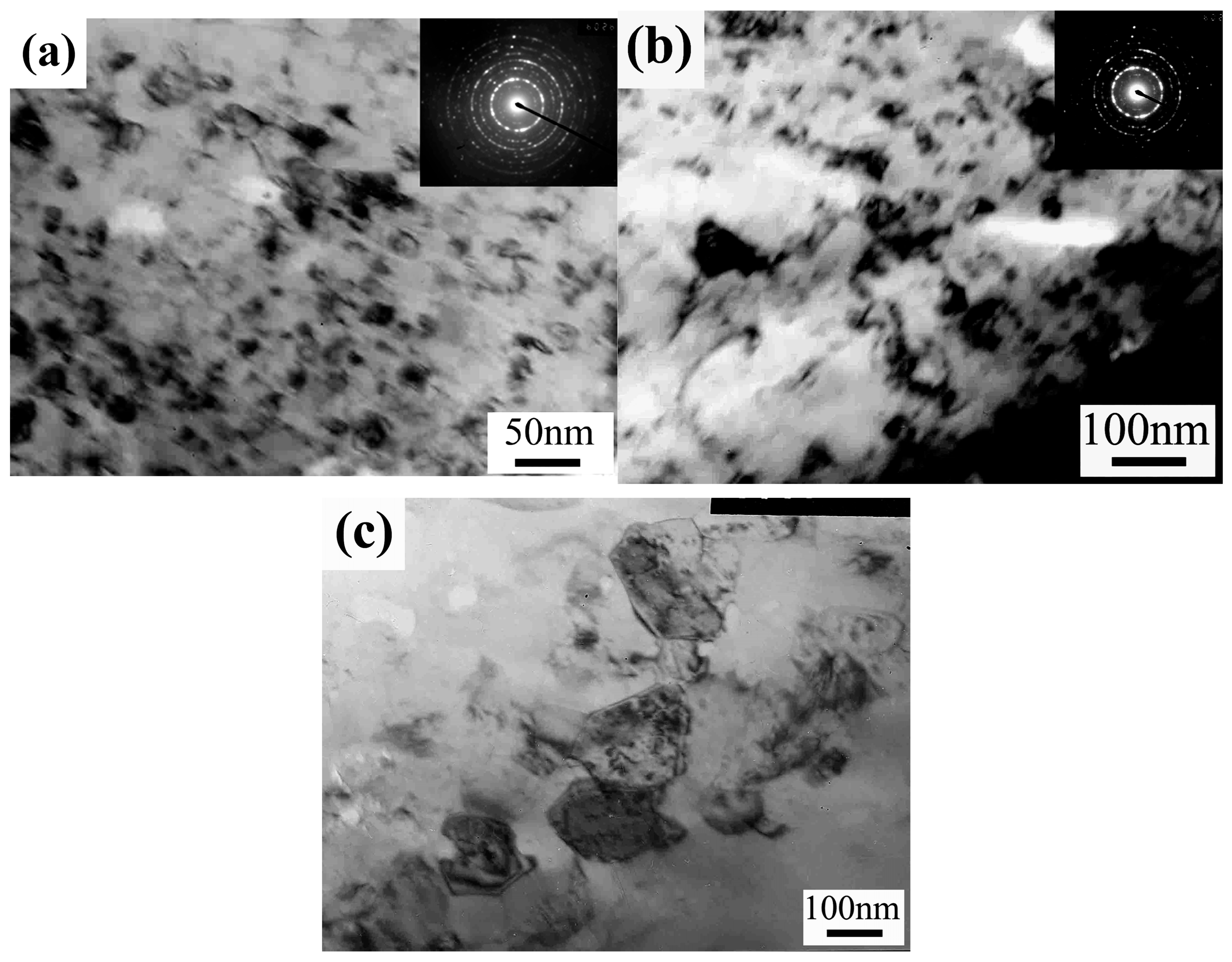

3.1. Microstructure Characterization of the As-Sprayed Coating

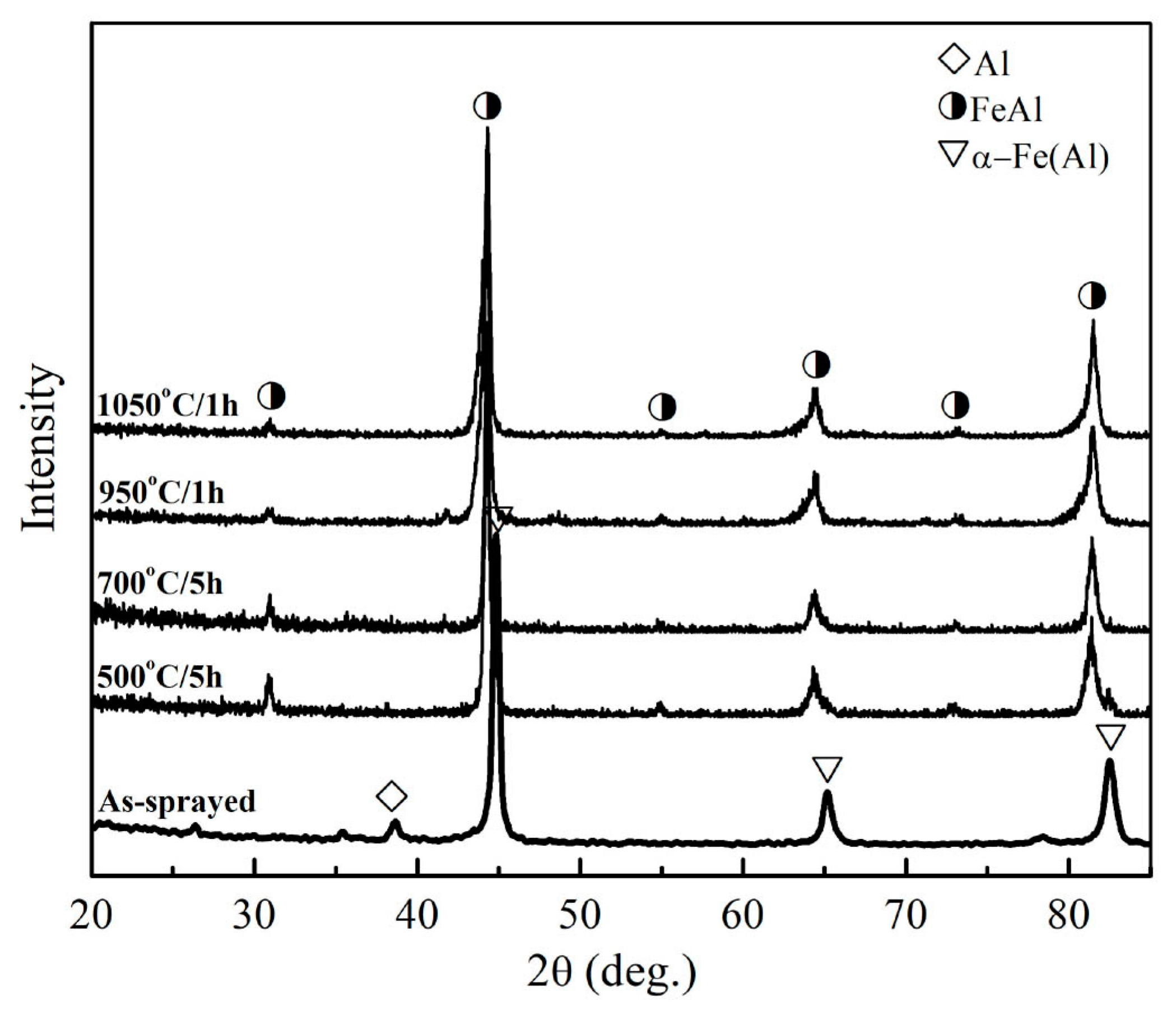

3.2. Phase Structure Evolution during Annealing Treatment

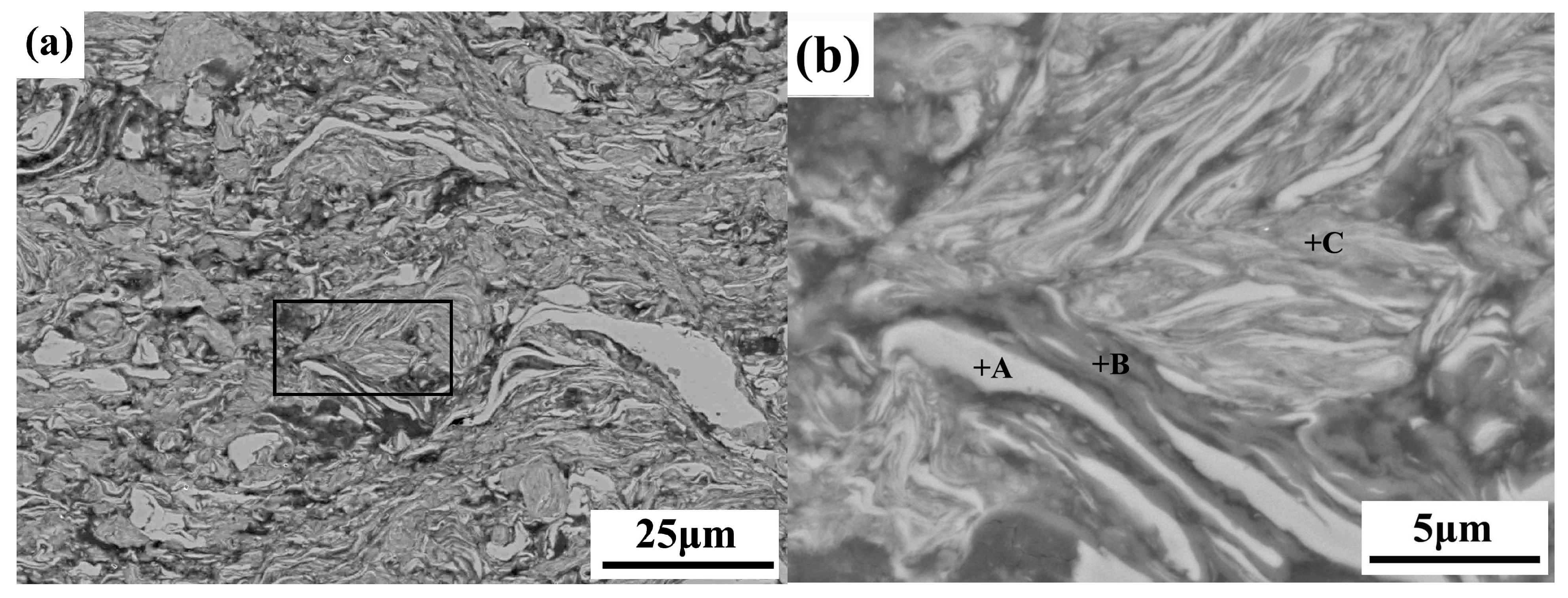

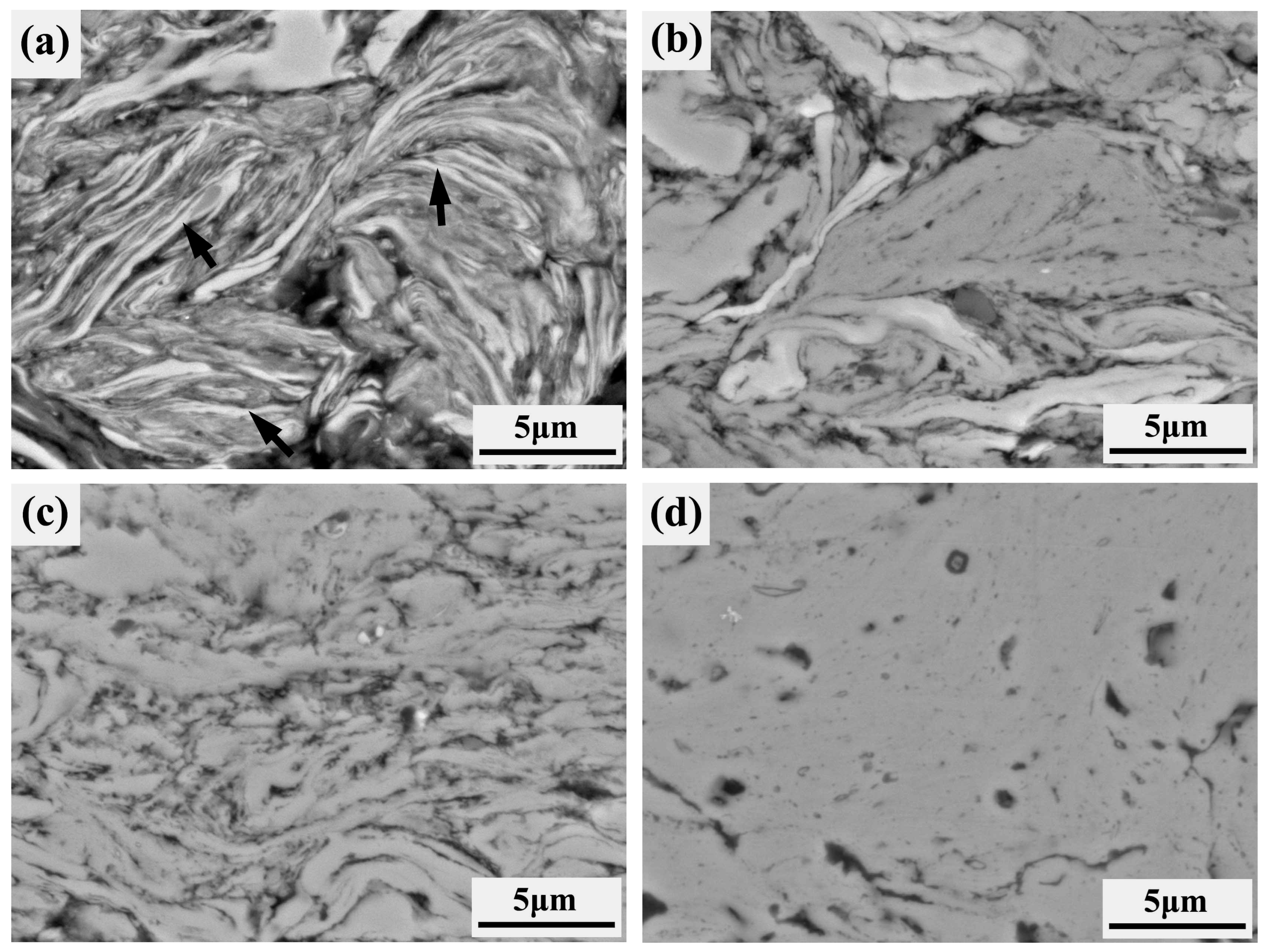

3.3. Microstructure Evolution during Annealing Treatment

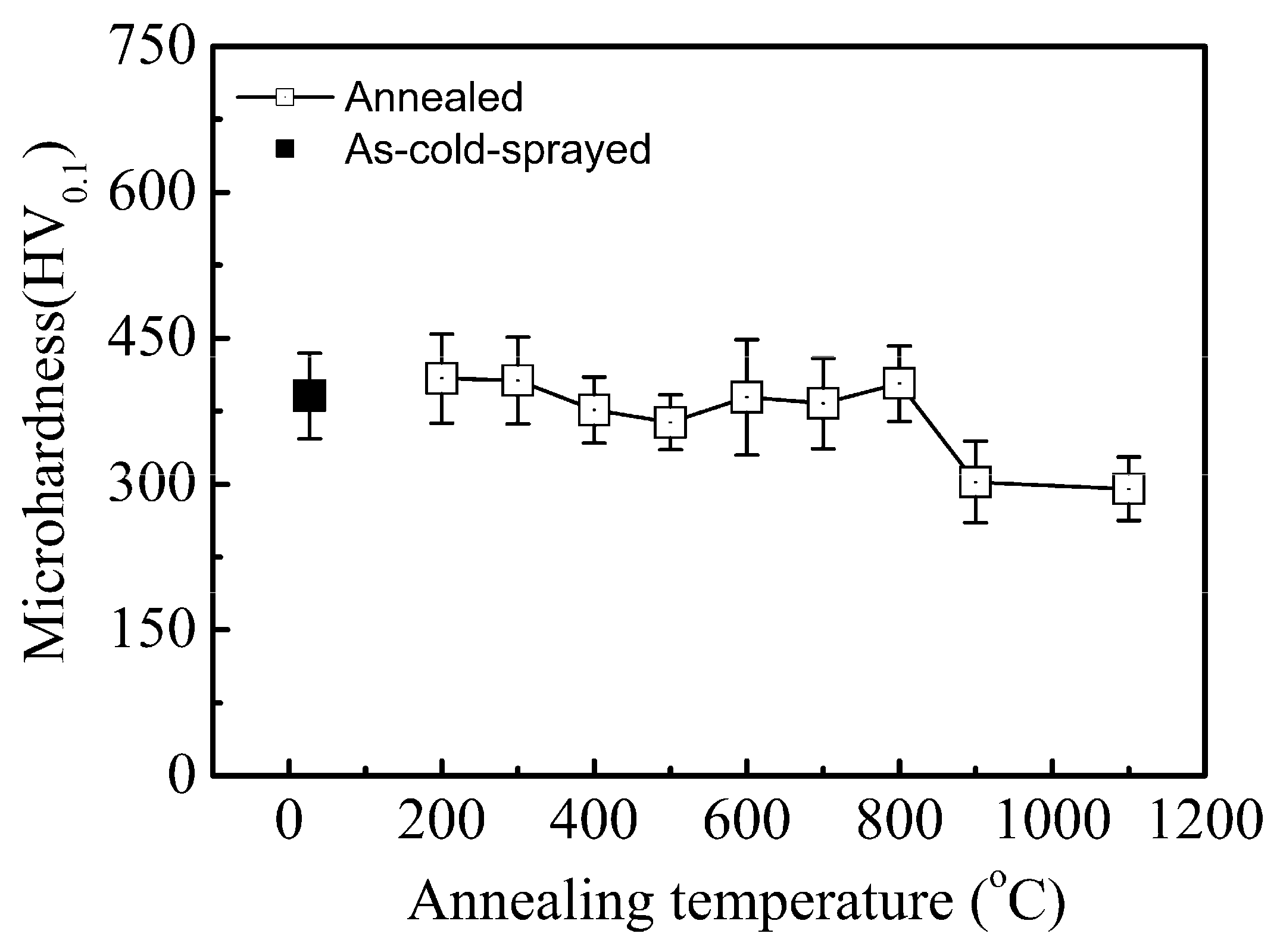

3.4. Microhardness Evolution during Annealing Treatment

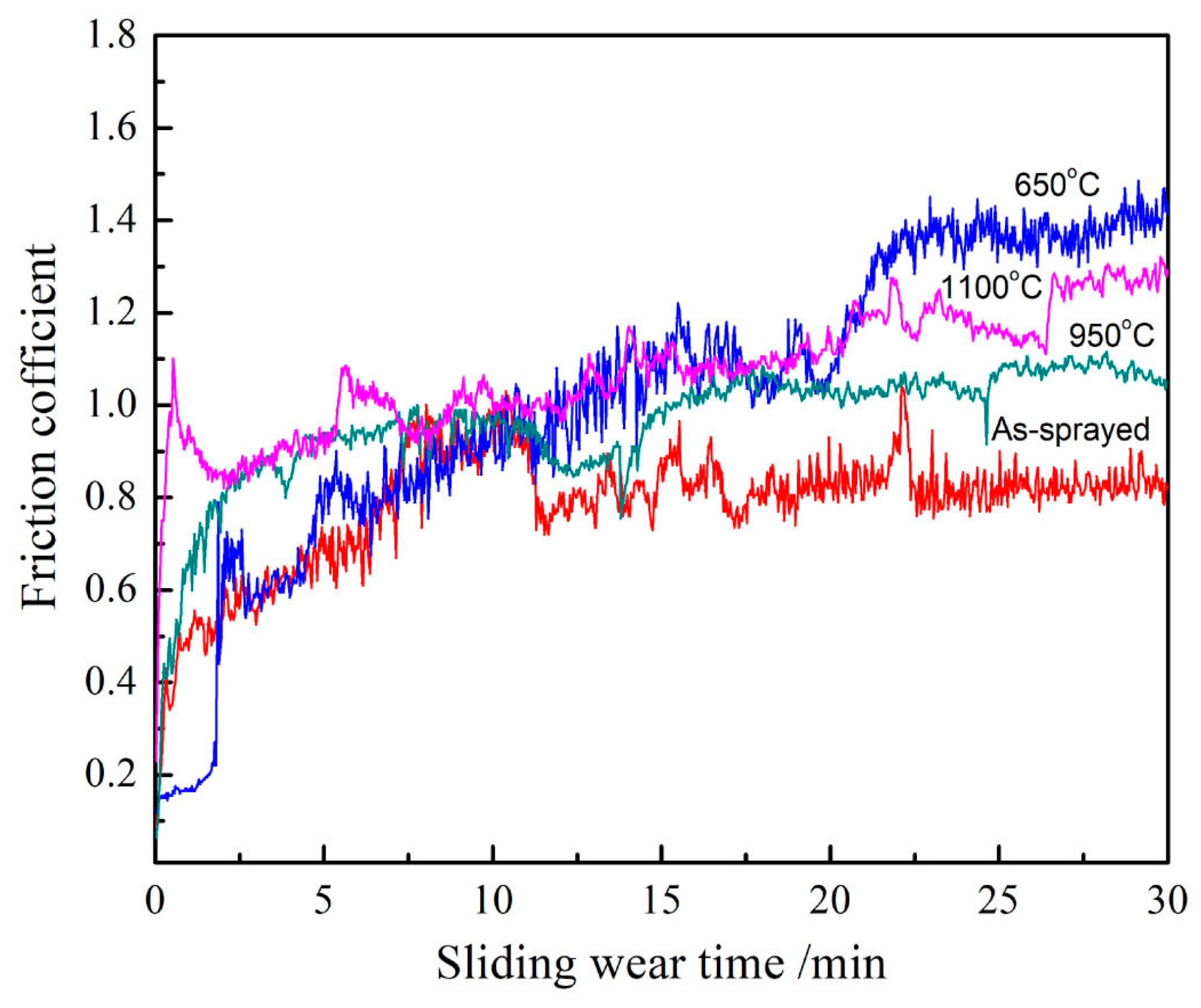

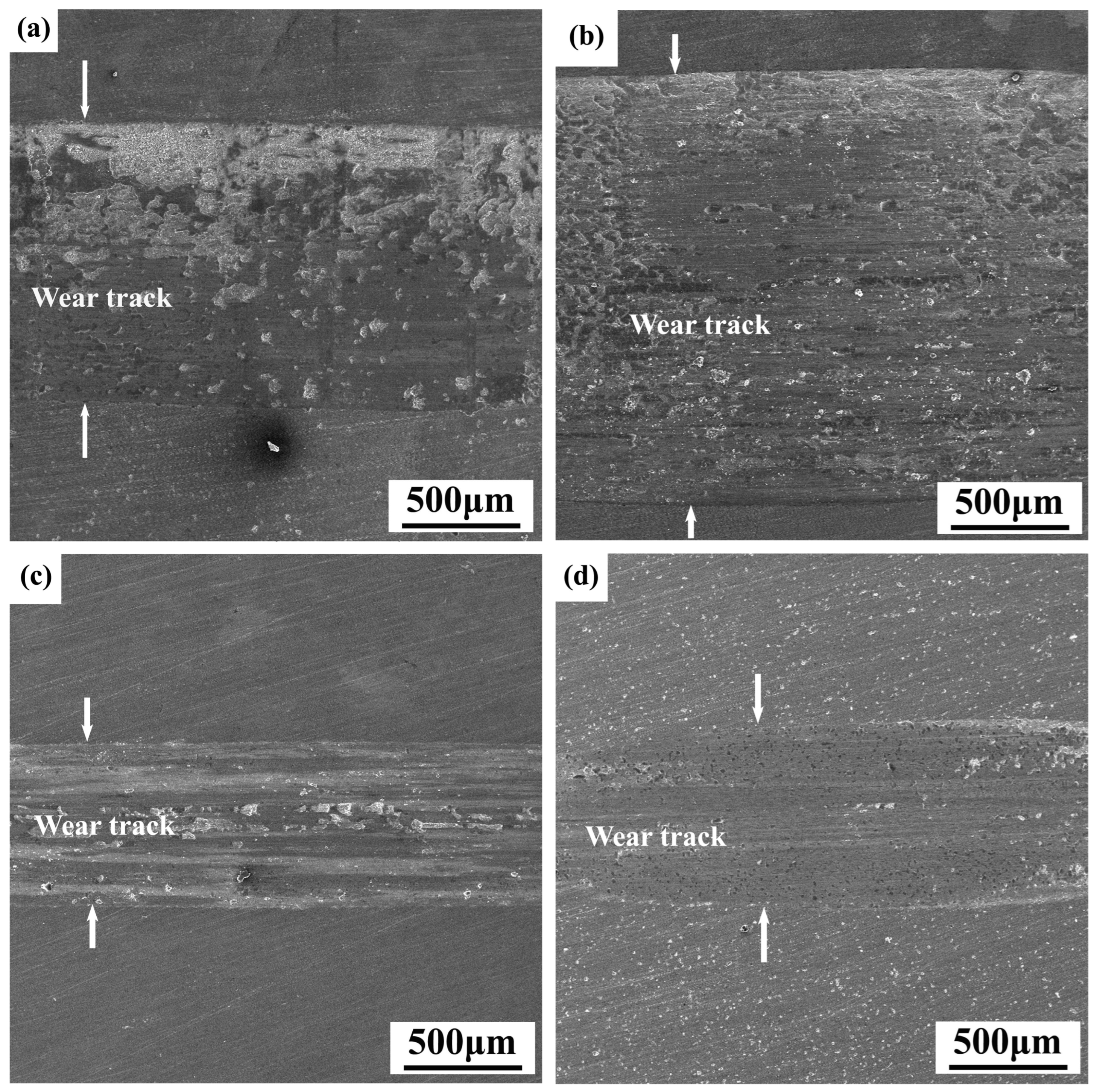

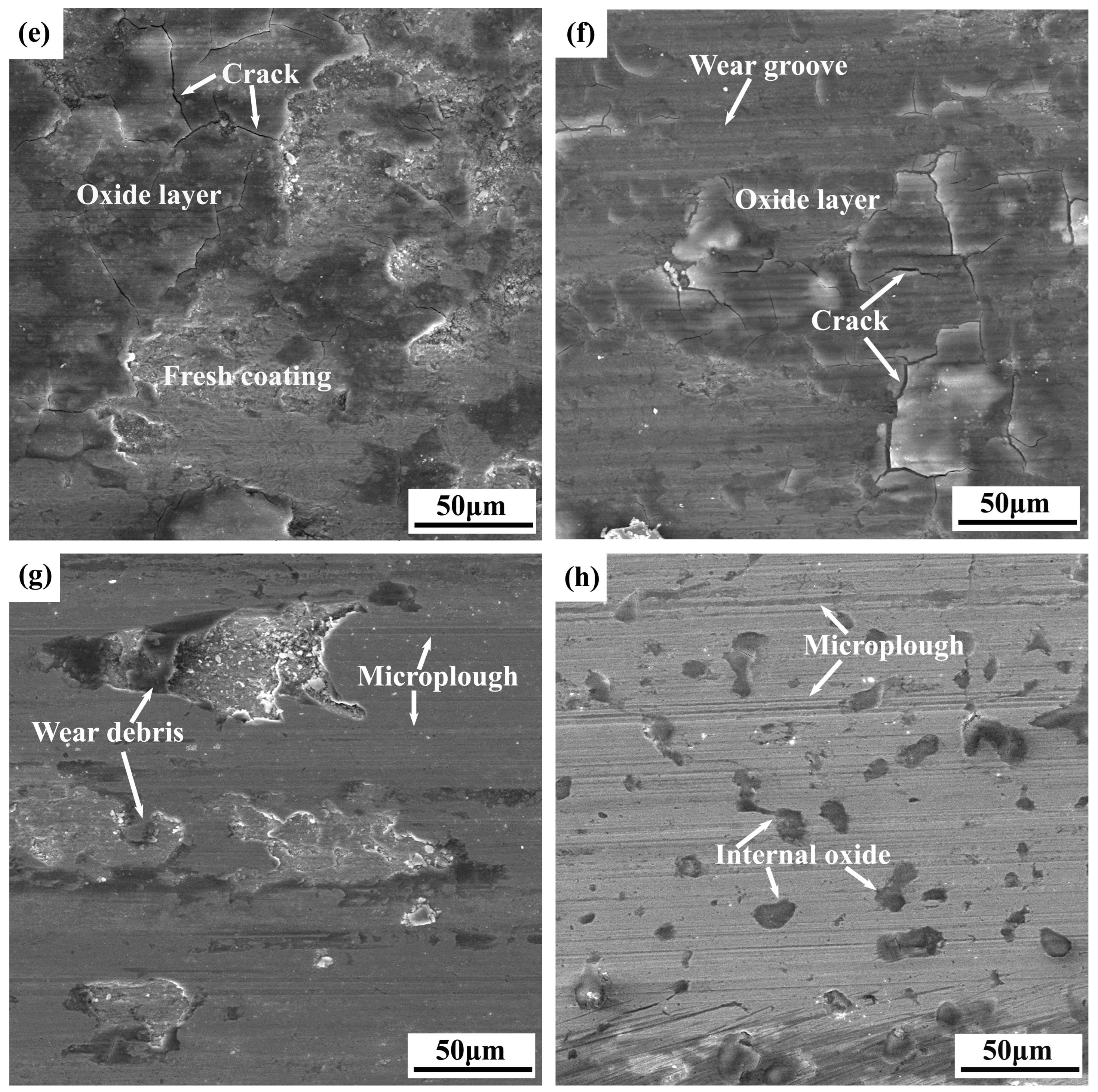

3.5. Wear Property Evolution during Annealing Treatment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tortorelli, P.F.; Natesan, K. Critical factors affecting the high-temperature corrosion performance of iron aluminides. Mater. Sci. Eng. A 1998, 258, 115–125. [Google Scholar] [CrossRef]

- Stoloff, N.S. Iron Aluminides: Present status and future prospects. Mater. Sci. Eng. A 1998, 258, 1–14. [Google Scholar] [CrossRef]

- McKamey, C.G.; DeVan, J.H.; Tortorelli, P.F.; Sikka, V.K. A review of recent developments on Fe3Al-based alloys. J. Mater. Res. 1991, 6, 1779–1805. [Google Scholar] [CrossRef]

- Alman, D.E.; Hawk, J.A.; Tylczak, J.H.; Dogan, C.P.; Wilson, R.D. Wear of iron-aluminide intermetallic-based alloys and composites by hard particles. Wear 2001, 251, 875–884. [Google Scholar] [CrossRef]

- Deevi, S.C.; Sikka, V.K.; Processing, C.T.L. Properties, and applications of nickel and iron aluminides. Prog. Mater. Sci. 1997, 42, 177–192. [Google Scholar] [CrossRef]

- McFadden, S.X.; Mishra, R.S.; Valiev, R.Z.; Zhilyaev, A.P.; Mukherjee, A.K. Mukherjee: Low-temperature superplasticity in nanostructured nickel and metal alloys. Nature 1999, 398, 684–686. [Google Scholar] [CrossRef]

- Kumar, S.; Selvarajan, V.; Padmanabhan, P.V.A.; Sreekumarand, K.P. Characterization and comparison between ball milled and plasma processed iron-aluminium thermal spray coatings. Surf. Coat. Technol. 2006, 201, 1267–1275. [Google Scholar] [CrossRef]

- Hearley, J.A.; Little, J.A.; Sturgeon, A.J. The effect of spray parameters on the properties of high velocity oxy-fuel NiAl intermetallic coatings. Surf. Coat. Technol. 2000, 123, 210–218. [Google Scholar] [CrossRef]

- Ji, G.; Grosdidier, T.; Liao, H.L.; Morniroli, J.P.; Coddet, C. Spray forming thick nanostructured and microstructured FeAl deposits. Intermetallics 2005, 13, 596–607. [Google Scholar] [CrossRef]

- Wang, H.T.; Ji, G.C.; Li, C.J. Characterization of microstructure and properties of nanostructured Fe-Al/WC intermetallic composite coating deposited by cold spraying. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering, Wuhan, China, 26–28 June 2010. [Google Scholar]

- Ajdelsztajn, L.; Jodoin, B.; Schoenung, J.M. Synthesis and mechanical properties of nanocrystalline Ni coatings produced by cold gas dynamic spraying. Surf. Coat. Technol. 2006, 201, 1166–1172. [Google Scholar] [CrossRef]

- Shukla, V.; Elliott, G.S.; Kear, B.H.; McCandlish, L.E. Hyperkinetic deposition of nanopowders by supersonic rectangular jet impingement. Scr. Mater. 2001, 44, 2179–2182. [Google Scholar] [CrossRef]

- Li, C.-J.; Li, W.Y. Deposition characteristics of titanium coatings in cold spraying. Surf. Coat. Technol. 2003, 167, 278–283. [Google Scholar] [CrossRef]

- Morelli, D.T.; Elmoursi, A.A.; Van Steenkiste, T.H.; Gorkiewicz, D.W.; Gillispie, B. Kinetic spray of aluminum metal matrix composites for thermal management applications. In Thermal Spray 2003: Advancing the Science and Applying the Technology; Marple, B.R., Moreau, C., Eds.; ASM International: Materials Park, OH, USA, 2003; pp. 85–90. [Google Scholar]

- Van Steenkiste, T.H.; Elmoursi, A.; Gorkiewicz, D.; Gillispie, B. Fracture study of aluminum composite coatings produced by the kinetic spray method. Surf. Coat. Technol. 2005, 194, 103–110. [Google Scholar] [CrossRef]

- Li, W.-Y.; Zhang, G.; Zhang, C.; Elkedim, O.; Liao, H.; Coddet, C. Effect of ball milling of feedstock powder on microstructure and properties of TiN particle-reinforced Al alloy-based composites fabricated by cold spraying. J. Therm. Spray Technol. 2008, 17, 316–322. [Google Scholar] [CrossRef]

- Lima, R.S.; Karthikeyan, J.; Kay, C.M.; Lindemann, J.; Berndt, C.C. Microstructural characteristics of cold-sprayed nanostructured WC-Co coatings. Thin Solid Film. 2002, 416, 129–135. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, C.H.; Hwang, S.Y. Superhard nano WC-12%Co coating by cold spray deposition. Mater. Sci. Eng. A 2005, 391, 243–248. [Google Scholar] [CrossRef]

- Gao, P.H.; Li, C.-J.; Yang, G.J.; Li, Y.G.; Li, C.X. Influence of substrate hardnes transition on built-up of nanostructured WC–12Co by cold spraying. Appl. Surf. Sci. 2010, 256, 2263–2268. [Google Scholar] [CrossRef]

- Wang, H.T.; Li, C.-J.; Yang, G.J.; Li, C.X.; Zhang, Q.; Li, W.Y. Microstructural characterization of cold-sprayed nanostructured FeAl intermetallic compound coating and its ball-milled feedstock powders. J. Therm. Spray Technol. 2007, 16, 669–676. [Google Scholar] [CrossRef]

- Wang, H.T.; Li, C.-J.; Yang, G.J.; Li, C.X. Effect of heat treatment on the microstructure and property of cold-sprayed nanostructured FeAl/Al2O3 intermetallic composite coating. Vacuum 2008, 83, 146–152. [Google Scholar] [CrossRef]

- Li, W.Y.; Li, C.-J.; Liao, H.L. Effect of annealing treatment on the microstructure and properties of cold-sprayed Cu coating. J. Therm. Spray Technol. 2006, 15, 206–211. [Google Scholar] [CrossRef]

- Borchers, C.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Formation of persistent dislocation loops by ultra-high stain-rate deformation during cold spraying. Acta Mater. 2005, 53, 2991–3000. [Google Scholar] [CrossRef]

- Decker, M.K.; Neiser, R.A.; Gilmore, D.; Tran, H.D. Microstructureand properties of cold spray nickel. In Thermal Spray 2001: New Surfaces for a New Millennium, Proceedings of the International Thermal Spray Conference, Singapore, 28–30 May 2001; Berndt, C.C., Khor, K.A., Lugscheider, E.F., Eds.; ASM International: Materials Park, OH, USA, 2001; pp. 433–439. [Google Scholar]

- McCune, R.C.; Donlon, W.T.; Popoola, O.O.; Cartwright, E.L. Characterization of copper Layers produced by cold gas-dynamic spraying. J. Therm. Spray Technol. 2000, 9, 73–82. [Google Scholar] [CrossRef]

- Li, W.Y.; Guo, X.P.; Verdy, C.; Dembinski, L.; Liao, H.L.; Coddet, C. Improvement of microstructure and property of cold-sprayed Cu-4 at.%Cr-2 at.%Nb alloy by heat treatment. Scr. Mater. 2006, 55, 327–330. [Google Scholar] [CrossRef]

- Li, C.-J.; Wang, H.T.; Yang, G.J.; Bao, C.G. Characterization of high-temperature abrasive wear of cold-sprayed FeAl intermetallic compound coating. J. Therm. Spray Technol. 2011, 20, 227–233. [Google Scholar] [CrossRef]

- Wang, H.T.; Li, C.-J.; Yang, G.J. influence of hard phase on the properties of cold-sprayed FeAl intermetallic compound coatings. Mater. Prot. 2010, 43, 93–94. (In Chinese) [Google Scholar]

- Knauth, P.; Charaï, A.; Gas, P. Grain growth of pure nickel and of a Ni-Si solid solution studied by differential scanning calorimetry on nanometer-sized crystals. Scr. Metall. Mater. 1993, 28, 325–330. [Google Scholar] [CrossRef]

- Boylan, K.; Ostrander, D.; Erb, U.; Palumbo, G.; Aust, K.T. An in-situ tem study of the thermal stability of nanocrystalline Ni. Scr. Metall. Mater. 1991, 25, 2711–2716. [Google Scholar] [CrossRef]

- Gao, Z.; Fultz, B. The thermal stability of nonocrystalline Fe-Si-Nb prepared by mechanical alloying. Nanostruct. Mater. 1993, 2, 231–240. [Google Scholar] [CrossRef]

- Morris, D.G.; Gutierrez-Urrutia, I.; Munoz-Morris, M.A. Hardening and softening in milled nanostructured FeAl on annealing. Scr. Mater. 2007, 57, 369–372. [Google Scholar] [CrossRef]

- Gialanella, S.; Amils, X.; Barò, M.D.; Delcroix, P.; Le Caër, G.; Lutterotti, L.; Suriñac, S. Microstructural and kinetic aspects of the transformations induced in a FeAl alloy by ball-milling and thermal treatments. Acta Mater. 1998, 46, 3305–3316. [Google Scholar] [CrossRef]

- Stott, F.H.; Glascott, J.; Wood, G.C. The sliding wear of commercial Fe-12%Cr alloys at high temperature. Wear 1985, 101, 311–324. [Google Scholar] [CrossRef]

| Spraying Parameters | Value |

|---|---|

| Accelerating gas | N2 |

| Powder carrying gas | N2 |

| Accelerating gas pressure/MPa | 2.0 |

| Powders carrying gas pressure/MPa | 2.5 |

| Accelerating gas temperature/°C | 500 |

| Gun traverse speed over substrate/mm/s | 40 |

| Standoff distance/mm | 20 |

| Positions | Al K (at.%) | Fe K (at.%) |

|---|---|---|

| Point A | 5.70 | 94.30 |

| Point B | 87.55 | 12.45 |

| Point C | 27.94 | 72.06 |

| As-Sprayed | 650 °C | 950 °C | 1100 °C | |

|---|---|---|---|---|

| Friction coefficient | 0.82 | 1.13 | 1.05 | 1.08 |

| Wear track width/μm | 1102 ± 68 | 1717 ± 46 | 552 ± 11 | 569 ± 58 |

| Wear volume/mm3 | 16.5 × 10−2 | 79.5 × 10−2 | 8.5 × 10−3 | 6.5 × 10−3 |

| Wear rate/mm3·N−1·m−1 | 1.8 × 10−4 | 8.8 × 10−4 | 9.4 × 10−6 | 7.2 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; An, F.; Bai, X.; Yao, H.; Zhang, M.; Chen, Q.; Ji, G.; Ramachandran, C.S. Improvement of Microstructure and Sliding Wear Property of Cold-Sprayed FeAl Intermetallic Compound Coating by Annealing Treatment. Coatings 2023, 13, 1260. https://doi.org/10.3390/coatings13071260

Wang H, An F, Bai X, Yao H, Zhang M, Chen Q, Ji G, Ramachandran CS. Improvement of Microstructure and Sliding Wear Property of Cold-Sprayed FeAl Intermetallic Compound Coating by Annealing Treatment. Coatings. 2023; 13(7):1260. https://doi.org/10.3390/coatings13071260

Chicago/Turabian StyleWang, Hongtao, Fenghui An, Xiaobo Bai, Hailong Yao, Mengxian Zhang, Qinyu Chen, Gangchang Ji, and Chidambaram Seshadri Ramachandran. 2023. "Improvement of Microstructure and Sliding Wear Property of Cold-Sprayed FeAl Intermetallic Compound Coating by Annealing Treatment" Coatings 13, no. 7: 1260. https://doi.org/10.3390/coatings13071260

APA StyleWang, H., An, F., Bai, X., Yao, H., Zhang, M., Chen, Q., Ji, G., & Ramachandran, C. S. (2023). Improvement of Microstructure and Sliding Wear Property of Cold-Sprayed FeAl Intermetallic Compound Coating by Annealing Treatment. Coatings, 13(7), 1260. https://doi.org/10.3390/coatings13071260