Design of an Ultra-Thick Film and Its Friction and Wear Performance under Different Working Conditions

Abstract

:1. Introduction

2. Preparation and Characterization

3. Results and Discussion

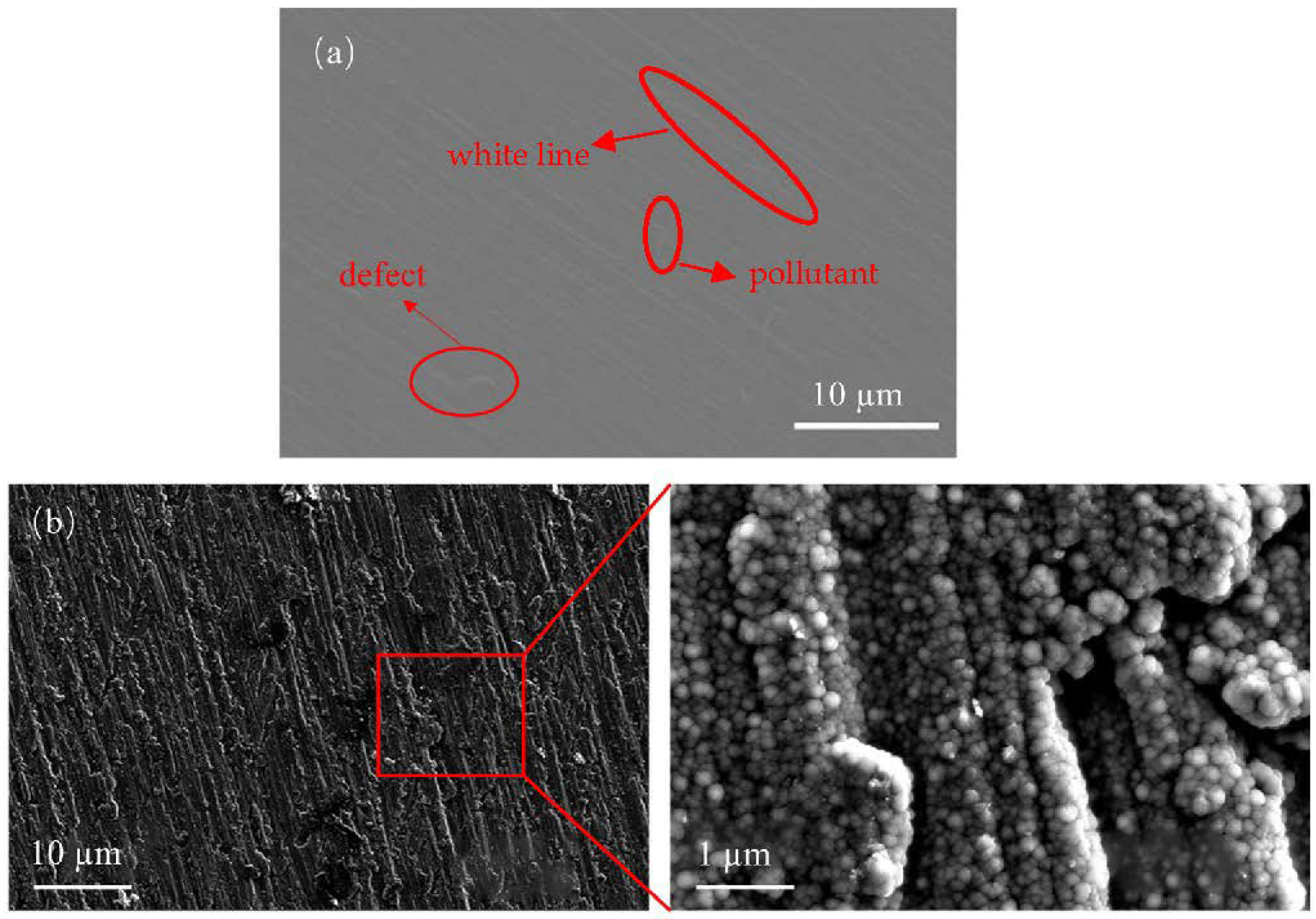

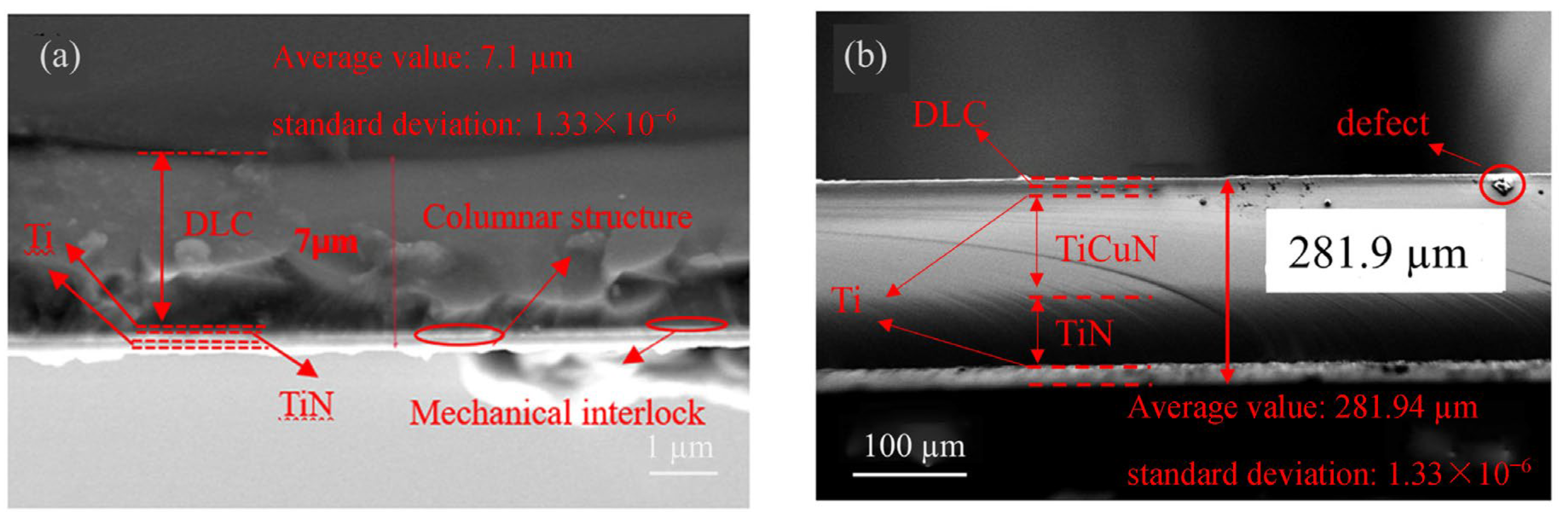

3.1. Surface Topography

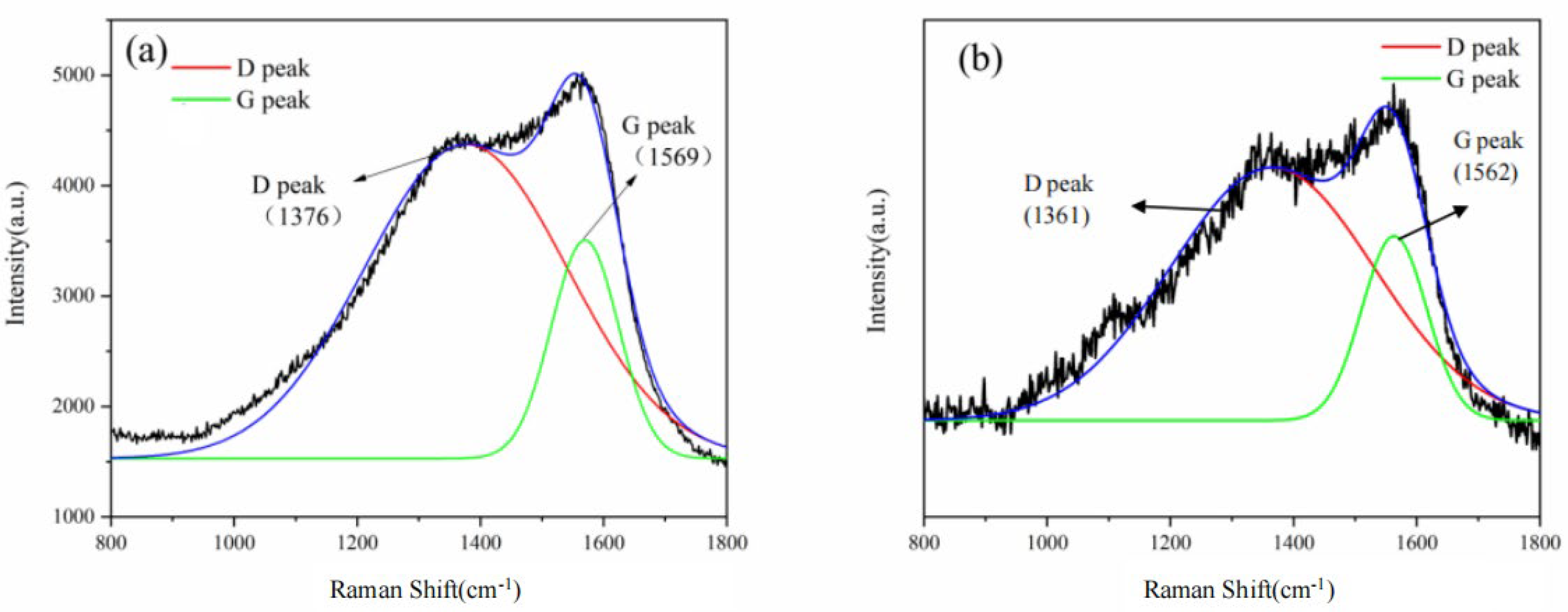

3.2. Raman Spectroscopy

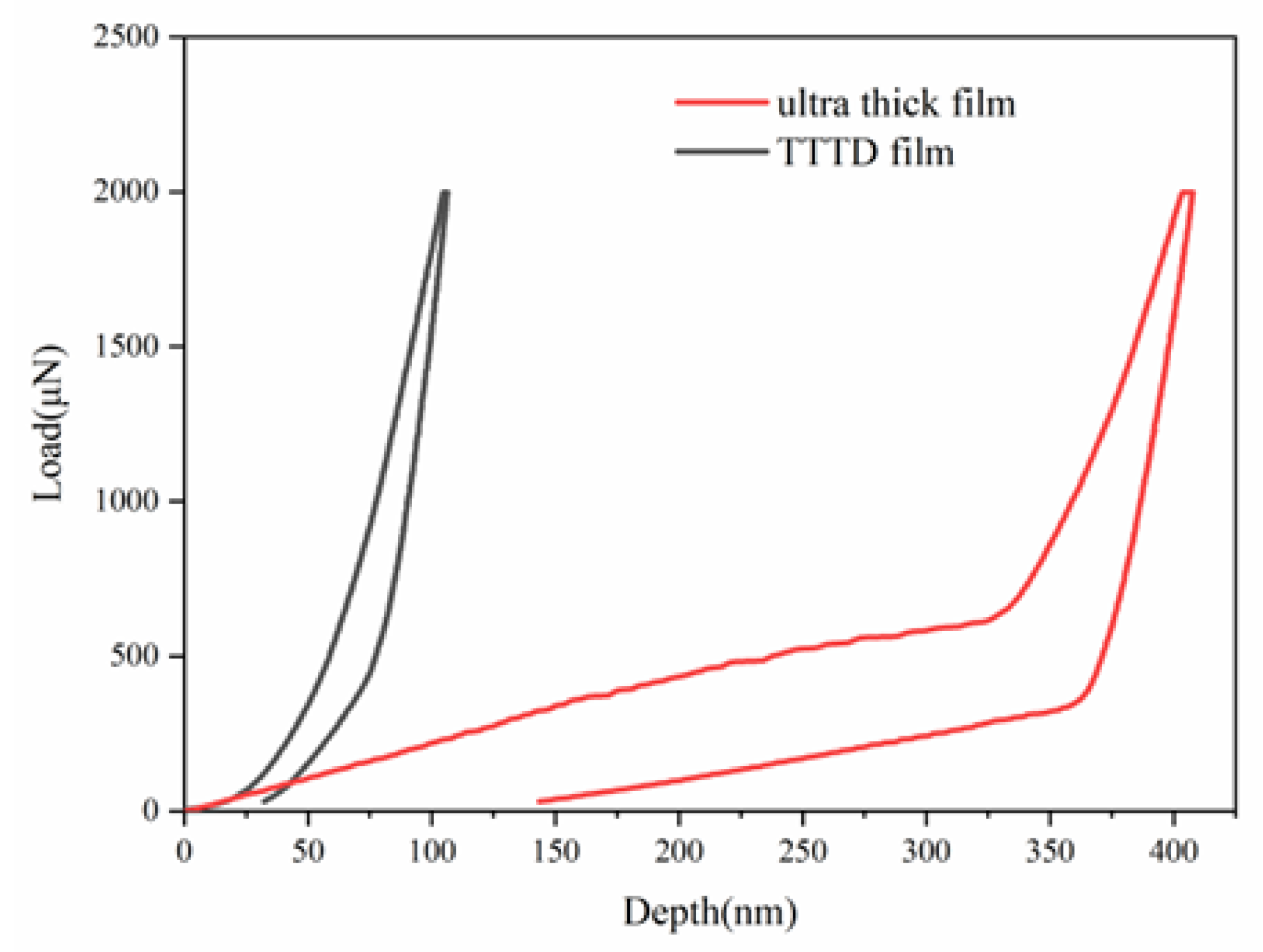

3.3. Wear Behavior

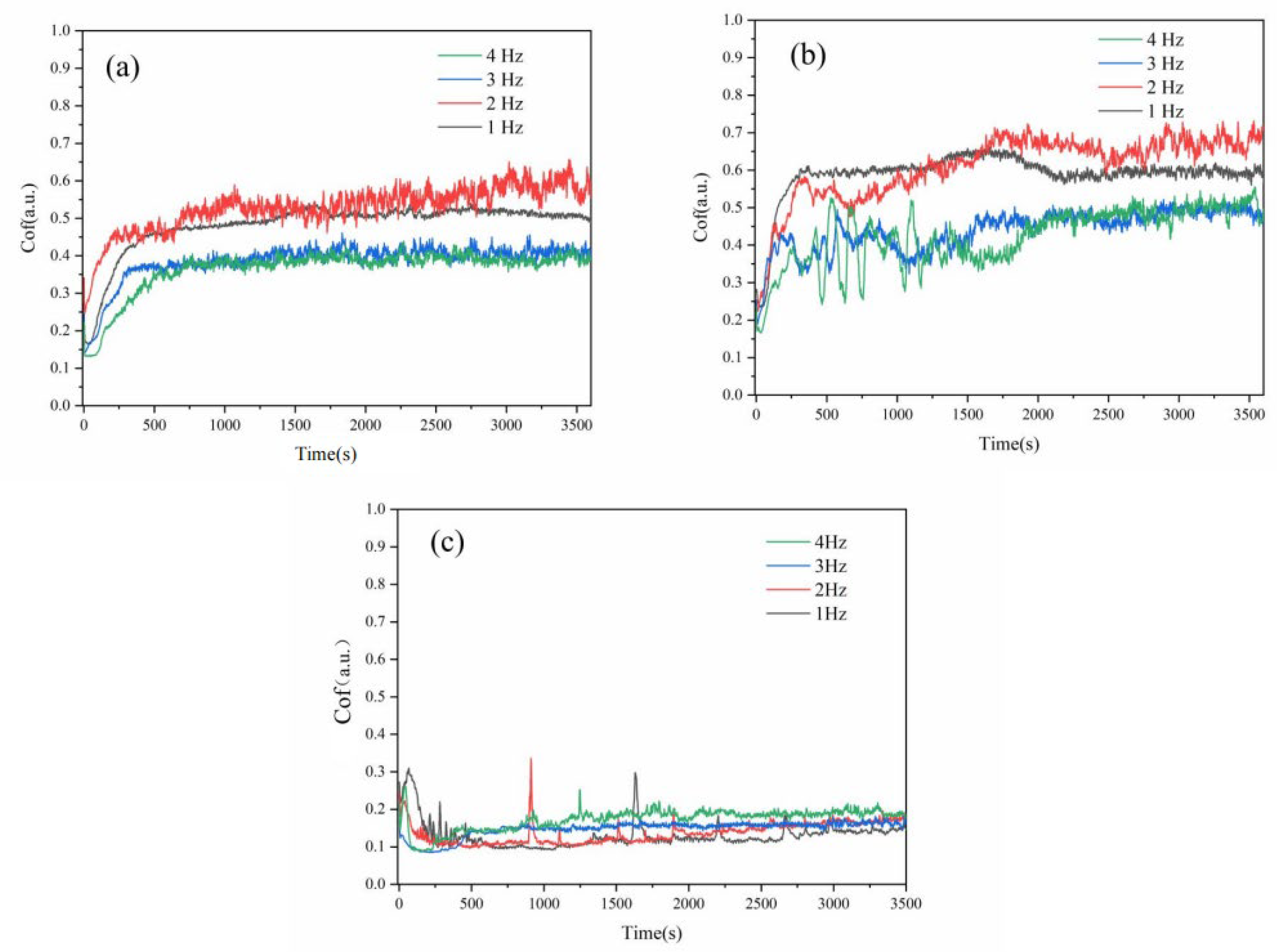

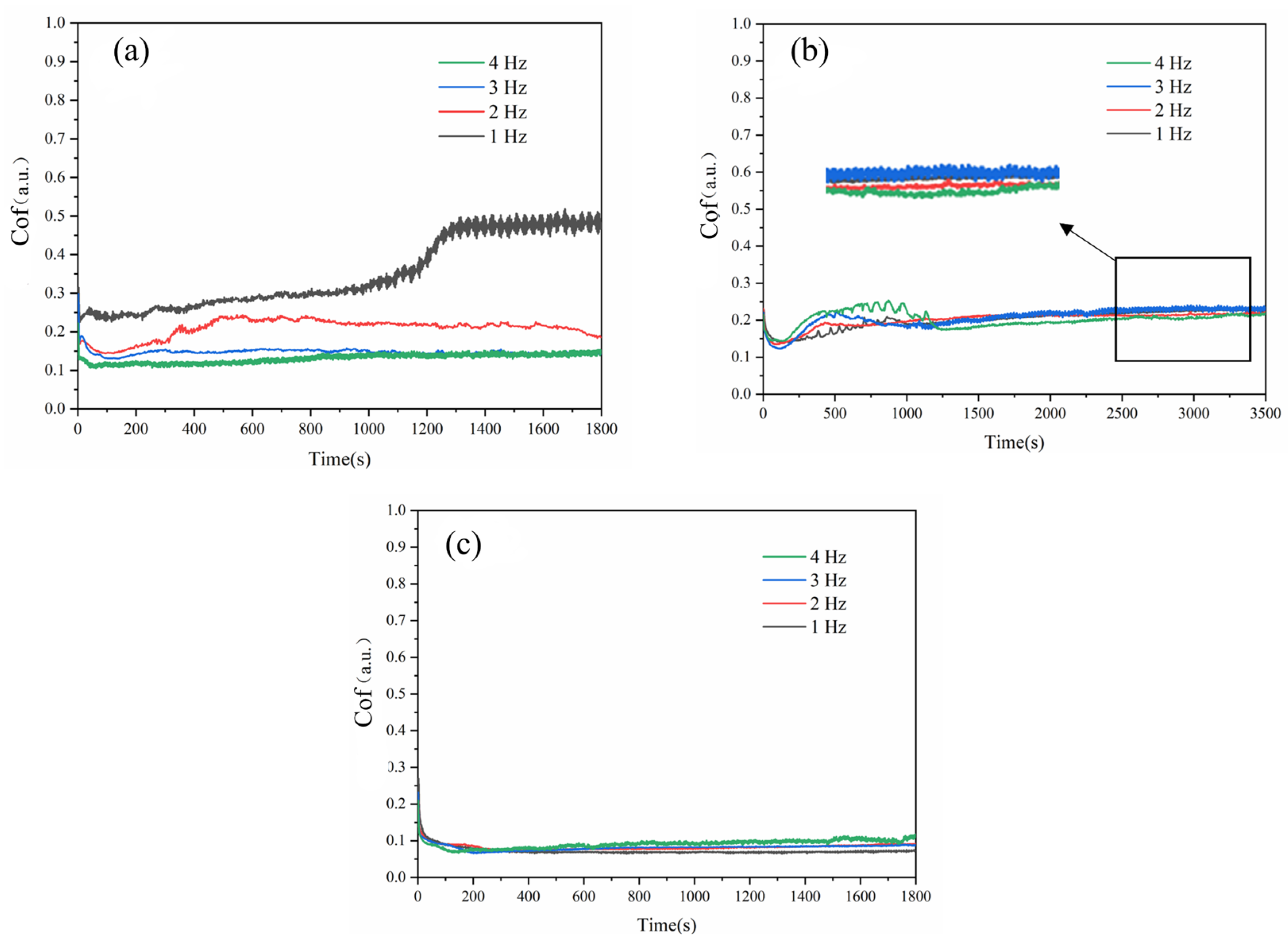

3.4. Friction Coefficient

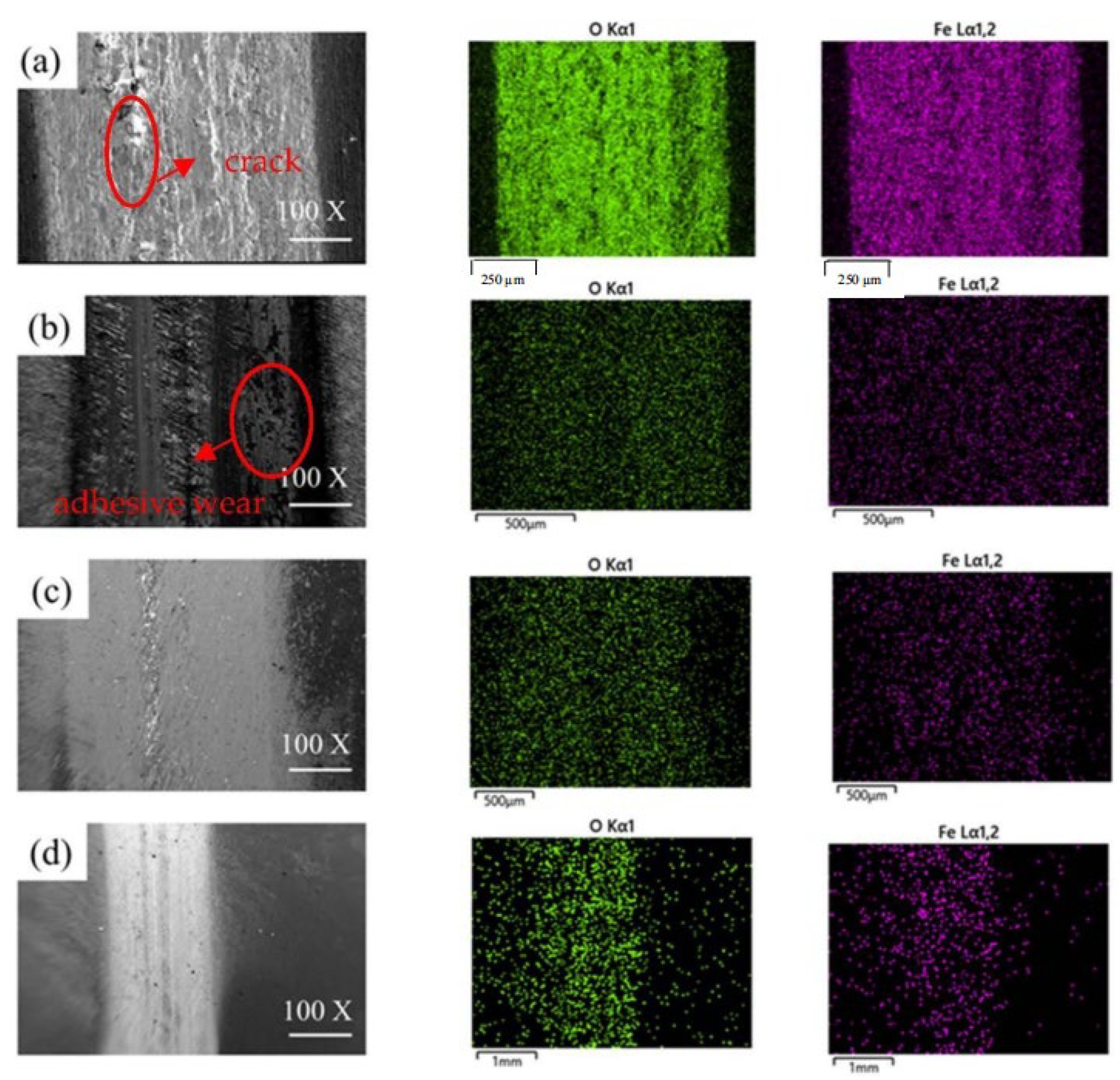

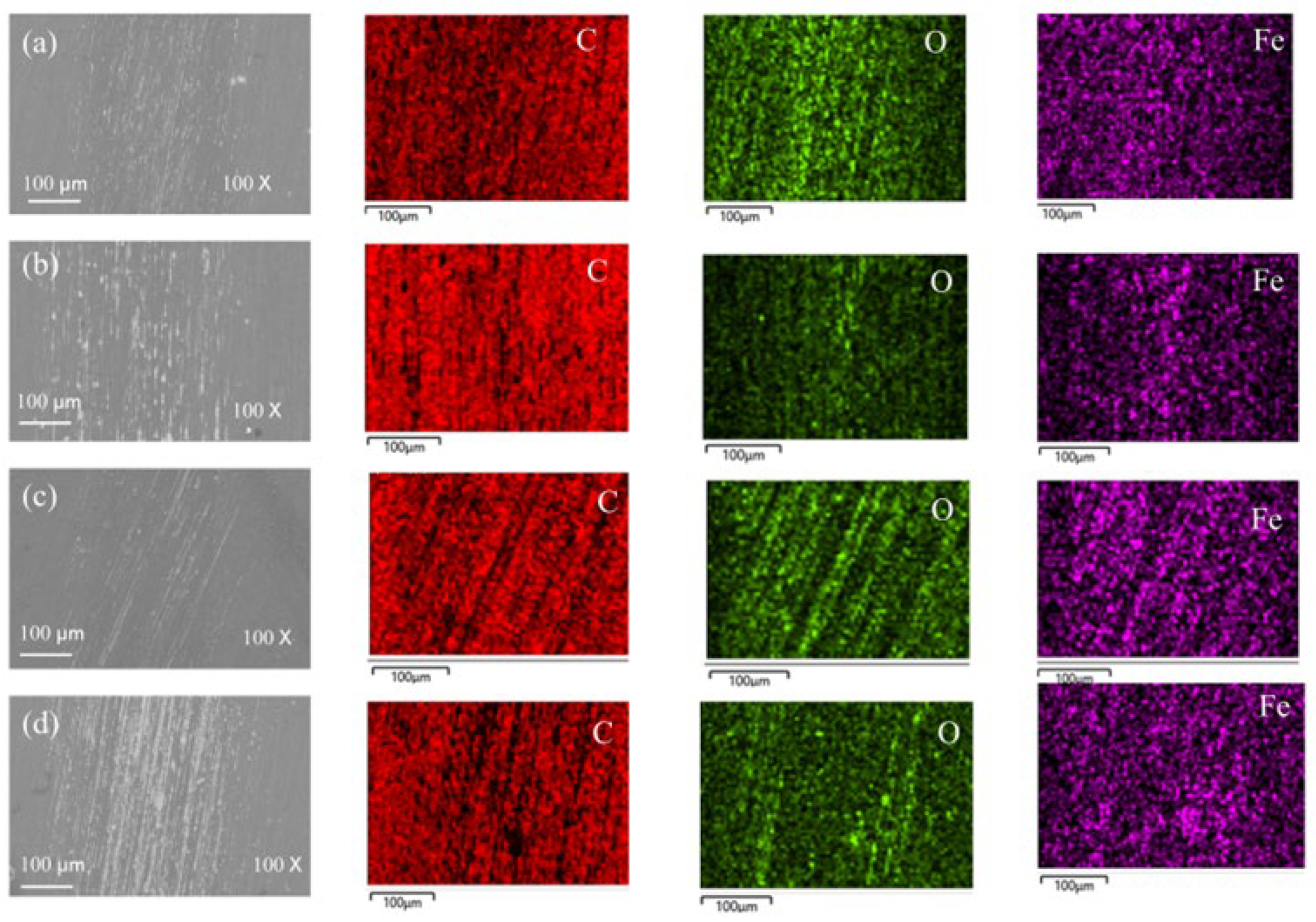

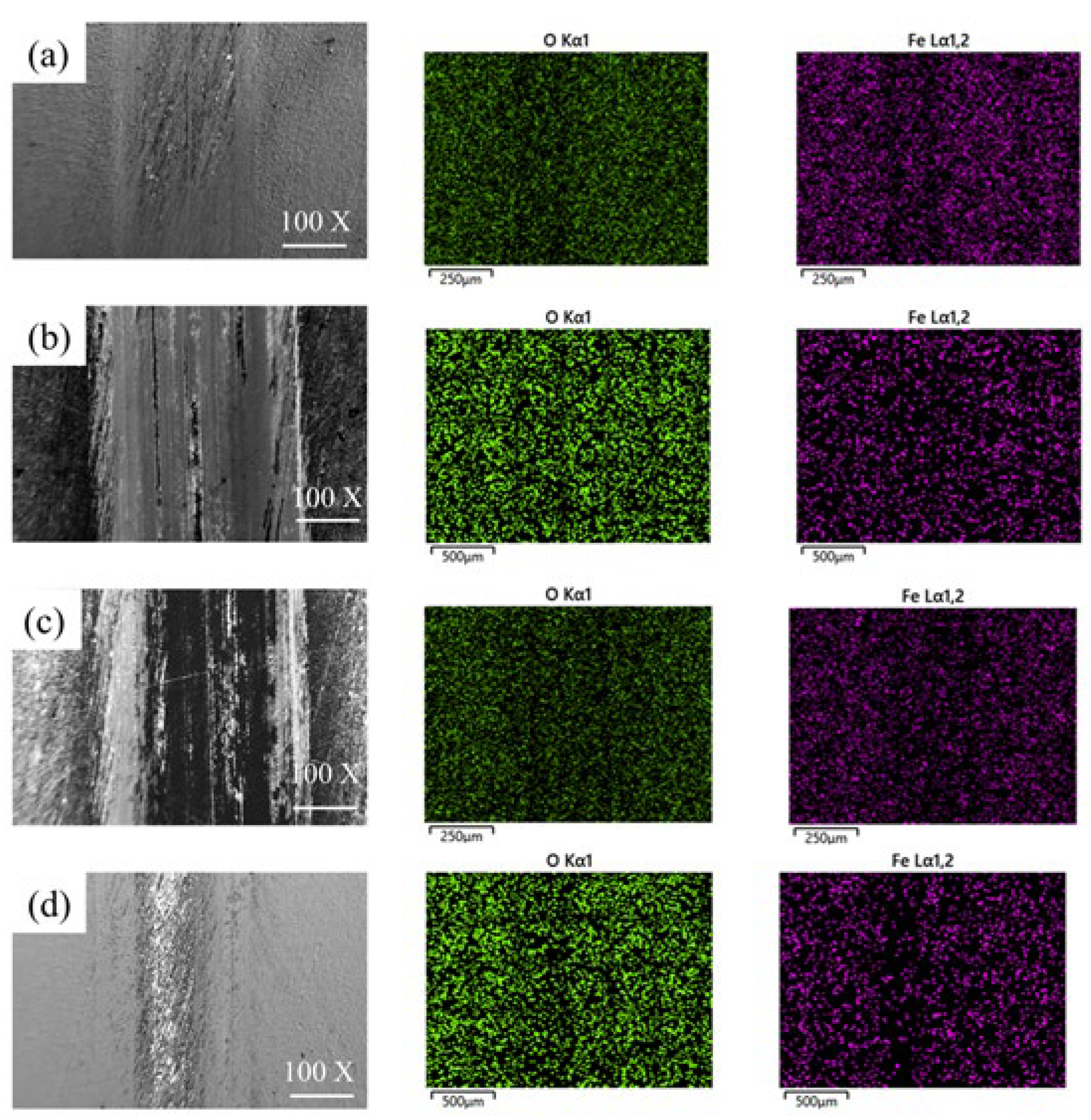

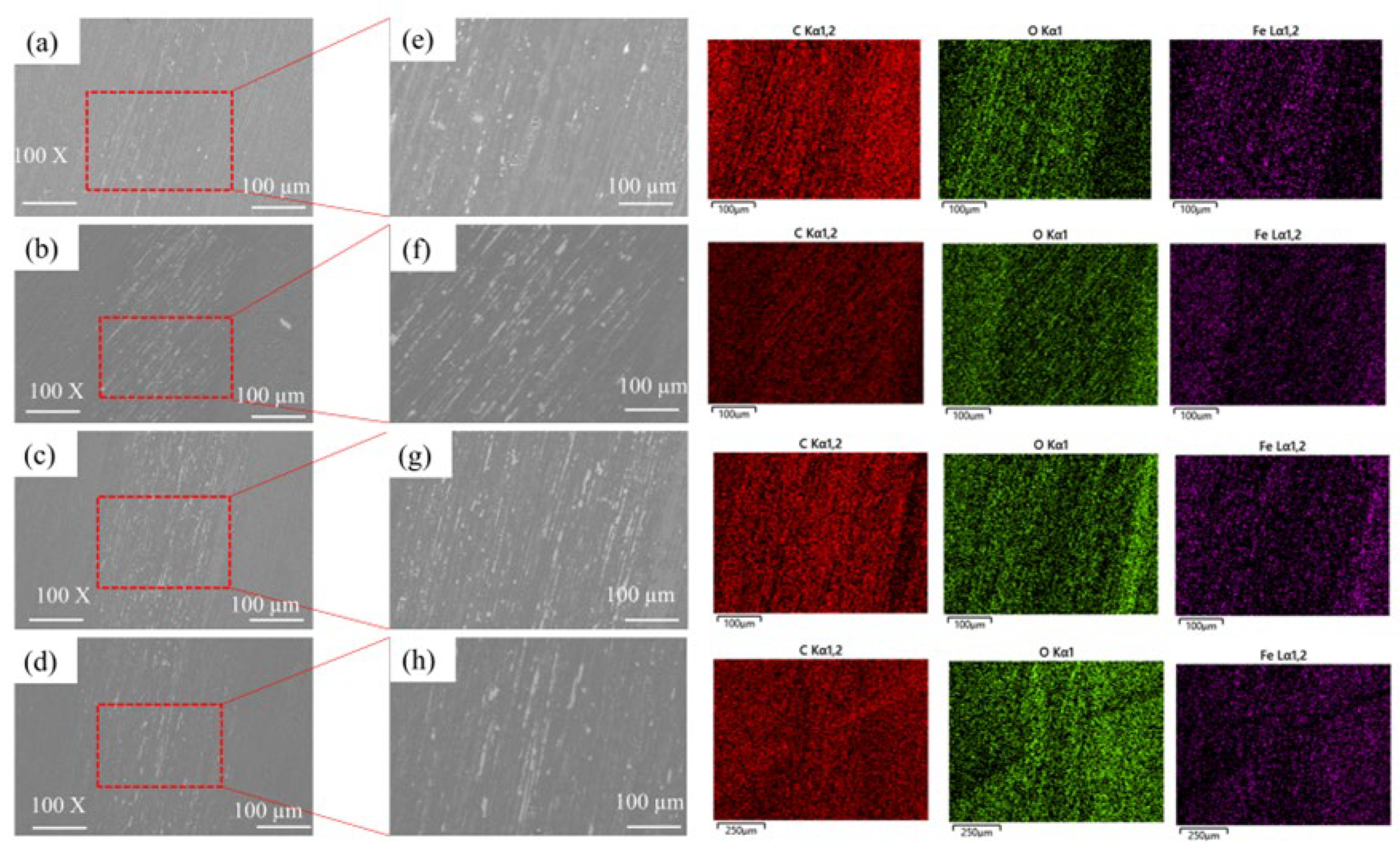

3.5. Morphology

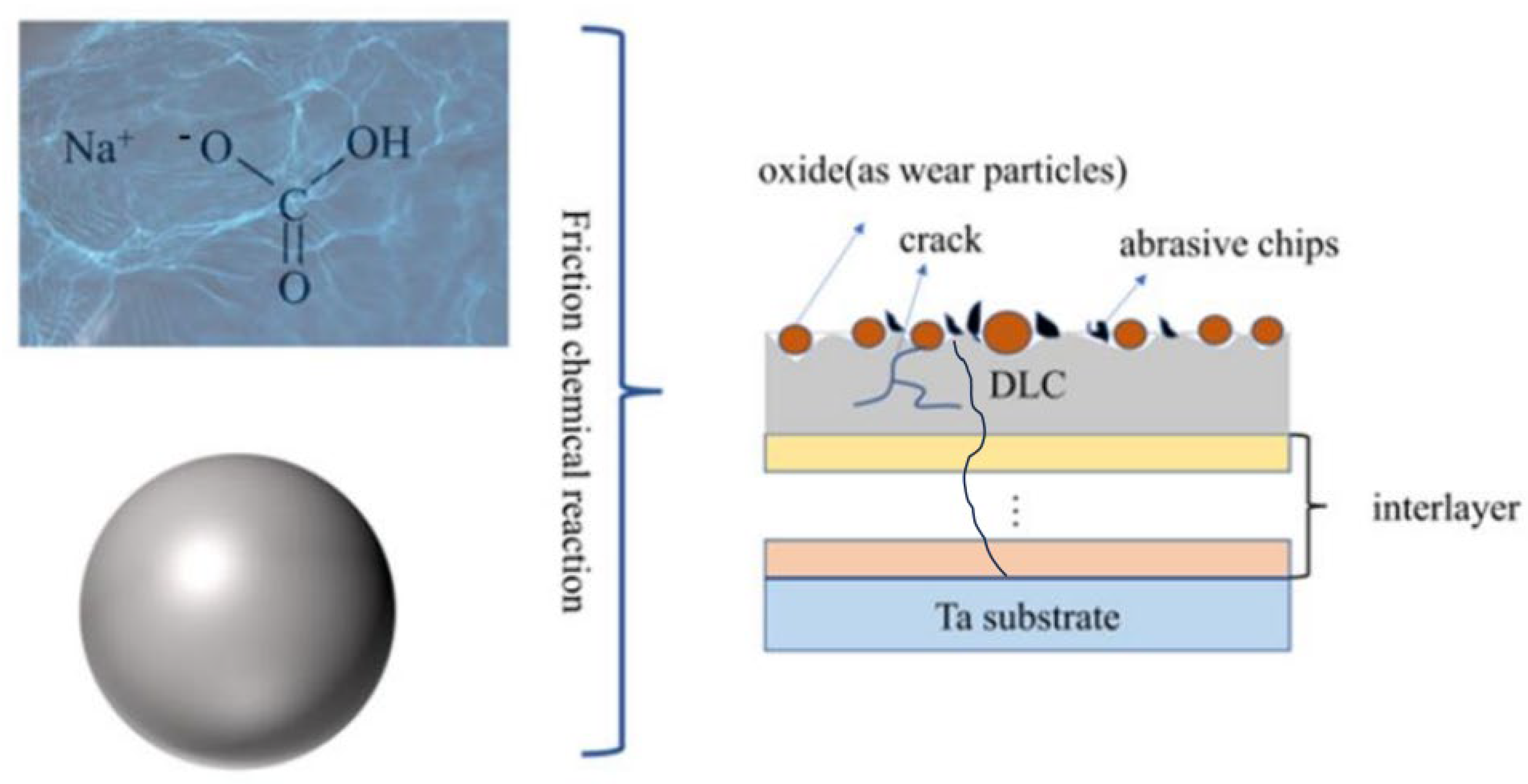

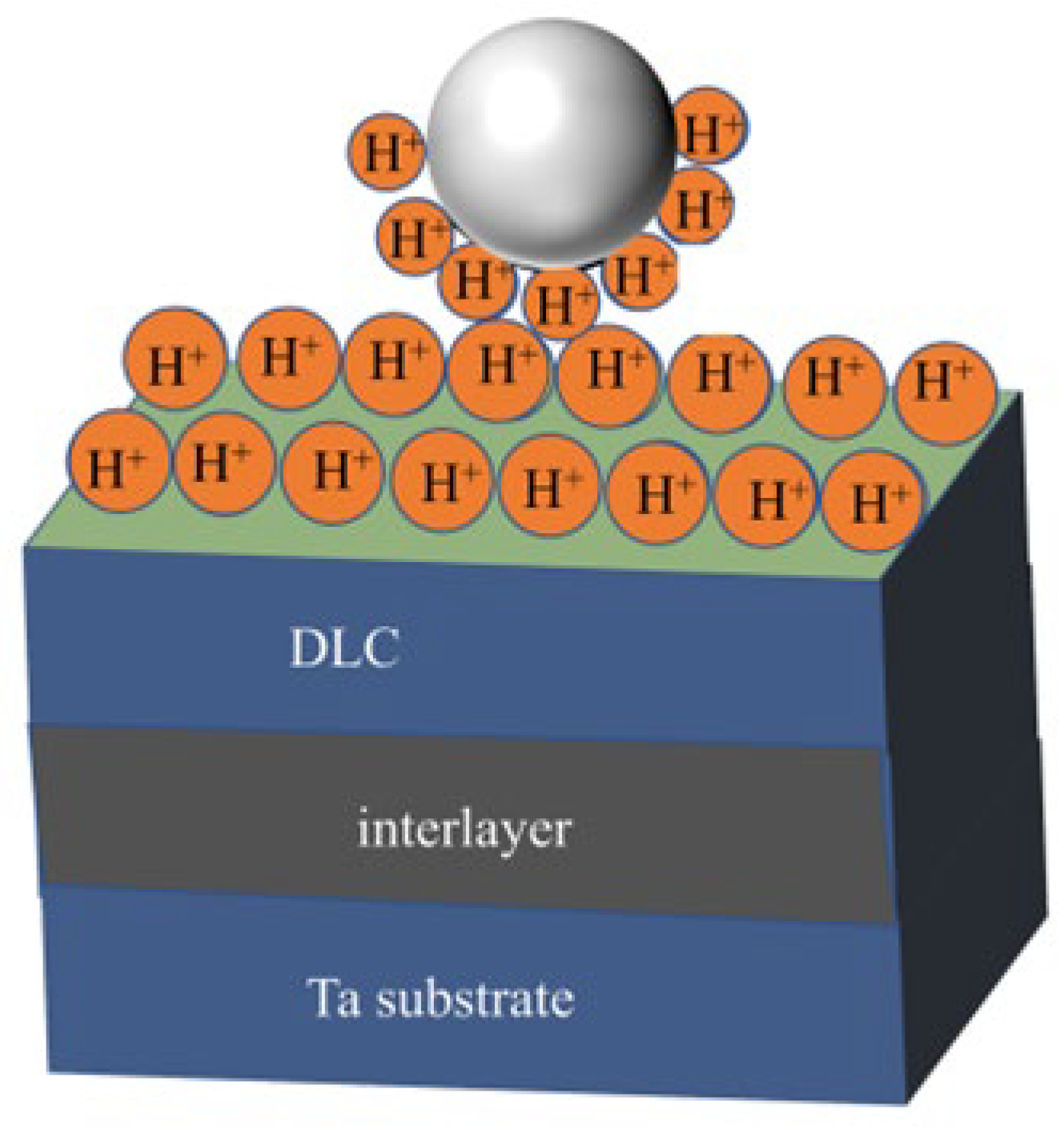

3.6. Friction and Wear Mechanism

4. Conclusions

- (1)

- The hardness of TTTD film is nearly 15 times that of ultra-thick film, and the residual stress is also nearly twice smaller. Therefore, the TTTD film is less prone to detachment;

- (2)

- The friction coefficient of the TTTD film is lower than that of the ultra-thick film under different working conditions, mainly due to the appropriate sp3 bond content inside, the smooth and dense structure more easily forming boundary lubrication, and high hardness;

- (3)

- The friction coefficient of the TTTD film in lactic acid solution is lower than 0.1 at different frequencies, while the friction coefficient of the ultra-thick film is lower than 0.2 under the same operating conditions. This is because there are fewer oxides formed by non-oxidizing lactic acid, and hydrogen ions passivate the free-hanging bonds on the surface of DLC film;

- (4)

- The TiCuN interlayer can significantly increase the overall thickness of the film; the structure of the TiCuN interlayer affects the growth mode of the top DLC film, causing it to grow in spheres and resulting in more defects in the DLC film;

- (5)

- The TiCuN interlayer affects the internal structure of the DLC film, causing a shift from sp3 to sp2 bonds in the film, thus making the film less tough and causing higher residual stress.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meng, Z.Q. Bionics of artificial joint materials and the clinical application. J. Clin. Rehabil. Tissue Eng. Res. 2010, 14, 4101–4104. [Google Scholar]

- Liu, Y.Y.; Zhao, W.W.; Liu, G.X.; Bu, T.Z.; Xia, Y.C.; Xu, S.H.; Zhang, C.; Zhang, H.Y. Self-powered artificial joint wear debris sensor based on triboelectric nanogenerator. Nano Energy 2021, 85, 105967. [Google Scholar] [CrossRef]

- Sua, C.Y.; Chena, C.C.; Huanga, Y.L. Optimization of biomolecular additives for a reduction of friction in the artificial joint system. Tribo. Int. 2017, 111, 220–225. [Google Scholar] [CrossRef]

- Cicek, H. Wear behaviors of TiN/TiCN/DLC composite coatings in different environments. Ceram. Int. 2018, 44, 4853–4858. [Google Scholar] [CrossRef]

- Cui, M.J.; Pu, J.B.; Zhang, G.A.; Wang, L.P.; Xue, Q.J. The corrosion behaviors of multilayer diamond-like carbon coatings: Influence of deposition periods and corrosive medium. RSC Adv. 2016, 6, 28570. [Google Scholar] [CrossRef]

- Dai, W.; Gao, X.; Liu, J.M.; Hun, K.S.; Wang, Q.M. Compositionally modulated multilayer diamond-like carbon coatings with AlTiSi multi-doping by reactive high power impulse magnetron sputtering. Appl. Surf. Sci. 2017, 425, 855–861. [Google Scholar] [CrossRef]

- Jia, D.X.; Ma, G.J.; Liu, X.; Sun, G. Effect of different transition layer structures on Cr-DLC coating properties. Vac. Cryog. 2023, 29, 137–145. [Google Scholar]

- Wu, S.Z.; Zhang, S.L.; Huang, T.L.; Guo, D.; Ma, X.H.; Ding, W.J. Research Progress of Thick Diamond-like Carbon Coating. Hot Work. Technol. 2023, 52, 14–19. [Google Scholar]

- Paul, R. Uniformly dispersed nanocrystalline silver reduces the residual stress within diamond-like carbon hard coatings. NanoStructures NanoObjects 2017, 10, 69–79. [Google Scholar] [CrossRef]

- Guo, D.; Zhang, S.L.; Gan, Z.Y.; Guo, F. Study on Optimization Technology of Bonding Strength of DLC Films. Ningxia Eng. Technol. 2022, 21, 84–91. [Google Scholar]

- Lin, Y.Y.; Zhou, Z.F.; Li, K.Y. Improved wear resistance at high contact stresses of hydrogen-free diamond-like carbon coatings by carbon/carbon multilayer architecture. App. Surf. Sci. 2019, 477, 137–146. [Google Scholar] [CrossRef]

- Ding, J.C.; Mei, H.; Zheng, J.; Wang, Q.M.; Kang, M.C.; Zhang, T.F.; Kim, K.H. Microstructure and wettability of novel Al-containing diamond-like carbon films deposited by a hybrid sputtering system. J. Alloys Compd. 2021, 868, 159130. [Google Scholar] [CrossRef]

- Keles, S.; Duymus, Z.Y.I.; Sadeler, R.; Mehmet, E.; Emrah, M. Structural, mechanical and cytotoxic properties of Ta-doped diamond-like carbon films deposited via radio frequence magnetron sputtering on polyether ether ketone. Thin Solid Film. 2023, 769, 139736. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Huo, Y.Q.; Luan, B.F.; Zhang, T.F.; Wang, J.B. Effects of interlayers on tribological property of diamond-like carbon multilayer films on TC4 titanium alloy. Chin. J. Vac. Sci. Technol. 2023, 43, 331–338. [Google Scholar]

- Xu, H.J.; Chen, R.D.; Zhou, G.X.; Ye, Y.M.; Wang, A.Y. Effect of working pressure on structure and properties of Si/O-DLC films deposited on inner wall of the tube. Surf. Technol. 2023, 6, 439–449. [Google Scholar]

- Wu, H.; Xia, Y.Q.; Wu, L.N.; Lin, F.H. Effect of Copper-Doped TiN Coating and Ionic Liquid Composite Lubrication System on Current-Carrying Tribological Properties of Copper/Copper Friction Pair. Mater. Mech. Eng. 2023, 47, 86–92. [Google Scholar]

- Xu, T.Y.; Zhan, H.; Zhang, Y.J.; Wu, J.Y.; Wang, R.J. Effects of Pulse Voltage on Microstructure and Properties for Si-DLC Films on Internal Spline Tooth. China Surf. Eng. 2022, 35, 257–265. [Google Scholar]

- Chen, G.F.; Su, F.H. Effects of Pulse Bias Voltages on Structure and Property of DLC Films Prepared by PECVD Technique. Lubr. Eng. 2018, 43, 17–22. [Google Scholar]

- Dong, C.H.; Wei, X.T.; Li, Z.Y.; Zhang, W.; Li, S.; Wang, Z.G.; Shi, W.L. Friction Properties of Hydrogen Free Diamond-Like Carbon Coating. Mater. Prot. 2017, 50, 18–22. [Google Scholar]

- Modabberasl, A.; Kameli, P.; Ranjbar, M.; Salamati, H.; Ashiri, R. Fabrication of DLC thin films with improved diamond-like carbon character by the application of external magnetic field. Carbon 2015, 94, 485–493. [Google Scholar] [CrossRef]

- Zhang, T.F.; Jiang, F.; Liao, T.T.; Deng, Q.Y.; Li, S.S.; Wang, Y.; Leng, Y.X. Tribological behavior of diamond like carbon film sliding against CoCrMo or Al2O3 in air and water environment. Tribo. Int. 2016, 95, 456–461. [Google Scholar] [CrossRef]

- Zuo, S.W.; Miao, Q.; Liang, W.P.; Xiao, F.N.; Liu, R.X.; Liu, Y.Y.; Ding, Z.; Yang, Z.G. A study on the mechanical performance and medium temperature tribological behavior of plasma nitrocarburizing/TiAlSiN/DLC composite coating. Surf. Interf. 2021, 27, 101489. [Google Scholar] [CrossRef]

- Polaki, S.R.; Kumar, N.; Madapu, K.; Ganesan, K.; Srivastava, S.K.; Abhaya, S.; Kamruddin, M.; Dash, S.; Tyagi, A.K. Interpretation of friction and wear in DLC film: Role of surface chemistry and test environment. J. Phys. D Appl. Phys. 2016, 49, 445302. [Google Scholar] [CrossRef]

- Xu, W.; Zhou, K.S.; Lin, S.S.; Dai, M.J.; Shi, Q.; Wei, C.B. Structural properties of hydrogenated Al-doped diamond-like carbon films fabricated by a hybrid plasma system. Diam. Relat. Mater. 2018, 87, 177–185. [Google Scholar] [CrossRef]

- Ding, J.C.; Mei, H.J.; Jeong, S.H.; Zheng, J.; Wang, Q.M.; Kim, K.H. Effect of bias voltage on the microstructure and properties of Nb-DLC films prepared by a hybrid sputtering system. J. Alloys Compd. 2021, 861, 158505. [Google Scholar] [CrossRef]

- Zhang, S.D.; Yan, M.F.; Yang, Y.; Zhang, Y.X.; Yan, F.Y.; Li, H.T. Excellent mechanical, tribological and anti-corrosive performance of novel Ti-DLC nanocomposite thin films prepared via magnetron sputtering method. Carbon 2019, 151, 136–147. [Google Scholar] [CrossRef]

- Kabir, M.S.; Zhou, Z.F.; Xie, Z.H.; Munroe, P. Designing multilayer diamond like carbon coatings for improved mechanical properties. J. Mater. Sci. Technol. 2021, 65, 108–117. [Google Scholar] [CrossRef]

- Liu, J.Q.; Wu, Z.Y.; Cao, H.T.; Wen, F.; Pei, Y.T. Effect of bias voltage on the tribological and sealing properties of rubber seals modified by DLC films. Surf. Coat. Technol. 2019, 360, 391–399. [Google Scholar] [CrossRef]

- Dai, W.; Gao, X.; Liu, J.M.; Wang, Q.M. Microstructure, mechanical property and thermal stability of diamond-like carbon coatings with Al, Cr and Si multi-doping. Diam. Relat. Mater. 2016, 70, 98–104. [Google Scholar] [CrossRef]

- Shi, X.R.; Shi, Y.J.; Chen, J.; Tomasz, L.; Beake, B.D.; Zhou, Z.H.; Wang, Z.H.; Wu, G.H. Influence of gradient interlayer thickness on corrosion and tribological behavior of Ti-containing multilayer graphite-like carbon films. Wear 2022, 488, 488–489. [Google Scholar] [CrossRef]

- Hao, T.M.; Du, J.; Su, G.S.; Zhang, P.R.; Sun, Y.J.; Zhang, J.J. Mechanical and cutting performance of cemented carbide tools with Cr/x/DLC composite coatings. Int. J. Adv. Manuf. Technol. 2020, 106, 5241–5254. [Google Scholar] [CrossRef]

- Guan, X.Y.; Wang, Y.X.; Wang, L.P.; Xue, Q.J. Progress in Tribological Performances of Carbon-Based Films in Liquid Lubrication Environments. Tribology 2017, 37, 270–282. [Google Scholar]

- Ji, J.H.; Zhou, J.P.; Wang, M.Y.; Wang, W.; Fu, Y.H. Effect of Initial Roughness on the Tribological Properties of Textured Surfaces with Micro-grooves. Surf. Technol. 2019, 48, 139–143. [Google Scholar]

- Shi, J.D.; Han, C.H.; Liu, Q.; Ma, G.Z.; Wang, H.D.; Li, G.L. Research Status and Prospect of Common Carbon-based Solid Lubricating Films. Surf. Technol. 2020, 49, 81–96. [Google Scholar]

- Li, Z.C.; Guan, X.Y.; Wang, Y.X.; Li, J.L.; Cheng, X.Y.; Lu, X.; Wang, L.P.; Xue, Q.J. Comparative study on the load carrying capacities of DLC, GLC and CrN coatings under sliding-friction condition in different environments. Surf. Coat. Technol. 2017, 321, 350–357. [Google Scholar] [CrossRef]

| Sample | D Peak (cm−1) | G Peak (cm) | ID/IG | G-Peak Half-Peak width (cm−1) |

|---|---|---|---|---|

| Ultra-thick film | 1365 | 1563 | 1.17 | 124 |

| TTTD film | 1376 | 1569 | 1.18 | 227 |

| Sample | H (GPa) | E (GPa) | H/E | H3/E2 (GPa) | Residual Stress (GPa) |

|---|---|---|---|---|---|

| Ultra-thick film | 0.52 | 26.1 | 0.019 | 0.0002 | −6.08 |

| TTTD film | 7.65 | 133.6 | 0.057 | 0.025 | −3.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, D.; Zhang, S.; Wu, S.; Huang, T.; Ma, X.; Guo, F. Design of an Ultra-Thick Film and Its Friction and Wear Performance under Different Working Conditions. Coatings 2023, 13, 1173. https://doi.org/10.3390/coatings13071173

Guo D, Zhang S, Wu S, Huang T, Ma X, Guo F. Design of an Ultra-Thick Film and Its Friction and Wear Performance under Different Working Conditions. Coatings. 2023; 13(7):1173. https://doi.org/10.3390/coatings13071173

Chicago/Turabian StyleGuo, Dong, Shuling Zhang, Shuaizheng Wu, Tenglong Huang, Xinghua Ma, and Feng Guo. 2023. "Design of an Ultra-Thick Film and Its Friction and Wear Performance under Different Working Conditions" Coatings 13, no. 7: 1173. https://doi.org/10.3390/coatings13071173

APA StyleGuo, D., Zhang, S., Wu, S., Huang, T., Ma, X., & Guo, F. (2023). Design of an Ultra-Thick Film and Its Friction and Wear Performance under Different Working Conditions. Coatings, 13(7), 1173. https://doi.org/10.3390/coatings13071173