Tunable Thermal, Mechanical, and Tribological Properties of Polybenzoxazine-Based Composite for Vehicle Applications

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

2.2. Preparation of Polybenzoxazine-Based Composites

2.3. Characterization

3. Results and Discussion

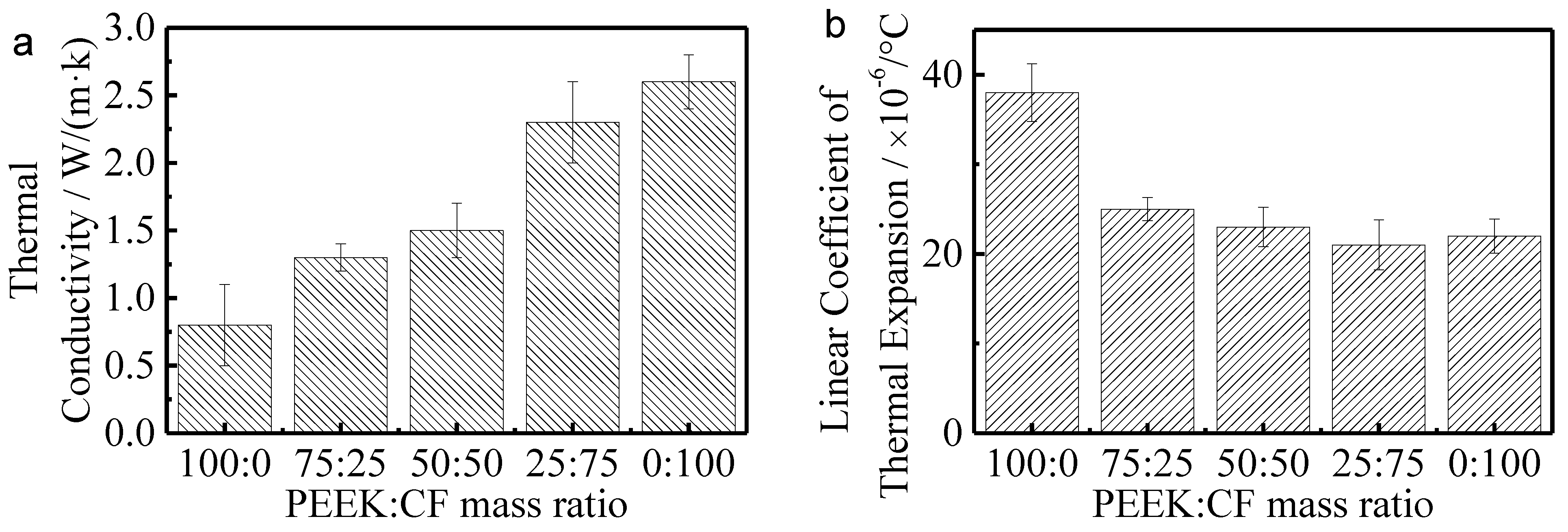

3.1. Thermal Conductivity

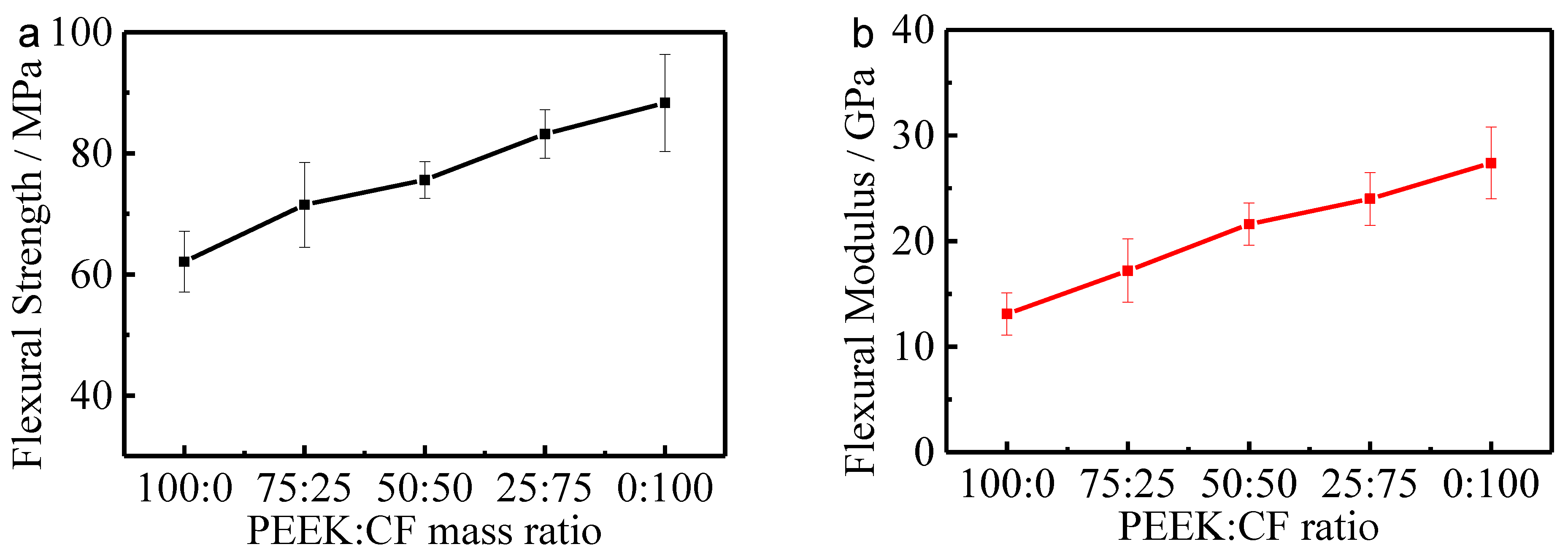

3.2. Mechanical Properties

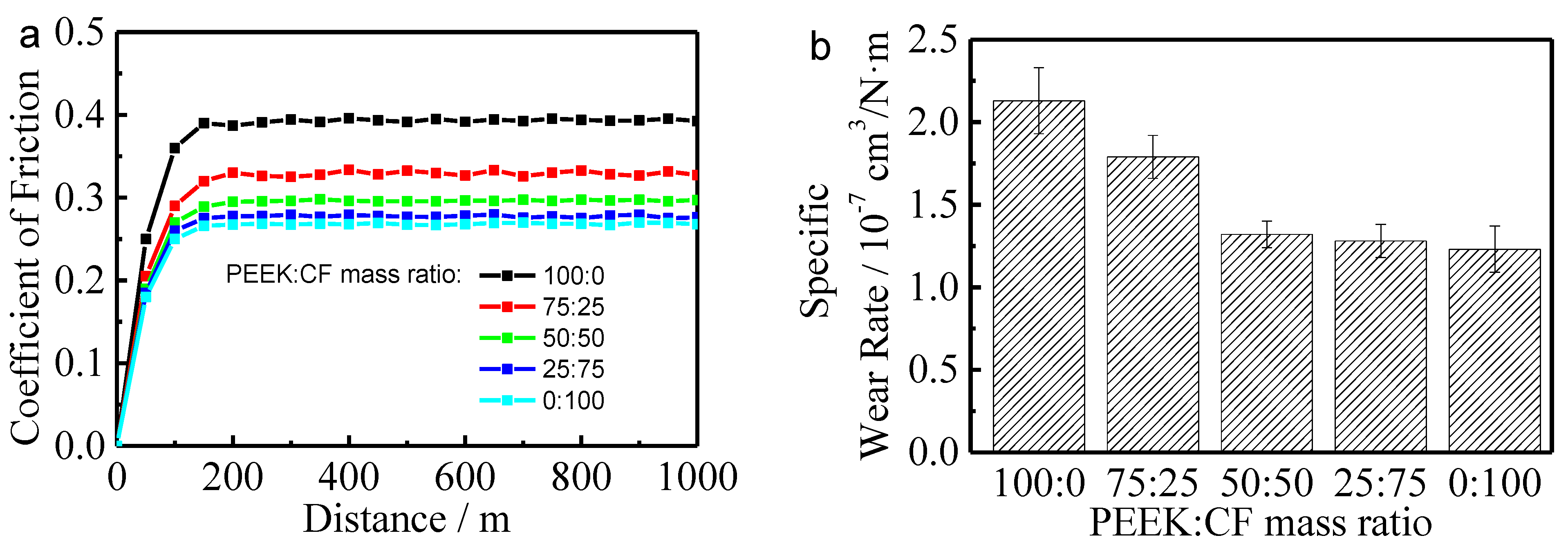

3.3. Tribological Properties

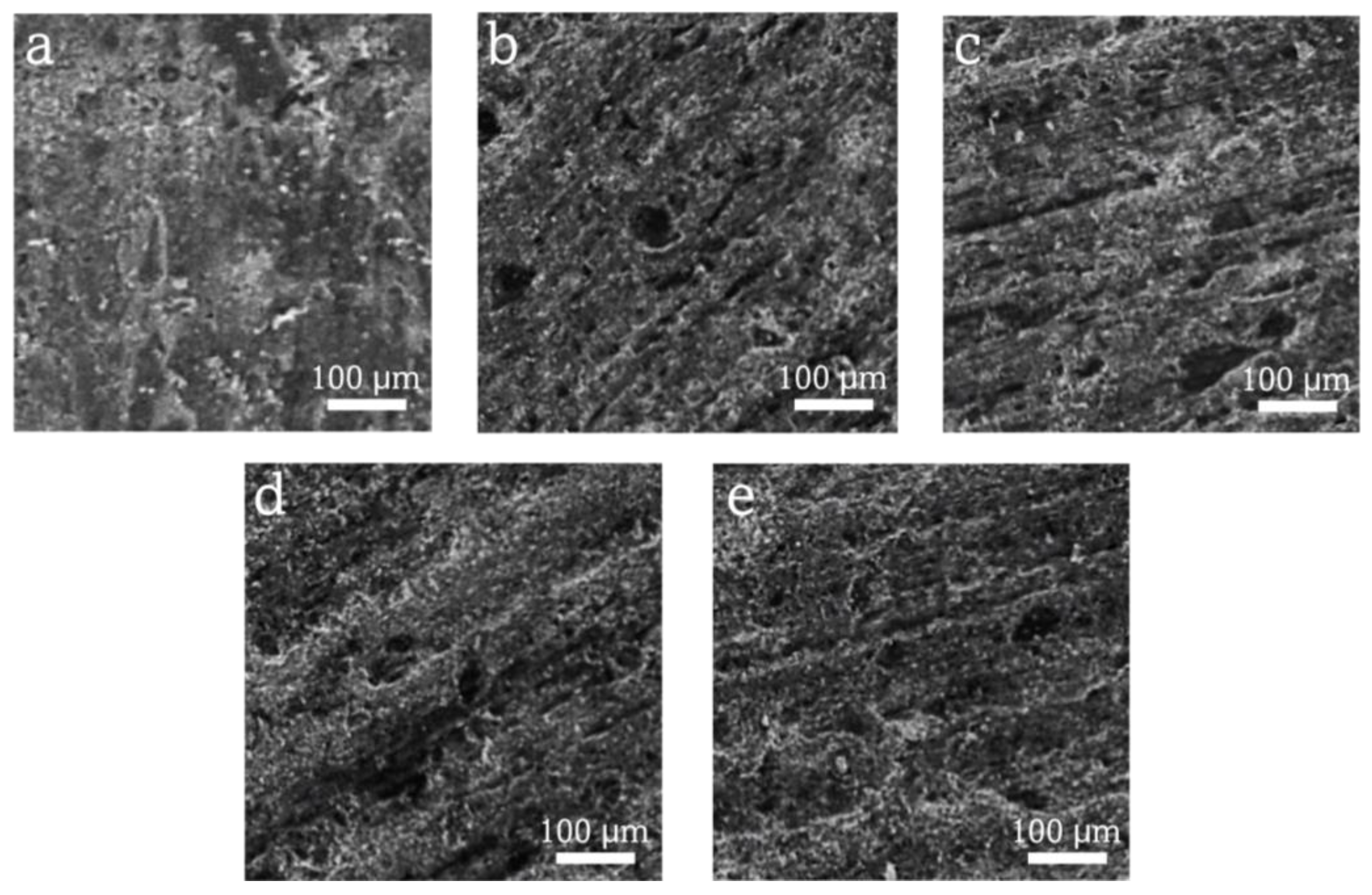

3.4. Morphological Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, Q.; Yang, Y.; Luo, C.; Yang, Z.; Fu, C. A novel electro-hydraulic compound braking system coordinated control strategy for a four-wheel-drive pure electric vehicle driven by dual motors. Energy 2022, 241, 122750. [Google Scholar] [CrossRef]

- Ilie, F.; Cristescu, A.-C. Tribological Behavior of Friction Materials of a Disk-Brake Pad Braking System Affected by Structural Changes—A Review. Materials 2022, 15, 4745. [Google Scholar] [PubMed]

- Wang, Q.; Wang, Z.; Mo, J.; Zhu, S.; Gou, Q. Evaluation of the dynamic behaviors of a train braking system considering disc–block interface characteristics. Mech. Syst. Signal Process. 2023, 192, 110234. [Google Scholar] [CrossRef]

- Manoharan, S.; Sai Krishnan, G.; Ganesh Babu, L.; R, V.; Lenin Singaravelu, D. Synergistic effect of red mud-iron sulfide particles on fade-recovery characteristics of non-asbestos organic brake friction composites. Mater. Res. Express 2019, 6, 105311. [Google Scholar] [CrossRef]

- Lertwassana, W.; Parnklang, T.; Mora, P.; Jubsilp, C.; Rimdusit, S. High performance aramid pulp/carbon fiber-reinforced polybenzoxazine composites as friction materials. Compos. Part B Eng. 2019, 177, 107280. [Google Scholar] [CrossRef]

- Jara, D.C.; Jang, H. Synergistic effects of the ingredients of brake friction materials on friction and wear: A case study on phenolic resin and potassium titanate. Wear 2019, 430–431, 222–232. [Google Scholar] [CrossRef]

- Nogueira, A.P.G.; Leonardi, M.; Straffelini, G.; Gialanella, S. Sliding Behavior and Particle Emissions of Cu-Free Friction Materials with Different Contents of Phenolic Resin. Tribol. Trans. 2020, 63, 770–779. [Google Scholar] [CrossRef]

- Ke, H.; Zhao, L.; Zhang, X.; Qiao, Y.; Wang, G.; Wang, X. Performance of high-temperature thermosetting polyimide composites modified with thermoplastic polyimide. Polym. Test. 2020, 90, 106746. [Google Scholar] [CrossRef]

- Kumar, V.V.; Kumaran, S.S. Friction material composite: Types of brake friction material formulations and effects of various ingredients on brake performance–a review. Mater. Res. Express 2019, 6, 082005. [Google Scholar] [CrossRef]

- Tang, Z.; Guo, L.; Xu, M.; Ruan, H.; Yang, J.; Wang, T.; Zhang, J.; Wang, Q.; Zhang, Y. Tribological behavior of shape memory cyanate ester materials and their tunable friction mechanism. Friction 2023. [Google Scholar] [CrossRef]

- Zhou, L.; Fu, Y.; Yin, T.; Luo, Z. Synergetic effect of epoxy resin and carboxylated nitrile rubber on tribological and mechanical properties of soft paper-based friction materials. Tribol. Int. 2019, 129, 314–322. [Google Scholar] [CrossRef]

- Jubsilp, C.; Jantaramaha, J.; Mora, P.; Rimdusit, S. Tribological Performance and Thermal Stability of Nanorubber-Modified Polybenzoxazine Composites for Non-Asbestos Friction Materials. Polymers 2021, 13, 2435. [Google Scholar] [CrossRef]

- Wongpayakyotin, A.; Jubsilp, C.; Tiptipakorn, S.; Mora, P.; Bielawski, C.W.; Rimdusit, S. Effects of Alkyl-Substituted Polybenzoxazines on Tribological Properties of Non-Asbestos Composite Friction Materials. Polymers 2021, 13, 567. [Google Scholar] [CrossRef]

- Bîru, E.I.; Gârea, S.A.; Iovu, H. Developing Polybenzoxazine Composites Based on Various Carbon Structures. Macromol. Chem. Phys. 2019, 220, 1800322. [Google Scholar] [CrossRef]

- Carlevaris, D.; Menapace, C.; Straffelini, G.; Fambri, L. Characterization of benzoxazine resins for brake pad friction materials manufacturing. J. Therm. Anal. Calorim. 2023, 148, 767–787. [Google Scholar] [CrossRef]

- Yao, H.; Jia, Y.; Shi, Y.; Yan, H.-X.; Li, S.; Liu, T. Bismaleimides blend with a synthesised phosphorus-containing benzoxazine and its mechanical and tribological properties. Plast. Rubber Compos. 2019, 48, 234–239. [Google Scholar] [CrossRef]

- Su, M.; Liang, L.; Ren, F.; Yao, W.; Yu, M.; Ren, M.; Sun, J. Influence of reinforcing fiber on the dry sliding wear behavior of hybrid fabric/benzoxazine composites. Text. Res. J. 2019, 89, 5153–5164. [Google Scholar] [CrossRef]

- Song, W.; Park, J.; Choi, J.; Lee, J.J.; Jang, H. Effects of reinforcing fibers on airborne particle emissions from brake pads. Wear 2021, 484–485, 203996. [Google Scholar] [CrossRef]

- Saindane, U.V.; Soni, S.; Menghani, J.V. Recent research status on synthesis and characterization of natural fibers reinforced polymer composites and modern friction materials—An overview. Mater. Today Proc. 2020, 26, 1616–1620. [Google Scholar] [CrossRef]

- Venkatesh, S.; Murugapoopathiraja, K. Scoping Review of Brake Friction Material for Automotive. Mater. Today Proc. 2019, 16, 927–933. [Google Scholar] [CrossRef]

- Bernstein, D.M. The health effects of short fiber chrysotile and amphibole asbestos. Crit. Rev. Toxicol. 2022, 52, 89–112. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Gao, G.; Tong, J.; Zhuang, J.; Song, W.; Ma, Y.; Liu, G.; Cao, F.; Yuan, S.; Zhang, Q. Tribological and mechanical behaviours of resin-based friction materials based on microcrack filling. Biosurf. Biotribol. 2023, 9, 1–8. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, K.; Ye, J.; Li, X.; Zhao, X.; Qu, T.; Liu, Q.; Gao, B. The effects of filler type on the friction and wear performance of PEEK and PTFE composites under hybrid wear conditions. Wear 2022, 490–491, 204178. [Google Scholar] [CrossRef]

- Lin, L.; Ecke, N.; Huang, M.; Pei, X.-Q.; Schlarb, A.K. Impact of nanosilica on the friction and wear of a PEEK/CF composite coating manufactured by fused deposition modeling (FDM). Compos. Part B Eng. 2019, 177, 107428. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, F.; Zhang, J.; Myshkin, N.K.; Zhang, G. Significant friction and wear-reduction role of attapulgite nanofibers compounded in PEEK-Based materials. Compos. Sci. Technol. 2022, 230, 109449. [Google Scholar] [CrossRef]

- Ahmadijokani, F.; Shojaei, A.; Arjmand, M.; Alaei, Y.; Yan, N. Effect of short carbon fiber on thermal, mechanical and tribological behavior of phenolic-based brake friction materials. Compos. Part B Eng. 2019, 168, 98–105. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Ahmadijokani, F.; Alaei, Y.; Shojaei, A.; Arjmand, M.; Yan, N. Frictional behavior of resin-based brake composites: Effect of carbon fibre reinforcement. Wear 2019, 420–421, 108–115. [Google Scholar] [CrossRef]

- Xian, G.; Zhang, Z. Sliding wear of polyetherimide matrix composites: I. Influence of short carbon fibre reinforcement. Wear 2005, 258, 776–782. [Google Scholar] [CrossRef]

- Satapathy, B.K.; Bijwe, J. Performance of friction materials based on variation in nature of organic fibres: Part I. Fade and recovery behaviour. Wear 2004, 257, 573–584. [Google Scholar] [CrossRef]

- Santhosh Kumar, K.S.; Reghunadhan Nair, C.P.; Radhakrishnan, T.S.; Ninan, K.N. Bis allyl benzoxazine: Synthesis, polymerisation and polymer properties. Eur. Polym. J. 2007, 43, 2504–2514. [Google Scholar] [CrossRef]

- Li, M.; Ali, Z.; Wei, X.; Li, L.; Song, G.; Hou, X.; Do, H.; Greer, J.C.; Pan, Z.; Lin, C.-T.; et al. Stress induced carbon fiber orientation for enhanced thermal conductivity of epoxy composites. Compos. Part B Eng. 2021, 208, 108599. [Google Scholar] [CrossRef]

- Schadler, L.S.; Giannaris, S.C.; Ajayan, P.M. Load transfer in carbon nanotube epoxy composites. Appl. Phys. Lett. 1998, 73, 3842–3844. [Google Scholar] [CrossRef]

- Singh, T.; Patnaik, A.; Chauhan, R.; Chauhan, P.; Kumar, N. Physico-mechanical and tribological properties of nanoclay filled friction composite materials using Taguchi design of experiment approach. Polym. Compos. 2018, 39, 1575–1581. [Google Scholar] [CrossRef]

- Mohanty, S.; Chugh, Y.P. Development of fly ash-based automotive brake lining. Tribol. Int. 2007, 40, 1217–1224. [Google Scholar] [CrossRef]

- Eriksson, M.; Jacobson, S. Tribological surfaces of organic brake pads. Tribol. Int. 2000, 33, 817–827. [Google Scholar] [CrossRef]

- Li, W.; Wang, C.; Gao, B.; Wang, Y.; Jin, X.; Zhang, L.; Sakyi, P.A. Determination of multi-element concentrations at ultra-low levels in alternating magnetite and pyrite by HR-ICP-MS using matrix removal and preconcentration. Microchem. J. 2016, 127, 237–246. [Google Scholar] [CrossRef]

- Byeong-Choon, G.; In-Sik, C. Microstructural Analysis and Wear Performance of Carbon-Fiber-Reinforced SiC Composite for Brake Pads. Materials 2017, 10, 701. [Google Scholar] [CrossRef]

- Song, H.-J.; Zhang, Z.-Z.; Luo, Z.-Z. A study of tribological behaviors of the phenolic composite coating reinforced with carbon fibers. Mater. Sci. Eng. A 2007, 445–446, 593–599. [Google Scholar] [CrossRef]

- Dong, F.; Hou, G.; Cao, F.; Yan, F.; Liu, L.; Wang, J. The lubricity and reinforcement of carbon fibers in polyimide at high temperatures. Tribol. Int. 2016, 101, 291–300. [Google Scholar] [CrossRef]

- Kim, S.J.; Hyung Cho, M.; Hyung Cho, K.; Jang, H. Complementary effects of solid lubricants in the automotive brake lining. Tribol. Int. 2007, 40, 15–20. [Google Scholar] [CrossRef]

- Wu, Y.; Zeng, M.; Xu, Q.; Hou, S.; Jin, H.; Fan, L. Effects of glass-to-rubber transition of thermosetting resin matrix on the friction and wear properties of friction materials. Tribol. Int. 2012, 54, 51–57. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Y. Mechanical and tribological properties of ceramic-matrix friction materials with steel fiber and mullite fiber. Mater. Des. 2014, 57, 449–455. [Google Scholar] [CrossRef]

- Amirjan, M. Microstructure, wear and friction behavior of nanocomposite materials with natural ingredients. Tribol. Int. 2019, 131, 184–190. [Google Scholar] [CrossRef]

- Öztürk, B.; Arslan, F.; Öztürk, S. Effects of Different Kinds of Fibers on Mechanical and Tribological Properties of Brake Friction Materials. Tribol. Trans. 2013, 56, 536–545. [Google Scholar] [CrossRef]

- Cheng, D.-Q.; Wang, X.-T.; Zhu, J.; Qiu, D.-H.; Cheng, X.-W.; Guan, Q.-F. Friction and wear behavior of carbon fiber reinforced brake materials. Front. Mater. Sci. China 2009, 3, 56–60. [Google Scholar] [CrossRef]

- Öztürk, B.; Öztürk, S. Effects of Resin Type and Fiber Length on the Mechanical and Tribological Properties of Brake Friction Materials. Tribol. Lett. 2011, 42, 339–350. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y.; Wang, L.; Tong, J.; Zhuang, J.; Jia, H. Performance assessment of hybrid fibers reinforced friction composites under dry sliding conditions. Tribol. Int. 2018, 119, 262–269. [Google Scholar] [CrossRef]

- Jubsilp, C.; Rimdusit, S. Chapter 44—Polybenzoxazine-Based Self-Lubricating and Friction Materials. In Advanced and Emerging Polybenzoxazine Science and Technology; Ishida, H., Froimowicz, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 945–974. [Google Scholar] [CrossRef]

- Jiménez, A.E.; Bermúdez, M.D. 2—Friction and wear. In Tribology for Engineers; Davim, J.P., Ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 33–63. [Google Scholar] [CrossRef]

- Tang, H.; Zeng, X.; Xiong, X.; Li, L.; Jizhao, Z. Mechanical and tribological properties of short-fiber-reinforced SiC composites. Tribol. Int. 2009, 42, 823–827. [Google Scholar] [CrossRef]

| Ingredients (wt%) | Ingredient Compositions | ||||

|---|---|---|---|---|---|

| 100:0 | 75:25 | 50:50 | 250:75 | 0:100 | |

| Benzoxazine resin (D940) | 15 | 15 | 15 | 15 | 15 |

| PEEK fiber | 5 | 3.75 | 2.5 | 1.25 | 0 |

| CF | 0 | 1.25 | 2.5 | 3.75 | 5 |

| GF | 10 | 10 | 10 | 10 | 10 |

| SF | 25 | 25 | 25 | 25 | 25 |

| Graphite | 15 | 15 | 15 | 15 | 15 |

| ZrSiO4 | 6 | 6 | 6 | 6 | 6 |

| BaSO4 | 20 | 20 | 20 | 20 | 20 |

| Rubber dust | 4 | 4 | 4 | 4 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Chen, X.; Wu, G.; Huang, S. Tunable Thermal, Mechanical, and Tribological Properties of Polybenzoxazine-Based Composite for Vehicle Applications. Coatings 2023, 13, 1147. https://doi.org/10.3390/coatings13071147

Guo Y, Chen X, Wu G, Huang S. Tunable Thermal, Mechanical, and Tribological Properties of Polybenzoxazine-Based Composite for Vehicle Applications. Coatings. 2023; 13(7):1147. https://doi.org/10.3390/coatings13071147

Chicago/Turabian StyleGuo, Yue, Xuhui Chen, Guorong Wu, and Shiwen Huang. 2023. "Tunable Thermal, Mechanical, and Tribological Properties of Polybenzoxazine-Based Composite for Vehicle Applications" Coatings 13, no. 7: 1147. https://doi.org/10.3390/coatings13071147

APA StyleGuo, Y., Chen, X., Wu, G., & Huang, S. (2023). Tunable Thermal, Mechanical, and Tribological Properties of Polybenzoxazine-Based Composite for Vehicle Applications. Coatings, 13(7), 1147. https://doi.org/10.3390/coatings13071147