Effect of Substrate Bias Voltage on Microstructure and Mechanical Properties of Cr-Nb-Ti-Zr-N-O Ceramic Thin Films Produced by Reactive Sputtering

Abstract

1. Introduction

2. Materials and Methods

2.1. Coatings Preparation

2.2. Characterization Analysis

3. Results and Discussion

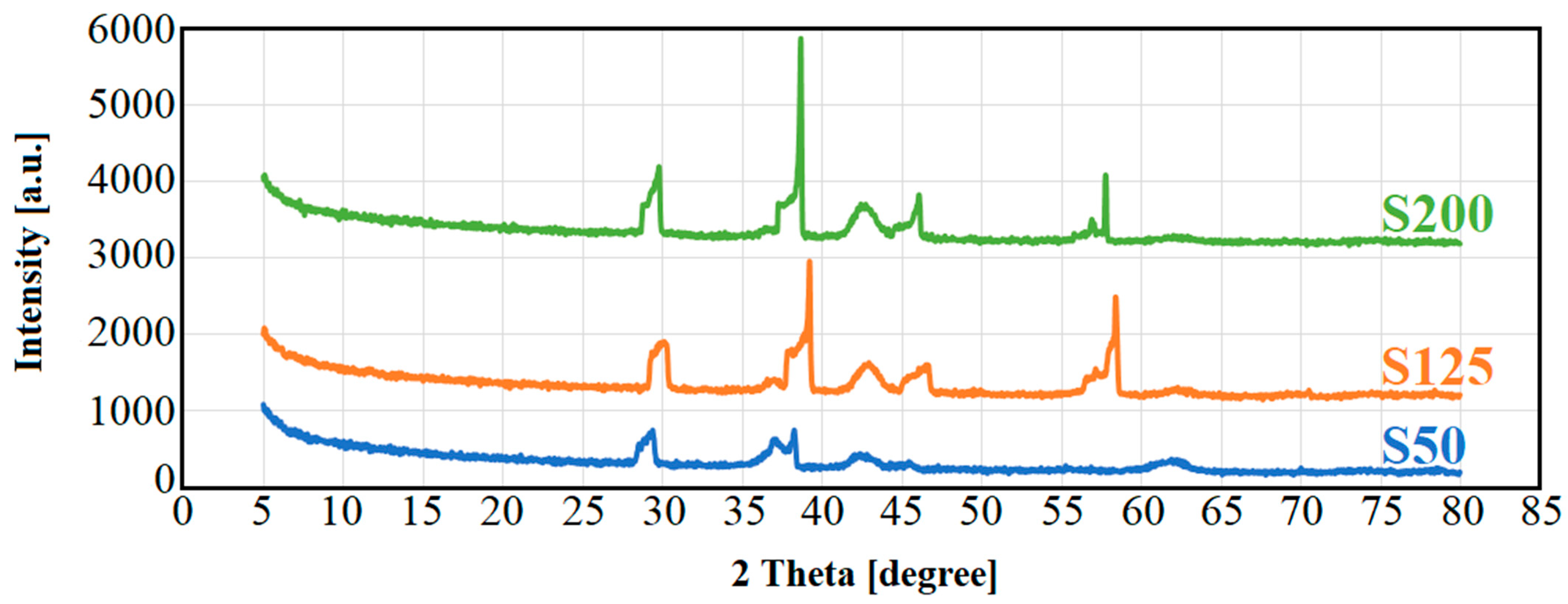

3.1. Chemical Analysis

3.2. Morphological Analysis

3.3. Mechanical Properties of the Coatings

4. Discussion

5. Conclusions

- -

- Under high voltage and temperature, oxygen can enter into thin films not only as an impurity but also as a principal element (according to EDS measurement, the oxygen atomic percentage in all thin films is more than 8.6%). This leads to the formation of the oxide crystalline phase (CrO2).

- -

- Increasing the substrate bias voltage (from −50 to −125 V) during the deposition of Cr-Nb-Ti-Zr-N-O ceramic films can cause a defectless and uniform surface. However, by increasing the voltage more than this optimum level (such as in sample S200), the pores/open boundaries density will be raised.

- -

- Ti and O can enhance the mechanical properties of thin films, because the hardness, Young’s modulus and toughness (H/E) of Cr-Nb-Ti-Zr-N-O thin films are higher than the ones related to the Cr-Zr-Nb-N medium-entropy alloy coatings.

- -

- To gain a wear-resistant coating (sample S125), it is important to achieve the minimum level of roughness (lower than 16.6 nm), skewness (0.2) and kurtosis (lower than 3).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Lyu, L.; Yang, J.; Zhou, M.; Yan, M.; Yang, J. Microstructure, mechanical properties and lead-bismuth eutectic corrosion behavior of (AlCrFeTiMo)NO and (AlCrFeTiNb)NO high entropy metal sublattice ceramic coatings. Vacuum 2023, 209, 111774. [Google Scholar] [CrossRef]

- Chang, L.; Tzeng, C.; Chen, Y. Effects of W Content on Structural and Mechanical Properties of TaWN Films. Coatings 2022, 12, 700. [Google Scholar] [CrossRef]

- Tang, J.; Lin, C.; Yang, F.; Chang, C. Influence of Nitrogen Content and Bias Voltage on Residual Stress and the Tribological and Mechanical Properties of CrAlN Films. Coatings 2020, 10, 546. [Google Scholar] [CrossRef]

- Yin, X.; Wu, S.; Dastan, D.; Nie, S.; Liu, Y.; Li, Z.; Zhou, Y.; Li, J.; Faik, A.; Shan, K.; et al. Sensing selectivity of SnO2-Mn3O4 nanocomposite sensors for the detection of H2 and CO gases. Surf. Interfaces 2021, 25, 101190. [Google Scholar] [CrossRef]

- Bueno, C.; Maestre, D.; Díaz, T.; Juárez, H.; Pacio, M.; Cremades, A.; Piqueras, J. High-yield growth of Ti doped ZnO nano- and microstructures by a vapor-solid method. J. Alloys Compd. 2017, 726, 201–208. [Google Scholar] [CrossRef]

- Rimmaudo, I.; Loeza-Poot, M.; Camacho-Espinosa, E.; Mis-Fernández, R.; Peña, J. Enhanced uniformity of sputtered oxygenated cadmium sulfide (CdS:O) films for large area photovoltaic applications. Sol. Energy 2018, 173, 1025–1031. [Google Scholar] [CrossRef]

- Mitterer, C.; Mayrhofer, P.H.; Musil, J. Thermal stability of PVD hard coatings. Vacuum 2003, 71, 279–284. [Google Scholar] [CrossRef]

- Musil, J.; Vlcek, J. Magnetron sputtering of hard nanocomposite coatings and their properties. Surf. Coat. Technol. 2001, 142–144, 557–566. [Google Scholar] [CrossRef]

- Aissani, L.; Alhussein, A.; Wasy Zia, A.; Mamba, G.; Rtimi, S. Magnetron Sputtering of Transition Metal Nitride Thin Films for Environmental Remediation. Coatings 2022, 12, 1746. [Google Scholar] [CrossRef]

- Glechner, T.; Hahn, R.; Wojcik, T.; Holec, D.; Kolozsvári, S.; Zaid, H.; Kodambaka, S.; Mayrhofer, P.; Riedl, H. Assessment of ductile character in superhard Ta-C-N thin films. Acta Mater. 2019, 179, 17–25. [Google Scholar] [CrossRef]

- Kindlund, H.; Sangiovanni, D.; Petrov, I.; Greene, J.; Hultman, L. A review of the intrinsic ductility and toughness of hard transition-metal nitride alloy thin films. Thin Solid Film. 2019, 688, 137479. [Google Scholar] [CrossRef]

- Friedrich, A.; Winkler, B.; Juarez-Arellano, E.; Bayarjargal, L. Synthesis of Binary Transition Metal Nitrides, Carbides and Borides from the Elements in the Laser-Heated Diamond Anvil Cell and Their Structure-Property Relations. Materials 2011, 4, 1648–1692. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Petrov, I.; Hultman, L.; Greczynski, G. Determining role of W+ ions in the densification of TiAlWN thin films grown by hybrid HiPIMS/DCMS technique with no external heating. J. Vac. Sci. Technol. A 2023, 41, 013407. [Google Scholar] [CrossRef]

- Yan, K.; Xian, G.; Zhao, H.; Fan, H.; Wang, J.; Wang, H.; Du, H. Effect of Mo content on the structure and mechanical properties of TiAlMoN films deposited on WC–Co cemented carbide substrate by magnetron sputtering. Int. J. Refract. Met. Hard Mater. 2015, 52, 29–35. [Google Scholar] [CrossRef]

- Hu, C.; Xu, Y.; Chen, L.; Pei, F.; Zhang, L.; Du, Y. Structural, mechanical and thermal properties of CrAlNbN coatings. Surf. Coat. Technol. 2018, 349, 894–900. [Google Scholar] [CrossRef]

- Hu, C.; Xu, Y.; Chen, L.; Pei, F.; Du, Y. Mechanical properties, thermal stability and oxidation resistance of Ta-doped CrAlN coatings. Surf. Coat. Technol. 2019, 368, 25–32. [Google Scholar] [CrossRef]

- Jun Kim, D.; Min Kim, S.; Hyun La, J.; Yul Lee, S.; Sun Hong, Y.; Hyung Lee, M. Synthesis and characterization of CrZrAlN films using unbalanced magnetron sputtering with segment targets. Met. Mater. Int. 2013, 19, 1295–1299. [Google Scholar] [CrossRef]

- Navinšek, B.; Panjan, P.; Cvelbar, A. Characterization of low temperature CrN and TiN (PVD) hard coatings. Surf. Coat. Technol. 1995, 75, 155–161. [Google Scholar] [CrossRef]

- Mansoor, N.; Fattah-alhosseini, A.; Elmkhah, H.; Shishehian, A. Electrochemical behavior of TiN, CrN and TiN/CrN nanostructured coatings on the nickel-chromium alloy used in dental fixed prosthesis. J. Asian Ceram. Soc. 2020, 8, 694–710. [Google Scholar] [CrossRef]

- Beltrami, M.; Mavrič, A.; Dal Zilio, S.; Fanetti, M.; Kapun, G.; Lazzarino, M.; Sbaizero, O.; Čekada, M. A comparative study of nanolaminate CrN/Mo2N and CrN/W2N as hard and corrosion resistant coatings. Surf. Coat. Technol. 2023, 455, 129209. [Google Scholar] [CrossRef]

- Marques de Castilho, B.; de Sousa Mazuc, F.; Mendes Rodrigues, A.; Tavares Avila, P.; Chefer Apolinario, R.; Daum, P.; Pereira da Costa, F.; Rodrigues Menezes, R.; de Araújo Neves, G.; Greiner, C.; et al. Tailoring the Hybrid Magnetron Sputtering Process (HiPIMS and dcMS) to Manufacture Ceramic Multilayers: Powering Conditions, Target Materials, and Base Layers. Nanomaterials 2022, 12, 2465. [Google Scholar] [CrossRef]

- Hones, P.; Sanjines, R.; Levy, F. Sputter deposited chromium nitride based ternary compounds for hard coatings. Thin Solid Film. 1998, 332, 240–246. [Google Scholar] [CrossRef]

- Aouadi, S.; Maeruf, T.; Twesten, R.; Mihut, D.; Rohde, S. Physical and mechanical properties of chromium zirconium nitride thin films. Surf. Coat. Technol. 2006, 200, 3411–3417. [Google Scholar] [CrossRef]

- Ataie, S.A.; Keshtmand, R.; Zamani-Meymian, M.R. Nano-mechanical properties of Cr-Zr-Nb-N medium entropy alloy films produced by reactive sputtering. Int. J. Refract. Met. Hard Mater. 2023, 110, 106006. [Google Scholar] [CrossRef]

- Panjan, P.; Cekada, M.; Panjan, M.; Kek-Merl, D. Growth defects in PVD hard coatings. Vacuum 2009, 84, 209–214. [Google Scholar] [CrossRef]

- Mei, H.; Cai, Z.; Ding, J.; Yan, K.; Li, Q.; Zhao, Z.; Zhao, J.; Cheng, L.; Liu, M.; Gong, W. The Additions of V and Cu on the Microstructure and Mechanical Properties of Mo-N Coatings. Coatings 2022, 12, 1129. [Google Scholar] [CrossRef]

- Cavaleiro, A.; Louro, C. Nanocrystalline structure and hardness of thin films. Vacuum 2002, 64, 211–218. [Google Scholar] [CrossRef]

- Pristáš, G.; Bačkai, J.; Orendáč, M.; Gabáni, S.; Košuth, F.; Kuzmiak, M.; Szabó, P.; Gažo, E.; Franz, R.; Hirn, S.; et al. Superconductivity in medium- and high-entropy alloy thin films: Impact of thickness and external pressure. Phys. Rev. B 2023, 107, 024505. [Google Scholar] [CrossRef]

- Ataie, S.A.; Soltanieh, M.; Naghizadeh, R.; Ahmadi, M.; Ghanaatshoar, M. Effects of substrate temperature and reactive gas flow rate on the crystalline ceramic phases formation and tribological properties of W–Ti–Co–C–N thin films produced by co-sputtering. Ceram. Int. 2020, 46, 29137–29149. [Google Scholar] [CrossRef]

- Kumada, T.; Ohtsuka, M.; Fukuyama, H. Influence of substrate temperature on the crystalline quality of AlN layers deposited by RF reactive magnetron sputtering. AIP Adv. 2015, 5, 017136. [Google Scholar] [CrossRef]

- Ferreira, F.; Cavaleiro, A.; Oliveira, J. Tribological performance of DLC coatings deposited by DOMS in mixed Ar-Ne discharges. Mater. Lett. 2021, 285, 129056. [Google Scholar] [CrossRef]

- Dastan, D.; Shan, K.; Jafari, A.; Gity, F.; Yin, X.; Shi, Z.; Alharbi, N.; Ahmad Reshi, B.; Fu, W.; Ţălu, S.; et al. Influence of nitrogen concentration on electrical, mechanical, and structural properties of tantalum nitride thin films prepared via DC magnetron sputtering. Appl. Phys. A 2022, 128, 400. [Google Scholar] [CrossRef]

- Ataie, S.A.; Soltanieh, M.; Naghizadeh, R.; Cavaleiro, A.; Evaristo, M.; Fernandes, F.; Ferreira, F. Effect of substrate bias voltage on structural and tribological properties of W-Ti-C-N thin films produced by combinational HiPIMS and DCMS co-sputtering. Wear 2023, 520–521, 204654. [Google Scholar] [CrossRef]

- Ferreira, F.; Cavaleiro, A.; Oliveira, J. Effect of substrate biasing on the structure and properties of tantalum coatings deposited using HIPIMS in deep oscillation magnetron sputtering mode. Metals 2020, 10, 1618. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, B.; Guo, L.; Fu, D. Effect of bias voltage on the structure and hardness of TiSiN composite coatings synthesized by cathodic arc assisted middle-frequency magnetron sputtering. J. Alloys Compd. 2009, 473, 437–441. [Google Scholar] [CrossRef]

- Sert, Y.; Küçükömeroğlu, T.; Efeoğlu, I. Investigating the structure, adhesion and tribological properties of Al and Zr-doped TiN coatings with various substrate bias voltage and working pressure. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 6. [Google Scholar] [CrossRef]

- Ferreira, F.; Serra, R.; Oliveira, J.; Cavaleiro, A. Effect of peak target power on the properties of Cr thin films sputtered by HiPIMS in deep oscillation magnetron sputtering (DOMS) mode. Surf. Coat. Technol. 2014, 258, 249–256. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, D.; Fu, Y.; Du, H. Effect of sputtering target power on microstructure and mechanical properties of nanocomposite nc-TiN/a-SiNx thin films. Thin Solid Film. 2004, 447–448, 462–467. [Google Scholar] [CrossRef]

- Thornton, J.A. The microstructure of sputter-deposited coatings. J. Vac. Sci. Technol. A 1986, 4, 3059–3065. [Google Scholar] [CrossRef]

- Bavadi, R.; Valedbagi, S. Physical properties of titanium nitride thin film prepared by DC magnetron sputtering. Mater. Phys. Mech. 2012, 15, 167–172. [Google Scholar]

- Valvoda, V.; Černý, R.; Kužel, R., Jr.; Musil, J.; Poulek, V. Dependence of microstructure of TiN coatings on their thickness. Thin Solid Film. 1988, 158, 225–232. [Google Scholar] [CrossRef]

- Musil, J.; Poláková, H. Hard nanocomposite Zr–Y–N coatings, correlation between hardness and structure. Surf. Coat. Technol. 2000, 127, 99–106. [Google Scholar] [CrossRef]

- Aliramaji, S.; Keuter, P.; Neuß, D.; Hans, M.; Primetzhofer, D.; Depla, D.; Schneider, J. Effect of Growth Temperature and Atmosphere Exposure Time on Impurity Incorporation in Sputtered Mg, Al, and Ca Thin Films. Materials 2023, 16, 414. [Google Scholar] [CrossRef] [PubMed]

- Adjaottor, A.A.; Meletis, E.I.; Logothetidis, S.; Alexandrou, I.; Kokkou, S. Effect of substrate bias on sputter-deposited TiCx, TiNy and TiCxNy thin films. Surf. Coat. Technol. 1995, 76–77, 142–148. [Google Scholar] [CrossRef]

- Vuurman, M.A.; Wachs, I.E. In situ Raman spectroscopy of alumina-supported metal oxide catalysts. J. Phys. Chem. 1992, 96, 5008–5016. [Google Scholar] [CrossRef]

- Kotwal, C.A.; Bhushan, B. Contact analysis of non-Gaussian surfaces for minimum static and kinetic friction and wear. Tribol. Trans. 1996, 39, 890–898. [Google Scholar] [CrossRef]

- Zamani-Meymian, M.R.; Abdolvahab, R.H.; Mehr, A. Fractal characteristics of TiO2-Ag nanocomposite fi lms deposited by a grid- assisted co-sputtering method. Appl. Surf. Sci. 2019, 480, 593–600. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, D.; Fu, Y.; Du, H. Toughness measurement of thin films: A critical review. Surf. Coat. Technol. 2005, 198, 74–84. [Google Scholar] [CrossRef]

- Meindlhumer, M.; Ziegelwanger, T.; Zalesak, J.; Hans, M.; Lofler, L.; Spor, S.; Jager, N.; Stark, A.; Hruby, H.; Daniel, R.; et al. Precipitation-based grain boundary design alters inter- to trans-granular fracture in AlCrN thin films. Acta Mater. 2022, 237, 118156. [Google Scholar] [CrossRef]

| Sample Code | Cr (at. %) | Nb (at. %) | Ti (at. %) | Zr (at. %) | N (at. %) | O (%) |

|---|---|---|---|---|---|---|

| S50 | 24.4 | 22.0 | 7.5 | 2.9 | 30.3 | 12.5 |

| S125 | 22.6 | 19.3 | 6.8 | 2.5 | 40.1 | 8.6 |

| S200 | 23.1 | 21.8 | 8.3 | 3.4 | 33.1 | 10.1 |

| Sample Code | Ra (nm) | Rq (nm) | Sk (-) | Ku (-) | D (-) |

|---|---|---|---|---|---|

| S50 | 20.2 | 23.7 | −0.5 | 3.5 | 2.3 |

| S125 | 13.5 | 16.6 | −0.2 | 2.8 | 2.3 |

| S200 | 19.2 | 21.4 | −0.4 | 3.2 | 2.2 |

| Sample Code | H (GPa) | E (GPa) | H/E (-) | H3/E2 (GPa) |

|---|---|---|---|---|

| S50 | 14.3 ± 2.6 | 221.5 ± 7.9 | 0.064 | 0.059 |

| S125 | 24.5 ± 1.1 | 228.9 ± 5.1 | 0.107 | 0.280 |

| S200 | 22.8 ± 1.9 | 244.3 ± 5.8 | 0.093 | 0.198 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ataie, S.A.; Qashqay, S.M.; Zamani-Meymian, M.R.; Ferreira, F. Effect of Substrate Bias Voltage on Microstructure and Mechanical Properties of Cr-Nb-Ti-Zr-N-O Ceramic Thin Films Produced by Reactive Sputtering. Coatings 2023, 13, 1141. https://doi.org/10.3390/coatings13071141

Ataie SA, Qashqay SM, Zamani-Meymian MR, Ferreira F. Effect of Substrate Bias Voltage on Microstructure and Mechanical Properties of Cr-Nb-Ti-Zr-N-O Ceramic Thin Films Produced by Reactive Sputtering. Coatings. 2023; 13(7):1141. https://doi.org/10.3390/coatings13071141

Chicago/Turabian StyleAtaie, Sayed Alireza, S. Mahmoudi Qashqay, Mohammad Reza Zamani-Meymian, and Fabio Ferreira. 2023. "Effect of Substrate Bias Voltage on Microstructure and Mechanical Properties of Cr-Nb-Ti-Zr-N-O Ceramic Thin Films Produced by Reactive Sputtering" Coatings 13, no. 7: 1141. https://doi.org/10.3390/coatings13071141

APA StyleAtaie, S. A., Qashqay, S. M., Zamani-Meymian, M. R., & Ferreira, F. (2023). Effect of Substrate Bias Voltage on Microstructure and Mechanical Properties of Cr-Nb-Ti-Zr-N-O Ceramic Thin Films Produced by Reactive Sputtering. Coatings, 13(7), 1141. https://doi.org/10.3390/coatings13071141