Abstract

Photocatalytic coatings based on TiO2 nanoparticles have been applied to building materials over the past few decades, following encouraging results obtained by many laboratory studies and a few onsite testing campaigns showing their self-cleaning, antimicrobial and depolluting performance. However, these results clearly point out the need for a deeper understanding of the effectiveness of TiO2-based treatments when applied over different substrates and their durability when exposed to an outdoor environment. The present paper investigates the behavior of a nanodispersion of titania nanoparticles applied to cement-based substrates. Cementitious materials are widely used in building façades, roofs, structures, roads and tunnels; hence, any improvement in their performance and/or the introduction of new and unique functionalities have potentially a very high impact on everyday life. A TiO2 nanodispersion was applied by brushing and spraying on three cement-based substrates (a render, a prefabricated board and a painted prefabricated board), investigating its photocatalytic activity. Then, the samples were subjected to two artificially weathering procedures, involving rain washout and UV light exposure, and the changes in terms of the photocatalytic activity and contact angle were measured. The results suggest that the nature of the substrate plays a key role in the performance of the coating and that weathering has a significant impact too.

1. Introduction

Over the past few decades, the use of coatings based on TiO2 nanoparticles has emerged as a method for providing building materials’ surfaces with self-cleaning, antimicrobial and depolluting properties [1,2]. In fact, the photocatalytic behavior of TiO2 under light radiation (mostly UV) has been shown to degrade several pollutants (such as nitrogen oxides) and biological contaminants (such as bacteria), also providing super-hydrophilic properties that enhance the removal of dust and soiling by rain [3]. Of the two main polymorphs of titanium dioxide, namely anatase and rutile, anatase is generally accepted as the one with greater photocatalytic activity, but it was shown that a mixture of both phases is required for efficient photocatalysis [4,5] and that doping can significantly increase the photocatalytic activity of materials [6,7,8,9]. Many studies in the literature have also highlighted that, although the photocatalytic behavior of TiO2 was demonstrated a long time ago, many parameters influence the actual photocatalytic effectiveness and self-cleaning performance of titania, such as the size and size distribution of nanoparticles [10], and the strategies aimed at resolving the agglomeration problem of TiO2 [11].

Different nano-TiO2 coatings can be applied over the surface during the manufacturing process of materials, as in the case of ceramic tiles and glass, or directly onsite, by brushing or spraying them onto the building surfaces. The use of photocatalytic TiO2 nanoparticles in cement-based materials (either added to the mixture or applied over the hardened surface) began towards the end of the 1980s, aiming at the enhancement of the aesthetic durability of buildings and a reduction in environmental pollution [3,12,13]. Cementitious materials are widely used in outdoor applications, such as building façades, structures, roads and tunnels; hence, any improvement in their performance and/or the introduction of new and unique functionalities have potentially a very high impact on everyday life [8,14].

Many laboratory studies have provided experimental evidence on the depolluting effect of photocatalytic cement-based materials, showing their effectiveness in the abatement of nitrogen oxide and volatile organic compounds (NOx and VOCs), which are considered the most harmful gaseous compounds in polluted air [3,15]. VOCs are transformed mainly into H2O and CO2, while NOx is transformed into NO3− ions that can be easily washed out by rain [15]. The photocatalytic behavior of concrete pavements and external building surfaces incorporating TiO2 has also been shown in some onsite applications [15,16,17,18].

Although the studies performed so far have suggested a very positive contribution of cementitious materials incorporating TiO2 to the reduction in air pollutants and soiling, many questions still remain. In particular, a deep understanding of the actual photocatalytic activity of nano-TiO2 when coupled with different substrates seems necessary [19], as it has been shown that interactions may occur between cement and titania, thus influencing the effectiveness of the latter [20,21]. In fact, the chemistry of the cement environment and the pH of the pore solution may influence band edge positions in the semiconductor photocatalyst and redox processes taking place at the photocatalyst surface, as well as the agglomeration of the nanoparticles [3,13,18].

The durability of the photocatalytic activity in real applications is another aspect which deserves deeper investigation [22,23]. The carbonation of concrete (possibly occluding the nano-TiO2 in the surface region), the accumulation of various contaminants (especially in horizontal surfaces, such as roads and pavements) and the partial removal of TiO2 by rain have been suggested as possible factors reducing the self-cleaning and depolluting efficiency [20,22].

In the present paper, the photocatalytic behavior of an aqueous nano-TiO2 dispersion applied over three different cementitious substrates, namely a cement-based render and a prefabricated cement-based board with and without surface painting, was investigated. The application was performed by brushing and spraying to investigate the possible role of the application technique on the material’s performance. The type of application is very important to consider, not only for the final performance of the coating, but also for the possible health effect of nano-TiO2, as spraying increases the risk of inhalation of nanoparticles by the workers. In fact, the health and environmental effects of titania nanoparticles are still under investigation, and the International Agency on Research on Cancer (IARC) classified titanium dioxide in the Group 2B—”possibly carcinogenic to humans”, because there is “inadequate evidence in humans” and “sufficient evidence in experimental animals”, pointing out the urgent need of research in this field [1,24,25]. Moreover, there is limited information about the effects of TiO2 nanoparticles in the ecosystem and living organisms [26] which causes us to approach this material with a high level of carefulness.

Besides considering the role of different substrates and application techniques, the durability of the coating was investigated in this paper through artificial weathering tests. A first test was carried out by exposing the samples to water spray, simulating the rainfall affecting building surfaces; therefore, the variations in the photocatalytic behavior and in the titania amount were evaluated. In the second test, the samples were exposed to UV lamps for different durations, and we monitored the variation in the static contact angle due to possible modifications in the coating. Although measuring the contact angle was impossible for the render due to its very high roughness, the results obtained for the other two substrates allowed us to make some interesting observations.

2. Materials and Methods

2.1. Substrates

Three different kinds of commercially available cement-based substrates were used as follows:

- -

- Render: a commercially available dry-mix render constituted of hydraulic lime, Portland cement and quartz-calcite sand < 3 mm (class M5 according to EN 998-2) (Q-Malt, Omnia, Italy). The render was prepared using the amount of water recommended by the manufacturer and was applied with a thickness of 1.5 cm over a fired-clay brick substrate, aiming at an easier handling of the specimens. The brick surface to which the render was applied was 25 cm × 12.5 cm.

- -

- Board: a prefabricated composite board made of Portland cement, sand and fiberglass network reinforcement with a total thickness of 12 mm (Aquapanel Outdoor, Knauf, Iphofen, German) and size 20 cm × 10 cm.

- -

- Painted board: the same board as that described above, painted with a water-repellent acrylic-siloxane white paint (Muresko, Caparol, Odenwald, German) applied by brushing, as recommended by the manufacturer.

These substrates were selected as they were considered as representative of building materials that could benefit from the application of self-cleaning treatments, namely renders and boards exposed to possible soiling, darkening and biofilm growth.

2.2. TiO2-Based Treatment and Its Application

The photocatalytic treatment used in the tests was a commercial 0.9% aqueous suspension of TiO2 nanoparticles (anatase) with a size of <8 nm according to the manufacturer’s datasheet (TA2207, Nadico). This anatase-based suspension was selected as it was considered representative of a number of products available on the Italian market for the surface treatment of finishing materials in residential and commercial buildings, as well as in heritage buildings. The TiO2 aqueous suspension was not applied directly onto the substrate, but immediately after the preliminary application of a pre-treatment acting as coupling agent, i.e., promoting the adhesion of the TiO2 suspension. The pre-treatments were provided by the same manufacturer. For the render, the pre-treatment consisted in a first coating reducing the surface porosity of the substrate (TP2225, Nadico), labelled as coating#1, followed by a second coating containing a coupling agent (TP2220, Nadico), labelled as coating#2, whose nature was not declared by the manufacturer. For the board and the painted board, only coating#2 was used.

Two methods of application of the TiO2 suspension were used: brushing (4 brush strokes) and high-volume low-pressure spray (0.7 bar, distance between nozzle and sample was ~15 cm). Each specimen was treated by brushing on approximately one third of the surface and by spraying on another third, leaving the remaining third (at the center) untreated for comparison, according to the scheme in Figure 1a. The spraying and brushing applications were carried out covering the adjacent parts with a sheet, as shown in Figure 1b,c, respectively. Notably, spraying was carried out after covering the remaining part of the samples (Figure 1b) and then the brushing was carried out after covering the untreated part only (Figure 1c). In this way, the areas of the samples already treated with TiO2 were not altered by the application of any covering. After the treatments’ application, the specimens were left to dry for one week in laboratory conditions (temperature 20 ± 2 °C, relative humidity 55% ± 5%) after the application of the suspension, before any testing.

Figure 1.

(a) Scheme of the different treatments applied over each specimen; (b) spraying of the TiO2 suspension on a render specimen (the brick used as substrate can be seen too); (c) brushing of the TiO2 suspension on a board specimen.

2.3. Artificial Rain Washout

To evaluate the resistance of the treatment to rain washout, half of each specimen was exposed to deionized water spray, protecting the other half with an impermeable sheet, as in Figure 2. Water was sprayed onto the specimens placed in vertical position (Figure 2a) and was aimed at simulating one year of rain exposure at the location of Bologna, Italy. Considering that the mean rain precipitation in the period of 1991–2016 was 670 mm [27] and that the spray hit a circular surface with a diameter of 3 cm, 473 g of water was sprayed in 75 cycles (with a 2-minute break between cycles).

Figure 2.

A specimen during water spraying.

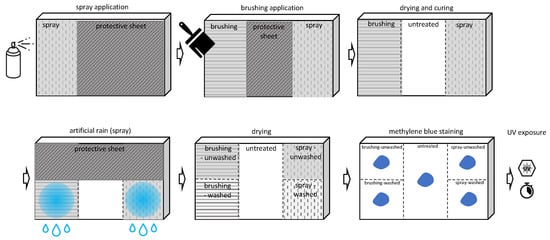

An overview of the entire procedure is shown in Figure 3. It can be observed that each specimen was divided into 5 different areas representing all the conditions (Figure 3). This allowed us to evaluate the effectiveness of the different treatments exactly on the same specimen (slab), overcoming the problems related to the possible heterogeneity of different specimens. In this way, the maximum comparability of results was achieved, although the number of zones under testing in the methylene blue discoloration test (Section 2.4) was limited to 5.

Figure 3.

Schematic outline of the procedure followed in this study.

2.4. Methods

The photocatalytic action of the surface was evaluated by the methylene blue discoloration test, one of the most used tests for this purpose. Two drops of a 50 mg L−1 solution of methylene blue in deionized water were applied in each position, and then the specimens were irradiated with UV light (UV lamp OSRAM DULUX S BL UVA 9 W/78, OSRAM SpA, Milano, Italy), observing the discoloration at different times: 1, 4, 8, 24, 28 h and 9 days. One specimen per each substrate was used. The test was performed in each of the five areas in Figure 3.

At the end of the test, small fragments were also collected from the surface of the specimens in order to analyze them by SEM (Zeiss EP EVO 50, Carl Zeiss S.p.A., Milano, Italy) and energy-dispersive spectrometry (EDS) (Oxford Instruments INCA ENERGY 350 detector, Oxford Instruments, High Wycombe, UK) in order to evaluate the amount of TiO2 in the samples. The fragments were obviously collected in zones where the methylene blue was not present and were made conductive by a gold sputter coating.

A different set of specimens was exposed to accelerated light irradiation under UV lamp (OSRAM DULUX S BL UVA 9 W/78, OSRAM SpA, Milano, Italy) for 1, 3 and 15 h, and the contact angle was measured and compared to the initial one in order to evaluate the possible deterioration of the TiO2-based coating. Static contact angle was measured in all of the five areas of each specimen by a DSA30S (Krüss, Hamburg, Germany) with 3 points for each area. It was not possible to perform this test on the render, due to its high roughness, making a reliable determination of the contact angle impossible. Hence, these data are available for the board and painted board only.

3. Results and Discussion

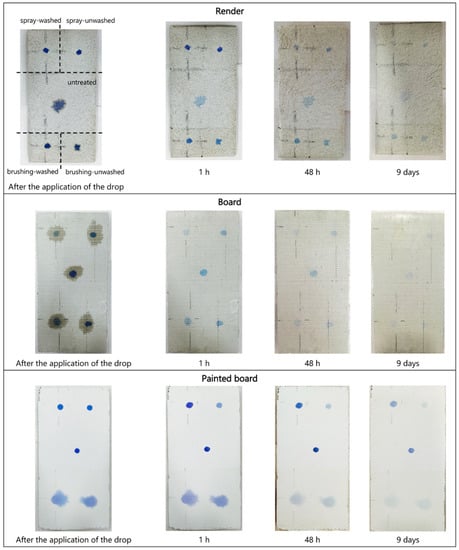

The appearance of the samples immediately after the application of the methylene blue solution and the subsequent decomposition of the methylene blue dye with UV exposure are reported in Figure 4 for a few significant exposure times, i.e., at 1 h, 48 h and 9 days. The contact angles immediately before (time 0) and during the methylene blue degradation test (1, 3 and 15 h) are reported in Table 1 for the board and painted board only, as it was not possible to perform this measurement on the render, as explained above.

Figure 4.

Test of discoloration of the methylene blue stain. Photos were taken immediately after the release of the drop and during the UV exposure. The UV exposure (and the relevant times) started 4 h after the drop application, when the stain was dry. The identification of the 5 zones in the samples is reported in the first image only.

Table 1.

Board and painted board: contact angles (°) at different times of artificial light exposure. The measurement was carried out at least in 3 points, few minutes after the UV exposure. Standard deviations of the values are in brackets.

The aspect of the blue drop immediately after its release on the surface (Figure 4 on the right) was different in the three substrates, because their porosity was clearly not the same and caused a different absorption of the drop. In the render sample, the drop spread quite a lot in the untreated zone, due to the high porosity of the substrate, but the colorant was retained at the center while the water was further absorbed by the substrate (dark wet zone around the blue stain in the picture). In all the treated zones of the render sample, the drop spread much less. Considering that the aqueous nano-TiO2 dispersion is expected not to have any pore-blocking effects due to its low concentration and to cause, if anything, an increase in surface wettability, this effect can be ascribed to the primers used before the nanodispersion application and in particular to coating#1, which decreased the surface capillary absorption of the material (it is defined as a ‘porosity reducer’ in the technical datasheet by the manufacturer). In the board sample, the drop spread quite a lot in both the treated and untreated zones, due to the porosity and hydrophilicity of the substrate (with a contact angle of 45.3°), and again the colorant was retained by the material, while the solvent was further absorbed by the substrate. Here, the primer apparently had no significant impact on the capillary absorption of the surface, and in fact, only coating#2 (coupling agent without a porosity reduction effect) was used, and it caused just a slight increase in the contact angle compared to that of the untreated zone.

In the painted board, the drop exhibited basically no spreading in the untreated areas, probably due to the presence of the paint, which was less porous than the substrate and even hydrophobic, as confirmed by the high contact angle (119.2° for the untreated surface). In the treated zones, as only coating#2 was used, and no pore blocking effect was observed. Instead, lower contact angles were found compared to those of the untreated zone, due to the hydrophilic behavior of the TiO2 nanodispersion. In the case of the spray application of the nanodispersion, the drop size was comparable with that of the untreated zone, while the drop spread very widely in the area treated by brushing, for which the amount of TiO2 deposited on the surface was probably much higher compared to that for spraying.

Upon exposure to artificial UV light, the following observations were made:

- (a)

- Render sample

The discoloration of the methylene blue in the untreated and treated zones was comparable (Figure 4), although its evaluation was made difficult by the different spreading and hence the different color of the dye in the untreated versus treated areas. The artificial washing of the treated surfaces seems to have had no impact in terms of the discoloration rate;

- (b) Board sample

The discoloration seems to be only slightly stronger in the treated zones compared to that of the untreated zone. No effect from the artificial washing was observed. However, large standard deviations were found in the measurement of the static contact angle (Table 1), due to the roughness and porosity of the investigated substrates, leading to a quick absorption of the water drop;

- (c) Painted board sample

The discoloration was much more evident in the treated zones than in the untreated one, with a higher effectiveness for surfaces treated by brushing, consistent with the higher amount of TiO2 expected to be retained on the surface. In this case, especially in the case of the spray application, the artificial washing visibly reduced the photocatalytic activity of the surface. This effect was not present in the case of the brushing application, probably because of the higher amount of TiO2 deposited at the beginning.

Although measuring the rate of the photocatalytic decomposition of an organic dye, such as methylene blue, rhodamine B or others, is one of most widely used methods for evaluating the self-cleaning performance of TiO2-based coatings, the present results clearly indicate that the porosity, wettability and rate of capillary absorption of the substrate play a significant role in the test, as they modify the shape, depth of penetration and hence the color of the stain. Moreover, methylene blue could be preferentially retained by some substrates through mechanisms of adsorption, possibly also influencing its degradability.

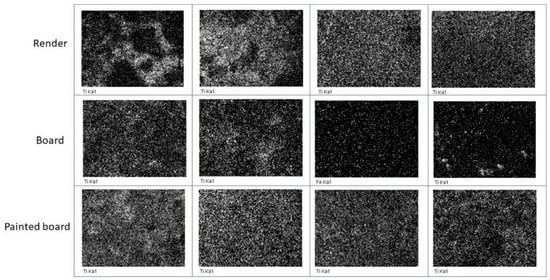

The amounts of TiO2 found on the samples by EDS are reported in Table 2, while some representative EDS maps of the Ti distribution on the samples’ surfaces are reported in Figure 5. Although the areas investigated are quite small and there is a certain scattering of data, the results allow us to make some observations. The EDS analysis did not detect any Ti presence in the untreated render and board samples, as expected, while abundant Ti was found on the painted board, likely owing to the rutile pigment in the paint. After the application of the coating, the following observations were made.

Table 2.

Ti amounts (wt%) found by EDS on the surface of the samples (average of 2 measurement areas of about 1200 μm2). The standard deviation values are reported in brackets.

Figure 5.

EDS mapping of Ti on the different surfaces (size of the investigated surface: 300 μm × 400 μm).

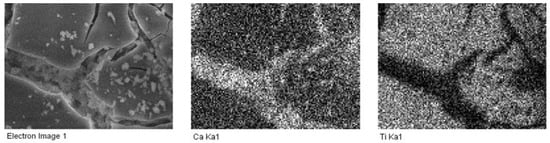

The amount of Ti on the surface was higher for the render than for the board, likely due to the presence of coating#1 in the render, preventing the absorption of nanoparticles by the substrate. This effect can be better observed in Figure 6, where a SEM image and the Ca and Ti maps are reported for a render sample treated by brushing (unwashed). The two coatings (but likely mainly coating#1) applied before the nanodispersion produced a compact layer over the surface, which prevented the nanodispersion absorption by the substrate. This effect is particularly evident in correspondence with a crack in the coating, where a low Ti amount and a high Ca amount were found, the latter being representative of the cementitious substrate.

Figure 6.

Render sample treated by brushing (unwashed): details of the surface observed on SEM and EDS maps (Ca and Ti) of the same surface (size: 60 μm × 90 μm).

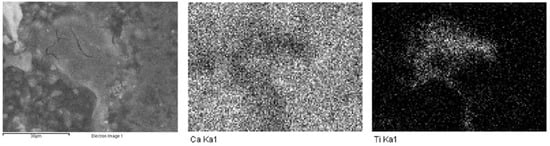

In both the render and board, brushing produced a higher concentration of TiO2 on the surface compared to that of spraying (about double, Table 2), an occurrence that was also observed for other kinds of products [28,29], but with a less even distribution of the nanoparticles. In both the render and board, the impact of washing was almost negligible, except for the sample render treated by brushing, which originally had the highest titanium concentration. The Ti maps in Figure 5 basically confirm the observations made for the render and board, also highlighting how the heterogeneity of the samples (porosity and roughness) influenced the titania distribution over the surface, causing local accumulations. The detail of a sample board treated by spraying after washing is reported in Figure 7, where it can be observed that Ti accumulated in a small area, likely in correspondence with a higher presence of coating#2.

Figure 7.

Board sample treated by spraying after washing: details of the surface observed on SEM and EDS maps (Ca and Ti) of the same surface (size: 60 μm × 90 μm).

In the painted board, quantifying the Ti before and after washing was almost impossible due to the presence of TiO2 in the paint.

The results showed that the titania nanoparticles were retained on the surface after an artificial water spraying simulating one year of rainfall, while in other studies, the nanoparticles deposited by the application of an aqueous dispersion over renders [30,31] and stone surfaces [32] were easily washed out in similar conditions. Although the roughness of the surface of the substrates investigated in this study might play a role in the nanoparticles’ retention on the surface, the main reason for this behavior seems to be the presence of the underlying coatings, which promote adhesion, either directly due to the presence of coupling agents or by creating a compact coating which prevents the nanodispersion absorption.

4. Conclusions

The tests in this study were carried out using a commercial TiO2 coating, adopting the application procedures recommended by the manufacturer and selecting three different real cementitious substrates. The results highlighted that the photocatalytic behavior of the surface treatment in terms of methylene blue discoloration under UV radiation is far from being certain. The coatings that are applied in the field on the substrates before the nanodispersion to either reduce the surface porosity of the substrate and/or promote the adhesion of the nanoparticles play a key role in the behavior of nano-TiO2; hence, their specific interaction with the nanoparticles should be better clarified. In general, these previously applied coatings seem effective in promoting the adhesion of the nanoparticles and preventing their washout by artificial rain. However, a local agglomeration of the nanoparticles was observed, and the photo-activity of the treatment was found to be negligible in two of the three investigated substrates (render and board), while some effectiveness was observed in the painted board, although this was after several hours of UV exposure.

The results obtained in this study are consistent and allowed us to make some interesting observations that may help in better understanding the factors affecting the effectiveness and durability of the investigated coatings. However, further studies specifically investigating these factors are in progress. In fact, although ready-to-use solutions are available on the market in terms of TiO2-based self-cleaning coatings, this study confirms that the actual effectiveness of these coatings is far from being ascertained, and further studies are necessary to elucidate the pros and cons of these coatings for real substrates and conditions.

Author Contributions

Conceptualization, A.F., L.V. and E.F.; methodology, A.F. and E.F.; investigation, A.F. and E.F.; resources, A.F. and L.V.; data curation, A.F. and E.F.; writing—original draft preparation, A.F. and E.F.; writing—review and editing, A.F., L.V. and E.F.; visualization, E.F.; supervision, E.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used in this study are not digital and hence they are not publicly available.

Acknowledgments

Valentina Guerra is gratefully acknowledged for her support in the tests.

Conflicts of Interest

The authors declare no conflict of interest.

References and Note

- Lee, J.; Mahendra, S.; Alvarez, P.J.J. Nanomaterials in the construction industry: A review of their applications and environmental health and safety considerations. ACS Nano 2010, 4, 3580–3590. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Poon, C.-S. Photocatalytic construction and building materials: From fundamentals to applications. Build. Environ. 2009, 44, 1899–1906. [Google Scholar] [CrossRef]

- Folli, A.; Pade, C.; Hansen, T.B.; De Marco, T.; Macphee, D.E. TiO2 photocatalysis in cementitious systems: Insights into self-cleaning and depollution chemistry. Cem. Concr. Res. 2012, 42, 539–548. [Google Scholar] [CrossRef]

- McManamon, C.; O’Connell, J.; Delaney, P.; Rasappa, S.; Holmes, J.D.; Morris, M.A. A facile route to synthesis of S-doped TiO2 nanoparticles for photocatalytic activity. J. Mol. Catal. A Chem. 2015, 406, 51–57. [Google Scholar] [CrossRef]

- Han, C.; Andersen, J.; Pillai, S.C.; Fagan, R.; Falaras, P.; Byrne, J.A.; Dunlop, P.C.M.; Choi, H.; Jiang, W.; O’Shea, K. Chapter Green Nanotechnology: Development of Nanomaterials for Environmental and Energy Applications. In Sustainable Nanotechnology and the Environment: Advances and Achievements; ACS Symposium Series Vol. 1124; American Chemical Society: Washington, DC, USA, 2013; pp. 201–229. [Google Scholar]

- Cerrato, E.; Gaggero, E.; Calza, P.; Paganini, M.C. The role of Cerium, Europium and Erbium doped TiO2 photocatalysts in water treatment: A mini-review. Chem. Eng. J. Adv. 2022, 10, 100268. [Google Scholar] [CrossRef]

- Serga, V.; Burve, R.; Krumina, A.; Pankratova, V.; Popov, A.I.; Pankratov, V. Study of phase composition, photocatalytic activity, and photoluminescence of TiO2 with Eu additive produced by the extraction-pyrolytic method. J. Mater. Res. Technol. 2021, 13, 2350–2360. [Google Scholar] [CrossRef]

- Gryparis, C.; Krasoudaki, T.; Maravelaki, P.-N. Self-Cleaning Coatings for the Protection of Cementitious Materials: The Effect of Carbon Dot Content on the Enhancement of Catalytic Activity of TiO2. Coatings 2022, 12, 587. [Google Scholar] [CrossRef]

- Gesenhues, U. Al-doped TiO2 pigments: Influence of doping on the photocatalytic degradation of alkyd resins. J. Photochem. Photobiol. A Chem. 2001, 139, 243–251. [Google Scholar] [CrossRef]

- Dorosheva, I.B.; Valeeva, A.A.; Rempel, A.A.; Trestsova, M.A.; Utepova, I.A.; Chupakhin, O.N. Synthesis and Physicochemical Properties of Nanostructured TiO2 with Enhanced Photocatalytic Activity. Inorg. Mater. 2021, 57, 503–510. [Google Scholar] [CrossRef]

- Papoulis, D. Halloysite based nanocomposites and photocatalysis: A Review. Appl. Clay Sci. 2018, 168, 164–174. [Google Scholar] [CrossRef]

- Paul, S.C.; van Rooyen, A.S.; van Zijl, G.P.; Petrik, L.F. Properties of cement-based composites using nanoparticles: A comprehensive review. Const. Build. Mater. 2018, 189, 1019–1034. [Google Scholar] [CrossRef]

- Hamidi, F.; Aslani, F. TiO2-based Photocatalytic Cementitious Composites: Materials, Properties, Influential Parameters, and Assessment Techniques. Nanomaterials 2019, 9, 1444. [Google Scholar] [CrossRef] [PubMed]

- Franzoni, E.; Bignozzi, M.C.; Bonvicini, G. TiO2 in Building Sector. In Titanium Dioxide (TiO2) and Its Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 449–479. [Google Scholar]

- Banerjee, S.; Dionysiou, D.D.; Pillai, S.C. Self-cleaning applications of TiO2 by photo-induced hydrophilicity and photocatalysis. Appl. Catal. B Environ. 2015, 176-177, 396–428. [Google Scholar] [CrossRef]

- Ângelo, J.; Andrade, L.; Mendes, A. Highly active photocatalytic paint for NOx abatement under real-outdoor conditions. Appl. Catal. A Gen. 2014, 484, 17–25. [Google Scholar] [CrossRef]

- Maggos, T.; Plassais ABartzis JGVasilakos, C.; Moussiopoulos, N.; Bonafous, L. Photocatalytic degradation of NOx in a pilot street canyon configuration using TiO2-mortar panels. Environ. Monit. Assess. 2008, 1369, 35–44. [Google Scholar] [CrossRef]

- Folli, A.; Strøm, M.; Madsen, T.P.; Henriksen, T.; Lang, J.; Emenius, J.; Klevebrant, T.; Nilsson, A. Field study of air purifying paving elements containing TiO2. Atmos. Environ. 2015, 107, 44–51. [Google Scholar] [CrossRef]

- Hüsken, G.; Hunger, M.; Brouwers, H. Experimental study of photocatalytic concrete products for air purification. Build. Environ. 2009, 44, 2463–2474. [Google Scholar] [CrossRef]

- Macphee, D.E.; Folli, A. Photocatalytic concretes—The interface between photocatalysis and cement chemistry. Cem. Concr. Res. 2016, 85, 48–54. [Google Scholar] [CrossRef]

- Folli, A.; Pochard, I.; Nonat, A.; Jakobsen, U.H.; Shepherd, A.M.; Macphee, D.E. Engineering photocatalytic cements: Understanding TiO2 surface chemistry to control and modulate photocatalytic performances. J. Am. Ceram. Soc. 2010, 93, 3360–3369. [Google Scholar] [CrossRef]

- Boonen, E.; Beeldens, A.; Dirkx, I.; Bams, V. Durability of Cementitious Photocatalytic Building Materials. Catal. Today 2017, 287, 196–202. [Google Scholar] [CrossRef]

- Bersch, J.D.; Flores-Colen, I.; Masuero, A.B.; Dal Molin, D.C.C. Photocatalytic TiO2-Based Coatings for Mortars on Facades: A Review of Efficiency, Durability, and Sustainability. Buildings 2023, 13, 186. [Google Scholar] [CrossRef]

- Adesina, A. Durability enhancement of concrete using nanomaterials: An overview. Mater. Sci. Forum 2019, 967, 221–227. [Google Scholar] [CrossRef]

- Mahinroosta, M.; Allahverdi, A. A Scoping Review on Integrating Inorganic Nanomaterials into Cement Composites. Adv. Civ. Eng. Mater. 2019, 8, 526–553. [Google Scholar] [CrossRef]

- Moreno, V.; Zougagh, M.; Ríos, A. Analytical nanometrological approach for screening and confirmation of titanium dioxide nano/micro-particles in sugary samples based on Raman spectroscopy—Capillary electrophoresis. Anal. Chim. Acta 2019, 1050, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Data supplied directly by ARPA-SIMC—Agenzia Regionale Prevenzione e Ambiente dell’Emilia-Romagna (Regional Agency for Prevention and Environment of Emilia-Romagna), Bologna, Italy.

- Barbieri, E.; Trevisiol, F.; Pizzigatti, C.; Bitelli, G.; Franzoni, E. Evaluating water-repellents applied to brick masonry: An experimental study by thermal imaging and water transport properties’ characterization. Constr. Build. Mater. 2022, 356, 129319. [Google Scholar] [CrossRef]

- Franzoni, E.; Sassoni, E.; Graziani, G. Brushing, poultice or immersion? Role of the application technique on the performance of a novel hydroxyapatite-based consolidating treatment for limestone. J. Cult. Herit. 2015, 16, 173–184. [Google Scholar] [CrossRef]

- Franzoni, E.; Fregni, A.; Gabrielli, R.; Graziani, G.; Sassoni, E. Compatibility of photocatalytic TiO2-based finishing for renders in architectural restoration: A preliminary study. Build. Environ. 2014, 80, 125–135. [Google Scholar] [CrossRef]

- Franzoni, E.; Gabrielli, R.; Sassoni, E.; Fregni, A.; Graziani, G.; Roveri, N.; D’Amen, E. Performance and permanence of TiO2-based surface treatments for architectural heritage: Some experimental findings from on-site and laboratory testing. In Science and Art: A Future for Stone, Proceedings of the 13th International Congress on the Deterioration and Conservation of Stone, Paisley, UK, 6–10 September 2016; Hughes, J., Howind, T., Eds.; University of the West of Scotland: Paisley, UK, 2016; Volume II, pp. 761–768. [Google Scholar]

- Sassoni, E.; D’Amen, E.; Roveri, N.; Scherer, G.W.; Franzoni, E. Durable self-cleaning coatings for architectural surfaces by incorporation of TiO2 nano-particles into hydroxyapatite films. Materials 2018, 11, 177. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).