Microstructural and Morphological Characterization of the Cobalt-Nickel Thin Films Deposited by the Laser-Induced Thermionic Vacuum Arc Method

Abstract

1. Introduction

2. Materials and Methods

2.1. The LTVA System

2.2. Analysis of the CoNi Thin Films

3. Results

3.1. Microstructural Analysis

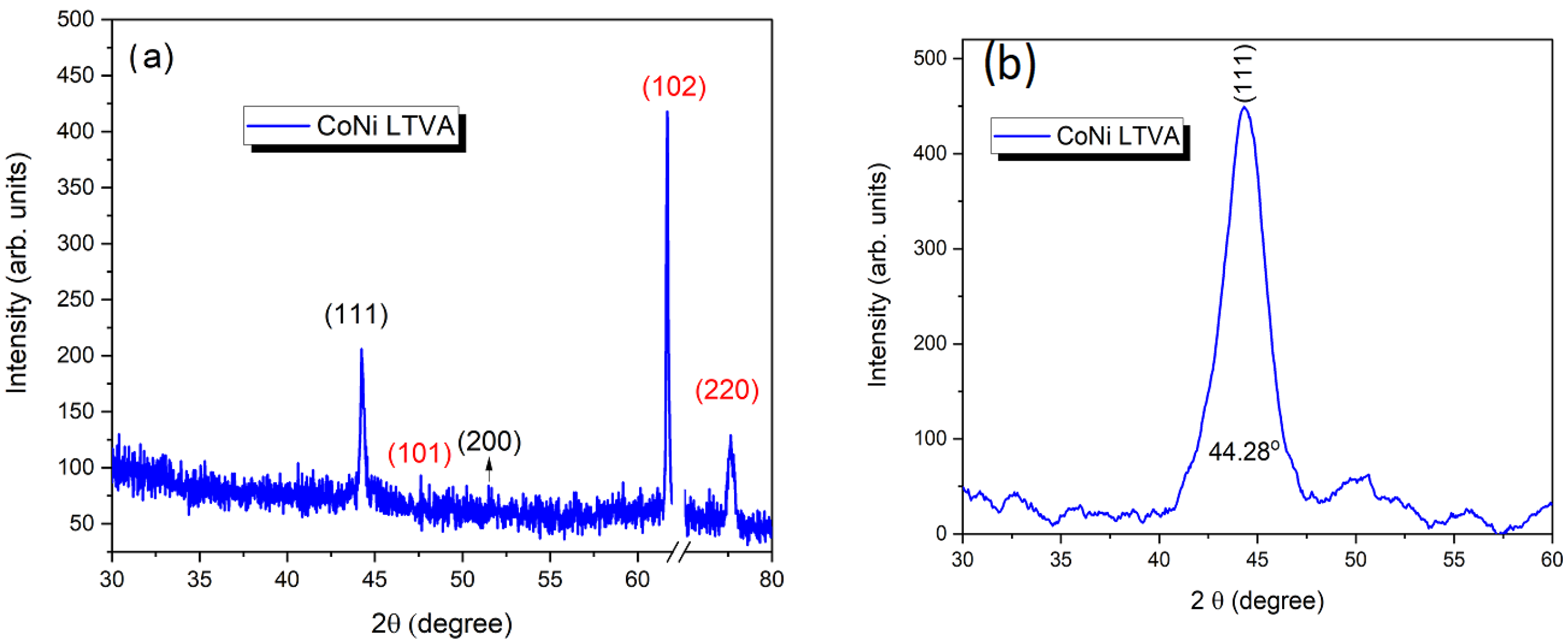

3.1.1. X-ray Diffraction

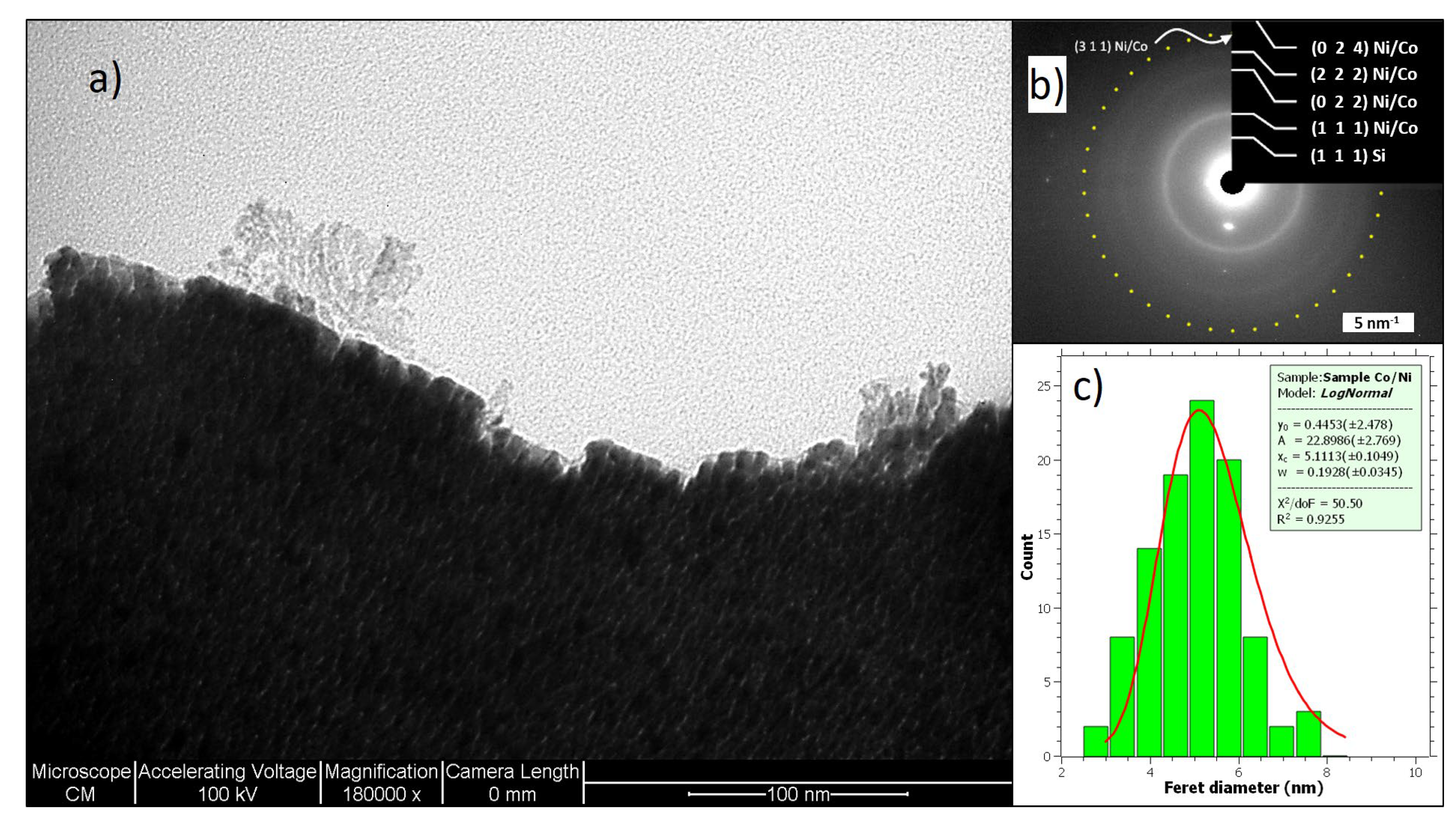

3.1.2. HRTEM and SAED Measurements

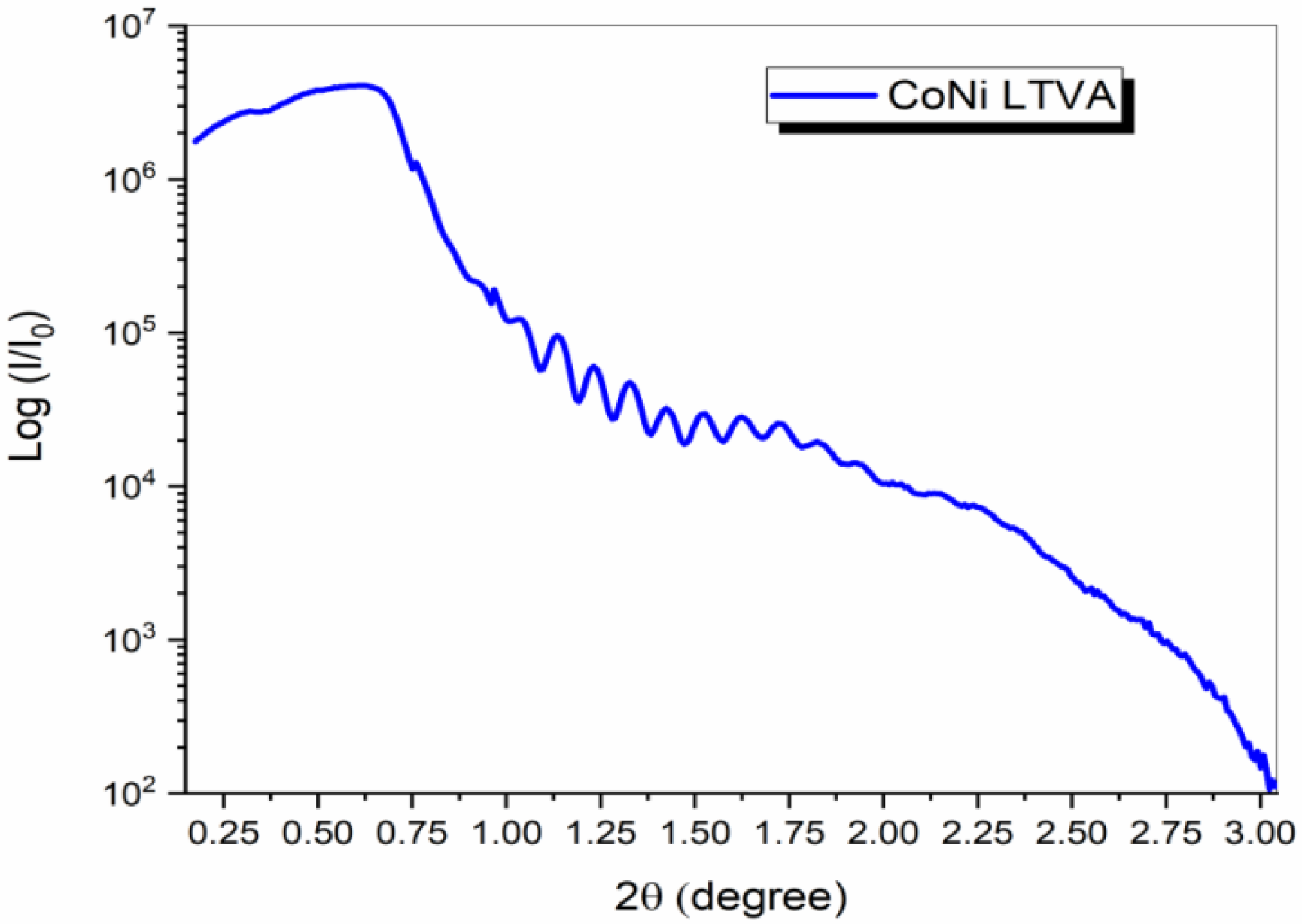

3.2. X-ray Reflectometry

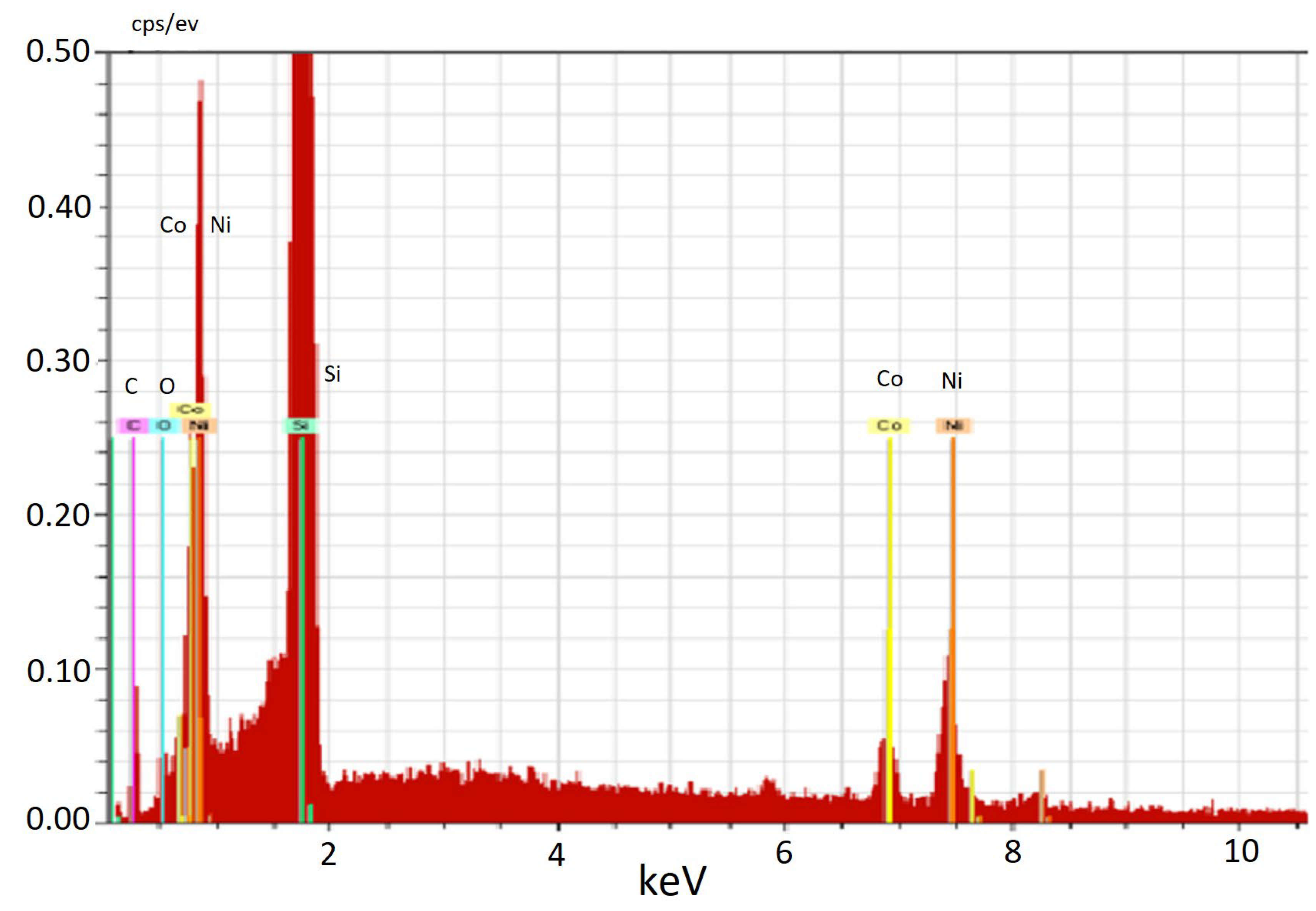

3.3. SEM and EDX Analysis

3.4. Surface and Magnetic Properties

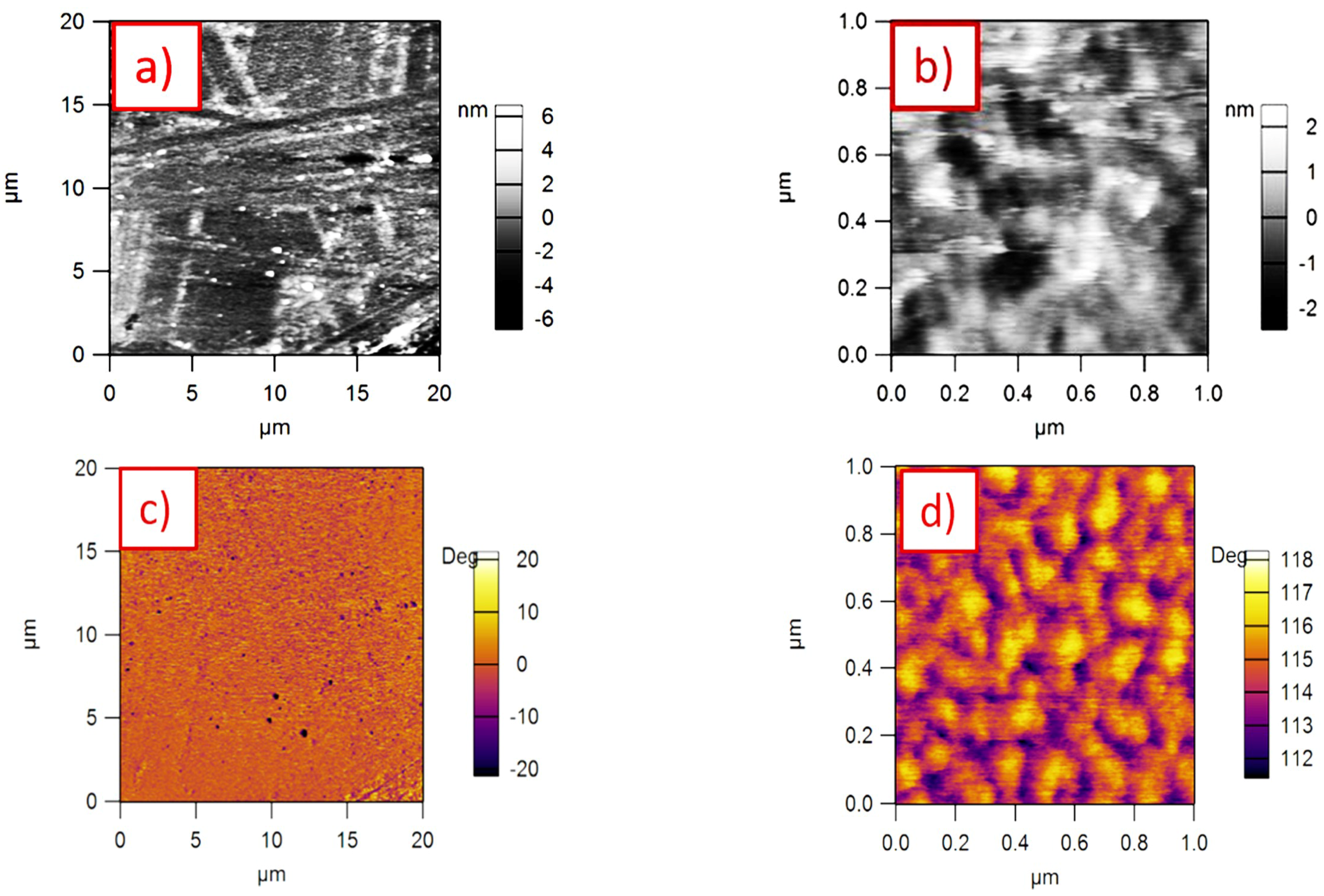

3.4.1. Atomic and Magnetic Force Microscopy

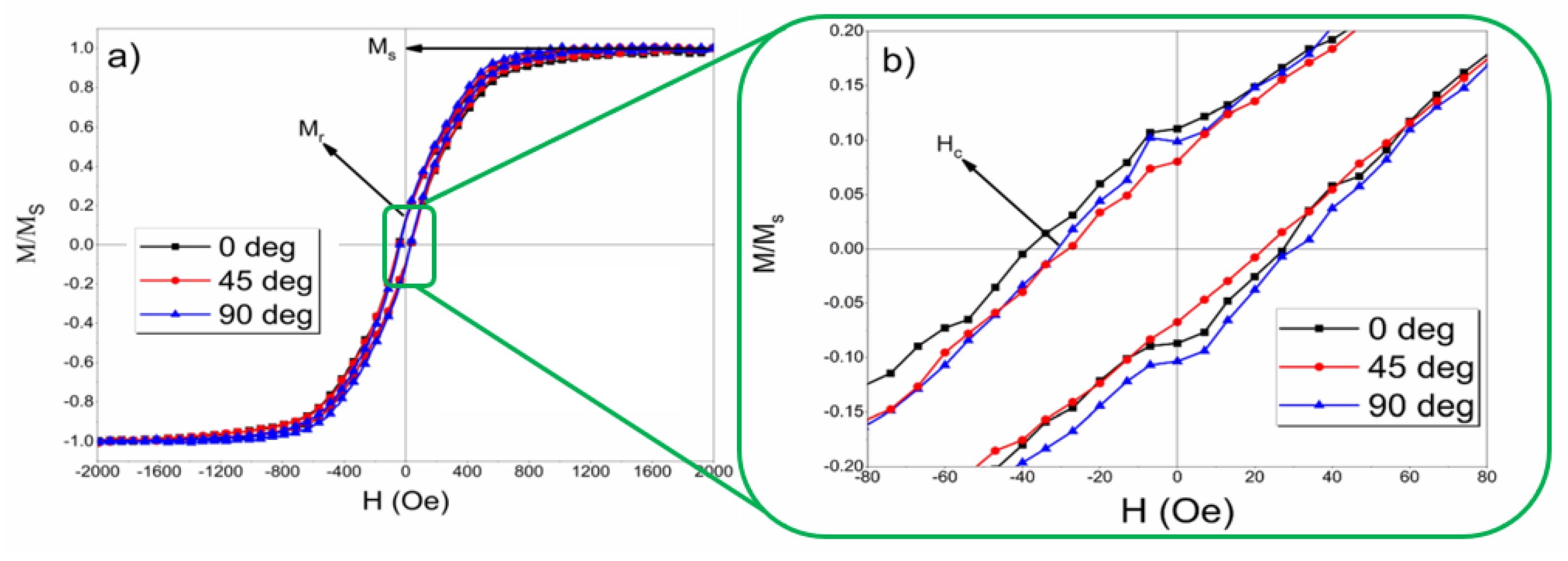

3.4.2. Longitudinal MOKE Method

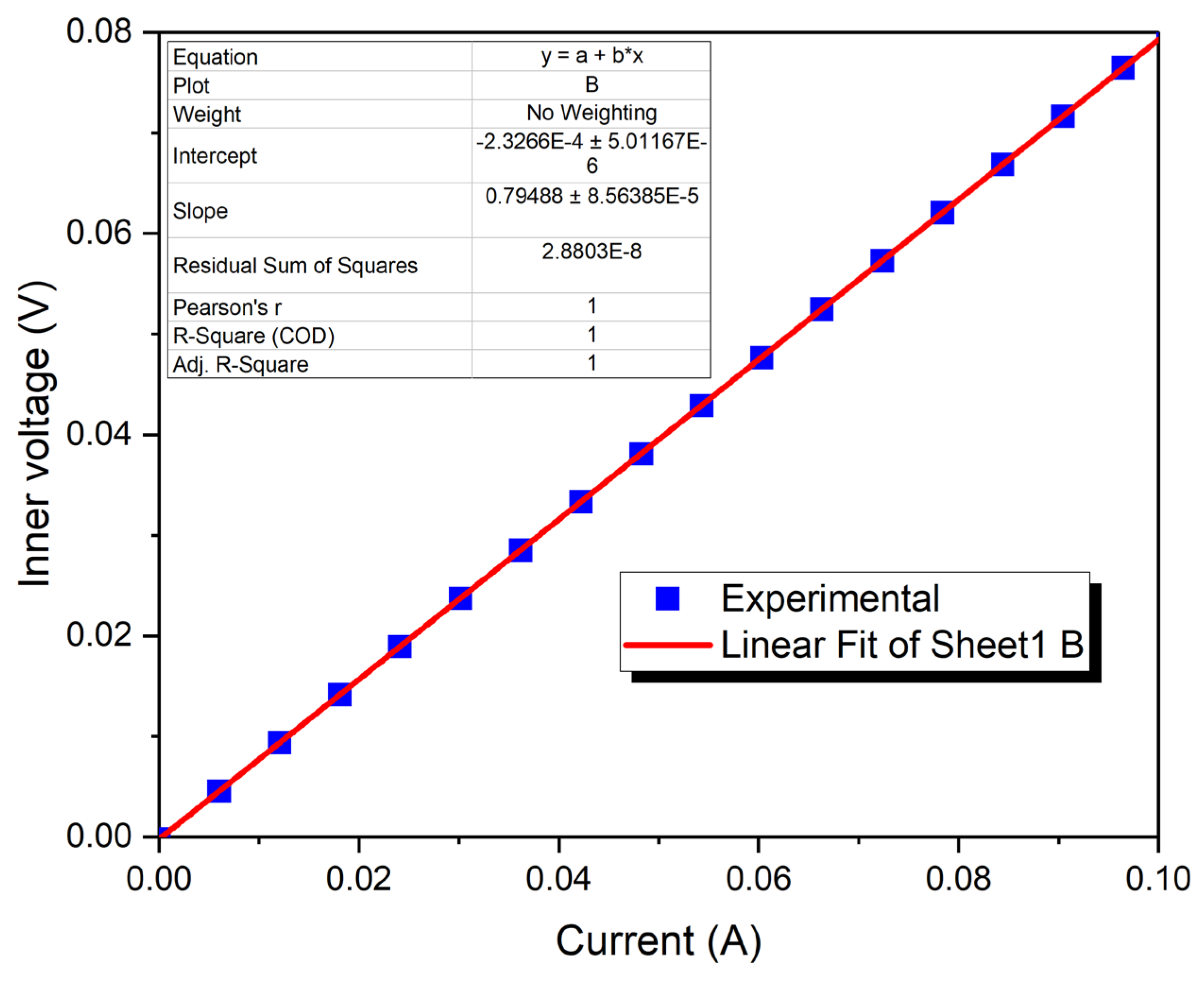

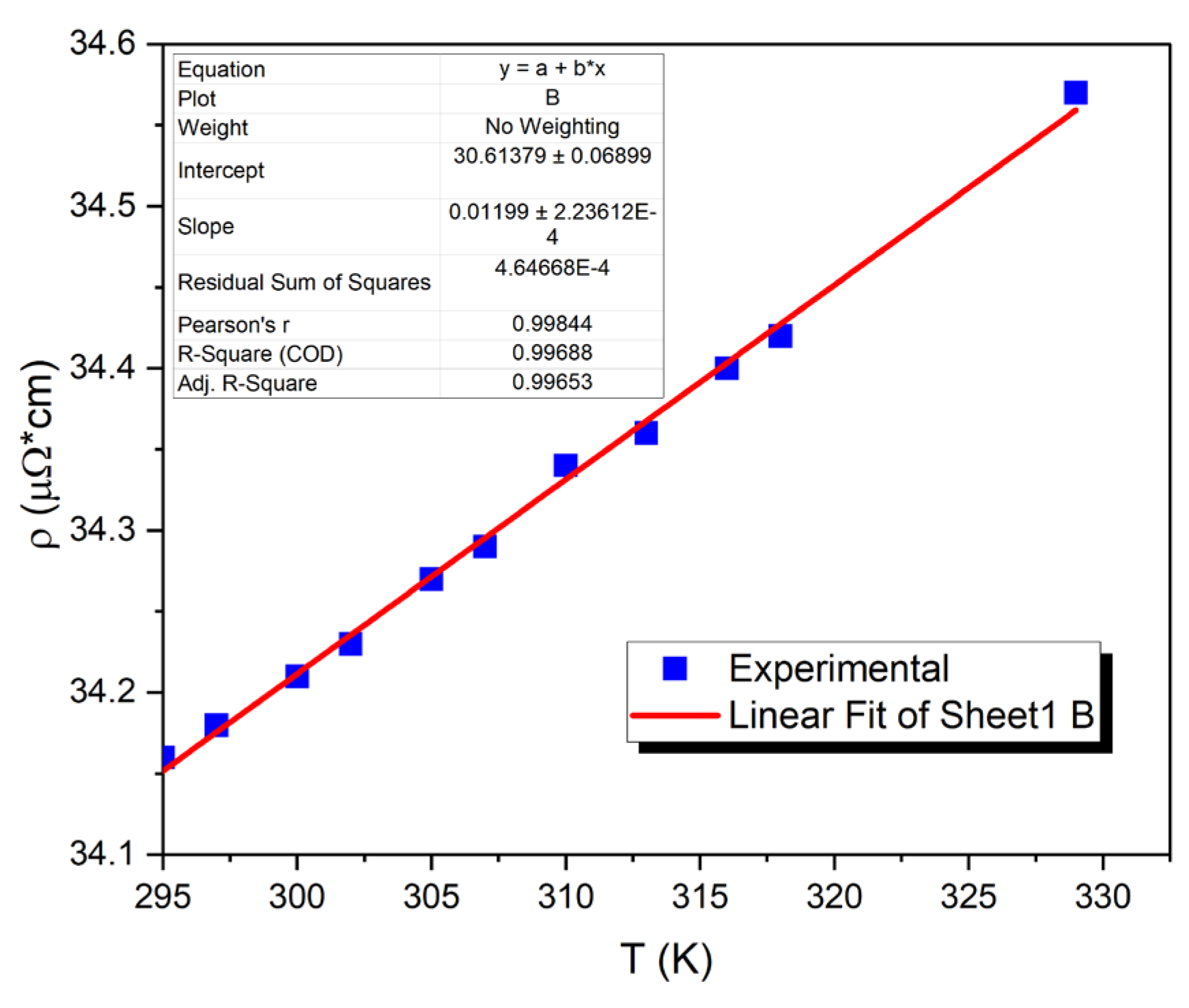

3.5. Electrical Measurements

4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, M.; Zhu, L.; Li, Z.; Guo, C.; Wang, M.; Wang, C.; Du, M. CoNi bimetallic metal–organic framework as an efficient biosensing platform for miRNA 126 detection. Appl. Surf. Sci. 2021, 542, 148586. [Google Scholar] [CrossRef]

- Gui, L.; Pan, G.; Ma, X.; You, M.; He, B.; Yang, Z.; Sun, J.; Zhou, W.; Xu, J.; Zhao, L. In-situ exsolution of CoNi alloy nanoparticles on LiFe0.8Co0.1Ni0.1O2 parent: New opportunity for boosting oxygen evolution and reduction reaction. Appl. Surf. Sci. 2021, 543, 148817. [Google Scholar] [CrossRef]

- Xie, Y.; Feng, C.; Guo, Y.; Li, S.; Guo, C.; Zhang, Y.; Wang, J. MOFs derived carbon nanotubes coated CoNi alloy nanocomposites with N-doped rich-defect and abundant cavity structure as efficient trifunctional electrocatalyst. Appl. Surf. Sci. 2021, 536, 147786. [Google Scholar] [CrossRef]

- Li, R.; Li, X.; Liu, C.; Ye, M.; Yang, Q.; Liu, Z.; Xie, L.; Yang, G. Enhanced electron transport through a nanoforest-like structure of CoNi nanoalloy@nitrogen-doped carbon nanotubes for highly efficient catalysis of overall water splitting. Appl. Surf. Sci. 2020, 517, 145841. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials, 2nd ed.; Wiley Hoboken: New Jersey, NJ, USA, 2009; pp. 154–196. [Google Scholar]

- Kefalas, J.H. Effect of electroplating parameters on magnetic properties of Ni-Co alloys. J. Appl. Phys. 1966, 37, 1160. [Google Scholar] [CrossRef]

- Tutovan, V.; Velican, N. Magnetic properties of electrodeposited Ni-Co thin films. Thin Solid. Film. 1971, 7, 219–227. [Google Scholar] [CrossRef]

- Tutovan, V.; Velican, N. Stripe domains in electrodeposited NiCo thin films. Thin Solid. Film. 1973, 15, 31–37. [Google Scholar] [CrossRef]

- Rhen, F.M.F.; Roy, S. Dependence of magnetic properties on micro- to nanostructure of CoNiFe films. J. Appl. Phys. 2008, 103, 103901. [Google Scholar] [CrossRef]

- Wu, C.; Wang, K.; Li, D.; Lou, C.; Zhao, Y.; Gao, Y.; Wang, Q. Tuning microstructure and magnetic properties of electrodeposited CoNiP films by high magnetic field annealing. J. Magn. Magn. Mater. 2016, 416, 61–65. [Google Scholar] [CrossRef]

- Ducharme, S.; Fridkin, V.M.; Bune, A.V.; Palto, S.P.; Blinov, L.M.; Petukhova, N.N.; Yudin, S.G. Intrinsic Ferroelectric Coercive Field. Phys. Rev. Lett. 2000, 84, 175–178. [Google Scholar] [CrossRef]

- Jo, J.Y.; Kim, Y.S.; Noh, T.W.; Yoon, J.G.; Song, T.K. Coercive fields in ultrathin BaTiO3 capacitors. Appl. Phys. Lett. 2006, 89, 232909. [Google Scholar] [CrossRef]

- Thanikaikarasan, S.; Mahalingam, T.; Ahamad, T.; Alshehri, S.M. Role of substrate on film thickness, structural, compositional and magnetic properties of CoNi alloy thin films by low temperature electrodeposition technique. J. Saudi Chem. Soc. 2020, 24, 955–962. [Google Scholar] [CrossRef]

- Chena, Q.S.; Zhou, Z.Y.; Guo, G.C.; Sun, S.G. Electrodeposition of nanostructured CoNi thin films and their anomalous infrared properties. Electrochim. Acta 2013, 113, 694–705. [Google Scholar] [CrossRef]

- Park, D.Y.; Song, R.Y.; Ko, J.M.; Yoo, B.Y.; Myung, N.V. Stress Changes of Nanocrystalline CoNi Thin Films Electrodeposited from Chloride Baths. Electrochem. Sol. State. Lett. 2005, 8, C23–C25. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Yanagisawa, M. Magnetic properties and structures of sputtered CoNi/Cr films. IEEE Trans. Magn. 1986, 22, 576–578. [Google Scholar] [CrossRef]

- Lee, H.J. The crystal growth and magnetic properties of sputtered CoNi films on bcc polycrystalline underlayers. J. Appl. Phys. 1988, 63, 3269. [Google Scholar] [CrossRef]

- Spencer, A.G.; Howson, R.P. The properties of magnetron sputtered CoNi thin films. Vacuum 1986, 36, 103–105. [Google Scholar] [CrossRef]

- Vladoiu, R.; Mandes, A.; Dinca, V.; Kudrna, P.; Tichý, M.; Polosan, S. Magnesium-silver cathodes for efficient charge-injection into Organic Light Emitting Diodes deposited by LTVA method. J. Alloy. Comp. 2021, 869, 159364. [Google Scholar] [CrossRef]

- Vladoiu, R.; Tichý, M.; Mandes, A.; Dinca-Balan, V.; Kudrna, P. Thermionic Vacuum Arc—A versatile technology for thin film deposition and its applications. Coatings 2020, 10, 211. [Google Scholar] [CrossRef]

- Ekem, N.; Musa, G.; Pat, S.; Balbag, Z.; Cenik, I.; Vladoiu, R. Carbon thin film deposition by Thermionic Vacuum Arc (TVA). J. Opt. Adv. Mater. 2008, 10, 672–674. [Google Scholar]

- Staicu, C.; Locovei, C.; Dinu, A.A.; Burducea, I.; Butoi, B.; Pompilian, O.G.; Porosnicu, C.; Lungu, C.P.; Kuncser, V. Structural and Magnetic Specificities of Fe-B Thin Films Obtained by Thermionic Vacuum Arc and Magnetron Sputtering. Coatings 2022, 10, 1592. [Google Scholar] [CrossRef]

- Durmus, C.; Akan, T. Vanadium pentoxide thin films deposited by the thermionic vacuum arc plasma. Thin Solid. Film. 2023, 770, 139764. [Google Scholar] [CrossRef]

- Lungu, C.P.; Mustata, I.; Musa, G.; Lungu, A.M.; Brinza, O.; Moldovan, C.; Rotaru, C.; Iosub, R.; Sava, F.; Popescu, M. Unstressed carbon-metal films deposited by thermionic vacuum arc method. J. Opt. Adv. Mater. 2006, 8, 74–77. [Google Scholar]

- Kuncser, V.; Valeanu, M.; Scanteie, G.; Filoti, G.; Mustata, I.; Lungu, C.P.; Anghel, A.; Chiriac, H.; Vladoiu, R.; Bartolomeu, J. Exchange Bias and spin valve systems with Fe-Mn antiferromagnetic prinning layers, obtained by TVA method. J. Magn. Magn. Mater. 2008, 320, e226–e230. [Google Scholar] [CrossRef]

- Pat, S.; Celik, O.; Odabas, A.; Korkmaz, S. Optical properties of Nb2O5 doped ZnO nanocomposite thin film deposited by thermionic vacuum arc. Optik 2022, 258, 168928. [Google Scholar] [CrossRef]

- Vladoiu, R.; Mandes, A.; Dinca-Balan, V.; Prodan, G.; Kudrna, P.; Tichý, M. Magnesium plasma diagnostics by heated probe and characterization of the Mg thin films deposited by thermionic vacuum arc technology. Plasma Sources Sci. Technol. 2015, 24, 035008. [Google Scholar] [CrossRef]

- Mandes, A.; Vladoiu, R.; Dinca, V.; Prodan, G. Binary C-Ag Plasma Breakdown and Structural Characterization of the Deposited Thin Films by Thermionic Vacuum Arc Method. IEEE Trans. Plasma Sci. 2014, 42, 2806–2807. [Google Scholar] [CrossRef]

- Vladoiu, R.; Ciupina, V.; Contulov, M.; Mandes, A.; Dinca, V.; Prodan, G.; Lungu, C.P. Structure and tribological properties of carbon-based nanocomposites grown by TVA method. J. Opt. Adv. Mater. 2010, 12, 553–556. [Google Scholar]

- Ozkan, M.; Erdem, S.S.; Mohammadigharehbagh, R.; Kurtaran, S.; Pat, S. Investigation of substrate effect on Co-doped ZnO thin films prepared by thermionic vacuum arc technique. Inorg. Chem. Comm. 2022, 146, 110095. [Google Scholar] [CrossRef]

- Vladoiu, R.; Mandes, A.; Dinca, V.; Ciupina, V.; Matei, E.; Polosan, S. The synergistic effect of the laser beam on the thermionic vacuum arc method for titanium-doped chromium thin film deposition method. Coatings 2022, 12, 470. [Google Scholar] [CrossRef]

- Rachinger, W.A. A Correction for the α1 α2 Doublet in the Measurement of Widths of X-ray Diffraction Lines. J. Sci. Instrum. 1948, 25, 254–255. [Google Scholar] [CrossRef]

- Laetsch, T.; Downs, R. Software for Identification and Refinement of Cell Parameters from Powder Diffraction Data of Minerals Using the RRUFF Project and American Mineralogist Crystal Structure Databases. In Proceedings of the 19th General Meeting of the International Mineralogical Association, Kobe, Japan, 23–28 July 2006. [Google Scholar]

- Teodorescu, V.S.; Blanchin, M.G. Fast and Simple Specimen Preparation for TEM Studies of Oxide Films Deposited on Silicon Wafers. Microsc. Microanal. 2009, 15, 15–19. [Google Scholar] [CrossRef]

- Sirisathitkul, C.; Pansong, Y.; Rattanasuporn, S. Longitudinal and Polar MOKE Magnetometry of Magnetoresistive Cobalt Thin Films Prepared by Thermal Evaporation. Sains Malays. 2012, 41, 617–621. [Google Scholar]

- Smits, F.M. Measurement the of Sheet Resistivities Four-Point Probe. Bell Syst. Tech. J. 1958, 37, 711–718. [Google Scholar] [CrossRef]

- Uhlir, A., Jr. The Potentials of Infinite Systems of Sources and Numerical Solutions of Problems in Semiconductor Engineering. Bell Syst. Tech. J. 1955, 34, 105–128. [Google Scholar] [CrossRef]

- Xu, C.; Nie, D.; Chen, H.; Wang, Y.; Liu, Y. Solvothermal synthesis of caulifower-like CoNi microstructures with enhanced magnetic property. Mater. Lett. 2015, 142, 246–249. [Google Scholar] [CrossRef]

- He, X.; Yin, F.; Li, G.; Chen, B.; Wanga, S.; Gu, M. CoNi alloys with slight oxidation@N,O Co-doped carbon: Enhanced collective contributions of cores and shells to multifunctional electrocatalytic activity and Zn–air batteries. J. Mater. Chem. A 2020, 8, 25805. [Google Scholar] [CrossRef]

- Chen, N.; Jiang, J.T.; Xu, C.Y.; Yan, S.J.; Zhen, L. Rational Construction of Uniform CoNi-Based Core-Shell Microspheres with Tunable Electromagnetic Wave Absorption Properties. Sci. Rep. 2018, 8, 3196. [Google Scholar] [CrossRef]

- Klinger, M. CrysTBox-Crystallographic Toolbox; Institute of Physics of the Czech Academy of Sciences: Prague, Czech Republic, 2015; ISBN 978-80-905962-3-8. [Google Scholar]

- Haglund, J.; Fernandez Guillermet, A.; Grimvall, G.; Korling, M. Theory of bonding in transition-metal carbides and nitrides. Phys. Rev. B Condens. Matter. 1993, 48, 11685–11691. [Google Scholar] [CrossRef]

- Taylor, A. Lattice parameters of binary nickel-cobalt alloys. J. Inst. Met. 1950, 77, 585–594. [Google Scholar]

- Nelson, J.B.; Riley, D.P. An Experimental Investigation of Extrapolation Methods in the Derivation of Accurate Unit-Cell Dimenions of Crystals. Proc. Phys. Soc. 1945, 57, 160–176. [Google Scholar] [CrossRef]

- Vignaud, G.; Gibaud, A. REFLEX: A program for the analysis of specular X-ray and neutron reflectivity data. J. Appl. Cryst. 2019, 52, 201–213. [Google Scholar] [CrossRef]

- Technical Data for Cobalt. Available online: https://periodictable.com/Elements/027/data.html (accessed on 15 January 2023).

- Angeloni, L.; Passeri, D.; Scaramuzzo, F.A.; Schiavi, P.G.; Pagnanelli, F.; Rossi, M. Magnetic force microscopy characterization of core–shell cobalt-oxide/hydroxide nanoparticles. J. Magn. Magn. Mater. 2020, 516, 167299. [Google Scholar] [CrossRef]

- Hartmann, U. The point dipole approximation in magnetic force microscopy. Phys. Lett. A 1989, 137, 475–478. [Google Scholar] [CrossRef]

- Nishizawa, T.; Ishida, K. The Co−Ni (Cobalt-Nickel) system. Bull. Alloy. Phase Diagr. 1983, 4, 390–395. [Google Scholar] [CrossRef]

- Montiel, M.G.; Santiago-Jacinto, P.; Dıaz Gongora, J.A.I.; Reguera, E.; Rodriguez-Gattorno, G. Synthesis and Thermal Behavior of Metallic, Cobalt Micro and Nanostructures. Nano-Micro Lett. 2011, 3, 12–19. [Google Scholar] [CrossRef]

- Satish Kumar, A.; Ramudu, M.; Seshubai, V. Structural and magnetic investigations in the vicinity of first-order transformations in Ni–Mn–Ga–Co ferromagnetic shape memory alloys. Phase Transit. 2012, 85, 1045–1059. [Google Scholar] [CrossRef]

- Shih, T.-S.; Huang, L.W.; Chen, Y.J. Relative porosity in aluminium and in aluminium alloys. Int. J. Cast Met. Res. 2005, 18, 301–308. [Google Scholar] [CrossRef]

- Gräfe, J.; Schmidt, M.; Audehm, P.; Schütz, G.; Goering, E. Application of magneto-optical Kerr effect to first-order reversal curve measurements. Rev. Sci. Instr. 2014, 85, 023901. [Google Scholar] [CrossRef]

- Aubry, E.; Liu, T.; Billard, A.; Dekens, A.; Perry, F.; Mangin, S.; Hauet, T. Influence of the Cr and Ni concentration in CoCr and CoNi alloys on the structural and magnetic properties. J. Magn. Magn. Mater. 2017, 422, 391–396. [Google Scholar] [CrossRef]

- DeVries, J.W.C. Temperature and thickness dependence of the resistivity of thin polycrystalline aluminium, cobalt, nickel, palladium, silver and gold films. Thin Solid. Film. 1988, 167, 25–32. [Google Scholar] [CrossRef]

- Mayadas, A.F.; Shatzkes, M.; Janak, J.F. Electrical resistivity model for polycrystalline films: The case of specular reflection at external surfaces. Appl. Phys. Lett. 1969, 14, 345. [Google Scholar] [CrossRef]

- Kayal, S.; Brajpuriya, R.K.; Kumar, A. Structural and Resistive Property of Cobalt/Silicon Thin Film as a Function of Thickness. Int. J. Sci. Res. 2015, 4, 2542–2544. [Google Scholar]

- Van Gurp, G.J. Resistivity, grain size, and structure of vacuum-deposited Co films. J. Appl. Phys. 1975, 46, 1922. [Google Scholar] [CrossRef]

- Kasap, S.; Koughia, C.; Ruda, H.E. Electrical Conduction in Metals and Semiconductors. In Springer Handbook of Electronic and Photonic Materials; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

| Experimental Conditions | Ua [V] | Ia [A] | E [mJ] | IL [GW/cm2] |

|---|---|---|---|---|

| 900 | 0.205 | 50 | 10 | |

| If [A] | 55 | |||

| Ub [V] | 3000 | |||

| p [Pa] | 3.4 × 10–5 | |||

| tdep [s] | 420 | |||

| d [nm] | 95 | |||

| No. | Peak Location (°) | (hkl) | Peak Width | d-Spacing (Å) | Cell Parameter (nm) | Symmetry |

|---|---|---|---|---|---|---|

| 1 | 44.28 | (111) | 0.1157 | 2.0438 | 3.4084 | Fm-3m cubic |

| 2 | 51.58 | (200) | - | 1.7885 |

| Peak | dhkl (Å) | 2θ (°) | I/I0 | hkl | FWHM | LDS (nm) |

|---|---|---|---|---|---|---|

| 1 | 2.0376 | 1.0405 | 10,000 | 111 | 0.11 | 3.3943 |

| 2 | 1.7988 | 1.1786 | 1734 | 200 | 0.09 | 3.2335 |

| 3 | 1.2471 | 1.7001 | 1265 | 220 | 0.04 | 3.4980 |

| 4 | 1.0656 | 1.9897 | 833 | 311 | 0.03 | 3.4053 |

| 3.3828 |

| Structure | SG Symmetry Group | a|c (Å) | a|c Cohen (Å) | Errors (%) |

|---|---|---|---|---|

| Cubic Ni | Fm-3m | 3.45 [42] | 3.4951 | 1.3108 |

| Cubic Co | Fm-3m | 3.42 [43] | 3.4951 | 2.1969 |

| Hexagonal Co0.75Ni0.25 | P63/mmc | 2.504|4.065 [44] | 2.6162|4.3834 | 4.4802|7.8331 |

| Element | Atomic No. | Point 1 (at.%) | Point 2 (at.%) | Point 3 (at.%) | Mean Error |

|---|---|---|---|---|---|

| Co | 27 | 1.35 | 1.40 | 1.32 | 0.2 |

| Ni | 28 | 3.20 | 3.26 | 3.24 | 0.1 |

| Si | 14 | 77.54 | 78.42 | 77.88 | 3.2 |

| O | 8 | 7.01 | 6.07 | 6.81 | 0.9 |

| C | 6 | 10.89 | 10.86 | 10.75 | 1.1 |

| Total | 100 | 100 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dinca, V.; Mandes, A.; Vladoiu, R.; Prodan, G.; Ciupina, V.; Polosan, S. Microstructural and Morphological Characterization of the Cobalt-Nickel Thin Films Deposited by the Laser-Induced Thermionic Vacuum Arc Method. Coatings 2023, 13, 984. https://doi.org/10.3390/coatings13060984

Dinca V, Mandes A, Vladoiu R, Prodan G, Ciupina V, Polosan S. Microstructural and Morphological Characterization of the Cobalt-Nickel Thin Films Deposited by the Laser-Induced Thermionic Vacuum Arc Method. Coatings. 2023; 13(6):984. https://doi.org/10.3390/coatings13060984

Chicago/Turabian StyleDinca, Virginia, Aurelia Mandes, Rodica Vladoiu, Gabriel Prodan, Victor Ciupina, and Silviu Polosan. 2023. "Microstructural and Morphological Characterization of the Cobalt-Nickel Thin Films Deposited by the Laser-Induced Thermionic Vacuum Arc Method" Coatings 13, no. 6: 984. https://doi.org/10.3390/coatings13060984

APA StyleDinca, V., Mandes, A., Vladoiu, R., Prodan, G., Ciupina, V., & Polosan, S. (2023). Microstructural and Morphological Characterization of the Cobalt-Nickel Thin Films Deposited by the Laser-Induced Thermionic Vacuum Arc Method. Coatings, 13(6), 984. https://doi.org/10.3390/coatings13060984