Microstructure and Properties of Phosphorus Bronze/Brass Joints Produced by Resistance Projection Welding

Abstract

1. Introduction

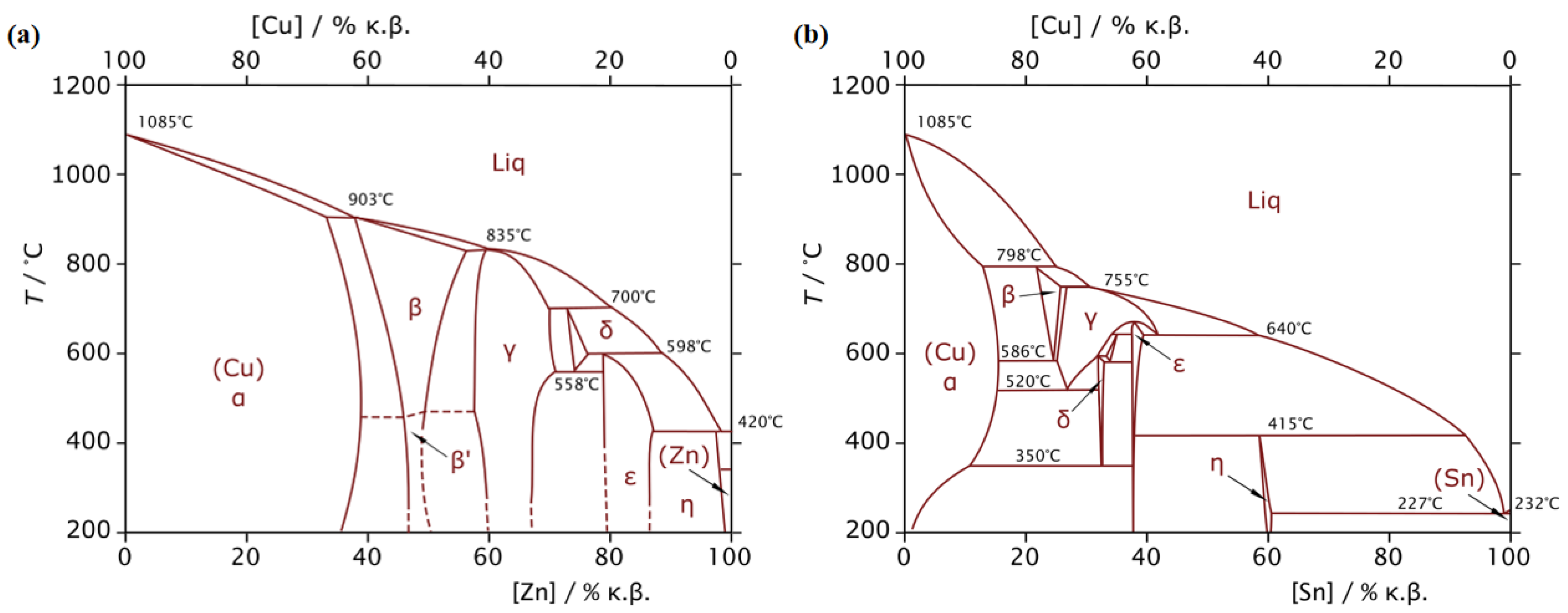

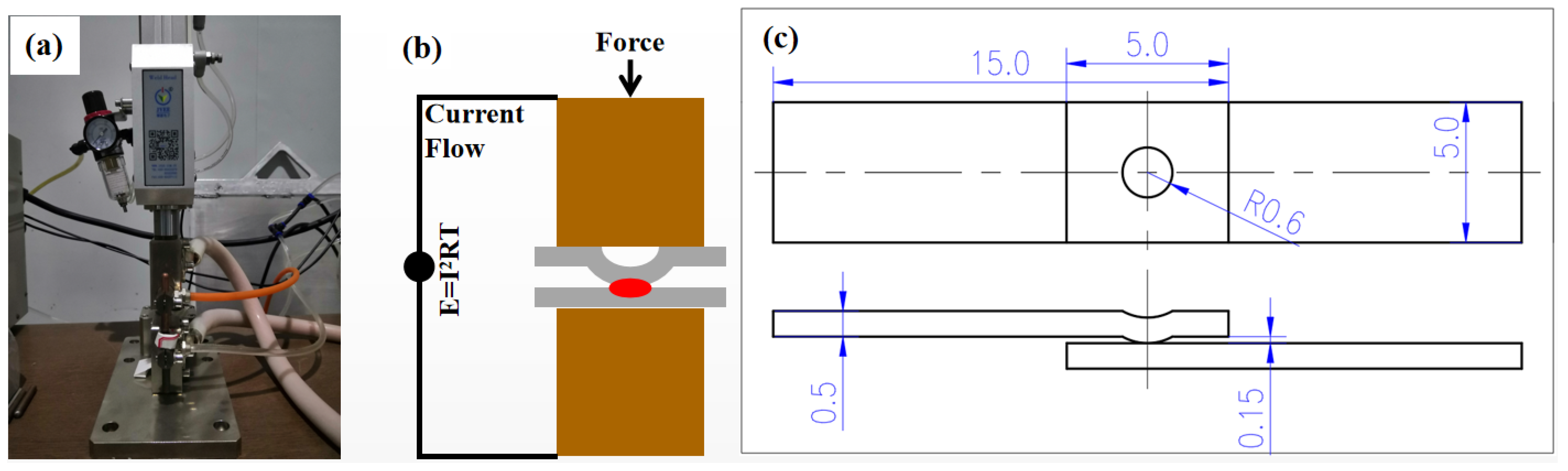

2. Materials and Methods

3. Results and Discussion

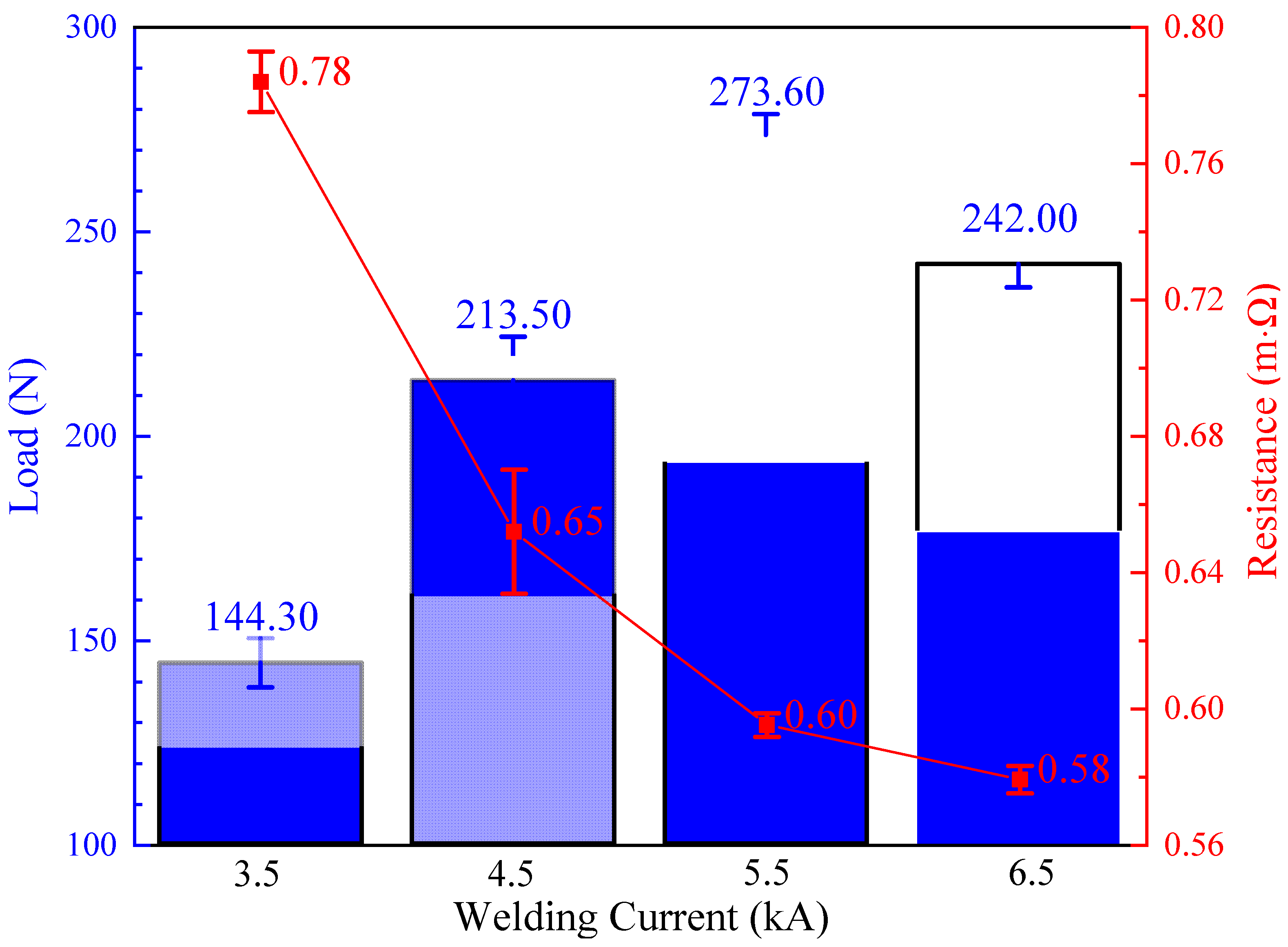

3.1. Properties of the Weld Joints

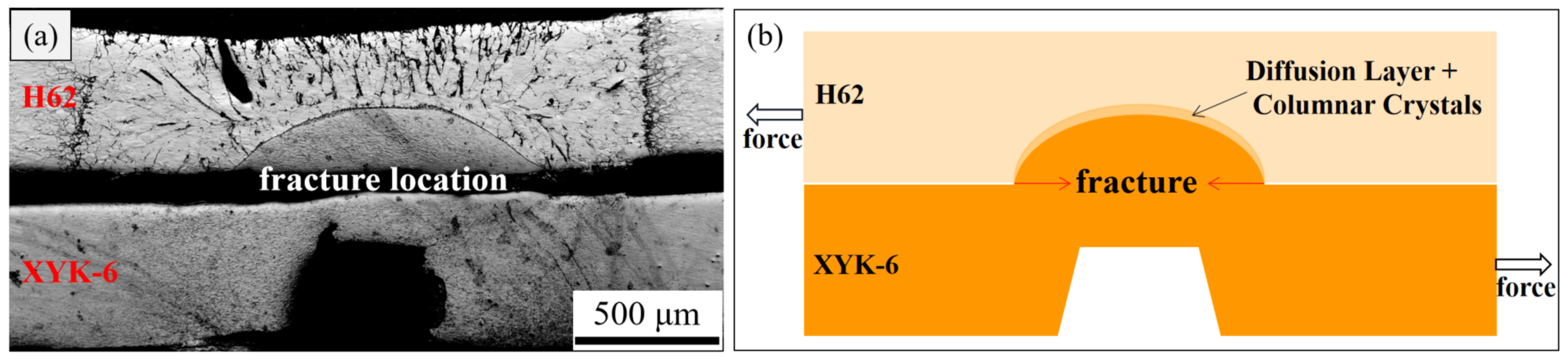

3.2. Macro- and Micrographs of the Weld Joints

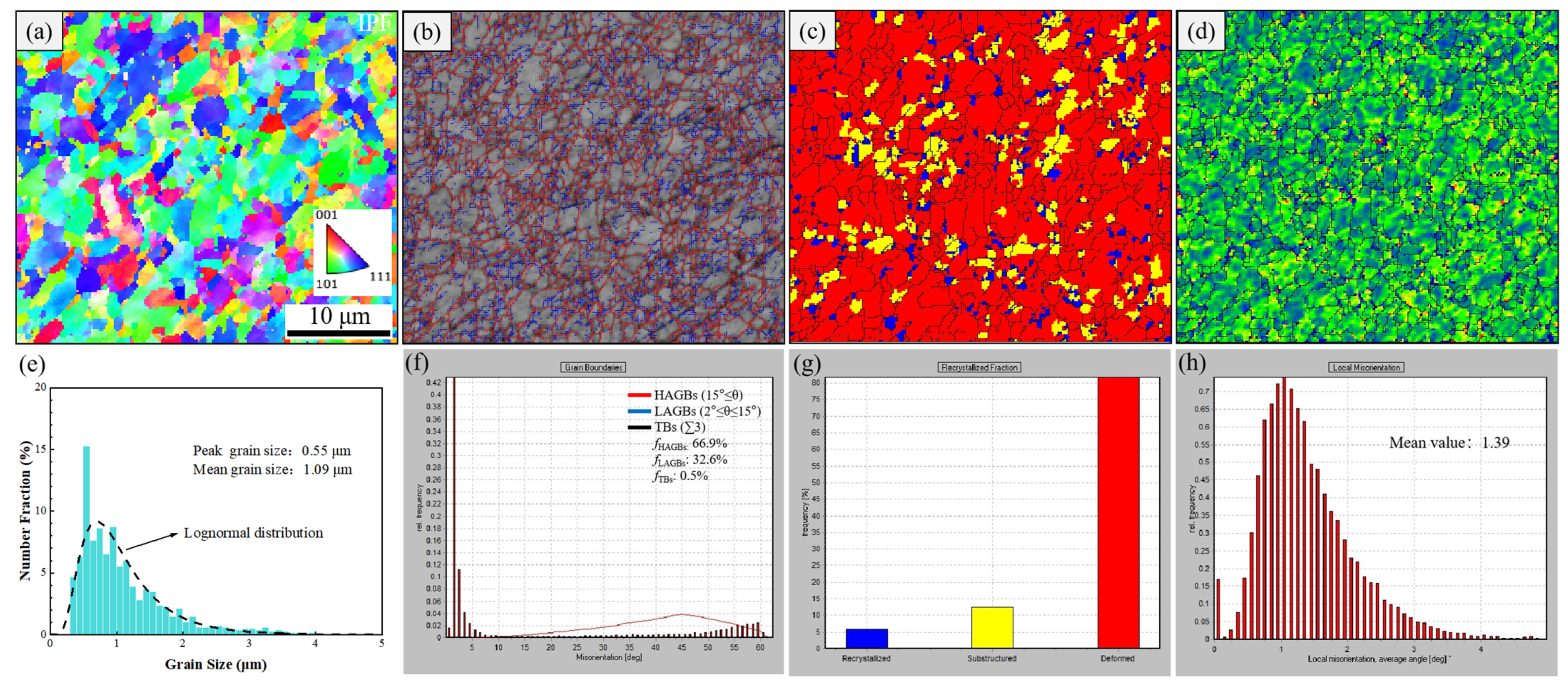

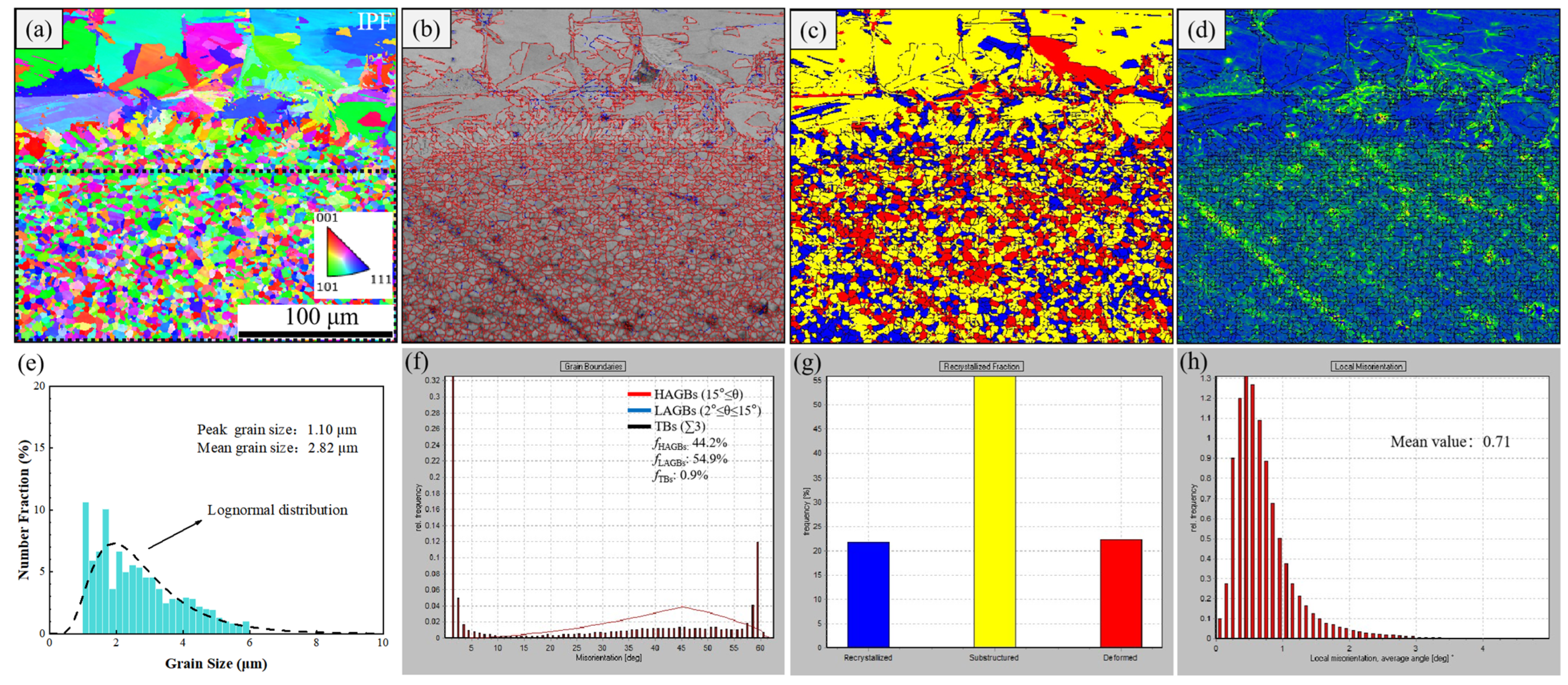

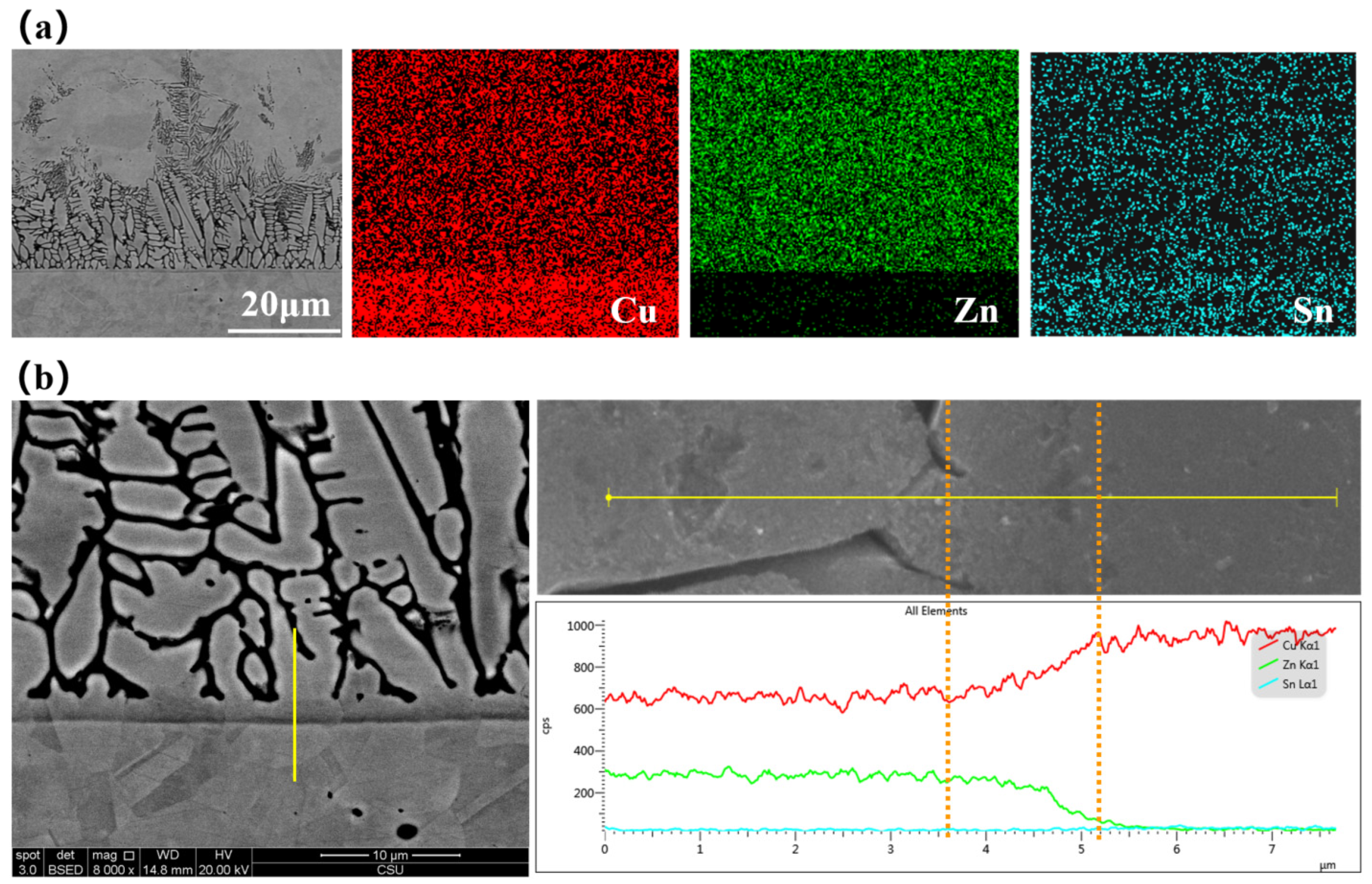

3.3. Metallurgical Characteristics

4. Conclusions

- Resistance projection welding is a suitable method for producing robust welds between bronze and brass. The welded joints show a good quality tensile shear load and electrical conductivity.

- The tensile shear load of the joint increased as the welding current increased. When the welding current was 5.5 kA, it reached the maximum value of 273.60 kN. The resistance of the joint decreased with the increase in the welding current.

- At a welding current of 5.5 kA, a reaction layer is formed at the interface adjacent to the boundary of phosphorus bronze. This layer consists of a columnar crystal solidification layer and a diffusion layer. A tensile shear fracture occurred on the metal side of XYK-6, passing through the bump instead of the welding interface.

- The formation mechanism of the welding interface is revealed for the first time, demonstrating a shift from solid-phase diffusion welding to liquid-phase diffusion welding, ultimately resulting in a robust welded joint. The results revealed that resistance projection welding is an effective method for welding copper alloys, suggesting the broad prospects of this technology in welding electrical parts, such as in the electrical and automotive industries.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Freudenberger, J.; Warlimont, H. Copper and Copper Alloys. In Springer Handbook of Materials Data; Springer International Publishing: Cham, Switzerland, 2018; pp. 297–305. [Google Scholar]

- Davis, J.R. Copper and Copper Alloys; ASM International: Materials Park, OH, USA, 2001. [Google Scholar]

- Nayak, B.; Baliarsingh, A.K.; Biswajit, G.R. Investigation of Mechanical Properties of high Thickness Brass by TIG Welding. Juni Khyat 2021, 11, 559–564. [Google Scholar]

- Auwal, S.; Ramesh, S.; Yusof, F.; Manladan, S.M. A review on laser beam welding of copper alloys. Int. J. Adv. Manuf. Technol. 2018, 96, 475–490. [Google Scholar] [CrossRef]

- Nakata, K. Friction stir welding of copper and copper alloys. Weld. Int. 2005, 19, 929–933. [Google Scholar] [CrossRef]

- Ni, Z.; Yang, J.; Li, S.; Wang, X.; Ye, F. A review on ultrasonic spot welding of copper alloys. Mater. Sci. Technol. 2020, 36, 264–283. [Google Scholar] [CrossRef]

- Hasap, A.; Noraphaiphipaksa, N.; Kanchanomai, C. The microstructure and strength of copper alloy brazing joints. Weld. J. 2014, 93, 116–123. [Google Scholar]

- Li, Z.; Yi, Y.; He, D.; Lai, R. Interfacial Microstructure and Shear Strength of Brazed Cu-Cr-Zr Alloy Cylinder and Cylindrical Hole by Au Based Solder. Metals 2017, 7, 247. [Google Scholar] [CrossRef]

- Li, Y.; Chen, C.; Yi, R.; Ouyang, Y. Special brazing and soldering. J. Manuf. Process. 2020, 60, 608–635. [Google Scholar] [CrossRef]

- Wehle, M. Basics of Process Physics and Joint Formation in Resistance Projection Welding Processes. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2020. [Google Scholar]

- Lienert, T.; Siewert, T.; Babu, S.; Acoff, S.W.P.V. Specifications, ASM handbook. In Welding Fundamentals and Processes; ASM International: Materials Park, OH, USA, 2011; Volume 6A. [Google Scholar]

- Polajnar, I. Fundamentals of Resistance Welding Processes; Univerza v Ljubljani, Fakulteta za strojništvo: Ljubljana, Slovenia, 2007. [Google Scholar]

- Baobuangoen, J.; Pornsing, C. Productivity Improvement in Projection welding Process by Design and Analysis of Experiment A case of an Automobile Parts Manufacturer; Silpakorn University: Bangkok, Thailand, 2021. [Google Scholar]

- Paliakou, A.Y. Effect of Electrode Pressing Force on the Amount of Energy Supplied to Interelectrode Space in Resistance Projection Welding with Constant Current Welding Machine; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; p. 012034. [Google Scholar]

- Wang, X.; Zhang, Y. Effects of Welding Procedures on Resistance Projection Welding of Nuts to Sheets. ISIJ Int. 2017, 57, 2194–2200. [Google Scholar] [CrossRef]

- Ha, S.; Murugan, S.P.; Marimuthu, K.P.; Park, Y.; Lee, H. Estimation of lobe curve with material strength in resistance projection welding. J. Mater. Process. Technol. 2019, 263, 101–111. [Google Scholar] [CrossRef]

- Han, G.; Ha, S.; Marimuthu, K.P.; Murugan, S.P.; Park, Y.; Lee, H. Estimation of shear fracture load in resistance projection welded sheets with dissimilar strength and thickness. Eng. Fail. Anal. 2021, 120, 105042. [Google Scholar] [CrossRef]

- Mikno, Z.; Stepien, M.; Grzesik, B. Optimization of resistance welding by using electric servo actuator. Weld. World 2017, 61, 453–462. [Google Scholar] [CrossRef]

- Ha, S.; Han, G.; Lee, H.; Murugan, S.P.; Park, Y. Optimal Design of Square Weld Nut by Taguchi Method and FE Analyses in Nut Projection Welding. Trans. Korean Soc. Mech. Eng. C 2019, 43, 409–418. [Google Scholar] [CrossRef]

- Ren, K.; Qiu, R.; Ma, H.; Shi, H. Joining Aluminum Alloy to Steel by Resistance Projection-Plug Welding. J. Mater. Eng. Perform. 2020, 29, 4087–4094. [Google Scholar] [CrossRef]

- Sejč, P.; Belanová, J.; Gábrišová, Z.; Vanko, B. The Influence of Parameters of the Resistance Projection Welding of M10 Steel Nuts to the Galvanized Steel Sheet DP 600 on Selected Joint Characteristics. Manuf. Technol. 2020, 20, 822–833. [Google Scholar] [CrossRef]

- Chun, E.-J.; Sung-Sang, L.; Young-Tae, K.; Nam, K.-S.; Young-Min, K.; Young-Whan, P.; Murugan, S.P.; Park, Y.-D. Influence of heat-treated Al–Si coating on the weldability and microstructural inhomogeneity for hot stamped steel resistance nut projection welds. Met. Mater. Int. 2019, 25, 179. [Google Scholar] [CrossRef]

- Van Rymenant, P. Mechanical Characterisation and Modelling of Resistance Welding; KU Lueven Publishing: Lueven, Belgium, 2010. [Google Scholar]

- Luo, J.; Zhou, Z.; Cao, X.; Zou, C.; Zou, C. Microstructure and Failure Analysis of Resistance Projection Welding of Nuts to AHSS with Capacitor Discharge Welding. ISIJ Int. 2019, 59, 305–311. [Google Scholar] [CrossRef]

- Nielsen, C.V.; Zhang, W.; Martins, P.A.F.; Bay, N. 3D numerical simulation of projection welding of square nuts to sheets. J. Mater. Process. Technol. 2015, 215, 171–180. [Google Scholar] [CrossRef]

- Gintrowski, G.; Reisgen, U.; Schiebahn, A.; Schmachtenberg, M.; Hibert, V. Characteristics of resistance projection–welded aluminum-copper interconnects. Weld. World 2019, 63, 1593–1599. [Google Scholar] [CrossRef]

- Mat Saad, H.N. Effect of Resistance Spot Welding Parameters on Copper and Brass. Master’s Thesis, Universiti Sains Malaysia, Penang, Malaysia, 2012. [Google Scholar]

- Baker, H.; Okamato, H. ASM Handbook, Vol. 3, Alloy Phase Diagrams; ASM International: Materials Park, OH, USA, 1992. [Google Scholar]

- Jiang, J.; Britton, T.B.; Wilkinson, A.J. Evolution of dislocation density distributions in copper during tensile deformation. Acta Mater. 2013, 61, 7227–7239. [Google Scholar] [CrossRef]

| Materials | Chemical Composition % | ||||||

|---|---|---|---|---|---|---|---|

| Cu | Zn | Sn | P | Fe | Ni | Pb | |

| H62 | 60.5~63.5 | Bal. | - | - | ≤0.07 | - | ≤0.09 |

| XYK-6 | Bal. | 1.00 | 1.8~2.7 | 0.03~0.10 | 0.10 | 0.1~0.4 | 0.02 |

| Materials | Conductivity (%IACS) | Tensile Strength (MPa) |

|---|---|---|

| H62 | 25 | 350~470 |

| XYK-6 | 32 | 480~530 |

| Electrode Force (N) | Welding Current (kA) | Welding Time (ms) | Cooling Time (ms) |

|---|---|---|---|

| 200 | 3.5, 4.5, 5.5, 6.5 | 20 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, R.; Zhang, W.; Sheng, X.; Ye, X.; Cai, Y.; Zhang, X.; Luo, T.; Chen, P.; Lei, Q.; Li, Y. Microstructure and Properties of Phosphorus Bronze/Brass Joints Produced by Resistance Projection Welding. Coatings 2023, 13, 1032. https://doi.org/10.3390/coatings13061032

Lai R, Zhang W, Sheng X, Ye X, Cai Y, Zhang X, Luo T, Chen P, Lei Q, Li Y. Microstructure and Properties of Phosphorus Bronze/Brass Joints Produced by Resistance Projection Welding. Coatings. 2023; 13(6):1032. https://doi.org/10.3390/coatings13061032

Chicago/Turabian StyleLai, Ruilin, Weijun Zhang, Xiaofei Sheng, Xianjue Ye, Yingfeng Cai, Xiwei Zhang, Temiao Luo, Pinghu Chen, Qian Lei, and Yunping Li. 2023. "Microstructure and Properties of Phosphorus Bronze/Brass Joints Produced by Resistance Projection Welding" Coatings 13, no. 6: 1032. https://doi.org/10.3390/coatings13061032

APA StyleLai, R., Zhang, W., Sheng, X., Ye, X., Cai, Y., Zhang, X., Luo, T., Chen, P., Lei, Q., & Li, Y. (2023). Microstructure and Properties of Phosphorus Bronze/Brass Joints Produced by Resistance Projection Welding. Coatings, 13(6), 1032. https://doi.org/10.3390/coatings13061032