Low-Pressure Cold Spray Deposition Window Derived from a One-Dimensional Analytical Model

Abstract

1. Introduction

2. Materials and Methods

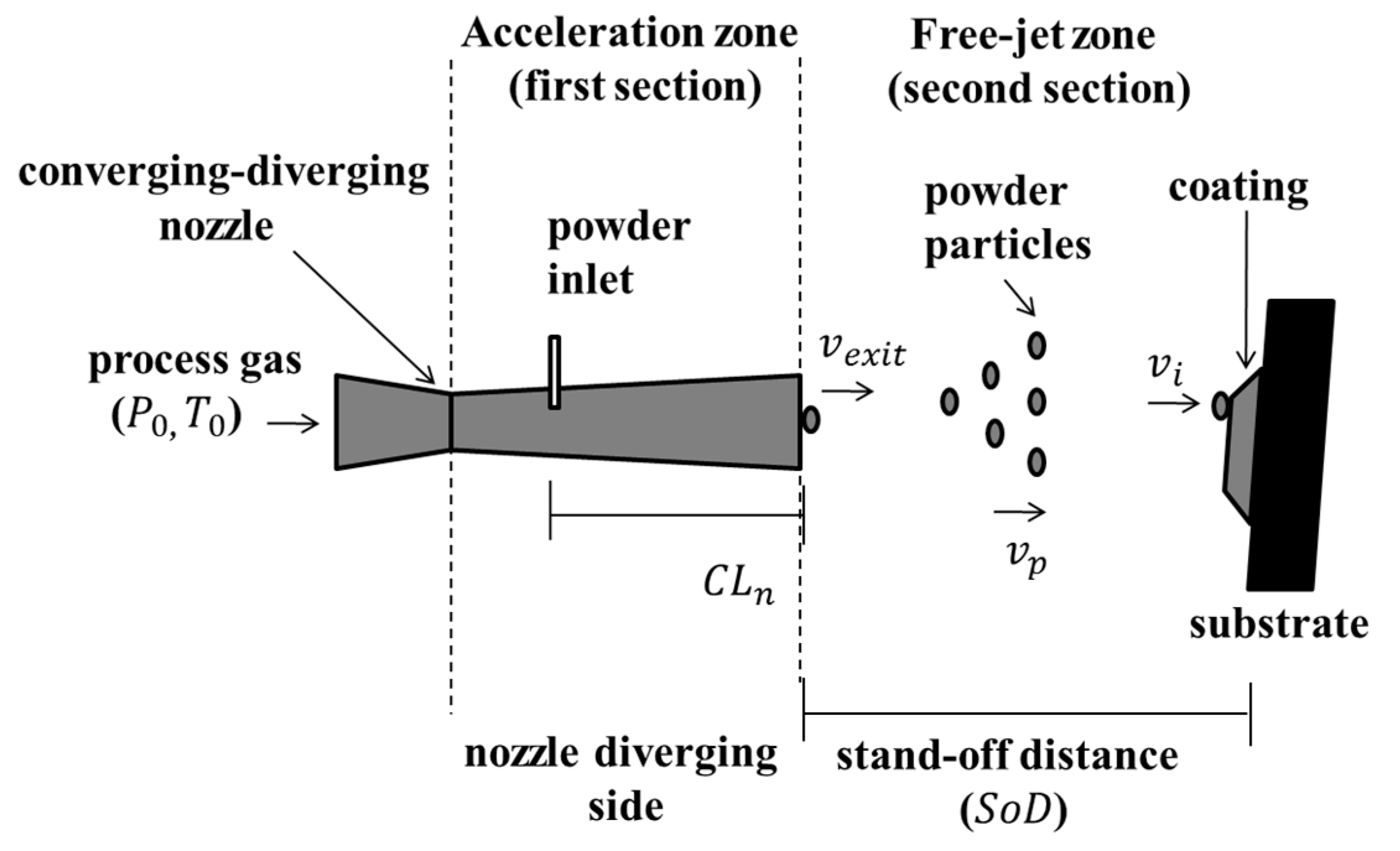

2.1. Analytical Model

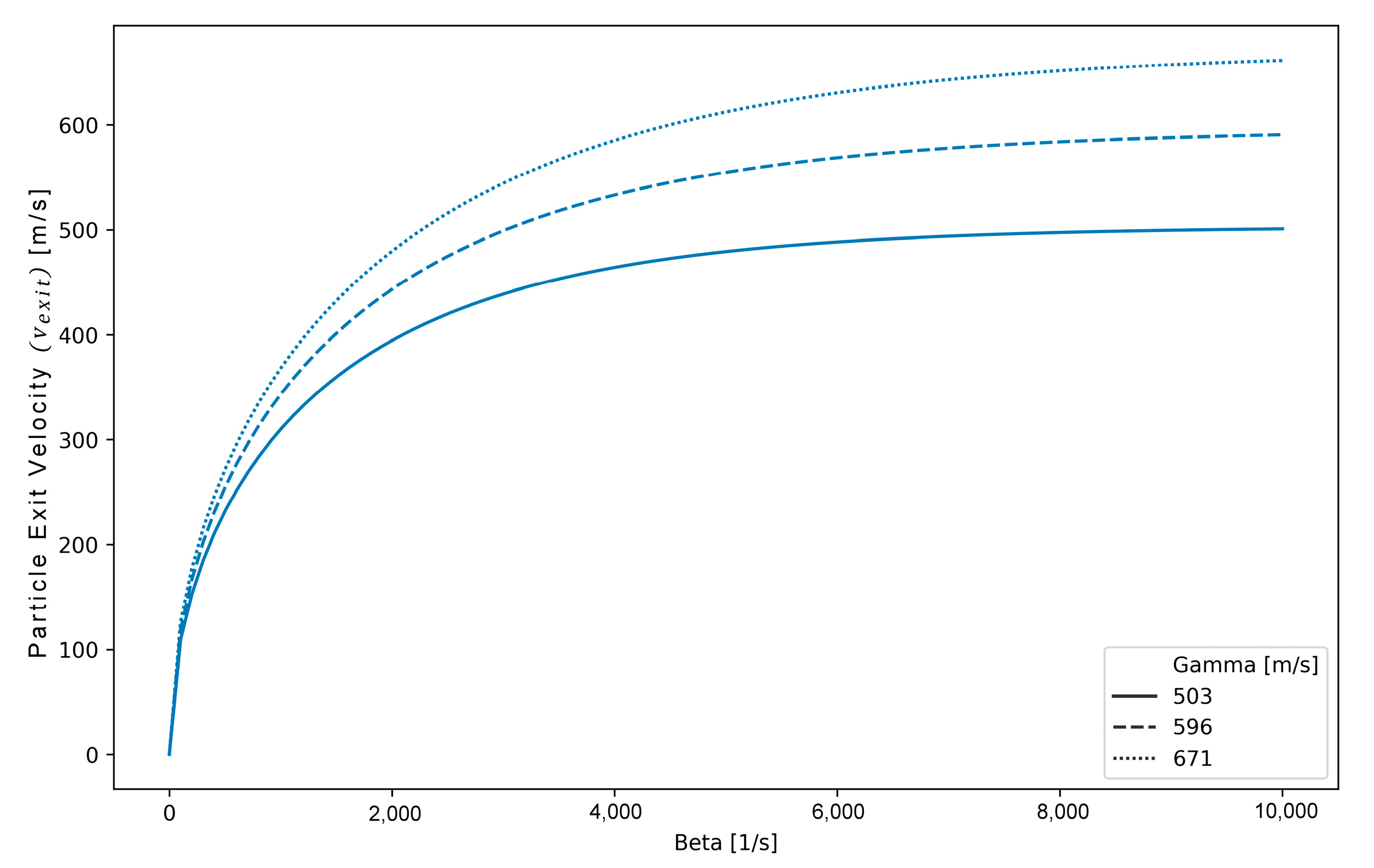

2.2. Particle Velocity Estimation at the Exit of the Nozzle ()

2.3. Impact Particle Velocity Estimation ()

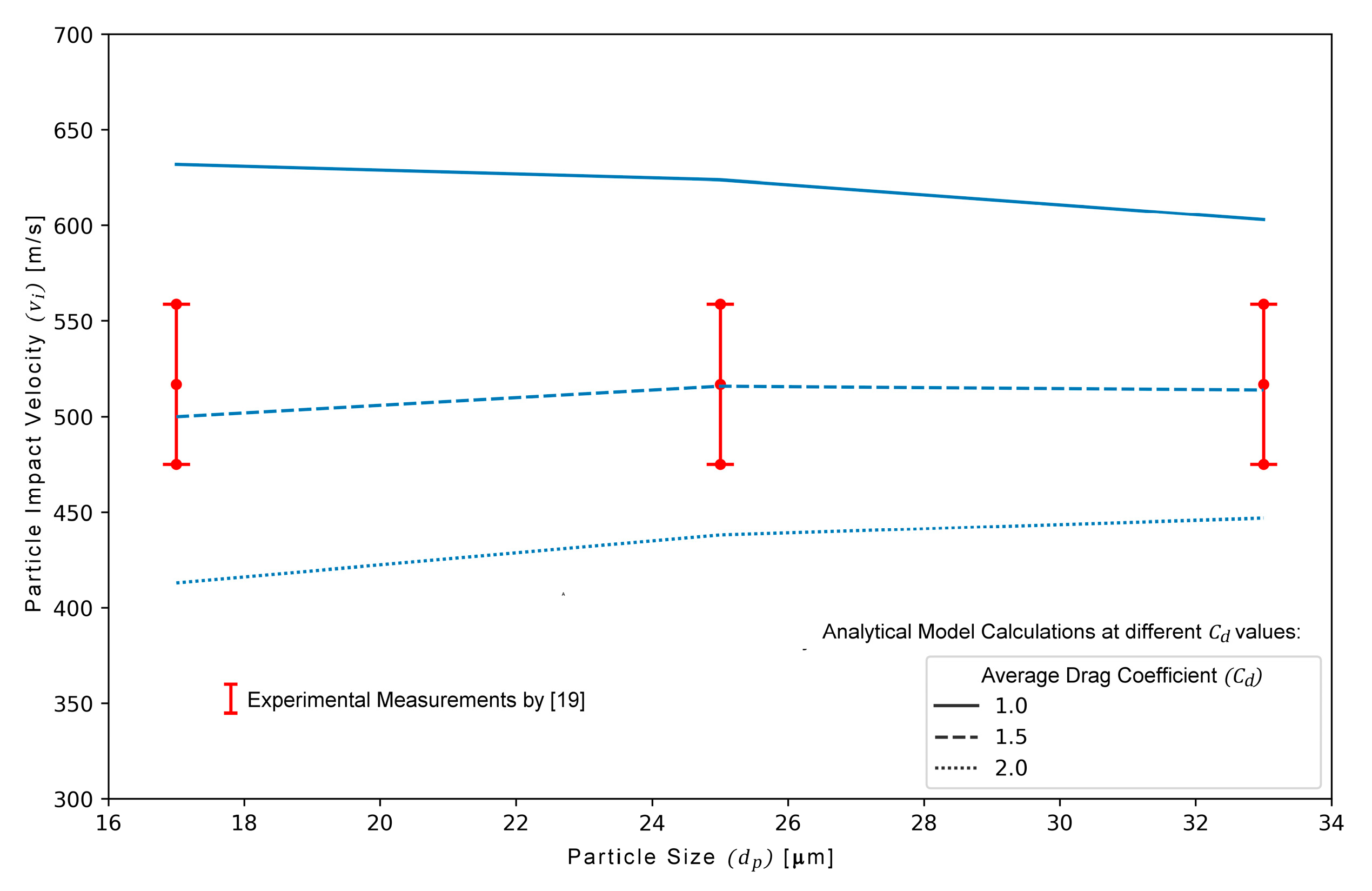

3. Average Drag Coefficient

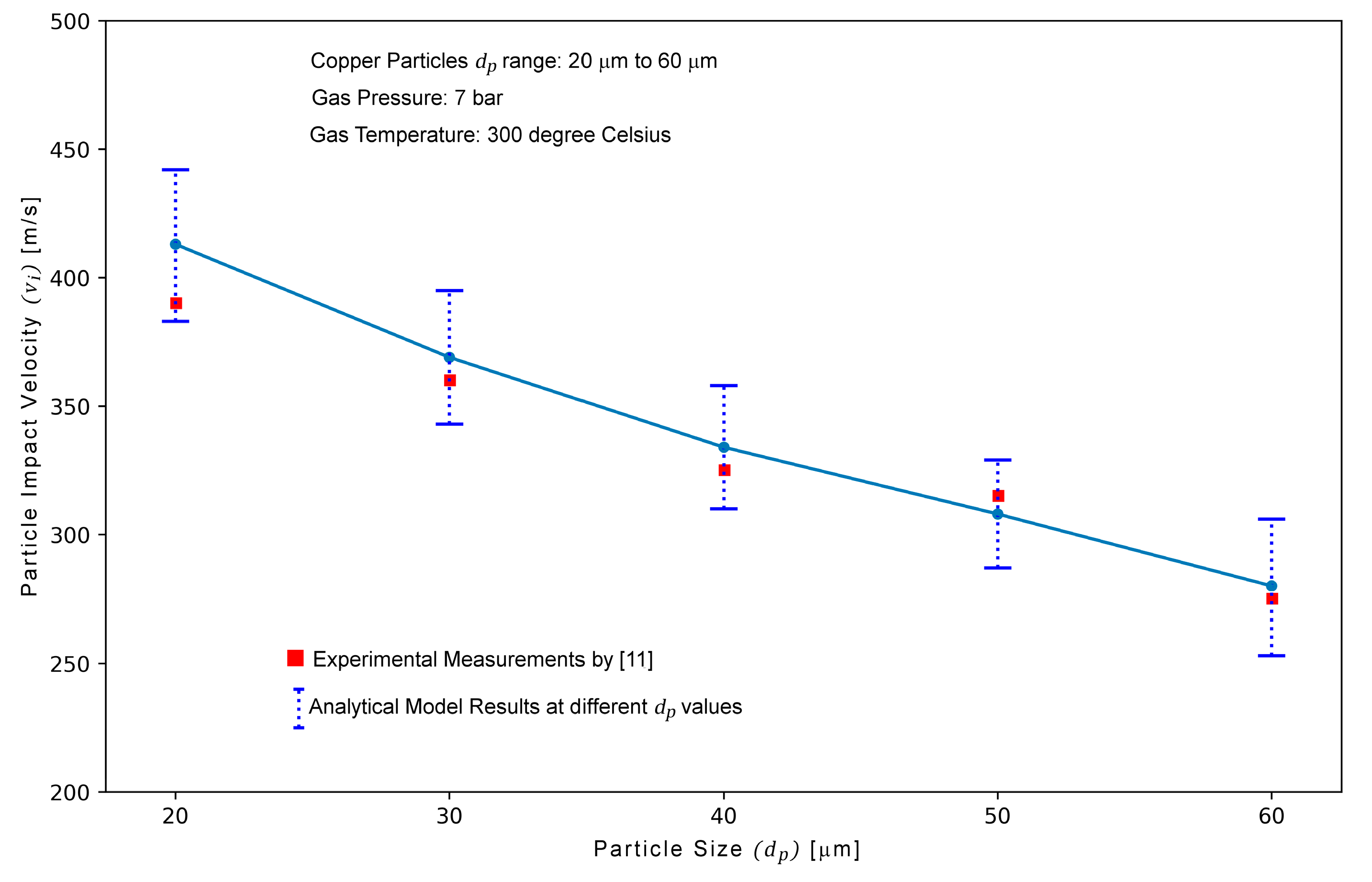

4. Comparison of Model Results with Published Experimental Data

4.1. Particle Velocity at the Exit of the Nozzle ()

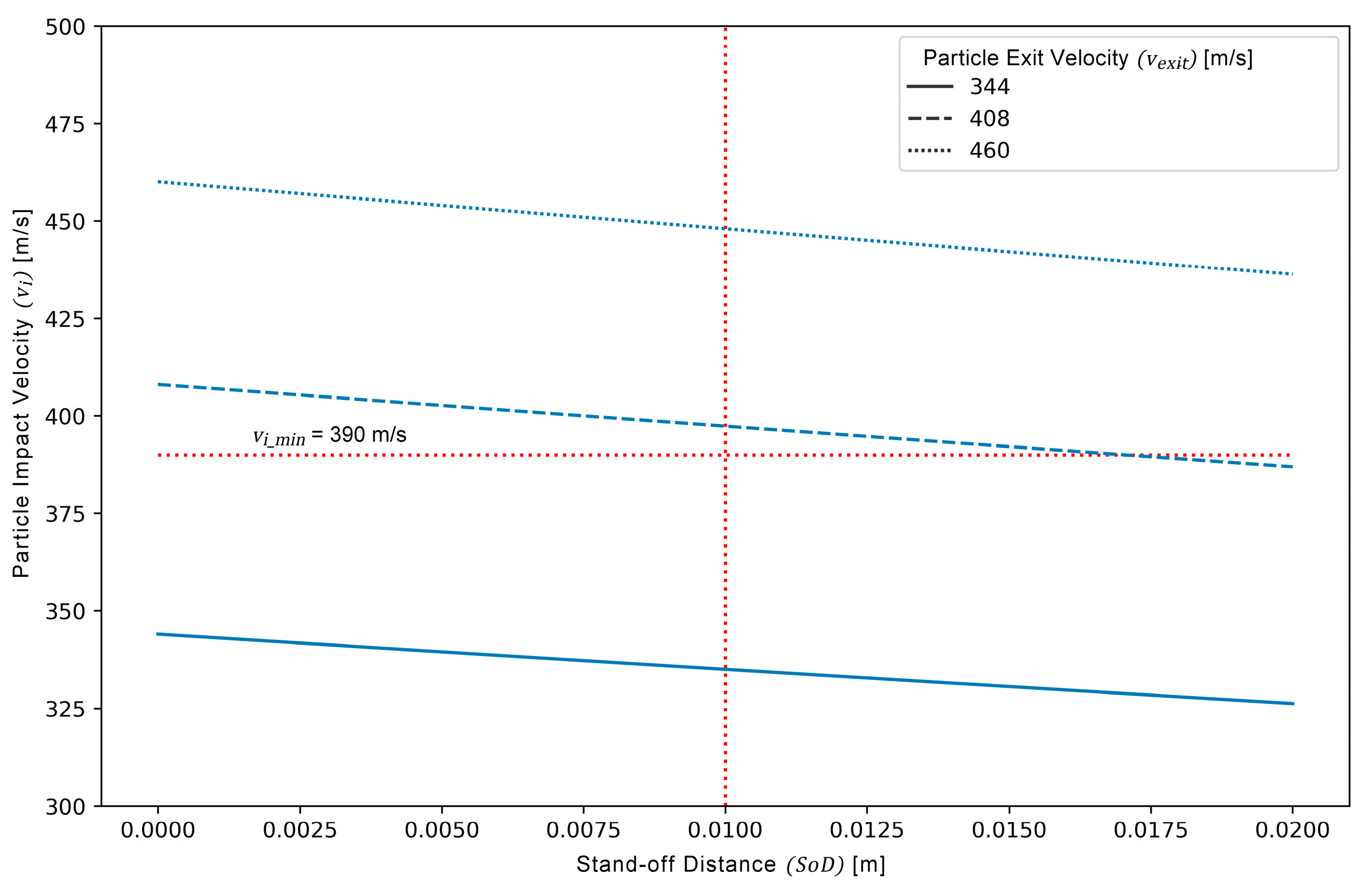

4.2. Particle Impact Velocity ()

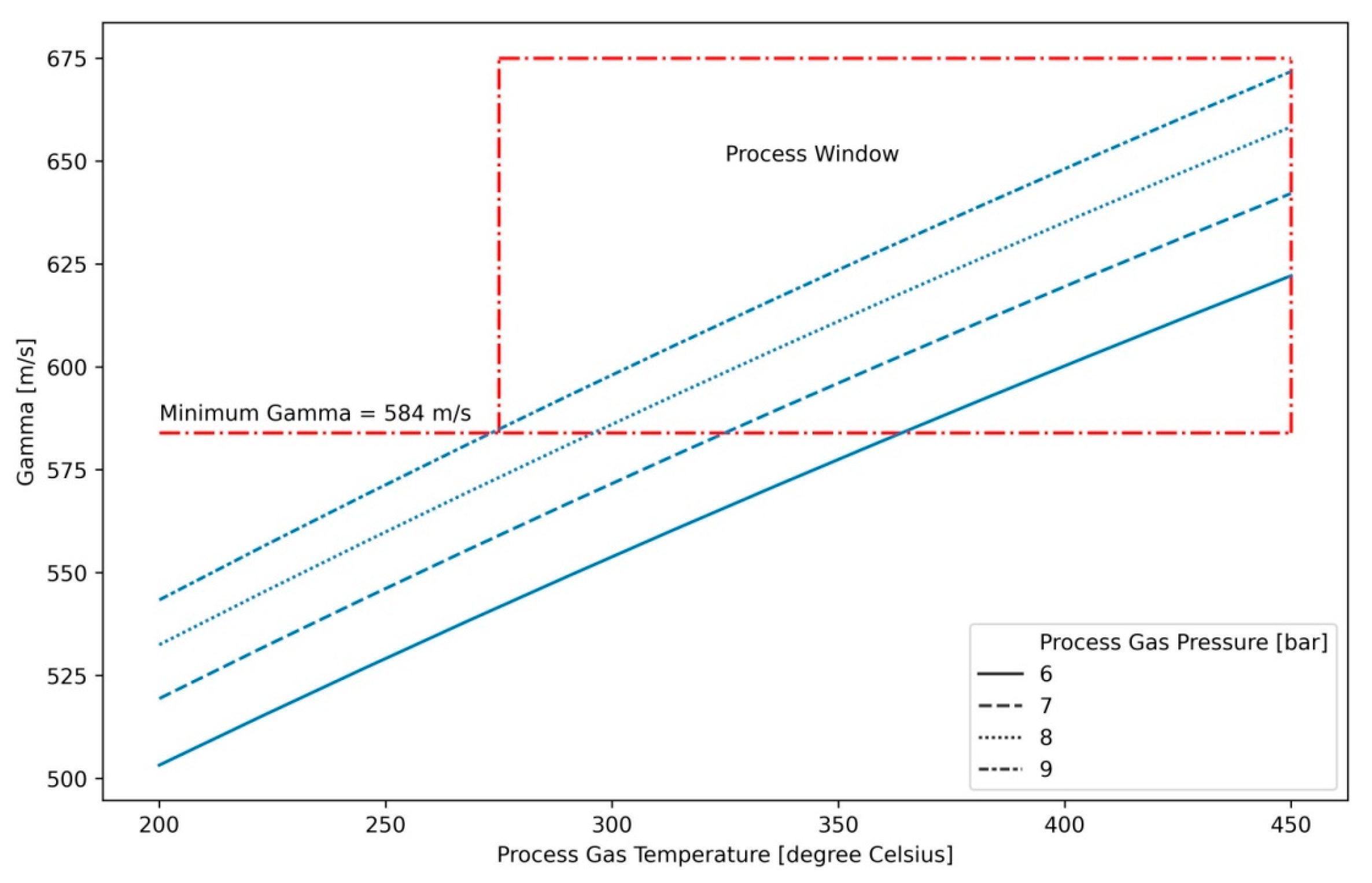

4.3. Deposition Window Definition for LPCS Process with Zinc

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Koivuluoto, H.; Coleman, A.; Murray, K.; Kearns, M.; Vuoristo, P. High pressure cold sprayed (HPCS) and low pressure cold sprayed (LPCS) coatings prepared from OFHC cu feedstock: Overview from powdercharacteristics to coating properties. J. Therm. Spray Technol. 2012, 21, 1065–1075. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gärtner, F.; Klassen, T. Cold spraying—A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef][Green Version]

- King, P.; Yandouzi, M.; Jodoin, B. The physics of cold spray. In Modern Cold Spray; Villafuerte, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Villafuerte, J. Commercial Cold Spray Equipment. In Cold Spray in the Realm of Additive Manufacturing. Materials Forming, Machining and Tribology; Pathak, S., Saha, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Maev, R.; Leshchynsky, V. Low-pressure cold spray (LPCS). In Cold-Spray Coatings; Cavaliere, P., Ed.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Maledi, N.B.; Oladijo, O.P.; Botef, I.; Ntsoane, T.P.; Madiseng, A.; Moloisane, L. Influence of cold spray parameters on the microstructures and residual stress of Zn coatings sprayed on mild Steel. Surf. Coat. Technol. 2017, 318, 106–113. [Google Scholar] [CrossRef]

- Assadi, H.; Schmidt, T.; Richter, H.; Kliemann, J.O.; Binder, K.; Gärtner, F.; Klassen, T.; Kreye, H. On Parameter selection in cold spraying. J. Therm. Spray Technol. 2011, 20, 1161–1176. [Google Scholar] [CrossRef]

- Marzbanrad, B.; Toyserkani, R.; Jahed, H. Characterization of single-and multilayer cold-spray coating of Zn on AZ31B. Surf. Coat. Technol. 2021, 416, 127–155. [Google Scholar] [CrossRef]

- Nastic, A.; Jodoin, B.; Poirier, D.; Legoux, J.G. Particle temperature effect in cold spray: A study of soft particle deposition on hard substrate. Surf. Coat. Technol. 2021, 406, 126735. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Aubignat, E.; Planche, M.P.; Costil, S.; Langlade, C.; Liao, H. Low pressure cold spraying under 6 bar pressure deposition: Exploration of high deposition efficiency solutions using a mathematical modelling. Surf. Coat. Technol. 2016, 302, 47–55. [Google Scholar] [CrossRef]

- Ning, J.X.; Jang, J.H.; Kim, H.J. The effects of powder properties on in-flight particle velocity and deposition process during low pressure cold spray process. Appl. Surf. Sci. 2007, 253, 7449–7455. [Google Scholar] [CrossRef]

- Hussain, T.; Yue, S.; Li, C.J. Characteristics of feedstock materials. In Modern Cold Spray; Villafuerte, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Schmidt, T.; Assadi, H.; Gärtner, F.; Richter, H.; Stoltenhoff, T.; Kreye, H.; Klassen, T. From particle acceleration to impact and bonding in cold spraying. J. Therm. Spray Technol. 2009, 18, 794–808. [Google Scholar] [CrossRef][Green Version]

- Helfritch, D.; Champagne, V. A Model Study of Powder Particle Size Effects in Cold Spray Deposition; Army Research Lab, Aberdeen Proving Ground: Adelphi, MD, USA, 2008. [Google Scholar]

- Sutton, G.P.; Biblarz, O. Rocket Propulsion Elements, 7th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; ISBN 978-1-11-875365-1. [Google Scholar]

- Pattison, J.; Celotto, S.; Khan, A.; O’neill, W. Standoff distance and bow shock phenomena in the Cold Spray process. Surf. Coat. Technol. 2008, 202, 1443–1454. [Google Scholar] [CrossRef]

- Moreno-Murguia, B.; Mora-Garcia, A.G.; Canales-Siller, H.; Giraldo-Betancur, A.L.; Espinosa-Arbelaez, D.G.; Muñoz-Saldaña, J. Influence of stand-off distance and pressure in copper coatings deposition efficiency and particle velocity. Surf. Coat. Technol. 2022, 430, 127986. [Google Scholar] [CrossRef]

- Loth, E.; Daspit, J.T.; Jeong, M.; Nagata, T.; Nonomura, T. Supersonic and hypersonic drag coefficients for a sphere. AIAA J. 2021, 59, 3261–3274. [Google Scholar] [CrossRef]

- Dewar, M.P.; McDonald, A.G.; Gerlich, A.P. Interfacial heating during low-pressure cold-gas dynamic spraying of aluminum coatings. J. Mater. Sci. 2012, 47, 184–198. [Google Scholar] [CrossRef]

- Schmidt, T.; Gärtner, F.; Assadi, H.; Kreye, H. Development of a generalized parameter window for cold spray deposition. Acta Mater. 2006, 54, 729–742. [Google Scholar] [CrossRef]

- Martienssen, W. The Elements. In Springer Handbook of Condensed Matter and Materials Data; Martienssen, W., Warlimont, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

| a | Isentropic expansion factor of the process gas |

| Cd | Average drag coefficient |

| dp | Particle diameter (µm) |

| SoD | Stand-off distance, from the nozzle exit to the substrate (m) |

| CLn | Calculated length traveled by the particle inside the nozzle’s diverging side (m) |

| M | Gas molecular mass |

| P0 | Process gas stagnation pressure (bar) |

| Pe | Pressure at nozzle exit (bar) |

| R | Universal gas constant (kJ kg−1 K−1) |

| Tm | Melting temperature (°C) |

| T0 | Process gas stagnation temperature (°C) |

| vcr | Critical velocity (m/s) |

| vg | Gas velocity (m/s) |

| vi | Impact velocity (m/s) |

| vi min | Minimum impact velocity (m/s) |

| vp | Particle velocity (m/s) |

| vexit | Particle velocity at the nozzle exit (m/s) |

| α | Characteristic parameter alpha (1/m) |

| β | Characteristic parameter beta (1/s) |

| γ | Characteristic parameter gamma (m/s) |

| ρg | Gas density (kg m−3) |

| ρp | Particle density (kg m−3) |

| Parameter | Value |

|---|---|

| R | 8.314 m3·Pa·K−1·mol−1 |

| Pe | 1.013 bar |

| dp | 20–60 µm |

| Cd | 0.5–2.5 |

| Process Gas | - |

| M | 28.9 g/mol |

| aa | 1.393 |

| ρg | 0.391–0.501 kg·m−3 |

| P0 | 5–9 bar |

| To | 200–630 °C |

| Al Powder | - |

| ρp | 2710 kg·m−3 |

| Cu Powder | - |

| ρp | 8630–8960 kg·m−3 |

| Zn Powder | - |

| ρp | 6830 kg·m−3 |

| Parameter | Value | Units |

|---|---|---|

| dp | 40 | µm |

| ρp | 6830 | kg/m3 |

| Cd | 1.5 | - |

| SoD | 0.01 | m |

| Vi min | 390 | m/s |

| Condition | Pressure (bar) | Temperature (°C) |

|---|---|---|

| 1 | 7 | 350 |

| 2 | 7 | 400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Flores, M.; Cervantes-Cabello, J.J.; Barba-Pingarrón, A. Low-Pressure Cold Spray Deposition Window Derived from a One-Dimensional Analytical Model. Coatings 2023, 13, 1015. https://doi.org/10.3390/coatings13061015

Martínez-Flores M, Cervantes-Cabello JJ, Barba-Pingarrón A. Low-Pressure Cold Spray Deposition Window Derived from a One-Dimensional Analytical Model. Coatings. 2023; 13(6):1015. https://doi.org/10.3390/coatings13061015

Chicago/Turabian StyleMartínez-Flores, Mónica, José Javier Cervantes-Cabello, and Arturo Barba-Pingarrón. 2023. "Low-Pressure Cold Spray Deposition Window Derived from a One-Dimensional Analytical Model" Coatings 13, no. 6: 1015. https://doi.org/10.3390/coatings13061015

APA StyleMartínez-Flores, M., Cervantes-Cabello, J. J., & Barba-Pingarrón, A. (2023). Low-Pressure Cold Spray Deposition Window Derived from a One-Dimensional Analytical Model. Coatings, 13(6), 1015. https://doi.org/10.3390/coatings13061015