Simulation of Turbulent Flow Structure and Particle Deposition in a Three-Dimensional Heat Transfer Duct with Convex Dimples

Abstract

1. Introduction

- The presence or absence of convex dimples in the channel affected the flow field structure and particle deposition.

- The effect of different inlet airflow velocities on flow and particle deposition in the channel.

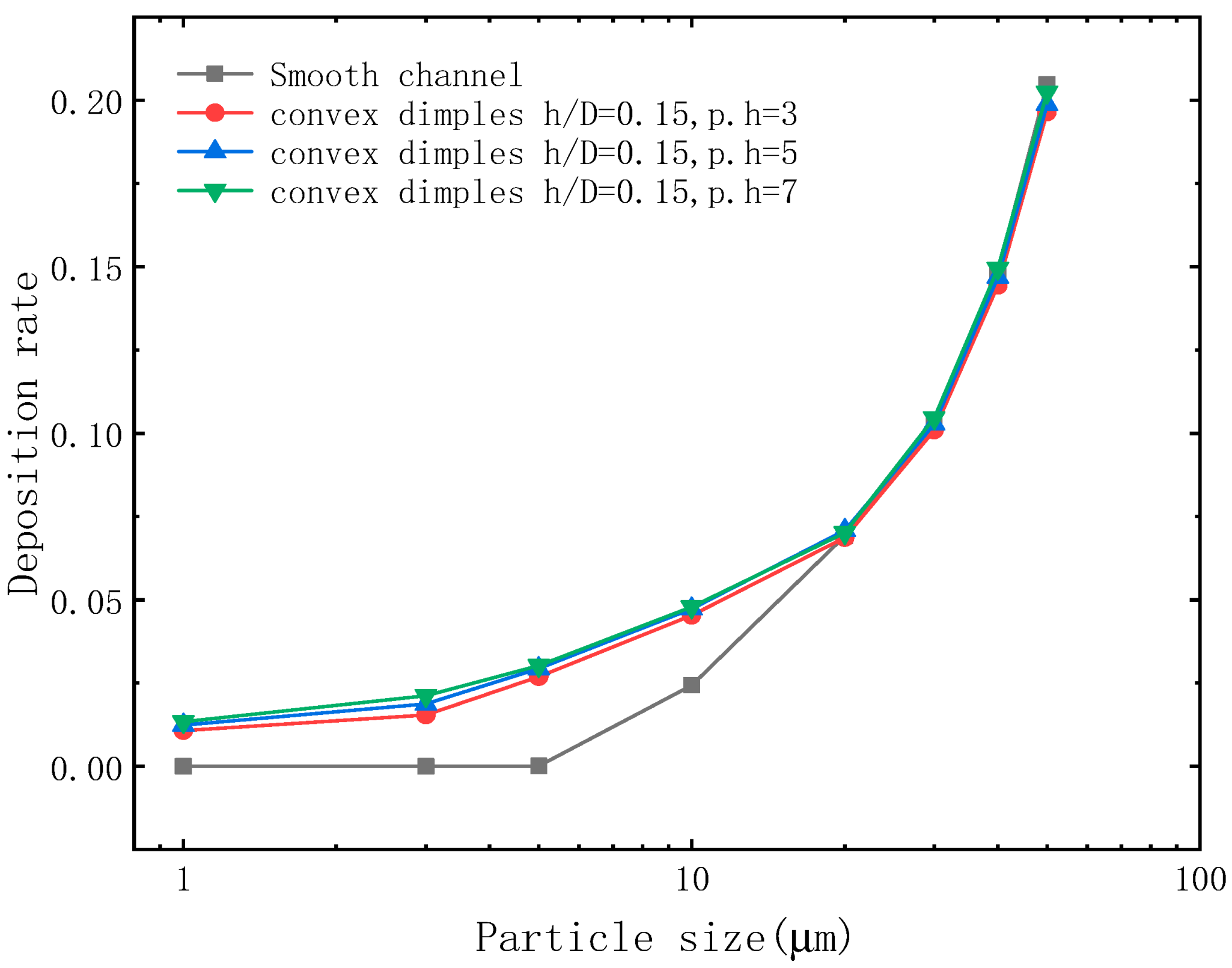

- The effect of different particle sizes on the deposition of particles in the channel.

- The effect of convex dimples with different parameters (vortex width ratio p/h and vortex height ratio h/D) on the flow field in the channel as well as on the particle deposition.

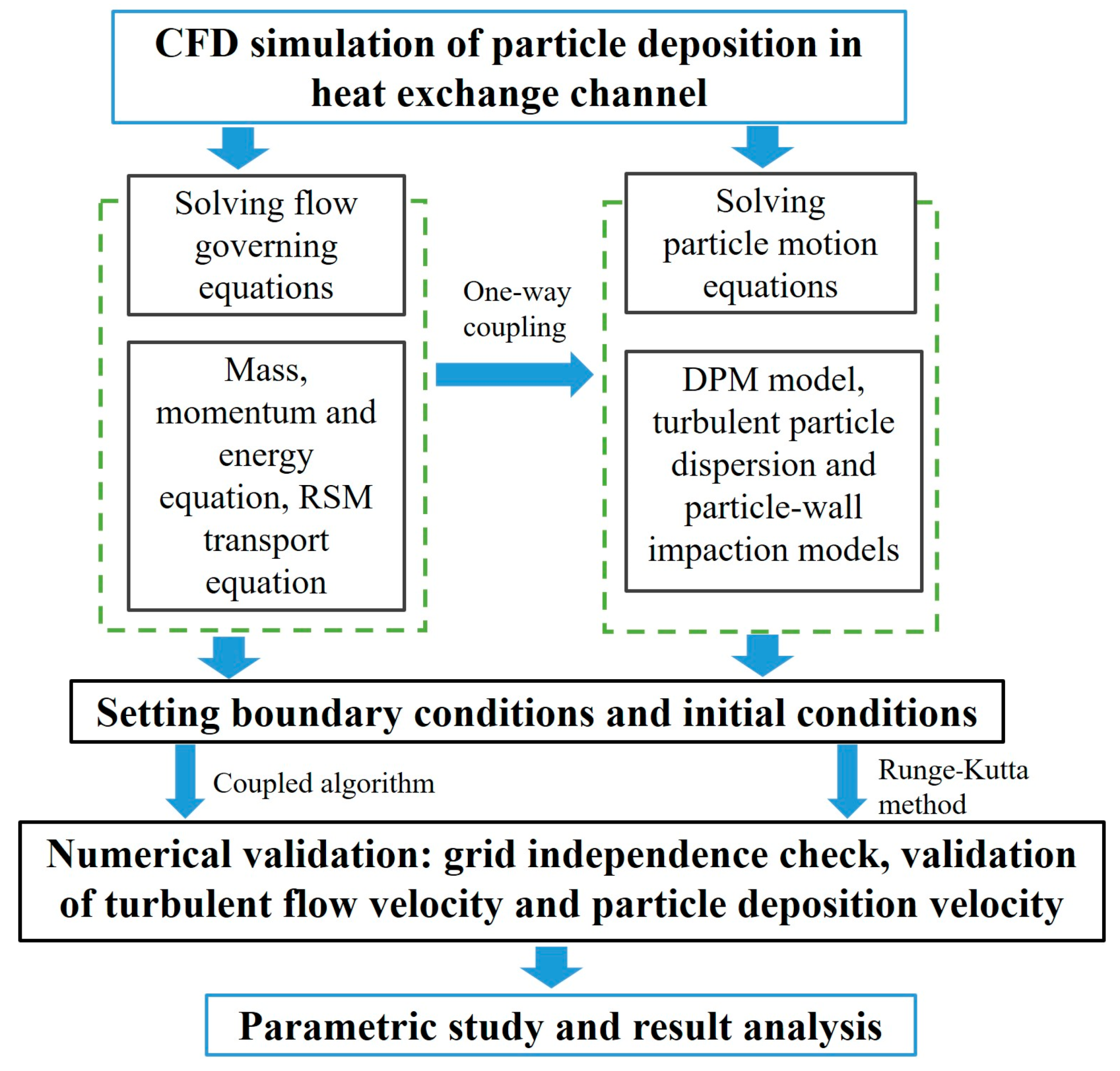

2. Materials and Methods

2.1. Turbulent Airflow Model

2.2. Discrete Phase Model

2.2.1. Drag Force FD

2.2.2. Gravity and Buoyancy FG

2.2.3. Brownian FB

2.2.4. Saffman Lift FS

2.2.5. Thermophoresis Force FT

2.3. Turbulent Dispersion of Particles

3. Case Description and Solution Method

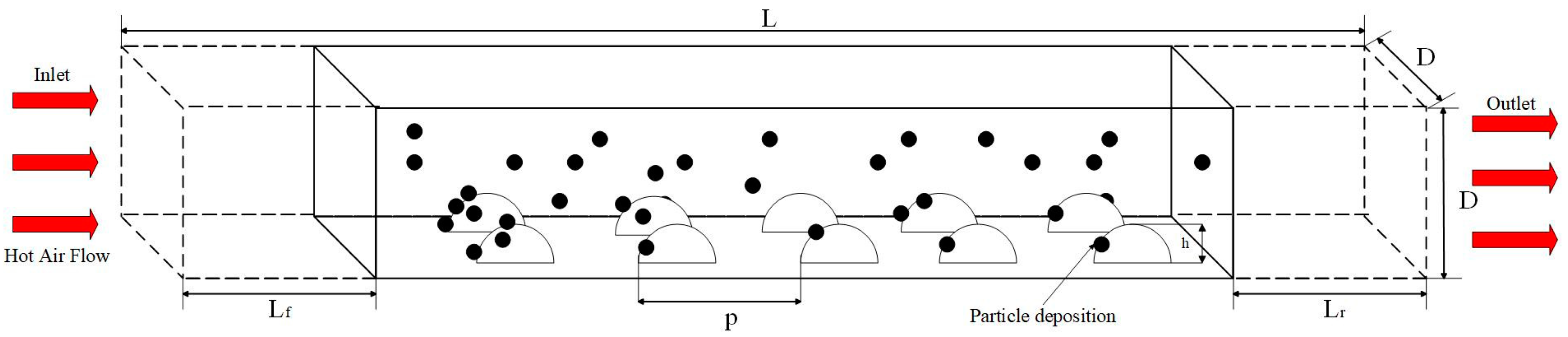

3.1. Case Description

3.2. Boundary Conditions

3.3. Solution Method

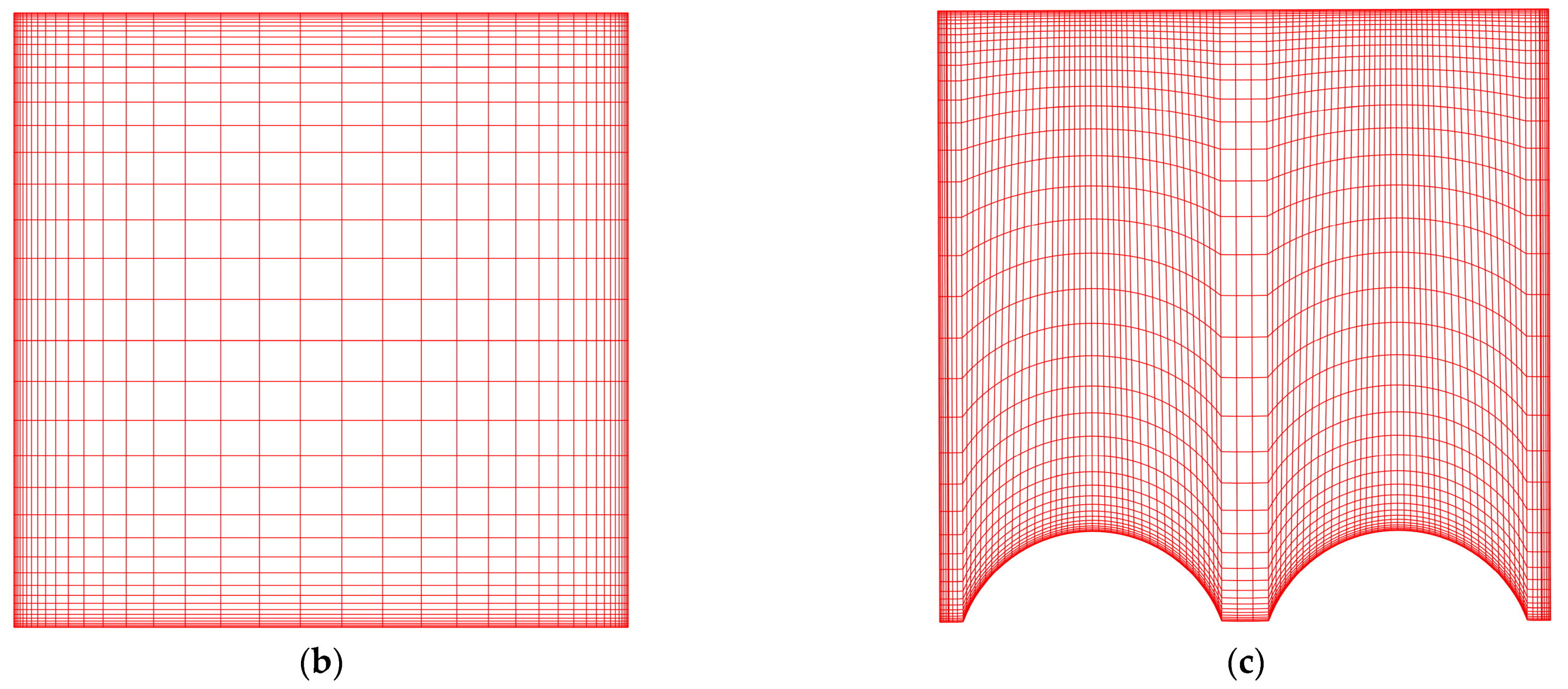

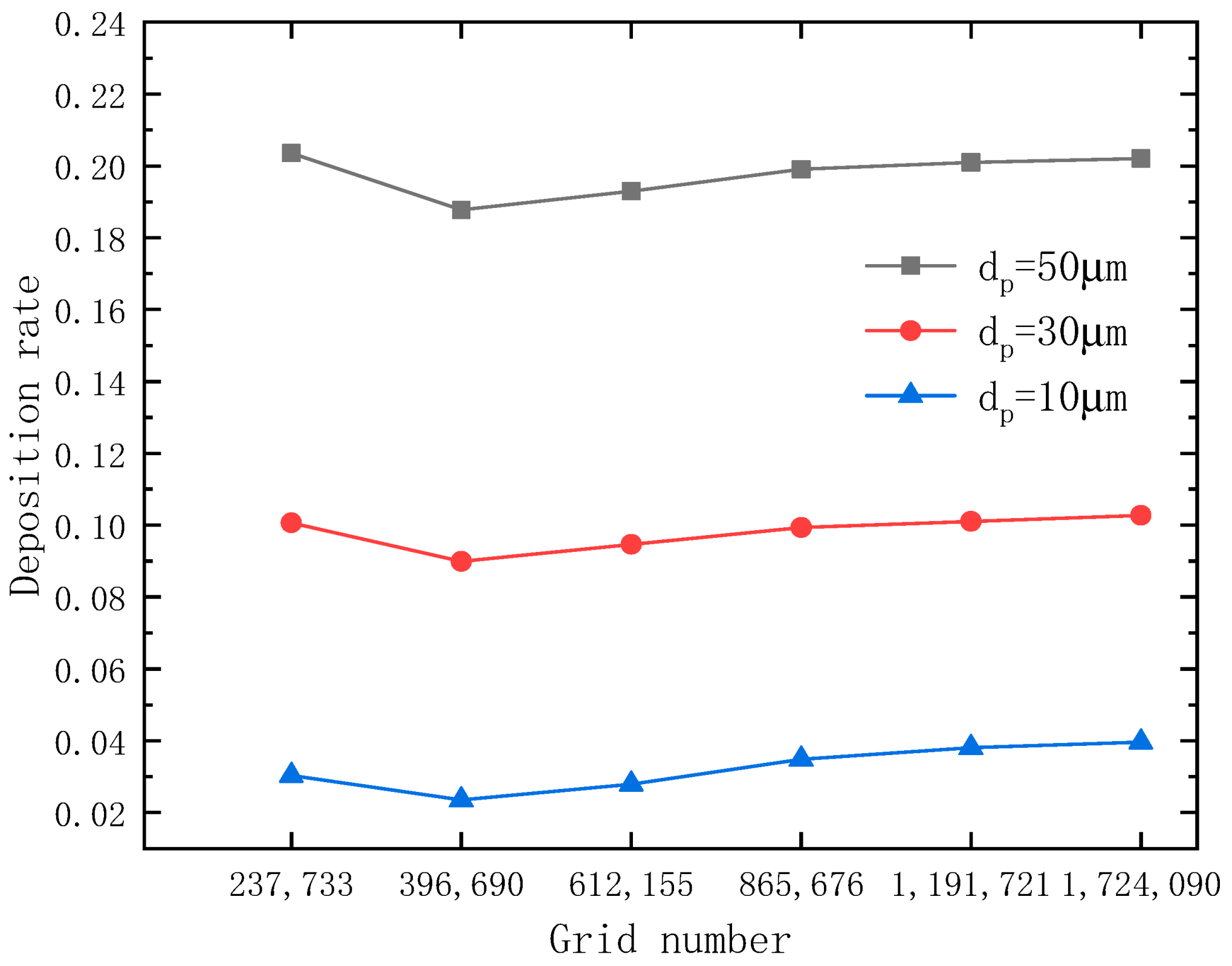

3.4. Structured Grid and Grid Independence Analysis

4. Results

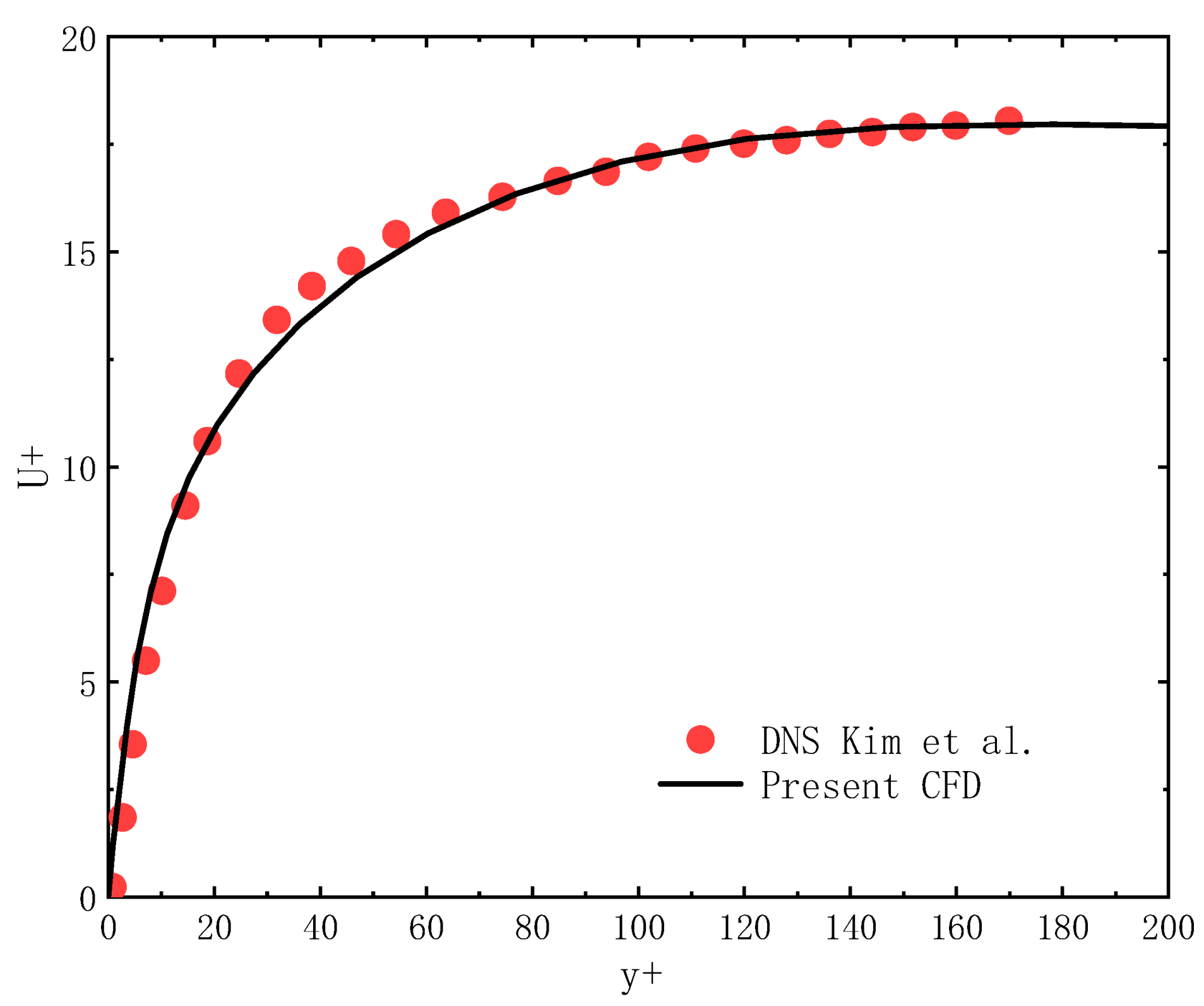

4.1. Numerical Validation

4.1.1. Verification of Turbulent Air Flow

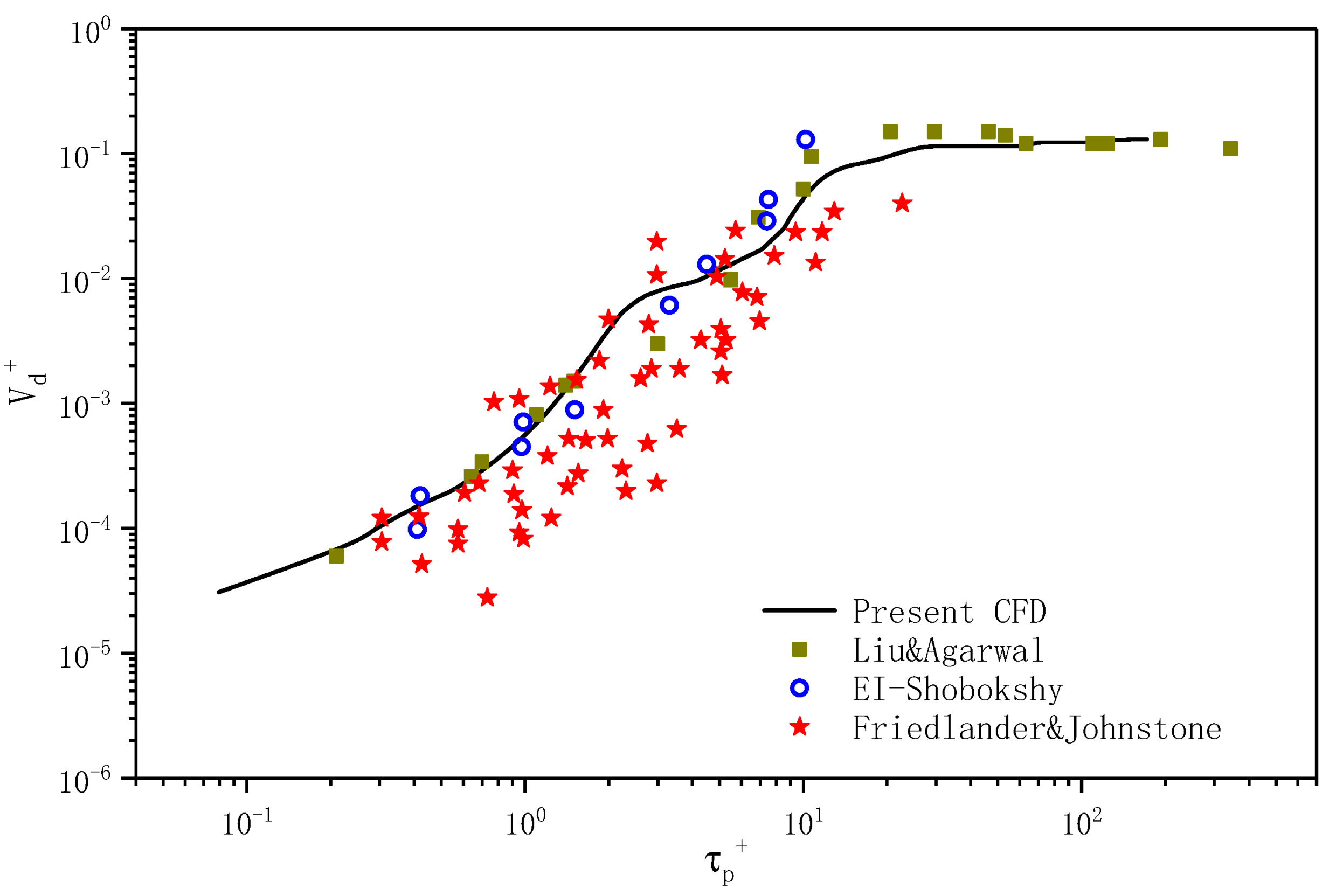

4.1.2. Verification of Particle Deposition

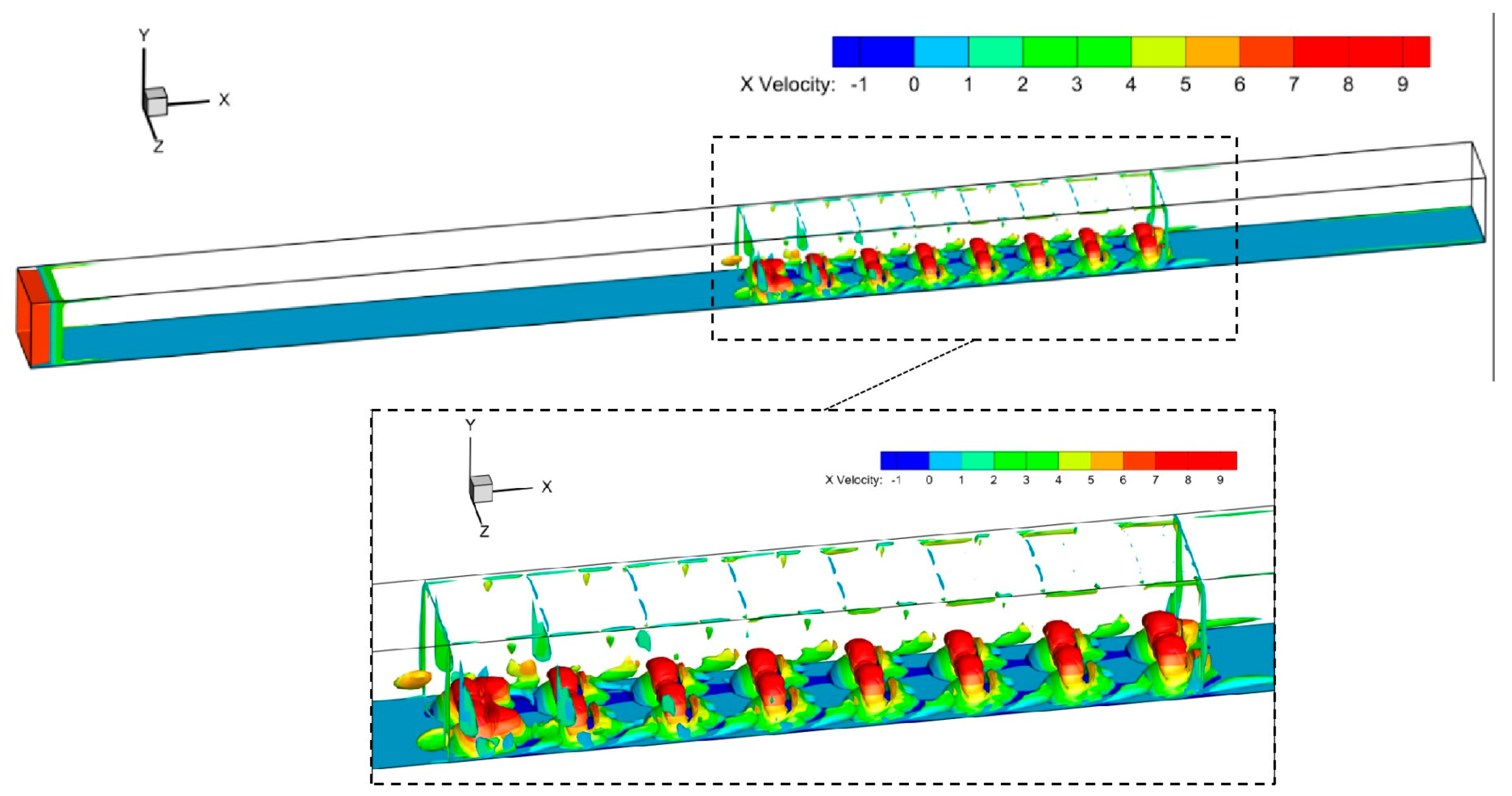

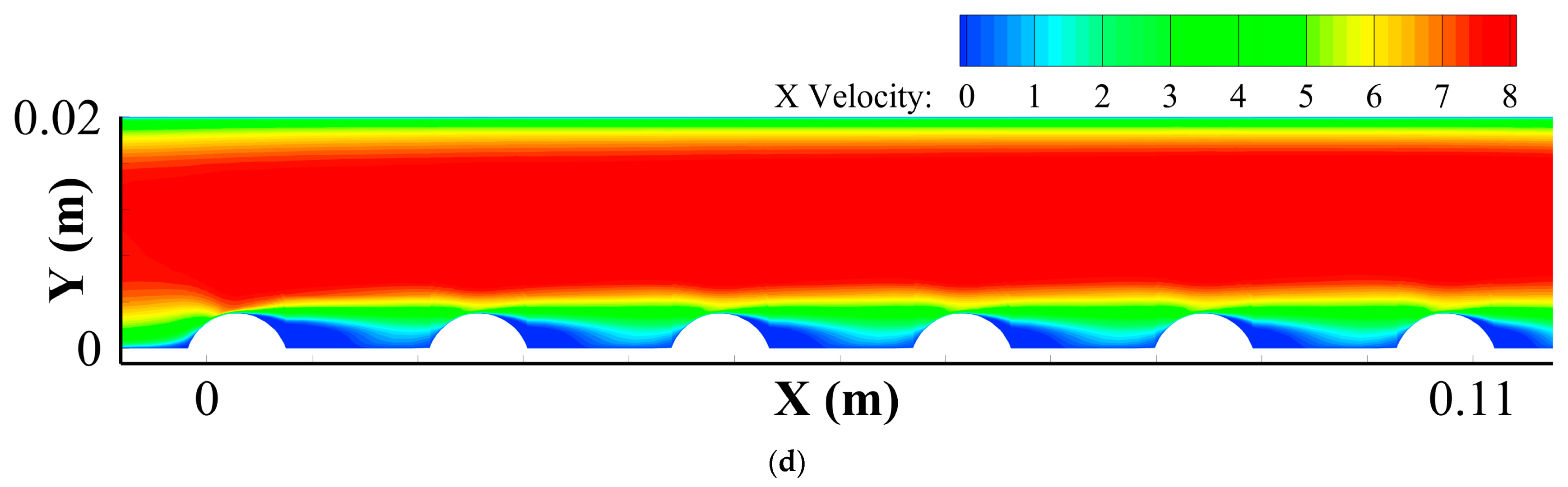

4.2. Analysis of Turbulent Flow Field

4.2.1. The Vorticity Field

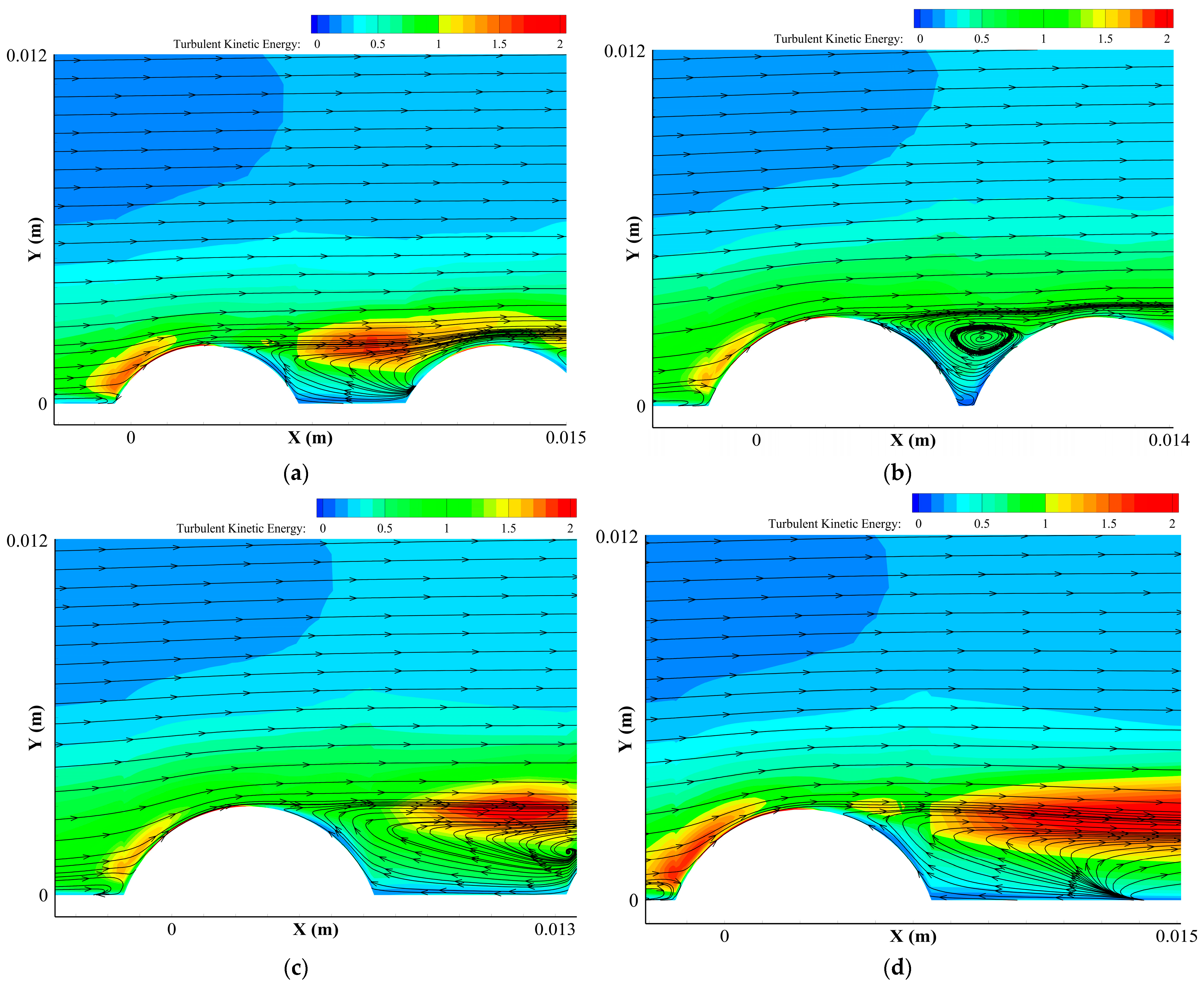

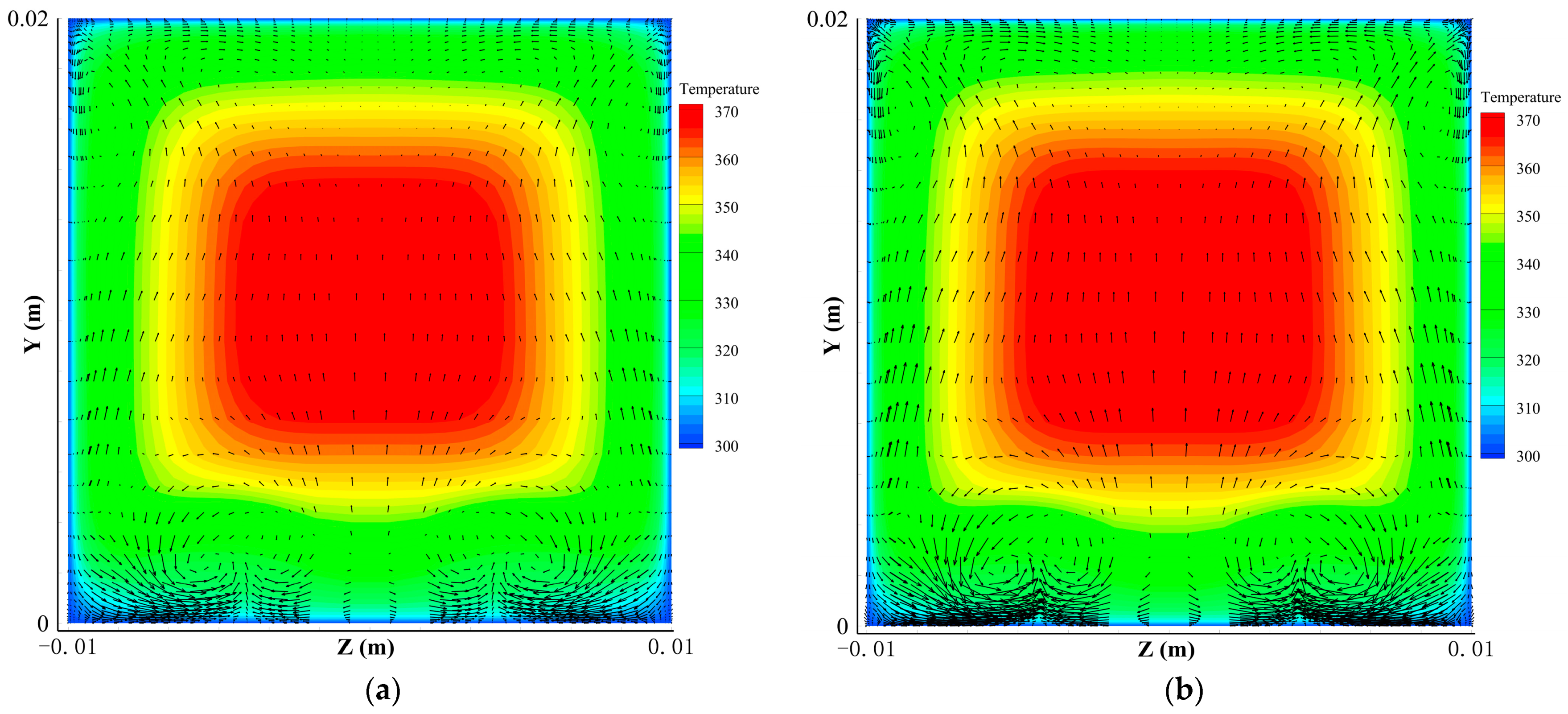

4.2.2. Flow Structures and Secondary Flow for Different h/D’s and p/h’s

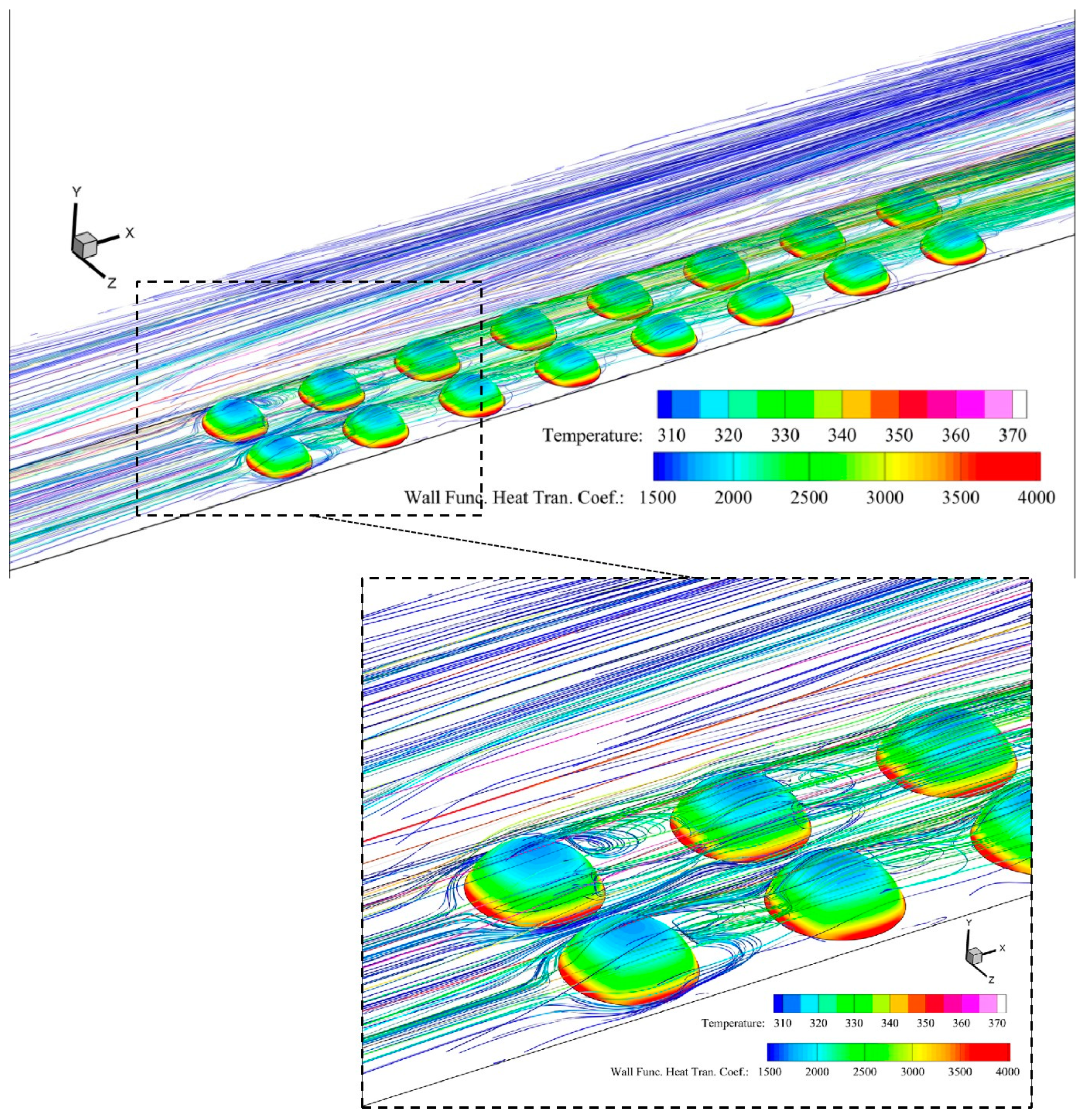

4.2.3. Effect of Different Positions of Dimples on Heat Transfer

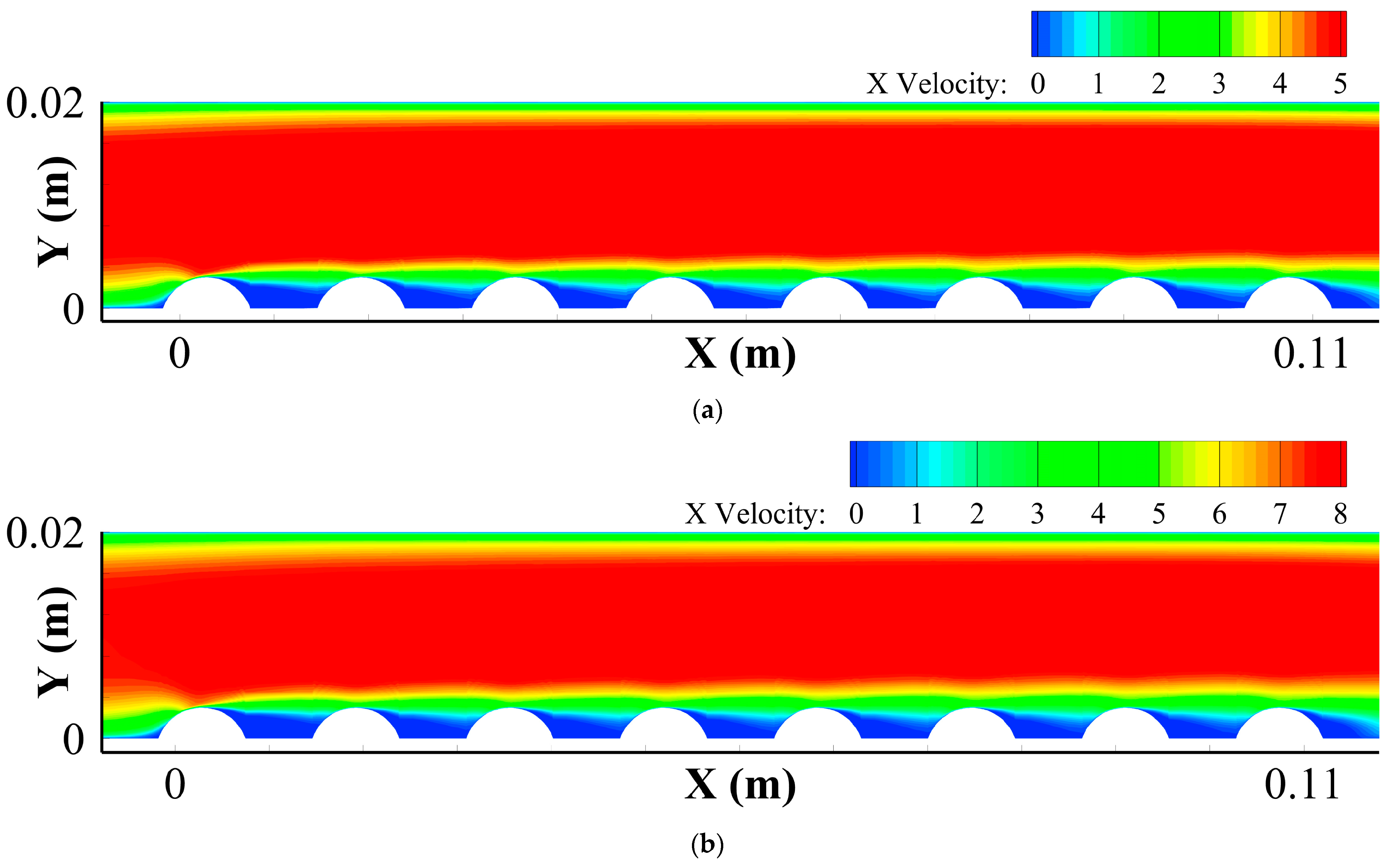

4.2.4. Influence of Airflow Velocity

4.3. Particle Deposition Patterns

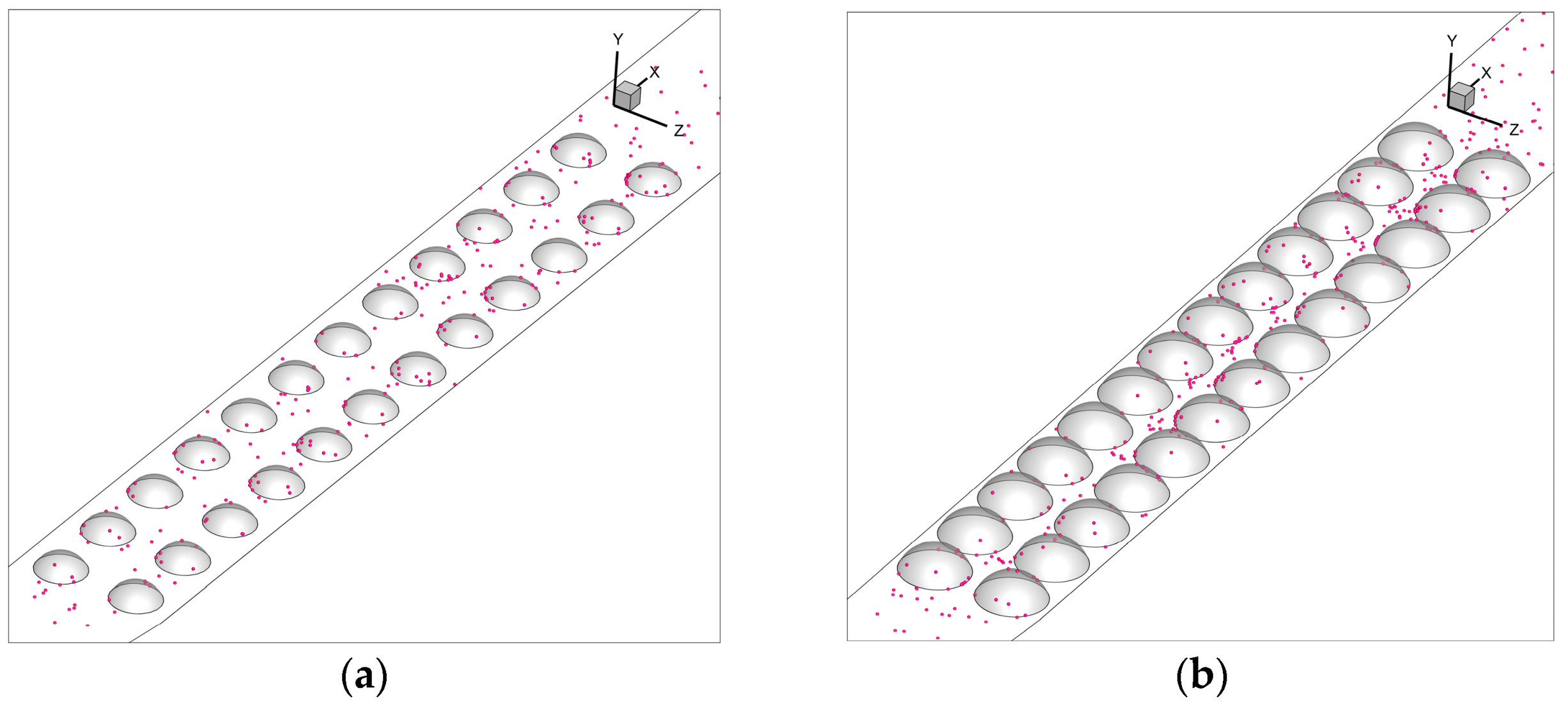

4.3.1. Influence of Convex Dimples on Particle Trajectories

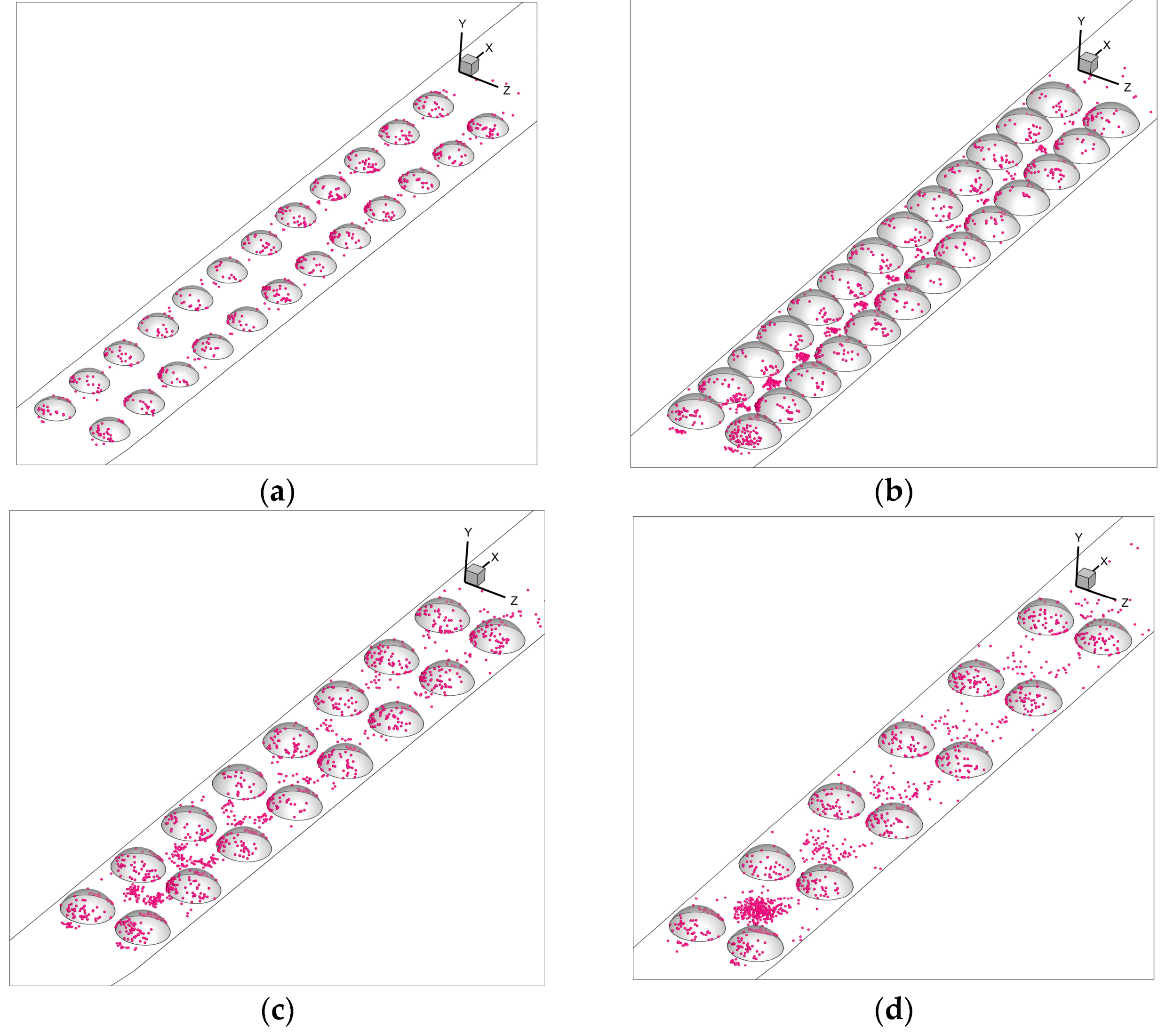

4.3.2. Effects of h/D and p/h on Particulate Deposition

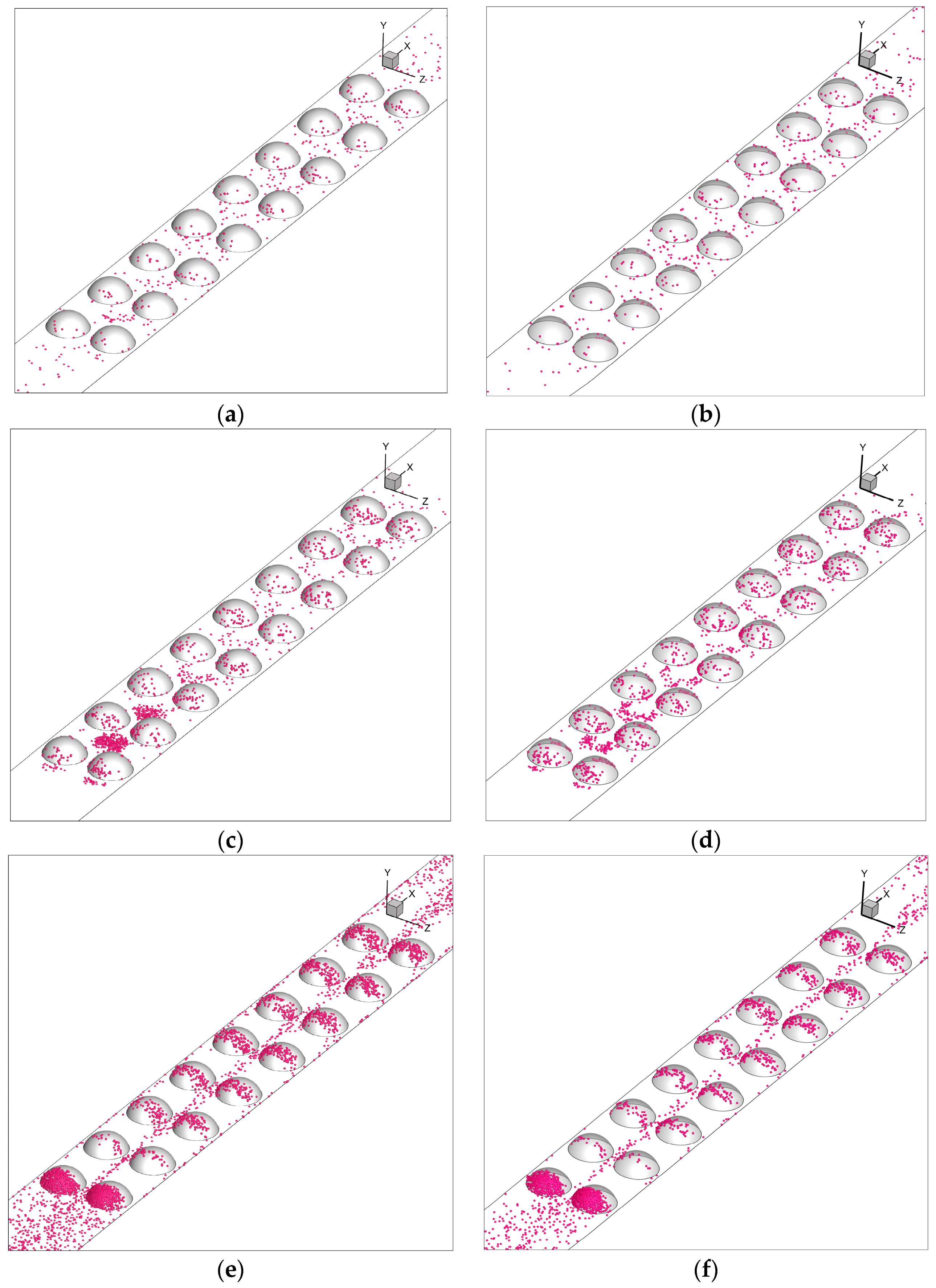

4.3.3. Effect of Air Velocity on Particulate Deposition

4.4. Analysis of Particle Deposition Efficiency

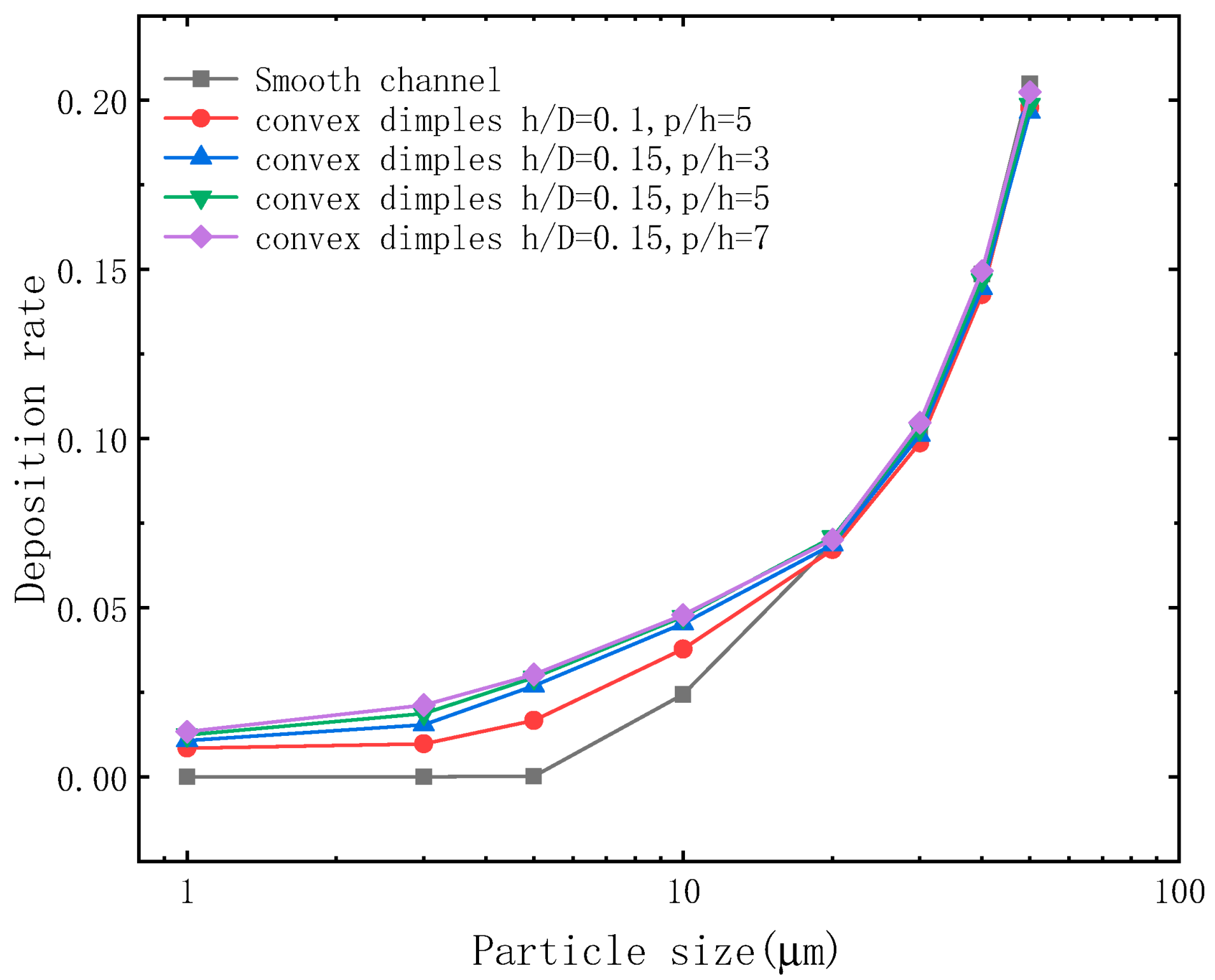

4.4.1. Effect of Convex Dimples’ Existence and Particle Size on Deposition Efficiency

4.4.2. Influence of p/h

4.4.3. Influence of h/D

4.4.4. Influence of Wind Speed

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Cunningham correction factor | |

| drag coefficient of particle | |

| diameter of dust particle (μm) | |

| hydraulic diameter (m) | |

| thermophoretic coefficient | |

| Brownian force (N) | |

| gravitation and buoyancy (N) | |

| Saffman’s lift (N) | |

| thermophoretic force (N) | |

| f | Fanning friction factor |

| g | gravitational acceleration (m/s2) |

| k | turbulent kinetic energy (m2/s2) |

| average roughness height (mm) | |

| Saffman’s lift force coefficient | |

| time-averaged pressure (cm) | |

| Reynolds number | |

| particle Reynolds number | |

| the ratio of particle-to-fluid density | |

| spectral intensity of a Gaussian white noise random process | |

| air inlet velocity (m/s) | |

| friction velocity | |

| time-averaged velocity (m/s) | |

| particle deposition velocity | |

| dimensionless particle deposition velocity | |

| streamwise fluctuating velocity of air | |

| wall-normal fluctuating velocity of air | |

| spanwise fluctuating velocity of air | |

| R | kinematic restitution coefficient |

| dimensionless distance from the wall | |

| dissipation rate of turbulent kinetic energy | |

| density of particle (kg/m3) | |

| density of fluid (kg/m3) | |

| kinetic viscosity of air | |

| normal distributed random number | |

| vs | Poisson’s ratios of the channel wall |

| vp | Poisson’s ratios of the particle |

| τ | particle relaxation time |

| particle relaxation time (s) | |

| dimensionless particle relaxation time |

References

- Tao, W.Q. Numerical Heat Transfer; Xi’an Jiao Tong University Press: Xi’an, China, 2003. [Google Scholar]

- He, Y.L.; Han, H.; Tao, W.Q.; Zhang, Y.W. Numerical study of heat-transfer enhancement by punched winglet-type vortex generator arrays in fin-and-tube heat exchangers. Int. J. Heat Mass Transf. 2012, 55, 5449–5458. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z.; Feng, W.; Zhang, T.; Xing, W. Study of Particulate Fouling Inhibition Characteristics on a Novel Composite Coating. Coatings 2023, 13, 274. [Google Scholar] [CrossRef]

- Zhan, F.; Zhuang, D.; Ding, G.; Tang, J. Numerical model of particle deposition on fin surface of heat exchanger. Int. J. Refrig. 2016, 72, 27–40. [Google Scholar] [CrossRef]

- Lu, H.; Lu, L.; Jiang, Y. Numerical study of monodispersed particle deposition rates in variable-section ducts with different expanding or contracting ratios. Appl. Therm. Eng. 2017, 110, 150–161. [Google Scholar] [CrossRef]

- Ma, J.; Sun, Y.; Li, S. Element Differential Method for Non-Fourier Heat Conduction in the Convective-Radiative Fin with Mixed Boundary Conditions. Coatings 2022, 12, 1862. [Google Scholar] [CrossRef]

- Lai, X.; Wang, C.; Peng, D.; Yang, H.; Wei, Z. Analysis of heat transfer characteristics of a heat exchanger based on a lattice filling. Coatings 2021, 11, 1089. [Google Scholar] [CrossRef]

- Petrovic, M.; Fukui, K.; Kominami, K. Numerical and experimental performance investigation of a heat exchanger designed using topologically optimized fins. Appl. Therm. Eng. 2023, 218, 119232. [Google Scholar] [CrossRef]

- Selvan, M.; Abdul Aziz, M.S.; Salleh, M.A.A.M.; Sharif, N.M.; Khor, C.Y.; Ong, H.P.; Zainol, M.R.R.M.A.; Vizureanu, P.; Burduhos-Nergis, D.-P.; Sandu, A.V. Influence of Fin Thickness on the Thermal Performance and Selection of Coating Method for a Bus Duct Conductor. Coatings 2023, 13, 12. [Google Scholar] [CrossRef]

- Ryms, M.; Tesch, K.; Lewandowski, W.M. Optimization of the distance between the vertical plates in the convective air heat exchanger. Int. J. Therm. Sci. 2023, 185, 108064. [Google Scholar] [CrossRef]

- Shi, S.; Niu, J.; Wu, Z.; Luo, S.; Gao, X.; Fang, Y.; Zhang, Z. Experimental and numerical investigation on heat transfer enhancement of vertical triplex tube heat exchanger with fractal fins for latent thermal energy storage. Int. J. Heat Mass Transf. 2022, 198, 123386. [Google Scholar] [CrossRef]

- Akbarnataj, K.; Hamidpour, M.R.; Shirani, E.; Salimpour, M.R. Optimization of porous finned heat exchanger configuration using the comprehensive performance methodology. Int. Commun. Heat Mass Transf. 2022, 138, 106318. [Google Scholar] [CrossRef]

- Firat, I.; Karagoz, S.; Yildirim, O.; Sonmez, F. Experimental investigation of the thermal performance effects of turbulators with different fin angles in a circular pipe. Int. J. Therm. Sci. 2023, 184, 107969. [Google Scholar] [CrossRef]

- Han, Q.; Liu, Z.; Li, W. Enhanced thermal performance by spatial chaotic mixing in a saw-like microchannel. Int. J. Therm. Sci. 2023, 186, 108148. [Google Scholar] [CrossRef]

- Wang, J.; Fan, Y.; Ge, J.; Liu, X. Effect of streamwise vortex induced by streamwise grooves on drag reduction and heat transfer performance. Int. J. Therm. Sci. 2023, 186, 108117. [Google Scholar] [CrossRef]

- Xu, Z.; Han, Z.; Qu, H. Comparison between Lagrangian and Eulerian approaches for prediction of particle deposition in turbulent flows. Powder Technol. 2020, 360, 141–150. [Google Scholar] [CrossRef]

- Li, L.; Liu, C.-L.; Li, B.-R.; Zhu, H.-R.; Wu, Z.; Chen, W.-B. Numerical study on particles deposition in the U-bend ribbed passage. J. Heat Transf. 2021, 143, 023002. [Google Scholar] [CrossRef]

- Shengnan, C.; Jizu, L.; Peng, W.; Chengzhi, H.; Minli, B. Numerical investigation on the influence of particle deposition on nanofluid turbulent flow and heat transfer characteristics. Int. Commun. Heat Mass Transf. 2021, 126, 105466. [Google Scholar] [CrossRef]

- Han, Z.; Xu, Z.; Yu, X.; Sun, A.; Li, Y. Numerical simulation of ash particles deposition in rectangular heat exchange channel. Int. J. Heat Mass Transf. 2019, 136, 767–776. [Google Scholar] [CrossRef]

- Awais, M.; Bhuiyan, A.A. Recent advancements in impedance of fouling resistance and particulate depositions in heat exchangers. Int. J. Heat Mass Transf. 2019, 141, 580–603. [Google Scholar] [CrossRef]

- Zhan, F.; Ding, G.; Zhuang, D. Numerical model of particle deposition on wet fin surfaces of heat exchanger under dehumidifying conditions. Int. J. Heat Mass Transf. 2020, 149, 119258. [Google Scholar] [CrossRef]

- Sajjadi, H.; Salmanzadeh, M.; Ahmadi, G.; Jafari, S. Lattice Boltzmann method and RANS approach for simulation of turbulent flows and particle transport and deposition. Particuology 2017, 30, 62–72. [Google Scholar] [CrossRef]

- Kim, S.; Ko, H.S.; Shin, D.H. Fluid flow and heat transfer characteristics of corona wind in cross-cut finned channel. Int. J. Therm. Sci. 2023, 184, 107962. [Google Scholar] [CrossRef]

- He, M.-J.; Sun, Y.-S.; Wang, Z.-L.; Wang, B.-X. Micro/Nanomaterials for Heat Transfer, Energy Storage and Conversion. Coatings 2022, 13, 11. [Google Scholar] [CrossRef]

- Lu, H.; Quan, Y. A CFD study of particle deposition in three-dimensional heat exchange channel based on an improved deposition model. Int. J. Heat Mass Transf. 2021, 178, 121633. [Google Scholar] [CrossRef]

- Yan, L.; Qi, X.; Han, X.; Wang, J.; He, F. Study on the Flow State of Circulating Cooling Water for the Industrial Heat Exchange Tube in the Electromagnetic Anti-Fouling Process. ACS Omega 2021, 6, 28515–28527. [Google Scholar] [CrossRef]

- Khizhov, M.; Mironova, L. Evaluation of the Ratio of Heat Exchanging Tube Finning on Heat Exchanger Efficiency. In Proceedings of the MATEC Web of Conferences, Sibiu, Romania, 2–4 June 2021; p. 03028. [Google Scholar]

- Won, S.Y.; Ligrani, P. Numerical predictions of flow structure and local Nusselt number ratios along and above dimpled surfaces with different dimple depths in a channel. Numer. Heat Transf. Part A Appl. 2004, 46, 549–570. [Google Scholar] [CrossRef]

- Burgess, N.; Ligrani, P. Effects of dimple depth on channel Nusselt numbers and friction factors. J. Heat Transfer. 2005, 127, 839–847. [Google Scholar] [CrossRef]

- Kim, K.-Y.; Choi, J.-Y. Shape optimization of a dimpled channel to enhance turbulent heat transfer. Numer. Heat Transf. Part A Appl. 2005, 48, 901–915. [Google Scholar] [CrossRef]

- Kim, S.; Lee, Y.J.; Choi, E.Y.; Kwak, J.S. Effect of dimple configuration on heat transfer coefficient in a rotating channel. J. Thermophys. Heat Transf. 2011, 25, 165–172. [Google Scholar] [CrossRef]

- Elyyan, M.A.; Rozati, A.; Tafti, D.K. Investigation of dimpled fins for heat transfer enhancement in compact heat exchangers. Int. J. Heat Mass Transf. 2008, 51, 2950–2966. [Google Scholar] [CrossRef]

- Lotfi, B.; Sundén, B. Thermo-hydraulic performance enhancement of finned elliptical tube heat exchangers by utilizing innovative dimple turbulators. Heat Transf. Eng. 2020, 41, 1117–1142. [Google Scholar] [CrossRef]

- Chang, S.W.; Chiou, S.F.; Chang, S.F. Heat transfer of impinging jet array over concave-dimpled surface with applications to cooling of electronic chipsets. Exp. Therm. Fluid Sci. 2007, 31, 625–640. [Google Scholar] [CrossRef]

- Kim, H.-M.; Moon, M.-A.; Kim, K.-Y. Multi-objective optimization of a cooling channel with staggered elliptic dimples. Energy 2011, 36, 3419–3428. [Google Scholar] [CrossRef]

- Tian, L.; Ahmadi, G. Particle deposition in turbulent duct flows—Comparisons of different model predictions. J. Aerosol Sci. 2007, 38, 377–397. [Google Scholar] [CrossRef]

- Gao, N.; Niu, J.; He, Q.; Zhu, T.; Wu, J. Using RANS turbulence models and Lagrangian approach to predict particle deposition in turbulent channel flows. Build. Environ. 2012, 48, 206–214. [Google Scholar] [CrossRef]

- FLUENT Incorporation FLUENT User’s Guide; FLUENT Incorporated: Lebanon, NH, USA, 2021.

- Zhao, B.; Wu, J. Modeling particle deposition onto rough walls in ventilation duct. Atmos. Environ. 2006, 40, 6918–6927. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, H.; Zhou, Q.; Li, T. Effects of granular temperature on inter-phase drag in gas-solid flows. Powder Technol. 2017, 321, 435–443. [Google Scholar] [CrossRef]

- Ueda, Y.; Nakajima, T.; Iguchi, M. Random Walk of a Particle Due to Brownian Force by a Two-Dimensional Vortex Particle Method (Implementation of a PSE Method). J. Jpn. Soc. Exp. Mech. 2012, 12, 213–219. [Google Scholar]

- AlQdah, K.S.; Khan, N.M.; Bacha, H.B.; Chung, J.-D.; Shah, N.A. Marangoni convection of dust particles in the boundary layer of Maxwell nanofluids with varying surface tension and viscosity. Coatings 2021, 11, 1072. [Google Scholar] [CrossRef]

- Zhang, S.; Bogy, D.B. Effects of lift on the motion of particles in the recessed regions of a slider. Phys. Fluids 1997, 9, 1265–1272. [Google Scholar] [CrossRef]

- Montassier, N.; Boulaud, D.; Renoux, A. Thermophoretic effect of particle deposition in laminar tube flow. J. Aerosol Sci. 1991, 22, S207–S210. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, Q. Prediction of particle deposition onto indoor surfaces by CFD with a modified Lagrangian method. Atmos. Environ. 2009, 43, 319–328. [Google Scholar] [CrossRef]

- Kim, J.; Moin, P.; Moser, R. Turbulence statistics in fully developed channel flow at low Reynolds number. J. Fluid Mech. 1987, 177, 133–166. [Google Scholar] [CrossRef]

- Brach, R.M.; Dunn, P.F. A mathematical model of the impact and adhesion of microsphers. Aerosol Sci. Technol. 1992, 16, 51–64. [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A. Surface energy and the contact of elastic solids. Proc. R. Soc. Lond. A Math. Phys. Sci. 1971, 324, 301–313. [Google Scholar]

- Han, Z.; Xu, Z.; Sun, A.; Yu, X. The deposition characteristics of micron particles in heat exchange pipelines. Appl. Therm. Eng. 2019, 158, 113732. [Google Scholar] [CrossRef]

- El-Shobokshy, M. Experimental measurements of aerosol deposition to smooth and rough surfaces. Atmos. Environ. 1983, 17, 639–644. [Google Scholar] [CrossRef]

- Lu, H.; Zhao, W. Numerical study of particle deposition in turbulent duct flow with a forward-or backward-facing step. Fuel 2018, 234, 189–198. [Google Scholar] [CrossRef]

- Lu, H.; Lu, L.; Jiang, Y. Numerical simulation of particle deposition in duct air flows with uniform, expanding or contracting cross-section. Energy Build. 2016, 128, 867–875. [Google Scholar] [CrossRef]

- Lu, H.; Lu, L. Numerical investigation on particle deposition enhancement in duct air flow by ribbed wall. Build. Environ. 2015, 85, 61–72. [Google Scholar] [CrossRef]

- Wang, M.; Liu, J.; Wang, X.; Yan, X.; Yao, L.; Yue, Q. Automatic determination of coupling time step and region in unresolved DEM-CFD. Powder Technol. 2022, 400, 117267. [Google Scholar] [CrossRef]

- Yerry, M.A.; Shephard, M.S. Automatic three-dimensional mesh generation by the modified-octree technique. Int. J. Numer. Methods Eng. 1984, 20, 1965–1990. [Google Scholar] [CrossRef]

- Liu, B.Y.; Agarwal, J.K. Experimental observation of aerosol deposition in turbulent flow. J. Aerosol Sci. 1974, 5, 145–155. [Google Scholar] [CrossRef]

- Friedlander, S.; Johnstone, H. Deposition of suspended particles from turbulent gas streams. Ind. Eng. Chem. 1957, 49, 1151–1156. [Google Scholar] [CrossRef]

- Hunt, J.C.; Wray, A.A.; Moin, P. Eddies, streams, and convergence zones in turbulent flows. In Studying Turbulence Using Numerical Simulation Databases, 2. In Proceedings of the 1988 Summer Program, Seoul, Republic of Korea, 17 September–2 October 1988. [Google Scholar]

- Lu, J.; Qian, Z.; Lee, Y.-H. Numerical investigation of unsteady characteristics of a pump turbine under runaway condition. Renew. Energy 2021, 169, 905–924. [Google Scholar] [CrossRef]

- Koulali, A.; Abderrahmane, A.; Jamshed, W.; Hussain, S.M.; Nisar, K.S.; Abdel-Aty, A.-H.; Yahia, I.S.; Eid, M.R. Comparative study on effects of thermal gradient direction on heat exchange between a pure fluid and a nanofluid: Employing finite volume method. Coatings 2021, 11, 1481. [Google Scholar] [CrossRef]

| Case no. | Air Velocity (m/s) | Particle Diameter (μm) | Vortex Height Ratio | Vortex Width Ratio |

|---|---|---|---|---|

| A. smooth | 6 m/s | 1, 3, 5, 10, 20, 30, 40, 50 | — | — |

| B. rough | 4 or 6 m/s | 1, 3, 5, 10, 20, 30, 40, 50 | 3, 5, 7 | 0.1, 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Han, Z.; Li, H.; Chang, X.; Dong, L.; Fan, M.; Kong, D.; Jing, X. Simulation of Turbulent Flow Structure and Particle Deposition in a Three-Dimensional Heat Transfer Duct with Convex Dimples. Coatings 2023, 13, 900. https://doi.org/10.3390/coatings13050900

Lu H, Han Z, Li H, Chang X, Dong L, Fan M, Kong D, Jing X. Simulation of Turbulent Flow Structure and Particle Deposition in a Three-Dimensional Heat Transfer Duct with Convex Dimples. Coatings. 2023; 13(5):900. https://doi.org/10.3390/coatings13050900

Chicago/Turabian StyleLu, Hao, Zunshi Han, Hongchang Li, Xiqiang Chang, Lijiang Dong, Mao Fan, Dean Kong, and Xuehui Jing. 2023. "Simulation of Turbulent Flow Structure and Particle Deposition in a Three-Dimensional Heat Transfer Duct with Convex Dimples" Coatings 13, no. 5: 900. https://doi.org/10.3390/coatings13050900

APA StyleLu, H., Han, Z., Li, H., Chang, X., Dong, L., Fan, M., Kong, D., & Jing, X. (2023). Simulation of Turbulent Flow Structure and Particle Deposition in a Three-Dimensional Heat Transfer Duct with Convex Dimples. Coatings, 13(5), 900. https://doi.org/10.3390/coatings13050900