Effect of High-Energy Shot Peening on Properties of High-Velocity Oxygen-Fuel Spraying

Abstract

1. Introduction

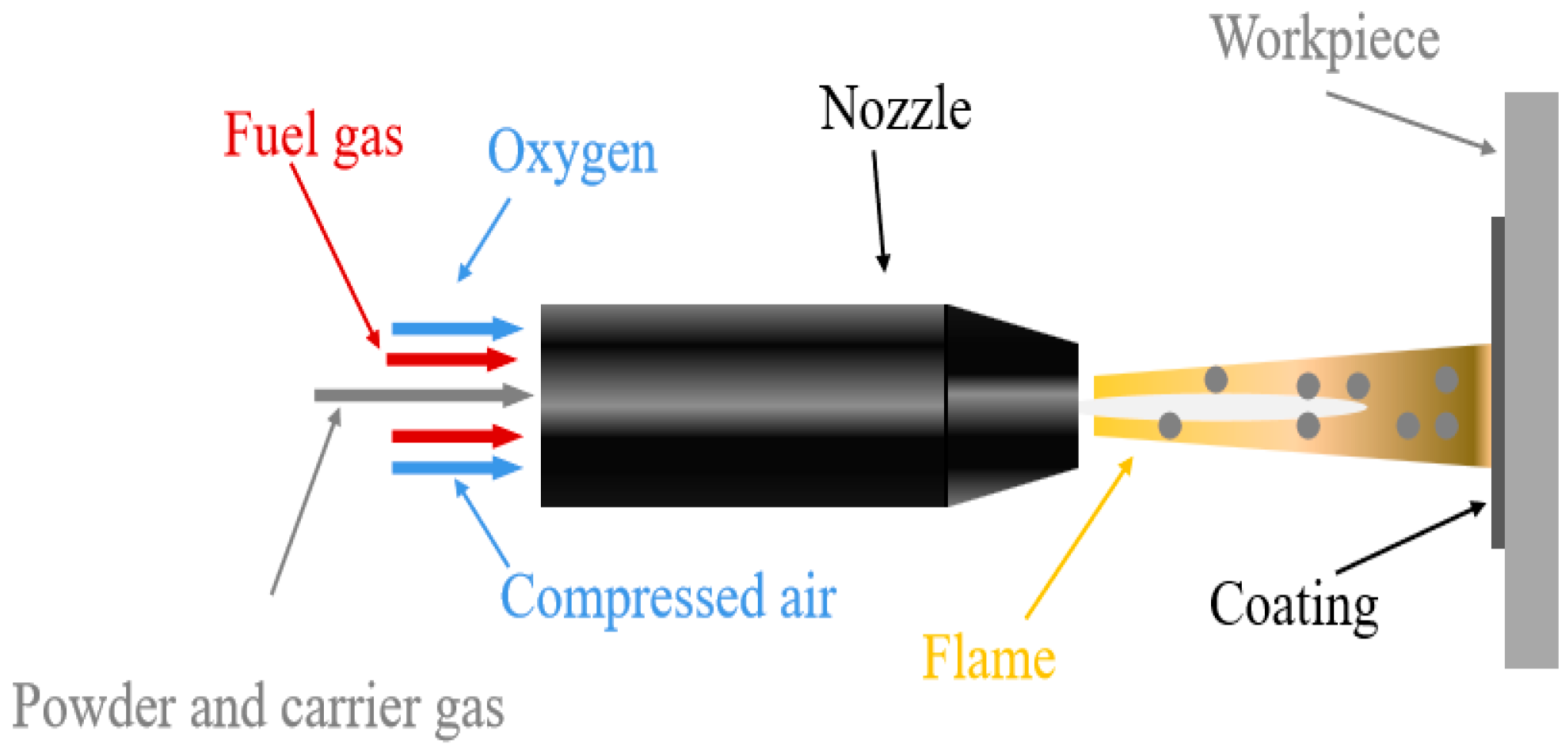

2. Materials and Methods

3. Results

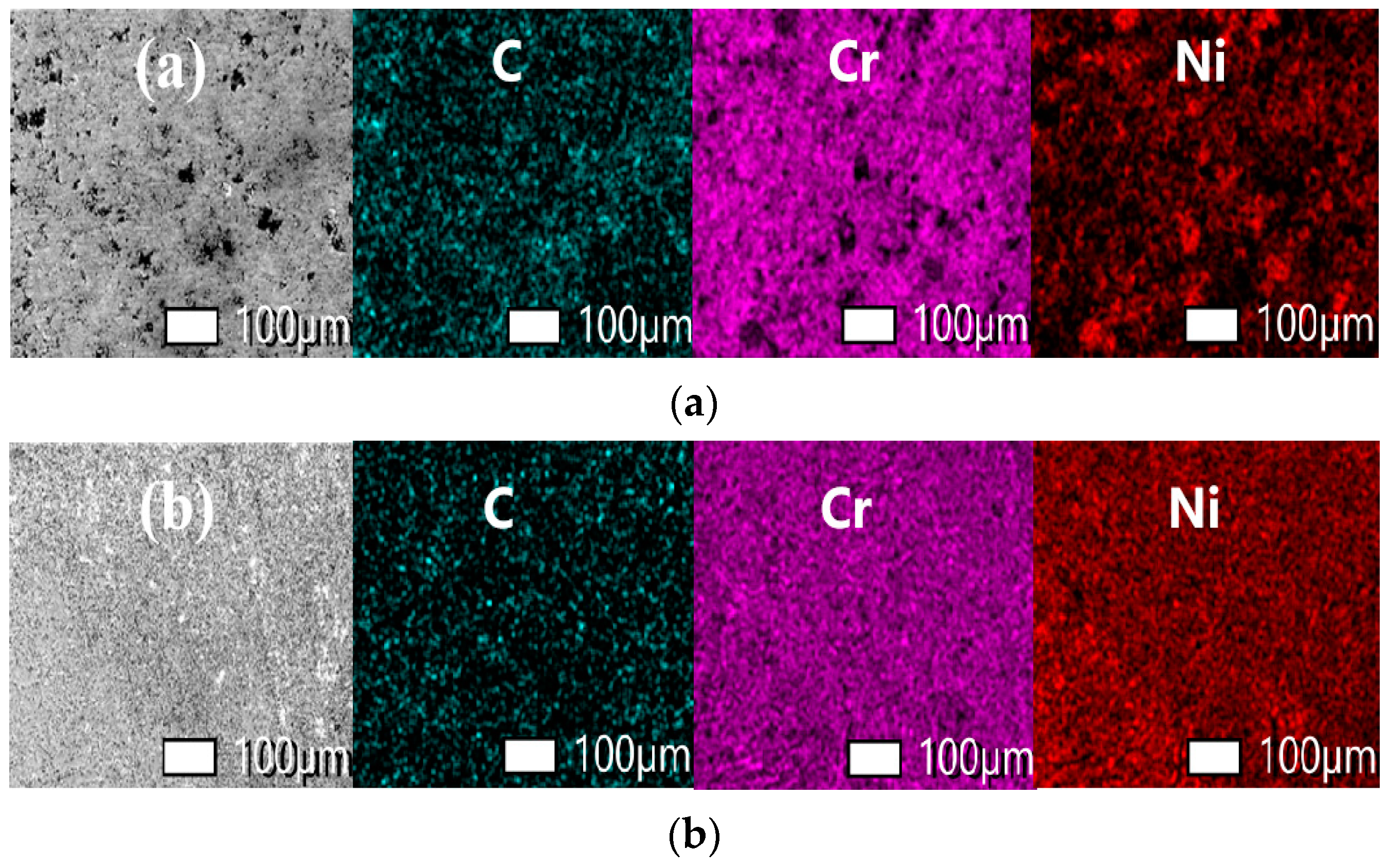

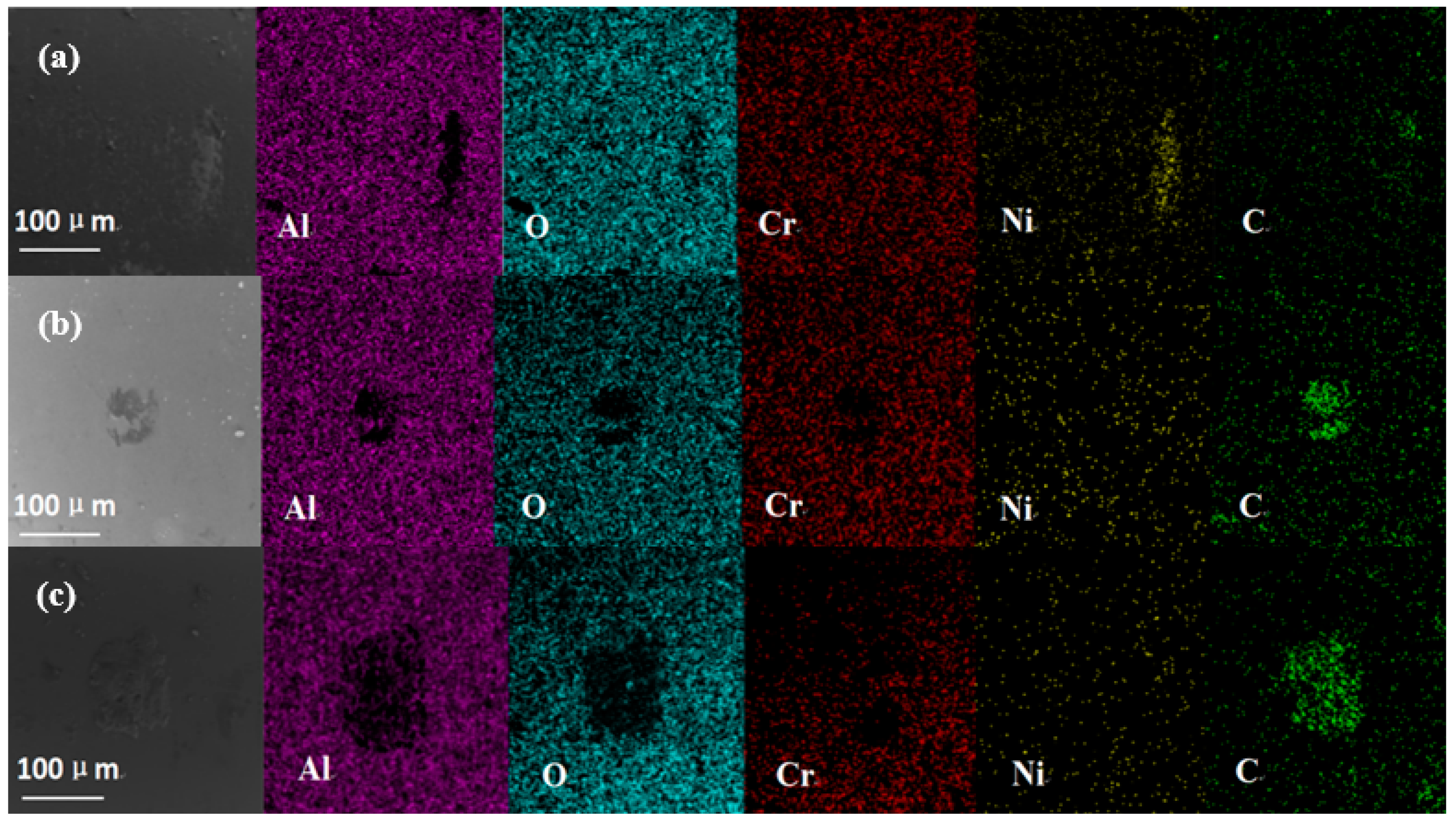

3.1. SEM and EDS Investigation of Coating

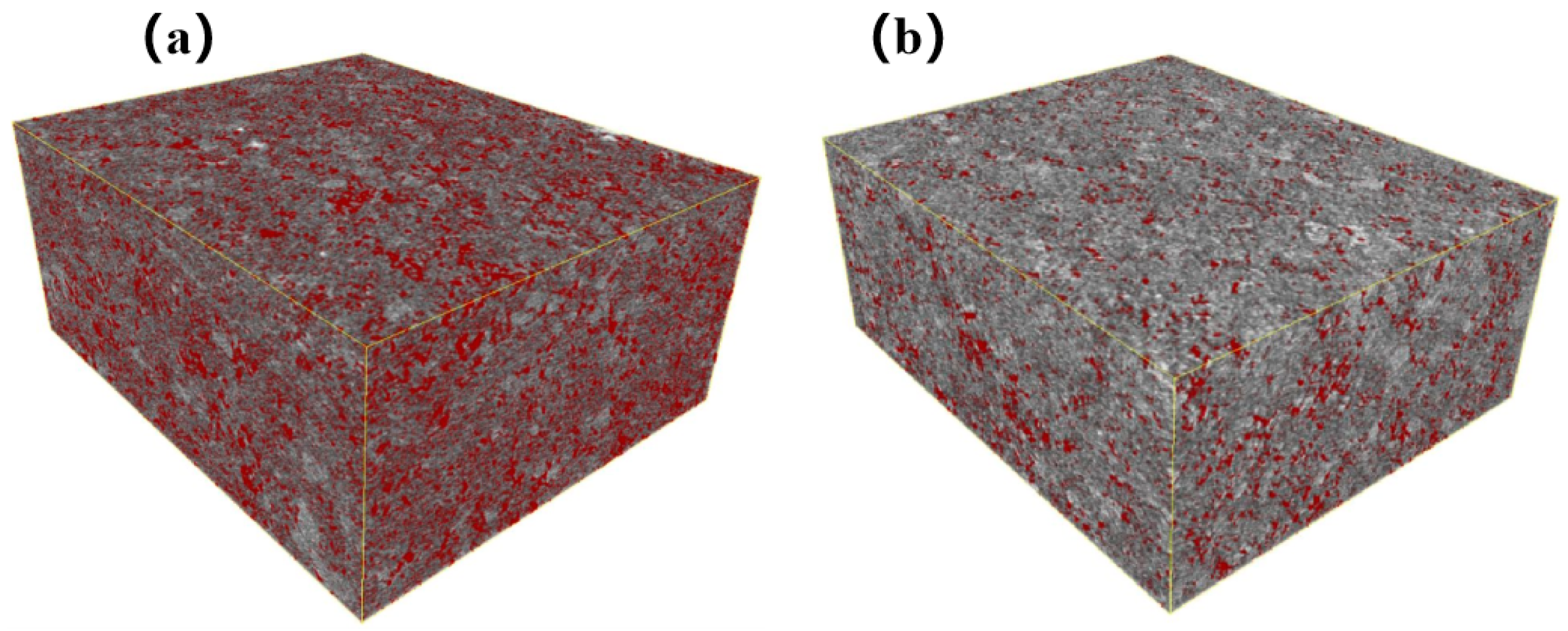

3.2. Porosity Analysis

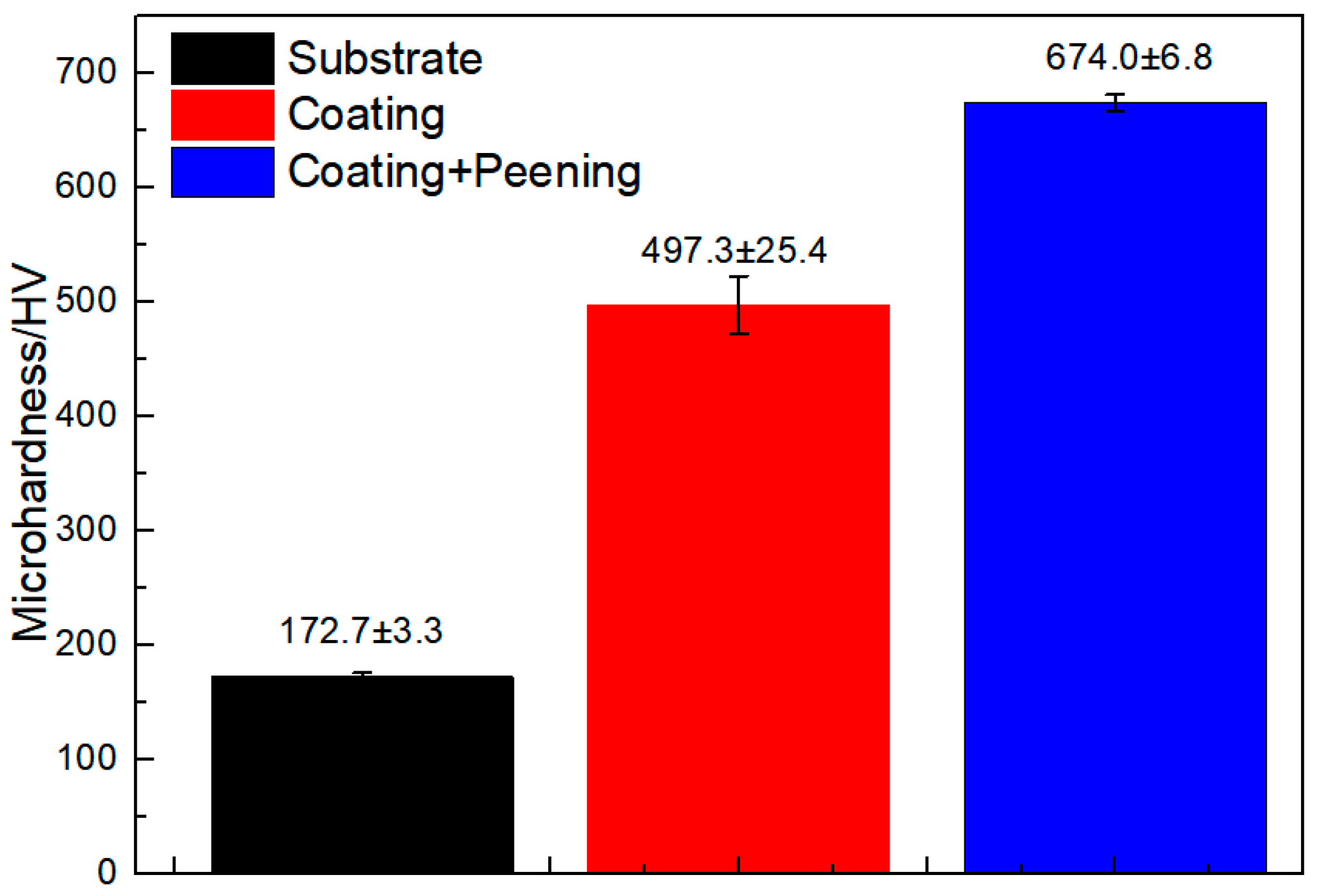

3.3. Hardness Test

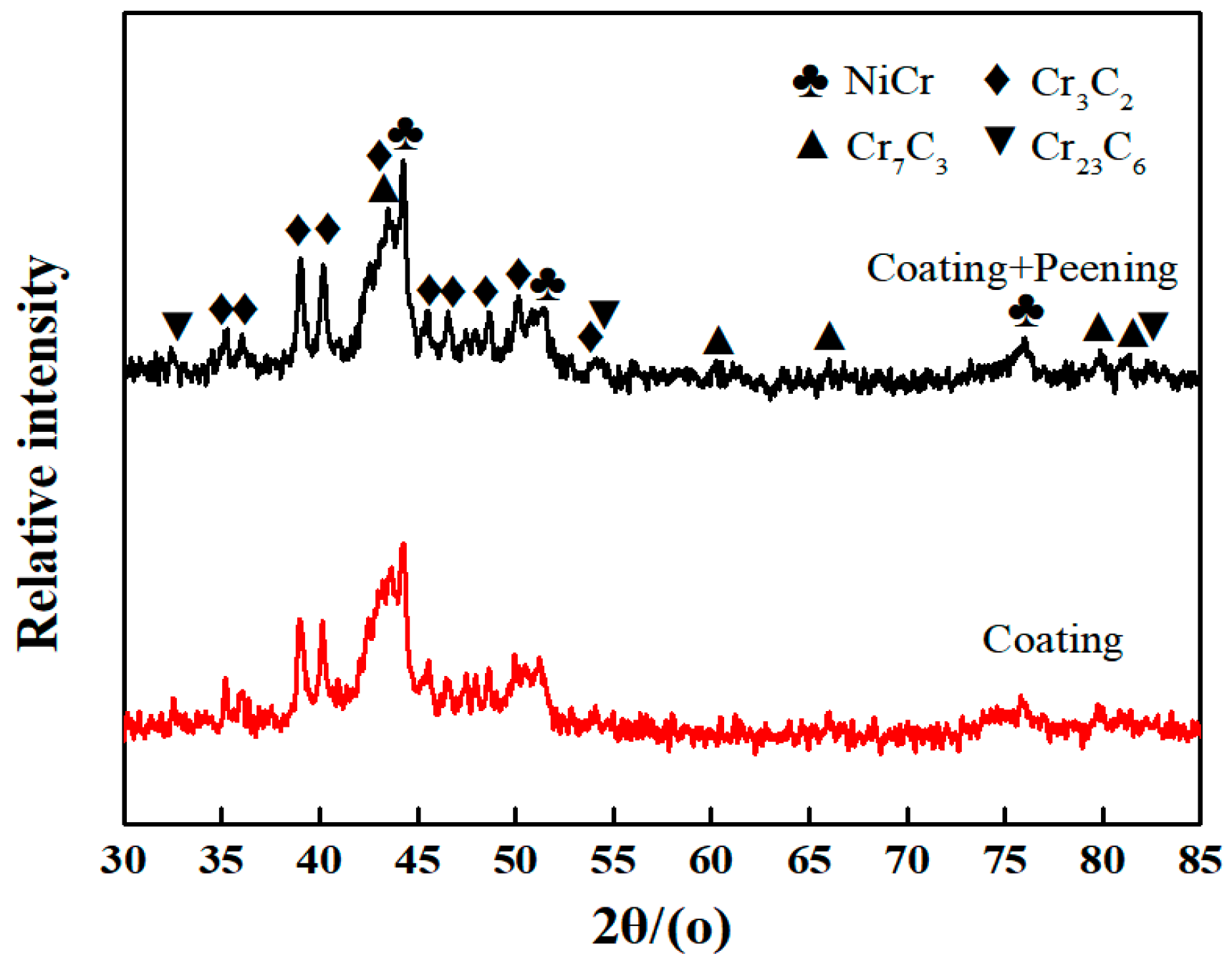

3.4. XRD Phase and Residual Stress Detection

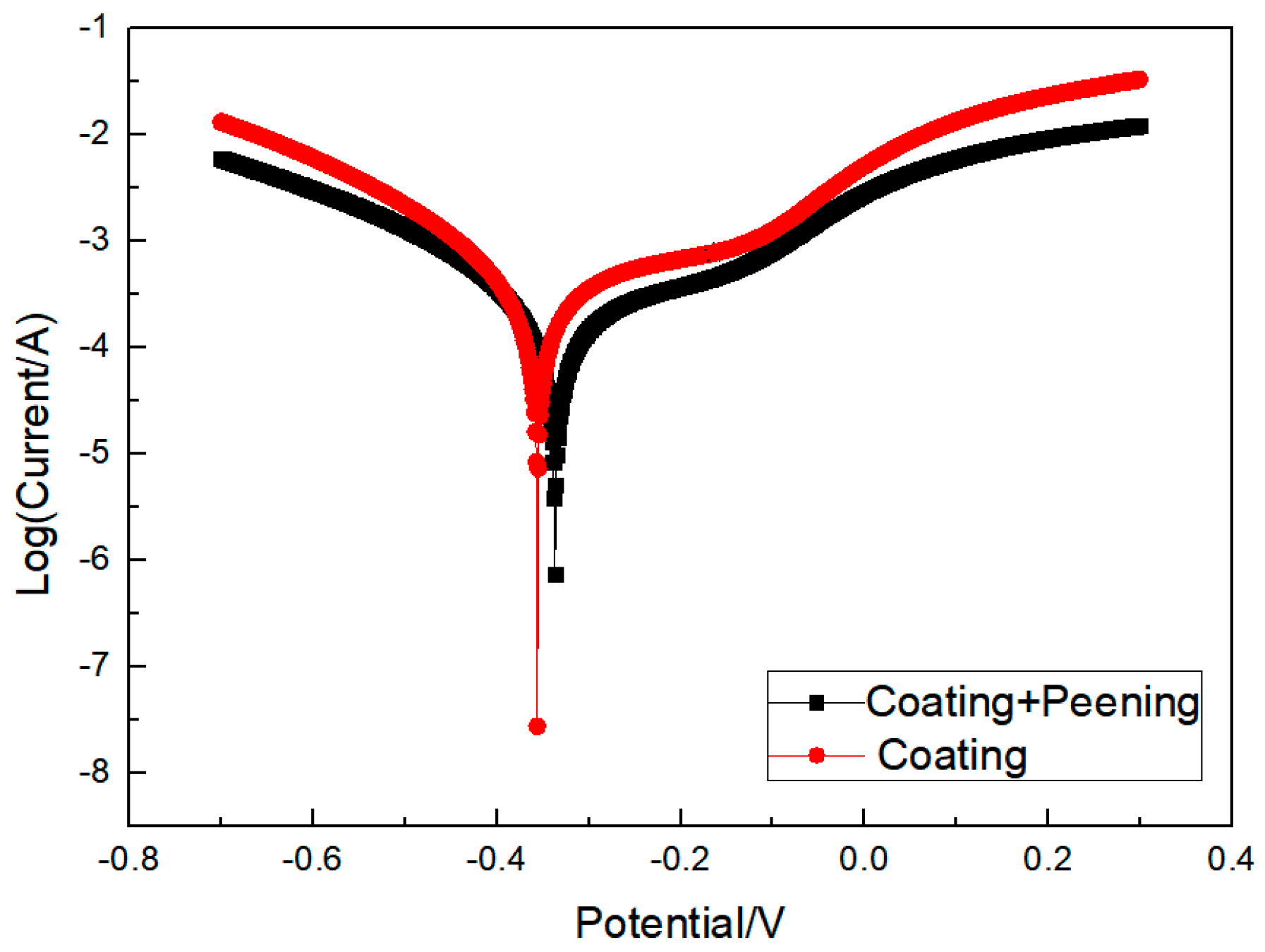

3.5. Electrochemical Corrosion Resistance

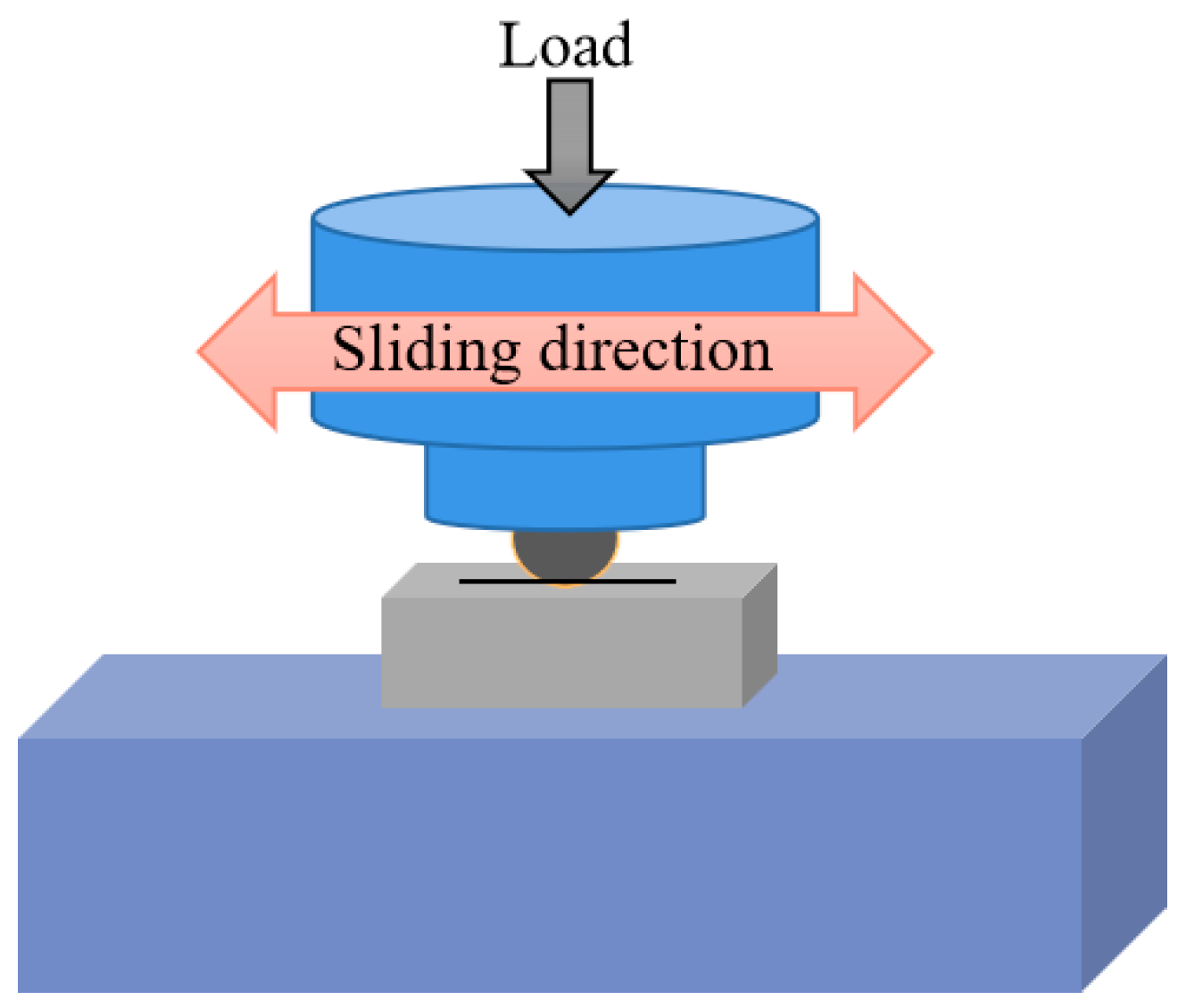

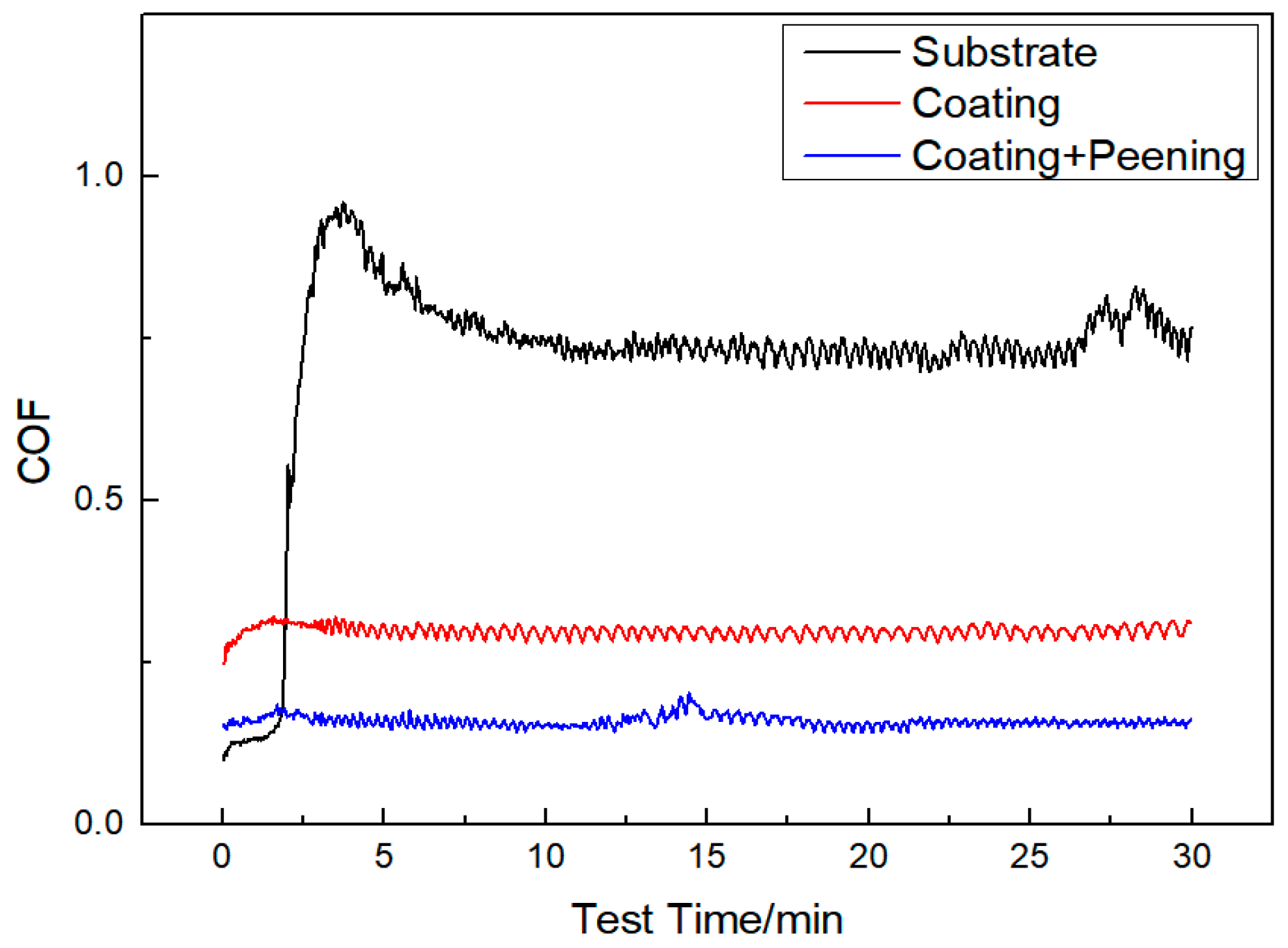

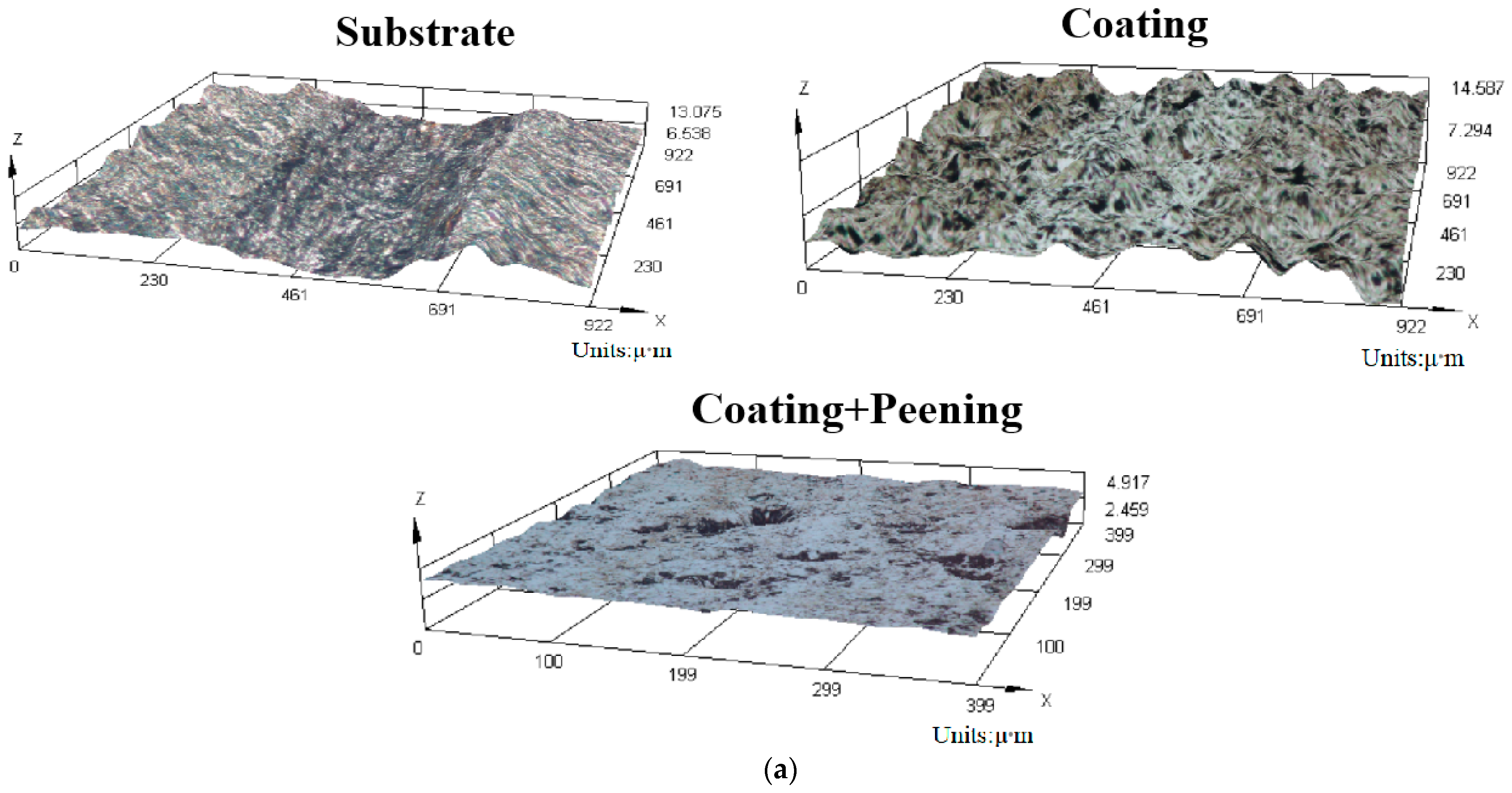

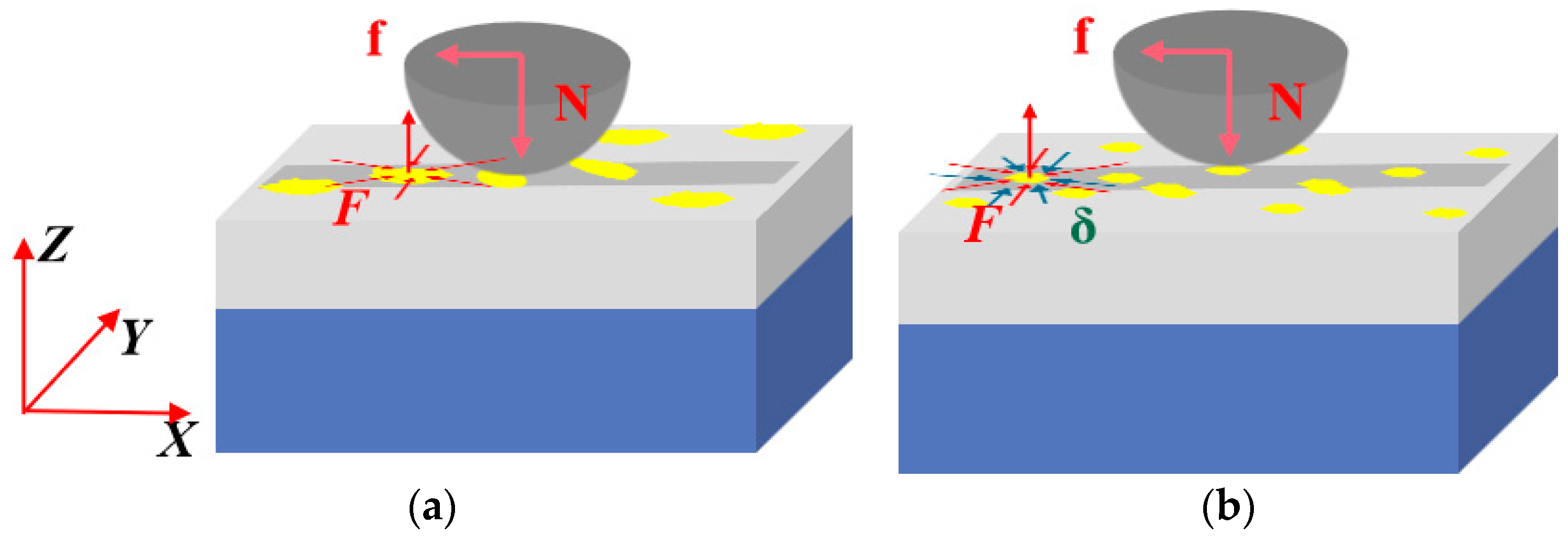

3.6. Friction and Wear Properties

4. Discussion

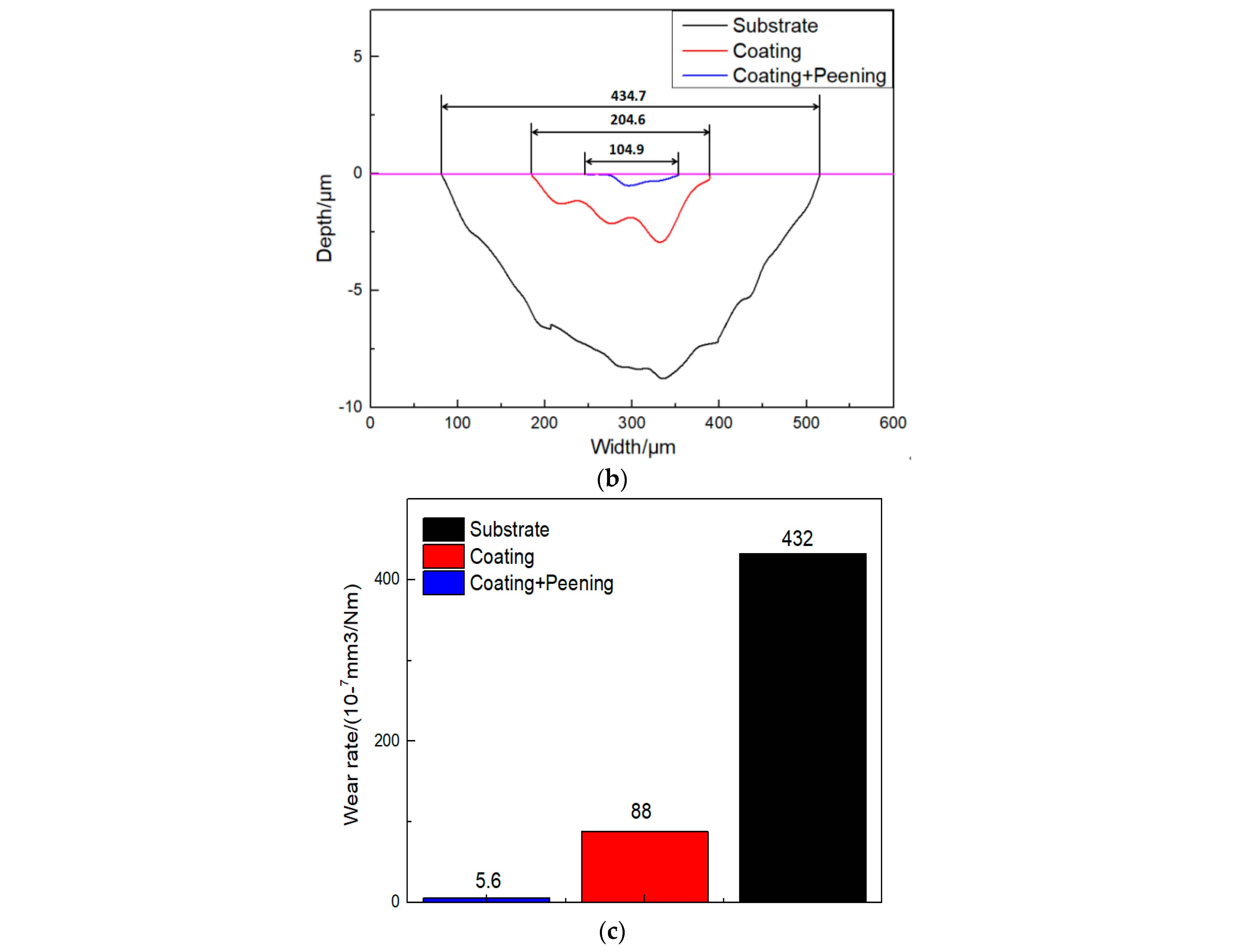

4.1. Morphology Analysis of Friction Marks

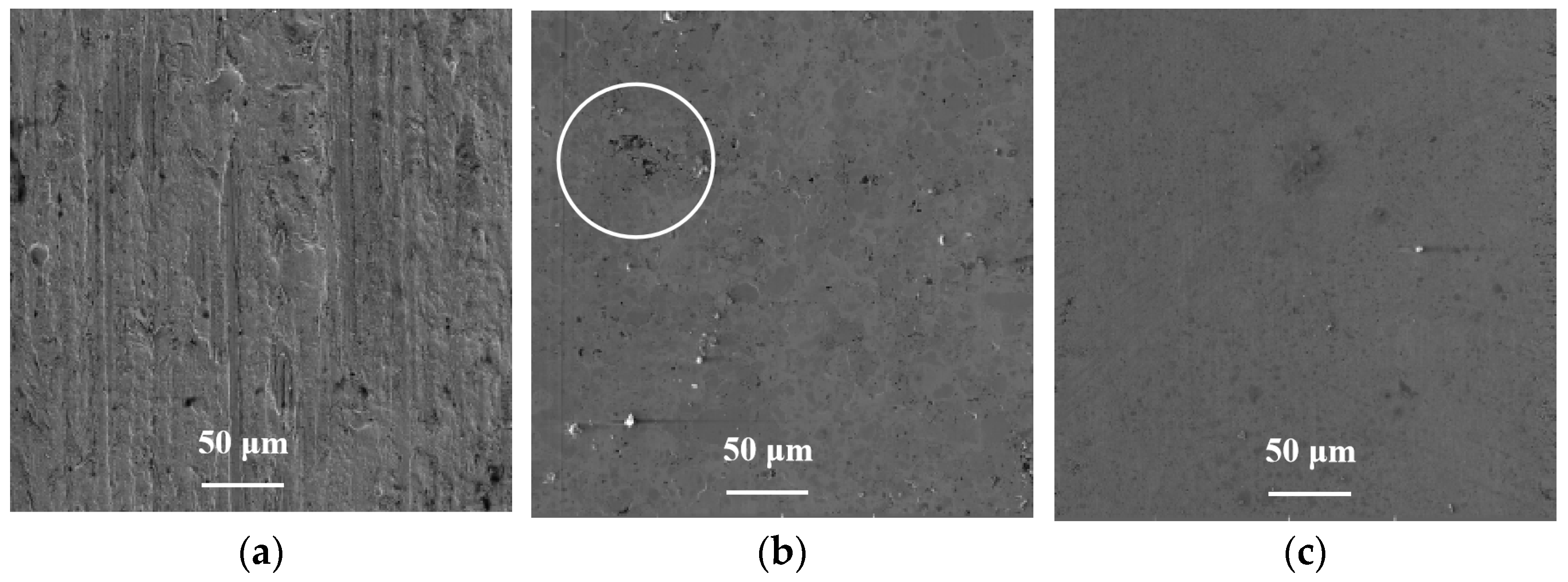

4.2. Morphology and EDS Analysis of Friction Pair

4.3. Stress Analysis

4.4. Effect of Surface Strengthening Layer on Wear Properties

5. Conclusions

- After high-energy shot peening, the compactness of the coating was improved and the porosity was significantly reduced.

- The microhardness of the Cr3C2-Al2O3-NiCr high-velocity oxygen-fuel coating can reach 2.9 times of that of the INCONEL600 substrate, and the hardness of the coating after high-energy shot peening can reach 3.9 times of that of the substrate.

- After high-energy shot peening, the corrosion tendency of the coating was reduced and the corrosion resistance was improved in the HCl environment.

- Compared with the INCONEL600 substrate, the friction coefficient and calculated wear rate of the Cr3C2-Al2O3-NiCr high-velocity oxygen-fuel coating decrease by 62.5% and 79.6%, respectively. After high-energy shot peening, the friction coefficient and calculated wear rate of the coating decrease by 75% and 98.7%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, K.Y.; Hwang, C.S.; Kim, S.J.; Kim, G.G.; Kim, J.H.; Yoon, C.S. Reciprocating Sliding Wear Behavior of Inconel 600 Mated with SUS 304 Stainless Steel at Elevated Temperatures; Trans Tech Publications: Chengdu, China, 2006; pp. 270–273. [Google Scholar]

- Abels, J.M.; Strehblow, A.H. A surface analytical approach to the high temperature chlorination behaviour of inconel 600 at 700 °C. Corros. Sci. 1997, 39, 115–132. [Google Scholar] [CrossRef]

- Lim, M.K.; Oh, S.D.; Lee, Y.Z. Friction and wear of Inconel 690 and Inconel 600 for steam generator tube in room temperature water. Nucl. Eng. Des. 2003, 226, 97–105. [Google Scholar] [CrossRef]

- Kim, H.; Choi, J.H.; Kim, J.K.; Park, K.S.; Kim, S.T.; Kim, S.J. The Sliding Wear Behavior of Inconel 600 Mated with SUS 304. Korean J. Mater. Res. 2001, 11, 841–845. [Google Scholar]

- Wang, Q.; Chen, Z.H.; Ding, Z.X.; Liu, Z.L. Performance study of abrasive wear and erosive wear of WC-12Co coatings sprayed by HVOF. In Proceedings of the IEEE International Nanoelectronics Conference, Shanghai, China, 22–27 March 2008. [Google Scholar]

- Zhu, J.; Lim, C.J.; Grace, J.R.; Lund, J.A. Tube wear in gas fluidized beds—II. Low velocity impact erosion and semi-empirical model for bubbling and slugging fluidized beds. Chem. Eng. Sci. 1991, 46, 1151–1156. [Google Scholar] [CrossRef]

- Morita, T.; Hirano, Y.; Asakura, K.; Kumakiri, T.; Ikenaga, M.; Kagaya, C. Effects of plasma carburizing and DLC coating on friction-wear characteristics, mechanical properties and fatigue strength of stainless steel. Mater. Sci. Eng. A 2012, 558, 349–355. [Google Scholar] [CrossRef]

- Fazlalipour, F.; Niki Nushari, M.; Shakib, N.; Shokuhfar, A. Comparative Tribological Behavior of V(N,C) and VC Diffusion Coatings. In Defect & Diffusion Forum; Trans Tech Publications: Stafa-Zurich, Switzerland, 2010. [Google Scholar]

- Kagiyama, A.; Terakado, K.; Urao, R. Effect of nitriding and TiN coating temperatures on the corrosion resistance of the combined surface modification layer. Surf. Coat. Technol. 2003, 169, 397–400. [Google Scholar] [CrossRef]

- Novák, P.; Müller, M.; Hrabě, P. Application of overlaying material on surface of ploughshare for increasing its service life and abrasive wear resistance. Agron. Res. 2015, 13, 158–166. [Google Scholar]

- Tian, H.L.; Guo, M.Q.; Wang, C.L.; Tang, Z.H.; Cui, Y.J. Tribological behaviour of a self-lubricated GO/WC–12Co thermal spray coating. Surf. Eng. 2017, 34, 762–770. [Google Scholar] [CrossRef]

- Xiao, J.K.; Wu, Y.Q.; Zhang, W.; Chen, J.; Wei, X.L.; Zhang, C. Microstructure, wear and corrosion behaviors of plasma sprayed NiCrBSi-Zr coating. Surf. Coat. Technol. 2019, 360, 172–180. [Google Scholar] [CrossRef]

- Ding, Z.X.; Chen, W.; Wang, Q. Resistance of cavitation erosion of multimodal WC-12Co coatings sprayed by HVOF. Trans. Nonferrous Met. Soc. China 2011, 21, 2231–2236. [Google Scholar] [CrossRef]

- Vashishtha, N.; Khatirkar, R.; Sapate, S. Tribological behaviour of HVOF sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr coatings. Tribol. Int. 2017, 105, 55–68. [Google Scholar] [CrossRef]

- Murthy, J.; Venkataraman, B. Abrasive wear behaviour of WC–CoCr and Cr3C2–20(NiCr) deposited by HVOF and detonation spray processes. Surf. Coat. Technol. 2006, 200, 2642–2652. [Google Scholar] [CrossRef]

- Kuruba, M.; Gaikwad, G.; Natarajan, J.; Koppad, P.G. Effect of carbon nanotubes on microhardness and adhesion strength of high-velocity oxy-fuel sprayed NiCr–Cr3C2 coatings. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 86–96. [Google Scholar]

- Liu, J.; Wang, L.; Li, F.; Ran, X.; Peng, X. Life cycle Inventory of NiCrAl/NiCr-Cr3C2 Composite Coatings for Plasma Spraying Process. Procedia Manuf. 2020, 43, 559–566. [Google Scholar] [CrossRef]

- Shen, Z.; Liu, G.; Mu, R.; Yang, W.; Huang, G. The effect of vacuum heat treatment on microstructure, Al diffusion and thermal cycling lifetime of yttria stabilized zirconia by EB-PVD. Appl. Surf. Sci. Adv. 2021, 4, 100080. [Google Scholar] [CrossRef]

- Zheng, J.; Yang, D.; Gao, Y. Effect of Vacuum Heat Treatment on the High-Temperature Oxidation Resistance of NiCrAlY Coating. Coatings 2020, 10, 1089. [Google Scholar] [CrossRef]

- Sheng, T.; Kong, D. Wear behaviors of HVOF sprayed WC-12Co coatings by laser remelting under lubricated condition. Opt. Laser Technol. 2017, 89, 86–91. [Google Scholar]

- Panziera, R.C.; de Oliveira, A.C.C.; Pereira, M.; Ratszunei, F. Study of the effects of the laser remelting process on the microstructure and properties of the WC–10Co–4Cr coating sprayed by HVOF. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 119. [Google Scholar] [CrossRef]

- Mateos, J.; Cuetos, J.M.; Fernandez, E.; Vijande, R. Tribological behaviour of plasma-sprayed WC coatings with and without laser remelting. Wear 2000, 239, 274–281. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, S.; Gong, J.; Jiang, X.; Sun, C. Effect of Heat Treatment on the Microstructure and Residual Stresses in (Ti,Al)N Films. J. Mater. Sci. Technol. 2011, 27, 385–392. [Google Scholar] [CrossRef]

- Fard, S.B.; Guagliano, M. Effects of surfaces nanocrystallization induced by shot peening on material properties: A Review. Frat. Integrità Strutt. 2009, 3, 3–16. [Google Scholar] [CrossRef]

- Lu, F.F.; Ma, K.; Li, C.X.; Yasir, M.; Luo, X.T.; Li, C.J. Enhanced corrosion resistance of cold-sprayed and shot-peened aluminum coatings on LA43M magnesium alloy. Surf. Coat. Technol. 2020, 394, 125865. [Google Scholar] [CrossRef]

- Kawakita, J.; Kuroda, S.; Kodama, T. Evaluation of through-porosity of HVOF sprayed coating. Surf. Coat. Technol. 2003, 166, 17–23. [Google Scholar] [CrossRef]

- Yao, H.-L.; Hu, X.-Z.; Yi, Z.-H.; Xia, J.; Tu, X.-Y.; Li, S.-B.; Yu, B.; Zhang, M.-X.; Bai, X.-B.; Chen, Q.-Y.; et al. Microstructure and Improved Anti-corrosion Properties of Cold-sprayed Zn Coatings Fabricated by Post Shot-peening Process. Surf. Coat. Technol 2021, 422, 127557. [Google Scholar] [CrossRef]

- Chukwuike, V.I.; Echem, O.G.; Prabhakaran, S.; AnandKumar, S.; Barik, R.C. Laser shock peening (LSP): Electrochemical and hydrodynamic investigation of corrosion protection pre-treatment for a copper surface in 3.5% NaCl medium. Corros. Sci. 2020, 179, 109156. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Xi, T.F.; Lai, C.; Ye, H.Q. Influence of heat treatment on interface of Cu/Al bimetal composite fabricated by cold rolling. Compos. Part B Eng. 2011, 42, 1468–1473. [Google Scholar] [CrossRef]

- Zhao, X.; Munroe, P.; Habibi, D.; Xie, Z. Roles of compressive residual stress in enhancing the corrosion resistance of nano nitride composite coatings on steel. J. Asian Ceram. Soc. 2013, 1, 86–94. [Google Scholar] [CrossRef]

- Ma, A.; Liu, D.; Zhang, X.; Liu, Y.; Zhao, W.; Wang, R.; He, G. Improving Fatigue Performance of TiZrN/TiZr-Coated Ti-6Al-4V Alloy by Inducing a Stabile Compressive Residual Stress Field. J. Alloys Compd. 2022, 925, 16679. [Google Scholar] [CrossRef]

- Roy, M.; Venkataraman, B.; Bhanuprasad, V.V.; Mahajan, Y.R.; Sundararajan, G. The effect of participate reinforcement on the sliding wear behavior of aluminum matrix composites. Metall. Trans. A 1992, 23, 2833–2847. [Google Scholar] [CrossRef]

- Garcia, I.; Fransaer, J.; Celis, J.P. Electrodeposition and sliding wear resistance of nickel composite coatings containing micron and submicron SiC particles. Surf. Coat. Technol. 2001, 148, 171–178. [Google Scholar] [CrossRef]

- Luo, X.; Hong, Y.; Wu, J.; Li, S.; Yang, Q. Effect of WC Grain Size of Ultrafine WC-Co Cemented Carbide on its Friction and Wear Properities. Rare Met. Cem. Carbides 2022, 050, 93–97. [Google Scholar]

- Du, D.; Liu, D.; Zhang, X.; Tang, J.; Meng, B. Effects of WC-17Co Coating Combined with Shot Peening Treatment on Fatigue Behaviors of TC21 Titanium Alloy. Materials 2016, 9, 865. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Yao, Z.Q.; Min, Q.I. The effect of high-energy shot peening commercial pure titanium on hydroxyapatite coating by mineralization. J. Funct. Mater. 2007, 38, 1345. [Google Scholar]

- Zhou, Z.; Shang, J.; Chen, Y.; Liang, X.; Shen, B.; Zhang, Z. Synchronous Shot Peening Applied on HVOF for Improvement on Wear Resistance of Fe-based Amorphous Coating. Coatings 2020, 10, 107. [Google Scholar] [CrossRef]

- Farhat, Z.N.; Ding, Y.; Northwood, D.O.; Alpas, A.T. Effect of grain size on friction and wear of nanocrystalline aluminum. Mater. Sci. Eng. A 1996, 206, 302–313. [Google Scholar] [CrossRef]

- Gao, Y.B.; Li, X.Y.; Kitchen, M.; Ding, Y.T.; Luo, Q.S. Formation mechanism and wear behavior of gradient nanostructured Inconel 625 alloy. Trans. Nonferrous Met. Soc. China 2022, 32, 1910–1925. [Google Scholar] [CrossRef]

- Chao, L.Y.; Lakshminarayanan, R.; Shetty, D.K.; Cutler, R.A. Rolling-Contact Fatigue and Wear of CVD-SiC with Residual Surface Compression. J. Am. Ceram. Soc. 2010, 78, 2307–2313. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | P | S | Cr | Ni | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | ≤0.15 | ≤1.00 | ≤0.50 | ≤0.030 | ≤0.015 | 14.0–17.0 | 71.0–78.0 | ≤0.50 | 6.0–10.0 |

| Sample | Coating | Coating + Peening |

|---|---|---|

| Residual stress (MPa) | 15 ± 4 | −131 ± 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Zhang, C.; Pang, Q.; Fang, G.; Xu, G. Effect of High-Energy Shot Peening on Properties of High-Velocity Oxygen-Fuel Spraying. Coatings 2023, 13, 872. https://doi.org/10.3390/coatings13050872

Li F, Zhang C, Pang Q, Fang G, Xu G. Effect of High-Energy Shot Peening on Properties of High-Velocity Oxygen-Fuel Spraying. Coatings. 2023; 13(5):872. https://doi.org/10.3390/coatings13050872

Chicago/Turabian StyleLi, Fengbo, Conghui Zhang, Qingtao Pang, Gang Fang, and Guoqiang Xu. 2023. "Effect of High-Energy Shot Peening on Properties of High-Velocity Oxygen-Fuel Spraying" Coatings 13, no. 5: 872. https://doi.org/10.3390/coatings13050872

APA StyleLi, F., Zhang, C., Pang, Q., Fang, G., & Xu, G. (2023). Effect of High-Energy Shot Peening on Properties of High-Velocity Oxygen-Fuel Spraying. Coatings, 13(5), 872. https://doi.org/10.3390/coatings13050872