Tribological Properties and Corrosion Resistance of Stellite 20 Alloy Coating Prepared by HVOF and HVAF

Abstract

1. Introduction

2. Materials and Methods

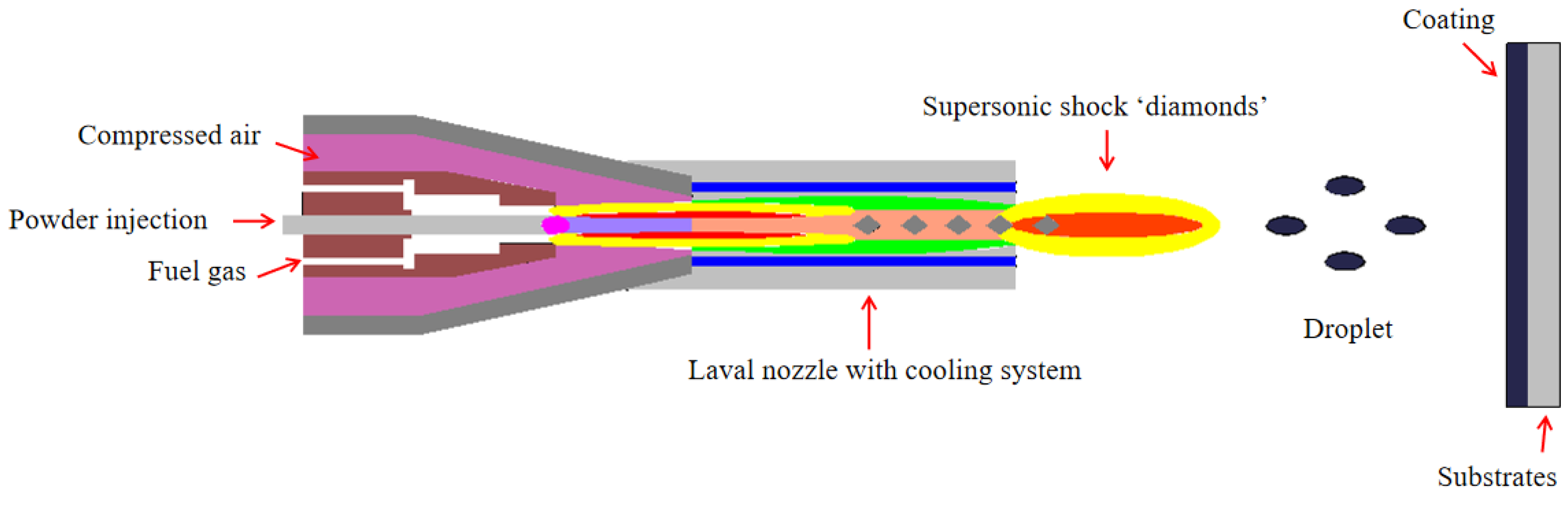

2.1. Coating Preparation

2.2. Performance Characterization

3. Results and Discussion

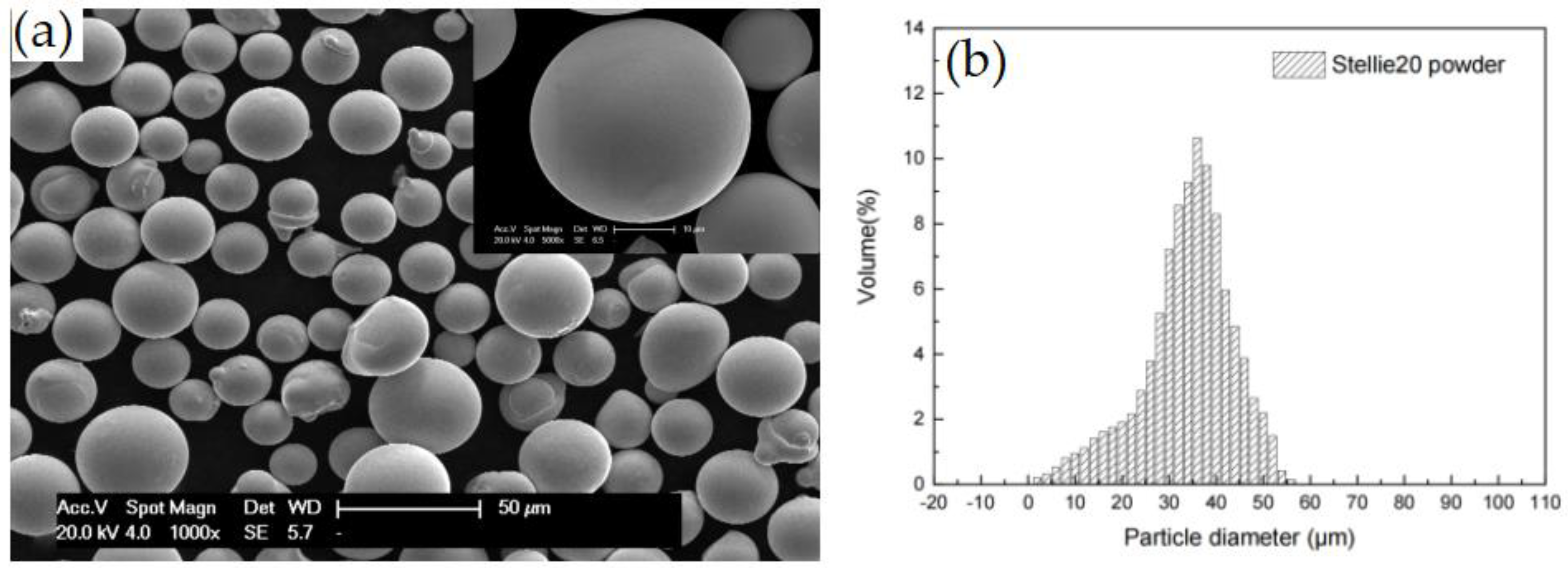

3.1. Powder Morphology

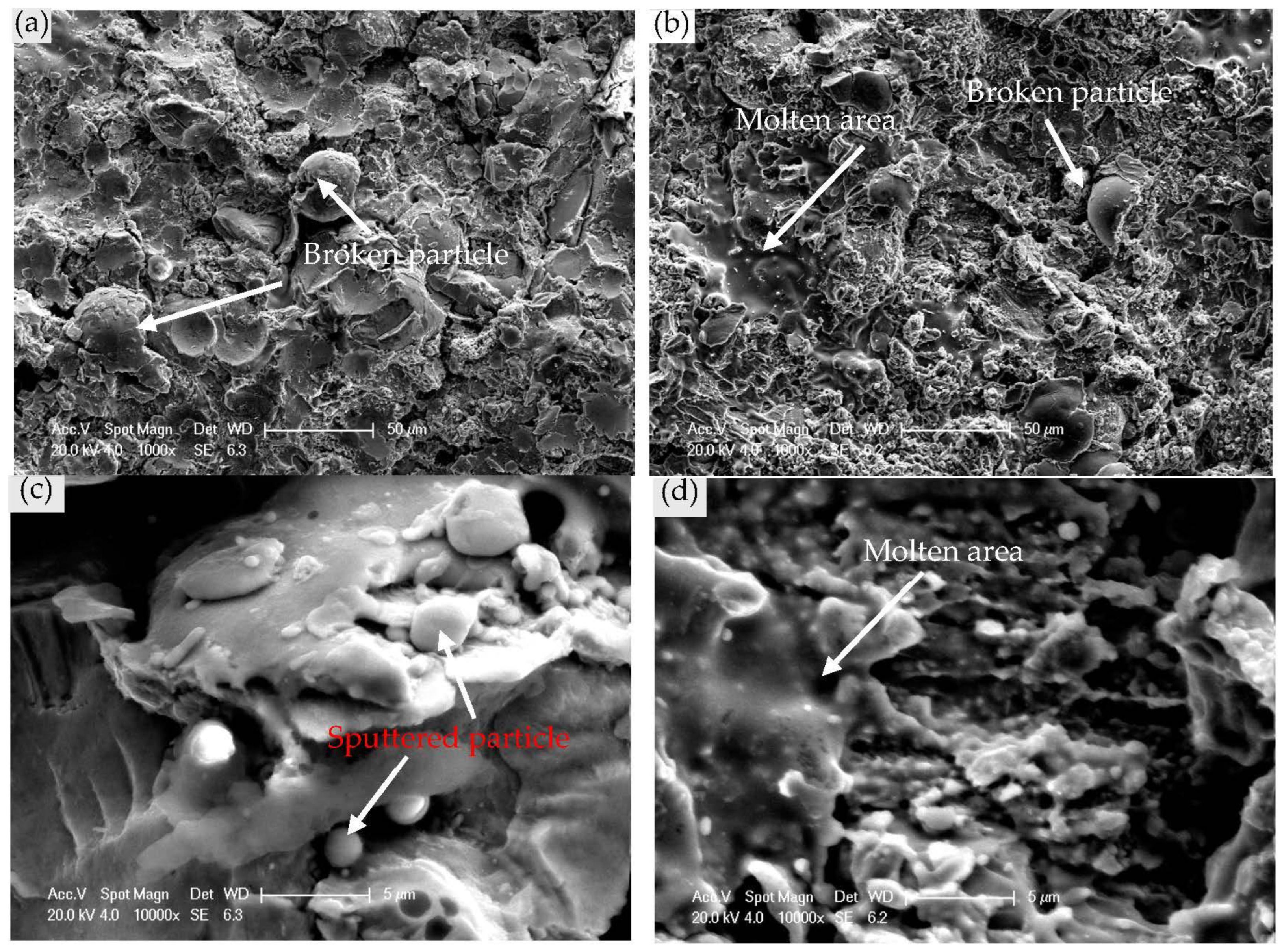

3.2. Surface Morphology

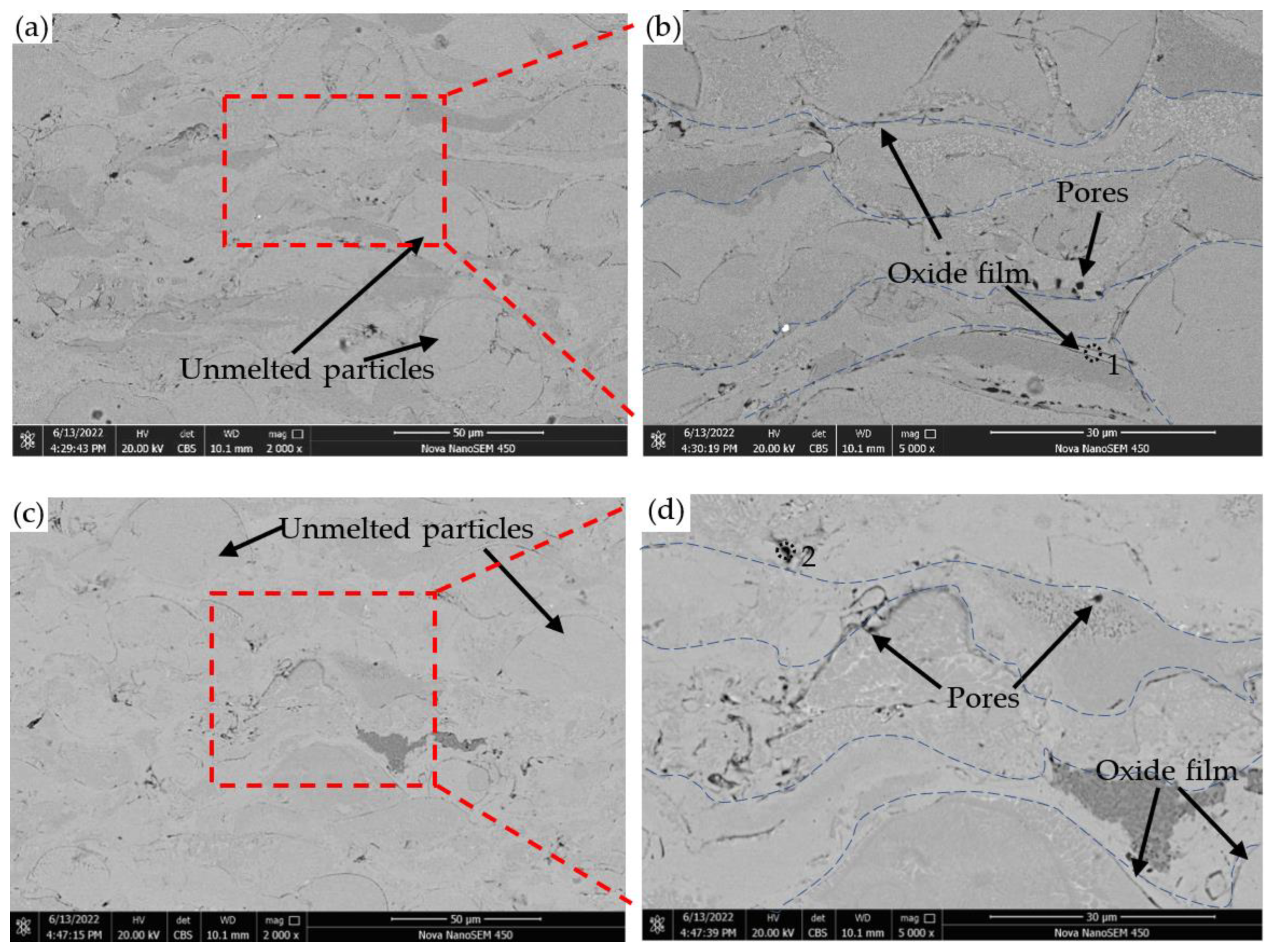

3.3. Section Morphology

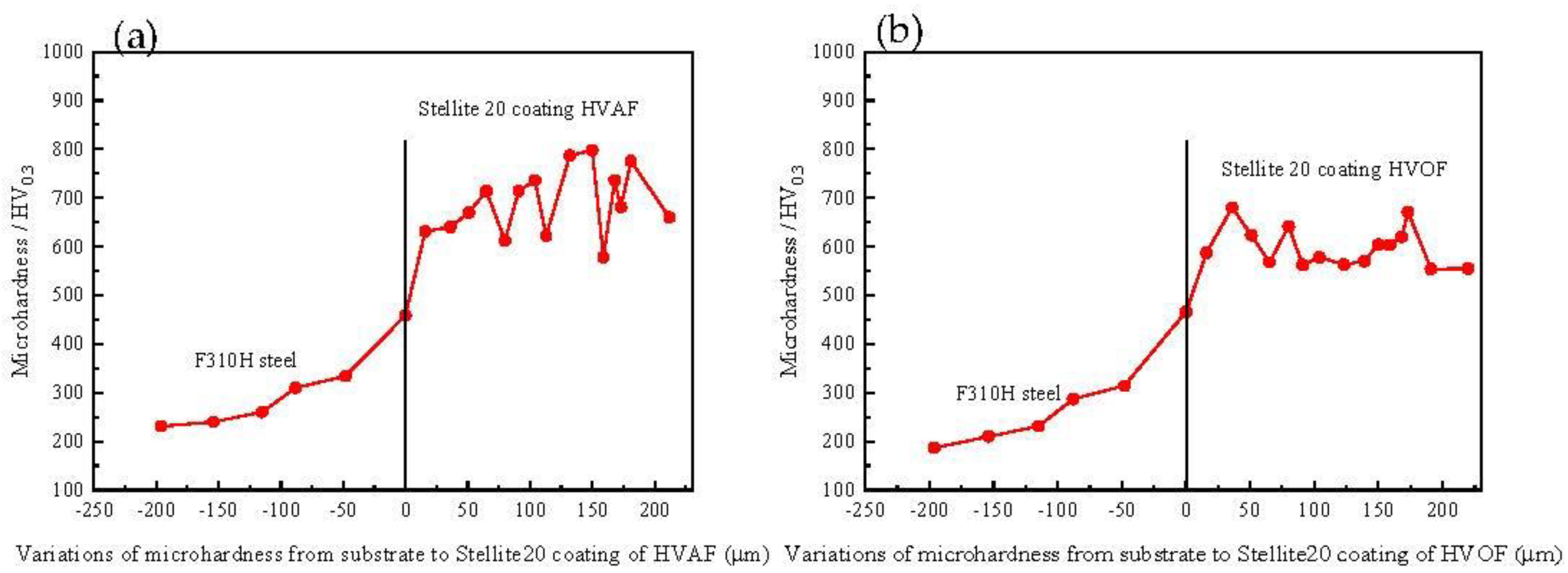

3.4. Microhardness and Weibull Distribution

3.5. Wear Behavior

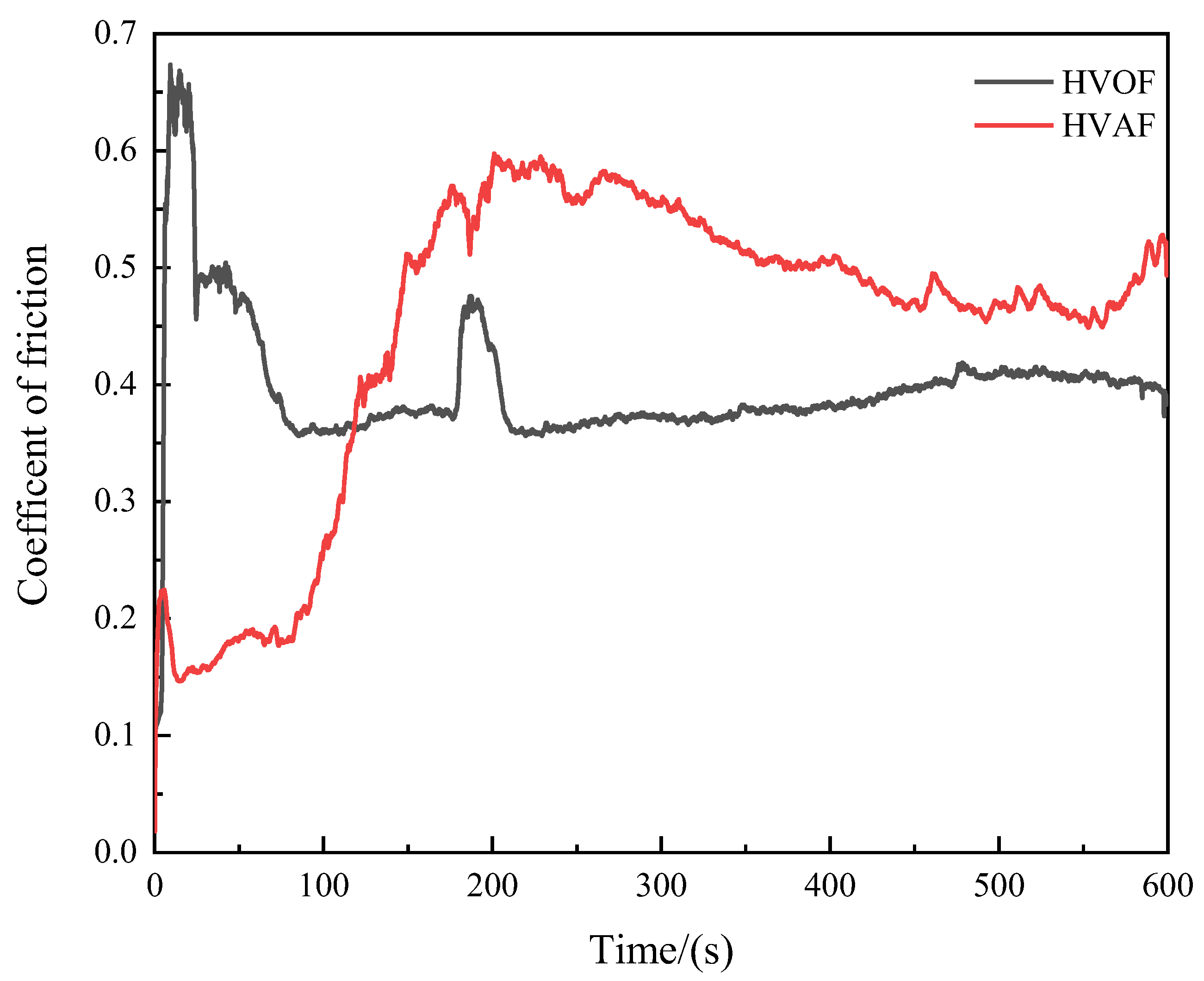

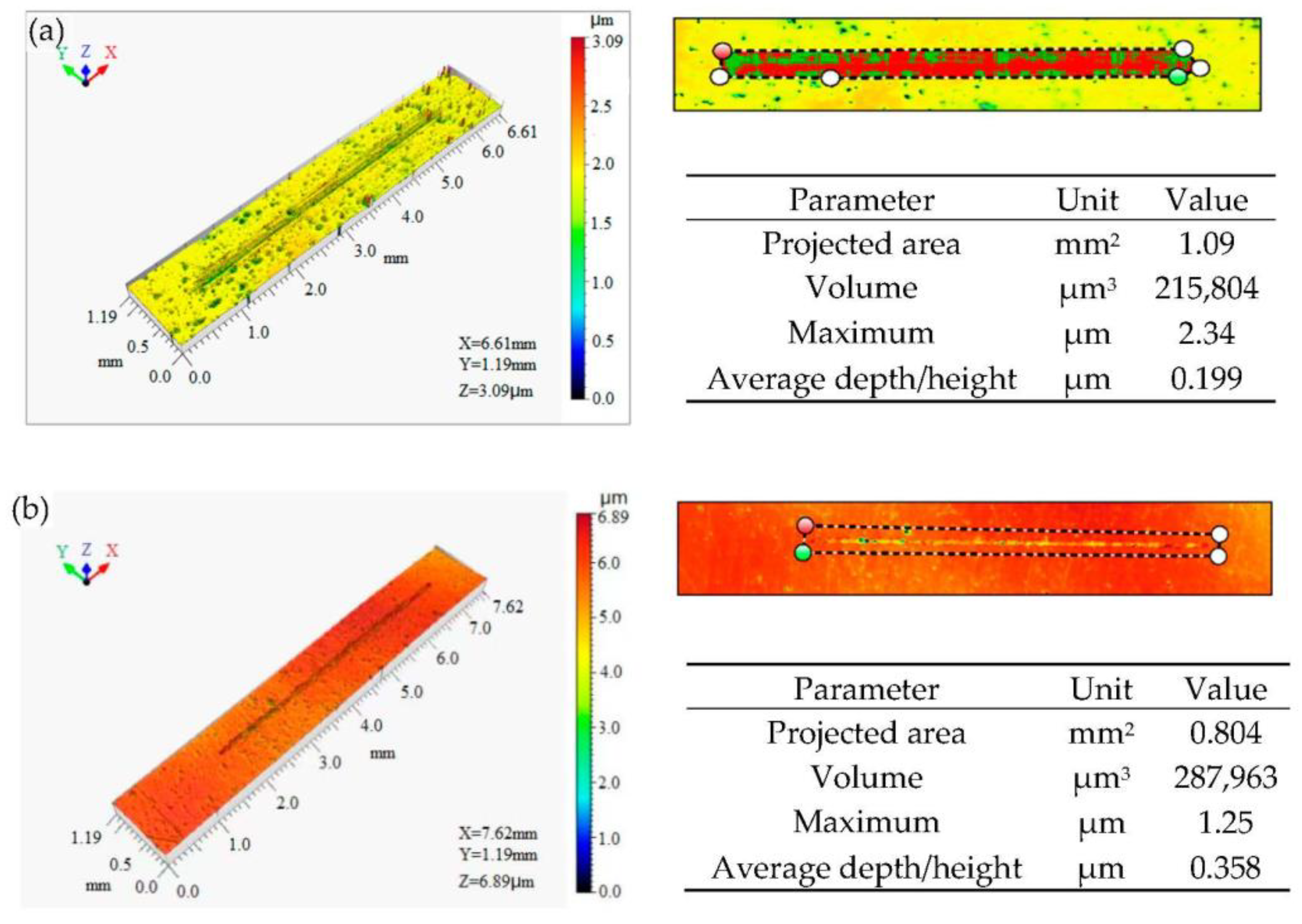

3.5.1. Friction Coefficient and Wear Volume

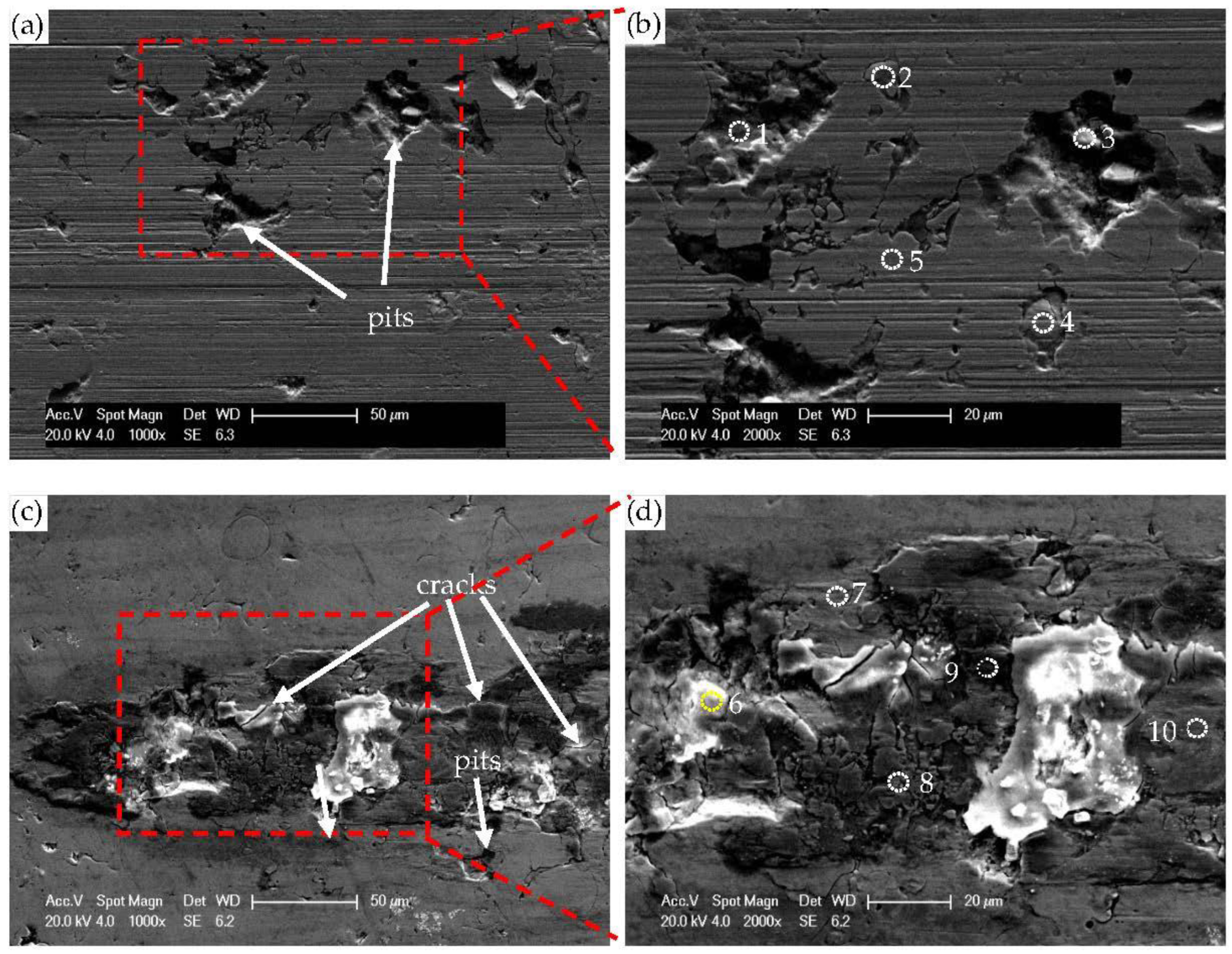

3.5.2. Wear Mechanism

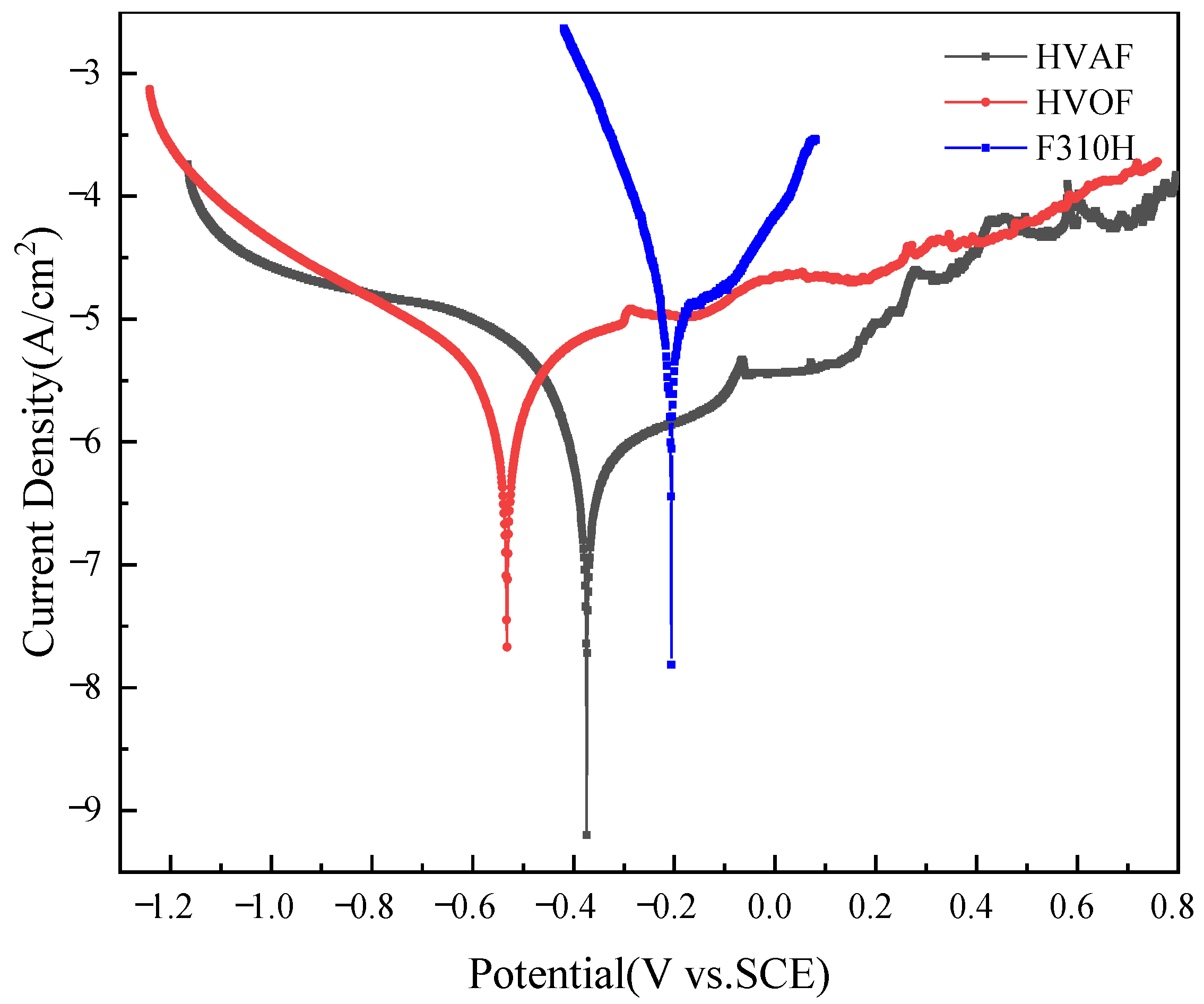

3.6. Corrosion Resistance

4. Conclusions

- The HVOF and HVAF-prepared Stellite 20 coatings exhibit typical thermal spray coating structures, with the HVOF coating composed of partially melted and fully melted zones and a small number of fragmented particles, while the HVAF coating is composed of fragmented particles and partially melted zones, with a small amount of fully melted zones.

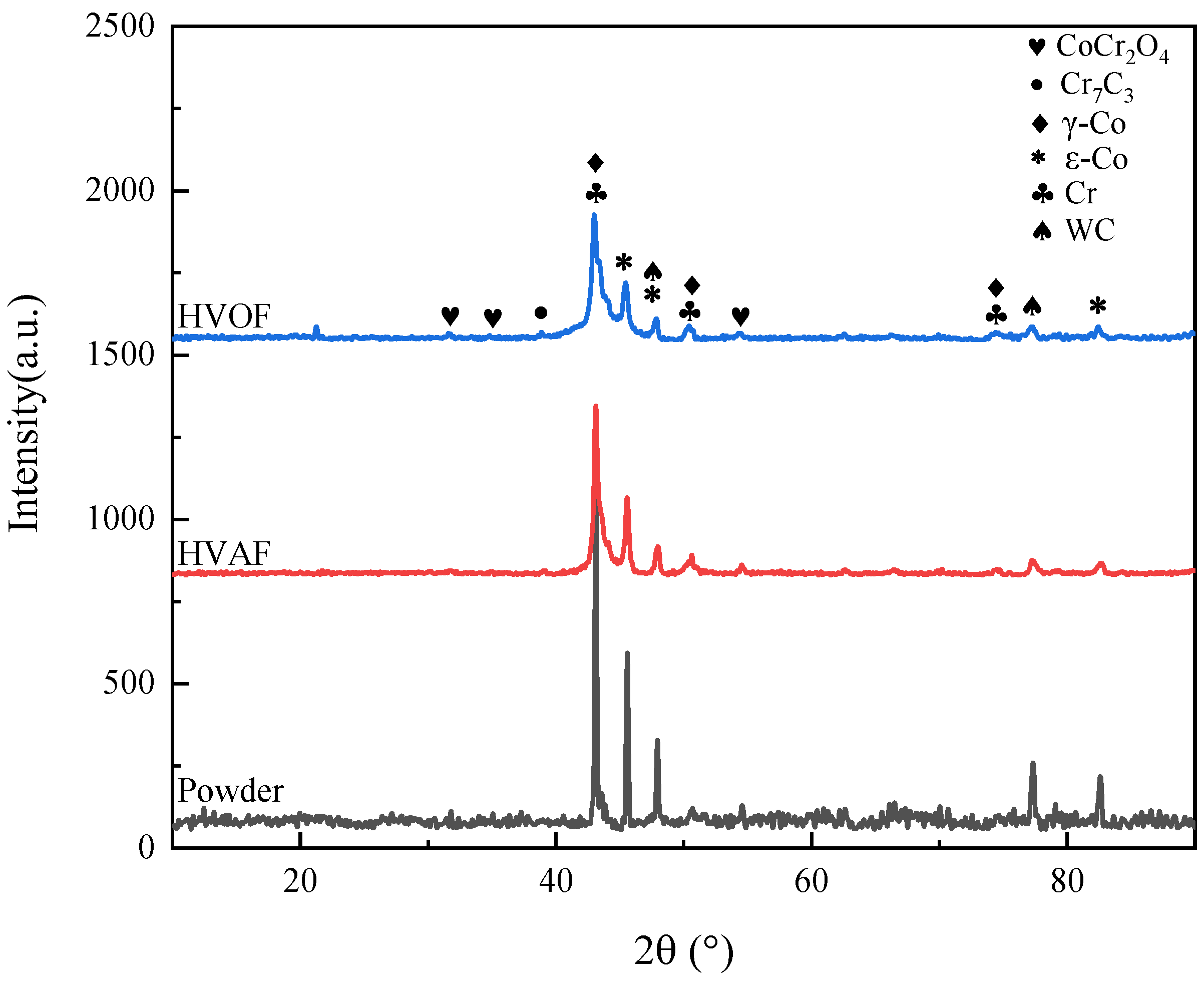

- Both HVOF and HVAF-prepared coatings show grain refinement compared to the powder raw materials and consist of γ-Co solid solution, ε-Co solid solution, Cr-rich solid solution, Cr7C3, WC, and trace amounts of CoCr2O4.

- The microhardness of the Stellite 20 coatings prepared by HVOF and HVAF processes is three times higher than that of the F310H substrate. The HVOF coating exhibits a relatively smooth surface and a porosity of 0.41%, and the HVAF coating exhibits a relatively rough surface and a porosity of 0.32%. The HVOF coating has a smaller hardness dispersion, indicating higher mechanical stability.

- The wear mechanisms of the coatings are different, with the HVAF coating exhibiting abrasive wear, while the HVOF coating exhibits mainly fatigue wear with slight abrasive wear. The HVAF coating shows better wear resistance due to its higher hardness.

- The HVAF coating exhibits lower corrosion current density, measuring 6.268 × 10−7 Acm−2, one order of magnitude lower than that of the HVOF coating. This is attributed to the lower oxide content and porosity of the HVAF-prepared Stellite 20 coating, resulting in better corrosion resistance compared to the HVOF coating.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, E.-J.; Li, T.-J.; Li, W.; Li, Y.; Liu, G. Thermal corrosion resistance of Ni-based coating prepared by HVOF/HVAF. Heat Treat. Met. 2018, 43, 209–214. [Google Scholar]

- Sadeghi, E.; Joshi, S. Corrosion and erosion-corrosion of HVAF and HVOF-sprayed amorphous Fe-based coatings. Surf. Coat. Technol. 2019, 371, 20–35. [Google Scholar] [CrossRef]

- Meißner, T.; Montero, X.; Fähsing, D.; Galetz, M. Cr diffusion coatings on a ferritic-martensitic steel for corrosion protection in KCl-rich biomass co-firing environments. Corros. Sci. 2019, 164, 108343. [Google Scholar] [CrossRef]

- Qu, Z.-P.; Zhong, R.-G.; Wang, L.; Tian, X.-L.; Wang, H.-J. Research progress of high temperature corrosion protection technology for waste incineration power generation boliers. Hot Work. Technol. 2021, 50, 6–11. [Google Scholar]

- Smolina, I.; Kobiela, K. Characterization of Wear and Corrosion Resistance of Stellite 6 Laser Surfaced Alloyed (LSA) with Rhenium. Coatings 2021, 11, 292. [Google Scholar] [CrossRef]

- Radu, I.; Li, D.; Llewellyn, R. Tribological behavior of Stellite 21 modified with yttrium. Wear 2004, 257, 1154–1166. [Google Scholar] [CrossRef]

- Yu, H.; Ahmed, R.; Lovelock, H.D.V. A Comparison of the Tribo-Mechanical Properties of a Wear Resistant Cobalt-Based Alloy Produced by Different Manufacturing Processes. J. Tribol. 2007, 129, 586–594. [Google Scholar] [CrossRef]

- Ou.; Yang, C.-Y.; Li, Y.-L.; Wang, R.; Bai, Q.-F.; Zhang, J.-G. Microstructure and corrosion properties of laser cladding stellite 12 coating on 304 steel. Suface Technol. 2022, 51, 295–304. [Google Scholar]

- Wu, Y.; Schmitt, T.; Bousser, E.; Khelfaoui, F.; Najarian, V.; Klemberg-Sapieha, J.-E.; Brochu, M. Effects of interfacial microstructure on mechanical properties of Stellite-hardfaced coating during long-term aging. Surf. Coat. Technol. 2020, 398, 125989. [Google Scholar] [CrossRef]

- Balaguru, S.; Gupta, M. Hardfacing studies of Ni alloys: A critical review. J. Mater. Res. Technol. 2020, 10, 1210–1242. [Google Scholar] [CrossRef]

- Cheng, Q.; Shi, H.; Zhang, P.; Yu, Z.; Wu, D.; He, S.; Tian, Y. Microstructure, oxidation resistance and mechanical properties of stellite 12 composite coating doped with submicron TiC/B4C by laser cladding. Surf. Coat. Technol. 2020, 395, 125810. [Google Scholar] [CrossRef]

- Yao, J.; Ding, Y.; Liu, R.; Zhang, Q.; Wang, L. Wear and corrosion performance of laser-clad low-carbon high-molybdenum Stellite alloys. Opt. Laser Technol. 2018, 107, 32–45. [Google Scholar] [CrossRef]

- Seraj, R.A.; Abdollah-Zadeh, A.; Dosta, S.; Assadi, H.; Cano, I.G. Comparison of Stellite coatings on low carbon steel produced by CGS and HVOF spraying. Surf. Coat. Technol. 2019, 372, 299–311. [Google Scholar] [CrossRef]

- Houdková, Š.; Pala, Z.; Smazalová, E.; Vostřák, M.; Česánek, Z. Microstructure and sliding wear properties of HVOF sprayed, laser remelted and laser clad Stellite 6 coatings. Surf. Coat. Technol. 2017, 318, 129–141. [Google Scholar] [CrossRef]

- Seraj, R.A.; Abdollah-Zadeh, A.; Dosta, S.; Canales, H.; Assadi, H.; Cano, I.G. The effect of traverse speed on deposition efficiency of cold sprayed Stellite 21. Surf. Coat. Technol. 2019, 366, 24–34. [Google Scholar] [CrossRef]

- Yu, H.; Ahmed, R.; Lovelock, H.D.V.; Davies, S. Influence of Manufacturing Process and Alloying Element Content on the Tribomechanical Properties of Cobalt-Based Alloys. J. Tribol. 2008, 131, 011601. [Google Scholar] [CrossRef]

- Shen, X.-F.; Huang, J.-J.; Li, Z.-K.; Wang, Q.-W.; Fan, L.-F.; Ma, W.; Zhang, P.-S. Perparation of Cr coating by HCOF and its oxidatin performance. Surf. Technol. 2023, 52, 412–421. [Google Scholar]

- Kumar, G.S.P.; Keshavamurthy, R.; Umesh, V.; Tambrallimath, V.; Yadav, Y.; Toufeeq, T.; Arun, S. Dry Sliding Friction and Wear Performance of HVOF Sprayed WC–Co Coatings Deposited on Aluminium Alloy. J. Inst. Eng. Ser. D 2021, 102, 331–344. [Google Scholar] [CrossRef]

- Sadeghimeresht, E.; Hooshyar, H.; Markocsan, N.; Joshi, S.; Nylén, P. Oxidation Behavior of HVAF-Sprayed NiCoCrAlY Coating in H2–H2O Environment. Oxid. Met. 2016, 86, 299–314. [Google Scholar] [CrossRef]

- Hanson, T.C.; Hackett, C.M.; Settles, G.S. Independent control of HVOF particle velocity and temperature. J. Therm. Spray Technol. 2002, 11, 75–85. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, Z.-C. The application and discussion of ac-hvaf spraying process in power station equipment. Therm. Spray Technol. 2011, 3, 44–47. [Google Scholar]

- Sadeghimeresht, E.; Markocsan, N.; Nylén, P.; Björklund, S. Corrosion performance of bi-layer Ni/Cr2C3-NiCr HVAF thermal spray coating. Appl. Surf. Sci. 2016, 369, 470–481. [Google Scholar] [CrossRef]

- Song, Y.-J. Microstructure and Properties of Stellite 20/Nb Cladding Layer by Laser Cladding. Master’s Dissertation, Jilin University, Jilin, China, 2019. [Google Scholar]

- ASTM E2109-01; Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings. ASTM International: West Conshohocken, PA, USA, 2001. Available online: www.astm.org (accessed on 16 August 2017). [CrossRef]

- ASTM B596-89; Standard Specification for Gold-Copper Alloy Electrical Contact Material. ASTM International: West Con-shohocken, PA, USA, 2017. Available online: www.astm.org (accessed on 2 December 2021). [CrossRef]

- Bi, E.-B.; Sun, H.-F.; Wang, C.-M.; Li, C.; Yuan, B.; Zuo, J.-W.; Wen, F.-X. Weibull distribution of microhardness of plasma sprayed nanostructured ceramic coating and relation between phase composition and microhardness. Mater. Prot. 2012, 45, 24–27. [Google Scholar]

- ASTM G99-05; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2011. Available online: www.astm.org (accessed on 20 January 2017). [CrossRef]

- Bae, G.; Kang, K.; Na, H.; Kim, J.-J.; Lee, C. Effect of particle size on the microstructure and properties of kinetic sprayed nickel coatings. Surf. Coat. Technol. 2010, 204, 3326–3335. [Google Scholar] [CrossRef]

- Cho, T.Y.; Yoon, J.H.; Yoon, S.H.; Joo, Y.K. The effects of particle size on the surface properties of an HVOF coating of WC-Co. J. Korean Inst. Met. Mater. 2017, 55, 227–231. [Google Scholar]

- Davis, J.R. Handbook of Thermal Spray Technology; ASM International: Detroit, MI, USA, 2004. [Google Scholar]

- Bezerra, U.O.O. Laser Treatment of Alloys: Processing, Microstructure and Structural Properties; University of Groningen: Groningen, The Netherlands, 2007. [Google Scholar]

- Duflos, F.; Jean-François, S. Comparison of the quench rates attained in gas-atomized powders and melt-spun ribbons of Co- and Ni-base superalloys: Influence on resulting microstructures. J. Mater. Sci. 1981, 8, 3641–3652. [Google Scholar] [CrossRef]

- King, P.C.; Zahiri, S.H.; Jahedi, M. Microstructural Refinement within a Cold-Sprayed Copper Particle. Met. Mater. Trans. A 2009, 40, 2115–2123. [Google Scholar] [CrossRef]

- Richer, P.; Zúñiga, A.; Yandouzi, M.; Jodoin, B. CoNiCrAlY microstructural changes induced during Cold Gas Dynamic Spraying. Surf. Coat. Technol. 2008, 203, 364–371. [Google Scholar] [CrossRef]

- Cinca, N.; Guilemany, J. Cold gas sprayed stellite-6 coatings and their wear resistance. J. Mater. Sci. Eng. 2013, 2, 2169-0022. [Google Scholar]

| C | Mn | Si | S | P | Ni | Cr | Fe |

|---|---|---|---|---|---|---|---|

| 0.09 | 1.86 | 0.63 | 0.02 | 0.03 | 21.17 | 25.53 | Bal. |

| C | Cr | Fe | Mn | Mo | Ni | P | S | Si | W | Co |

|---|---|---|---|---|---|---|---|---|---|---|

| 2.43 | 32.47 | 1.47 | 0.1 | 0.09 | 1.61 | 0.01 | 0.014 | 0.63 | 17.31 | Bal. |

| HVOF | Oxygen flow (L/min) | Kerosene flow (L/h) | Nitrogen flow (L/min) | Air flow (m3/min) | Spraying distance (mm) | Powder speed (mm/s) | Powder feeding (g/min) |

| 1820 | 21 | 20 | 10 | 370 | 720 | 110 | |

| HVAF | Air pressure (MPa) | Propane pressure (MPa) | Nitrogen flow (L/min) | Air flow (m3/min) | Spraying distance (mm) | Powder speed (mm/s) | Powder feeding (g/min) |

| 0.54 | 0.49 | 60 | 20 | 230 | 800 | 110 |

| Areas | Element | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| O | Co | Cr | C | Fe | W | Ni | Mo | Si | Sr | Ti | |

| 1 | 3.63 | 23.62 | 23.41 | 38.62 | 1.62 | 3.40 | 1.67 | 1.09 | 1.75 | 1.19 | - |

| 2 | 3.98 | 22.24 | 18.29 | 49.85 | 1.43 | 2.58 | 1.40 | - | - | - | 0.23 |

| Areas | Elements | |||||

|---|---|---|---|---|---|---|

| Co | Cr | C | O | W | Fe | |

| 1 | 9.02 | 9.01 | 31.99 | 44.62 | 2.11 | 0.75 |

| 2 | 8.37 | 7.60 | 29.23 | 45.64 | 7.99 | 0.55 |

| 3 | 17.40 | 16.93 | 51.33 | 6.73 | 2.69 | 0.80 |

| 4 | 18.89 | 20.85 | 48.63 | - | 3.53 | 2.16 |

| 5 | 21.60 | 24.85 | 38.56 | 3.65 | 3.82 | 1.79 |

| 6 | 26.62 | 12.20 | - | 53.45 | 1.75 | 1.25 |

| 7 | 38.97 | 32.72 | - | 14.24 | 4.44 | 2.52 |

| 8 | 40.24 | 32.36 | - | 17.35 | 4.62 | 2.40 |

| 9 | 26.62 | 12.20 | - | 53.45 | 1.5 | 1.25 |

| 10 | 45.14 | 38.96 | - | - | 4.73 | 3.13 |

| Coating | Ecorr/V | Icorr/A·cm−2 | βa/mV·dec−1 | −βc/mV·dec−1 | Rp/kΩ·cm2 |

|---|---|---|---|---|---|

| F310H | −0.210 | 4.220 × 10−6 | 77.00 | 35.90 | 2.520 × 103 |

| HVAF | −0.376 | 6.268 × 10−7 | 493.50 | 114.85 | 6.454 × 104 |

| HVOF | −0.532 | 1.692 × 10−6 | 216.07 | 205.63 | 2.704 × 104 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Yong, J.; Hao, J.; Sun, D.; Cheng, Q.; Jing, H.; Zhou, Z. Tribological Properties and Corrosion Resistance of Stellite 20 Alloy Coating Prepared by HVOF and HVAF. Coatings 2023, 13, 806. https://doi.org/10.3390/coatings13040806

Zhou Z, Yong J, Hao J, Sun D, Cheng Q, Jing H, Zhou Z. Tribological Properties and Corrosion Resistance of Stellite 20 Alloy Coating Prepared by HVOF and HVAF. Coatings. 2023; 13(4):806. https://doi.org/10.3390/coatings13040806

Chicago/Turabian StyleZhou, Zhiqiang, Jiahui Yong, Jiaoshan Hao, Deen Sun, Qian Cheng, Huan Jing, and Zhongyun Zhou. 2023. "Tribological Properties and Corrosion Resistance of Stellite 20 Alloy Coating Prepared by HVOF and HVAF" Coatings 13, no. 4: 806. https://doi.org/10.3390/coatings13040806

APA StyleZhou, Z., Yong, J., Hao, J., Sun, D., Cheng, Q., Jing, H., & Zhou, Z. (2023). Tribological Properties and Corrosion Resistance of Stellite 20 Alloy Coating Prepared by HVOF and HVAF. Coatings, 13(4), 806. https://doi.org/10.3390/coatings13040806