A Review of Vertical Graphene and Its Biomedical Applications

Abstract

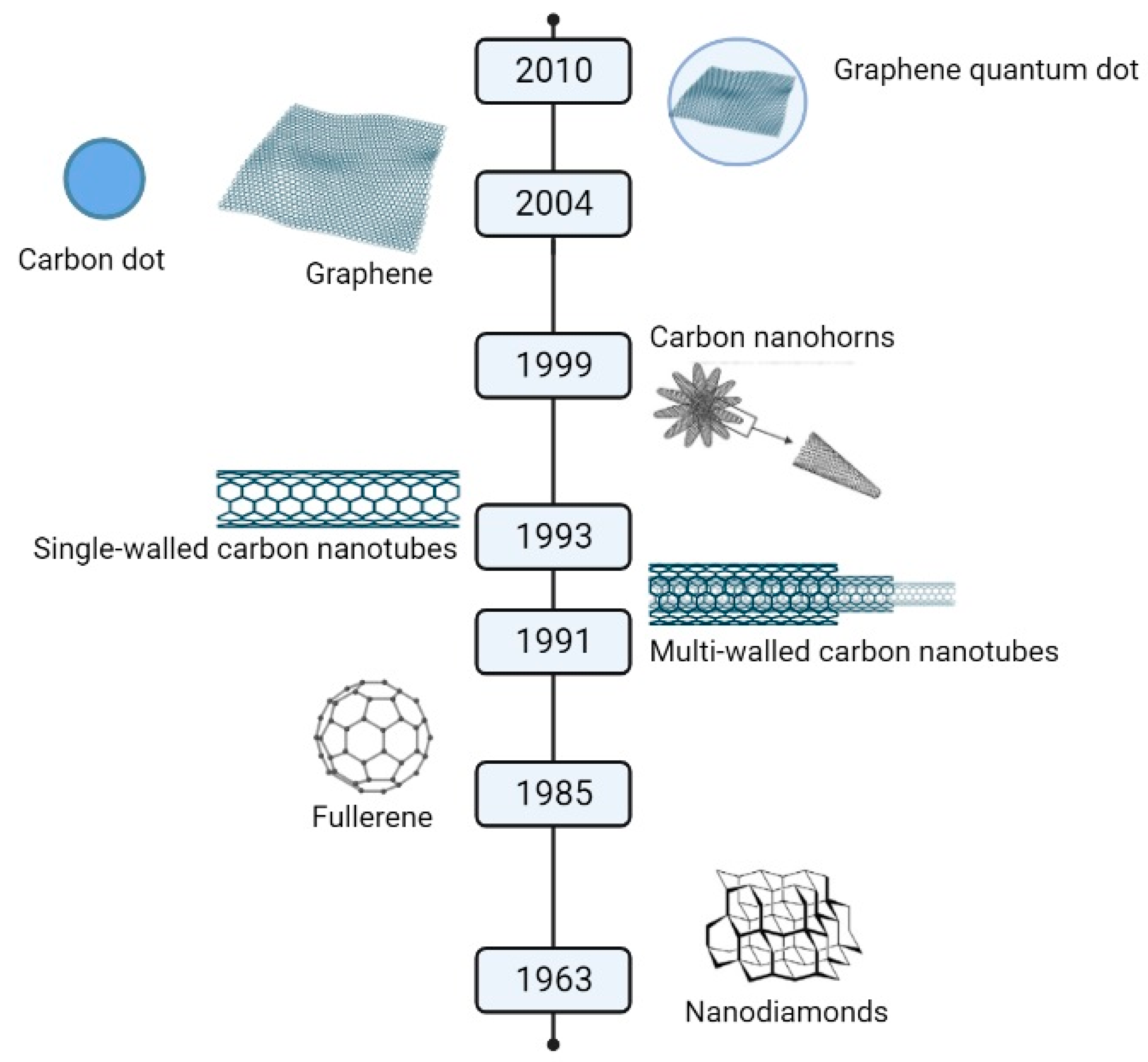

1. Introduction

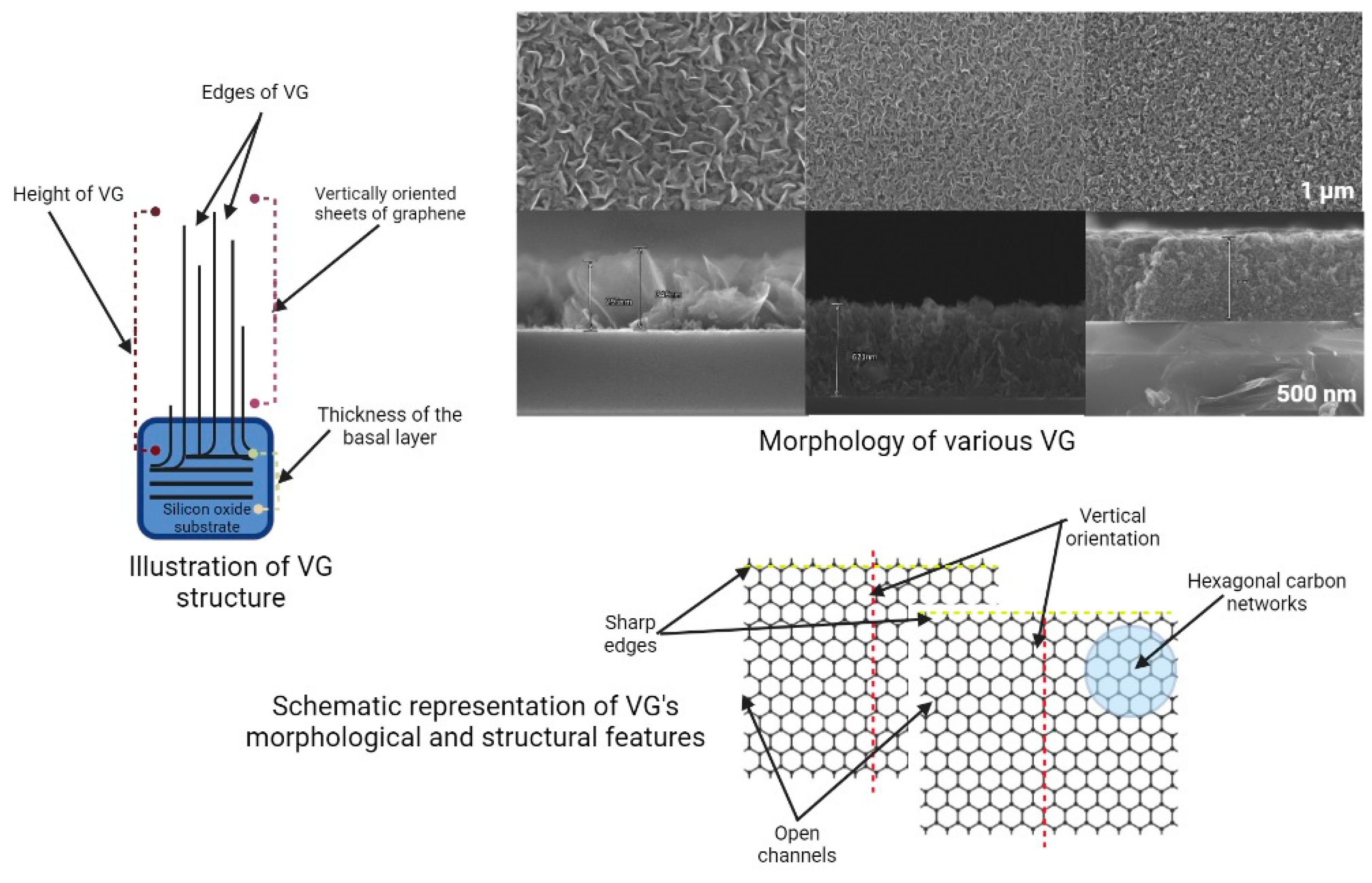

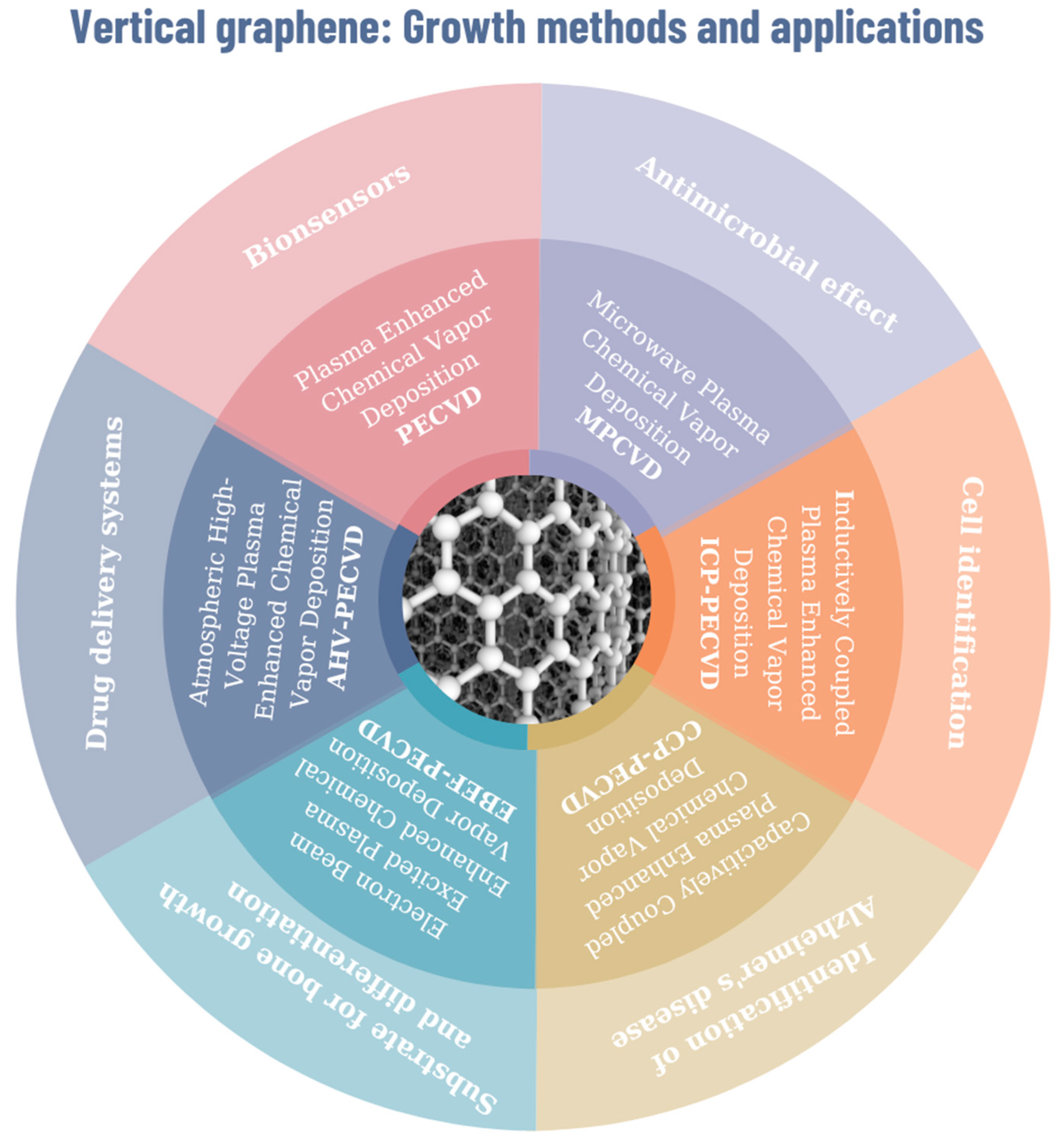

2. Growth Process of VG

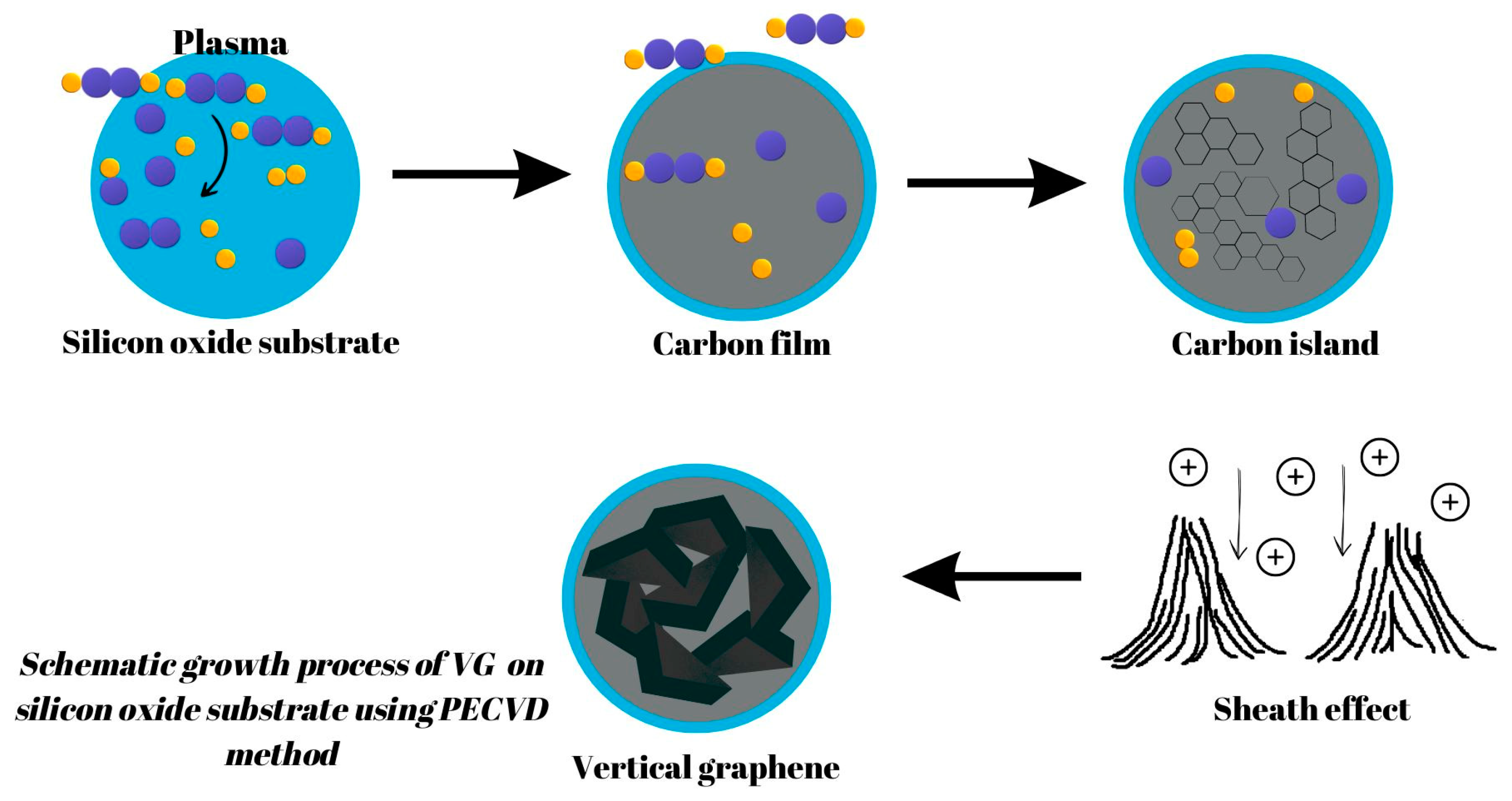

2.1. Plasma-Enhanced Chemical Vapor Deposition (PECVD) Method

- (1)

- The formation of a very thin amorphous carbon layer induced by hydrocarbon radicals (CH4) adsorbed on the substrate followed by ion irradiation to form dangling bonds on the growing surface, resulting in the creation of nucleation sites;

- (2)

- The formation of nano-islands with dangling bonds due to the migration of adsorbed carbon species on the surface;

- (3)

- The adsorption of CHx radicals on the surface enhanced by ion irradiation;

- (4)

- The formation process involves the nucleation of small and disordered nanosheets of graphene at the location of these dangling bonds. This is then accompanied by two-dimensional expansion, which results in the creation of nano-graphene sheets with a haphazard orientation;

- (5)

- When considering nucleated graphene sheets with varying orientations, those that are nearly vertical to the substrate are more likely to grow faster into vertically standing nanosheets, owing to the electromagnetic fields that are produced by the plasma.

2.1.1. Microwave Plasma-Enhanced Chemical Vapor Deposition (MPECVD) Method

2.1.2. Inductively Coupled Plasma-Enhanced Chemical Vapor Deposition (ICP-PECVD) Method

2.1.3. Capacitively Coupled Plasma-Enhanced Chemical Vapor Deposition (CCP-PECVD) Method

2.1.4. Atmospheric-Pressure High Voltage-Enhanced Chemical Vapor Deposition (AHV-PECVD) Method

2.1.5. Electron Beam Excited Plasma-Enhanced Chemical Vapor Deposition (EBEP-PECVD) Method

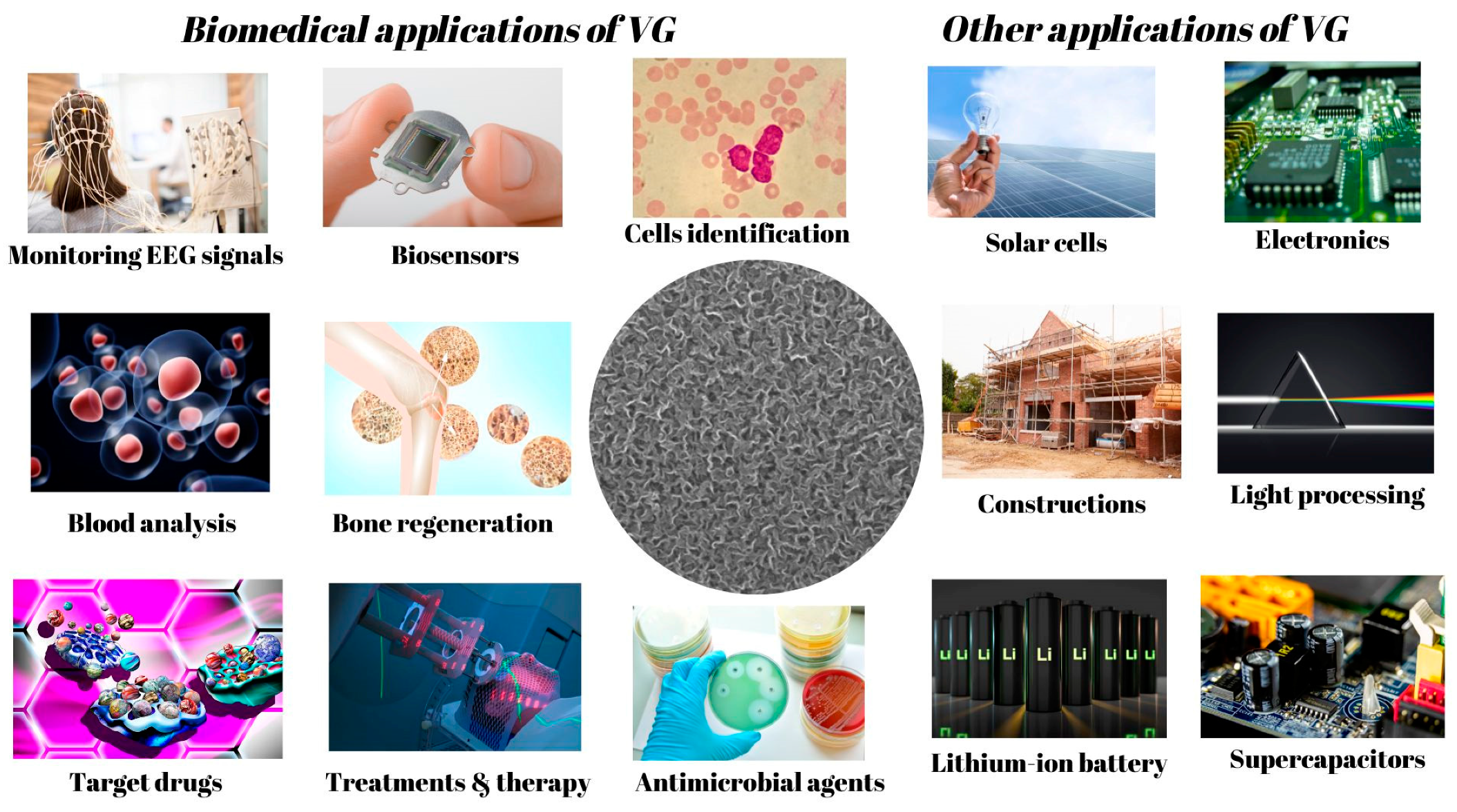

3. Applications of VG

3.1. Biological Affects and Activity

3.2. Biosensors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ando, Y.; Zhao, X.; Ohkohchi, M. Production of petal-like graphite sheets by hydrogen arc discharge. Carbon 1997, 35, 153. [Google Scholar] [CrossRef]

- Ren, J.; Han, J.; Ma, Y.; Wang, M.; Tong, Z.; Suhr, J.; Xiao, L.; Jia, S.; Chen, X. Morphology and surface engineering of vertical graphene films for dye photodegradation. Ceram. Int. 2022, 48, 9477–9482. [Google Scholar] [CrossRef]

- Bo, Z.; Mao, S.; Jun Han, Z.; Cen, K.; Chen, J.; Ostrikov, K. Emerging energy and environmental applications of vertically-oriented graphenes. Chem. Soc. Rev. 2015, 44, 2108–2212. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zou, Q.; Hsu, H.; Raina, S.; Xu, Y.; Kang, J.; Chen, J.; Deng, S.; Xu, N.; Kang, W. Morphology Effect of Vertical Graphene on the High Performance of Supercapacitor Electrode. ACS Appl. Mater. Interfaces 2016, 8, 7363–7369. [Google Scholar] [CrossRef]

- Tiwari, A. (Ed.) Graphene Bioelectronics; Elsevier: Amsterdam, The Netherlands, 2017; ISBN 978-0-12-813349-1. [Google Scholar]

- Anghel, E.; Simionescu, O.G.; Pachiu, C.; Tutunaru, O.; Avram, A.; Demetrescu, I. Preparation, Raman spectroscopy and Morphological analysis of Vertically aligned graphene nanosheets. UPB Sci. Bull. Ser. B 2020, 82, 181–189. [Google Scholar]

- Tincu, B.; Avram, M.; Tucureanu, V.; Mihailescu, C.; Tutunaru, O.; Avram, A.; Anghel, E. Single Layer Graphene and Vertical Graphene as a Promising Candidate for Electrochemical Biosensors. Rev. Chim. 2020, 71, 24–29. [Google Scholar] [CrossRef]

- Sun, J.; Rattanasawatesun, T.; Tang, P.; Bi, Z.; Pandit, S.; Lam, L.; Wasén, C.; Erlandsson, M.; Bokarewa, M.; Dong, J.; et al. Insights into the Mechanism for Vertical Graphene Growth by Plasma-Enhanced Chemical Vapor Deposition. ACS Appl. Mater. Interfaces 2022, 14, 7152–7160. [Google Scholar] [CrossRef]

- Shi, L.; Pang, C.; Chen, S.; Wang, M.; Wang, K.; Tan, Z.; Gao, P.; Ren, J.; Huang, Y.; Peng, H.; et al. Vertical Graphene Growth on SiO Microparticles for Stable Lithium Ion Battery Anodes. Nano Lett. 2017, 17, 3681–3687. [Google Scholar] [CrossRef]

- Yazdi, G.R.; Iakimov, T.; Yakimova, R. Epitaxial Graphene on SiC: A Review of Growth and Characterization. Crystals 2016, 6, 53. [Google Scholar] [CrossRef]

- Yuan, S.L.; Gao, G.; Yang, L.; Chhowalla, J.; Gharahcheshmeh, M.H.; Gleason, M.; Choi, K.; Hong, Y.; Liu, B. Chemical vapor deposition. Nat. Rev. Methods Prim. 2021, 1, 5. [Google Scholar]

- Abbas, Q.; Shinde, P.A.; Abdelkareem, M.A.; Alami, A.H.; Mirzaeian, M.; Yadav, A.; Olabi, A.G. Graphene Synthesis Techniques and Environmental Applications. Materials 2022, 15, 7804. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Bo, Z.; Lu, G. Vertically-Oriented Graphene; Springer International Publishing: Cham, Switzerland, 2015; ISBN 978-3-319-15302-5. [Google Scholar]

- Ghosh, S.; Ganesan, K.; Polaki, S.R.; Mathews, T.; Dhara, S.; Kamruddin, M.; Tyagi, A.K. Influence of substrate on nucleation and growth of vertical graphene nanosheets. Appl. Surf. Sci. 2015, 349, 576–581. [Google Scholar] [CrossRef]

- Muñoz, R.; Gómez-Aleixandre, C.J. Fast and non-catalytic growth of transparent and conductive graphene-like carbon films on glass at low temperature. Phys. D Appl. Phys. 2014, 47, 045305. [Google Scholar] [CrossRef]

- Malesevic, A.; Vitchev, R.; Schouteden, K.; Volodin, A.; Zhang, L.; Van Tendeloo, G.; Vanhulsel, A.; Van Haesendonck, C. Synthesis of few-layer graphene via microwave plasma-enhanced chemical vapor deposition. Nanotechnology 2008, 19, 305604. [Google Scholar] [CrossRef] [PubMed]

- Davami, K.; Shaygan, M.; Kheirabi, N.; Zhao, J.; Kovalenko, D.A.; Rummeli, M.H.; Opitz, J.; Cuniberti, G.; Lee, J.-S.; Meyyappan, M. Synthesis and characterization of carbon nanowalls on different substrates by radio frequency plasma enhanced chemical vapor deposition. Carbon 2014, 72, 372–380. [Google Scholar] [CrossRef]

- Cai, M.; Outlaw, R.A.; Butler, S.M.; Miller, J.R. A high density of vertically oriented graphenes for use in electric double layer capacitors. Carbon 2012, 50, 5481–5488. [Google Scholar] [CrossRef]

- Bo, Z.; Yu, K.; Lu, G.; Wang, P.; Mao, S.; Chen, J. Understanding growth of carbon nanowalls at atmospheric pressure using normal glow discharge plasma-enhanced chemical vapor deposition. Carbon 2011, 49, 1849–1858. [Google Scholar] [CrossRef]

- Hiramatsu, M.; Kondo, H.; Hori, M. Graphene Nanowalls Ch.9. In New Progress on Graphene Research; InTech: Rijeka, Croatia, 2013; ISBN 978-953-51-1091-0. [Google Scholar]

- Wu, Y.H.; Yu, T.; Shen, Z.X. Two-dimensional Carbon Nanostructures: Fundamental Properties, Synthesis, Characterization, and Potential Applications. J. Appl. Phys. 2010, 108, 071301. [Google Scholar] [CrossRef]

- Chuang, A.T.H.; Boskovic, B.O.; Robertson, J. Freestanding Carbon Nanowalls by Microwave Plasma-enhanced Chemical Vapour Deposition. Diam. Relat. Mater. 2006, 15, 1103–1106. [Google Scholar] [CrossRef]

- Thomas, R.; Rao, G.M. Synthesis of 3-dimensional Porous Graphene Nanosheets Using Electron Cyclotron Resonance Plasma Enhanced Chemical Vapour Deposition. RSC Adv. 2015, 5, 84927–84935. [Google Scholar] [CrossRef]

- Tanaka, K.; Yoshimura, M.; Okamoto, A.; Ueda, K. Growth of carbon nanowalls on a SiO2 substrate by microwave plasma-enhanced chemical vapor deposition. Jpn. J. Appl. Phys. 2005, 44, 2074–2076. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhu, M.Y.; Outlaw, R.A.; Zhao, X.; Manos, D.M.; Holloway, B.C. Synthesis of Carbon Nanosheets by Inductively Coupled Radio-frequency Plasma Enhanced Chemical Vapor Deposition. Carbon 2004, 42, 2867–2872. [Google Scholar] [CrossRef]

- Seo, D.H.; Rider, A.E.; Kumar, S.; Randeniya, L.K.; Ostrikov, K. Vertical Graphene Gas- and Bio-sensor Via Catalyst-free, Reactive Plasma Reforming of Natural Honey. Carbon 2013, 60, 221. [Google Scholar] [CrossRef]

- Zhu, M.; Wang, J.; Outlaw, R.A.; Hou, K.; Manos, D.M.; Holloway, B.C. Synthesis of carbon nanosheets and carbon nanotubes by radio frequency plasma enhanced chemical vapor deposition. Diam. Relat. Mater. 2007, 16, 196–201. [Google Scholar] [CrossRef]

- Hishikawa, T.; Hiramatsu, M.; Hori, M. Growth of carbon nanowalls using inductively coupled plasma-enhanced chemical vapor deposition. In Proceedings of the 29th International Symposium on Dry Process, Tokyo, Japan, 13–14 November 2007; pp. 253–254. [Google Scholar]

- Cuxart, M.G.; Šics, I.; Goñi, A.R.; Pach, E.; Sauthier, G.; Paradinas, M.; Foerster, M.; Aballe, L.; Fernandez, H.M.; Carlino, V.; et al. Inductively coupled remote plasma-enhanced chemical vapor deposition (rPE-CVD) as a versatile route for the deposition of graphene micro- and nanostructures. Carbon 2017, 117, 331–342. [Google Scholar] [CrossRef]

- Kondo, S.; Hori, M.; Yamakawa, K.; Den, S.; Kano, H.; Hiramatsu, M. Highly Reliable Growth Process of Carbon Nanowalls Using Radical Injection Plasma-enhanced Chemical Vapor Deposition. J. Vac. Sci. Technol. B 2008, 26, 1294. [Google Scholar] [CrossRef]

- Shiji, K.; Hiramatsu, M.; Enomoto, A.; Nakamura, M.; Amano, H.; Hori, M. Vertical Growth of Carbon Nanowalls Using RF Plasma Enhanced Chemical Vapor Deposition. Diam. Relat. Mater. 2005, 14, 831.dik. [Google Scholar] [CrossRef]

- Chabert, P.; Braithwaite, N. Physics of Radio-Frequency Plasmas; Cambridge University Press: New York, NY, USA, 2001; pp. 1–385. [Google Scholar]

- Lieberman, M.A.; Lichtenberg, A.J. Principles of Plasma Discharges and Materials Processing, 2nd ed.; Wiley: Hoboken, NJ, USA, 2005; pp. 1–757. [Google Scholar]

- Vizireanu, S.; Stoica, S.D.; Luculescu, C.; Nistor, L.C.; Mitu, B.; Dinescu, G. Plasma techniques for nanostructured carbon materials synthesis. A case study: Carbon nanowall growth by low pressure expanding RF plasma. Plasma Sources Sci. Technol. 2010, 19, 034016. [Google Scholar] [CrossRef]

- Malesevic, A.; Vizireanu, S.; Kemps, R.; Vanhulsel, A.; Van Haesendonck, C.; Dinescu, G. Combined growth of carbon nanotubes and carbon nanowalls by plasma-enhanced chemical vapor deposition. Carbon 2007, 45, 2932–2937. [Google Scholar] [CrossRef]

- Bo, Z.; Cui, S.M.; Yu, K.H.; Lu, G.H.; Mao, S.; Chen, J.H. Note: Continuous Synthesis of Uniform Vertical Graphene on Cylindrical Surfaces. Rev. Sci. Instrum. 2011, 82, 086116. [Google Scholar] [CrossRef]

- Mori, T.; Hiramatsu, M.; Yamakawa, K.; Takeda, K.; Hori, M. Fabrication of Carbon Nanowalls Using Electron Beam Excited Plasma-enhanced Chemical Vapor Deposition. Diam. Relat. Mater. 2008, 17, 1513–1517. [Google Scholar] [CrossRef]

- Guo, X.; Quin, S.C.; Bai, S.; Yue, H.W.; Li, Y.L.; Chen, Q.; Li, J.S.; He, D.Y. Vertical Graphene Nanosheets Synthesized by Thermal Chemical Vapor Deposition and the Field Emission Properties. J. Phys. D Appl. Phys. 2016, 49, 385301. [Google Scholar] [CrossRef]

- Zheng, S.H.; Li, Z.L.; Wu, Z.S.; Dong, Y.F.; Zhou, F.; Wang, S.; Fu, Q.; Sun, C.L.; Guo, L.W.; Bao, S.H. High Packing Density Unidirectional Arrays of Vertically Aligned Graphene with Enhanced Areal Capacitance for High Power Micro-Supercapacitors. ACS Nano 2017, 11, 4009. [Google Scholar] [CrossRef]

- Dikonimos, T.; Giorgi, L.; Giorgi, R.; Lisi, N.; Salernitano, E.; Rossi, R. DC plasma enhanced growth of oriented carbon nanowall films by HFCVD. Diam. Relat. Mater. 2007, 16, 1240–1243. [Google Scholar] [CrossRef]

- Park, H.J.; Ahn, B.W.; Kim, T.Y.; Lee, J.W.; Jung, Y.H.; Choi, Y.S.; Song, Y.I.; Suh, S.J. Direct synthesis of multi-layer graphene film on various substrates by microwave plasma at low temperature. Thin Solid Films 2015, 587, 8–13. [Google Scholar] [CrossRef]

- Ghosh, S.; Polaki, S.R.; Kumar, N.; Amirthapandian, S.; Kamruddin, M.; Ostrikov, K.K. Process-specific mechanisms of vertically oriented graphene growth in plasmas. Beilstein J. Nanotechnol. 2017, 8, 1658–1670. [Google Scholar] [CrossRef]

- Yang, Q.; Wu, J.; Li, S.; Zhang, L.; Fu, J.; Huang, F.; Cheng, Q. Vertically-oriented graphene nanowalls: Growth and application in Li-ion batteries. Diam. Relat. Mater. 2019, 91, 54–63. [Google Scholar] [CrossRef]

- Giese, A.; Schipporeit, S.; Buck, V.; Wohrl, N. Synthesis of carbon nanowalls from a single-source metal-organic precursor. Beilstein J. Nanotechnol. 2018, 9, 1895–1905. [Google Scholar] [CrossRef]

- Li, J.H.; Zhu, M.J.; An, Z.L.; Wang, Z.Q.; Toda, M.; Ono, T. Constructing in-chip micro-supercapacitors of 3D graphene nanowall/ruthenium oxides electrode through silicon-based microfabrication technique. J. Power Sources 2018, 401, 204–212. [Google Scholar] [CrossRef]

- Lehmann, K.; Yurchenko, O.; Urban, G. Effect of the aromatic precursor flow rate on the morphology and properties of carbon nanostructures in plasma enhanced chemical vapor deposition. RSC Adv. 2016, 6, 32779–32788. [Google Scholar] [CrossRef]

- Tan, Q.; Wu, C.; Li, L.; Shao, W.; Luo, M. Nanomaterial-Based Prosthetic Limbs for Disability Mobility Assistance: A Review of Recent Advances. J. Nanomater. 2022, 2022, 3425297. [Google Scholar] [CrossRef]

- Al-Jumaili, A.; Alancherry, S.; Bazaka, K.; Jacob, M. Review on the Antimicrobial Properties of Carbon Nanostructures. Materials 2017, 10, 1066. [Google Scholar] [CrossRef] [PubMed]

- Borghi, F.F.; Bean, P.A.; Evans, M.D.M.; van der Laan, T.; Kumar, S.; Ostrikov, K. van der Laan; Kumar, S.; Ostrikov, K. Nanostructured Graphene Surfaces Promote Different Stages of Bone Cell Differentiation. Micro-Nano Lett. 2018, 10, 47. [Google Scholar] [CrossRef]

- Al-Jumaili, A.; Zafar, M.A.; Bazaka, K.; Weerasinghe, J.; Jacob, M.V. Bactericidal vertically aligned graphene networks derived from renewable precursor. Carbon Trends 2022, 7, 100157. [Google Scholar] [CrossRef]

- Boonkaew, S.; Dettlaff, A.; Sobaszek, M.; Bogdanowicz, R.; Jonsson-Niedziolka, M. Electrochemical determination of neurotransmitter serotonin using boron/nitrogen co-doped diamond-graphene nanowall-structured particles. J. Electroanal. Chem. 2022, 926, 116938. [Google Scholar] [CrossRef]

- Bahamonde, J.P.; Nguyen, H.N.; Fanourakis, S.K.; Rodrigues, D.F. Recent advances in graphene-based biosensor technology with applications in life sciences. J. Nanobiotechnol. 2018, 16, 75. [Google Scholar] [CrossRef]

- Cho, I.-H.; Lee, J.; Kim, J.; Kang, M.S.; Paik, J.K.; Ku, S. Current technologies of electrochemical immunosensors: Perspective on signal amplification. Sensors 2018, 18, 207. [Google Scholar] [CrossRef]

- Liu, A.; Wang, K.; Weng, S.; Lei, Y.; Lin, L.; Chen, W. Development of electrochemical DNA biosensors. Trends Anal. Chem. 2012, 37, 101–111. [Google Scholar] [CrossRef]

- Song, Y.; Luo, Y.; Zhu, C.; Li, H.; Du, D.; Lin, Y. Recent advances in electrochemical biosensors based on graphene two-dimensional nanomaterials. Biosens. Bioelectron. 2016, 76, 195–212. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E.; Rahighi, R. Toward single-DNA electrochemical biosensing by graphene nanowalls. ACS Nano 2012, 6, 2904–2916. [Google Scholar] [CrossRef]

- Dong, H.; Zhu, Z.; Ju, H.; Yan, F. Triplex signal amplification for electrochemical DNA biosensing by coupling probe-gold nanoparticles–graphene modified electrode with enzyme functionalized carbon sphere as tracer. Biosens. Bioelectron. 2012, 33, 228–232. [Google Scholar] [CrossRef] [PubMed]

- Mao, S.; Yu, K.; Chang, J.; Steeber, D.A.; Ocola, L.E.; Chen, J. Direct Growth of Vertically-oriented Graphene for Field-Effect Transistor Biosensor. Sci. Rep. 2013, 3, 1696. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Sun, T.; Song, X.; Ran, Q.; Yu, C.; Yang, J.; Feng, H.; Yu, L.; We, D. Flexible electrochemical biosensors based on graphene nanowalls for the real-time measurement of lactate. Nanotechnology 2017, 28, 315501. [Google Scholar] [CrossRef] [PubMed]

- Tzouvadaki, I.; Aliakbarinodehi, N.; Pineda, D.D.; De Micheli, G.; Carrara, S. Graphene nanowalls for high-performance chemotherapeutic drug sensing and anti-fouling properties. Sens. Actuators B Chem. 2018, 262, 395–403. [Google Scholar] [CrossRef]

- Tincu, B.; Burinaru, T.; Enciu, A.M.; Preda, P.; Chiriac, E.; Marculescu, C.; Avram, M.; Avram, A. Vertical Graphene-Based Biosensor for Tumor Cell Dielectric Signature Evaluation. Micromachines 2022, 13, 1671. [Google Scholar] [CrossRef]

- Burinaru, T.; Adiaconita, B.; Avrama, M.; Preda, P.; Enciu, A.M.; Chiriac, E.; Marculescu, C.; Constantin, T. Electrochemical impedance spectroscopy based microfluidic biosensor for the detection of circulating tumor cells. Mater. Today Commun. 2022, 32, 104016. [Google Scholar] [CrossRef]

- Yao, D.; Wu, L.; Shiwei, A.; Zhang, M.; Fang, H.; Li, D.; Sun, Y.; Gao, X.; Lu, C. Stretchable vertical graphene arrays for electronic skin with multifunctional sensing capabilities. Chem. Eng. J. 2022, 431, 134038. [Google Scholar] [CrossRef]

- Yang, C.; Shen, Z.; Yao, C.; Huang, S.; Huang, X.; Mo, J.; Yang, C.; Chen, M.; Chen, H.-J.; Xie, X.; et al. Integrated Strain Sensors with Stretchable Vertical Graphene Networks for Non-invasive Physiological Assessment. ACS Appl. Electron. Mater. 2022, 4, 964–973. [Google Scholar] [CrossRef]

- Chen, Z.; Li, B.; Liu, J.; Li, H.; Li, C.; Xuan, X.; Li, M. A label-free electrochemical immunosensor based on a gold–vertical graphene/TiO2 nanotube electrode for CA125 detection in oxidation/reduction dual channels. Microchim. Acta 2022, 189, 257. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Li, M.; Liu, Q.; Xu, T. Portable Vertical Graphene@Au-Based Electrochemical Aptasensing Platform for Point-of-Care Testing of Tau Protein in the Blood. Biosensors 2022, 12, 564. [Google Scholar] [CrossRef]

- Zhai, P.; Xuan, X.; Li, H.; Li, C.; Li, P.; Li, M. Boron and nitrogen co-doped vertical graphene electrodes for scalp electroencephalogram recording. Carbon 2022, 189, 71–80. [Google Scholar] [CrossRef]

- Sun, D.; Li, H.; Li, M.; Li, C.; Qian, L.; Yang, B. Electrochemical immunosensors with AuPt-vertical graphene/glassy carbon electrode for alpha-fetoprotein detection based on label-free and sandwich-type strategies. Biosens. Bioelectron. 2019, 132, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Abolpour, M.; Azadi, S.; Belford, A.; Razmjou, A.; Wu, S.; Han, Z.; Asadnia, M. Development of an Ultra-Sensitive and Flexible Piezoresistive Flow Sensor Using Vertical Graphene Nanosheets. Nano-Micro Lett. 2020, 12, 109. [Google Scholar] [CrossRef] [PubMed]

| Gas Used | Temp. (°C) | Growth Rate/Time | Method | Substrate | Observations | Ref. |

|---|---|---|---|---|---|---|

| CH4/H2 | 600–900 | ~several m/h | ICP-PECVD | Si, SiO2, Al2O3, Mo, Zr, Ti, Hf, Nb, W, Ta, Cu, stainless steel 304 | As temperature and CH4 concentration increased, the rate of growth increased. VG had a similar morphology on all surfaces. | [25] |

| C2F6, CH4, CF4, CHF3 or C4F8 with H2 | 500 | ~180 nm/h | CCP-PECVD + ICP for H radical injection | Si | C2F6/H2 > CHF3 > CH4 > CF4/H2. VG did not grow in C4F8/H2 gas. | [31] |

| CH4/H2 | - | ~8 m/h | MW-PECVD | SiO2 | The VG height varied according to a square root law over time. | [24] |

| CH4/He | 1000 | ~7 nm/min | DC-PECVD | Si | The size of the average and the thickness of the film both increased when the total plasma current was growing. | [40] |

| CH4/H2 | ~400 | up to 180 s | ECR-MW PECVD | SiO2, glass, Cu | The temperature required for deposition varied depending on the type of substrate material. | [41] |

| CH4/Ar | 625–800 | ~10 nm/min | ECR-PECVD | SiO2/Si | Enhanced VG growth rate and quality could be achieved by increasing the temperature of the substrate, reducing the distance between the MW source and the substrate, and boosting the MW power. It is worth noting that there was no growth observed below 625 °C. | [42] |

| CH4/H2 | 680 | 1 µm/20 min | RF PECVD | Cu, Si, and Si with a film of Ni or Au | The morphology of VG depended on the type of substrate. | [17] |

| Ar/CH4 | 750–900 | up to 10 min | CCP PECVD | Cu | As the substrate temperature, plasma power, and deposition time increased, the density of VG also increased. | [43] |

| aluminum acetylacetonate + Ar | 350, 425, 500 | 50 min | ICP PECVD | Stainless steel, Ni, Al, Si | The morphological features of VG were significantly impacted by the bias voltage, substrate temperature, and substrate material, evidenced by nanorods and thorny, straight, or curled VG being observed. | [44] |

| Ar/H2/CH4 | 520–550 | 12 nm/min | ICP PECVD | SiO2 | The quality of VG increased with plasma power and temperature. | [45] |

| p-xylene | 450 | 20 min | ICP-PECVD | Si coated with TiN | The formation of carbon nanostructures was found to be dependent on the rate of flow, resulting in the creation of three different structures: fibers, free-standing nanowalls, and interconnected nanowalls. | [46] |

| Ar/CH4 | 700 | ~300 nm/min in lateral size | Atmospheric DC PECVD | Polished stainless steel | The growth rate was much higher compared to low-pressure synthesis. | [19] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anghel, E.; Adiaconita, B.; Demetrescu, I.; Avram, A. A Review of Vertical Graphene and Its Biomedical Applications. Coatings 2023, 13, 761. https://doi.org/10.3390/coatings13040761

Anghel E, Adiaconita B, Demetrescu I, Avram A. A Review of Vertical Graphene and Its Biomedical Applications. Coatings. 2023; 13(4):761. https://doi.org/10.3390/coatings13040761

Chicago/Turabian StyleAnghel, Elena, Bianca Adiaconita, Ioana Demetrescu, and Andrei Avram. 2023. "A Review of Vertical Graphene and Its Biomedical Applications" Coatings 13, no. 4: 761. https://doi.org/10.3390/coatings13040761

APA StyleAnghel, E., Adiaconita, B., Demetrescu, I., & Avram, A. (2023). A Review of Vertical Graphene and Its Biomedical Applications. Coatings, 13(4), 761. https://doi.org/10.3390/coatings13040761