Investigations into Power Plant Alloys’ (Inconel 718) Oxidation Resistance by Compound Composite (Cr2O3 + YSZ) Coatings

Abstract

1. Introduction

2. Methods and Materials

2.1. Experimental Setup

2.2. Materials Selection

2.3. Sample Preparation for Coatings

2.4. Thermal Spray Coatings (TSC)

2.5. High-Temperature Oxidation

2.6. Testing and Evaluation

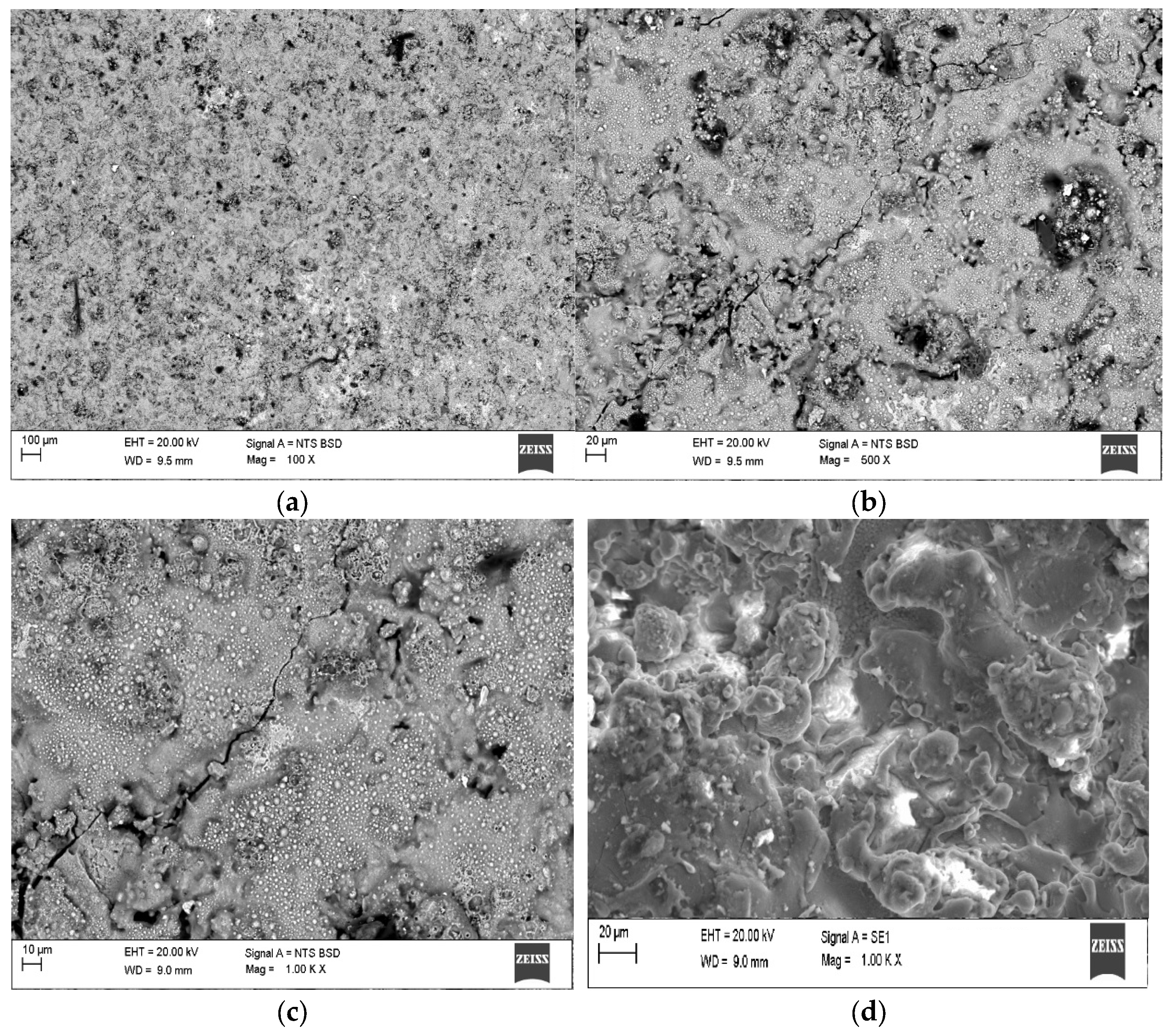

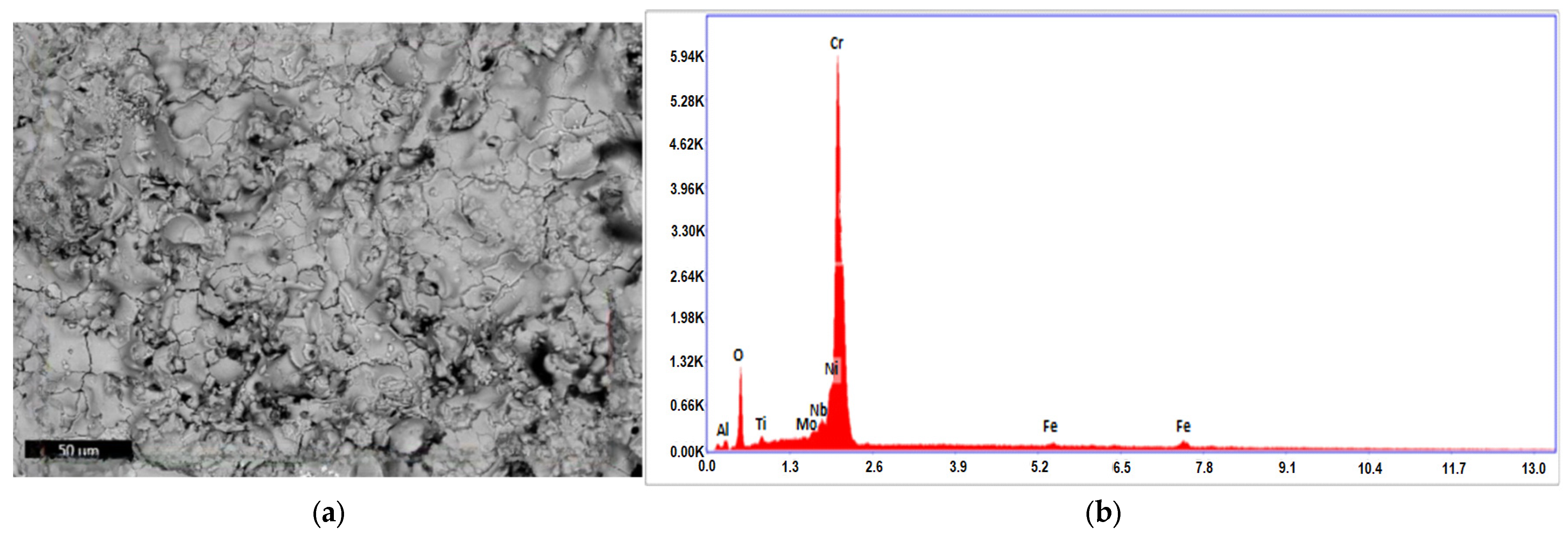

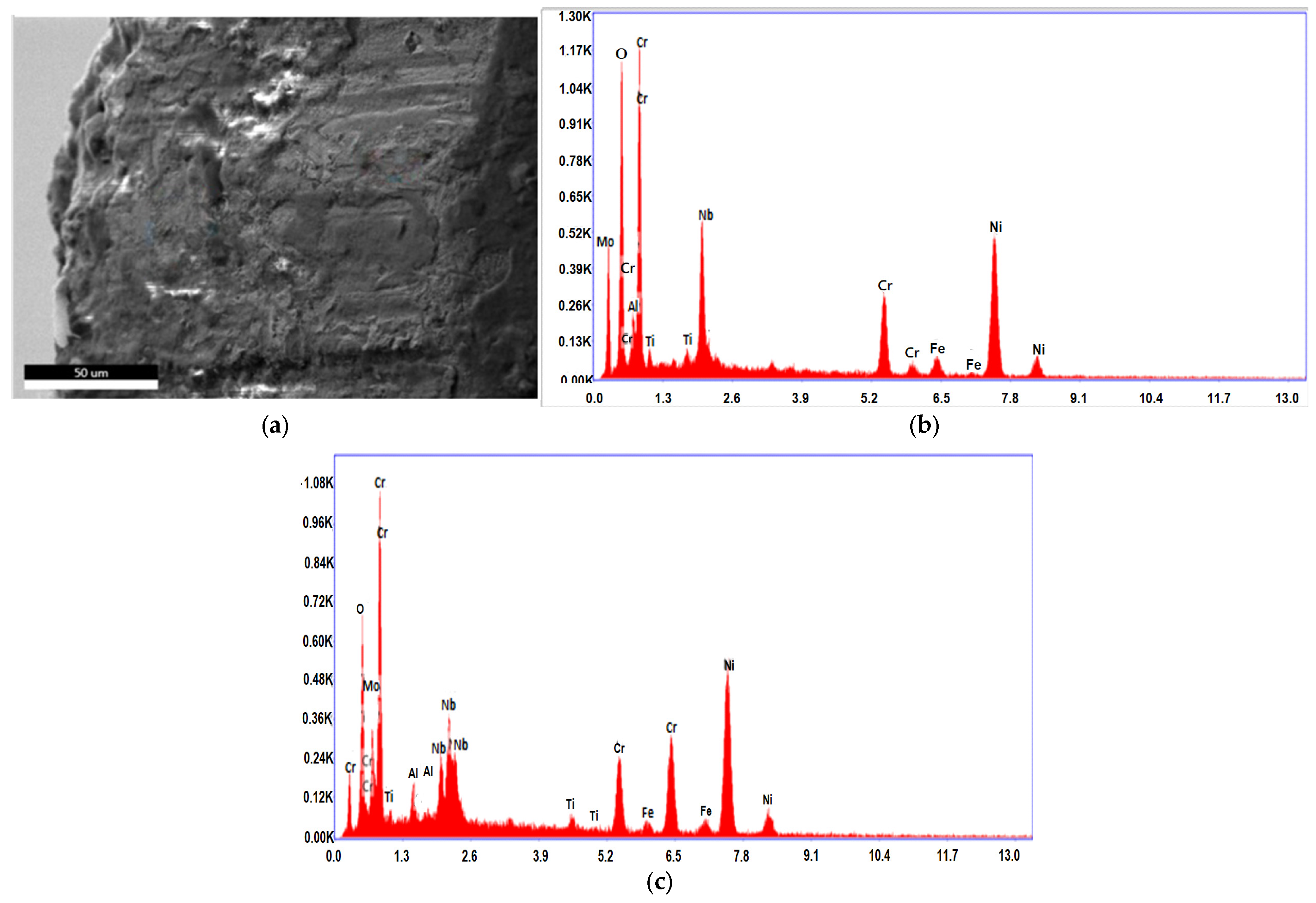

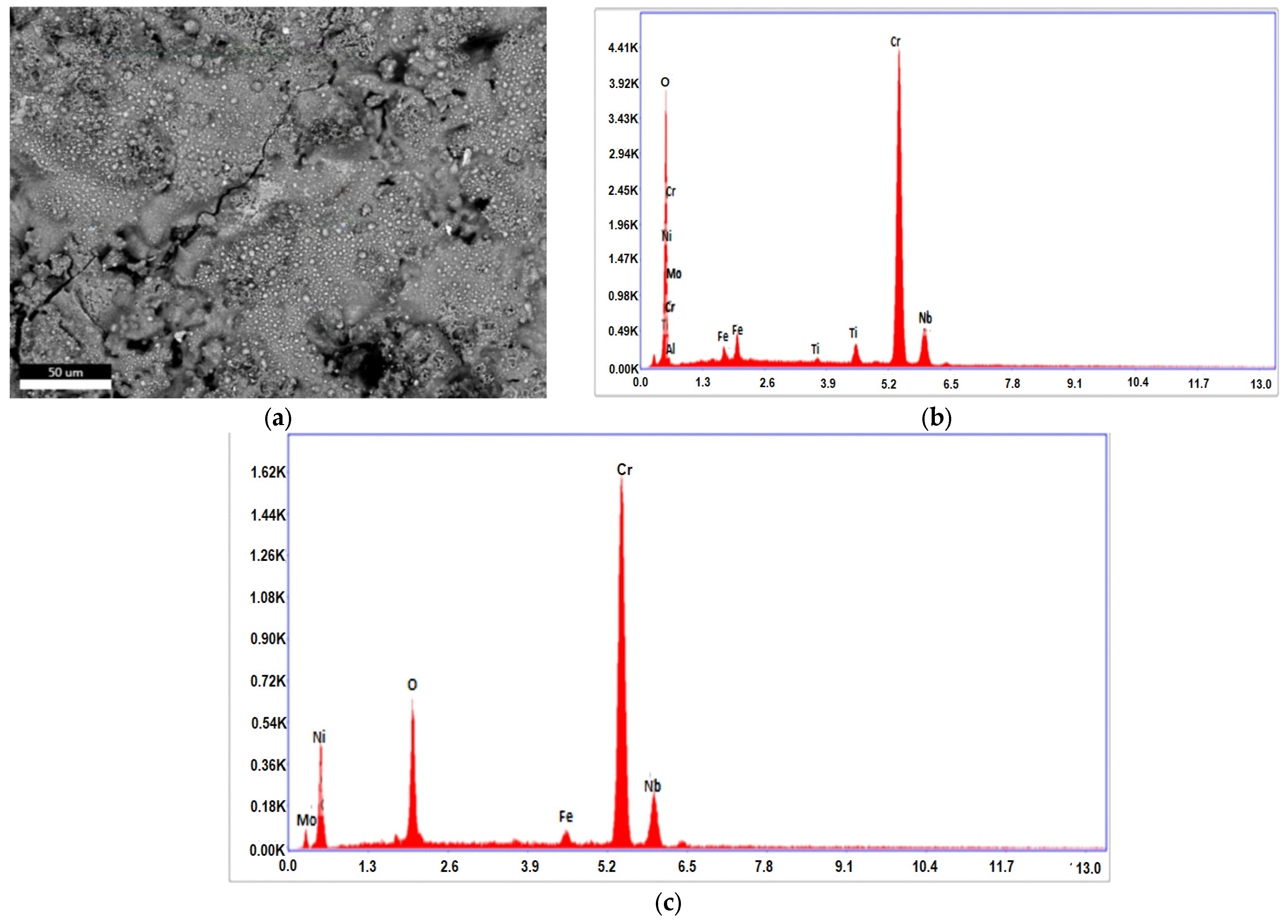

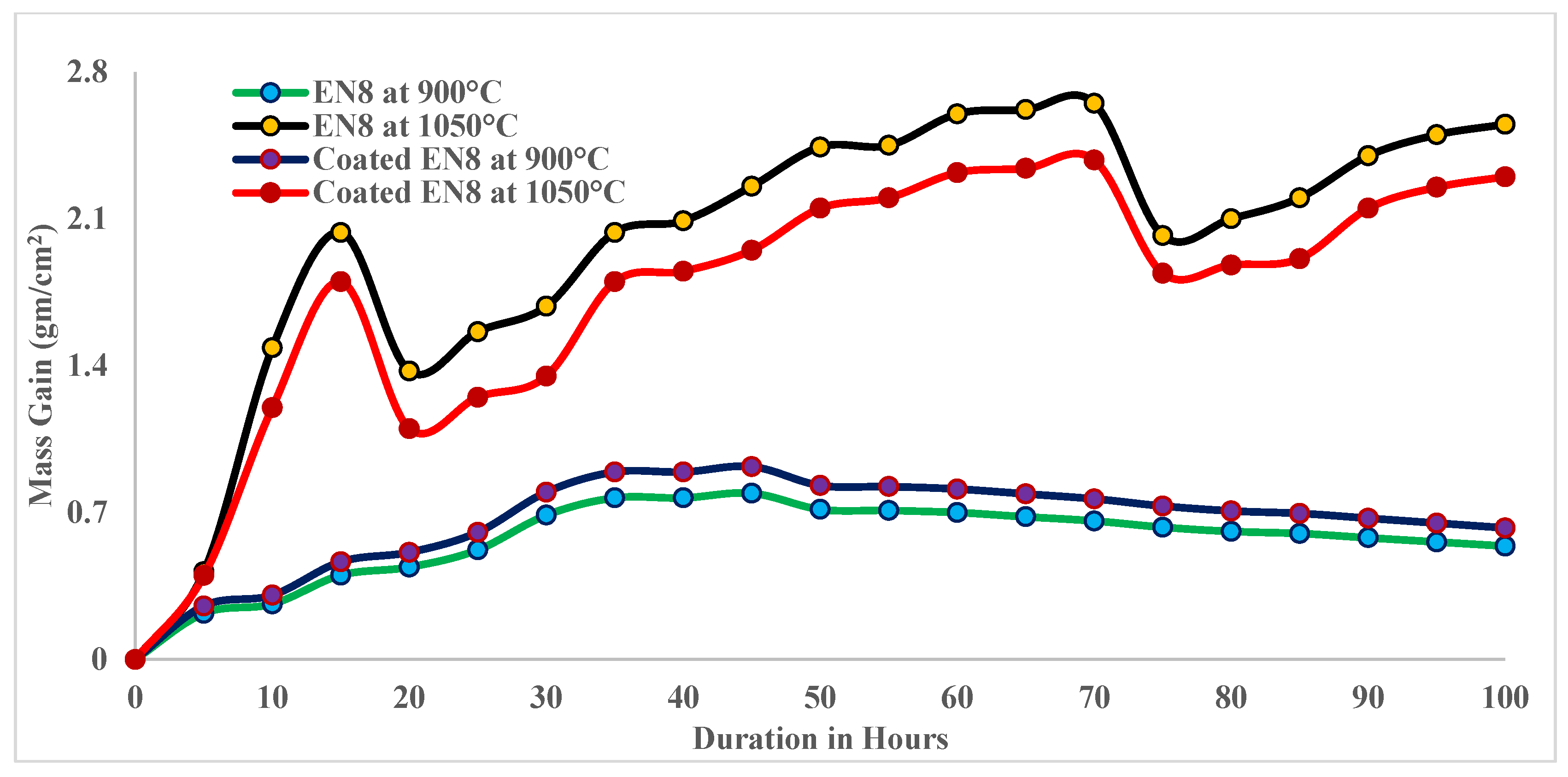

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fu, T.; Cui, K.; Zhang, Y.; Wang, J.; Shen, F.; Yu, L.; Qie, J.; Zhang, X. Oxidation Protection of Tungsten Alloys for Nuclear Fusion Applications: A Comprehensive Review. J. Alloys Compd. 2021, 884, 161057. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Thomas, A.; El-Wahabi, M.; Cabrera, J.M.; Prado, J.M. High Temperature Deformation of Inconel 718. J. Mater. Process. Technol. 2006, 177, 469–472. [Google Scholar] [CrossRef]

- Wright, I.; Gibbons, T. Recent Developments in Gas Turbine Materials and Technology and Their Implications for Syngas Firing. Int. J. Hydrog. Energy 2007, 32, 3610–3621. [Google Scholar] [CrossRef]

- Al-hatab, K.A.; Al-bukhaiti, M.A.; Krupp, U.; Kantehm, M. Cyclic Oxidation Behavior of in 718 Superalloy in Air at High Temperatures. Oxid. Met. 2010, 75, 209–228. [Google Scholar] [CrossRef]

- Mishra, T.; Datta, A.; Mukhopadhyay, A. Comparison of the Structures of Methane–Air and Propane–Air Partially Premixed Flames. Fuel 2006, 85, 1254–1263. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, T.; Cui, K.; Shen, F.; Wang, J.; Yu, L.; Mao, H. Evolution of Surface Morphology, Roughness and Texture of Tungsten Disilicide Coatings on Tungsten Substrate. Vacuum 2021, 191, 110297. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, K.; Fu, T.; Wang, J.; Shen, F.; Zhang, X.; Yu, L. Formation of MoSi2 and Si/MoSi2 Coatings on TZM (Mo–0.5Ti–0.1Zr–0.02C) Alloy by Hot Dip Silicon-Plating Method. Ceram. Int. 2021, 47, 23053–23065. [Google Scholar] [CrossRef]

- Basha, A.K.M.; Srinivasan, S.; Srinivasan, N. Studies on Thermally Grown Oxide as an Interface between Plasma-Sprayed Coatings and a Nickel-Based Superalloy Substrate. Int. J. Miner. Metall. Mater. 2017, 24, 681–690. [Google Scholar] [CrossRef]

- Chellaganesh, D.; Khan, M.A.; Winowlin Jappes, J.T. High Temperature Oxidation Behavior of Thermally Sprayed Alumina—Titania Coatings on Nickel Based Superalloys. Mater. Res. Express 2019, 6, 086521. [Google Scholar] [CrossRef]

- Asadullah, M.; Bhagyashekar, M.S.; Yunus, M. RSM Multi-Properties Optimization of Various Input Factors of Thermal Barrier Composites. Multiscale Multidiscip. Model. Exp. Des. 2021, 5, 67–80. [Google Scholar] [CrossRef]

- Lai, G.Y. High-Temperature Corrosion and Materials Applications; ASM International: Novelty, OH, USA, 2007. [Google Scholar]

- Wang, P.; Deng, S.; He, Y.; Liu, C.; Zhang, J. Oxidation and Hot Corrosion Behavior of Al2O3/YSZ Coatings Prepared by Cathode Plasma Electrolytic Deposition. Corros. Sci. 2016, 109, 13–21. [Google Scholar] [CrossRef]

- Yuan, L.; Hu, R.; Zhang, T.; Han, Y.; Xue, X.; Li, J. Precipitation Behavior of σ-FeCr Phases in Hastelloy C-2000 Superalloy under Plastic Deformation and Aging Treatment. J. Mater. Eng. Perform. 2014, 24, 565–571. [Google Scholar] [CrossRef]

- Doleker, K.M.; Odabas, O.; Ozgurluk, Y.; Askerov, H.; Karaoglanli, A.C. Effect of High Temperature Oxidation on Inconel 718 and Inconel 718/YSZ/Gd2Zr2O7. Mater. Res. Express 2019, 6, 086456. [Google Scholar] [CrossRef]

- Sun, L.; Berndt, C.C.; Gross, K.A.; Kucuk, A. Material Fundamentals and Clinical Performance of Plasma-Sprayed Hydroxyapatite Coatings: A Review. J. Biomed. Mater. Res. 2001, 58, 570–592. [Google Scholar] [CrossRef]

- Doleker, K.M.; Ozgurluk, Y.; Ahlatci, H.; Karaoglanli, A.C. Evaluation of Oxidation and Thermal Cyclic Behavior of YSZ, Gd2Zr2O7 and YSZ/Gd2Zr2O7 TBCs. Surf. Coat. Technol. 2019, 371, 262–275. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, C.; Lan, H.; Du, L.; Zhang, W. Oxidation and Hot Corrosion Behavior of Plasma-Sprayed MCrAlY–Cr2O3 Coatings. J. Therm. Spray Technol. 2016, 25, 1208–1216. [Google Scholar] [CrossRef]

- Jian, L.; Yuh, C.Y.; Farooque, M. Oxidation Behavior of Superalloys in Oxidizing and Reducing Environments. Corros. Sci. 2000, 42, 1573–1585. [Google Scholar] [CrossRef]

- Greene, G.A.; Finfrock, C.C. Oxidation of Inconel 718 in Air at High Temperatures. Oxid. Met. 2001, 55, 505–521. [Google Scholar] [CrossRef]

- Delaunay, F.; Berthier, C.; Lenglet, M.; Lameille, J.-M. SEM-EDS and XPS Studies of the High Temperature Oxidation Behaviour of Inconel 718. Microchim. Acta 2000, 132, 337–343. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective Laser Melting Additive Manufactured Inconel 718 Superalloy Parts: High-Temperature Oxidation Property and Its Mechanisms. Opt. Laser Technol. 2014, 62, 161–171. [Google Scholar] [CrossRef]

- Fox, A.C.; Clyne, T.W. Oxygen Transport by Gas Permeation through the Zirconia Layer in Plasma Sprayed Thermal Barrier Coatings. Surf. Coat. Technol. 2004, 184, 311–321. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P. Thermal Conductivity and Thermal Cyclic Fatigue of Multilayered Gd2Zr2O7/YSZ Thermal Barrier Coatings Processed by Suspension Plasma Spray. Surf. Coat. Technol. 2015, 283, 329–336. [Google Scholar] [CrossRef]

- Leckie, R.M.; Krämer, S.; Rühle, M.; Levi, C.G. Thermochemical Compatibility between Alumina and ZrO2–GdO3/2 Thermal Barrier Coatings. Acta Mater. 2005, 53, 3281–3292. [Google Scholar] [CrossRef]

- Adam Khan, M.; Sundarrajan, S.; Natarajan, S. Influence of Plasma Coatings on Inconel 617 for Gas Turbine Applications. Surf. Eng. 2014, 30, 656–661. [Google Scholar] [CrossRef]

- Asadullah, M.; Yunus, M. Optimization of Coating Thickness for various Properties of Composite type Thermal Barrier Coated with INCONEL 718 Alloy. High Temp. Mater. Process. Int. Q. High-Technol. Plasma Process. 2019, 23, 377–389. [Google Scholar] [CrossRef]

- Softah, G.J. Characterization and Performance Study of DCMD in Different Configurations after Membrane Thermal Treatment. J. Umm Al-Qura Univ. Eng. Archit. 2020, 11, 33–38. [Google Scholar]

- Mohammed, W.A.; Ahmed, H.B. Influence of Infill density and Orientation on the Mechanical Response of PLA+ Specimens Produced using FDM 3D Printing. Int. J. Adv. Sci. Technol. 2020, 29, 3362–3371. [Google Scholar]

- Padhan, S.; Das, S.R.; Das, A.; Alsoufi, M.S.; Ibrahim, A.M.M.; Elsheikh, A. Machinability Investigation of Nitronic 60 Steel Turning Using SiAlON Ceramic Tools under Different Cooling/Lubrication Conditions. Materials 2022, 15, 2368. [Google Scholar] [CrossRef]

| EN8 | Ni | Fe | Cr | Nb | Mo | Ti | Al | Si | C | Co | Cu & W |

|---|---|---|---|---|---|---|---|---|---|---|---|

| In wt% | 54 | 17.26 | 18 | 5.31 | 3.03 | 0.96 | 0.56 | 0.09 | 0.005 | 0.16 | 0.350 & 0.278 |

| Materials | Zr (wt%) | Cr (wt%) | Ni (wt%) | O (wt%) | Y (wt%) | Al (wt%) |

|---|---|---|---|---|---|---|

| YSZ (Inner) | 68.1 | - | - | 28.7 | 3.2 | - |

| Cr2O3 (Exterior) | - | 74 | - | 26 | - | - |

| NiCrAlY (bond) | - | 15–25 | 59.5–74.8 | - | 0.2–0.5 | 10–15 |

| S. No. | Spray Settings | Spraying Condition | Units |

|---|---|---|---|

| 1 | Plasma-Arc-current | 500 | A |

| 2 | Arc-Voltage | 65–75 | V |

| 3 | Plasma Gas (Argon) Flow rate | 78–90 | L/min |

| 4 | Secondary gas (Hydrogen) Flow rate | 1.8–2.4 | L/min |

| 5 | Plasma Gas (Argon) Pressure | 0.70–0.80 | MPa |

| 6 | Secondary gas (Hydrogen) Pressure | 0.35 | MPa |

| 7 | Power feed rate | 39.6–50 | g/min |

| 8 | Torch to base (standoff) distance | 100–125 | mm |

| Elements | Coated EN8 for 12 h at 900 °C (wt.%) | Coated EN8 for 24 h (wt.%) | Coated EN8 at 48 h (wt.%) | Coated EN8 at 100 h (wt.%) | |||

|---|---|---|---|---|---|---|---|

| At 900 °C | At 1050 °C | At 900 °C | At 1050 °C | At 900 °C | At 1050 °C | ||

| O | 26.75 | 28.91 | 29.27 | 26.94 | 26.51 | 18.62 | 14.51 |

| Ni | 8.03 | 7.35 | 5.1 | 7.4 | 4.6 | 5.27 | 7.17 |

| Nb | 4.52 | 3.87 | 3.2 | 3.26 | 2.1 | 2.18 | 2.12 |

| Mo | 3.71 | 3.84 | 3.0 | 2.1 | 2.2 | 1.75 | 2.1 |

| Ti | 0.74 | 0.75 | 1.2 | 1.1 | 1.4 | 1.2 | 0.8 |

| Cr | 51.74 | 53.29 | 55.93 | 56.4 | 60.1 | 68.75 | 71.07 |

| Fe | 2.3 | 0.71 | 1.1 | 1.3 | 1.2 | 1.03 | 1.05 |

| Al | 2.2 | 1.3 | 1.2 | 1.5 | 1.89 | 1.2 | 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yunus, M.; Alfattani, R.A.; Alamro, T.; Asadullah, M. Investigations into Power Plant Alloys’ (Inconel 718) Oxidation Resistance by Compound Composite (Cr2O3 + YSZ) Coatings. Coatings 2023, 13, 744. https://doi.org/10.3390/coatings13040744

Yunus M, Alfattani RA, Alamro T, Asadullah M. Investigations into Power Plant Alloys’ (Inconel 718) Oxidation Resistance by Compound Composite (Cr2O3 + YSZ) Coatings. Coatings. 2023; 13(4):744. https://doi.org/10.3390/coatings13040744

Chicago/Turabian StyleYunus, Mohammed, Rami A. Alfattani, Turki Alamro, and Mohammed Asadullah. 2023. "Investigations into Power Plant Alloys’ (Inconel 718) Oxidation Resistance by Compound Composite (Cr2O3 + YSZ) Coatings" Coatings 13, no. 4: 744. https://doi.org/10.3390/coatings13040744

APA StyleYunus, M., Alfattani, R. A., Alamro, T., & Asadullah, M. (2023). Investigations into Power Plant Alloys’ (Inconel 718) Oxidation Resistance by Compound Composite (Cr2O3 + YSZ) Coatings. Coatings, 13(4), 744. https://doi.org/10.3390/coatings13040744