Comparative Analysis of Strength Fatigue Properties and Abrasive Wear Resistance for a New Composition of Polymer Concrete Coated with Metal Alloy Powders

Abstract

1. Introduction

2. Materials and Methods

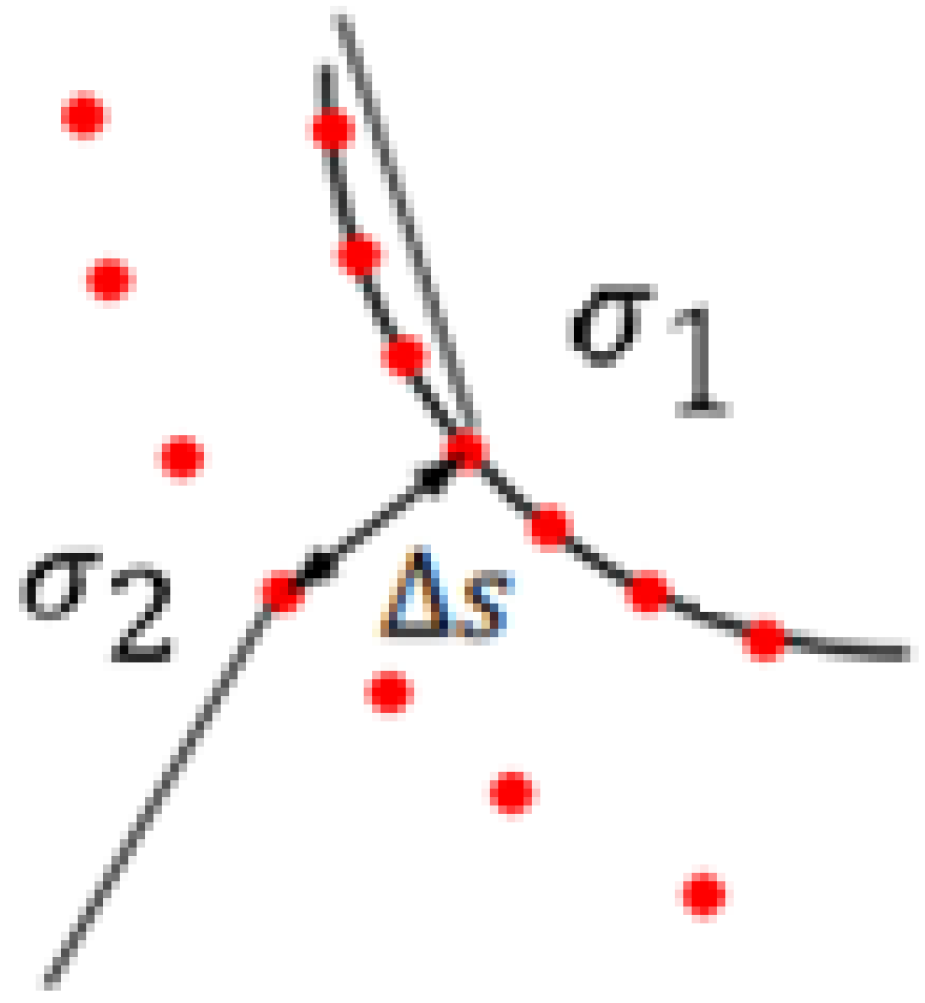

2.1. Study of the Mechanical Properties of Polymer Concrete of Various Grades

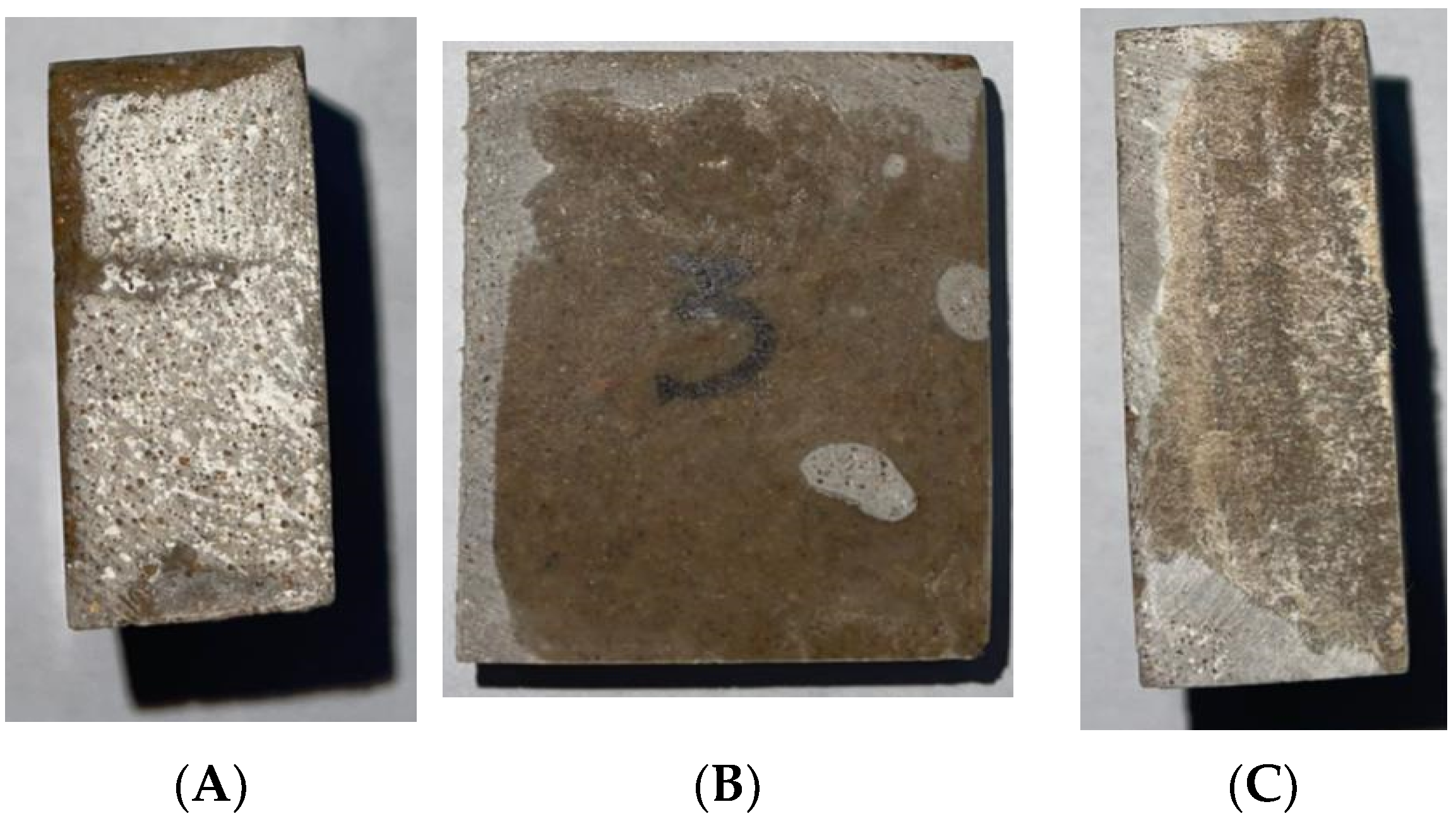

2.1.1. Sample Preparation

- –

- the effect of changing the composition of the polymer-concrete material on its mechanical properties;

- –

- the effect of changing polymer-concrete variables on its mechanical properties;

- MMA compound is an elastic compound with the following advantages: resistance to vibration and movement of the substrate, good wear resistance, high impact resistance, and resistant to many chemicals designed for heavy loads [29].

- Polyethylene-polyamine (PEPA) is a hardener that provides higher physical and mechanical properties, greater heat resistance, and low exothermicity [30].

- (1)

- mixing of components;

- (2)

- casting into a special mold;

- (3)

- compacting on a vibro-table;

- (4)

- finishing operations.

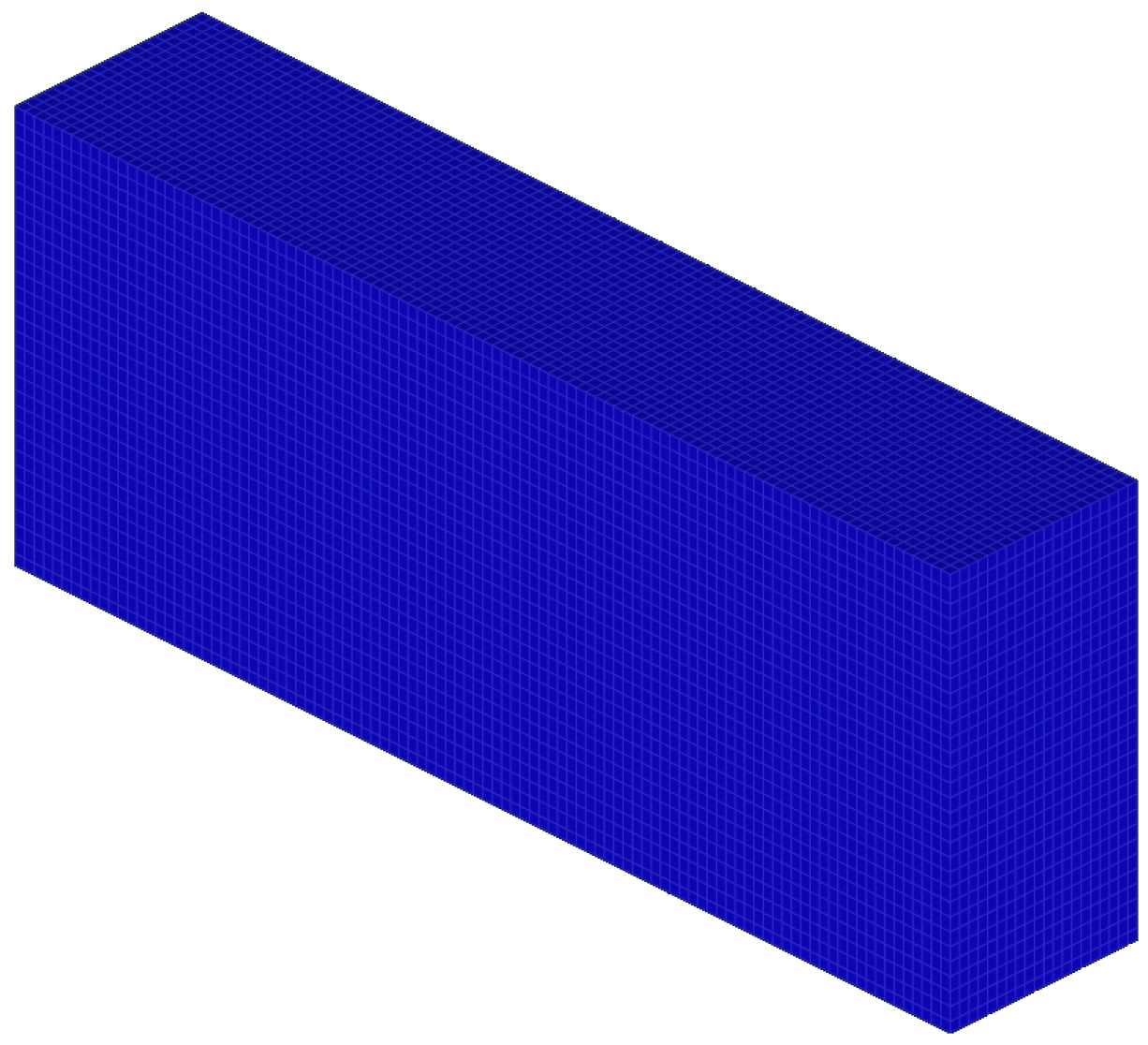

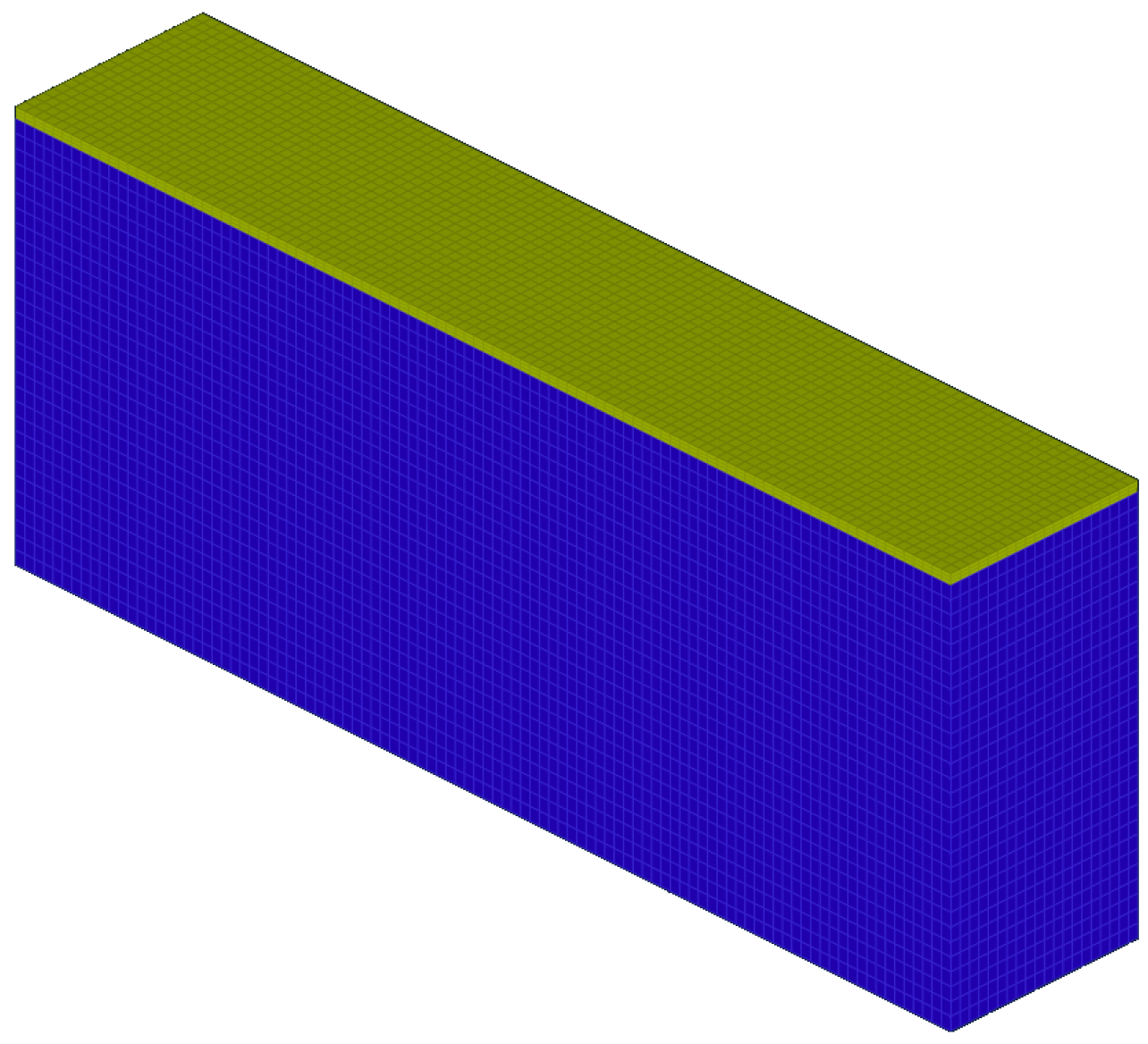

2.1.2. Conducting an Experiment

- (1)

- the values of gravity and axial force in the range of 50 kN;

- (2)

- geometric parameters of the sample—200 × 500 × 100 mm;

- (3)

- (4)

- the ambient temperature was 30 °C.

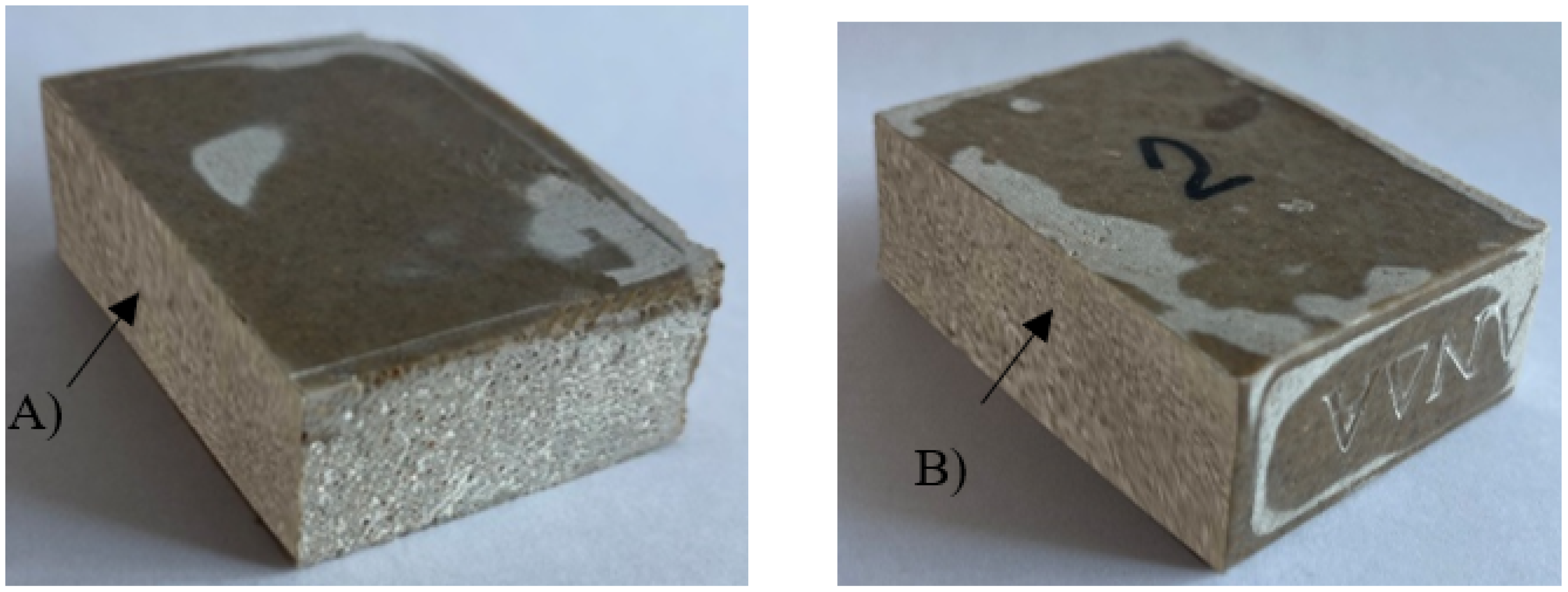

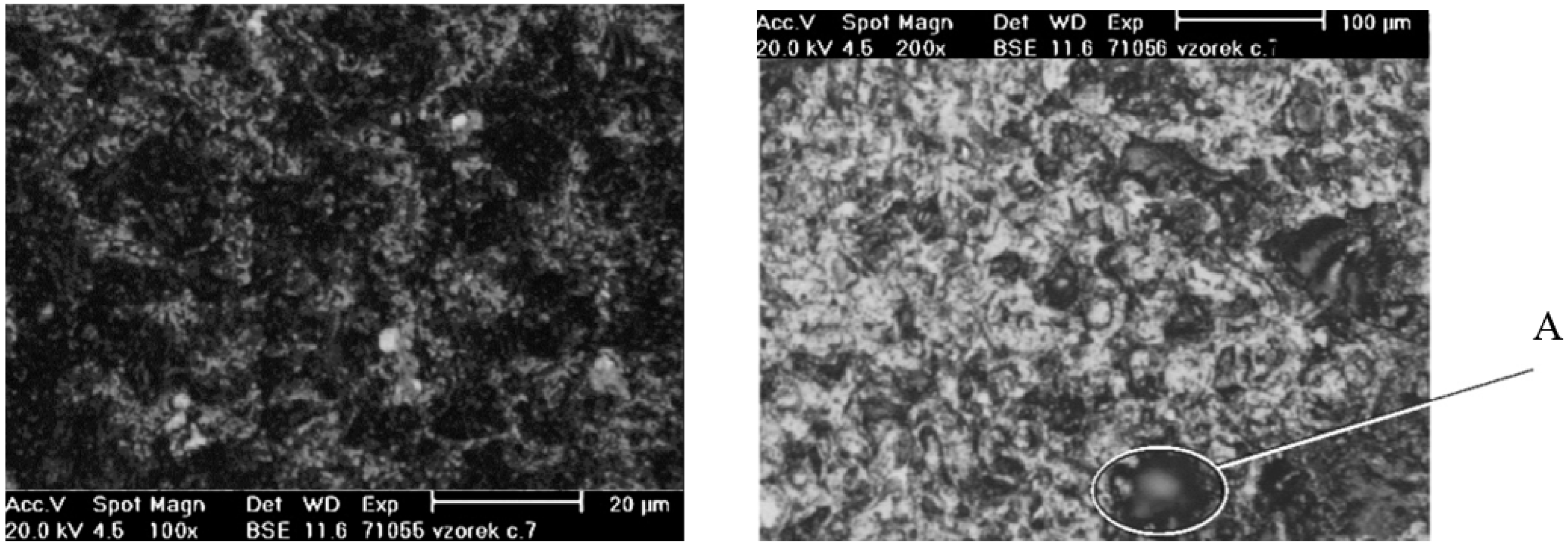

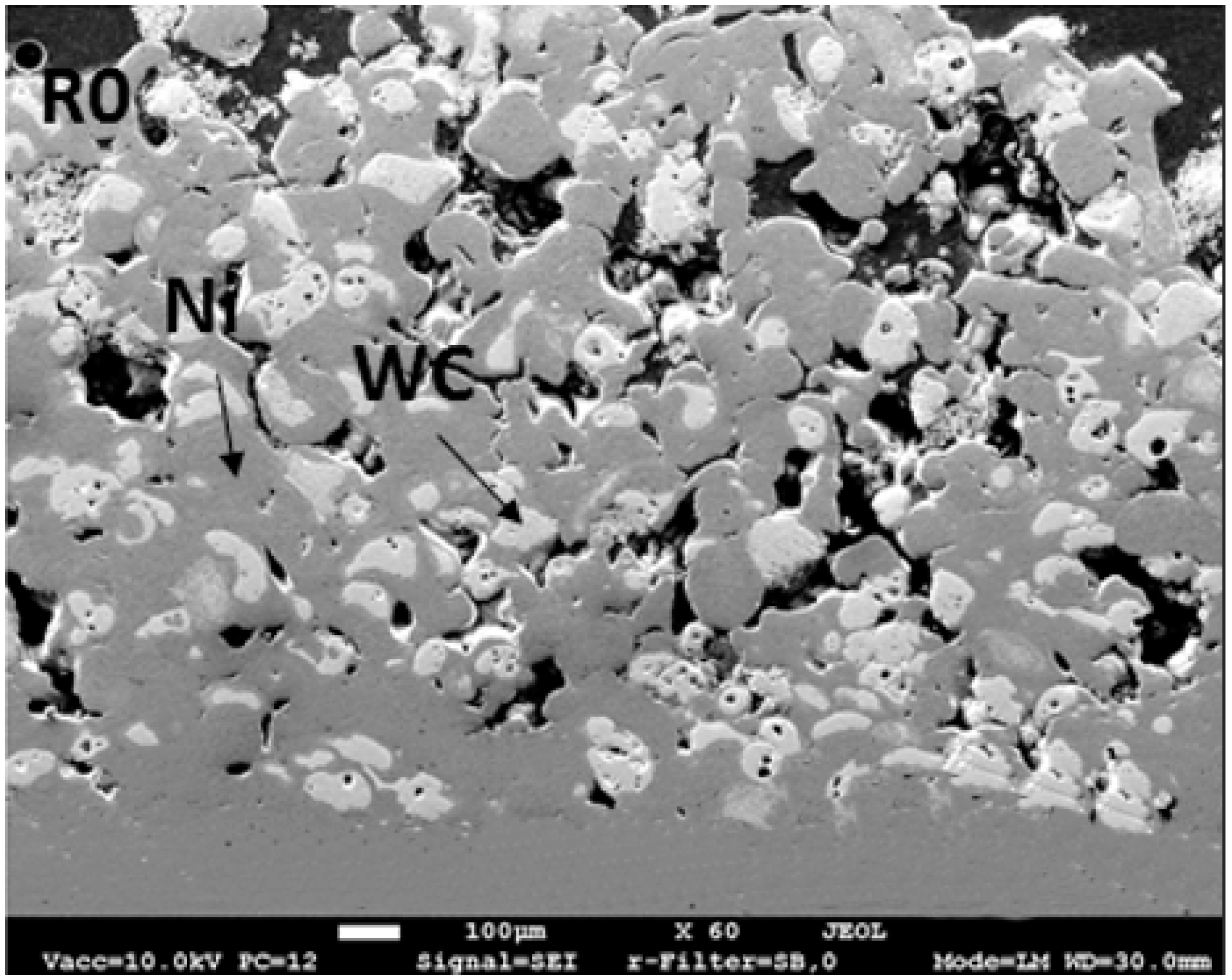

2.2. Experiments on the Deposition of Coatings and Studying the Properties of the Obtained Layers

- (1)

- META Ceram 28010 (Castolin Eutectic, Dublin, Ireland);

- (2)

- Eutalloy SF PE 8215 (Castolin Eutectic, Dublin, Ireland).

- –

- low electrical conductivity;

- –

- high resistance to wear;

- –

- high hardness;

- –

- high protection against corrosion;

- –

- low coefficient of friction.

- (1)

- the values of gravity and axial force in the range of 50 kN;

- (2)

- the geometric parameters of the sample—200 × 500 × 100 mm;

- (3)

- the ambient temperature was 20 ± 5 °C.

- (4)

- the sample compositions according to Table 2.

- (5)

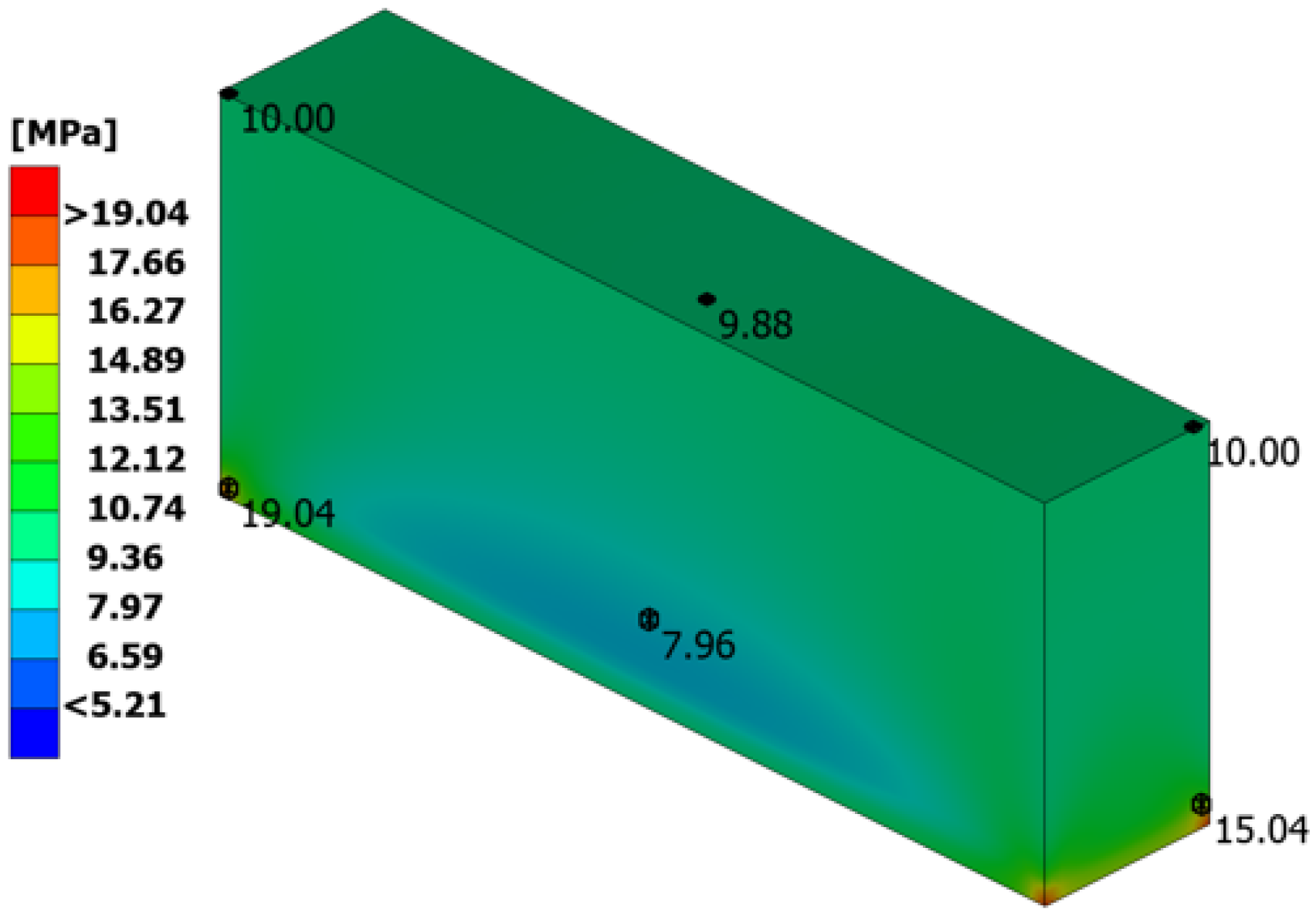

3. Results

4. Discussion

5. Conclusions

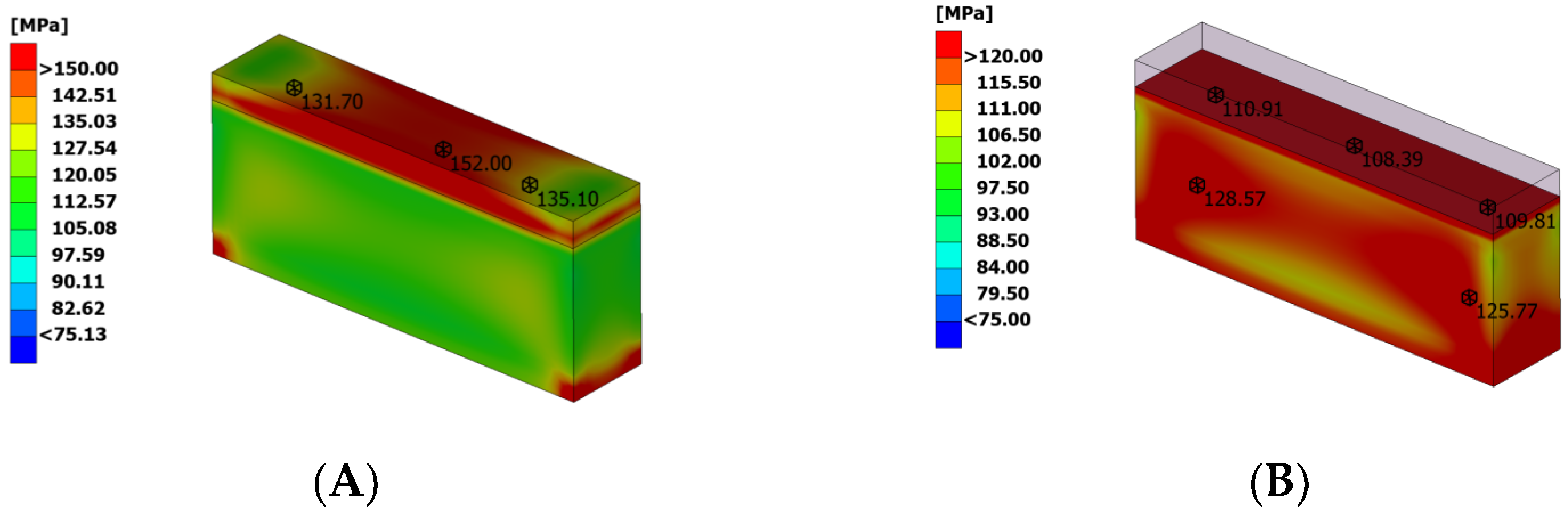

- The use of thermally sprayed surfaces on polymer concrete machine tool frames can reduce internal stresses by approximately 21.6% and increase fatigue strength from 14% to 21% (depending on the type of composition).

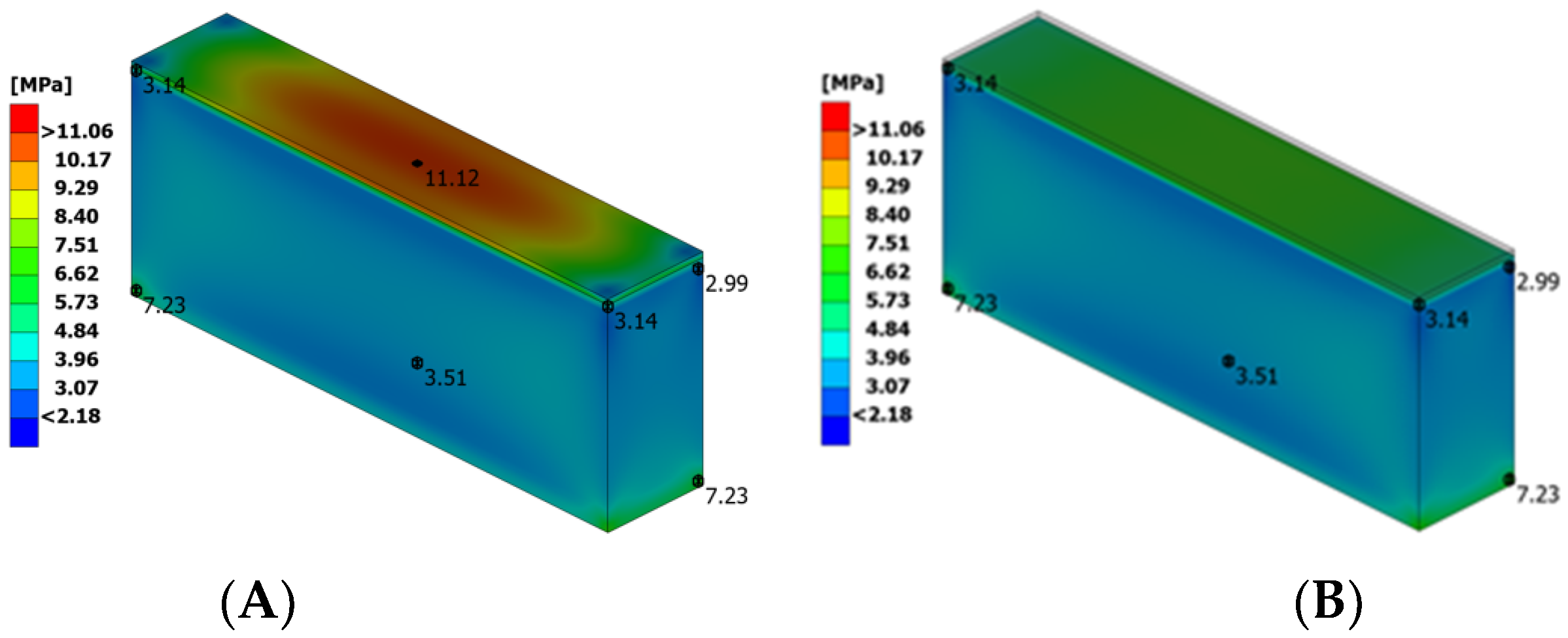

- When comparing the impacts of the use of 7Cr-3Fe + 60% WC and Cr2O3 thermal coatings, it can be seen that the first can be characterized by a greater reduction in internal stresses (11.12 MPa and 17.65 MPa, respectively) of 37%. Polymer concrete without Ni-7Cr-3Fe + 60% WC coating is characterized by a lower fatigue strength of 63% (36 MPa and 100 MPa, respectively).

- The applied coating also increased wear resistance by 12%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Haddad, H.; Al Kobaisi, M. Optimization of the Polymer Concrete Used for Manufacturing Bases for Precision Tool Machines. Compos. Part B Eng. 2012, 43, 3061–3068. [Google Scholar] [CrossRef]

- Shafei, B.; Kazemian, M.; Dopko, M.; Najimi, M. State-of-the-Art Review of Capabilities and Limitations of Polymer and Glass Fibers Used for Fiber-Reinforced Concrete. Materials 2021, 14, 409. [Google Scholar] [CrossRef]

- Shiravi, M.M.; Eftekhar, M.R.; Hamadani, A.Z. Establishing an empirical relation between the compressive, tensile, and flexural strengths of polymer concrete. Innov. Infrastruct. Solut. 2023, 8, 87. [Google Scholar] [CrossRef]

- Struk, V.A.; Kravchenko, V.I.; Kostyukovich, G.A.; Skaskevich, A.A. Composite polymeric coatings for reconditioning friction units of machines and process equipment. Trenie Iznos 2002, 23, 329–333. [Google Scholar]

- Vipulanandan, C.; Paul, E. Characterisation of polyester polymer and polymer concrete. J. Mater. Civ. Eng. 1993, 5, 62–82. [Google Scholar] [CrossRef]

- Sanaei Ataabadi, H.; Arash Sedaghatdoost, A.; Rahmani, H.; Zare, A. Microstructural characterization and mechanical properties of lightweight polymer concrete exposed to elevated temperatures. Constr. Build. Mater. 2021, 311, 125293. [Google Scholar] [CrossRef]

- Jafari, K.; Tabatabaeian, M.; Joshaghani, A.; Ozbakkaloglu, T. Optimizing the mixture design of polymer concrete: An experimental investigation. Constr. Build. Mater. 2018, 167, 185–196. [Google Scholar] [CrossRef]

- Zhetessova, G.; Nikonova, T.; Gierz, Ł.; Berg, A.; Yurchenko, V.; Zharkevich, O.; Alexey, K. A Comparative Analysis of the Dynamic Strength Properties of the Long Guides of Intelligent Machines for a New Method of the Thermal Spraying of Polymer Concrete. Appl. Sci. 2022, 12, 10376. [Google Scholar] [CrossRef]

- Ergun, A.; Mahmut, N.G. Usability of Polymer Concrete as a Machine-Making Material Regarding Fatigue Strength. World J. Eng. Technol. 2013, 1, 59–64. [Google Scholar] [CrossRef]

- Abbasnejadfard, M.; Morteza Bastami, M.; Hashemi, S.-A. Experimental investigation on the stress-strain behavior of unsaturated polyester polymer concrete subjected to monotonic and cyclic loadings. J. Build. Eng. 2022, 48, 103966. [Google Scholar] [CrossRef]

- Rebeiz, K.S. Precast use of polymer concrete using unsaturated polyester resin based on reccles PET waste. Constr. Build. Mater. 1996, 10, 215–220. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Mebarkia, S. Aggregates, fibers and coupling agents in polymer concrete. In Proceedings of the 1st Materials Engineering Conference, Denver, CO, USA, 13–15 August 1990; pp. 785–794. [Google Scholar]

- Okada, K.; Yonezawa, T. Thermo dependent properties of polyester resin concrete. J. Soc. Mater. Sci. Jpn. 1975, 24, 394–400. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Dharmarajan, N.; Ching, E. Mechanical behaviour of polymer concrete systems. Mater. Struct. 1988, 21, 268–277. [Google Scholar] [CrossRef]

- Bruni, C.; Forcellese, A.; Gabrielli, F.; Simoncini, M. Hard turning of an alloy steel on a machine tool with a polymer concrete bed. J. Mater. Process. Technol. 2008, 202, 493–499. [Google Scholar] [CrossRef]

- Vrtanoski, G.; Dukovski, V. Design of polymer concrete main spindle housing for CNC lathe. In Proceedings of the 13th International Scientific Conference on Achievements of Mechanical and Materials Engineering, Gliwice, Poland, 13–16 June 2005; pp. 696–698. [Google Scholar]

- Cortes, F.; Castillo, G. Comparison between the dynamical properties of polymer concrete and grey cast iron. Mater. Des. 2007, 28, 1461–1466. [Google Scholar] [CrossRef]

- Suh, J.D.; Lee, D.G. Design and manufacture of hybrid polymer concrete bed for high-speed CNC milling machine. Int. J. Mech. Mater. Des. 2008, 4, 113–121. [Google Scholar] [CrossRef]

- Sezan, O. Investigation of vibration damping on polymer concrete with polyester resin. Cem. Concr. Res. 2000, 30, 171–174. [Google Scholar] [CrossRef]

- Suh, J.D.; Lee, D.G.; Kegg, R. Composite Machine Tool Structures for High Speed Milling Machines. CIRP Ann. Manuf. Technol. 2002, 51, 285–288. [Google Scholar] [CrossRef]

- Yin, J.; Zhang, J.; Wang, W. Effective resin content and its effect on the overall performance of polymer concrete for precision machine tools. Constr. Build. Mater. 2019, 222, 203–212. [Google Scholar] [CrossRef]

- Hassani Niaki, M.; Fereidoon, A.; Ghorbanzadeh Ahangari, M. Mechanical properties of epoxy/basalt polymer concrete: Experimental and analytical study. Struct. Concr. 2018, 19, 366–373. [Google Scholar] [CrossRef]

- Möhring, H.-C. Composites in Production Machines. Procedia CIRP 2017, 66, 2–9. [Google Scholar] [CrossRef]

- Mula, V.R.; Ramachandran, A.; Pudukarai Ramasamy, T. A review on epoxy granite reinforced polymer composites in machine tool structures—Static, dynamic and thermal characteristics. Polym. Compos. 2023; Early View. [Google Scholar] [CrossRef]

- Mayr, J.; Jedrzejewski, J.; Uhlmann, E.; Donmez, M.A.; Knapp, W.; Hartig, F.; Wendt, K.; Moriwaki, T.; Shore, P.; Schmitt, R.; et al. Thermal issues in machine tools. CIRP Ann. Manuf. Technol. 2012, 61, 771–791. [Google Scholar] [CrossRef]

- Hameed, A.M.; Hamza, M.T. Characteristics of polymer concrete produced from wasted construction materials. Energy Procedia 2019, 157, 43–50. [Google Scholar] [CrossRef]

- Lokuge, W.; Aravinthan, T. Effect of fly ash on the behaviour of polymer concrete with different types of resin. Mater. Des. 2013, 51, 175–181. [Google Scholar] [CrossRef]

- Jafari, K.; Toufigh, V. Experimental and analytical evaluation of rubberized polymer concrete. Constr. Build. Mater. 2017, 155, 495–510. [Google Scholar] [CrossRef]

- Kuenzel, C.; Grover, L.M.; Vandeperre, L.; Boccaccini, A.R.; Cheeseman, C.R. Production of nepheline/quartz ceramics from geopolymer mortars. J. Eur. Ceram. Soc. 2013, 33, 251–258. [Google Scholar] [CrossRef]

- Sorokin, V.; Avdeychik, S.; Struk, V.; Antonov, A. Activation of components functional polymer materials according to energy technologies. In Proceedings of the 21st International Scientific Conference: Mechanika, Kaunas, Lithuania, 12–13 May 2016; pp. 241–244. Available online: https://elib.grsu.by/doc/19511 (accessed on 25 December 2022).

- Cao, J.; Luo, Y. Study on tribological properties of epoxy resin composites. J. Phys. Conf. Ser. 2022, 2256, 012014. [Google Scholar] [CrossRef]

- Kumar, M.S.; Raju NM, S.; Sampath, P.S.; Vivek, U. Tribological analysis of nano clay/epoxy/glass fiber by using Taguchi’s technique. Mater. Des. 2015, 70, 1–9. [Google Scholar] [CrossRef]

- Ciaran McSwiggan, A.F. Bio-based resins for flexural strengthening of reinforced concrete beams with FRP sheets. Constr. Build. Mater. 2017, 131, 618–629. [Google Scholar] [CrossRef]

- Foruzanmehr, M.; Elkoun, S.; Fam, A.; Robert, M. Degradation characteristics of new bio-resin based-fiber-reinforced polymers for external rehabilitation of structures. J. Compos. Mater. 2016, 50, 1227–1239. [Google Scholar] [CrossRef]

- Available online: https://www.beta-cae.com/why_ansa_meta.htm (accessed on 20 December 2022).

- Rennert, R.; Kulling, E. Rechnerischer Festigkeitsnachwe1s fur Maschinenbauteile aus Stahl, Eisenguss- und Aluminiumwerkstoffen; Forschungskuratorium Maschincnbau (FKM): Frankfurt, Germany, 2020; p. 230. [Google Scholar]

- Nikonova, T.Y.; Zhetesova, G.S.; Yurchenko, V.V.; Zharkevich, O.M.; Zhunuspekov, D.S.; Kalinin, A.A. Calculation of Technological. Parameters of Coating Application during Gas Thermal Treatment (Certificate for an Object Protected by the Law of the Republic of Kazakhstan), No. 27846. 2022. Available online: https://copyright.kazpatent.kz/?!.iD=zXkt (accessed on 15 January 2023).

| Consumption of Composition No. 15 | |||

|---|---|---|---|

| Components | Fraction, mm | % | kg/m3 |

| Sand: quartz gabbro | 0.14–1.25 0.315–1.25 | 31.0–55.0 – | 1145–1165 – |

| Filler | 0.14 | 26.5–27.5 | 560–580 |

| Epoxy resin | – | 8–9 | 170–190 |

| Fam resin | – | 8–9 | 170–190 |

| Polyethylene-polyamine (PEPA) | – | 3.2–3.6 | 68–76 |

| MMA compound | – | – | – |

| Consumption of Composition No. 23 | |||

|---|---|---|---|

| Components | Fraction, mm | % | kg/m3 |

| Sand: quartz gabbro | 0.14–2.5 0.315–2.5 | 57.0–58.5 – | 1225–1260 – |

| Filler | 0.14 | 24–25 | 515–540 |

| FAM resin | – | 7–8 | 150–170 |

| Epoxy resin ED–20 | – | 7–8 | 150–170 |

| Polyethylene-polyamine (PEPA) | – | 2.8–3.2 | 60–69 |

| Sand: quartz gabbro | 0.14–2.5 0.315–2.5 | 57.0–58.5 – | 1225–1260 – |

| Material Properties | |

|---|---|

| Material grade | pol |

| Tensile strength, MPa | Rm = 120 |

| Yield strength, MPa | Rp02 = 90 |

| Roughness (Default–200) | Rz = 200 |

| Material Fatigue Strength | σW,zd = 36 |

| Related Stress Gradient | Gσ = −0.014286 |

| Roughness Factor | KR,σ = 1.0452447 |

| Construction Factors | KWK,σ = 1.0033647 |

| Component Fatigue Strength | σW,K = 35.879276 |

| Material Fatigue Strength | σW,zd = 36 |

| Related Stress Gradient | Gσ = −0.009625 |

| Roughness Factor | KR,σ = 1.0452447 |

| Construction Factors | KWK,σ = 0.9876545 |

| Component Fatigue Strength | σW,K = 36.449979 |

| Stress Value (Polymer Concrete No. 23) | ||

|---|---|---|

| σmax, MPa | 19.04 | |

| σmin, MPa | −19.04 | |

| intermediate results (polymer concrete No. 23) | ||

| Stress amplitudes, MPa | σa = 19.04 | |

| Load type | R = −1 | |

| Stress sensitivity | Mσ = 0.172 | |

| Medium stress factor | KAK,σ = 1 | |

| Fatigue strength, MPa | σA,K = 35.87927604 | |

| Medium Stress, MPa | σm = 0 | |

| stress value (polymer concrete No. 15) | ||

| σmax, MPa | 20.9 | |

| σmin, MPa | −20.9 | |

| intermediate results (polymer concrete No. 15) | ||

| Stress amplitudes, MPa | σa = 20.9 | |

| Load type | R = −1 | |

| Stress sensitivity | Mσ = 0.172 | |

| Medium stress factor | KAK,σ = 1 | |

| Fatigue strength, MPa | σA,K = 36.44997973 | |

| Medium Stress, MPa | σm = 0 | |

| Number of Cycles (Default Number Work Cycles 4 × 106). | |

|---|---|

| N | 5,000,000 |

| intermediate results (polymer concrete No. 23) | |

| fatigue factor | |

| KBK | 1 |

| Fatigue strength of components, MPa | |

| σBK | 35.87927604 |

| intermediate results (polymer concrete No. 15) | |

| fatigue factor | |

| KBK | 1 |

| Fatigue strength of components, MPa | |

| σBK | 36.44997973 |

| Safety Factors of the Materials for Block Structures | ||||

|---|---|---|---|---|

| jf | damage consequences | |||

| high | medium | low | ||

| Supporting operations | no | 1.5 | 1.4 | 1.3 |

| yes | 1.35 | 1.25 | 1.2 | |

| output | no | 1.5 | 1.4 | 1.3 |

| output | ||||

| jf | 1.5 | |||

| intermediate results (polymer concrete No. 23) | ||||

| safety factor | ||||

| jD | 1.5 | |||

| αBK,σ | 0.796002683 | |||

| intermediate results (polymer concrete No. 15) | ||||

| safety factor | ||||

| jD | 1.5 | |||

| αBK,σ | 0.860082783 | |||

| HV0.5 (according to the dint diagonal) | 1200 ± 25 |

| HV0.5 (according to the diagram) | 1105 ± 40 |

| HV1 | 855 ± 80 |

| E (elasticity modulus), GPa | 187.5 ± 14 |

| Ra (roughness), µm | 0.8 ± 0.25 |

| HV0.5 (according to the dint diagonal) | 1280 ± 45 |

| HV0.5 (according to the diagram) | 755 ± 40 |

| HV1 | 900 ± 50 |

| E (elasticity modulus), GPa | 198 ± 27 |

| Ra (roughness), µm | 0.55 ± 0.15 |

| Material Properties | |

|---|---|

| Material grade | pol |

| Tensile strength, MPa | Rm = 230 |

| Yield strength, MPa | Rp02 = 85 |

| Roughness (Default—200) | Rz = 200 |

| Material fatigue strength | σW,zd = 103.5 |

| Related stress gradient | Gσ = −0.00236 |

| Roughness factor | KR,σ = 0.96927 |

| Construction factors | KWK,σ = 1.003371 |

| Component fatigue strength | σW,K = 100.124617 |

| Stress Value (Ni-7Cr-3Fe + 60% WC) | |

|---|---|

| σmax, MPa | 7.23 |

| σmin, MPa | −7.23 |

| intermediate results | |

| Stress amplitudes, MPa | σa = 7.23 |

| Load type | R = −1 |

| Stress sensitivity | Mσ = −0.0195 |

| Medium stress factor | KAK,σ = 1 |

| Fatigue strength, MPa | σA,K = 100.1246171 |

| Medium Stress, MPa | σm = 0 |

| Number of Cycles (Default Number Work Cycles 4 × 106) | |

|---|---|

| N | 5,000,000 |

| intermediate results | |

| fatigue factor | |

| KBK | 1 |

| Fatigue strength of components, MPa | |

| σBK | 100.1246171 |

| Safety Factors of the Materials for Block Structures | ||||

|---|---|---|---|---|

| jf | damage consequences | |||

| high | medium | low | ||

| Supporting operations | no | 1.5 | 1.4 | 1.3 |

| yes | 1.35 | 1.25 | 1.2 | |

| output | no | 1.5 | 1.4 | 1.3 |

| output | ||||

| jf | 1.5 | |||

| intermediate results | ||||

| safety factor | ||||

| jD | 1.5 | |||

| αBK,σ | 0.674159881 | |||

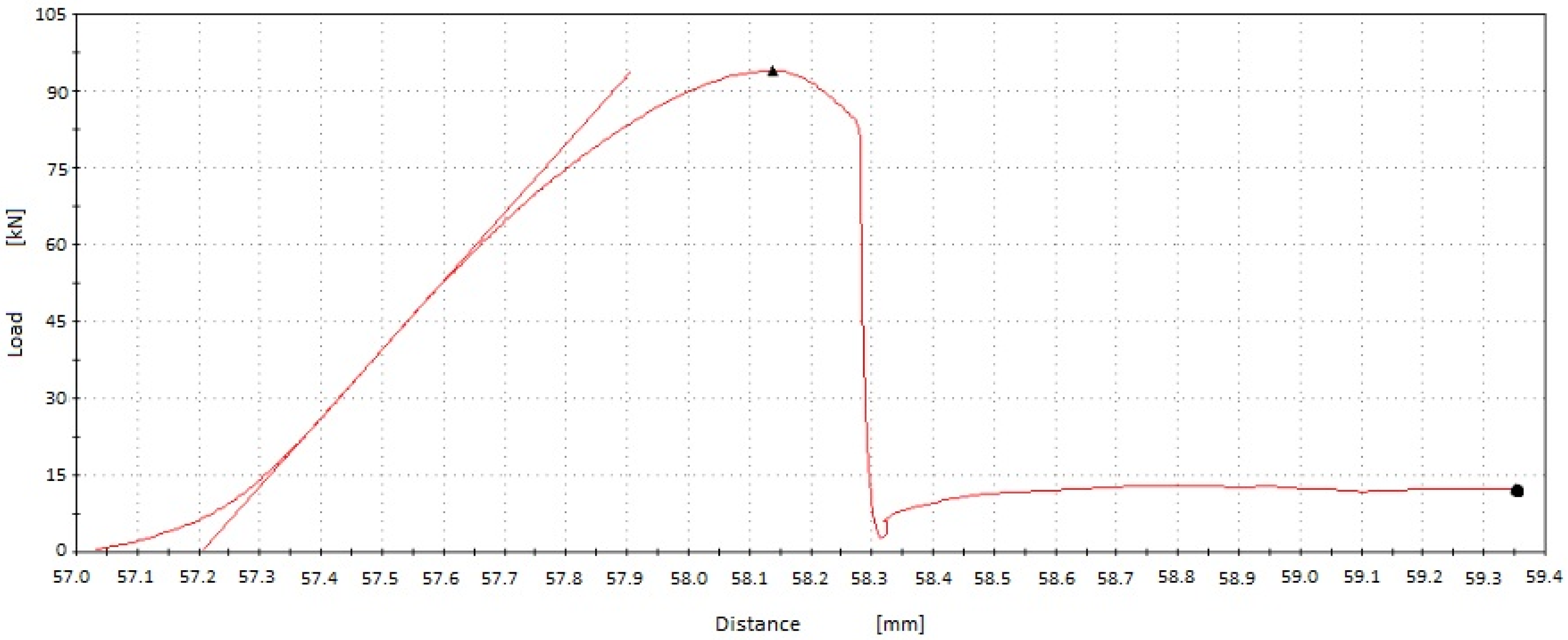

| Compression test plate height [mm] | 14.20000 |

| Maximum load [kN] | 93.94 |

| Compressive travel at maximum load [mm] | 58.13961 |

| Compressive displacement at specimen failure [mm] | 59.35169 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikonova, T.; Gierz, Ł.; Berg, A.; Turla, V.; Warguła, Ł.; Yurchenko, V.; Abdugaliyeva, G.; Zhunuspekov, D.; Wieczorek, B.; Robakowska, M.; et al. Comparative Analysis of Strength Fatigue Properties and Abrasive Wear Resistance for a New Composition of Polymer Concrete Coated with Metal Alloy Powders. Coatings 2023, 13, 586. https://doi.org/10.3390/coatings13030586

Nikonova T, Gierz Ł, Berg A, Turla V, Warguła Ł, Yurchenko V, Abdugaliyeva G, Zhunuspekov D, Wieczorek B, Robakowska M, et al. Comparative Analysis of Strength Fatigue Properties and Abrasive Wear Resistance for a New Composition of Polymer Concrete Coated with Metal Alloy Powders. Coatings. 2023; 13(3):586. https://doi.org/10.3390/coatings13030586

Chicago/Turabian StyleNikonova, Tatyana, Łukasz Gierz, Alexandra Berg, Vytautas Turla, Łukasz Warguła, Vassiliy Yurchenko, Gulnur Abdugaliyeva, Darkhan Zhunuspekov, Bartosz Wieczorek, Mariola Robakowska, and et al. 2023. "Comparative Analysis of Strength Fatigue Properties and Abrasive Wear Resistance for a New Composition of Polymer Concrete Coated with Metal Alloy Powders" Coatings 13, no. 3: 586. https://doi.org/10.3390/coatings13030586

APA StyleNikonova, T., Gierz, Ł., Berg, A., Turla, V., Warguła, Ł., Yurchenko, V., Abdugaliyeva, G., Zhunuspekov, D., Wieczorek, B., Robakowska, M., & Essim, D. (2023). Comparative Analysis of Strength Fatigue Properties and Abrasive Wear Resistance for a New Composition of Polymer Concrete Coated with Metal Alloy Powders. Coatings, 13(3), 586. https://doi.org/10.3390/coatings13030586