Experimental Investigation on Physical Properties of Concrete Containing Polypropylene Fiber and Water-Borne Epoxy for Pavement

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Specimen Preparation

2.3. Slump

2.4. Mechanical Strength

2.5. Shrinkage

2.6. Depth of Water Penetration

2.7. Abrasion Resistance

2.8. Scanning Electronic Microscopy (SEM)

3. Results and Discussion

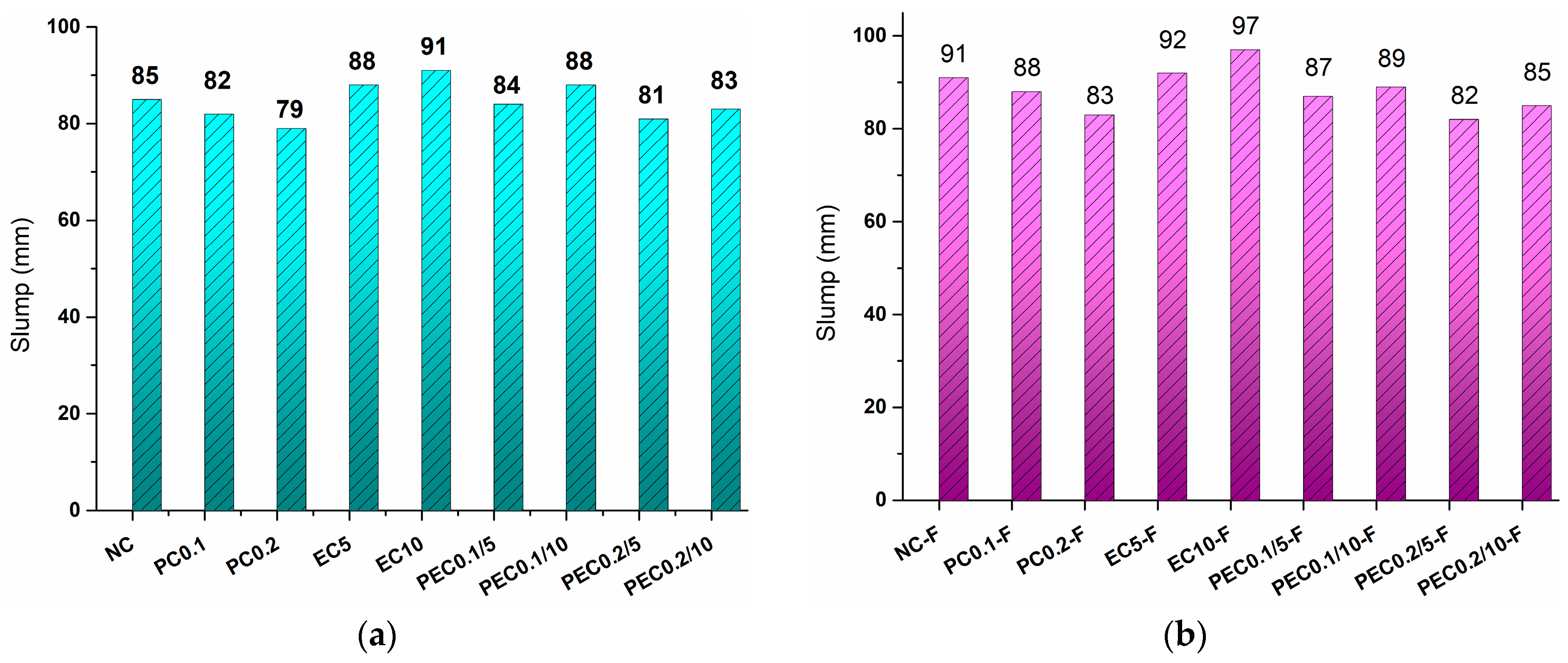

3.1. Slump

3.2. Mechanical Strength

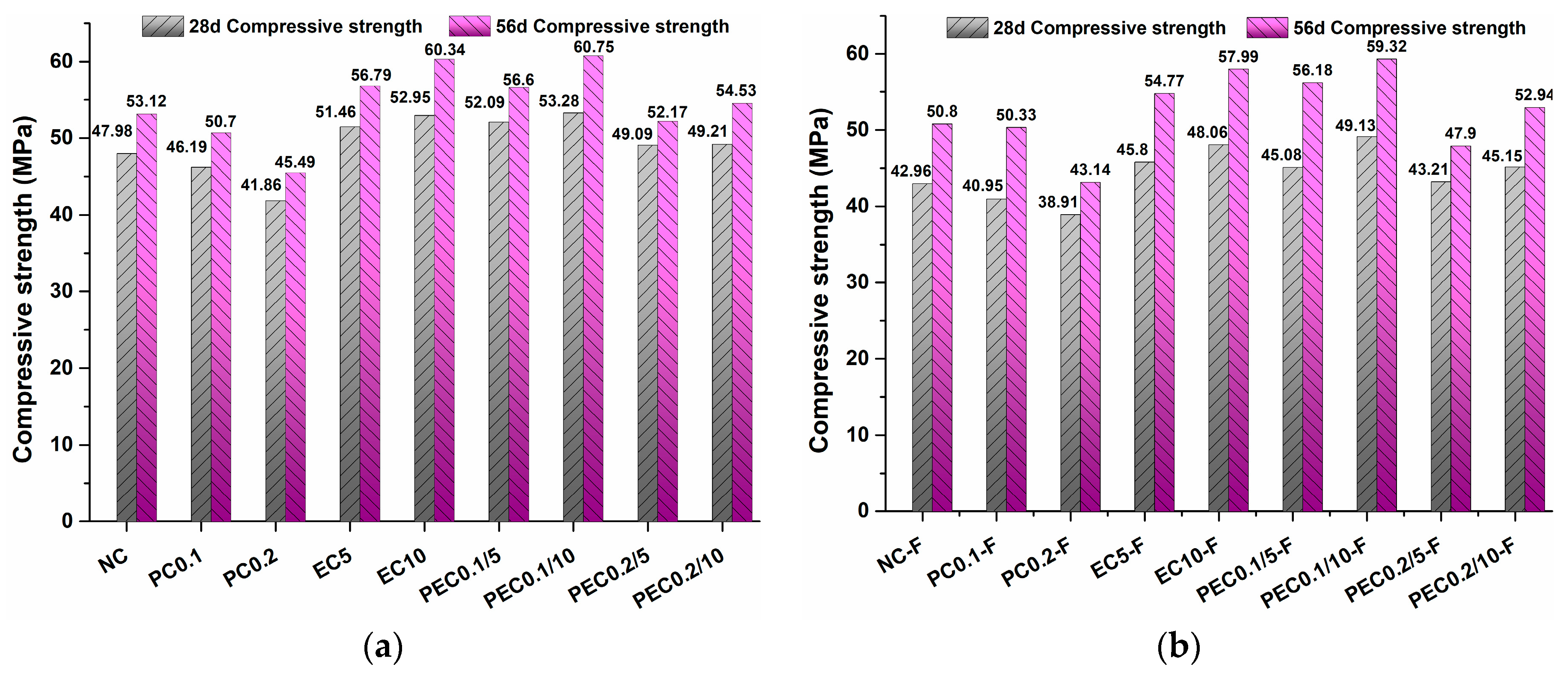

3.2.1. Compressive Strength

3.2.2. Flexural Strength

3.3. Shrinkage

3.4. Depth of Water Penetration

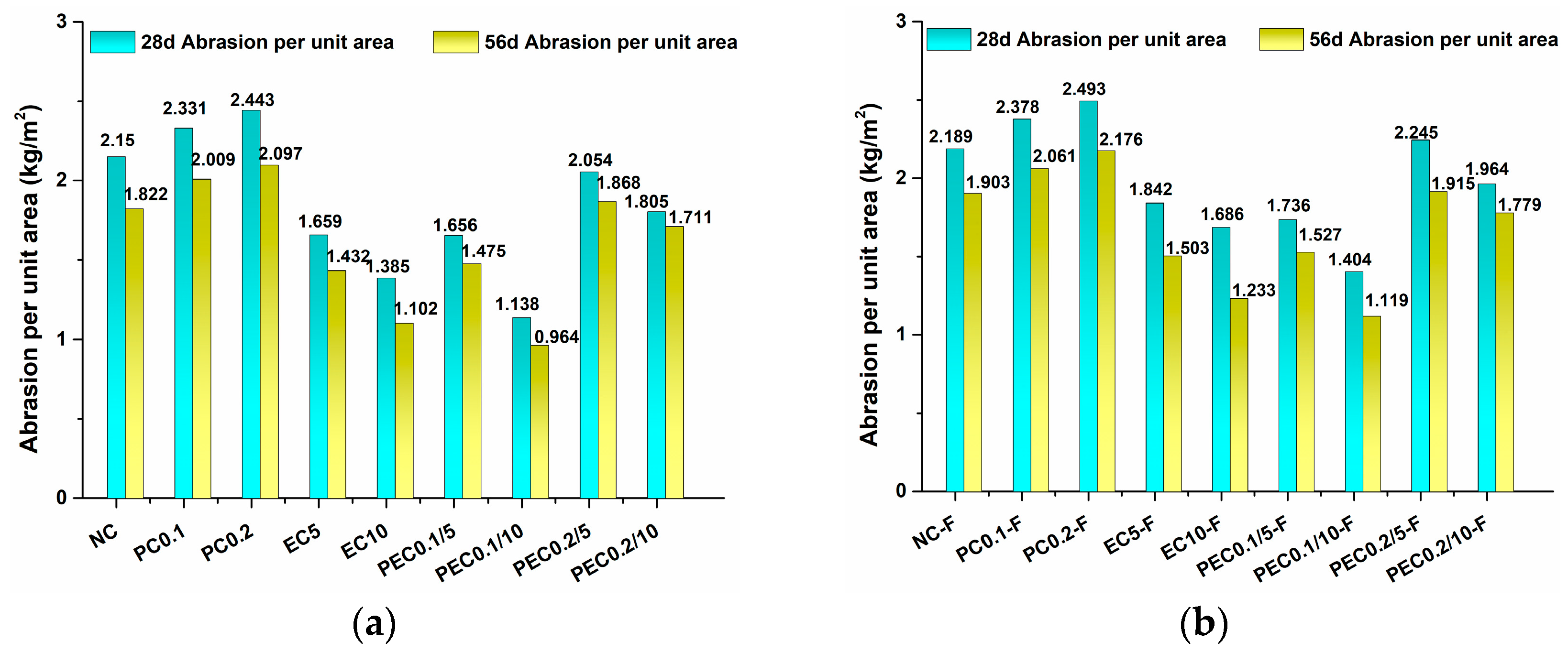

3.5. Abrasion Resistance

4. Conclusions

- (1)

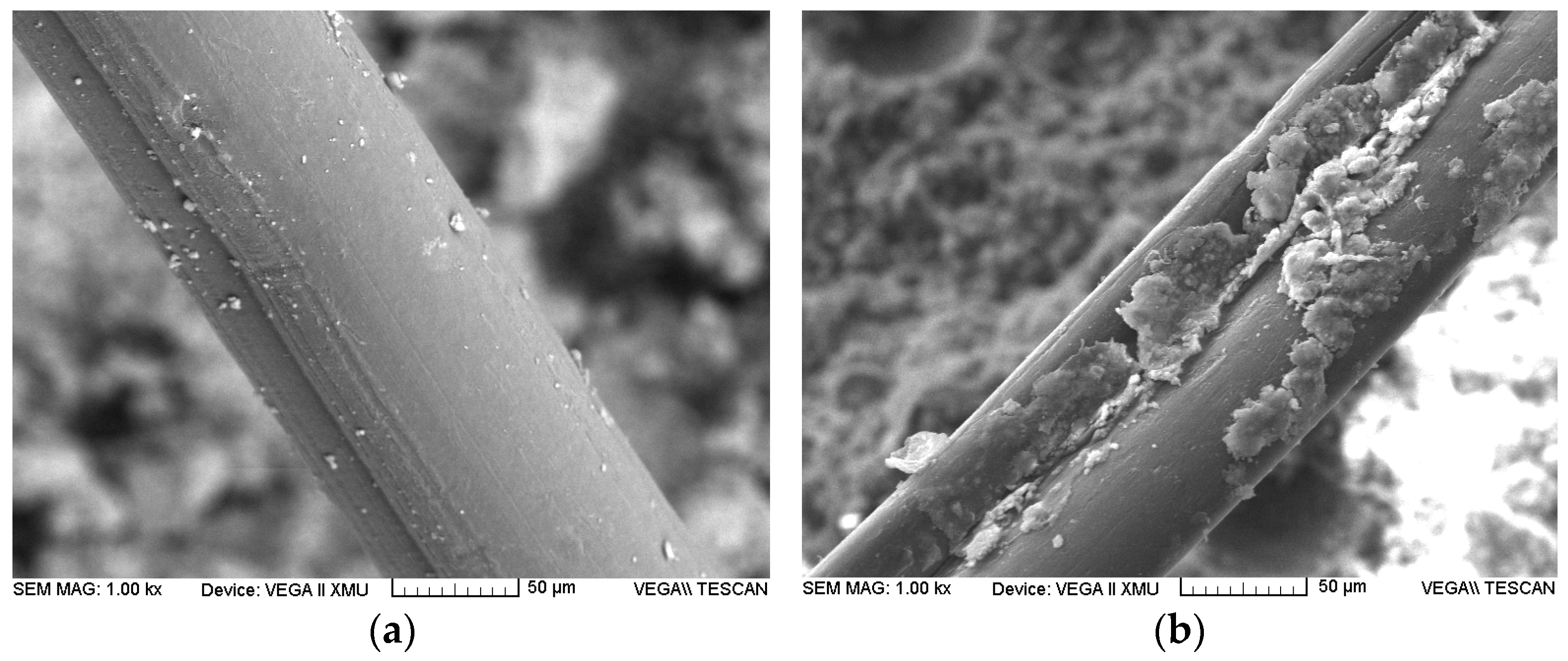

- The combined incorporation of PP fibers and WBE in concrete can maximize the advantages of the two materials. To be precise, the incorporation of PP fibers had a negative effect on the performance of the concrete due to the weak interfacial bonding between the PP fibers and the concrete, while WBE was found to be effective in improving this poor interfacial bonding owing to its filling effect densifying the microstructure, and its absorption of calcium ions to form a crosslinking structure of hydration products and epoxy polymers wrapping on the PP fibers to enhance their interfacial bonding with the concrete matrix.

- (2)

- The incorporation of PP fibers reduced the slump of concrete, while the use of WBE could improve the workability of PC due to the “ball bearing” effect of WBE. Moreover, the presence of FA further led to an increase in the slump owing to the “ball bearing” effect.

- (3)

- The compressive strength of PC was slightly lower when compared with that of NC due to the weak interfacial bonding between the PP fibers and the concrete, while EC showed an increase in compressive strength. With the combined incorporation of PP fibers and WBE, the compressive strength of PEC exhibited an improvement in comparison with the corresponding PC. PEC0.1/10 showed the highest compressive strength regardless of the curing age. The flexural strength of PEC0.1/10 was also the highest, and the increase in flexural strength was more obvious than that in compressive strength compared with PC, demonstrating the reinforcing effect of PP fibers was achieved.

- (4)

- Drying shrinkage of concrete could be restricted by the addition of PP fibers at an early stage, while at later stages the effective utilization of PP fibers to restrain shrinkage can be achieved by adding WBE. The addition of PP fibers could increase the permeability of concrete owing to increased porosity, while a reduction in depth of water penetration was found in EC mainly due to the filling and bonding effect of WBE to reduce the capillary pores in concrete. Combined use of PP fibers and WBE contributed to the reduction in abrasion. With regard to FA free concrete in this study, PEC0.1/10 exhibited the best durability.

- (5)

- After the replacement of 10% cement by FA, both the compressive strength and the flexural strength showed a slight decline due to the slow process of the pozzolanic reaction; moreover the abrasion also exhibited a slight increase. Despite this, the drying shrinkage resistance and impermeability were improved through the use of FA. Therefore, the use of FA in pavements should be properly treated according to the actual engineering condition, such as road grade, construction period limit, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Bozzoni, F.; Ozcebe, A.G.; Balia, A.; Lai, C.G.; Borzi, B.; Nascimbene, R.; Khairy, D.; Gabbianelli, G.; Ippoliti, L.; Berardi, S.; et al. Seismic ground response analyses at an international airport in northern Italy by using a stochastic-based approach. J. Mec. Theor. Appl. 2020, 58, 499–511. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.; Ali, M. Effectiveness of hair and wave polypropylene fibers for concrete roads. Constr. Build. Mater. 2018, 166, 581–591. [Google Scholar] [CrossRef]

- Nobili, A.; Lanzoni, L.; Tarantino, A.M. Experimental investigation and monitoring of a polypropylene-based fiber reinforced concrete road pavement. Constr. Build. Mater. 2013, 47, 888–895. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Pang, S.D. Combination of polypropylene fibre and superabsorbent polymer to improve physical properties of cement mortar. Mag. Concr. Res. 2018, 70, 350–364. [Google Scholar] [CrossRef]

- Sun, Z.; Xu, Q. Microscopic, physical and mechanical analysis of polypropylene fiber reinforced concrete. Mater. Sci. Eng. A 2009, 527, 198–204. [Google Scholar] [CrossRef]

- Lanzoni, L.; Nobili, A.; Tarantino, A.M. Performance evaluation of a polypropylene-based draw-wired fibre for concrete structures. Constr. Build. Mater. 2012, 28, 798–806. [Google Scholar] [CrossRef]

- Gupta, S.; Rao, V.K.; Sengupta, J. Evaluation of polyester fiber reinforced concrete for use in cement concrete pavement works. Road Mater. Pavement Des. 2008, 9, 441–461. [Google Scholar] [CrossRef]

- Aly, T.; Sanjayan, J.G.; Collins, F. Effect of polypropylene fibers on shrinkage and cracking of concretes. Mater. Struct. 2008, 41, 1741–1753. [Google Scholar] [CrossRef]

- Bendjillali, K.; Goual, M.S.; Chemrouk, M.; Damene, Z. Study of the reinforcement of limestone mortars by polypropylene fibers waste. Phys. Procedia 2011, 21, 42–46. [Google Scholar] [CrossRef]

- Han, J.W.; Jeon, J.H.; Park, C.G. Bond characteristics of macro polypropylene fiber in cementitious composites containing nanosilica and styrene butadiene latex polymer. Int. J. Polym. Sci. 2015, 2015, 207456. [Google Scholar] [CrossRef]

- Yazici, Ş.; Mardani-Aghabaglou, A.; Tuyan, M.; Üte, A.A. Mechanical properties and impact resistance of roller-compacted concrete containing polypropylene fibre. Mag. Concr. Res. 2015, 67, 867–875. [Google Scholar] [CrossRef]

- Won, J.P.; Park, C.G.; Lee, S.W.; Jang, C.I.; Kim, H.Y. Performance of synthetic macrofibres in reinforced concrete for tunnel linings. Mag. Concr. Res. 2009, 61, 165–172. [Google Scholar] [CrossRef]

- Zhang, D.; Tan, K.H. Effect of various polymer fibers on spalling mitigation of ultra-high performance concrete at high temperature. Cem. Concr. Compos. 2020, 114, 103815. [Google Scholar] [CrossRef]

- Sivakumar, A.; Santhanam, M. A quantitative study on the plastic shrinkage cracking in high strength hybrid fibre reinforced concrete. Cem. Concr. Compos. 2007, 2, 575–581. [Google Scholar] [CrossRef]

- Tu, L.; Kruger, D.; Wagener, J.B.; Carstens, P.A.B. Surface modified polypropylene fibres for use in concrete. Mag. Concr. Res. 1998, 50, 209–217. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Wang, Z. Study on micro-structure and durability of fiber concrete. Res. J. Appl. Sci. Eng. Technol. 2013, 5, 659–664. [Google Scholar] [CrossRef]

- Esmaeili, J.; Andalibi, K.; Gencel, O.; Maleki, F.K.; Maleki, V.A. Pull-out and bond-slip performance of steel fibers with various ends shapes embedded in polymer-modified concrete. Constr. Build. Mater. 2021, 271, 121531. [Google Scholar] [CrossRef]

- Fernández-Ruiz, M.A.; Gil-Martín, L.M.; Carbonell-Márquez, J.F.; Hernández-Montes, E. Epoxy resin and ground tyre rubber replacement for cement in concrete: Compressive behaviour and durability properties. Constr. Build. Mater. 2018, 173, 49–57. [Google Scholar] [CrossRef]

- Ariffin, N.F.; Hussin, M.W.; Sam, A.R.M.; Bhutta, M.A.R.; Khalid, N.H.A.; Mirza, J. Strength properties and molecular composition of epoxy-modified mortars. Constr. Build. Mater. 2015, 94, 315–322. [Google Scholar] [CrossRef]

- Wang, R.; Wang, P.M.; Li, X.G. Physical and mechanical properties of styrene–butadiene rubber emulsion modified cement mortars. Cem. Concr. Res. 2005, 35, 900–906. [Google Scholar] [CrossRef]

- Pang, B.; Zhang, Y.; Liu, G. Study on the effect of waterborne epoxy resins on the performance and microstructure of cement paste. Constr. Build. Mater. 2018, 167, 831–845. [Google Scholar] [CrossRef]

- Martinez-Barrera, G.; Menchaca-Campos, C.; Gencel, O. Polyester polymer concrete: Effect of the marble particle sizes and high gamma radiation doses. Constr. Build. Mater. 2013, 41, 204–208. [Google Scholar] [CrossRef]

- Varghese, A.S.S. A Study on Properties of SBR Latex Modified Polypropylene Fibre Reinforced Concrete. IJSTE-Int. J. Sci. Technol. Eng. 2017, 3, 81–86. [Google Scholar]

- ASTM C150; Standard Specification for Portland Cement. American Society for Testing and Materials: Philadelphia, PE, USA, 2009.

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials: West Conshohocken, PE, USA, 2012.

- ASTM C494; TYPE F: Standard Specification for Chemical Admixtures for Concrete. American Society for Testing and Materials: Philadelphia, PE, USA, 2017.

- ASTM C143/C143M-15; Standard Test Method for Slump of Hydraulic-Cement Concrete. American Society for Testing and Materials: West Conshohocken, PE, USA, 2015.

- JTG E30-2005; Test Methods of Cement and Concrete for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2005.

- Soroushian, P.; Plasencia, J.; Ravanbakhsh, S. Assessment of reinforcing effects of recycled plastic and paper in concrete. Mater. J. 2003, 100, 203–207. [Google Scholar]

- Sumathy, C.T.; Dharakumar, M.; Saroja Devi, M.; Saccubai, S. Modification of cement mortars by polymer latex. J. Appl. Polym. Sci. 1997, 63, 1251–1257. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Sun, M.; He, Z.; Xu, H.; Tan, J. Mechanical and permeability properties of polymer-modified concrete using hydrophobic agent. J. Build. Eng. 2020, 31, 101337. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Peng, Y.; Zeng, Q.; Xu, S.; Zhao, G.; Wang, P.; Liu, X. BSE-IA reveals retardation mechanisms of polymer powders on cement hydration. J. Am. Ceram. Soc. 2020, 103, 3373–3389. [Google Scholar] [CrossRef]

- Zeng, S.; Short, N.R.; Page, C.L. Early-age hydration kinetics of polymer-modified cement. Adv. Cem. Res. 1996, 8, 1–9. [Google Scholar] [CrossRef]

- Rashad, A.M. An exploratory study on high-volume fly ash concrete incorporating silica fume subjected to thermal loads. J. Clean. Prod. 2015, 87, 735–744. [Google Scholar] [CrossRef]

- Saje, D.; Bandelj, B.; Šušteršič, J.; Lopatič, J.; Saje, F. Shrinkage of polypropylene fiber-reinforced high-performance concrete. J. Mater. Civ. Eng. 2011, 23, 941–952. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Monteiro, P.J. The effect of steel and polypropylene fibers on the chloride diffusivity and drying shrinkage of high-strength concrete. Compos. Part B Eng. 2018, 139, 84–96. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; Ghavami, K.; Sanjuán, M.A.; England, G.L. Free, restrained and drying shrinkage of cement mortar composites reinforced with vegetable fibres. Cem. Concr. Compos. 2005, 27, 537–546. [Google Scholar] [CrossRef]

- Saha, A.K. Effect of class F fly ash on the durability properties of concrete. Sustain. Environ. Res. 2018, 28, 25–31. [Google Scholar] [CrossRef]

- Li, H.; Zhang, M.H.; Ou, J.P. Abrasion resistance of concrete containing nano-particles for pavement. Wear 2006, 260, 1262–1266. [Google Scholar] [CrossRef]

- Naik, T.R.; Singh, S.S.; Hossain, M.M. Abrasion resistance of concrete as influenced by inclusion of fly ash. Cem. Concr. Res. 1994, 24, 303–312. [Google Scholar] [CrossRef]

| Oxides | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Na2O | K2O | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 58.34 | 20.87 | 5.83 | 3.64 | 1.06 | 3.61 | 1.36 | 0.94 | 4.35 |

| Fly ash | 4.39 | 62.46 | 22.16 | 5.28 | 1.26 | 0.14 | 0.68 | 1.15 | 2.48 |

| Characteristic | Specification |

|---|---|

| Fiber length (mm) | 19 |

| Fiber diameter (μm) | Around 50 |

| Density (g/cm3) | 0.91 |

| Tensile strength (MPa) | More than 486 |

| Elastic modulus (GPa) | More than 4.8 |

| Corrosion resistance to acid and alkali | Very strong |

| Sorptivity | 0 |

| Characteristic | WBE | Hardener |

|---|---|---|

| Exterior | Milky white | Light yellow |

| Solid content (%) | 50 ± 3 | 50 ± 1 |

| pH | 6–8 | 9.5–10.5 |

| Viscosity (mPa·s) | 1218 | 6000 |

| Epoxy equivalent (g/eq) | 192.3 | - |

| Mixture Type | Cement | PP Fibers | Sand | Coarse Aggregate | FA | Water | WBE | ||

|---|---|---|---|---|---|---|---|---|---|

| Total | Solid | Water | |||||||

| NC (Control) | 400 | 0 | 690 | 1170 | 0 | 160 | - | - | - |

| PC0.1 | 0.91 | ||||||||

| PC0.2 | 1.82 | ||||||||

| EC5 | 0 | 140 | 40 | 20 | 20 | ||||

| EC10 | 0 | 120 | 80 | 40 | 40 | ||||

| PEC0.1/5 | 0.91 | 140 | 40 | 20 | 20 | ||||

| PEC0.1/10 | 0.91 | 120 | 80 | 40 | 40 | ||||

| PEC0.2/5 | 1.82 | 140 | 40 | 20 | 20 | ||||

| PEC0.2/10 | 1.82 | 120 | 80 | 40 | 40 | ||||

| NC-F | 360 | 0 | 40 | 160 | - | - | - | ||

| PC0.1-F | 0.91 | ||||||||

| PC0.2-F | 1.82 | ||||||||

| EC5-F | 0 | 140 | 40 | 20 | 20 | ||||

| EC10-F | 0 | 120 | 80 | 40 | 40 | ||||

| PEC0.1/5-F | 0.91 | 140 | 40 | 20 | 20 | ||||

| PEC0.1/10-F | 0.91 | 120 | 80 | 40 | 40 | ||||

| PEC0.2/5-F | 1.82 | 140 | 40 | 20 | 20 | ||||

| PEC0.2/10-F | 1.82 | 120 | 80 | 40 | 40 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Zhang, H.; Zhao, B.; Wang, B.; Zhao, Q.; Sun, M. Experimental Investigation on Physical Properties of Concrete Containing Polypropylene Fiber and Water-Borne Epoxy for Pavement. Coatings 2023, 13, 452. https://doi.org/10.3390/coatings13020452

Wang L, Zhang H, Zhao B, Wang B, Zhao Q, Sun M. Experimental Investigation on Physical Properties of Concrete Containing Polypropylene Fiber and Water-Borne Epoxy for Pavement. Coatings. 2023; 13(2):452. https://doi.org/10.3390/coatings13020452

Chicago/Turabian StyleWang, Li, Hongliang Zhang, Bendong Zhao, Biao Wang, Quanman Zhao, and Min Sun. 2023. "Experimental Investigation on Physical Properties of Concrete Containing Polypropylene Fiber and Water-Borne Epoxy for Pavement" Coatings 13, no. 2: 452. https://doi.org/10.3390/coatings13020452

APA StyleWang, L., Zhang, H., Zhao, B., Wang, B., Zhao, Q., & Sun, M. (2023). Experimental Investigation on Physical Properties of Concrete Containing Polypropylene Fiber and Water-Borne Epoxy for Pavement. Coatings, 13(2), 452. https://doi.org/10.3390/coatings13020452