Development and Performance of Eco-Sustainable Form-Stable Phase Change Materials (PCMs) for Mortars to Be Applied in Buildings Located in Different Climatic Areas

Abstract

1. Introduction

2. Materials and Methods

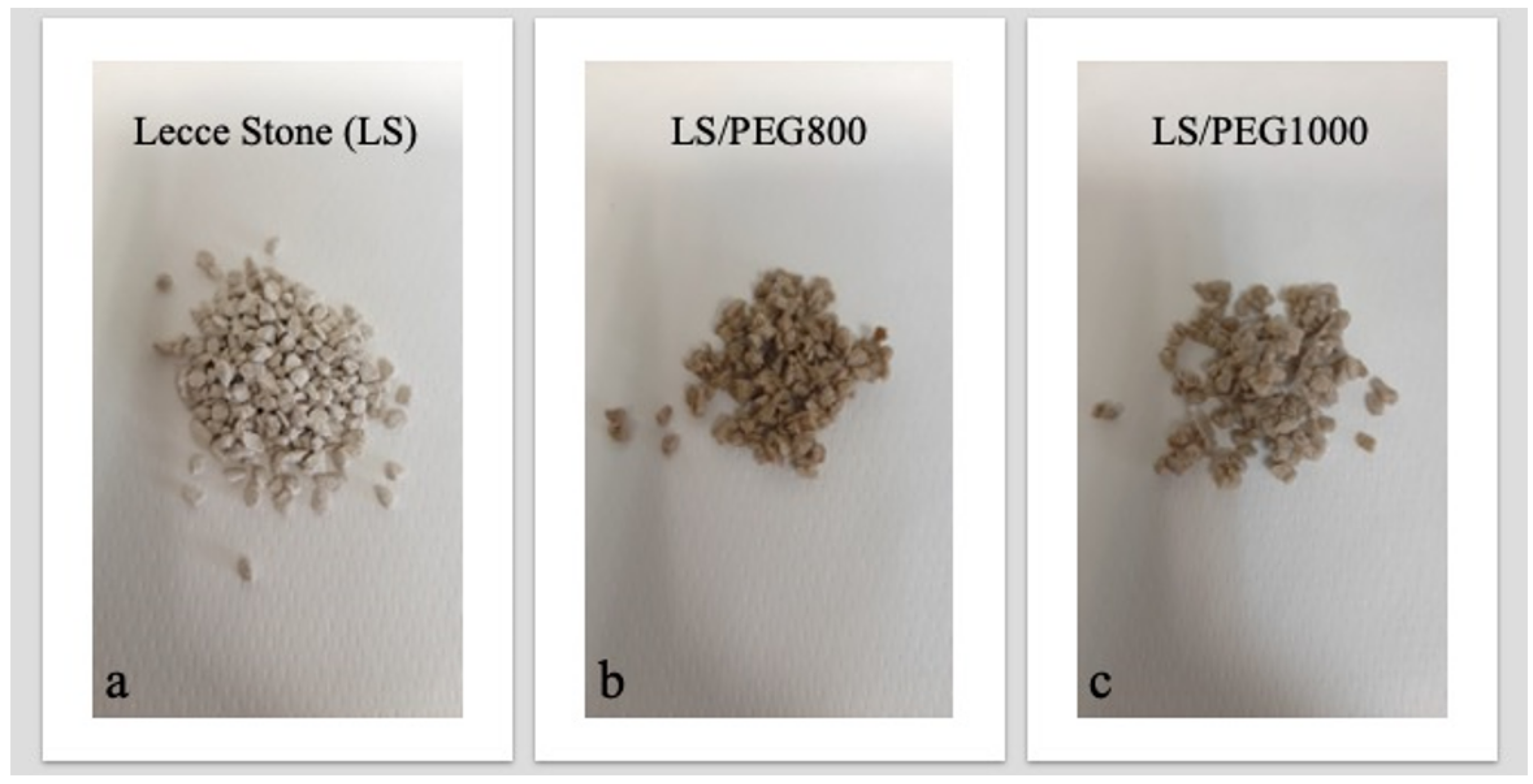

2.1. Materials

2.2. Methods

3. Results

3.1. Workability

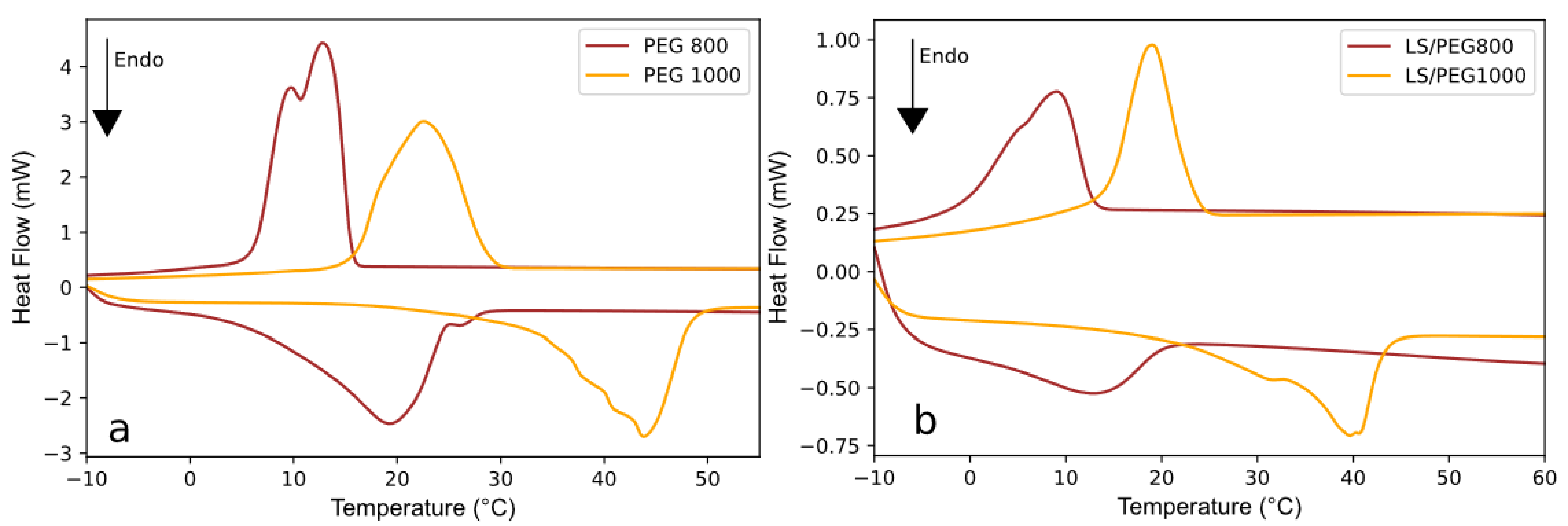

3.2. Latent Heats and Phase Change Temperatures, Leakage Test

3.3. Mechanical Properties

4. Conclusions

- It is possible to produce composites to be employed as effective phase change materials starting from non-toxic PEG polymers and waste stone materials, in compliance with sustainability and the principles of the circular economy;

- Since the type of PEG determines the temperature range in which the PCM operates, through an appropriate choice of the PEG, it is possible to create a PCM suitable for a specific climatic condition, i.e., for the first time it is possible to adapt the PCM to the expected climate;

- The presence of PEG-based PCMs in the mortars affected their characteristics, especially their mechanical properties; however, it was possible to obtain adequate mechanical properties by adequately adjusting the mortar compositions, using a high binder content in combination with a plasticizer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UN Environment Programme. 2021 Global Status Report For Buildings and Construction, Technical Report, Global Alliance for Buildings and Construction. 2021. Available online: http://Globalabc.Org/Resources/Publications/2021-Global-Status-Report-Buildings-and-Construction (accessed on 5 January 2023).

- International Energy Agency. Electricity Market Report, Technical Report. 2022. Available online: https://www.iea.org/reports/electricity-market-report-january-2022 (accessed on 5 January 2023).

- Chinnasamy, V.; Palaniappan, S.K.; Raj, M.K.A.; Rajendran, M.; Cho, H. Thermal Energy Storage and Its Applications. Mater. Sol. Energy Convers. Mater. Methods Appl. 2021, 353–377. [Google Scholar]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. A Review on Phase Change Materials for Thermal Energy Storage in Buildings: Heating and Hybrid Applications. J. Energy Storage 2021, 33, 101913. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Z.; Guo, Q.; Wang, H.; Wang, X.; Dong, X.; Tian, X.; Guo, X. Preparation and Thermal Characterization of Hollow Graphite Fibers/Paraffin Composite Phase Change Material. Coatings 2022, 12, 160. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Sanjayan, J.; Wang, X. Experimental Research on Using Form-Stable PCM-Integrated Cementitious Composite for Reducing Overheating in Buildings. Buildings 2019, 9, 57. [Google Scholar] [CrossRef]

- Hwang, R.-L.; Chen, B.-L.; Chen, W.-A. Analysis of Incorporating a Phase Change Material in a Roof for the Thermal Management of School Buildings in Hot-Humid Climates. Buildings 2021, 11, 248. [Google Scholar] [CrossRef]

- Rao, V.V.; Parameshwaran, R.; Ram, V.V. PCM-Mortar Based Construction Materials for Energy Efficient Buildings: A Review on Research Trends. Energy Build. 2018, 158, 95–122. [Google Scholar] [CrossRef]

- Han, H.; Zhou, H.; Dong, O.; Ma, J. Experimental Study on Phase Change Material with Solar Heater System for Building Heating. Coatings 2022, 12, 1476. [Google Scholar] [CrossRef]

- Yang, H.; Xu, Z.; Cui, H.; Bao, X.; Tang, W.; Sang, G.; Chen, X. Cementitious Composites Integrated Phase Change Materials for Passive Buildings: An Overview. Constr. Build. Mater. 2022, 361, 129635. [Google Scholar] [CrossRef]

- Soleiman Dehkordi, B.; Afrand, M. Energy-Saving Owing to Using PCM into Buildings: Considering of Hot and Cold Climate Region. Sustain. Energy Technol. Assess. 2022, 52, 102112. [Google Scholar] [CrossRef]

- Liu, L.; Hammami, N.; Trovalet, L.; Bigot, D.; Habas, J.-P.; Malet-Damour, B. Description of Phase Change Materials (PCMs) Used in Buildings under Various Climates: A Review. J. Energy Storage 2022, 56, 105760. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A.; Barroso de Aguiar, J. Sustainable Polymer-Based Phase Change Materials for Energy Efficiency in Buildings and Their Application in Aerial Lime Mortars. Constr. Build. Mater. 2020, 231, 117149. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Sutthiphasilp, T.; Chalodhorn, W.; Chindaprasirt, P. Improving Thermal Properties of Exterior Plastering Mortars with Phase Change Materials with Different Melting Temperatures: Paraffin and Polyethylene Glycol. Adv. Build. Energy Res. 2019, 13, 220–240. [Google Scholar] [CrossRef]

- Kulkarni, P.; Muthadhi, A. Polyethylene Glycol-600/Expanded Clay Aggregate with Alccofine1203 in Concrete. Mater. Today Proc. 2021, 43, 1081–1088. [Google Scholar] [CrossRef]

- Abbasi Hattan, H.; Madhkhan, M.; Marani, A. Thermal and Mechanical Properties of Building External Walls Plastered with Cement Mortar Incorporating Shape-Stabilized Phase Change Materials (SSPCMs). Constr. Build. Mater. 2021, 270, 121385. [Google Scholar] [CrossRef]

- Cunha, S.; Leite, P.; Aguiar, J. Characterization of Innovative Mortars with Direct Incorporation of Phase Change Materials. J. Energy Storage 2020, 30, 101439. [Google Scholar] [CrossRef]

- Wang, R.; Ren, M.; Gao, X.; Qin, L. Preparation and Properties of Fatty Acids Based Thermal Energy Storage Aggregate Concrete. Constr. Build. Mater. 2018, 165, 1–10. [Google Scholar] [CrossRef]

- Elert, K.; Rodriguez-Navarro, C.; Pardo, E.S.; Hansen, E.; Cazalla, O. Lime Mortars for the Conservation of Historic Buildings. Stud. Conserv. 2002, 47, 62–75. [Google Scholar] [CrossRef]

- Govaerts, Y.; Hayen, R.; de Bouw, M.; Verdonck, A.; Meulebroeck, W.; Mertens, S.; Grégoire, Y. Performance of a Lime-Based Insulating Render for Heritage Buildings. Constr. Build. Mater. 2018, 159, 376–389. [Google Scholar] [CrossRef]

- Lv, P.; Liu, C.; Rao, Z. Review on Clay Mineral-Based Form-Stable Phase Change Materials: Preparation, Characterization and Applications. Renew. Sustain. Energy Rev. 2017, 68, 707–726. [Google Scholar] [CrossRef]

- Mousavi, S.; Rismanchi, B.; Brey, S.; Aye, L. PCM Embedded Radiant Chilled Ceiling: A State-of-the-Art Review. Renew. Sustain. Energy Rev. 2021, 151, 111601. [Google Scholar] [CrossRef]

- Arumugam, P.; Ramalingam, V.; Vellaichamy, P. Effective PCM, Insulation, Natural and/or Night Ventilation Techniques to Enhance the Thermal Performance of Buildings Located in Various Climates—A Review. Energy Build. 2022, 258, 111840. [Google Scholar] [CrossRef]

- Mousavi, S.; Rismanchi, B.; Brey, S.; Aye, L. Lessons Learned from PCM Embedded Radiant Chilled Ceiling Experiments in Melbourne. Energy Rep. 2022, 8, 54–61. [Google Scholar] [CrossRef]

- Sarcinella, A.; de Aguiar, J.L.B.; Frigione, M. Physical Properties of Eco-Sustainable Form-Stable Phase Change Materials Included in Mortars Suitable for Buildings Located in Different Continental Regions. Materials 2022, 15, 2497. [Google Scholar] [CrossRef] [PubMed]

- Sarcinella, A.; de Aguiar, J.L.B.; Frigione, M. Physical Properties of an Eco-Sustainable, Form-Stable Phase Change Material Included in Aerial-Lime-Based Mortar Intended for Different Climates. Materials 2022, 15, 1192. [Google Scholar] [CrossRef]

- EN 998-1; Specification for Mortar for Masonry—Part 1: Rendering and Plastering Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- EN 1015-3; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- Zhang, J.; Li, H.; Tu, J.; Shi, R.; Luo, Z.; Xiong, C.; Jiang, M. Shape Stability of Polyethylene Glycol/Acetylene Black Phase Change Composites for Latent Heat Storage. Adv. Mater. Sci. Eng. 2018, 2018, 3954163. [Google Scholar] [CrossRef]

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- Sarcinella, A.; De Aguiar, J.L.B.; Lettieri, M.; Cunha, S.; Frigione, M. Thermal Performance of Mortars Based on Different Binders and Containing a Novel Sustainable Phase Change Material (PCM). Materials 2020, 13, 2055. [Google Scholar] [CrossRef]

- Cunha, S.; Aguiar, J.; Tadeu, A. Ranking Procedure Based on Mechanical, Durability and Thermal Behavior of Mortars with Incorporation of Phase Change Materials. Mater. Construc. 2015, 65, e068. [Google Scholar] [CrossRef]

- Cunha, S.; Aguiar, I.; Aguiar, J.B. Phase Change Materials Composite Boards and Mortars: Mixture Design, Physical, Mechanical and Thermal Behavior. J. Energy Storage 2022, 53, 105135. [Google Scholar] [CrossRef]

| Mortars | Binder Content | Aggregates | SP | Water Saturation 1 | Water | Water/ Binder | ||

|---|---|---|---|---|---|---|---|---|

| LS | PEG 800 Content | PEG 1000 Content | ||||||

| AL800_LS | 800 | 175 | 0 | 0 | 15 | 44 | 600 | 0.75 |

| AL800_LS/PEG 1000 | 220 | 0 | 51 | 15 | 0 | 600 | 0.75 | |

| AL1000_LS | 1000 | 668 | 0 | 0 | 20 | 168 | 347 | 0.35 |

| AL1000_LS/PEG 800 | 979 | 225 | 0 | 20 | 0 | 310 | 0.31 | |

| AL1000_LS/PEG 800_LS/PEG 1000 | 979 | 113 | 113 | 20 | 0 | 310 | 0.31 | |

| HL800_LS | 800 | 1092 | 0 | 0 | 15 | 275 | 320 | 0.40 |

| HL800_LS/PEG 1000 | 1729 | 0 | 398 | 15 | 0 | 375 | 0.47 | |

| HL1000_LS | 1000 | 682 | 0 | 0 | 20 | 171 | 380 | 0.38 |

| HL1000_LS/PEG 800 | 1082 | 249 | 0 | 20 | 0 | 320 | 0.32 | |

| HL1000_LS/PEG 800_LS/PEG 1000 | 1082 | 124 | 124 | 20 | 0 | 320 | 0.32 | |

| G800_LS | 800 | 1169 | 0 | 0 | 15 | 294 | 329 | 0.40 |

| G800_LS/PEG 1000 | 1472 | 0 | 339 | 15 | 0 | 340 | 0.43 | |

| G1000_LS | 1000 | 763 | 0 | 0 | 20 | 192 | 385 | 0.39 |

| G1000_LS/PEG 800 | 1129 | 260 | 0 | 20 | 0 | 336 | 0.34 | |

| G1000_LS/PEG 800_LS/PEG 1000 | 1129 | 130 | 130 | 20 | 0 | 340 | 0.34 | |

| C800_LS | 800 | 1070 | 0 | 0 | 15 | 269 | 296 | 0.37 |

| C800_LS/PEG 1000 | 1347 | 0 | 310 | 15 | 0 | 360 | 0.45 | |

| C1000_LS | 1000 | 772 | 0 | 0 | 20 | 194 | 390 | 0.39 |

| C1000_LS/PEG 800 | 1307 | 301 | 0 | 20 | 0 | 300 | 0.30 | |

| C1000_LS/PEG 800_LS/PEG 1000 | 1307 | 150 | 150 | 20 | 0 | 300 | 0.30 | |

| Mortar | Workability (mm) |

|---|---|

| AL800_LS | 175 ± 3.0 |

| AL800_LS/PEG 1000 | 180 ± 2.0 |

| AL1000_LS | 178 ± 2.0 |

| AL1000_LS/PEG 800 | 160 ± 3.0 |

| AL1000_LS/PEG 800_LS/PEG 1000 | 175 ± 2.0 |

| HL800_LS | 165 ± 2.0 |

| HL800_LS/PEG 1000 | 175 ± 2.0 |

| HL1000_LS | 175 ± 1.0 |

| HL1000_LS/PEG 800 | 170 ± 3.0 |

| HL1000_LS/PEG 800_LS/PEG 1000 | 163 ± 2.0 |

| G800_LS | 160 ± 1.0 |

| G800_LS/PEG 1000 | 160 ± 1.0 |

| G1000_LS | 170 ± 4.0 |

| G1000_LS/PEG 800 | 165 ± 3.0 |

| G1000_LS/PEG 800_LS/PEG 1000 | 163 ± 1.0 |

| C800_LS | 160 ± 1.0 |

| C800_LS/PEG 1000 | 178 ± 3.0 |

| C1000_LS | 180 ± 0.5 |

| C1000_LS/PEG 800 | 170 ± 1.0 |

| C1000_LS/PEG 800_LS/PEG 1000 | 170 ± 4.0 |

| Sample | ΔH (J/g) | Tp (°C) |

|---|---|---|

| Melting (heating stage) | ||

| LS/PEG 800 | 28.3 ± 3.4 | 12.7 ± 1.4 |

| AL1000_LS/PEG 800 | 11.8 ± 0.4 | 15.0 ± 1.0 |

| HL1000_LS/PEG 800 | 9.1 ± 0.9 | 14.0 ± 0.8 |

| G1000_LS/PEG 800 | 7.8 ± 0.6 | 16.4 ± 0.8 |

| C1000_LS/PEG 800 | 9.5 ± 0.5 | 17.3 ± 0.2 |

| LS/PEG 1000 | 27.7 ± 0.9 | 39.3 ± 0.7 |

| AL800_LS/PEG 1000 | 7.6 ± 1.3 | 27.9 ± 0.5 |

| AL1000_LS/PEG 800_LS/PEG 1000 | 9.7 ± 2.1 | 32.3 ± 0.8 |

| HL800_LS/PEG 1000 | 7.9 ± 0.9 | 26.0 ± 0.8 |

| HL1000_LS/PEG 800_LS/PEG 1000 | 9.1 ± 1.2 | 32.4 ± 2.6 |

| G800_LS/PEG 1000 | 7.8 ± 1.2 | 28.9 ± 1.0 |

| G1000_LS/PEG 800_LS/PEG 1000 | 8.1 ± 0.4 | 30.8 ± 1.6 |

| C800_LS/PEG 1000 | 7.7 ± 0.2 | 30.0 ± 0.3 |

| C1000_LS/PEG 800_LS/PEG 1000 | 9.7 ± 0.9 | 33.5 ± 0.2 |

| Crystallization (cooling stage) | ||

| LS/PEG 800 | 28.1 ± 0.9 | 9.3 ± 0.9 |

| AL1000_LS/PEG 800 | 12.5 ± 1.0 | 13.1 ± 1.1 |

| HL1000_LS/PEG 800 | 10.3 ± 1.2 | 12.4 ± 3.0 |

| G1000_LS/PEG 800 | 9.2 ± 1.1 | 11.0 ± 0.3 |

| C1000_LS/PEG 800 | 10.5 ± 1.0 | 13.0 ± 1.3 |

| LS/PEG 1000 | 26.2 ± 1.1 | 19.4 ± 0.9 |

| AL800_LS/PEG 1000 | 8.8 ± 1.2 | 14.6 ± 1.1 |

| AL1000_LS/PEG 800_LS/PEG 1000 | 10.8 ± 1.4 | 18.6 ± 1.6 |

| HL800_LS/PEG 1000 | 6.0 ± 0.7 | 13.5 ± 0.2 |

| HL1000_LS/PEG 800_LS/PEG 1000 | 9.2 ± 3.5 | 15.2 ± 0.5 |

| G800_LS/PEG 1000 | 7.5 ± 1.2 | 10.8 ± 0.7 |

| G1000_LS/PEG 800_LS/PEG 1000 | 9.2 ± 1.8 | 17.5 ± 2.3 |

| C800_LS/PEG 1000 | 8.7 ± 0.4 | 10.8 ± 0.3 |

| C1000_LS/PEG 800_LS/PEG 1000 | 11.3 ± 3.4 | 19.5 ± 2.4 |

| Mortar | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|

| AL800_LS | 0.9 ± 0.0 | 1.5 ± 0.1 (CS I) |

| AL800_LS/PEG 1000 | 0.5 ± 0.1 | 1.2 ± 0.1 (< CS I) |

| AL1000_LS | 0.6 ± 0.2 | 1.5 ± 0.2 (CS I) |

| AL1000_LS/PEG 800 | 0.3 ± 0.1 | 0.4 ± 0.0 (< CS I) |

| AL1000_LS/PEG 800_LS/PEG 1000 | 0.4 ± 0.0 | 0.6 ± 0.1 (< CS I) |

| HL800_LS | 2.8 ± 0.5 | 17.0 ± 0.2 (CS IV) |

| HL800_LS/PEG 1000 | 0.4 ± 0.1 | 1.5 ± 0.1 (CS I/CS II) |

| HL1000_LS | 5.2 ± 1.5 | 11.7 ± 0.5 (CS IV) |

| HL1000_LS/PEG 800 | 2.3 ± 0.4 | 3.5 ± 0.2 (CS II-CS III) |

| HL1000_LS/PEG 800_LS/PEG 1000 | 2.1 ± 0.5 | 3.6 ± 0.5 (CS II-CS III) |

| G800_LS | 4.1 ± 0.2 | 16.4 ± 0.6 (CS IV) |

| G800_LS/PEG 1000 | 1.6 ± 0.2 | 3.3 ± 0.3 (CS II) |

| G1000_LS | 9.3 ± 1.3 | 22.3 ± 0.2 (CS IV) |

| G1000_LS/PEG 800 | 1.7 ± 0.0 | 4.3 ± 1.7 (CS II-CS III) |

| G1000_LS/PEG 800_LS/PEG 1000 | 2.3 ± 0.0 | 6.2 ± 0.5 (CS II-CS III) |

| C800_LS | 9.2 ± 0.9 | 26.3 ± 0.4 (CS IV) |

| C800_LS/PEG 1000 | 1.9 ± 0.3 | 3.4 ± 0.8 (CS II) |

| C1000_LS | 11.8 ± 1.1 | 65.6 ± 6.1 (CS IV) |

| C1000_LS/PEG 800 | 2.1 ± 0.1 | 3.9 ± 1.2 (CS II-CS III) |

| C1000_LS/PEG 800_LS/PEG 1000 | 2.0 ± 0.2 | 4.4 ± 0.7 (CS II-CS III) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frigione, M.; Sarcinella, A.; Barroso de Aguiar, J.L. Development and Performance of Eco-Sustainable Form-Stable Phase Change Materials (PCMs) for Mortars to Be Applied in Buildings Located in Different Climatic Areas. Coatings 2023, 13, 258. https://doi.org/10.3390/coatings13020258

Frigione M, Sarcinella A, Barroso de Aguiar JL. Development and Performance of Eco-Sustainable Form-Stable Phase Change Materials (PCMs) for Mortars to Be Applied in Buildings Located in Different Climatic Areas. Coatings. 2023; 13(2):258. https://doi.org/10.3390/coatings13020258

Chicago/Turabian StyleFrigione, Mariaenrica, Antonella Sarcinella, and Josè Luis Barroso de Aguiar. 2023. "Development and Performance of Eco-Sustainable Form-Stable Phase Change Materials (PCMs) for Mortars to Be Applied in Buildings Located in Different Climatic Areas" Coatings 13, no. 2: 258. https://doi.org/10.3390/coatings13020258

APA StyleFrigione, M., Sarcinella, A., & Barroso de Aguiar, J. L. (2023). Development and Performance of Eco-Sustainable Form-Stable Phase Change Materials (PCMs) for Mortars to Be Applied in Buildings Located in Different Climatic Areas. Coatings, 13(2), 258. https://doi.org/10.3390/coatings13020258