Abstract

The growing concern for the environment and the depletion of raw materials such as fossil fuels is driving research towards the exploitation of new materials and the development of new technologies. Phase-change materials (PCMs) are increasingly used to reduce the energy required for the heating/cooling of buildings. The biggest challenge is to find a PCM with suitable characteristics able to meet the needs of the different climates in which it is placed. The originality of our research, therefore, lies in the possibility of selecting the most appropriate polymer to produce a PCM suitable for different climatic conditions that characterize the area in which a building is located. Furthermore, the proposed form-stable PCMs were obtained by including low-toxic, low-flammability polymers in waste stone fragments, according to the principles of a circular economy. These original sustainable PCMs were then used as aggregates by adding them to mortars (based on air lime, hydraulic lime, cement and gypsum). The mortars containing the PCMs were analyzed in fresh (workability) and hardened (flexural and compressive strengths and thermal characteristics) states. The results obtained showed that although the inclusion of PCM reduced the mechanical properties of the mortars, good mechanical properties can be still achieved by using an adequate binder content. The produced mortars were also analyzed by thermal analysis to assess how the addition of a PEG-based PCM affected their thermal behavior. The original PCMs were proven to be effective in improving the indoor temperature when included in mortars applied as plasters.

1. Introduction

The energy necessary for indoor thermoregulation (heating in the cold season and cooling in the hot season) of buildings is one of the main sources of consumption of energy based on fossil fuels. In European countries, almost 40% of energy is used for heating/cooling of buildings. This energy is then directly linked to CO2 emissions, which are responsible for the alarming change in climate [1,2]. Global warming is in turn continuously increasing the energy necessary to reduce indoor temperatures. To reduce energy consumption, and consequently contain the environmental problems connected to CO2 emissions, it is necessary to achieve high levels of energy efficiency in buildings.

Starting from these issues, scientific interest in new materials able to improve the energy efficiency of buildings is constantly growing. Among the most promising approaches are thermal energy storage (TES) systems, able to ensure the internal comfort of the inhabitants [3]. This approach involves the use of a phase change material (PCM), a system capable of absorbing and releasing energy following changes in external temperatures that change its physical state from solid to liquid and vice versa [4]. The integration of a suitable PCM in a building component, for example, in a mortar or in a plaster, can limit the indoor temperature variations regardless of the external conditions, ensuring human comfort along with a reduced energy consumption. In recent years, various PCMs have been developed and tested [5,6,7]. It is possible, therefore, to select the most appropriate system based on the purpose and specific application [8,9].

Adding a PCM to a mortar is an easy way to include such a system in the building elements, and it is also very efficient due to the large heat transfer surfaces that the mortars offer. In this regard, several studies on form-stable PCMs embedded in cementitious materials have been conducted [10,11,12], with the aim of improving the energy efficiency of a building, making it thermally sustainable. Since the incorporation of a PCM is reported to substantially modify the physical (mechanical, workability, etc.) properties of the mortar in which it is included [13,14,15,16], the composition of the mortar must be suitably modified. A solution to obtain adequate mechanical properties, for example, is the addition of a superplasticizer [17,18]. Hydraulic binders and air lime have been also proposed; the inclusion of PCMs in them can be, in fact, a solution to improve the energy efficiency of buildings of recognized historical and artistic value [19,20].

Among the three methods available for introducing a PCM into a mortar, namely the form-stable method, micro-encapsulation and macro-encapsulation, the first is the most commonly used. Compared to the other two, in fact, the form-stable method is generally more efficient and cheaper [10,21]. The active component of a form-stable PCM, for instance a polymer, is absorbed into an inert support to produce a composite PCM. The composite PCM granules are then added as aggregates to a mortar, giving the latter the ability to thermoregulate the internal environment in which it is applied. In this way, it is also possible to obtain a PCM with high thermal resistance, as the inert support retains the active (polymeric) phase, preventing its leakage during temperature variations [22,23,24].

In this context, original sustainable form-stable PCMs were produced. As an inert support, waste from the processing of a porous stone typical of Salento, Pietra Leccese, was used. As the active component of the PCM, a low-toxic and low-flammability polymer was chosen, namely polyethylene glycol (PEG). In addition to its low cost and sustainable characteristics, this polymer was selected because it is possible to obtain PEGs with different molecular weights corresponding to various intervals of phase change, i.e., different melting/crystallization temperature ranges. This feature allows the creation of PCMs that are capable of undergoing a phase change in response to different environmental conditions, thus producing different PCMs based on the expected outdoor climate. The PCMs were produced according to the principles of sustainability and the circular economy, selecting sustainable materials which were also derived from waste from other processes.

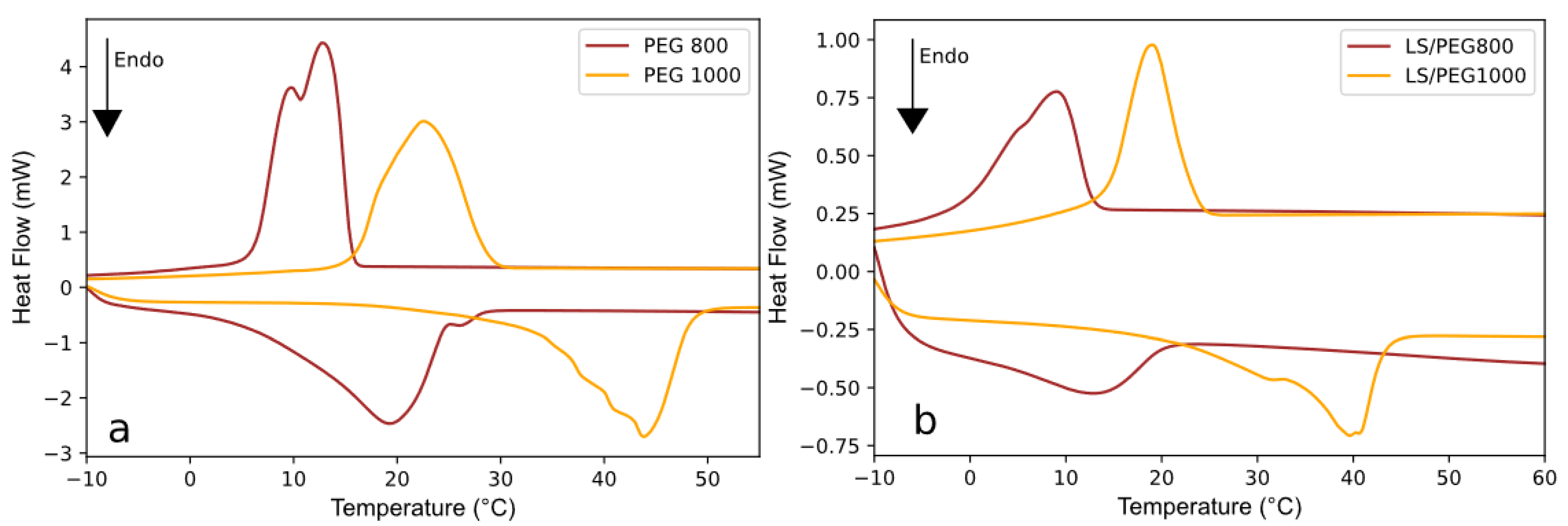

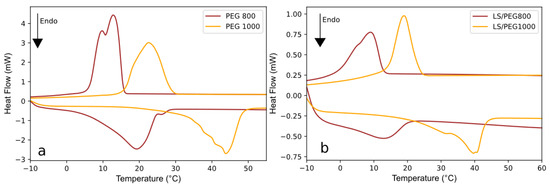

This work, which is part of a larger research project, proposes the integration of several PEG-based PCMs in mortars based on different binders. Two PEGs (i.e., PEG 800 and PEG 1000), selected on the basis of the different phase change ranges they offer (as showed in Figure 1a), were included in flakes of a porous stone, derived from the extraction and processing of Lecce stone. To activate the thermal energy accumulation/release process, the temperature of the environment in which the PCM is placed must be within the phase change temperature range of the PCM itself. Based on their respective phase change ranges, PEG 800 was selected to create a PCM suitable for a continental climate, while PEG 1000 was selected to produce a PCM for a Mediterranean climatic area (see Figure 1b). This is a further important novelty of the presented work, i.e., creating a PCM that can be adapted to any specific climatic condition. In addition, including PCMs based on both PEGs in the mortars, i.e., a 50/50 LS/PEG 800–LS/PEG 1000 mix, allows to extend the phase change interval, making the PCM effective over a wider temperature range.

The produced PCMs were then added as aggregates to mortars based on aerial and hydraulic lime, gypsum and cement. The effect of the inclusion of PCMs on the properties of mortars in the fresh (workability) and hardened state (compressive and flexural strength) was evaluated, taking the same mortars without PCM as a reference. In this way, it was possible to verify whether the mortars modified with PCM were still suitable as interior plaster. Finally, the thermal properties of the mortars containing the new PCMs were studied to evaluate their ability to absorb and release thermal energy as the environmental temperature varied, and therefore their ability to thermoregulate the rooms where the mortars are applied.

2. Materials and Methods

2.1. Materials

Two poly-ethylene glycol polymers were selected in this study, namely PEG 800 (Wuhan Fortuna Chemical Co., Wuhan, China) and PEG 1000 (Sigma-Aldrich Company, Darmstadt, Germany). They differ in their molecular weight (as also indicated in their trade names, e.g., PEG 800 and PEG 1000) and, consequently, in the respective phase change temperature range [25,26]. In Figure 1a, the thermograms obtained by differential scanning calorimetry (DSC, Stare System, Mettler Toledo, Columbus, OH, USA) analysis performed on both PEG polymers illustrates the melting and crystallization range of temperatures measured on PEG 800 and PEG 1000, respectively [26]. The same calorimetric test was repeated on the PCMs produced with the two PEGs. In Figure 1b, the DSC curves obtained for LS/PEG 800 PCM and LS/PEG 1000 PCMs are reported [26]. Based on these results, PEG 800 was proposed to produce a PCM suitable for a cold (continental) climate, while the PEG 1000-based PCM was considered suitable for a warm climate, characteristic of Mediterranean regions.

Figure 1.

DSC curves of: (a) PEG 800 and PEG 1000 polymers; (b) LS/PEG 800 PCM and LS/PEG 1000 PCMs. Reproduced with permission from Sarcinella A. et al., Physical Properties of an Eco-Sustainable, Form-Stable Phase Change Material Included in Aerial-Lime-Based Mortar Intended for Different Climates, published in Materials, 2022 [26].

The PEG 800 and PEG 1000 polymers were used to produce form-stable PCMs by including them in an inert matrix composed of flakes of Lecce stone (LS). Lecce stone, a calcareous limestone extracted in the Salento area (Cursi, Lecce, Italy), is characterized by a very high open porosity (average pore radius: 0.054 ± 0.036 µm, total open porosity: 30.33 ± 0.99%) [13]. Small pieces of LS, therefore, are suitable to serve as an inert support matrix for a PCM. By adopting this strategy, it was possible to enhance local waste stone (derived from extraction from quarries) which would otherwise be thrown away at additional costs. The stone fragments were ground with a mill and sieved to obtain particles with an adequate particle size (i.e., in the range of 1.6–2.0 mm) to be used as aggregates in mortars.

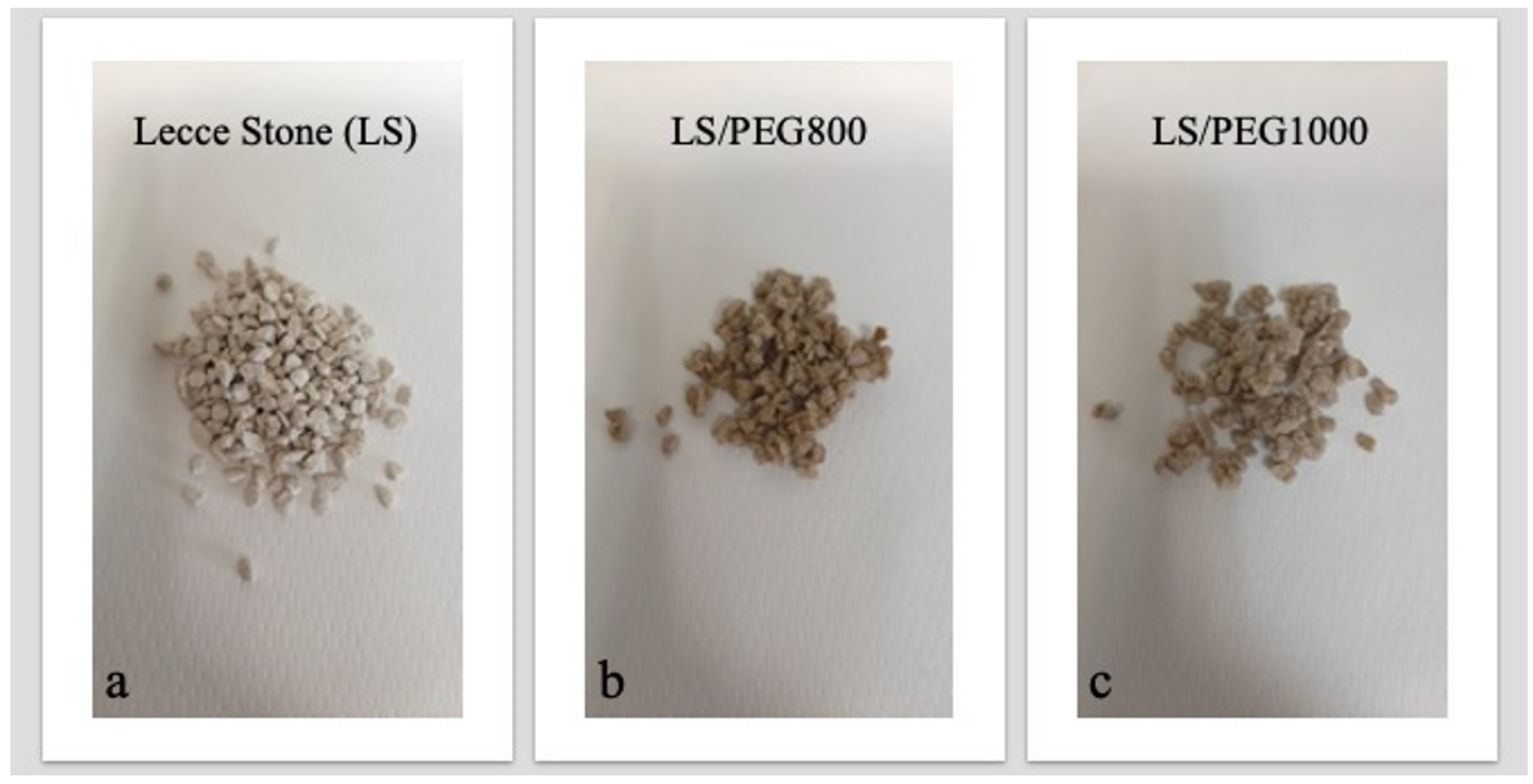

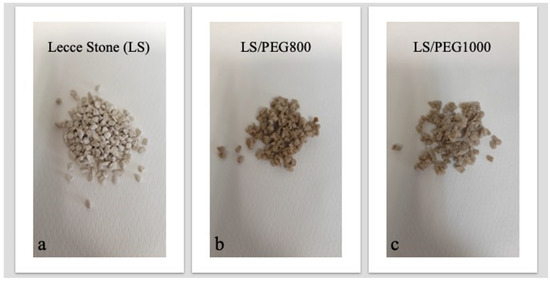

A simple and economical procedure was employed for the production of form-stable PCMs, obtained with each of the two PEGs. Each PEG was brought to a liquid state (i.e., heated above its melting point). Then, it was absorbed into Lecce stone granules by means of a vacuum impregnation process using a PEG/LS weight ratio of 1/5. The PCM composites obtained were referred to as LS/PEG 800 and LS/PEG 1000, respectively. The Lecce stone granules before the impregnation process, LS/PEG800 and LS/PEG1000 composites, are illustrated in Figure 2.

Figure 2.

Aggregates used to produce the mortars: (a) granules of Lecce stone (LS) to manufacture the reference mortars; (b) granules of LS/PEG800 composite PCM; (c) granules of LS/PEG1000 composite PCM.

LS/PEG 800 and LS/PEG 1000 PCMs were finally added to mortars based on different binders, namely aerial lime, hydraulic lime, gypsum and cement. The binders were supplied by different Portuguese companies, with the following reported properties: aerial lime, AL (density: 2450 kg/m3), by Lhoist (Alcanade, Portugal); hydraulic lime, HL (density: 2700 kg/m3), by Cimpor (Lisbon, Portugal); gypsum, G (density: 2960 kg/m3), by Sival (Souto da Carpalhosa, Leira, Portugal); and CEM I 42.5 R cement, C (density: 3030 kg/m3), by SECIL (Lisbon, Portugal). The mortars, containing one of the two PCMs or a mix of LS/PEG 800 and LS/PEG 1000 (50:50 by weight), were characterized in fresh and hardened state, determining their workability, flexural and compressive strength and thermal properties. For comparison purposes, reference mortars containing unimpregnated LS granules as aggregate were also produced and analyzed. A superplasticizer (SP), a polyacrylate (MasterGlenium SKY 627 supplied by BASF, Porto, Portugal), was added to each mortar in order to limit the quantity of water necessary to obtain an adequate level of workability. Table 1 reports the compositions of the mortars under study which offered the best mechanical properties, as proven in previous studies [25,26]. The mortars were produced according to European Standard EN 998-1 [27], cast in standard-sized iron molds and cured for 28 days under standard conditions (25 °C and R.H. of 50%).

Table 1.

Compositions of the produced mortars (reported as kg/m3).

2.2. Methods

The workability test was carried out on fresh mortars, on those containing a PEG-based PCM and on reference mortars using the flow table method, according to EN 1015-3 standard [28]. For each mortar formulation, the workability test was repeated at least three times, and the average of the results was taken.

The latent heats and the phase change temperatures were assessed on LS/PEG 800 and LS/PEG 1000 composites as well as on hardened mortars including a PEG-based PCM. To this aim, specimens of a LS/PEG composite or of a mortar were analyzed in a DSC1 (Stare System, Mettler Toledo, Columbus, OH, USA) instrument. Each sample (weight: 10–20 mg) was subjected to a thermal cycle, with first a heating stage in the range of −10 °C–+80 °C and a subsequent cooling stage in the range of +80 °C–−10 °C, employing a 10 °C/min heating/cooling rate. The DSC tests were performed under an inert (nitrogen) atmosphere on at least three specimens for each material, and the results were averaged.

A simple test, as suggested in [29], was performed on the granules of LS/PEG PCMs to evaluate any losses due to the permanence of each PCM at a temperature higher than its melting point, in order to evaluate whether heating the PEG 800 or PEG 1000 polymers causes them to come out of the LS flakes.

The effect of the addition of a PEG-based PCM on the mechanical properties of the mortars was evaluated through flexural and compressive tests, according to the European Standard EN 1015-11 [30]. The tests were performed in a Lloyd dynamometer (LR50K Plus by Ametek Company, Berwyn, PA, USA) machine, employing a speed of 6 µm/s in flexural tests and 12 µm/s in compressive tests. The results of the experiments performed on five specimens for each mortar, containing or not containing a PCM composite, were averaged.

Finally, the ability of some of the mortars containing PEG-based PCMs to improve the energy efficiency of the building where they were applied was assessed, employing a climatic chamber as detailed in [31]. With this procedure, it is possible to identify the optimal PCM for each climatic condition, i.e., the one which when incorporated in the mortar provides the best energy performance.

3. Results

3.1. Workability

The workability of the produced mortars was first assessed. The average results are reported in Table 2, with the range of data variation. From the observation of the data reported in Table 2, it can be concluded that all the produced mortars displayed an adequate workability, irrespective of their composition and of the presence or not of PCM. According to [32], workability must be in the range of 160–180 mm.

Table 2.

Workability values of the mortars whose compositions are reported in Table 1.

3.2. Latent Heats and Phase Change Temperatures, Leakage Test

In Table 3, the results of the DSC tests performed on LS/PEG 800 and LS/PEG 1000 composites and on the hardened mortars, including PEG-based PCMs, are shown. The range of data variation is also reported. From these tests it was possible to measure the latent heats during the melting and crystallization processes and the relative phase change temperatures. Mortars that did not contain PCM were also tested; in such materials, as expected, no melting/crystallization process was observed, therefore the results are not presented in Table 3.

Table 3.

Results of DSC tests performed on LS/PEG 800 and LS/PEG 1000 composites and on mortars containing a PEG-based PCM. (ΔH: enthalpy measured during melting or crystallization processes. Tp: peak temperature of melting or crystallization processes.)

From the observation of the data presented in Table 3, it can be concluded that the phase change temperature of the mortar mainly depends on the phase change temperature of the relative PEG that was contained in the mortar; the lower the peak temperature of melting (or crystallization) of PEG, the lower the peak temperature of melting (or crystallization) measured in mortar. This, in turn, implies that the most suitable PEG polymer can be selected based on the expected external temperature, i.e., the polymer that changes phase due to the temperature variations typical of a geographical area. This result confirms the correctness of the adopted strategy. Using a mix of both PEG-based PCMs, i.e., LS/PEG 800:LS/PEG 1000 50:50 wt., a wider phase change temperature range, during both the melting and crystallization processes, was measured. This PCM composite, therefore, could be suitable for a region where large temperature variations are expected (between day and night or between winter and summer).

The results of the leak test demonstrated that there was no loss of PEG polymer from the LS granules if the LS/PEG composites were left at a temperature equal to the melting point of the respective PEG (i.e., 30–35 °C for PEG 800 and 45–50 °C in the case of PEG 1000). By performing the same test at a temperature much higher than their respective melting points (i.e., 75–80 °C in both cases), minimal polymer loss was found in both PCMs, i.e., around 0.3–0.4%. This test therefore demonstrated that PCMs produced with the form-stable method, using Lecce stone granules as an inert matrix for a PEG polymer, are thermally stable. As further confirmation, thermal cycling tests are in progress on both PEG-based PCMs, the results will be presented in a forthcoming work.

3.3. Mechanical Properties

It is well known from the literature that the introduction of a PCM in a mortar leads to a decrease in its mechanical strength properties [16,33]. To ascertain whether the produced mortars containing a PEG-based PCM were still suitable for their intended purposes, their mechanical properties in flexural and compressive mode were measured after 28 days of aging. For comparison purposes, the same tests were also carried out on the reference mortars, i.e., those which did not contain a PCM. The results of the mechanical tests carried out on the mortars under analysis are summarized in Table 4; the ranges of variation in the results are also reported. The same table also shows the indication of the classification of each mortar, according to the NP EN 998-1 standard [27].

Table 4.

Mechanical properties of the mortars whose compositions are reported in Table 1 measured in flexural and compressive mode. (The category of mechanical strength of the mortars according to the NP EN 998-1 standard is shown in brackets.)

As expected, the introduction of a PCM into the mortars caused a significant reduction in their mechanical properties, regardless of the type of binder and PEG. Flexural strength is substantially dependent on the type of binder and its content in the mortars; no clear influence on this property can be attributed to the PCM composition, in particular to the PEG type. Flexural strength values not exceeding 2.3 MPa were found in all mortars containing a PEG-based PCM, the highest values were recorded in mortars with a binder content of 1000 kg/m3. Aerial lime-based mortars offered the lowest flexural properties, even in the absence of a PCM.

In relation to the compressive strength, it is possible to reach values suitable for the intended purpose (i.e., production of mortars for plasters) in the case of hydraulic lime, gypsum and concrete, especially in correspondence with the highest content of binder. The compressive strength of mortars with a binder content of 1000 kg/m3, in fact, reached at least the classification of CS II, according to the standard NP EN 998-1. Lime-based mortars could only be proposed for the internal restoration of historic buildings, where lower mechanical resistance is required and it is mandatory to select materials similar to those originally used.

The last part of this extensive project was dedicated to the evaluation of the effectiveness of the new PCMs as thermoregulators of an indoor environment when inserted in mortars applied as plasters. Experimental thermal tests were carried out on the mortars offering the highest mechanical strength values in a climatic chamber capable of simulating different external climatic conditions by recording the temperature inside a small room where the mortars under analysis were applied. Two climatic conditions relating to different European countries were simulated, namely those characteristic of the Mediterranean region and those of the continental areas. The results of these tests first confirmed that the new LS/PEG composites are effective as phase change materials. In fact, it was found that mortars containing a PCM were able to reduce internal temperature fluctuations in response to changes in external temperature. The efficacy of PEG-based PCMs was especially evident in the simulated warmest season. Therefore, the new PCMs will be particularly suitable for the thermoregulation of indoor environments during summer. The best performances were found for the PEG 1000-based PCM, i.e., the one that has a phase change interval shifted towards higher temperatures. Applying a mortar containing a PEG 1000-based PCM, therefore, could lead to a reduction in the energy consumption required for the internal cooling of buildings in hot climates. PEG 800, on the other hand, was best suited for temperate climates. With neither of the two PEGs was it possible to achieve high benefits in terms of energy savings during the cold seasons. Finally, mortars containing a mixture of both PEG-based PCMs, i.e., LS/PEG 800 and LS/PEG 1000, can be proposed for climates characterized by a wide temperature range.

The quantification of the energy savings, with relating cost, for cooling needs obtained with the introduction of a PCM in the mortars, is currently underway and will be presented in a forthcoming manuscript. Energy savings for cooling needs will be related to the specific climatic conditions of the place where the mortars will be applied, in order to select the PCM composition offering the greatest advantages in relation to the expected external climate.

4. Conclusions

In this work, the effect of the integration of form-stable PCMs, based on two polyethylene glycol polymers, in different mortars on their fluid and solid state properties was investigated. The PEGs used to produce the PCMs (i.e., PEG 800 and PEG1000) were selected on the basis of their phase change temperatures. The PEGs were included in an inert matrix composed of flakes of Lecce stone waste by means of a simple and inexpensive procedure, obtaining different PCMs. The composite PCMs, obtained in the form of granules, have been added as aggregates to mortars based on air lime, hydraulic lime, cement and gypsum. The main findings of the study can be summarized as follows:

- It is possible to produce composites to be employed as effective phase change materials starting from non-toxic PEG polymers and waste stone materials, in compliance with sustainability and the principles of the circular economy;

- Since the type of PEG determines the temperature range in which the PCM operates, through an appropriate choice of the PEG, it is possible to create a PCM suitable for a specific climatic condition, i.e., for the first time it is possible to adapt the PCM to the expected climate;

- The presence of PEG-based PCMs in the mortars affected their characteristics, especially their mechanical properties; however, it was possible to obtain adequate mechanical properties by adequately adjusting the mortar compositions, using a high binder content in combination with a plasticizer.

In further developments of the project, the durability of mortars containing a PEG-based PCM when exposed to different environmental conditions is being investigated. Furthermore, various porous inert supports capable of including the PEG polymer are being studied, exploiting different waste materials or by-products of other processes.

Author Contributions

Conceptualization, M.F. and J.L.B.d.A.; experimentation, A.S.; validation, M.F. and J.L.B.d.A.; formal analysis, A.S.; data curation, A.S.; writing—original draft preparation, M.F.; writing—review and editing, M.F. and J.L.B.d.A.; project administration, M.F.; funding acquisition, M.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partly funded by the CRUI Foundation (Fondazione CRUI, Conferenza dei Rettori delle Università Italiane, Rome, Italy), in the framework of the GO FOR IT Project, which supported one of the authors, and by PON “Ricerca e Innovazione” 2014–2020, Azione IV.6 “Contratti di ricerca su tematiche Green”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to thank Ingegnere Livio Pascali and the staff of S.I.PRE. Limited Liability Company (Cutrofiano, Lecce, Italy) for their technical support, L’essenza della Pietra Company (Taviano, Lecce, Italy) for supplying the Lecce Stone flakes and Eurostrade Company (Melissano, Lecce, Italy) for grinding the Lecce stone.

Conflicts of Interest

The authors declare no conflict of interest.

References

- UN Environment Programme. 2021 Global Status Report For Buildings and Construction, Technical Report, Global Alliance for Buildings and Construction. 2021. Available online: http://Globalabc.Org/Resources/Publications/2021-Global-Status-Report-Buildings-and-Construction (accessed on 5 January 2023).

- International Energy Agency. Electricity Market Report, Technical Report. 2022. Available online: https://www.iea.org/reports/electricity-market-report-january-2022 (accessed on 5 January 2023).

- Chinnasamy, V.; Palaniappan, S.K.; Raj, M.K.A.; Rajendran, M.; Cho, H. Thermal Energy Storage and Its Applications. Mater. Sol. Energy Convers. Mater. Methods Appl. 2021, 353–377. [Google Scholar]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. A Review on Phase Change Materials for Thermal Energy Storage in Buildings: Heating and Hybrid Applications. J. Energy Storage 2021, 33, 101913. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Z.; Guo, Q.; Wang, H.; Wang, X.; Dong, X.; Tian, X.; Guo, X. Preparation and Thermal Characterization of Hollow Graphite Fibers/Paraffin Composite Phase Change Material. Coatings 2022, 12, 160. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Sanjayan, J.; Wang, X. Experimental Research on Using Form-Stable PCM-Integrated Cementitious Composite for Reducing Overheating in Buildings. Buildings 2019, 9, 57. [Google Scholar] [CrossRef]

- Hwang, R.-L.; Chen, B.-L.; Chen, W.-A. Analysis of Incorporating a Phase Change Material in a Roof for the Thermal Management of School Buildings in Hot-Humid Climates. Buildings 2021, 11, 248. [Google Scholar] [CrossRef]

- Rao, V.V.; Parameshwaran, R.; Ram, V.V. PCM-Mortar Based Construction Materials for Energy Efficient Buildings: A Review on Research Trends. Energy Build. 2018, 158, 95–122. [Google Scholar] [CrossRef]

- Han, H.; Zhou, H.; Dong, O.; Ma, J. Experimental Study on Phase Change Material with Solar Heater System for Building Heating. Coatings 2022, 12, 1476. [Google Scholar] [CrossRef]

- Yang, H.; Xu, Z.; Cui, H.; Bao, X.; Tang, W.; Sang, G.; Chen, X. Cementitious Composites Integrated Phase Change Materials for Passive Buildings: An Overview. Constr. Build. Mater. 2022, 361, 129635. [Google Scholar] [CrossRef]

- Soleiman Dehkordi, B.; Afrand, M. Energy-Saving Owing to Using PCM into Buildings: Considering of Hot and Cold Climate Region. Sustain. Energy Technol. Assess. 2022, 52, 102112. [Google Scholar] [CrossRef]

- Liu, L.; Hammami, N.; Trovalet, L.; Bigot, D.; Habas, J.-P.; Malet-Damour, B. Description of Phase Change Materials (PCMs) Used in Buildings under Various Climates: A Review. J. Energy Storage 2022, 56, 105760. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A.; Barroso de Aguiar, J. Sustainable Polymer-Based Phase Change Materials for Energy Efficiency in Buildings and Their Application in Aerial Lime Mortars. Constr. Build. Mater. 2020, 231, 117149. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Sutthiphasilp, T.; Chalodhorn, W.; Chindaprasirt, P. Improving Thermal Properties of Exterior Plastering Mortars with Phase Change Materials with Different Melting Temperatures: Paraffin and Polyethylene Glycol. Adv. Build. Energy Res. 2019, 13, 220–240. [Google Scholar] [CrossRef]

- Kulkarni, P.; Muthadhi, A. Polyethylene Glycol-600/Expanded Clay Aggregate with Alccofine1203 in Concrete. Mater. Today Proc. 2021, 43, 1081–1088. [Google Scholar] [CrossRef]

- Abbasi Hattan, H.; Madhkhan, M.; Marani, A. Thermal and Mechanical Properties of Building External Walls Plastered with Cement Mortar Incorporating Shape-Stabilized Phase Change Materials (SSPCMs). Constr. Build. Mater. 2021, 270, 121385. [Google Scholar] [CrossRef]

- Cunha, S.; Leite, P.; Aguiar, J. Characterization of Innovative Mortars with Direct Incorporation of Phase Change Materials. J. Energy Storage 2020, 30, 101439. [Google Scholar] [CrossRef]

- Wang, R.; Ren, M.; Gao, X.; Qin, L. Preparation and Properties of Fatty Acids Based Thermal Energy Storage Aggregate Concrete. Constr. Build. Mater. 2018, 165, 1–10. [Google Scholar] [CrossRef]

- Elert, K.; Rodriguez-Navarro, C.; Pardo, E.S.; Hansen, E.; Cazalla, O. Lime Mortars for the Conservation of Historic Buildings. Stud. Conserv. 2002, 47, 62–75. [Google Scholar] [CrossRef]

- Govaerts, Y.; Hayen, R.; de Bouw, M.; Verdonck, A.; Meulebroeck, W.; Mertens, S.; Grégoire, Y. Performance of a Lime-Based Insulating Render for Heritage Buildings. Constr. Build. Mater. 2018, 159, 376–389. [Google Scholar] [CrossRef]

- Lv, P.; Liu, C.; Rao, Z. Review on Clay Mineral-Based Form-Stable Phase Change Materials: Preparation, Characterization and Applications. Renew. Sustain. Energy Rev. 2017, 68, 707–726. [Google Scholar] [CrossRef]

- Mousavi, S.; Rismanchi, B.; Brey, S.; Aye, L. PCM Embedded Radiant Chilled Ceiling: A State-of-the-Art Review. Renew. Sustain. Energy Rev. 2021, 151, 111601. [Google Scholar] [CrossRef]

- Arumugam, P.; Ramalingam, V.; Vellaichamy, P. Effective PCM, Insulation, Natural and/or Night Ventilation Techniques to Enhance the Thermal Performance of Buildings Located in Various Climates—A Review. Energy Build. 2022, 258, 111840. [Google Scholar] [CrossRef]

- Mousavi, S.; Rismanchi, B.; Brey, S.; Aye, L. Lessons Learned from PCM Embedded Radiant Chilled Ceiling Experiments in Melbourne. Energy Rep. 2022, 8, 54–61. [Google Scholar] [CrossRef]

- Sarcinella, A.; de Aguiar, J.L.B.; Frigione, M. Physical Properties of Eco-Sustainable Form-Stable Phase Change Materials Included in Mortars Suitable for Buildings Located in Different Continental Regions. Materials 2022, 15, 2497. [Google Scholar] [CrossRef] [PubMed]

- Sarcinella, A.; de Aguiar, J.L.B.; Frigione, M. Physical Properties of an Eco-Sustainable, Form-Stable Phase Change Material Included in Aerial-Lime-Based Mortar Intended for Different Climates. Materials 2022, 15, 1192. [Google Scholar] [CrossRef]

- EN 998-1; Specification for Mortar for Masonry—Part 1: Rendering and Plastering Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- EN 1015-3; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- Zhang, J.; Li, H.; Tu, J.; Shi, R.; Luo, Z.; Xiong, C.; Jiang, M. Shape Stability of Polyethylene Glycol/Acetylene Black Phase Change Composites for Latent Heat Storage. Adv. Mater. Sci. Eng. 2018, 2018, 3954163. [Google Scholar] [CrossRef]

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- Sarcinella, A.; De Aguiar, J.L.B.; Lettieri, M.; Cunha, S.; Frigione, M. Thermal Performance of Mortars Based on Different Binders and Containing a Novel Sustainable Phase Change Material (PCM). Materials 2020, 13, 2055. [Google Scholar] [CrossRef]

- Cunha, S.; Aguiar, J.; Tadeu, A. Ranking Procedure Based on Mechanical, Durability and Thermal Behavior of Mortars with Incorporation of Phase Change Materials. Mater. Construc. 2015, 65, e068. [Google Scholar] [CrossRef]

- Cunha, S.; Aguiar, I.; Aguiar, J.B. Phase Change Materials Composite Boards and Mortars: Mixture Design, Physical, Mechanical and Thermal Behavior. J. Energy Storage 2022, 53, 105135. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).