Influence of Powder Mass Flow Rates on Wear Resistance and Impact Toughness of Inconel 718 Surface Coatings

Abstract

:1. Introduction

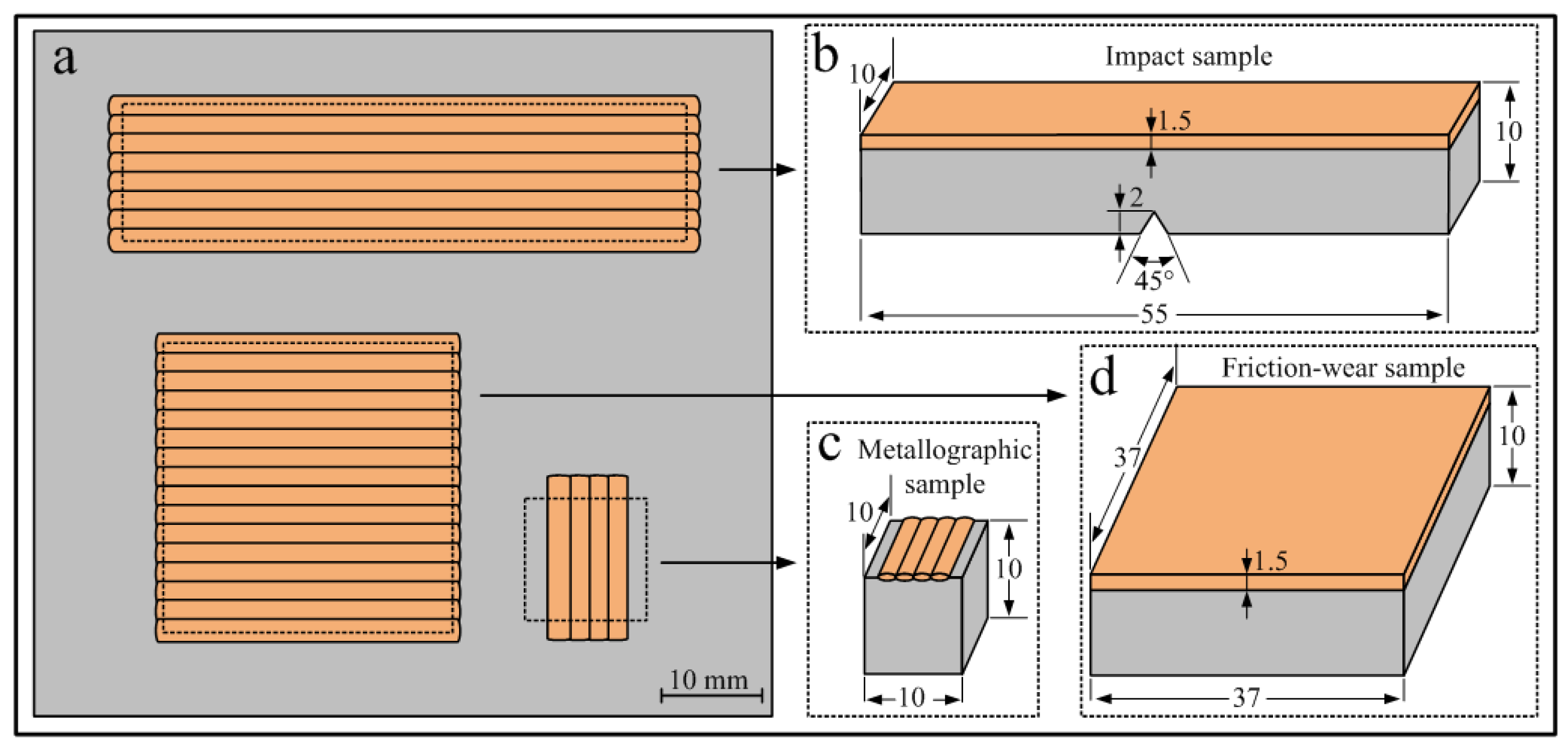

2. Experimental Procedure

3. Results and Discussion

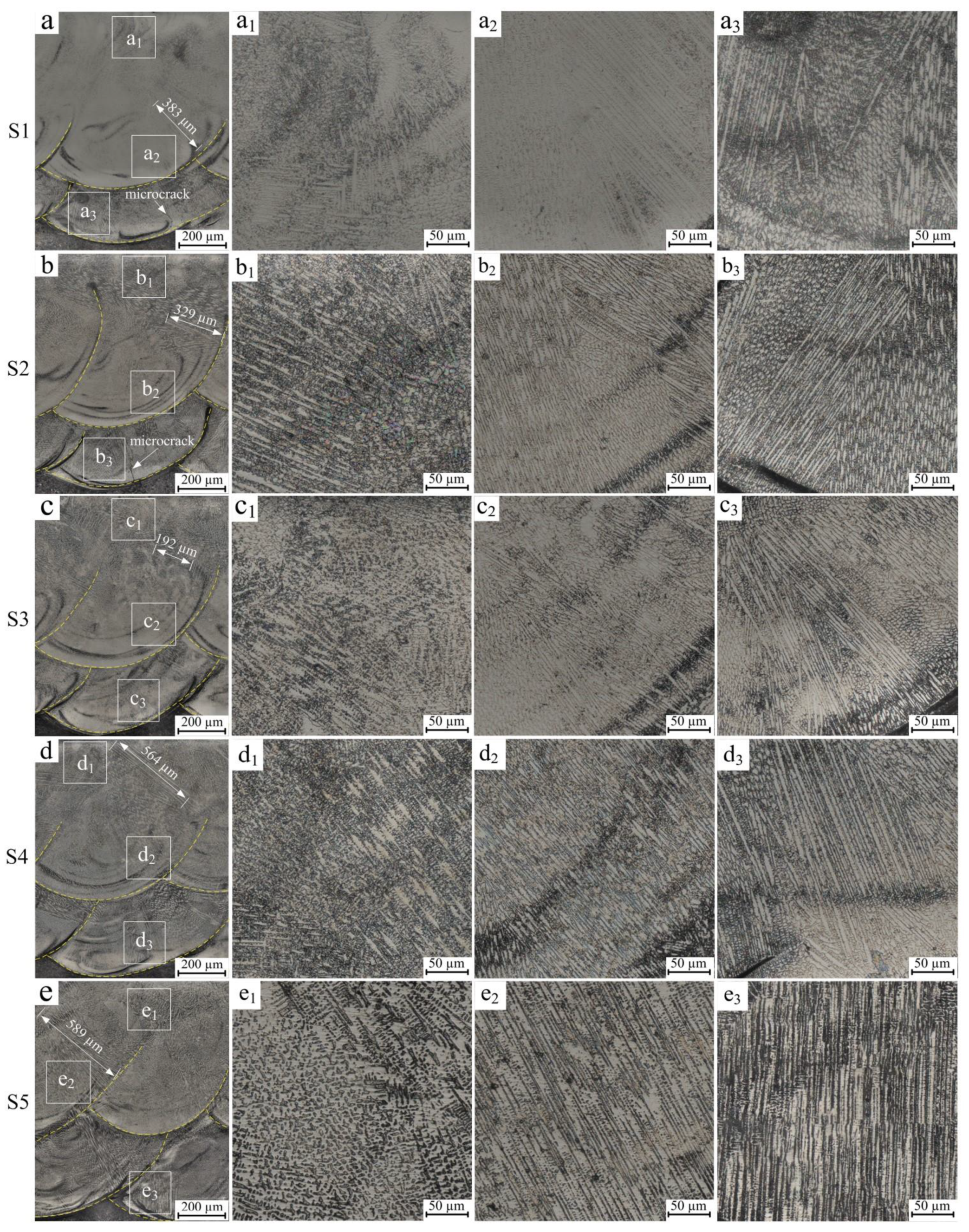

3.1. Microstructure of Cladding Layer Cross-Section

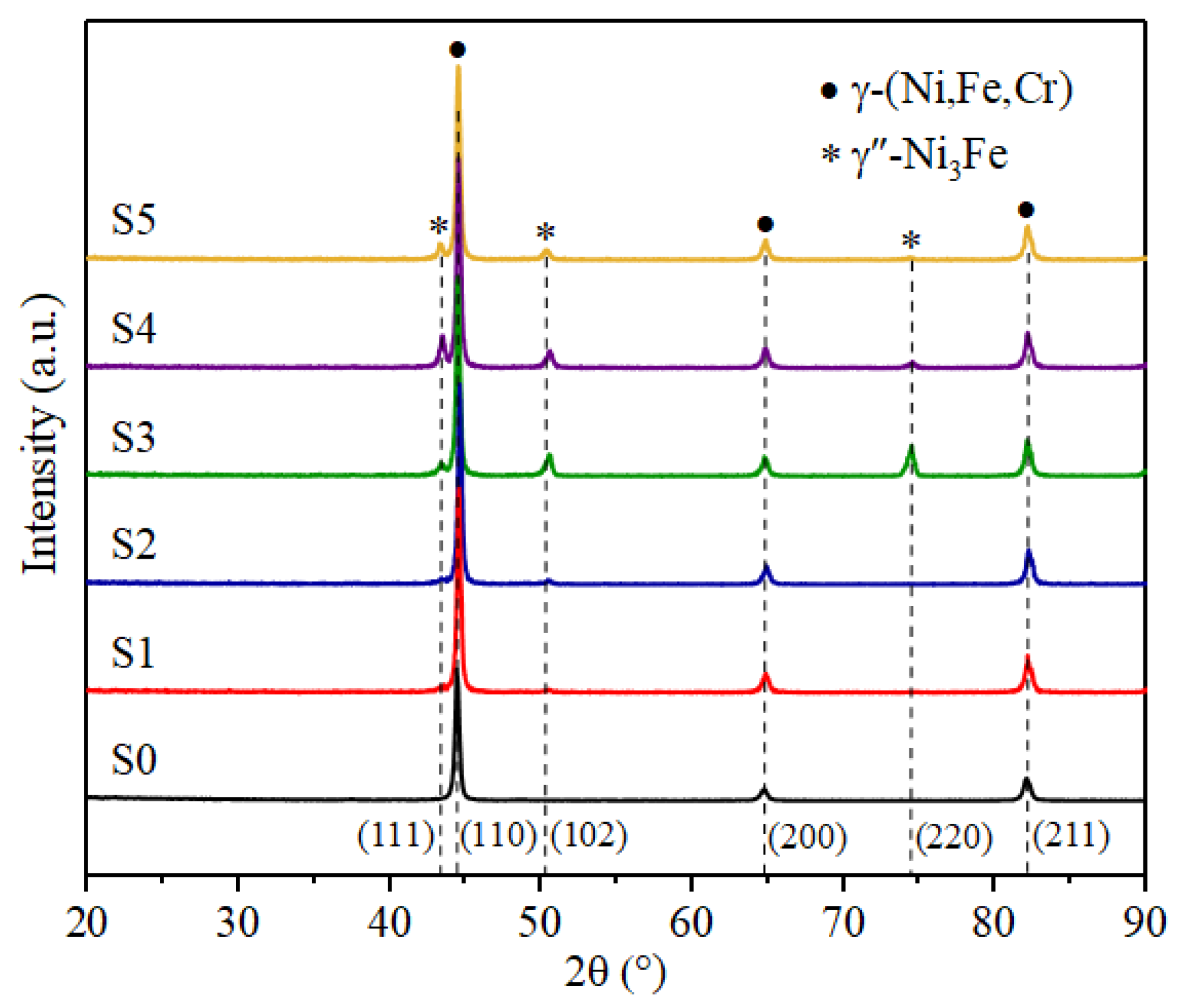

3.2. XRD Analysis

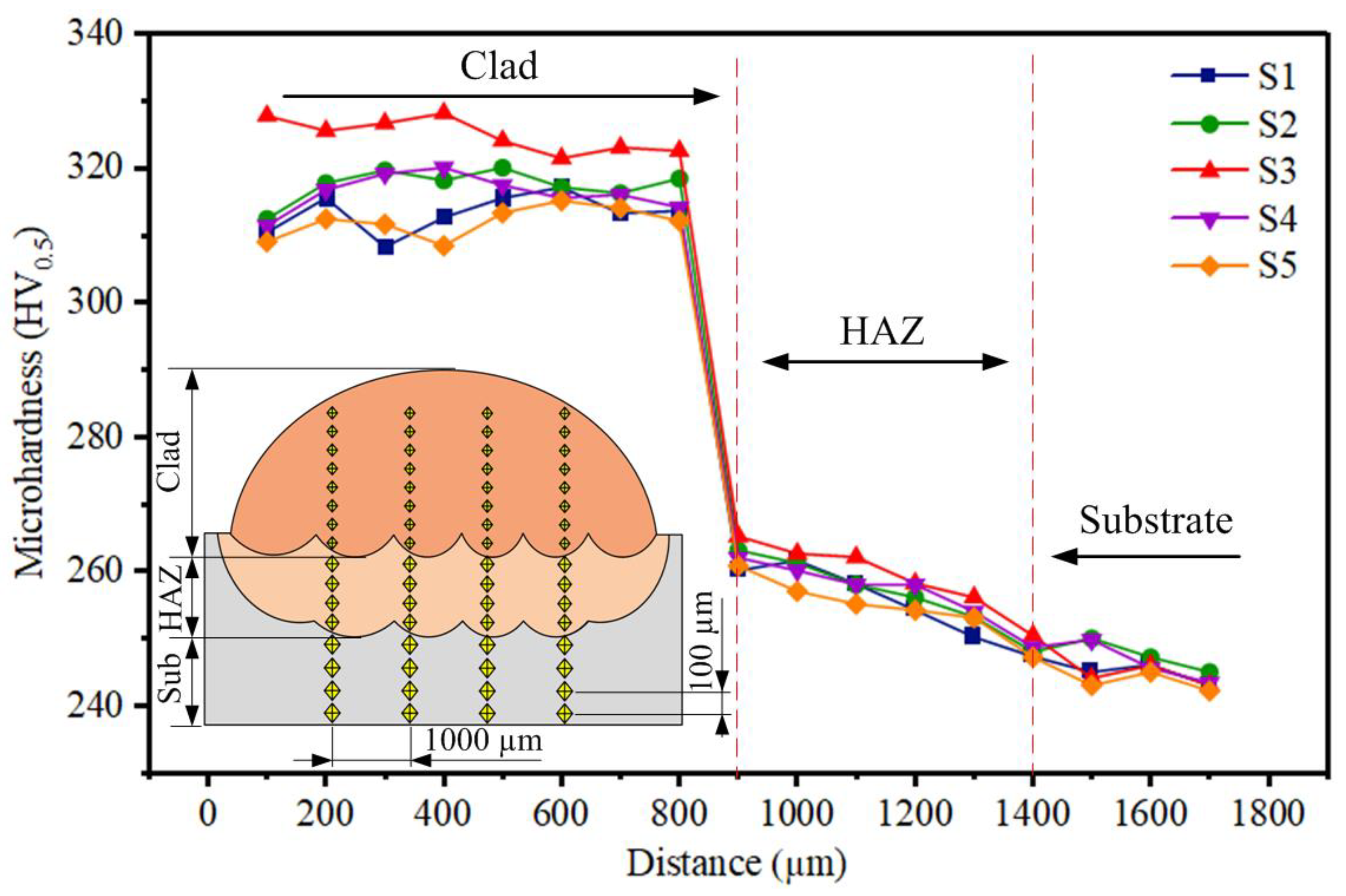

3.3. Micro-Hardness

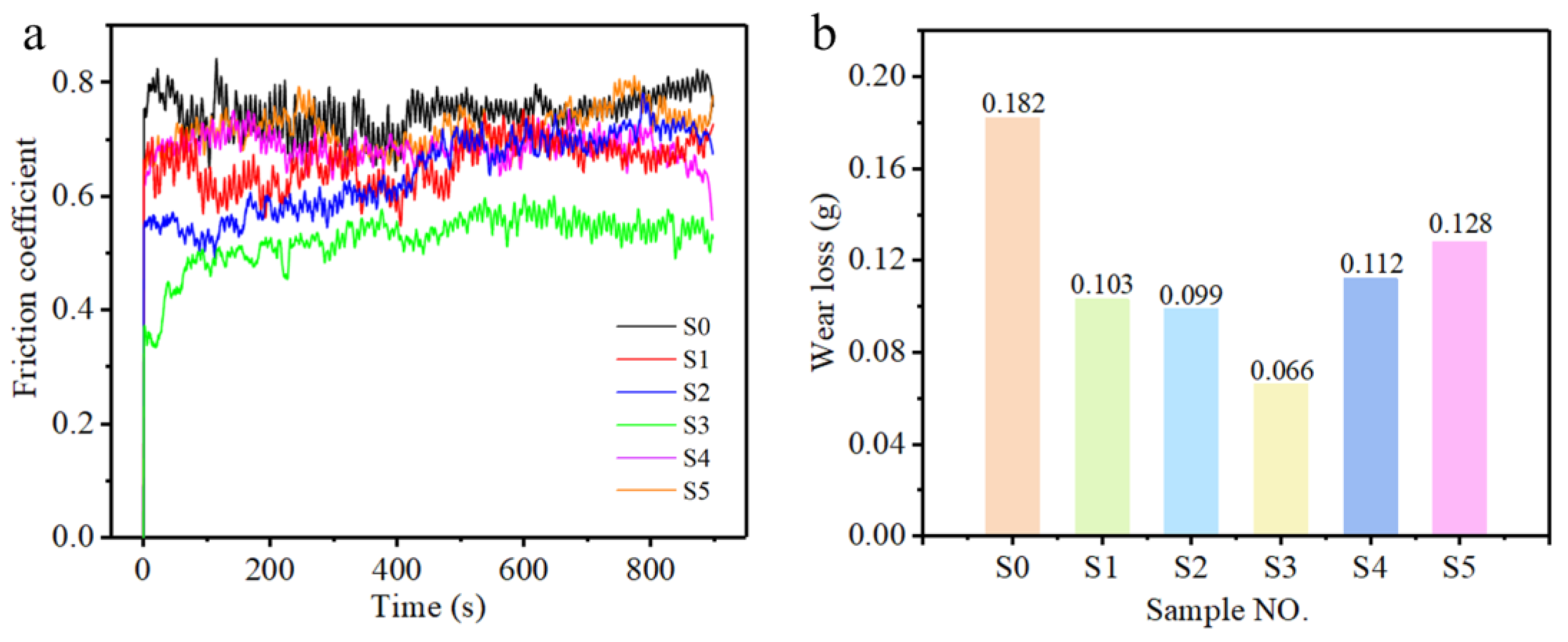

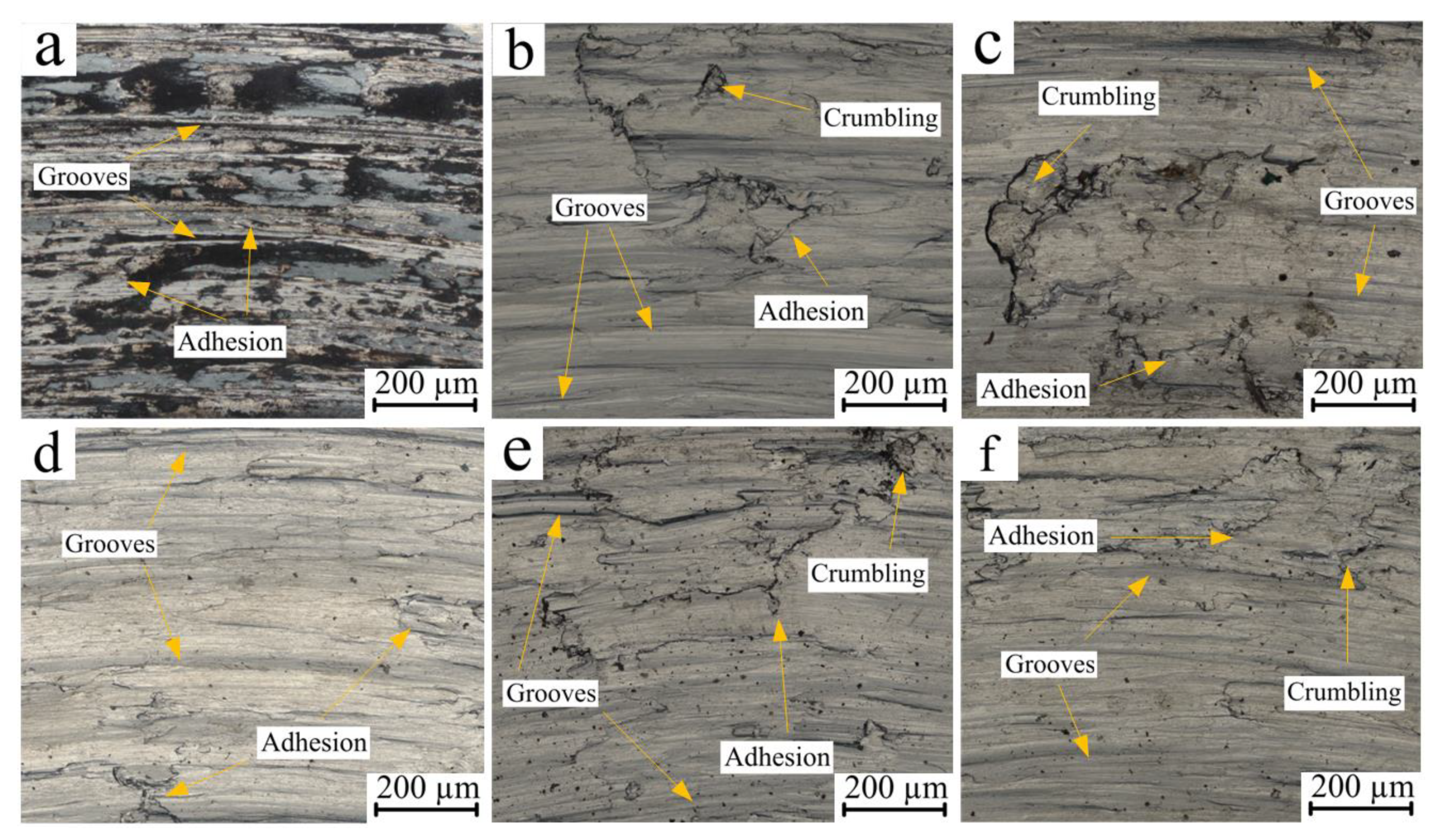

3.4. Friction and Wear Property

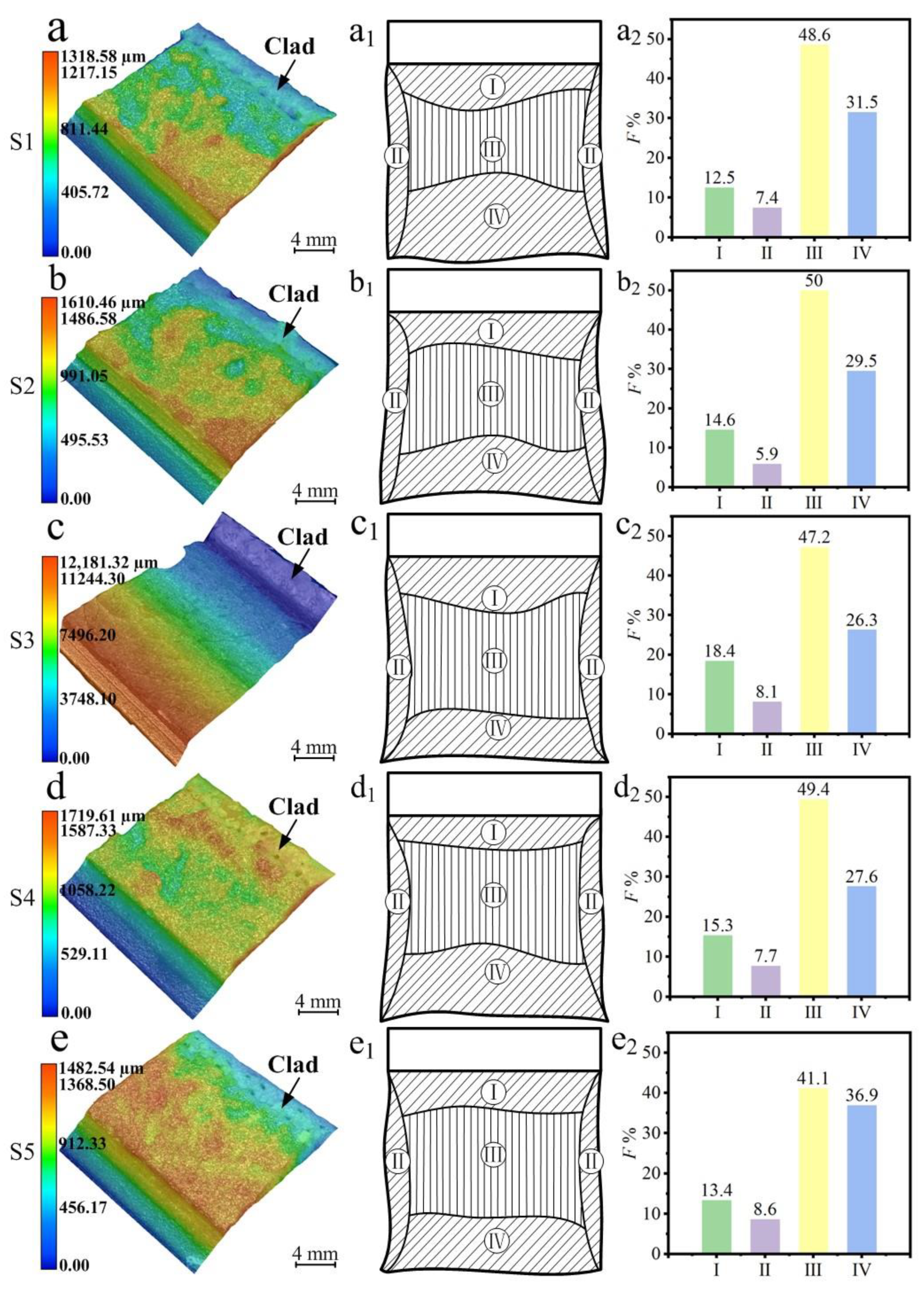

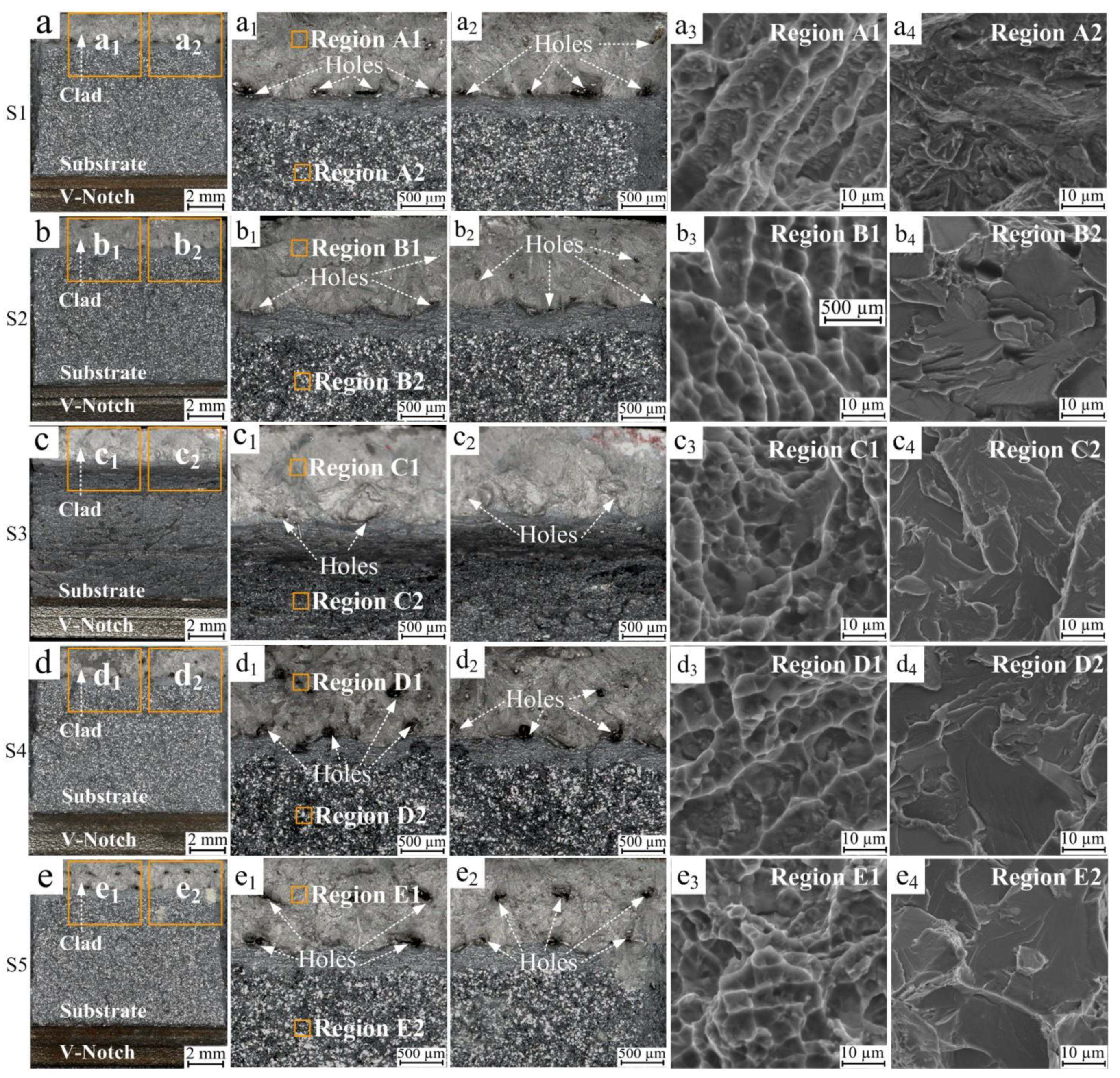

3.5. Impact Toughness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yong, Z.; Chang, L.; Jiang, S.; Xie, D.; Xing, F.; Shen, H.; Shen, L.; Tian, Z. Parameter optimization of T800 coating fabricated by EHLA based on response surface methodology. Opt. Laser Technol. 2023, 158, 108837. [Google Scholar] [CrossRef]

- Taşdemir, A.; Nohut, S. An overview of wire arc additive manufacturing (WAAM) in shipbuilding industry. Ships Offshore Struct. 2021, 16, 797–814. [Google Scholar] [CrossRef]

- Song, W.; Xia, X.; Yang, F.; Shi, D.; Song, M. Welding distortion investigation of rotary drill rig pipe with radial loading transition bars. Int. J. Press. Vessel. Pip. 2022, 199, 104704. [Google Scholar] [CrossRef]

- Chen, Y.; Gong, W.; Kang, R. Review and propositions for the sliding/impact wear behavior in a contact interface. Chin. J. Aeronaut. 2020, 33, 391–406. [Google Scholar] [CrossRef]

- Li, S.; Yu, H.; Lu, Y.; Lu, J.; Wang, W.; Yang, S. Effects of titanium content on the impact wear properties of high-strength low-alloy steels. Wear 2021, 474, 203647. [Google Scholar] [CrossRef]

- Marushchak, P.O.; Bishchak, R.T.; Vuherer, T.; Hlad’o, V.B. Impact toughness of specimens cut out from the rollers of machines for continuous casting of blanks with fused layers. Mater. Sci. 2013, 48, 704–714. [Google Scholar] [CrossRef]

- Singh, S.; Goyal, D.K.; Kumar, P.; Bansal, A. Laser cladding technique for erosive wear applications: A review. Mater. Res. Express 2020, 7, 012007. [Google Scholar] [CrossRef]

- Lu, K.; Zhu, J.; Guo, D.; Yang, M.; Sun, H.; Wang, Z.; Hui, X.; Wu, Y. Microstructures, Corrosion Resistance and Wear Resistance of High-Entropy Alloys Coatings with Various Compositions Prepared by Laser Cladding: A Review. Coatings 2022, 12, 1023. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, Y.; Song, B.; Yu, T.; Liu, Z. Modeling and simulation of 3D geometry prediction and dynamic solidification behavior of Fe-based coatings by laser cladding. Opt. Laser Technol. 2021, 139, 107009. [Google Scholar] [CrossRef]

- Wang, Q.; Zhai, L.; Zhang, L.; Zhang, J.; Ban, C. Effect of steady magnetic field on microstructure and properties of laser cladding Ni-based alloy coating. J. Mater. Res. Technol. 2022, 17, 2145–2157. [Google Scholar] [CrossRef]

- Cui, C.; Wu, M.; Miao, X.; Gong, Y.; Zhao, Z. The effect of laser energy density on the geometric characteristics, microstructure and corrosion resistance of Co-based coatings by laser cladding. J. Mater. Res. Technol. 2021, 15, 2405–2418. [Google Scholar] [CrossRef]

- Li, R.; Yuan, W.; Yue, H.; Zhu, Y. Study on microstructure and properties of Fe-based amorphous composite coating by high-speed laser cladding. Opt. Laser Technol. 2022, 146, 107574. [Google Scholar] [CrossRef]

- Xiao, Q.; Sun, W.; Yang, K.; Xing, X.; Chen, Z.; Zhou, H.; Lu, J. Wear mechanisms and micro-evaluation on WC particles investigation of WC-Fe composite coatings fabricated by laser cladding. J. Surf. Coat. Technol. 2021, 420, 127341. [Google Scholar] [CrossRef]

- Chen, L.; Yu, T.; Guan, C.; Zhao, Y. Microstructure and properties of metal parts remanufactured by laser cladding TiC and TiB2 reinforced Fe-based coatings. Ceram. Int. 2022, 48, 14127–14140. [Google Scholar] [CrossRef]

- Shan, B.; Chen, J.; Chen, S.; Ma, M.; Ni, L.; Shang, F.; Zhou, L. Laser cladding of Fe-based corrosion and wear-resistant alloy: Genetic design, microstructure, and properties. Surf. Coat. Technol. 2022, 433, 128117. [Google Scholar] [CrossRef]

- Jin, K.; Yang, Z.; Chen, P.; Huang, G.; Qiao, X. Dynamic solidification process during laser cladding of IN718: Multi-physics model, solute suppressed nucleation and microstructure evolution. Int. J. Heat Mass Transf. 2022, 192, 122907. [Google Scholar] [CrossRef]

- Sui, S.; Chen, J.; Li, Z.; Li, H.; Zhao, X.; Tan, H. Investigation of dissolution behavior of laves phase in inconel 718 fabricated by laser directed energy deposition. Addit. Manuf. 2020, 32, 101055. [Google Scholar] [CrossRef]

- Xu, P.; Zhu, L.; Xue, P.; Yang, Z.; Wang, S.; Ning, J.; Qin, S. Microstructure and properties of IN718/WC-12Co composite coating by laser cladding. Ceram. Int. 2022, 48, 9218–9228. [Google Scholar] [CrossRef]

- Xie, Y.; Chen, W.; Liang, L.; Huang, B.; Zhuang, J. Influence of laser power on the microstructure and properties of Fe314 alloy cladding layer on EA4T steel. Weld. World 2022, 66, 1551–1563. [Google Scholar] [CrossRef]

- Bartkowski, D.; Bartkowska, A.; Jurči, P. Laser cladding process of Fe/WC metal matrix composite coatings on low carbon steel using Yb: YAG disk laser. Opt. Laser Technol. 2021, 136, 106784. [Google Scholar] [CrossRef]

- Kim, T.G.; Shim, D.S. Effect of laser power and powder feed rate on interfacial crack and mechanical/microstructural characterizations in repairing of 630 stainless steel using direct energy deposition. Mater. Sci. Eng. 2021, 828, 142004. [Google Scholar] [CrossRef]

- Das, A.K. Recent trends in laser cladding and alloying on magnesium alloys: A review. Mater. Proc. 2021, 51, 723–727. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, L.; Wang, Y.; Lu, F.; Zhan, X. Crack defects and formation mechanism of FeCoCrNi high entropy alloy coating on TC4 titanium alloy prepared by laser cladding. J. Alloys Compd. 2022, 903, 163905. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, T.; Chen, L.; Yu, T.; Sun, J.; Guan, C. Microstructure and mechanical properties of Ti–C–TiN-reinforced Ni204-based laser-cladding composite coating. Ceram. Int. 2021, 47, 5918–5928. [Google Scholar] [CrossRef]

- Du, M.; Wang, L.; Gao, Z.; Yang, X.; Liu, T.; Zhan, X. Microstructure and element distribution characteristics of Y2O3 modulated WC reinforced coating on Invar alloys by laser cladding. Opt. Laser Technol. 2022, 153, 108205. [Google Scholar] [CrossRef]

- Wang, H.; Mo, J.; Mu, S.; Zhang, M.; Duan, W.; Li, J.; Zhou, Z. Effects of interfacial trapezoidal grooves on the mechanical properties of coatings by laser cladding. Surf. Coat. Technol. 2021, 421, 127425. [Google Scholar] [CrossRef]

- Xu, P.; Zhu, L.; Xue, P.; Meng, G.; Wang, S.; Yang, Z.; Ning, J.; Lan, Q. Multi-track alternated overlapping model suitable for variable laser cladding process parameters. Surf. Coat. Technol. 2021, 425, 127706. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Dong, S.; Ren, X.; Yan, S.; Xu, B. Influence of laser power on interface characteristics and cracking behavior during laser remanufacturing of nodular cast iron. Eng. Fail. Anal. 2021, 122, 105226. [Google Scholar] [CrossRef]

- Chen, L.; Xu, T.; Lu, S.; Wang, Z.; Chen, S.; Zhang, L. Improved hardness and wear resistance of plasma sprayed nanostructured NiCrBSi coating via short-time heat treatment. Surf. Coat. Technol. 2018, 350, 436–444. [Google Scholar] [CrossRef]

- Xu, C.; Chen, L.; Zheng, C.; Zhang, H.; Zhao, C.; Wang, Z.; Lu, S.; Zhang, J.; Zhang, L. Improved wear and corrosion resistance of microarc oxidation coatings on Ti–6Al–4V alloy with ultrasonic assistance for potential biomedical applications. Adv. Eng. Mater. 2021, 23, 2001433. [Google Scholar] [CrossRef]

- Yang, H.; Wen, J.; Quan, M.; Wang, J. Evaluation of the volume fraction of nanocrystals devitrified in Al-based amorphous alloys. J. Non-Cryst. Solids 2009, 355, 235–238. [Google Scholar] [CrossRef]

- Ding, H.; Yang, T.; Wang, W.; Zhu, Y.; Lin, Q.; Guo, J.; Liu, Q. Optimization and wear behaviors of 316L stainless steel laser cladding on rail material. Wear 2023, 523, 204830. [Google Scholar] [CrossRef]

- Yang, L.; Yang, X.; Zhang, T.; Sun, R. Optimization of microstructure and properties of composite coatings by laser cladding on titanium alloy. Ceram. Int. 2021, 47, 2230–2243. [Google Scholar] [CrossRef]

- Chen, W.; Peng, Y.; Wang, Y.; Cao, P.; Zhu, Y.; Guo, Y. Research on high-temperature friction and wear performances of Stellite 12 laser cladding layer against coated boron steels. Wear 2023, 520, 204665. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, S.; Wang, Z.; Zhang, C.; Chen, H.; Chen, J. New studies on wear and corrosion behavior of laser cladding FeNiCoCrMox high entropy alloy coating: The role of Mo. Int. J. Refract. Met. Hard Mater. 2022, 102, 105721. [Google Scholar] [CrossRef]

- Thawari, N.; Gullipalli, C.; Katiyar, J.K.; Gupta, T.V.K. Effect of multi-layer laser cladding of Stellite 6 and Inconel 718 materials on clad geometry, microstructure evolution and mechanical properties. Mater. Today Commun. 2021, 28, 102604. [Google Scholar] [CrossRef]

- Wolf, D.; Yamakov, V.; Phillpot, S.R.; Mukherjee, A.K. Deformation mechanism and inverse Hall—Petch behavior in nanocrystalline materials. Int. J. Mater. Res. 2022, 94, 1091–1097. [Google Scholar] [CrossRef]

- Song, C.; Wang, W.; Ren, Z.; Zhao, Y.; Zhou, L. Numerical and Experimental Study on the Properties of Laser Cladding of 6061Al Alloy. Trans. Indian Inst. Met. 2022, 75, 1355–1364. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, R.; Peng, C.; Cai, Z.; Zhou, Z.; Li, X.; Cao, X. Microstructural evolution and mechanical performance of in-situ TiB2/AlSi10Mg composite manufactured by selective laser melting. J. Alloys Compd. 2021, 853, 157287. [Google Scholar] [CrossRef]

| Samples | Laser Power (W) | Mass Flow Rate (g/min) | Scanning Speed (mm/s) | Carrier Gas Flow Rate (L/min) |

|---|---|---|---|---|

| S1 | 1800 | 16 | 22 | 10 |

| S2 | 1800 | 18 | 22 | 10 |

| S3 | 1800 | 20 | 22 | 10 |

| S4 | 1800 | 22 | 22 | 10 |

| S5 | 1800 | 24 | 22 | 10 |

| Samples | Width of Cladding Layer (μm) | Height of Cladding Layer (μm) | The Depth of the Melt Pool (μm) | Depth of HAZ (μm) |

|---|---|---|---|---|

| S1 | 7922 | 1264 | 364 | 584 |

| S2 | 7976 | 1344 | 339 | 571 |

| S3 | 8069 | 1434 | 322 | 567 |

| S4 | 8125 | 1548 | 284 | 575 |

| S5 | 8194 | 1683 | 222 | 597 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Shu, L.; Li, P.; Gong, J.; He, W.; Yu, H. Influence of Powder Mass Flow Rates on Wear Resistance and Impact Toughness of Inconel 718 Surface Coatings. Coatings 2023, 13, 1877. https://doi.org/10.3390/coatings13111877

Zhang C, Shu L, Li P, Gong J, He W, Yu H. Influence of Powder Mass Flow Rates on Wear Resistance and Impact Toughness of Inconel 718 Surface Coatings. Coatings. 2023; 13(11):1877. https://doi.org/10.3390/coatings13111877

Chicago/Turabian StyleZhang, Chaoming, Linsen Shu, Peiyou Li, Jiangtao Gong, Wei He, and Helong Yu. 2023. "Influence of Powder Mass Flow Rates on Wear Resistance and Impact Toughness of Inconel 718 Surface Coatings" Coatings 13, no. 11: 1877. https://doi.org/10.3390/coatings13111877

APA StyleZhang, C., Shu, L., Li, P., Gong, J., He, W., & Yu, H. (2023). Influence of Powder Mass Flow Rates on Wear Resistance and Impact Toughness of Inconel 718 Surface Coatings. Coatings, 13(11), 1877. https://doi.org/10.3390/coatings13111877