Abstract

AlCoCrFeNiTi0.5 high-entropy alloy (HEA) shows excellent properties in hardness and corrosion resistance. AlCoCrFeNiTi0.5 HEA was prepared using a non-consumable vacuum arc furnace. Hot-deformation behavior of AlCoCrFeNiTi0.5 HEA was explored under 1073–1373 K with a strain rate between 0.001 and 1 s−1 using a Gleeble-3800 thermomechanical simulator. The constitutive equation was established using the Arrhenius model, and the deformation activation energy and material constant were obtained. The processing map of HEA within 0.3–0.6 deformation was drawn according to dynamic material model (DMM). The results show that the hot-deformation process of HEA is dominated by work hardening combined with dynamic recovery, and dynamic recrystallization. The flow stress of HEA is significantly affected by deformation temperature and strain rate. The constitutive equation was constructed and verified, and the correlation coefficient of R2 = 0.9873 indicated that the constitutive equation can be used to accurately predict the flow stress of HEA. The processing map of HEA shows that the optimal hot-working process parameters are in the range of temperature 1150–1300 K and strain rate 0.002–0.05 s−1. This work will provide theoretical guidance for the hot-processing of HEA, which effectively promotes the application of the HEA in industry.

1. Introduction

High-entropy alloy (HEA) is a new kind of alloy that contain more than five principal elements in equal or near equal atomic percent. It has attracted increasing attentions because of unique compositions, microstructures, and properties [1,2], such as high strength, high ductility, wear resistance, corrosion resistance, and temperature resistance [3,4]. Due to the interaction of different elements, HEA exhibit a composite effect. The grain shape, grain diameter and grain boundary of HEA may be affected by some elements, which change the macroscopic properties.

CoCrFeNi HEA is composed of face-centered cubic (FCC) phases, which have been investigated by numerous researchers [5,6,7]. CoCrFeNi HEA exhibits excellent plasticity, toughness, and fracture toughness, but its application was limited because of low strength. Lots of studies have been conducted to improve the strength of CoCrFeNi HEA. The comprehensive performance of CoCrFeNi HEA can be improved by introduced body-centered cubic phases (BCC), such as Al, Ti, Cu, Mn and others. It has been reported that the hardness can be increased by adding Al and the corrosion resistance can be improved by adding Ti [8,9,10,11,12]. Qin et al. [13] reported that the yield strength and fracture strength of CoCrFeMnNi HEA was significantly improved by Mo addition. Mohamed et al. [14] investigated the effect of Cu addition on mechanical properties of AlCoCrFeNi HEA; they showed that the hardness decreased significantly with an increase in Cu content, the hardness decreases from 403 HV to 191 HV when the Cu content increases from 5 wt% to 20 wt%, whereas the compressive strength increases form 400.034 MPa to 599.527 MPa when the Cu content increases from 5 wt% to 15 wt%. Zhao et al. [15,16] studied the microstructure evolution, hardness and wear resistance of HEMB-Ni2B composite coating via first principle methods; the results show that the synergistic effect between the superhardness of HEMB and the large plastic deformation ability of Ni2B can significantly improve the wear resistance of HEMB-Ni2B coatings, with a friction coefficient as low as 0.13. Similar investigations have been also reported in references [15,16,17,18,19,20,21,22,23]. Yu et al. [17] demonstrated that the structure of AlxCoCrFeNi HEA transforms from a single FCC phase to an FCC + BCC dual phase with the increases in Al contents. Meanwhile, the hardness is improved by 146% with a 0.9% Al addition compared with CoCrFeNi. Zhang et al. [19] found that the surface roughness is the smallest of CoCrFeNiAlX (x = 0, 0.6, 1) with a 0.6 wt% Al addition. Wu et al. [20] reported that the transition temperature from order to disorder in FeCoNiAl1−xTix decreases with the increase in Ti content. Zhang et al. [22] showed that the average microhardness of the AlCoCrFeNiTi0.5 HEA coating reached 989 HV, which was 32% higher than AlCoCrFeNi and reduced wear by 85%. The addition of Ti increased the number of reinforcement phases in the alloy, which contributed to the formation of eutectic and amplitude-modulated decomposition structures, and this structure showed significant changes in performance.

Due to the mixing effect of HEA, adding different elements will have different effects, resulting in significant differences in microstructure and properties. Moreover, the inherent characteristics and casting defects of HEA, high resistance and poor plasticity during hot-working, cracking during forging and hot-rolling process, and other problems restrict the application of HEA [24,25]. The studies on HEA mainly focus on the composition, microstructure, and mechanical properties, whereas there are few studies on high-temperature deformation behavior [26,27]. So, the hot-deformation behavior and mechanism of HEA should be investigated in detail, which are meaningful for the production of bulk defect free HEA.

The combination of the dynamic material model (DMM) processing diagram and microstructure after high-temperature deformation can effectively describe the relationship between high-temperature deformation parameters and microstructure evolution [24], which is used to distinguish the safe and dangerous zones during the high-temperature plastic deformation process [28,29]. The hot-compression experiments of AlCoCrFeNiTi0.5 under different conditions (deformation temperature, strain rate) were conducted, and the deformation behavior at high temperature was analyzed. The flow stress constitutive equation within 0.1–0.7 deformation was established according to the Arrhenius model. The processing map of AlCoCrFeNiTi0.5 within 0.3–0.6 deformation was drawn according to DMM. This paper aims at providing theoretical basis for the formulation and optimization of HEA hot-deformation process parameters, which is beneficial to solving the problems including hot-work difficulties and cracking during the hot-processing of HEA.

2. Experiments

The tested material is as-cast AlCoCrFeNiTi0.5 HEA. The ingot was smelted using a WK-II non-consumable vacuum arc furnace (BNTET, Henan, China) with Al, Co, Cr, Fe, Ni, and Ti as raw materials (purity > 99.9%). During the melting process, Al, Co, Cr, Fe, Ni, and Ti are prepared in an atom ratio of 1:1:1:1:1:0.5 in order to reduce the volatilization of low-melting-point alloys before melting; the alloys are gradually placed in a copper crucible in the order of melting point from low to high. The ingot was repeatedly melted 5–6 times to ensure the uniformity of chemical composition. The chemical composition of the ingot is shown in Table 1.

Table 1.

Chemical composition of AlCoCrFeNiTi0.5 HEA (atom%).

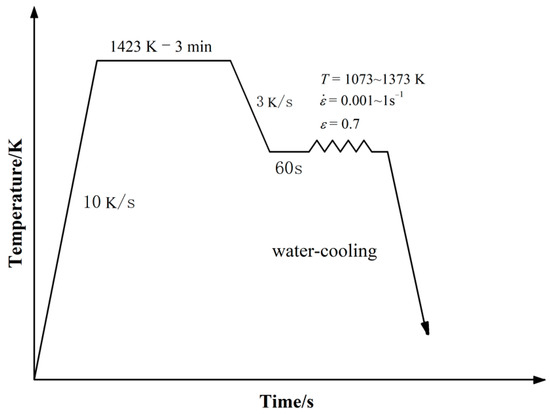

The ingot was processed into a cylinder with 8 mm in diameter and 10 mm in height for hot-compression experiments. Single-pass compression tests were carried out using the Gleeble-3800 thermomechanical simulator (DSI, Albany, NY, USA). The schematic diagram of the hot-compression experiment is shown in Figure 1. The specimens were heated to 1423 K at a rate of 10 K∙s−1 and held for 3 min to eliminate the internal temperature gradient, and cooled to deformation temperature at a rate of 3 K∙s−1. The deformation temperature was set as 1073 K, 1173 K, 1273 K or 1373 K. The strain rate was set as 0.001 s−1, 0.01 s−1, 0.1 s−1 or 1 s−1; the total deformation is 70%. When the temperature was reached, the specimens were held for 30 s, and then single-pass compressing tests were carried out and repeated for all the experiments under different temperature. The crystal structure of the sample was tested using an XRD-6100 Lab X-ray diffraction analyzer (SHIMADZU, Kyoto, Japan) with CuK α Ray, λ = 0.15406 nm. The working current is 30 mA, working voltage is 40 kV, scanning angle range is 20–90°, and scanning speed is 2 (°)/min. The microstructure of AlCoCrFeNiTi0.5 HEA is analyzed using the OLYMPUS BX51M optical microscope (OM, Olympus Corporation, Tokyo, Japan) after electropolishing with 4% fluoroboric acid.

Figure 1.

Schematic diagram of hot-compression experiment.

3. Results

3.1. Microstructure

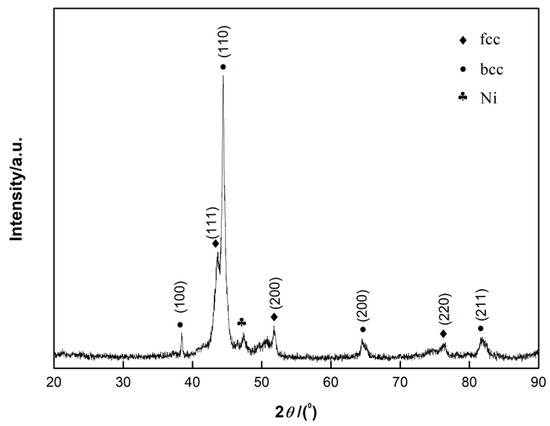

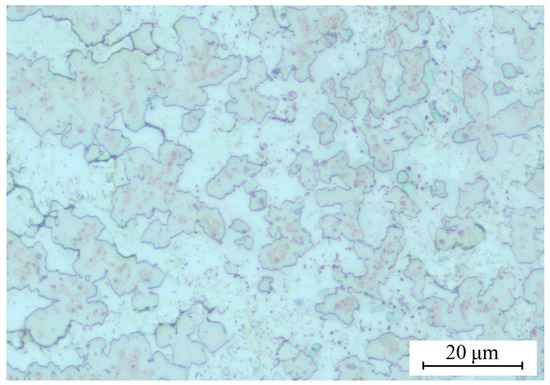

The XRD patterns of the specimens of AlCoCrFeNiTi0.5 HEA are shown in Figure 2; it can be inferred that the main components are FCC and BCC phases. The diffraction peaks of the FCC phase are crystal face (111), (200), and (220) with a structure of [Fe, Ni] solid solution. The lattice constant of FCC is 0.35807 nm, and the spatial group belongs to the Fm-3m (225) spatial structure. The diffraction peaks of BCC phase are crystal face (100), (110), (200), and (211) with a structure of [Fe, Cr] solid solution. The lattice constant of FCC is 0.28719 nm, and the spatial group belongs to the Im-3m (229) spatial structure. The microstructure of AlCoCrFeNiTi0.5 HEA is detected by OM, as shown in Figure 3, where there are two phases, which should belong to the BCC and FCC phase according to the result in Figure 2.

Figure 2.

XRD patterns of AlCoCrFeNiTi0.5 HEA.

Figure 3.

Microstructure of AlCoCrFeNiTi0.5 HEA.

3.2. Analysis of Stress–Strain Curve

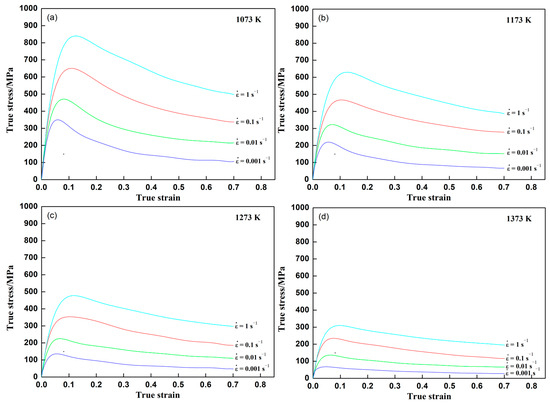

Figure 4 shows the flow stress–strain curve of AlCoCrFeNiTi0.5 HEA under different conditions. It can be observed that the flow stress is significantly affected by temperature and strain rate. The flow stress increases with the increase in strain rate and the decrease in temperature. During the hot-deformation process, both work hardening and dynamic softening mechanisms work simultaneously [30]. At the initial stage, the stress increases quickly with the increase in deformation, and the increase rate shows a gradual slowing trend before reaching the peak value. This indicates that this stage belongs to the dynamic recovery process. The hardworking plays the main role, where dislocation multiplication hinders the movement, the softening effect caused by dislocation movement is insufficient to offset the hardening effect caused by the increase in dislocation density, resulting in a rapid increase in flow stress and a significant increase in deformation resistance. Subsequently, dynamic recovery occurs, and the dislocations recombine and disappear, which makes the stress reach the peak value gradually. After that, the stress decreases gradually until it reaches a steady state with the increase in deformation. The dynamic softening mechanisms plays the main role at this stage. The synergy effect of dynamic recovery and dynamic recrystallization is stronger than that of work hardening, and the stress decreases gradually and reaches the steady state when it reaches the equilibrium state [31]. When the strain rate is constant, the dynamic recrystallization behavior becomes more obvious with the increase in deformation temperature, and the peak value of flow stress correspondingly decreases. With the increase in deformation temperature, the thermal activation effect of deformation increases, which enhances the mobility of grain boundaries, promoting the dynamic recrystallization nucleation, grain growth, and dislocation annihilation. This will reduce the flow stress [32]. When the deformation temperature is constant, the nucleation and growth of recrystallized grains become more complete with the decrease in strain rate, contributing fully to dynamic recrystallization. The interaction between dislocations leads to a sharp increase in dislocation density, which increases the deformation storage energy, leading to a decrease in the critical temperature of recrystallization and a corresponding increase in the degree of dynamic recrystallization.

Figure 4.

Flow stress–strain curve of AlCoCrFeNiTi0.5 HEA under different conditions: (a) 1073 K, (b) 1173 K, (c) 1273 K, (d) 1373 K.

3.3. Establishment of Constitutive Equation

It has been reported that the constitutive equation could be used to exhibit the relationship between flow stress and deformation parameters during the deformation process of alloys [33,34]. The constitutive equation for AlCoCrFeNiTi0.5 HEA can be expressed with the following equations [35,36]:

where Q is activation energy (kJ∙mol−1), R is the universal gas constant (8.314 J∙mol−1∙K−1), σ is flow stress (MPa), is strain rate (s−1), T is deformation temperature (K), A1, A2 and A3 are material constants, n and n1 are stress exponents, and α is stress factor (α = β/n1, MPa−1). It should be noticed that Equation (3) is suitable for any condition.

Zener and Hollomon used parameter Z to describe the effects of temperature and strain rate on deformation behaviors [37]:

The value of α, n, Q and A can be calculated by Equations (1)–(4), and then establish the constitutive equation under different deformation condition. In this paper, the constitutive equation is obtained when the strain is 0.2, and the stress at different conditions is shown in Table 2.

Table 2.

Stress of AlCoCrFeNiTi0.5 HEA under different conditions with 0.2 deformation (MPa).

By taking the logarithm of both sides of Equations (1) and (2), Equations (5) and (6) can be expressed as follows:

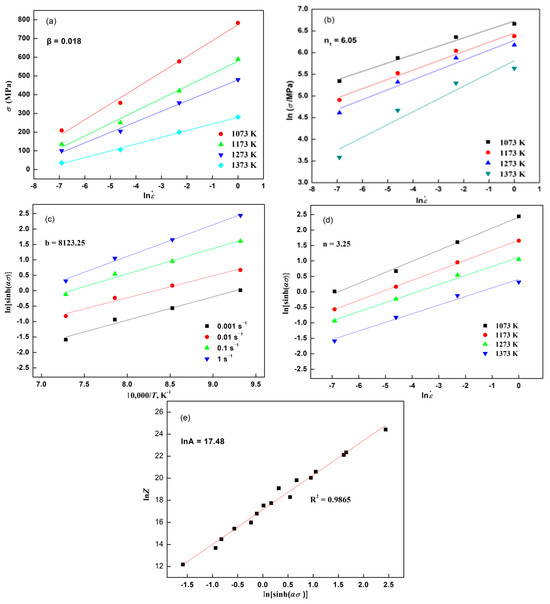

By performing a linear fitting on ln-lnσ and ln-σ, and finding the reciprocal of the slope of the line, the value of n1 and β can be obtained. The value of α can be calculated by α = β/n1. As shown in Figure 5a,c, n1 = 6.05, β = 0.026, and α = 0.0041.

Figure 5.

Parameter fitting relationship of of AlCoCrFeNiTi0.5 HEA with 0.2 deformation. (a) ln-lnσ, (b) ln-σ, (c) ln[sinh(ασ)]-1/T, (d) ln-ln[sinh(ασ)], (e) lnZ-ln[sinh(ασ)].

Equation (7) of Q can be obtained by taking the logarithm of both sides of Equation (3) and finding the partial differential:

The relationship between ln[sinh(ασ)]-1/T, and ln-ln[sinh(ασ)] is shown in Figure 5c,d. it can be inferred that b = 7948.35, n = 3.25, and Q = 218.36 kJ/mol.

By taking the logarithm of both sides of Equation (4), Equation (8) can be expressed as follows:

Perform linear fitting on lnZ-ln[sinh(ασ)], the reciprocal of the slope of the line is lnA = 17.42, and A = 3.68 × 107, as shown in Figure 5e.

Take the values of α, n, Q and A into Equation (3), the constitutive equation (strain = 0.2) is obtained.

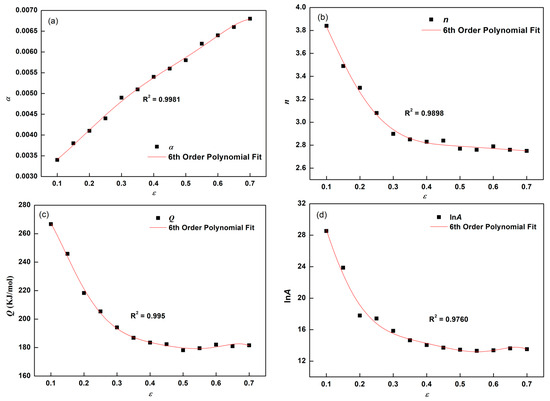

It has been reported that the rheological characteristics of an alloy can be described by the relationship between strain and material constant. The values of α, n, Q and lnA under different deformation conditions are shown in Table 3. The material constant is represented as a polynomial function of the strain, which can more accurately reflect the relationship between the material constant and the strain, and the corresponding results are shown in Figure 6. The correlation coefficient is higher than 0.9760, which indicates that the fitting effect is good. The relationship between stress and material constant can be obtained by combining Equations (3) and (4). Combining the calculated material constants with strain polynomial fitting results, the constitutive equation of AlCoCrFeNiTi0.5 can be expressed as follows.

Table 3.

Material constant of AlCoCrFeNiTi0.5 HEA under different deformation condition.

Figure 6.

Relationship curve between stress and (a) α, (b) n, (c) Q, (d) lnA.

3.4. Verification of Constitutive Equation

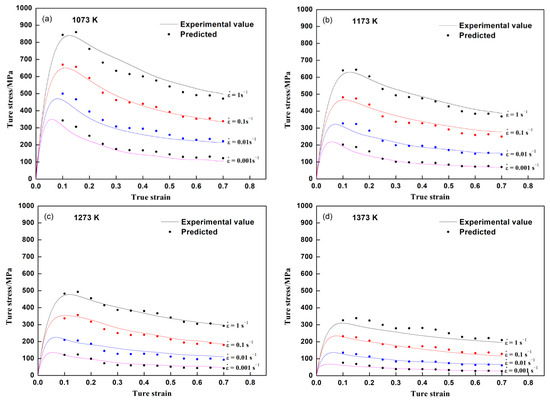

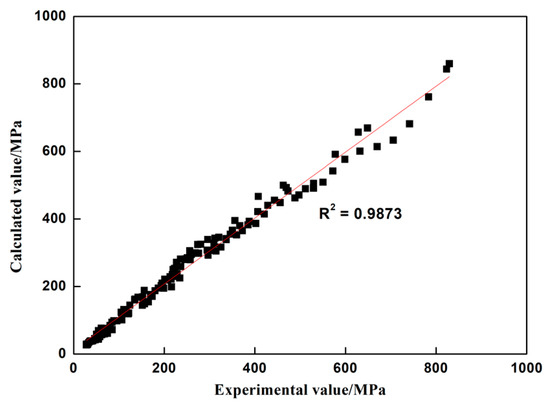

In order to verify the accuracy of the constitutive equation, the stress of AlCoCrFeNiTi0.5 HEA under different strain rates is calculated according to Equation (10); the corresponding results are shown in Figure 7. It can be concluded that the theoretical calculation values and experimental values are highly consistent when the strain rate is 0.001 s−1, 0.01 s−1 and 0.1 s−1. However, there is a significant deviation between the theoretical calculation value and the experimental value when the strain rate is 1 s−1 at 1073 K and 1373 K. Figure 8 shows the comparison between the theoretical and experimental values of flow stress. The slope of the curve is 0.9757, and the correlation coefficient is 0.9873, which indicates that the constitutive equation can accurately predict the flow stress of AlCoCrFeNiTi0.5 HEA.

Figure 7.

Comparison between experimental and theoretical values of stress under different deformation conditions: (a) 1073 K, (b) 1173 K, (c) 1273 K, (d) 1373 K.

Figure 8.

Contrast effect between the theoretical and experimental values of flow stress.

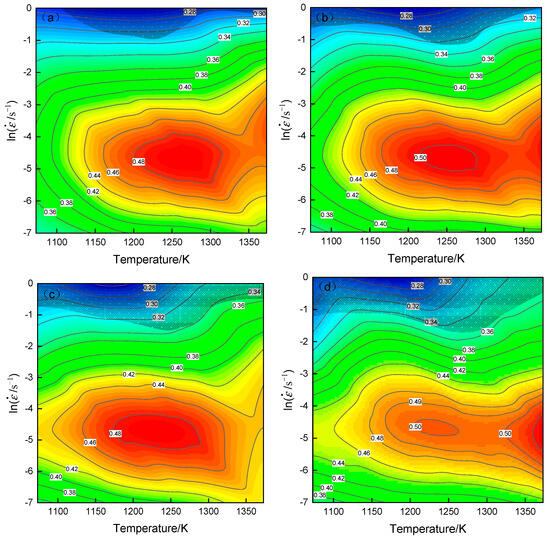

3.5. Processing Map

It has been reported that the processing map based on dynamic material model (DMM) is widely used to investigate the deformation behavior of materials at high temperature [38]. During the thermal deformation process, the total energy (P) absorbed by the material can be divided into two parts: the energy consumed by plastic deformation (G), and the energy consumed by microstructure transformation (J), following Equation (11) [39].

The relationship between flow stress and stain rate can be expressed by Equation (12) [40]:

where K is material constant, and m is strain rate sensitivity index, which is defined as follows [41]:

According to DMM theory [42], the hot-work material system is considered as a nonlinear energy dissipator, which can be characterized by energy dissipation efficiency factors η [43]:

The power dissipation diagram is a contour plot of the power dissipation rate as a function of temperature (T) and strain rate (ε). The area with a high η value may cause dynamic recovery and dynamic recrystallization, which exhibits good processing performance. However, in some cases, there are some unstable zones in high-value areas. Therefore, in order to obtain the optimal thermal processing parameters of the material, it is necessary to calculate the corresponding instability diagram based on the instability criterion. Prasad et al. [44] proposed a rheological instability criterion based on the maximum entropy principle to analyze the materials, as shown in Equation (15):

where ζ() is the instability factor. The instability map is the area where the instability factor varies with negative values in the contour map of temperature (T) and strain rate (). The rheological instability may occur in this area, which should be avoided during processing materials. The processing map is composed of power dissipation diagram and instability map. Figure 9 shows the processing map of AlCoCrFeNiTi0.5 HEA with strain at 0.3, 0.4, 0.5 and 0.6. The contour line represents the power dissipation coefficient, and the shaded area represents the unstable zone. It can be concluded that there is an unstable zone in all figures. When the strain is 0.3, the unstable zone is the area with temperature ranging from 1100 to 1130 K and strain rate ranging from 0.35 to 1 s−1. With the increase in deformation, the unstable area becomes larger. When the strain is 0.6, the unstable zone is the area with temperature ranging from 1073 to 1373 K and strain rate ranging from 0.13 to 1 s−1. Besides all above areas, the region corresponding to the highest energy dissipation rate during deformation is the optimal deformation zone for AlCoCrFeNiTi0.5 HEA. It can be seen that the optimal deformation zone is in the temperature range of 1150–1300 K and the strain rate range of 0.002–0.05 s−1.

Figure 9.

Processing map of AlCoCrFeNiTi0.5 HEA with strain at (a) 0.3, (b) 0.4, (c) 0.5 and (d) 0.6.

4. Conclusions

(1) Under the conditions of deformation temperature 1073–1373 K, strain rate 0.001–1 s−1, and strain rate 70%, the hot-deformation process of AlCoCrFeNiTi0.5 HEA is dominated by a softening mechanism that combines work hardening, dynamic recovery, and dynamic recrystallization. The strain rate and deformation temperature play a significant impact on the stress–strain curve.

(2) The constitutive equation is established and verified, the correlation coefficient is 0.9873, which indicates that the constitutive equation can accurately predict the flow stress of AlCoCrFeNiTi0.5 HEA. The constitutive equation of AlCoCrFeNiTi0.5 can be expressed as follows.

(3) The processing map is established, and the optimal deformation zone for AlCoCrFeNiTi0.5 HEA is in the temperature range of 1150–1300 K with a strain rate range of 0.002–0.05 s−1.

Author Contributions

Conceptualization, T.L. and X.K.; methodology, X.L.; validation, X.L.; formal analysis, Y.W.; investigation, C.Z.; resources, X.L.; data curation, X.L.; writing—original draft preparation, X.L.; writing—review and editing, Y.W. funding acquisition, X.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Scientific Research Project of Hunan Provincial Department of Education, grant number 19A126.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data that support the findings of this study are included within the article.

Acknowledgments

The authors thank the Scientific Research Project of Hunan Provincial Department of Education and Undergraduate Innovation and Entrepreneurship of Hunan Province.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Michael, C.G.; Karin, A.D.; Peter, K.L.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yi, J.J.; Wang, L.; Zeng, L.; Xu, M.; Tang, S. Excellent strength-ductility synergy in a novel single-phase equiatomic CoFeNiTiV high entropy alloy. Int. J. Refract. Met. Hard Mater. 2020, 95, 105416. [Google Scholar] [CrossRef]

- Parakh, A.; Vaidya, M.; Kumar, N.; Chetty, R.; Murty, B.S. Effect of crystal structure and grain size on corrosion properties of AlCoCrFeNi high entropy alloy. J. Alloys Compd. 2020, 863, 158056. [Google Scholar] [CrossRef]

- Bhattacharjee, T.; Wani, I.S.; Sheikh, S.; Clark, I.T.; Okawa, T.; Guo, S.; Bhattacharjee, P.P.; Tsuji, N. Simultaneous Strength-Ductility Enhancement of a Nano-Lamellar AlCoCrFeNi2.1 Eutectic High Entropy Alloy by Cryo-Rolling and Annealing. Sci. Rep. 2018, 8, 3276. [Google Scholar] [CrossRef]

- Shabani, M.; Indeck, J.; Hazeli, K.; Jablonski, P.D.; Pataky, G.J. Effect of Strain Rate on the Tensile Behavior of CoCrFeNi and CoCrFeMnNi High-Entropy Alloys. J. Mater. Eng. Perform. 2019, 28, 4348–4356. [Google Scholar] [CrossRef]

- Samoilova, O.; Shaburova, N.; Samodurova, M.; Pashkeev, K.; Moghaddam, A.O.; Doubenskaia, M.; Sova, A.; Trofimov, E. Microstructural evolution of Al0.25CoCrFeNi- Cu and Al0.45CoCrFeNiSi0.45 high-entropy alloys during laser cladding. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 1806–1813. [Google Scholar]

- Liu, Q.; Wang, X.Y.; Huang, Y.B.; Xie, L.; Xu, Q.; Li, L.H. Effect of Mo Content on Microstructure and Corrosion Resistance of CoCrFeNiMo High Entropy Alloy. Chin. J. Mater. Res. 2020, 34, 868–874. [Google Scholar]

- Zhang, A.; Han, J.; Meng, J.; Su, B.; Li, P. Rapid preparation of AlCoCrFeNi high entropy alloy by spark plasma sintering from elemental powder mixture. Mater. Lett. 2016, 181, 82–85. [Google Scholar] [CrossRef]

- Chuang, M.H.; Tsai, M.H.; Wang, W.R.; Lin, S.J.; Yeh, J.W. Microstructure and wear behavior of AlxCo1.5CrFe Ni1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Guo, L.; Ou, X.; Ni, S.; Liu, Y.; Song, M. Effects of carbon on the microstructures and mechanical properties of FeCoCrNiMn high entropy alloys. Mater. Sci. Eng. A 2019, 746, 356–362. [Google Scholar] [CrossRef]

- Verma, A.; Tarate, P.; Abhyankar, A.C.; Mohape, M.R.; Gowtam, D.S.; Deshmukh, V.P.; Shanmugasundaram, T. High emperature Wear in CoCrFeNiCux High Entropy Alloys: The Role of Cu. Scr. Mater. 2019, 161, 28–31. [Google Scholar] [CrossRef]

- Qin, G.; Chen, R.R.; Zheng, H.T.; Fang, H.Z.; Wang, L.; Su, Y.Q.; Fu, H.Z. Strengthening FCC CoCrFeMnNi high entropy alloys by Mo addition. J. Mater. Sci. Technol. 2019, 35, 578–583. [Google Scholar] [CrossRef]

- Mohamed, A.H.; Hossam, M.Y.; Ahmed, S.A.M.; Ahmed, E.E.N.; Omayma, A.E. Effect of Copper Addition on the AlCoCrFeNi High Entropy Alloys Properties via the Electroless Plating and Powder Metallurgy Technique. Crystals 2021, 11, 540. [Google Scholar]

- Zhao, P.B.; Zhu, J.P.; Yang, K.J.; Li, M.L.; Shao, G.; Lu, H.X.; Ma, Z.; Wang, H.L.; He, J.L. Outstanding wear resistance of plasma sprayed high-entropy monoboride composite coating by inducing phase structural cooperative mechanism. Appl. Surf. Sci. 2023, 616, 156516. [Google Scholar] [CrossRef]

- Zhao, P.B.; Zhu, J.P.; Li, M.L.; Shao, G.; Lu, H.X.; He, J.L. Theoretical and experimental investigations on the phase stability and fabrication of high-entropy monoborides. J. Eur. Ceram. Soc. 2023, 43, 2320–2330. [Google Scholar] [CrossRef]

- Yu, L.Y.; Wang, C.; Zhu, L.L.; Zhang, H.; Huang, H.L.; Ruan, J.J.; Zhang, S.Z.; Jiang, L.; Zhou, X. Microstructure and properties of AlxCoCrFeNi high entropy alloys fabricated by laser additive manufacturing. J. Mater. Eng. 2023. (In Chinese) [Google Scholar]

- Deng, C.; Li, R.D.; Yuan, T.C.; Niu, P.D. Influence of Al Content on Microstructure and Nanoindentation of Selective Laser Melting AlxCoCrFeNi(x = 0.3, 0.5, 0.7, 1.0). J. Mater. Eng. 2022, 50, 27–35. (In Chinese) [Google Scholar]

- Zhang, P.; Wang, S.X.; Lin, Z.Y.; Yue, X.J.; Gao, Y.R.; Zhang, S.T.; Yang, H.J. Investigation on the mechanism of micro-milling CoCrFeNiAlX high entropy alloys with end milling cutters. Vacuum 2023, 211, 111939. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Z.; Feng, H.; He, S. Atomic Interactions and Order-Disorder Transition in FCC-Type FeCoNiAl1-xTix High-Entropy Alloys. Materials 2022, 15, 3992. [Google Scholar] [CrossRef]

- Ye, H.M.; Yang, W.C.; Pang, X.Z. Effect of titanium content on wear resistance of CoCuFeNiVTix high-entropy alloys. J. Guangxi Univ. (Nat. Sci. Ed.) 2017, 42, 1187–1191. [Google Scholar]

- Zhang, L.; Sha, M.H.; Zhang, J.W.; Chen, Z.S.; Li, S.L. Effect of Titanium on the Microstructure and Wear Resistance of AlCoCrFeNiTi0.5 Alloy Coating Prepared by Laser Cladding. Mater. Prot. 2022, 55, 24–30. [Google Scholar] [CrossRef]

- Shun, T.T.; Chang, L.-Y.; Shiu, M.H. Microstructure and Mechanical Properties of Multiprincipal Component CoCrFeNiMox Alloys. Mater. Charact. 2012, 70, 63–67. [Google Scholar] [CrossRef]

- Liu, Z.; Xiong, Z.P.; Chen, X.W. Large-size high-strength and high-ductilityAlCoCrFeNi2.1 eutectic high-entropy alloy produced by hot-rolling and subsequent aging. Mater. Lett. 2022, 315, 131933. [Google Scholar] [CrossRef]

- Savaedi, Z.; Motallebi, R.; Mirzadeh, H. A review of hot deformation behaviorand constitutive models to predict flow stress of high-entropy alloys. J. Alloys Compd. 2022, 903, 163964. [Google Scholar] [CrossRef]

- Gao, P.F.; Fu, M.W.; Zhan, M.; Lei, Z.N.; Li, Y.X. Deformation behavior and microstructure evolution of titanium alloys with lamellar microstructure in hot working process: A review. J. Mater. Sci. Technol. 2020, 39, 56. [Google Scholar] [CrossRef]

- Dong, F.Y.; Yuan, Y.; Li, W.D.; Zhang, Y.; Liaw, P.K.; Yuan, X.G.; Huang, H.J. Hot deformation behavior and processing maps of an equiatomic MoNbHfZrTi refractory high entropy alloy. Intermetallics 2020, 126, 106921. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K. Dynamic materials model: Basis and principles. Metall. Mater. Trans. 1996, 27, 235. [Google Scholar] [CrossRef]

- Xiao, B.L.; Huang, Z.Y.; Ma, K.; Zhang, X.X.; Ma, Z.Y. Research on hot deformation behaviors of discontinuously reinforced aluminum composites. Acta Metall. Sin. 2019, 55, 59. [Google Scholar]

- Liu, X.B.; Wu, G.L.; Zhou, C.Y. Constitutive modeling of dynamic recrystallization behavior and processing map of Cr5 steel. J. Cent. South Univ. 2016, 23, 3065–3071. [Google Scholar] [CrossRef]

- Jeong, H.; Kim, W.J. Deformation Mechanisms and Processing Maps for High Entropy Alloys (Presentation of Processing Maps in Terms of Zener–Hollomon Parameter): Review. Materials 2023, 16, 919. [Google Scholar] [CrossRef] [PubMed]

- Mcqueen, H.J.; Ryan, N.D. Constitutive analysis in hot working. Mater. Sci. Eng. A 2002, 322, 43–46. [Google Scholar] [CrossRef]

- Trusov, P.; Kondratev, N.; Podsedertsev, A. Grain structure rearrangement by means the advanced statistical model modified for describing dynamic recrystallization. Metals 2023, 13, 113. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput. Mater. Sci. 2008, 42, 470. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wen, D.X.; Deng, J.; Liu, G.; Chen, J. Constitutive models for high temperature flow behaviors of a Ni-based superalloy. Mater. Des. 2014, 59, 115. [Google Scholar] [CrossRef]

- Ferdowsi, M.R.G.; Nakhaie, D.; Benhangi, P.H.; Ebrahimi, G.R. Modeling the high temperature flow behavior and dynamic recrystallization kinetics of a medium carbon microalloyed steel. J. Mater. Eng. Perform. 2014, 23, 1077–1087. [Google Scholar] [CrossRef]

- Ebrahimpourghandi, B.; Mahmudi, R. Hot deformation constitutive analysis and processing maps of the as-cast and wrought Mg-2.5Gd-0.5Zr alloy. J. Alloys Compd. 2023, 942, 169133. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243. [Google Scholar] [CrossRef]

- Sun, F.C.; Li, J.S.; Han, J.K.; Peng, Y.H.; Zhou, K.; Chen, L.J.; Cao, X. Hot deformation behavior and processing map of AlFeCoNi-Mo0.2 high-entropy alloy. J. Netshape Form. Eng. 2021, 13, 91–97. (In Chinese) [Google Scholar]

- Sumit, G.; Mahesh, C.S.; Daria, S.; Suhrit, M. Elucidation of deformation mechanisms and construction of processing maps for a Ti+Nb stabilized IF steel. Mater. Sci. Eng. A 2020, 790, 139648. [Google Scholar]

- Lou, Y.; Chen, H.; Ke, C.X.; Long, M. Hot tensile deformation characteristics and processing map of extruded AZ80 Mg alloys. J. Mater. Eng. Perform. 2014, 23, 1904–1914. [Google Scholar] [CrossRef]

- Sui, D.S.; Wang, T.; Zhu, L.L.; Ga, L.; Cui, Z.S. Mathematical modeling of high-temperature constitutive equations and hot processing maps for as-cast SA508-3 steel. JOM 2016, 68, 2944–2951. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Trans. 1984, 15, 1883. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).