Suppression of Secondary Electron Emissions on the Graphene-Coated Polyimide Materials Prepared by Chemical Vapor Deposition

Abstract

1. Introduction

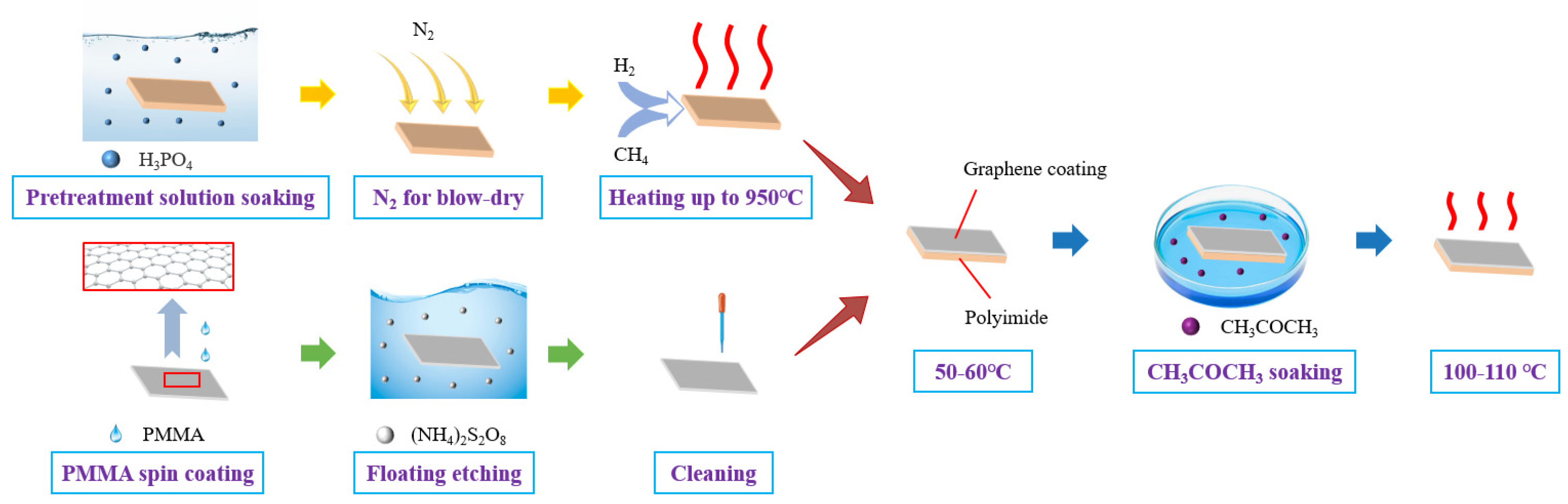

2. Materials and Methods

2.1. Material Preparation

2.2. Material Characterization

2.3. Secondary Electron Yield Measurement

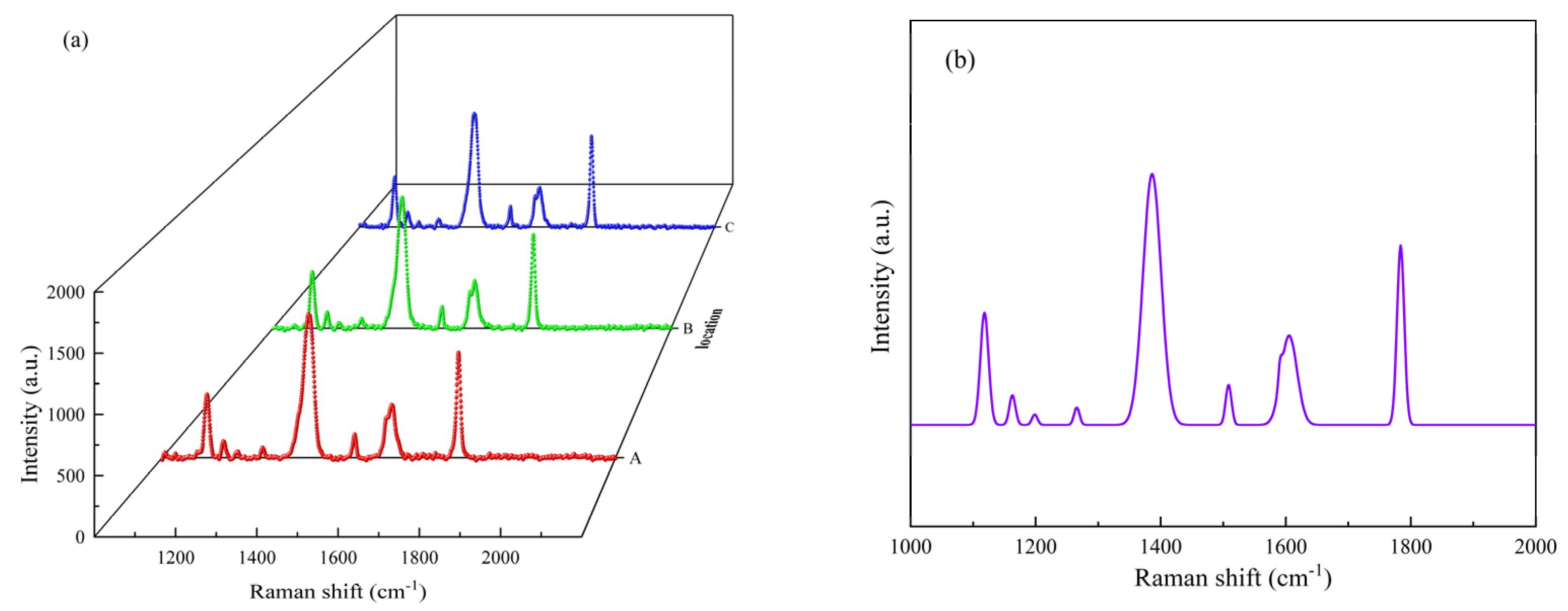

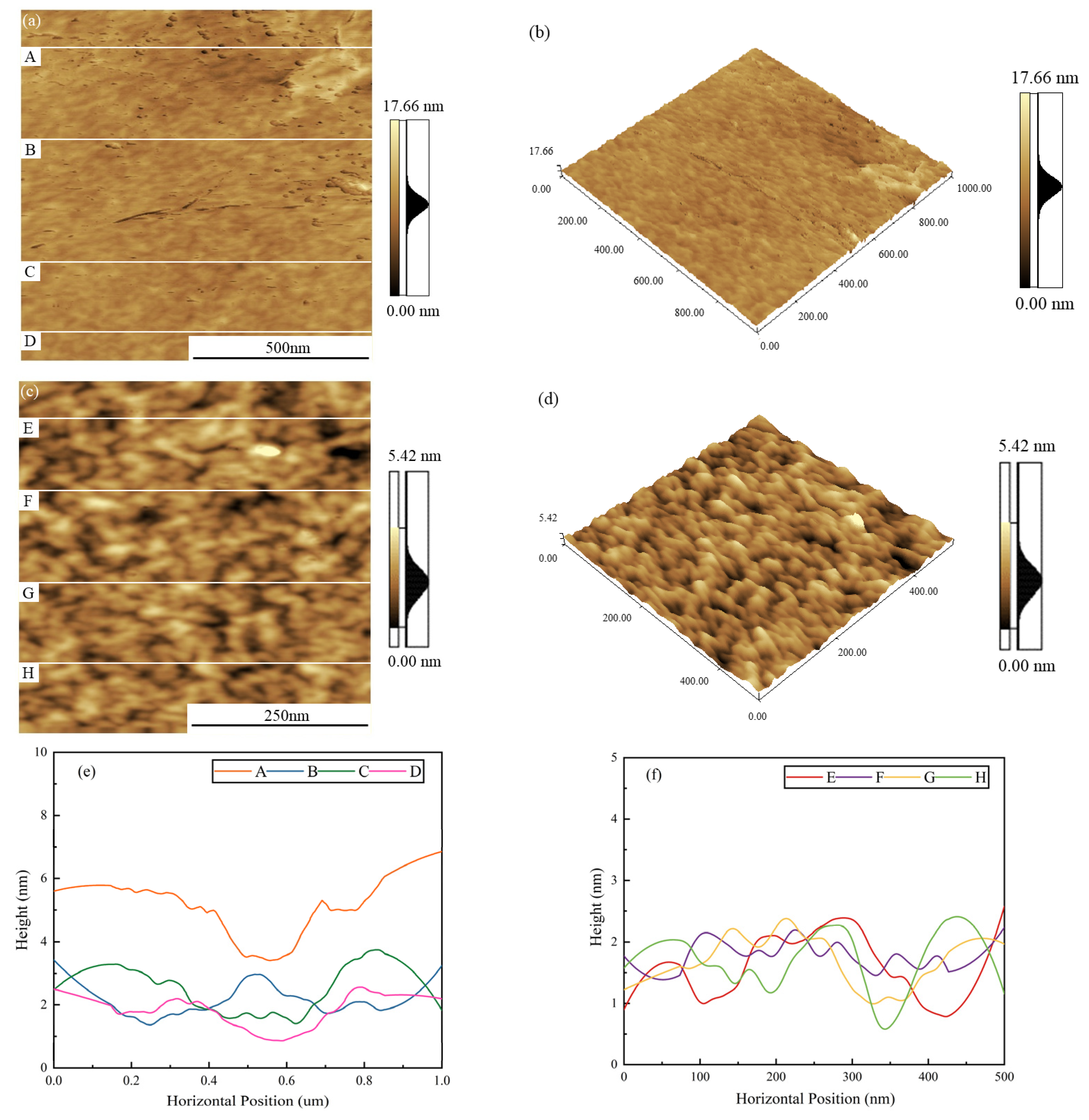

3. Results

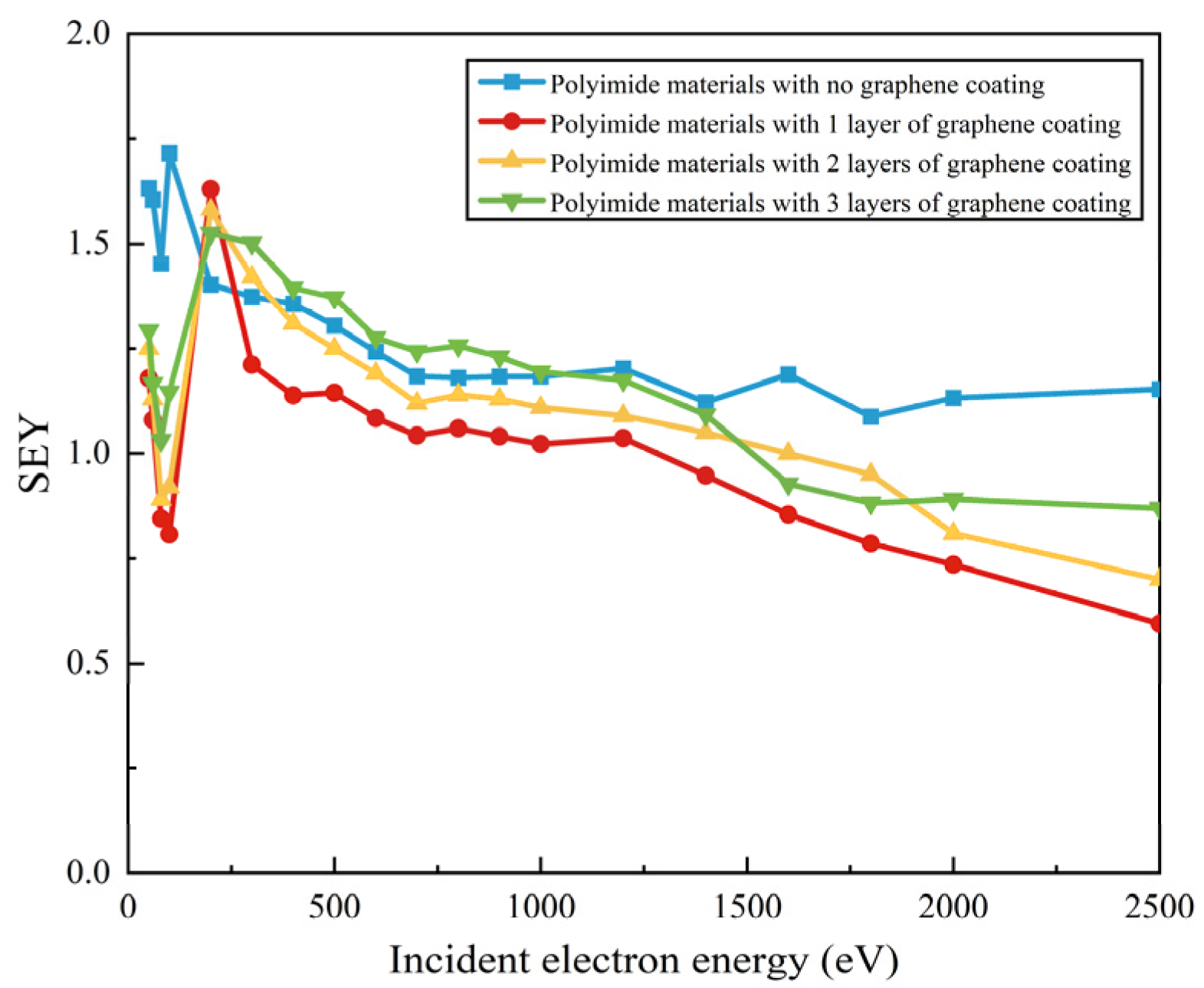

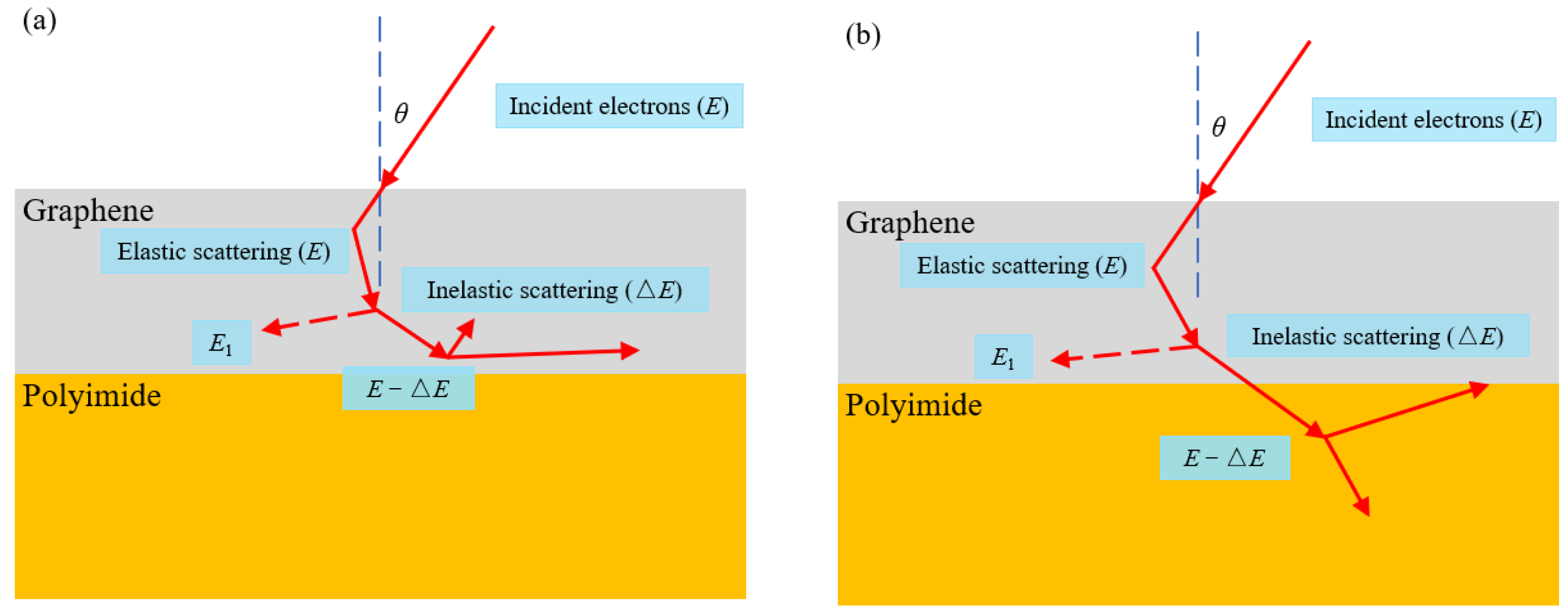

3.1. SEY and Theoretical Analysis

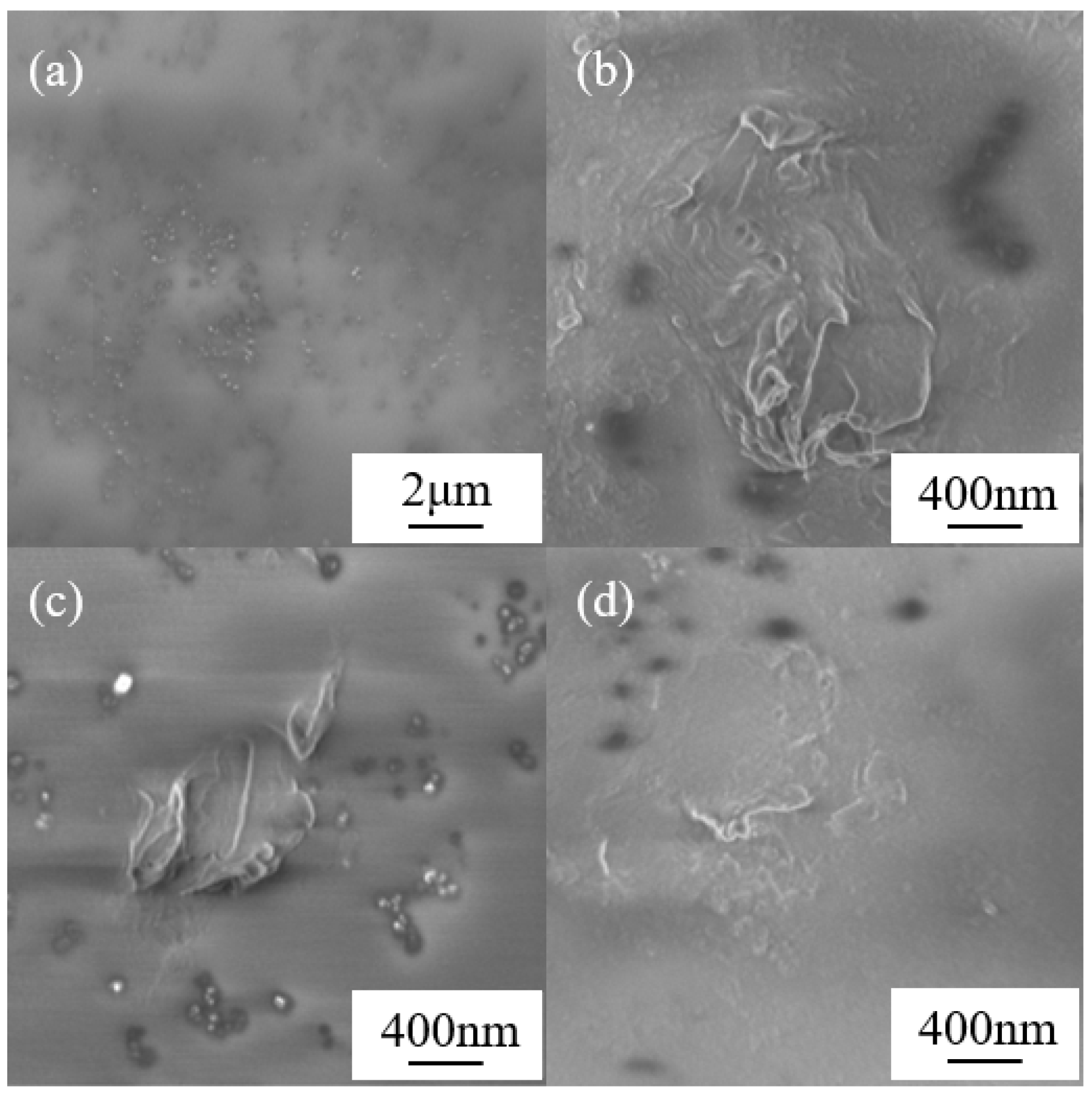

3.2. Surface Morphology Study of the Graphene-Coated Polyimide Materials

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Kong, F.; Zhang, P.H.; Yu, W.X.; Zhang, C.; Liu, J.B.; Ren, C.Y.; Shao, T. Enhanced surface insulating performance for polystyrene by atmospheric pressure plasma jet deposition. Appl. Surf. Sci. 2020, 527, 146826. [Google Scholar] [CrossRef]

- Wang, D.; He, Y.N.; Cui, W.Z. Secondary electron emission characteristics of TiN coatings produced by RF magnetron sputtering. J. Appl. Phys. 2018, 124, 053301. [Google Scholar] [CrossRef]

- Santos, A.; Bundaleski, N.; Shaw, B.J.; Silva, A.G.; Teodoro, O. Increase of secondary electron yield of amorphous carbon coatings under high vacuum conditions. Vacuum 2013, 98, 37–40. [Google Scholar] [CrossRef]

- Lapington, J.S.; Thompson, D.P.; May, P.W.; Fox, N.A.; Howorth, J.; Milnes, J.; Taillandier, V. Investigation of the secondary emission characteristics of CVD diamond films for electron amplification. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2009, 610, 253–257. [Google Scholar] [CrossRef]

- Costin, C. Secondary electron emission under magnetic constraint: From Monte Carlo simulations to analytical solution. Sci. Rep. 2021, 11, 1874. [Google Scholar] [CrossRef]

- Liu, X.W.; Mang, G.J.; Li, J.; Shi, G.L.; Zhou, M.Y.; Huang, B.Q.; Tang, Y.J.; Song, X.H.; Yang, W.F. Deep Learning for Feynman’s Path Integral in Strong-Field Time-Dependent Dynamics. Phys. Rev. Lett. 2020, 124, 113202. [Google Scholar] [CrossRef]

- Raitses, Y.; Kaganovich, I.D.; Khrabrov, A.; Sydorenko, D.; Fisch, N.J.; Smolyakov, A. Effect of Secondary Electron Emission on Electron Cross-Field Current in E x B Discharges. IEEE Trans. Plasma Sci. 2011, 39, 995–1006. [Google Scholar] [CrossRef]

- Liu, L.; Meng, X.N.; Miao, Z.; Zhou, S. Design of a novel thermoelectric module based on application stability and power generation. Case Stud. Therm. Eng. 2022, 31, 101836. [Google Scholar] [CrossRef]

- Choi, H.J.; Jung, S.M.; Seo, J.M.; Chang, D.W.; Dai, L.M.; Baek, J.B. Graphene for energy conversion and storage in fuel cells and supercapacitors. Nano Energy 2012, 1, 534–551. [Google Scholar] [CrossRef]

- Ma, J.Z.; Wei, L.F.; Bai, Y.R.; Bao, Y.; Kang, Q.L.; Zhang, W.B.; Cui, W.Z.; Hu, T.C.; Wu, D.D. Controllable preparation of silver nano-bowl coatings for suppressing secondary electron emission. Thin Solid Film. 2021, 725, 138633. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Y.; You, Z.M.; Fan, J.K.; Zhang, J.; Wang, S.; Xu, Z.L. Laser Induced Nano and Micro Structures of Molybdenum Surface Applied in Multistage Depressed Collector for Secondary Electron Suppression. Appl. Sci. 2019, 9, 4374. [Google Scholar] [CrossRef]

- Swanson, C.; Kaganovich, I.D. Modeling of reduced secondary electron emission yield from a foam or fuzz surface. J. Appl. Phys. 2018, 123, 023302. [Google Scholar] [CrossRef]

- Cimino, R.; Commisso, M.; Grosso, D.R.; Demma, T.; Baglin, V.; Flammini, R.; Larciprete, R. Nature of the Decrease of the Secondary-Electron Yield by Electron Bombardment and its Energy Dependence. Phys. Rev. Lett. 2012, 109, 064801. [Google Scholar] [CrossRef] [PubMed]

- Pivi, M.; King, F.K.; Kirby, R.E.; Raubenheimer, T.O.; Stupakov, G.; Le Pimpec, F. Sharp reduction of the secondary electron emission yield from grooved surfaces. J. Appl. Phys. 2008, 104, 104904. [Google Scholar] [CrossRef]

- Liu, L.; Feng, G.B.; Chen, B.D.; Wang, N.; Cui, W.Z. Characteristics of secondary electron emission and multipactor from a nested microtrap structure surface. AIP Adv. 2021, 11, 025332. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Wang, Y.G.; Wang, S.H.; Wei, W.; Ge, X.Q.; Zhu, B.L.; Shao, J.Q.; Wang, Y. Comparison of Carbon Thin Films with Low Secondary Electron Yield Deposited in Neon and Argon. Coatings 2020, 10, 884. [Google Scholar] [CrossRef]

- Wang, G.D.; Liu, D.M.; Fan, S.Q.; Li, Z.Y.; Su, J. High-k erbium oxide film prepared by sol-gel method for low-voltage thin-film transistor. Nanotechnology 2021, 32, 215202. [Google Scholar] [CrossRef]

- Nivas, J.J.J.; Valadan, M.; Salvatore, M.; Fittipaldi, R.; Himmerlich, M.; Rimoldi, M.; Passarelli, A.; Allahyari, E.; Oscurato, S.L.; Vecchione, A.; et al. Secondary electron yield reduction by femtosecond pulse laser-induced periodic surface structuring. Surf. Interfaces 2021, 25, 101179. [Google Scholar] [CrossRef]

- Jo, G.; Choe, M.; Lee, S.; Park, W.; Kahng, Y.H.; Lee, T. The application of graphene as electrodes in electrical and optical devices. Nanotechnology 2012, 23, 112001. [Google Scholar] [CrossRef]

- Park, J.H.; Park, J.M. Electrophoretic deposition of graphene oxide on mild carbon steel for anti-corrosion application. Surf. Coat. Technol. 2014, 254, 167–174. [Google Scholar] [CrossRef]

- Tang, H.C.; Yang, C.; Lin, Z.Y.; Yang, Q.H.; Kang, F.Y.; Wong, C.P. Electrospray-deposition of graphene electrodes: A simple technique to build high-performance supercapacitors. Nanoscale 2015, 7, 9133–9139. [Google Scholar] [CrossRef] [PubMed]

- Pavithra, C.L.P.; Sarada, B.V.; Rajulapati, K.V.; Rao, T.N.; Sundararajan, G. A New Electrochemical Approach for the Synthesis of Copper-Graphene Nanocomposite Foils with High Hardness. Sci. Rep. 2014, 4, 4049. [Google Scholar] [CrossRef] [PubMed]

- Geng, D.S.; Yang, S.L.; Zhang, Y.; Yang, J.L.; Liu, J.; Li, R.Y.; Sham, T.K.; Sun, X.L.; Ye, S.Y.; Knights, S. Nitrogen doping effects on the structure of graphene. Appl. Surf. Sci. 2011, 257, 9193–9198. [Google Scholar] [CrossRef]

- Mai, Y.J.; Zhou, M.P.; Ling, H.J.; Chen, F.X.; Lian, W.Q.; Jie, X.H. Surfactant-free electrodeposition of reduced graphene oxide/copper composite coatings with enhanced wear resistance. Appl. Surf. Sci. 2018, 433, 232–239. [Google Scholar] [CrossRef]

- Larciprete, R.; Grosso, D.R.; Di Trolio, A.; Cimino, R. Evolution of the secondary electron emission during the graphitization of thin C films. Appl. Surf. Sci. 2015, 328, 356–360. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, X.S.; Liu, W.H.; Wang, H.G.; Li, Y.D. Secondary electron emission of graphene-coated copper. Diam. Relat. Mater. 2017, 73, 199–203. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Xu, Y.H.; Zhang, Y.X.; Zhang, B.; Wei, W. Secondary electron emission characteristics of graphene films with copper substrate. Chin. Phys. C 2016, 40, 117003. [Google Scholar] [CrossRef]

- Sian, T.; Lin, Y.; Valizadeh, R.; Malyshev, O.B.; Xia, G.; Valles, C.; Yu, G.; Kinloch, I. Graphene coating for the reduction of the secondary electron yield. Proc. IPAC 2016, 2, 3688–3690. [Google Scholar]

- Aguincha, R.; Bundaleski, N.; Bundaleska, N.; Novakovi, M.; Teodoro, O. Low total electron yield graphene coatings produced by electrophoretic deposition. Appl. Surf. Sci. 2019, 504, 143870. [Google Scholar] [CrossRef]

- Luo, J.; Tian, P.; Pan, C.T.; Robertson, A.W.; Warner, J.H.; Hill, E.W.; Briggs, G. Ultralow Secondary Electron Emission of Graphene. ACS Nano 2011, 5, 1047. [Google Scholar] [CrossRef]

- Bundaleski, N.; Belhaj, M.; Gineste, T.; Teodoro, O. Calculation of the angular dependence of the total electron yield. Vacuum 2015, 122, 255–259. [Google Scholar] [CrossRef]

- Nguyen, H.K.A.; Mankowski, J.; Dickens, J.C.; Neuber, A.A.; Joshi, R.P. Calculations of secondary electron yield of graphene coated copper for vacuum electronic applications. AIP Adv. 2018, 8, 015325. [Google Scholar] [CrossRef]

- Fernandez, H.M.; Himmerlich, M.; Pinto, P.C.; Coroa, J.; Sousa, D.; Baris, A.; Taborelli, M. The impact of H-2 and N-2 on the material properties and secondary electron yield of sputtered amorphous carbon films for anti-multipacting applications. Appl. Surf. Sci. 2021, 542, 148552. [Google Scholar] [CrossRef]

- Fitting, H.J.; Touzin, M. Time-dependent start-up and decay of secondary electron emission in dielectrics. J. Appl. Phys. 2010, 108, 033711. [Google Scholar] [CrossRef]

- Tatarova, E.; Dias, A.; Henriques, J.; Abrashev, M.; Bundaleska, N.; Kovacevic, E.; Bundaleski, N.; Cvelbar, U.; Valcheva, E.; Arnaudov, B.; et al. Towards large-scale in free-standing graphene and N-graphene sheets. Sci. Rep. 2017, 7, 10175. [Google Scholar] [CrossRef]

- Montero, I.; Aguilera, L.; Davila, M.E.; Nistor, V.C.; Gonzalez, L.A.; Galan, L.; Raboso, D.; Ferritto, R. Secondary electron emission under electron bombardment from graphene nanoplatelets. Appl. Surf. Sci. 2014, 291, 74–77. [Google Scholar] [CrossRef]

- Zhang, W.H.; Nefedov, A.; Naboka, M.; Cao, L.; Woll, C. Molecular orientation of terephthalic acid assembly on epitaxial graphene: NEXAFS and XPS study. Phys. Chem. Chem. Phys. 2012, 14, 10125–10131. [Google Scholar] [CrossRef]

- Biesinger, M.C.; Lau, L.W.M.; Gerson, A.R.; Smart, R.S.C. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Sc, Ti, V, Cu and Zn. Appl. Surf. Sci. 2010, 257, 887–898. [Google Scholar] [CrossRef]

- Kadari, A.; Schemme, T.; Kadri, D.; Wollschlager, J. XPS and morphological properties of Cr2O3 thin films grown by thermal evaporation method. Results Phys. 2017, 7, 3124–3129. [Google Scholar] [CrossRef]

- Jung, R.H.; Tsuchiya, H.; Fujimoto, S. XPS characterization of passive films formed on Type 304 stainless steel in humid atmosphere. Corros. Sci. 2012, 58, 62–68. [Google Scholar] [CrossRef]

- Yang, X.; Sun, G.Y.; Zhou, R.D.; Huang, K.; Li, W.D.; Wang, C.; Dong, J.F.; Song, B.P.; Zhang, G.J. Ultralow secondary electron emission and improved vacuum surface insulation of polyimide with scalable nanocomposite coating. Appl. Surf. Sci. 2022, 592, 153221. [Google Scholar] [CrossRef]

- Zhang, H.F.; Ge, Y.; Pan, P.; Du, Y.H.; Fu, H.; Yan, M.J.; Li, P.; Long, H.M.; Zhang, C.Z.; Cai, J.; et al. Suppression of secondary electron emission on oxygen-free copper surface of reduced graphene oxide coatings prepared by electrophoretic deposition. Appl. Surf. Sci. 2022, 603, 1544900. [Google Scholar] [CrossRef]

- Lu, Q.; Yu, B.; Hu, Z.Q.; He, Y.; Hu, T.C.; Zhao, Y.N.; Wang, Z.G.; Zhou, Z.Y.; Cui, W.; Liu, M. Surface roughness evolution induced low secondary electron yield in carbon coated Ag/Al substrates for space microwave devices. Appl. Surf. Sci. 2020, 501, 144236. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, X.; Ma, Y.; Liu, S.; Nie, X.; Zhang, T.; Wu, Y.; Peng, W.; Hu, G. Suppression of Secondary Electron Emissions on the Graphene-Coated Polyimide Materials Prepared by Chemical Vapor Deposition. Coatings 2023, 13, 1805. https://doi.org/10.3390/coatings13101805

Qi X, Ma Y, Liu S, Nie X, Zhang T, Wu Y, Peng W, Hu G. Suppression of Secondary Electron Emissions on the Graphene-Coated Polyimide Materials Prepared by Chemical Vapor Deposition. Coatings. 2023; 13(10):1805. https://doi.org/10.3390/coatings13101805

Chicago/Turabian StyleQi, Xin, Yanzhao Ma, Sisheng Liu, Xiangyu Nie, Tao Zhang, Yong Wu, Weiping Peng, and Guoming Hu. 2023. "Suppression of Secondary Electron Emissions on the Graphene-Coated Polyimide Materials Prepared by Chemical Vapor Deposition" Coatings 13, no. 10: 1805. https://doi.org/10.3390/coatings13101805

APA StyleQi, X., Ma, Y., Liu, S., Nie, X., Zhang, T., Wu, Y., Peng, W., & Hu, G. (2023). Suppression of Secondary Electron Emissions on the Graphene-Coated Polyimide Materials Prepared by Chemical Vapor Deposition. Coatings, 13(10), 1805. https://doi.org/10.3390/coatings13101805