Resolving Selected Problems in Surface Topography Analysis by Application of the Autocorrelation Function

Abstract

1. Introduction

2. Materials and Methods

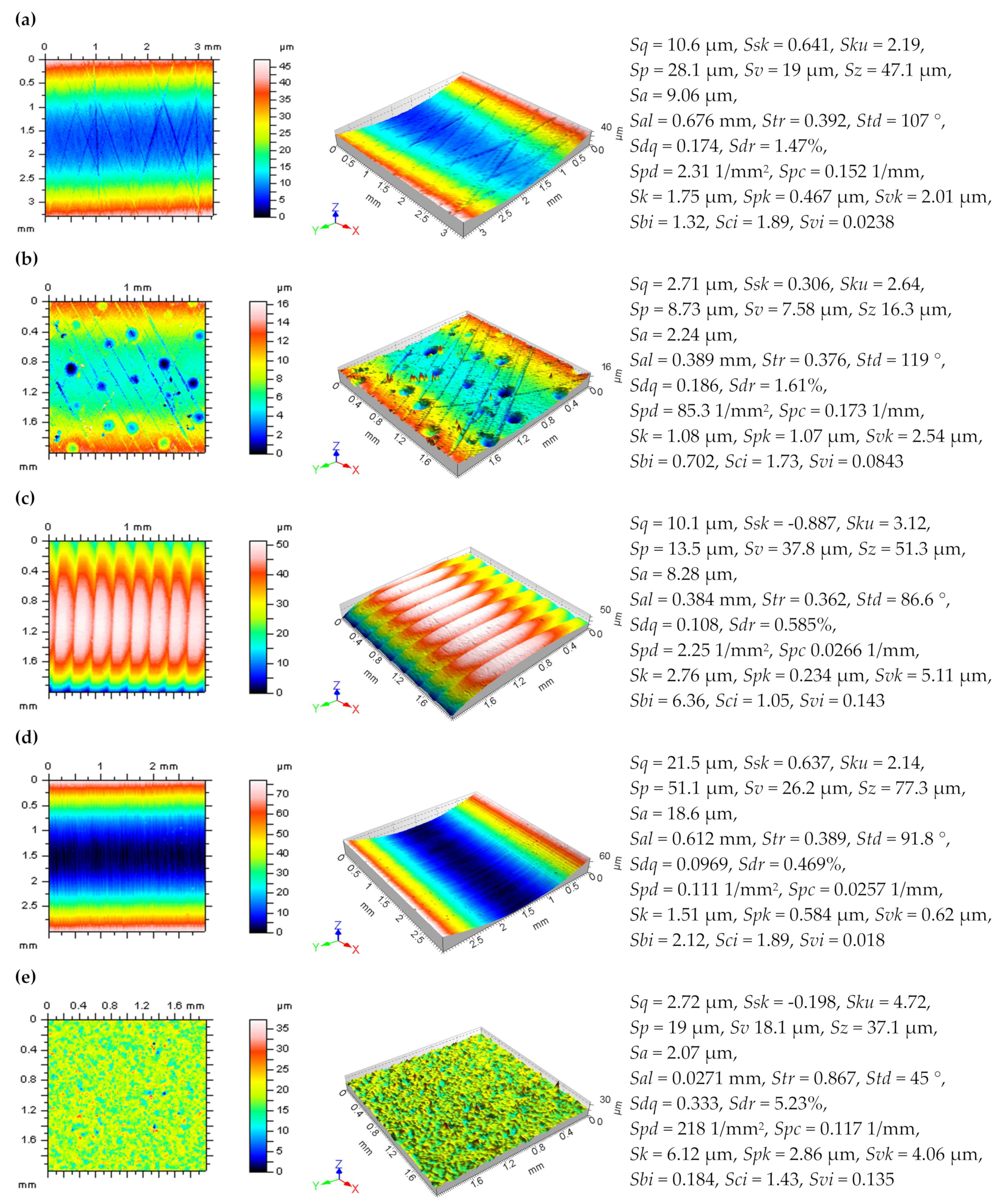

2.1. Analyzed Surfaces

2.2. Measurement Process

2.3. Proposals of Improvement of Methods for Surface Topography Analysis by Application of the Autocorrelation Function

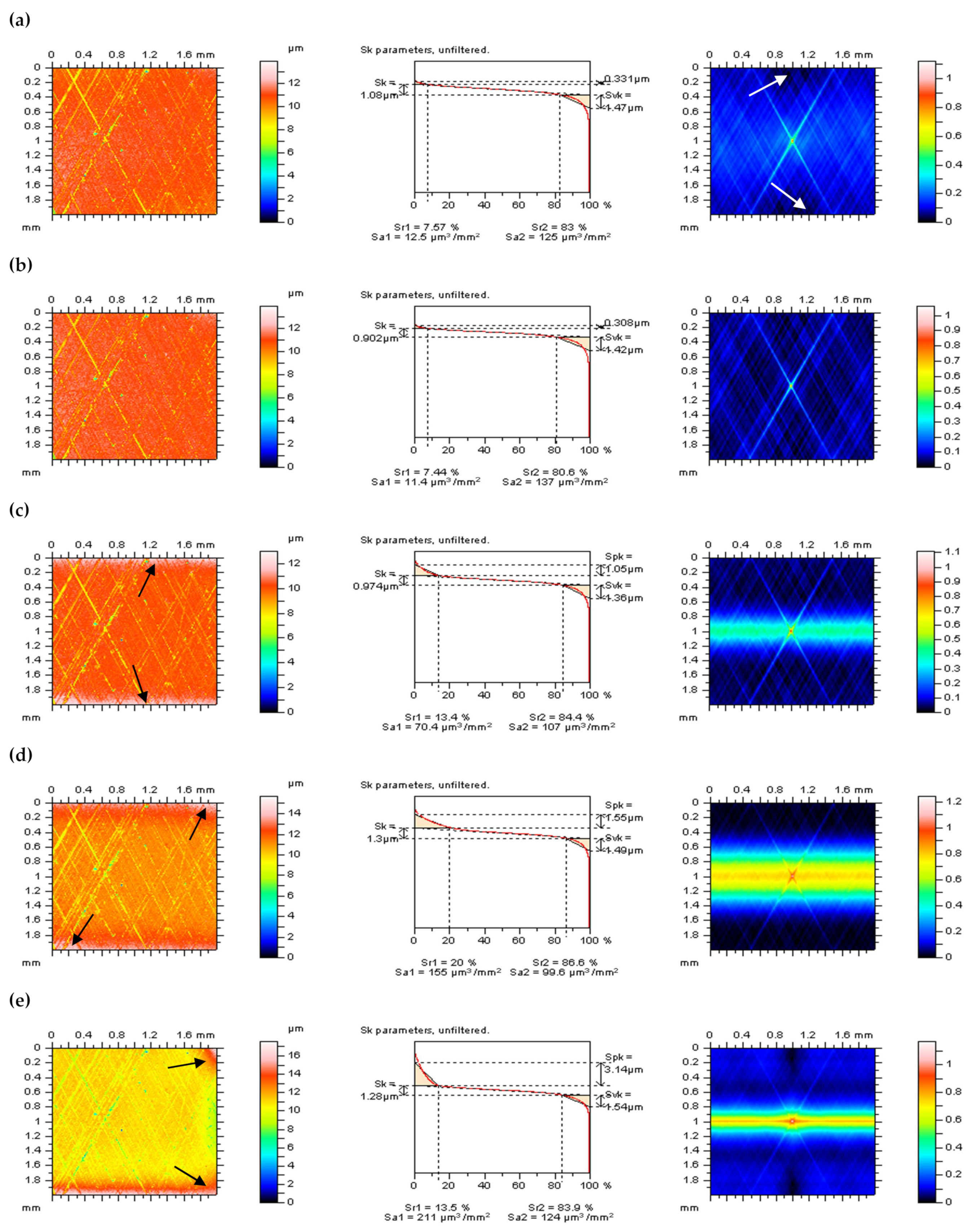

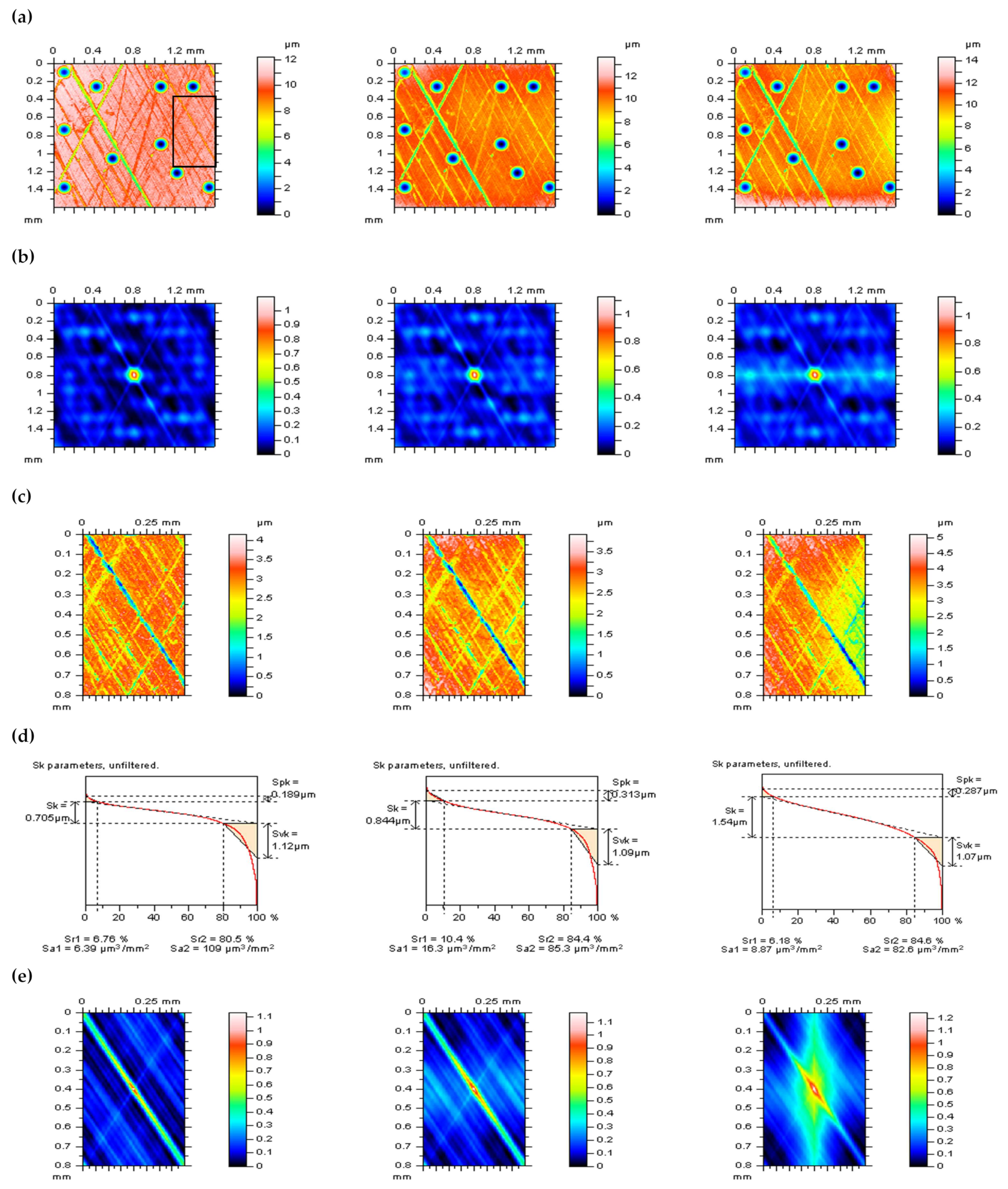

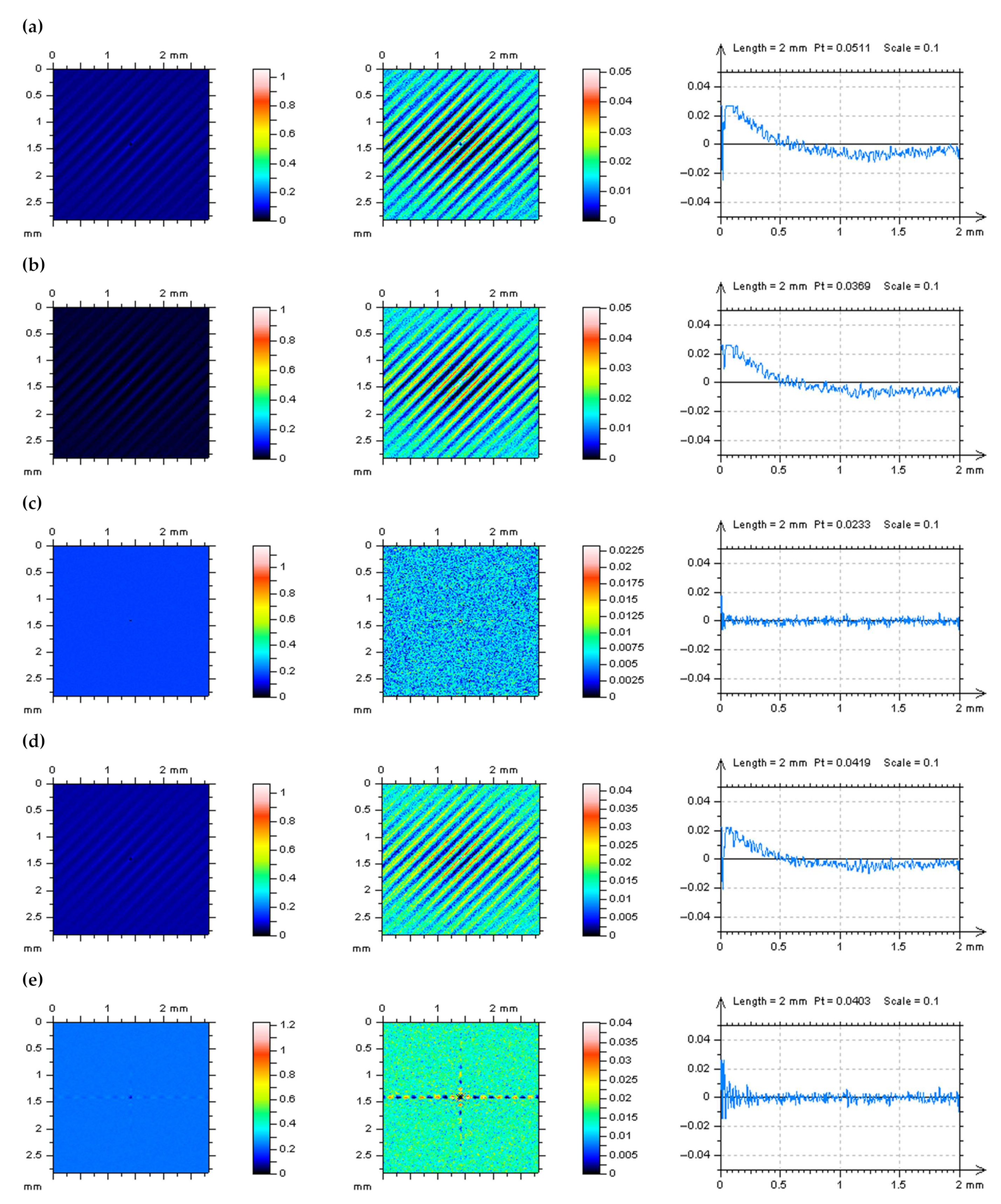

3. Results

3.1. Reducing Errors in an Areal Form Removal

3.2. Application of an Autocorrelation Function in the Reduction of High-frequency Measurement Errors

3.3. Improving Proposed Methods with a Modeled Data

4. Conclusions

- The autocorrelation function (ACF) can be exceedingly valuable in the validation of the methods for an areal form removal (definition of L-surface). It was presented that using an ACF with analysis of an isometric view of the measured surface topography can improve the applied method and can be crucial in the reduction of errors in ISO 25178 standard amplitude (height) parameter calculation.

- When considering the isometric view of the detail after L-surface removal, the distortion of some features (such as burnished dimples) can be important in both measured data and an areal ACF characterization. The higher distortion of data occurs, the greater differences in the isometric view and ACF were obtained. Reduction of errors in both data can, respectively, similarly reduce the distortion in the ISO 25178 roughness parameters calculations.

- The usage of ACF for details with out-of-feature characteristics can be highly beneficial when the surface contains some deep or wide features, such as dimples. In these cases, omitting the deep features can be necessary for ACF implementation that can affect proposed procedures to be useless. For both analyses, view of surface and ACF graphs, omitting the features is crucial for the definition of S-L-surface.

- Application of ACF for both profile (2D) and an areal (3D) data can be essential in the process of detection (definition) and reduction (removal) of high-frequency measurement errors from the results of surface roughness evaluation. For both types of data analysis, the center part of the ACF can characterize if the measurement errors in the high-frequency domain were reduced entirely. From that matter, filtering method suitability can also be evaluated.

- In some cases, the thresholding of the ACF is required. This technique is significant in the definition of S-surface especially. When applying truncation, some required properties of the S-surface (noise surface) can be defined more adequately. This approach, supporting the ACF characterization, can reduce the distortion of surface topography features, so, respectively, the errors in the calculation of the ISO 25178 surface roughness parameters can also be radically reduced.

- Considering thresholding and out-of-feature methods, they can be applied simultaneously when reducing surface height is crucial in the validation of the filtering technique. The sequence of application of those methods does not affect the analyzed type of surface, but, respectively, the sizes, densities, and distribution of the features located on the studied surface must be thoroughly considered.

- From all of the studies provided, it was presented that the application of the ACF scheme can significantly reduce the errors in the processes of an areal form removal (definition of L-surface) and suppression of high-frequency measurement noise (indicated as the S-surface). It was proved that even regular and commonly used methods can be especially valuable when applied appropriately.

- All of those data processing actions are crucial in the process of control of manufactured parts. Reducing errors in surface roughness measurement and data analysis can radically affect the validation of machined parts. Improper definition of S-L surface, especially L-surface, can cause classification of properly made parts as a lack and its rejection. From that matter, all of the actions made on the reduction of errors in roughness evaluation (definition of S-L surface) can be consequently crucial in industrial applications.

5. The Outlook

- Comprehensive analysis of the ACF for both 3D (areal) and 2D (profile) data must be improved in the edge effect of surface filtering. Many studies provide some general proposals for reducing the effect of edge data on the surface roughness evaluation; nevertheless, the reduction of errors in ISO 25178 parameters calculation with the usage of ACF was not already presented.

- Even though least-square methods, such as least-square fitted cylinder elements or polynomial planes of various degrees, are providing encouraging results, digital filtering, e.g., those based on the Gaussian function, is still often used and the results considered. From that matter, more studies on the Gaussian filtering methods must still be proposed.

- In some cases of analysis with ACF function, the thresholding method is required. Even though a range (0.13%–99.97%) of thresholding techniques was proposed, according to the previously studied cases, those values should be studied considering each type of surface texture. Moreover, the dependences on the surface feature size, density, and location can also be found when the thresholding method is used.

- The influence of surface directionality on the ACF characterization should be studied as well. It was introduced in some previous studies that direction methods can be exceedingly valuable in the process of high-frequency measurement noise reduction, improving its impact in both the detection and removal of noise data.

- The effect of the bi-directionality of surface features was not comprehensively studied in both L-surface and S-surface definitions. When reducing errors in high-frequency measurement noise reduction, the S-surface properties were studied when one or even two directions were defined on the analyzed surface. It must be studied widely, and, respectively, some proposals should be unified.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

References

- Panjan, P.; Drnovšek, A. Special Issue: Surface Topography Effects on the Functional Properties of PVD Coatings. Coatings 2022, 12, 1796. [Google Scholar] [CrossRef]

- Zheng, M.; Wang, B.; Zhang, W.; Cui, Y.; Zhang, L.; Zhao, S. Analysis and prediction of surface wear resistance of ball-end milling topography. Surf. Topogr. Metrol. Prop. 2020, 8, 025032. [Google Scholar] [CrossRef]

- Sherrington, I.; Smith, E. The significance of Surface topography in engineering. Precis. Eng. 1986, 8, 79–87. [Google Scholar] [CrossRef]

- Wizner, M.; Jakubiec, W.; Starczak, M. Description of surface topography of sealing rings. Wear 2011, 271, 571–575. [Google Scholar] [CrossRef]

- Shi, R.; Wang, B.; Yan, Z.; Wang, Z.; Dong, L. Effect of Surface Topography Parameters on Friction and Wear of Random Rough Surface. Materials 2019, 12, 2762. [Google Scholar] [CrossRef]

- Jiang, Y.; Suvanto, M.; Pakkanen, T.A. Selective surface modification on lubricant retention. Surf. Rev. Lett. 2015, 23, 1550097. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Awale, A.S.; Vashista, M.; Yusufzai, M.Z.K. Application of eco-friendly lubricants in sustainable grinding of die steel. Mater. Manuf. Process. 2021, 36, 702–712. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Nieslony, P.; Wojciechowski, S.; Legutko, S. Parametric and nonparametric description of the surface topography in the dry and MQCL cutting conditions. Measurement 2018, 121, 225–239. [Google Scholar] [CrossRef]

- Królczyk, G.; Kacalak, W.; Wieczorowski, M. 3D Parametric and Nonparametric Description of Surface Topography in Manufacturing Processes. Materials 2021, 14, 1987. [Google Scholar] [CrossRef]

- Cooper, L.F. A role for surface topography in creating and maintaining bone at titanium endosseous implants. J. Prosthet. Dent. 2000, 84, 522–534. [Google Scholar] [CrossRef] [PubMed]

- Podulka, P. Reduction of Influence of the High-Frequency Noise on the Results of Surface Topography Measurements. Materials 2021, 14, 333. [Google Scholar] [CrossRef] [PubMed]

- Matsumura, T.; Iida, F.; Hirose, T.; Yoshino, M. Micro machining for control of wettability with surface topography. J. Mater. Process. Technol. 2012, 212, 2669–2677. [Google Scholar] [CrossRef]

- Ohlsson, R.; Wihlborg, A.; Westberg, H. The accuracy of fast 3D topography measurements. Int. J. Mach. Tool Manuf. 2001, 41, 1899–1907. [Google Scholar] [CrossRef]

- Sherrington, I.; Smith, E.H. Modern measurement techniques in surface metrology: Part I; stylus instruments, electron microscopy and non-optical comparators. Wear 1988, 125, 271–288. [Google Scholar] [CrossRef]

- Leach, R. Optical Measurement of Surface Topography; Springer: Berlin, Germany, 2011. [Google Scholar]

- Sakakibara, R.; Yoshida, I.; Nagai, S.; Kondo, Y.; Yamashita, K. Surface roughness evaluation method based on roughness parameters in ISO 13565-3 using the least-squares method for running-in wear process analysis of plateau surface. Tribol. Int. 2021, 163, 107151. [Google Scholar] [CrossRef]

- Vorburger, T.V.; Rhee, H.G.; Renegar, T.B.; Song, J.-F.; Zheng, A. Comparison of optical and stylus methods for measurement of surface texture. Int. J. Adv. Manuf. Technol. 2007, 33, 110–118. [Google Scholar] [CrossRef]

- Mahovic Poljacek, S.; Risovic, D.; Furic, K.; Gojo, M. Comparison of fractal and profilometric methods for surface topography characterization. Appl. Surf. Sci. 2008, 254, 3449–3458. [Google Scholar] [CrossRef]

- Thompson, A.; Senin, N.; Giusca, C.; Leach, R. Topography of selectively laser melted surfaces: A comparison of different measurement methods. CIRP Ann. Manuf. Technol. 2017, 66, 543–546. [Google Scholar] [CrossRef]

- Podulka, P. Comparisons of envelope morphological filtering methods and various regular algorithms for surface texture analysis. Metrol. Meas. Syst. 2020, 27, 243–263. [Google Scholar] [CrossRef]

- Aich, U.; Banerjee, S. Characterizing topography of EDM generated surface by time series and autocorrelation function. Tribol. Int. 2017, 111, 73–90. [Google Scholar] [CrossRef]

- Dong, W.P.; Sullivan, P.J.; Stout, K.J. Comprehensive study of parameters for characterising three-dimensional surface topography: III: Parameters for characterising amplitude and some functional properties. Wear 1994, 178, 29–43. [Google Scholar] [CrossRef]

- Fubel, A.; Zech, M.; Leiderer, P.; Klier, J.; Shikin, V. Analysis of roughness of Cs surfaces via evaluation of the autocorrelation function. Surf. Sci. 2007, 601, 1684–1692. [Google Scholar] [CrossRef]

- Zou, L.; Liu, X.; Huang, Y.; Fei, Y. A numerical approach to predict the machined surface topography of abrasive belt flexible grinding. Int. J. Adv. Manuf. Technol. 2019, 104, 2961–2970. [Google Scholar] [CrossRef]

- Järnström, J.; Ihalainen, P.; Backfolk, K.; Peltonen, J. Roughness of pigment coatings and its influence on gloss. Appl. Surf. Sci. 2008, 254, 5741–5749. [Google Scholar] [CrossRef]

- Brown, L.G.; Shvaytser, H. Surface orientation from projective foreshortening of isotropic texture autocorrelation. IEEE Trans. Pattern Anal. 1990, 12, 584–588. [Google Scholar] [CrossRef]

- Liao, D.; Shao, W.; Tang, J.; Li, J. An improved rough surface modeling method based on linear transformation technique. Tribol. Int. 2018, 119, 786–794. [Google Scholar] [CrossRef]

- Brochard, J.; Khoudeir, M.; Augereau, B. Invariant feature extraction for 3D texture analysis using the autocorrelation function. Pattern Recogn. Lett. 2001, 22, 759–768. [Google Scholar] [CrossRef]

- Zhou, W.; Cao, Y.; Zhao, H.; Li, Z.; Feng, P.; Feng, F. Fractal Analysis on Surface Topography of Thin Films: A Review. Fractal Fract. 2022, 6, 135. [Google Scholar] [CrossRef]

- Kulesza, S.; Bramowicz, M. A comparative study of correlation methods for determination of fractal parameters in surface characterization. Appl. Surf. Sci. 2014, 293, 196–201. [Google Scholar] [CrossRef]

- Munoz, R.C.; Vidal, G.; Kremer, G.; Moraga, L.; Arenas, C.; Concha, A. Surface roughness and surface-induced resistivity of gold films on mica: Influence of roughness modelling. J. Phys. Condens. Matter 2000, 12, 2903. [Google Scholar] [CrossRef]

- Podulka, P. Improved Procedures for Feature-Based Suppression of Surface Texture High-Frequency Measurement Errors in the Wear Analysis of Cylinder Liner Topographies. Metals 2021, 11, 143. [Google Scholar] [CrossRef]

- Heilbronner, R.P. The autocorrelation function: An image processing tool for fabric analysis. Tectonophysics 1992, 212, 351–370. [Google Scholar] [CrossRef]

- Dhanasekar, B.; Mohan, N.K.; Bhaduri, B.; Ramamoorthy, B. Evaluation of surface roughness based on monochromatic speckle correlation using image processing. Precis. Eng. 2008, 32, 196–206. [Google Scholar] [CrossRef]

- Dusséaux, R.; Vannier, E. Soil surface roughness modelling with the bidirectional autocorrelation function. Biosyst. Eng. 2022, 220, 87–102. [Google Scholar] [CrossRef]

- Wang, W.-Z.; Chen, H.; Hu, Y.-Z.; Wang, H. Effect of surface roughness parameters on mixed lubrication characteristics. Tribol. Int. 2006, 39, 522–527. [Google Scholar] [CrossRef]

- Uchidate, M.; Shimizu, T.; Iwabuchi, A.; Yanagi, K. Generation of reference data of 3D surface texture using the non-causal 2D AR model. Wear 2004, 257, 1288–1295. [Google Scholar] [CrossRef]

- Hu, S.; Brunetiere, N.; Huang, W.; Liu, X.; Wang, Y. Bi-Gaussian surface identification and reconstruction with revised autocorrelation functions. Tribol. Int. 2017, 110, 185–194. [Google Scholar] [CrossRef]

- Patrikar, R.M. Modeling and simulation of surface roughness. Appl. Surf. Sci. 2004, 228, 213–220. [Google Scholar] [CrossRef]

- Krolczyk, G.; Raos, P.; Legutko, S. Experimental Analysis of Surface Roughness and Surface Texture of Machined and Fused Deposition Modelled Parts. Teh. Vjesn. 2014, 21, 217–221. [Google Scholar]

- Gharechelou, S.; Tateishi, R.; Johnson, B.A. A Simple Method for the Parameterization of Surface Roughness from Microwave Remote Sensing. Remote Sens. 2018, 10, 1711. [Google Scholar] [CrossRef]

- ISO 25178-3:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 3: Specification Operators. International Organization for Standardization: Geneva, Switzerland, 2012.

- Podulka, P. Fast Fourier Transform detection and reduction of high-frequency errors from the results of surface topography profile measurements of honed textures. Eksploat. Niezawodn. 2021, 23, 84–89. [Google Scholar] [CrossRef]

- Podulka, P. Selection of Methods of Surface Texture Characterisation for Reduction of the Frequency-Based Errors in the Measurement and Data Analysis Processes. Sensors 2022, 22, 791. [Google Scholar] [CrossRef]

- Pahk, H.; Stout, K.; Blunt, L. A Comparative Study on the Three-Dimensional Surface Topography for the Polished Surface of Femoral Head. Int. J. Adv. Manuf. Technol. 2000, 16, 564–570. [Google Scholar] [CrossRef]

- Podulka, P. Suppression of the High-Frequency Errors in Surface Topography Measurements Based on Comparison of Various Spline Filtering Methods. Materials 2021, 14, 5096. [Google Scholar] [CrossRef]

- De Groot, P.; DiSciacca, J. Definition and evaluation of topography measurement noise in optical instruments. Opt. Eng. 2020, 59, 064110. [Google Scholar] [CrossRef]

- Zhuo, Y.; Han, Z.; An, D.; Jin, H. Surface topography prediction in peripheral milling of thin-walled parts considering cutting vibration and material removal effect. Int. J. Mech. Sci. 2021, 211, 106797. [Google Scholar] [CrossRef]

- Podulka, P. Advances in Measurement and Data Analysis of Surfaces with Functionalized Coatings. Coatings 2022, 12, 1331. [Google Scholar] [CrossRef]

- Peta, K.; Mendak, M.; Bartkowiak, T. Discharge Energy as a Key Contributing Factor Determining Microgeometry of Aluminum Samples Created by Electrical Discharge Machining. Crystals 2021, 11, 1371. [Google Scholar] [CrossRef]

- Podulka, P. The effect of valley depth on areal form removal in surface topography measurements. Bull. Pol. Acad. Sci. Tech. Sci. 2019, 67, 391–400. [Google Scholar] [CrossRef]

- Podulka, P. Bisquare robust polynomial fitting method for dimple distortion minimisation in surface quality analysis. Surf. Interface Anal. 2020, 52, 875–881. [Google Scholar] [CrossRef]

- ISO 16610-28:2016; Geometrical Product Specifications (GPS). Filtration—Part 28: Profile Filters: End Effects. International Organization for Standardization: Geneva, Switzerland, 2016.

- Janecki, D. Edge effect elimination in the recursive implementation of Gaussian filters. Precis. Eng. 2012, 36, 128–136. [Google Scholar] [CrossRef]

- Podulka, P. The effect of valley location in two-process surface topography analysis. Adv. Sci. Technol. Res. J. 2018, 12, 97–102. [Google Scholar] [CrossRef]

- Janecki, D. Gaussian filters with profile extrapolation. Precis. Eng. 2011, 35, 602–606. [Google Scholar] [CrossRef]

- Podulka, P. Proposal of frequency-based decomposition approach for minimization of errors in surface texture parameter calculation. Surf. Interface Anal. 2020, 52, 882–889. [Google Scholar] [CrossRef]

- Giusca, C.L.; Leach, R. Calibration of the scales of areal surface topography measuring instruments: Part 3. Resolution. Meas. Sci. Technol. 2013, 24, 105010. [Google Scholar] [CrossRef]

- Podulka, P. The Effect of Surface Topography Feature Size Density and Distribution on the Results of a Data Processing and Parameters Calculation with a Comparison of Regular Methods. Materials 2021, 14, 4077. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, W. Numerical simulation of the geometrical factors affecting surface roughness measurements by AFM. Meas. Sci. Technol. 2004, 15, 2005–2010. [Google Scholar] [CrossRef]

- Pei, J.; Han, X.; Tao, Y.; Feng, S. Mixed elastohydrodynamic lubrication analysis of line contact with Non-Gaussian surface roughness. Tribol. Int. 2020, 151, 106449. [Google Scholar] [CrossRef]

- Fecske, S.K.; Gkagkas, K.; Gachot, C.; Vernes, A. Interdependence of Amplitude Roughness Parameters on Rough Gaussian Surfaces. Tribol. Lett. 2020, 68, 43. [Google Scholar] [CrossRef]

- Jacobs, T.D.B.; Junge, T.; Pastewka, L. Quantitative characterization of surface topography using spectral analysis. Surf. Topogr. Metrol. Prop. 2017, 5, 013001. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Nieslony, P.; Wieczorowski, M. Surface morphology analysis of Duplex Stainless Steel (DSS) in Clean Production using the Power Spectral Density. Measurement 2016, 94, 464–470. [Google Scholar] [CrossRef]

- Podulka, P. Proposals of Frequency-Based and Direction Methods to Reduce the Influence of Surface Topography Measurement Errors. Coatings 2022, 12, 726. [Google Scholar] [CrossRef]

- Cai, C.; An, Q.; Ming, W.; Chen, M. Modelling of machined surface topography and anisotropic texture direction considering stochastic tool grinding error and wear in peripheral milling. J. Mater. Process. Technol. 2021, 292, 117065. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, W.; Yan, P.; Qiu, T.; Gu, H.; Jiao, L.; Wang, X. Effect of milling surface topography and texture direction on fatigue behavior of ZK61M magnesium alloy. Int. J. Fatigue 2022, 156, 106669. [Google Scholar] [CrossRef]

- Podulka, P. Thresholding Methods for Reduction in Data Processing Errors in the Laser-Textured Surface Topography Measurements. Materials 2022, 15, 5137. [Google Scholar] [CrossRef]

- Maculotti, G.; Feng, X.; Su, R.; Galetto, M.; Leach, R.K. Residual flatness and scale calibration for a point autofocus surface topography measuring instrument. Meas. Sci. Technol. 2019, 30, 075005. [Google Scholar] [CrossRef]

- ISO 25178-2:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2012.

- Franco, L.A.; Sinatora, A. 3D surface parameters (ISO 25178-2): Actual meaning of Spk and its relationship to Vmp. Precis. Eng. 2015, 40, 106–111. [Google Scholar] [CrossRef]

- Grzesik, W. Prediction of the Functional Performance of Machined Components Based on Surface Topography: State of the Art. J. Mater. Eng. Perform. 2016, 25, 4460–4468. [Google Scholar] [CrossRef]

- Gao, F.; Leach, R.; Petzing, J.; Coupland, J.M. Surface measurement errors using commercial scanning white light interferometers. Meas. Sci. Technol. 2008, 19, 015303. [Google Scholar] [CrossRef]

- Lou, S.; Tang, D.; Zeng, W.; Zhang, T.; Gao, F.; Muhamedsalih, H.; Jiang, X.; Scott, P.J. Application of Clustering Filter for Noise and Outlier Suppression in Optical Measurement of Structured Surfaces. IEEE Trans. Instrum. Meas. 2020, 69, 6509–6517. [Google Scholar] [CrossRef]

- Podulka, P.; Pawlus, P.; Dobrzanski, P.; Lenart, A. Spikes removal in surface measurement. J. Phys. Conf. Ser. 2014, 483, 012025. [Google Scholar] [CrossRef]

- ISO 13565-3:1998; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having Stratified Functional Properties—Part 3: Height characterization using the Material Probability Curve. International Organization for Standardization: Geneva, Switzerland, 1998.

- Nagai, S.; Yoshida, I.; Oshiro, K.; Sakakibara, R. Acceleration of surface roughness evaluation using RANSAC and least squares method for Running-in wear process analysis of plateau surface. Measurement 2022, 203, 111912. [Google Scholar] [CrossRef]

- Dong, W.P.; Mainsah, E.; Stout, K.J. Reference planes for the assessment of surface roughness in three dimensions. Int. J. Mach. Tools Manuf. 1995, 35, 263–271. [Google Scholar] [CrossRef]

- Xue, M.; Peng, S.; Wang, F.; Ou, J.; Li, C.; Li, W. Linear relation between surface roughness and work function of light alloys. J. Alloys Compd. 2017, 692, 903–907. [Google Scholar] [CrossRef]

- Forbes, A.B. Least Squares Best Fit Geometric Elements; NLP Report DITC 140/89; National Physical Laboratory: Teddington, UK, 1989. [Google Scholar]

- Weber, T.; Motavalli, S.; Fallahi, B.; Cheraghi, S.H. A unified approach to form error evaluation. Precis. Eng. 2002, 26, 269–278. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Tian, Y.; Wang, Y.; Wang, J. Application of improved fireworks algorithm in grinding surface roughness online monitoring. J. Manuf. Process. 2022, 74, 400–412. [Google Scholar] [CrossRef]

- ISO 16610-21:2011; Geometrical Product Specifications (GPS)—Filtration—Part 21: Linear Profile Filters: Gaussian Filters. International Organization for Standardization: Geneva, Switzerland, 2011.

- Kondo, Y.; Yoshida, I.; Nakaya, D.; Numada, M.; Koshimizu, H. Verification of Characteristics of Gaussian Filter Series for Surface Roughness in ISO and Proposal of Filter Selection Guidelines. Nanomanufactur. Metrol. 2021, 4, 97–108. [Google Scholar] [CrossRef]

- Li, Y.; Otsubo, M.; Kuwano, R.; Nadimi, S. Quantitative evaluation of surface roughness for granular materials using Gaussian filter method. Powder Technol. 2021, 388, 251–260. [Google Scholar] [CrossRef]

- ISO 16610-31:2016; Geometrical Product Specifications (GPS)—Filtration—Part 31: Robust Profile Filters: Gaussian Regression Filters. International Organization for Standardization: Geneva, Switzerland, 2016.

- Li, H.; Cheung, C.F.; Jiang, X.Q.; Lee, W.B.; To, S. A novel robust Gaussian filtering method for the characterization of surface generation in ultra-precision machining. Precis. Eng. 2006, 30, 421–430. [Google Scholar] [CrossRef]

- Zhang, H.; Yuan, Y.; Piao, W. A universal spline filter for surface metrology. Measurement 2010, 43, 1575–1582. [Google Scholar] [CrossRef]

- Janecki, D. A two-dimensional isotropic spline filter. Precis. Eng. 2013, 37, 948–965. [Google Scholar] [CrossRef]

- He, B.; Zheng, H.; Ding, S.; Yang, R.; Shi, Z.A. review of digital filtering in evaluation of surface roughness. Metrol. Meas. Syst. 2021, 28, 217–253. [Google Scholar] [CrossRef]

- Zhongxiang, H.; Lei, Z.; Jiaxu, T.; Xuehong, M.; Xiaojun, S. Evaluation of three-dimensional surface roughness parameters based on digital image processing. Int. J. Adv. Manuf. Technol. 2009, 40, 342–348. [Google Scholar] [CrossRef]

- Kim, H.Y.; Shen, Y.F.; Ahn, J.H. Development of a surface roughness measurement system using reflected laser beam. J. Mater. Process. Technol. 2002, 130–131, 662–667. [Google Scholar] [CrossRef]

- Fan, S.; Jiao, L.; Wang, K.; Duan, F. Pool boiling heat transfer of saturated water on rough surfaces with the effect of roughening techniques. Int. J. Heat Mass Transf. 2020, 159, 120054. [Google Scholar] [CrossRef]

- González Martínez, J.F.; Nieto-Carvajal, I.; Abad, J.; Colchero, J. Nanoscale measurement of the power spectral density of surface roughness: How to solve a difficult experimental challenge. Nanoscale Res. Lett. 2012, 7, 174. [Google Scholar] [CrossRef]

- Gong, Y.; Misture, S.T.; Gao, P.; Mellott, N.P. Surface Roughness Measurements Using Power Spectrum Density Analysis with Enhanced Spatial Correlation Length. J. Phys. Chem. C 2016, 120, 22358–22364. [Google Scholar] [CrossRef]

- Sun, L. Simulation of pavement roughness and IRI based on power spectral density. Math. Comput. Simulat. 2003, 61, 77–88. [Google Scholar] [CrossRef]

- Dash, P.; Mallick, P.; Rath, H.; Tripathi, A.; Prakash, J.; Avasthi, D.K.; Mazumder, S.; Varma, S.; Satyam, P.V.; Mishra, N.C. Surface roughness and power spectral density study of SHI irradiated ultra-thin gold films. Appl. Surf. Sci. 2009, 256, 558–561. [Google Scholar] [CrossRef]

- Lawson, J.K.; Wolfe, C.R.; Manes, K.R.; Trertholme, J.B.; Aikens, D.M.; English, R.E.J. Specification of Optical Components Using the Power Spectral Density Function. In Optical Manufacturing and Testing, Proceedings of the SPIE’s 1995 International Symposium on Optical Science, Engineering, and Instrumentation, San Diego, CA, USA, 9–14 July 1995; SPIE Press: Bellingham, WA, USA, 1995; Volume 2536, pp. 38–50. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, S. Effects of Feed per Tooth and Radial Depth of Cut on Amplitude Parameters and Power Spectral Density of a Machined Surface. Materials 2020, 13, 1323. [Google Scholar] [CrossRef]

- Khan, G.S.; Sarepaka, R.G.V.; Chattopadhyay, K.D.; Jain, P.K.; Bajpai, R.P. Characterization of nanoscale roughness in single point diamond turned optical surfaces using power spectral density analysis. Indian J. Eng. Mater. Sci. 2004, 11, 25–30. [Google Scholar]

- Duparré, A.; Ferre-Borrull, J.; Gliech, S.; Notni, G.; Steinert, J.; Bennett, J.M. Surface Characterization Techniques for Determining the Root-Mean-Square Roughness and Power Spectral Densities of Optical Components. Appl. Opt. 2002, 41, 154–41171. [Google Scholar] [CrossRef] [PubMed]

- Peng, Z.; Kirk, T.B. Two-dimensional fast Fourier transform and power spectrum for wear particle analysis. Tribol. Int. 1997, 30, 583–590. [Google Scholar] [CrossRef]

- Wu, J.P.; Kirk, T.B.; Peng, Z.; Miller, K.; Zheng, M.H. Utilization of two-dimensional fast Fourier transform and power spectral analysis for assessment of early degeneration of articular cartilage. J. Musculoskelet. Res. 2005, 9, 119–131. [Google Scholar] [CrossRef]

- Cheung, C.F.; Lee, W.B. Characterisation of nanosurface generation in single-point diamond turning. Int. J. Mach. Tools Manuf. 2001, 41, 851–875. [Google Scholar] [CrossRef]

- Elson, J.; Bennett, J. Calculation of the power spectral density from surface profile data. Appl. Opt. 1995, 34, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Podulka, P.; Dobrzański, P.; Pawlus, P.; Lenart, A. The effect of reference plane on values of areal surface topography parameters from cylindrical elements. Metrol. Meas. Syst. 2014, 21, 247–256. [Google Scholar] [CrossRef][Green Version]

- Podulka, P. Edge-area form removal of two-process surfaces with valley excluding method approach. Matec. Web. Conf. 2019, 252, 05020. [Google Scholar] [CrossRef][Green Version]

- Sayles, R.S.; Thomas, T.R. The spatial representation of surface roughness by means of the structure function: A practical alternative to correlation. Wear 1977, 42, 263–276. [Google Scholar] [CrossRef]

- Gogolewski, D. Fractional spline wavelets within the surface texture analysis. Measurement 2021, 179, 109435. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Podulka, P. Resolving Selected Problems in Surface Topography Analysis by Application of the Autocorrelation Function. Coatings 2023, 13, 74. https://doi.org/10.3390/coatings13010074

Podulka P. Resolving Selected Problems in Surface Topography Analysis by Application of the Autocorrelation Function. Coatings. 2023; 13(1):74. https://doi.org/10.3390/coatings13010074

Chicago/Turabian StylePodulka, Przemysław. 2023. "Resolving Selected Problems in Surface Topography Analysis by Application of the Autocorrelation Function" Coatings 13, no. 1: 74. https://doi.org/10.3390/coatings13010074

APA StylePodulka, P. (2023). Resolving Selected Problems in Surface Topography Analysis by Application of the Autocorrelation Function. Coatings, 13(1), 74. https://doi.org/10.3390/coatings13010074