Recognition of Corrosion State of Water Pipe Inner Wall Based on SMA-SVM under RF Feature Selection

Abstract

1. Introduction

2. Related Work

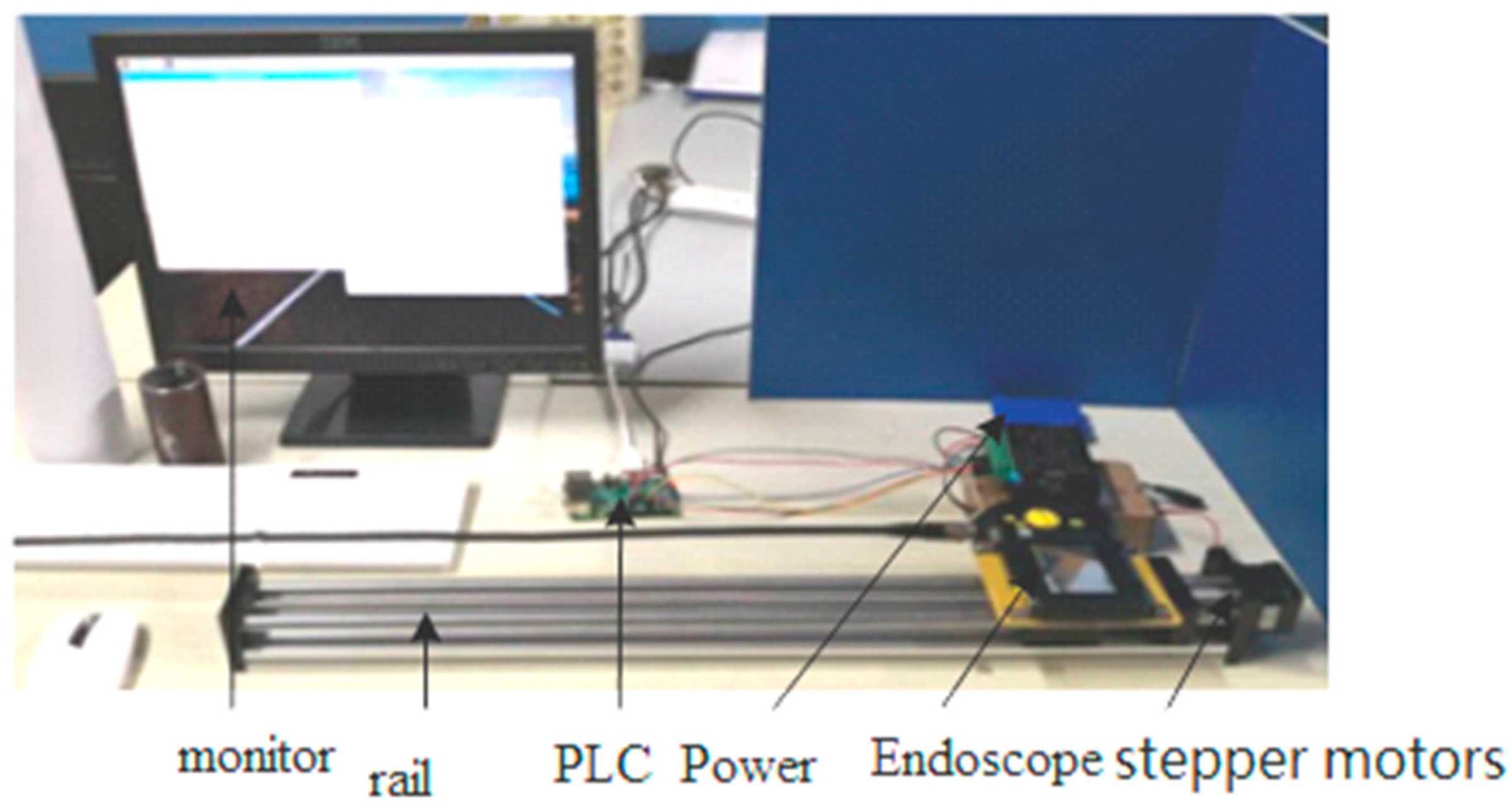

2.1. Video Image Acquisition of Pipeline Corrosion

2.2. Image Feature Extraction

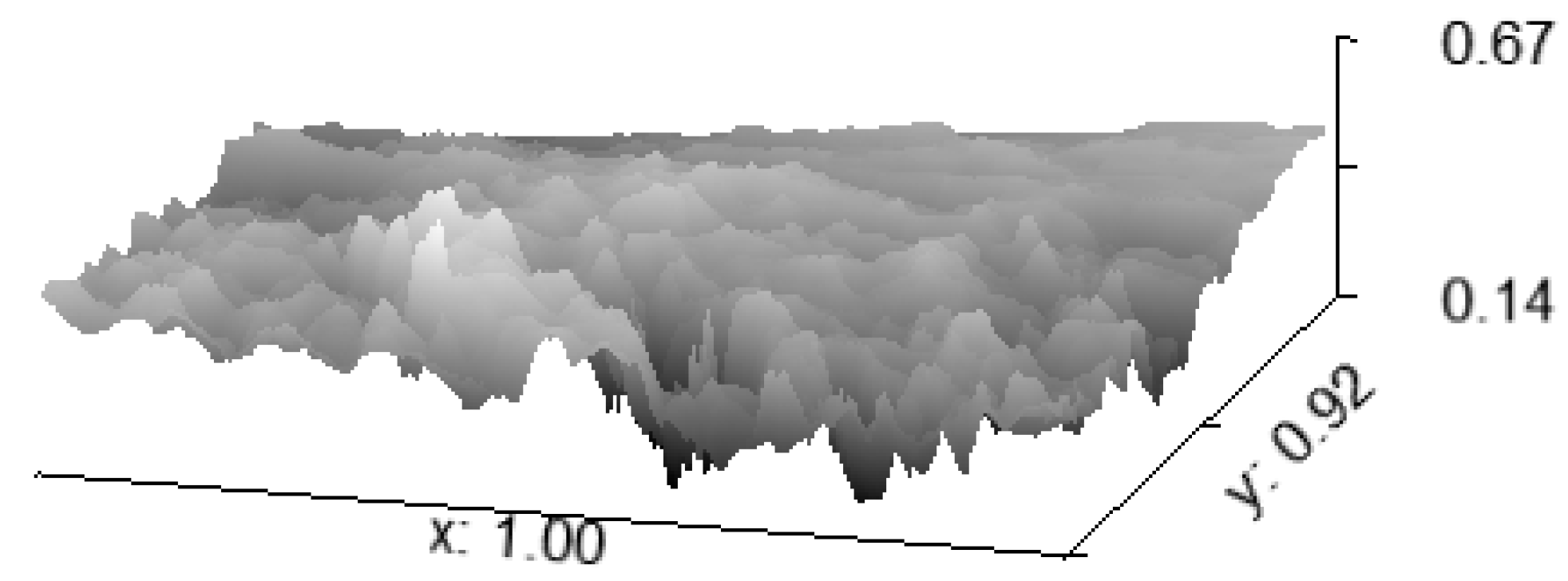

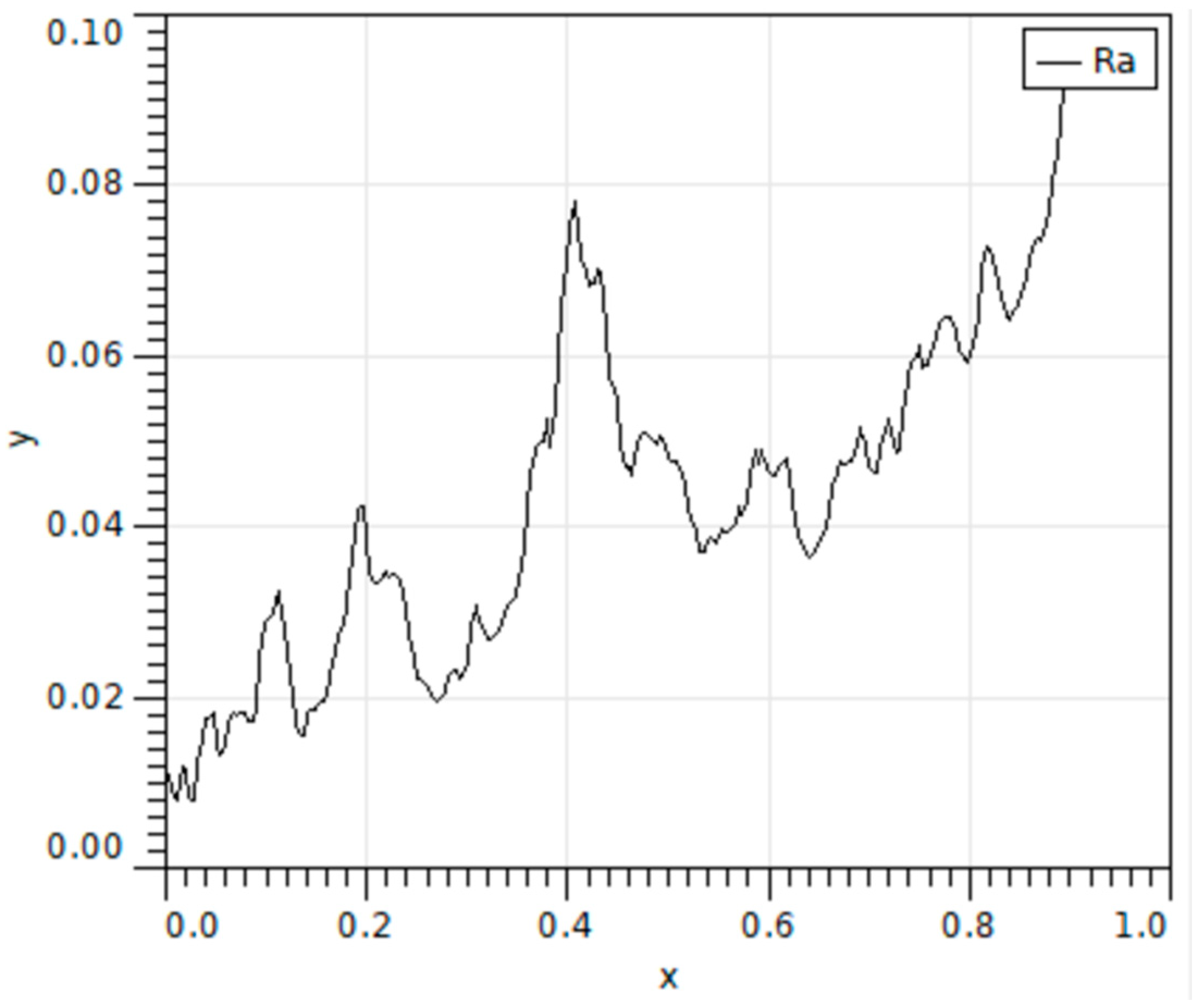

2.3. Surface Roughness Measurement

3. Method

3.1. Feature Selection

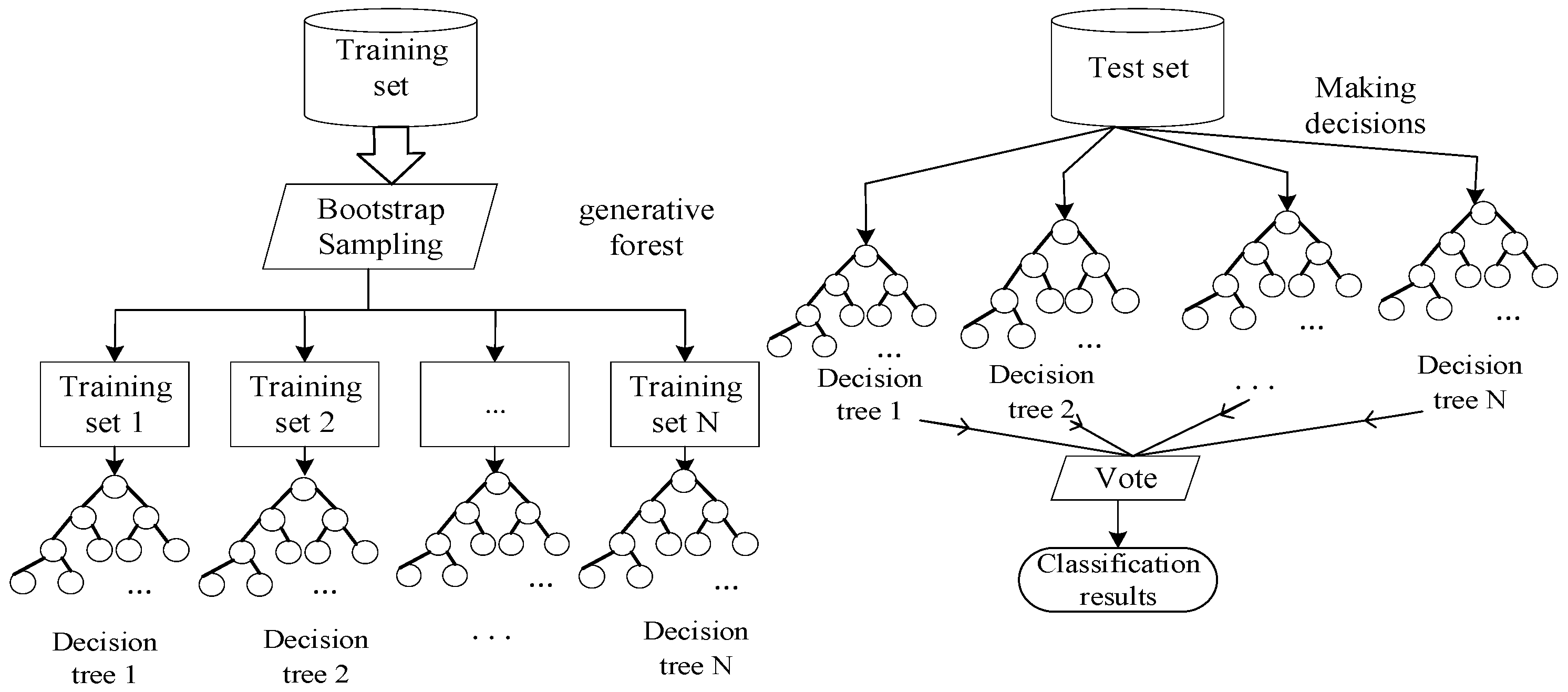

3.1.1. Random Forest Algorithm

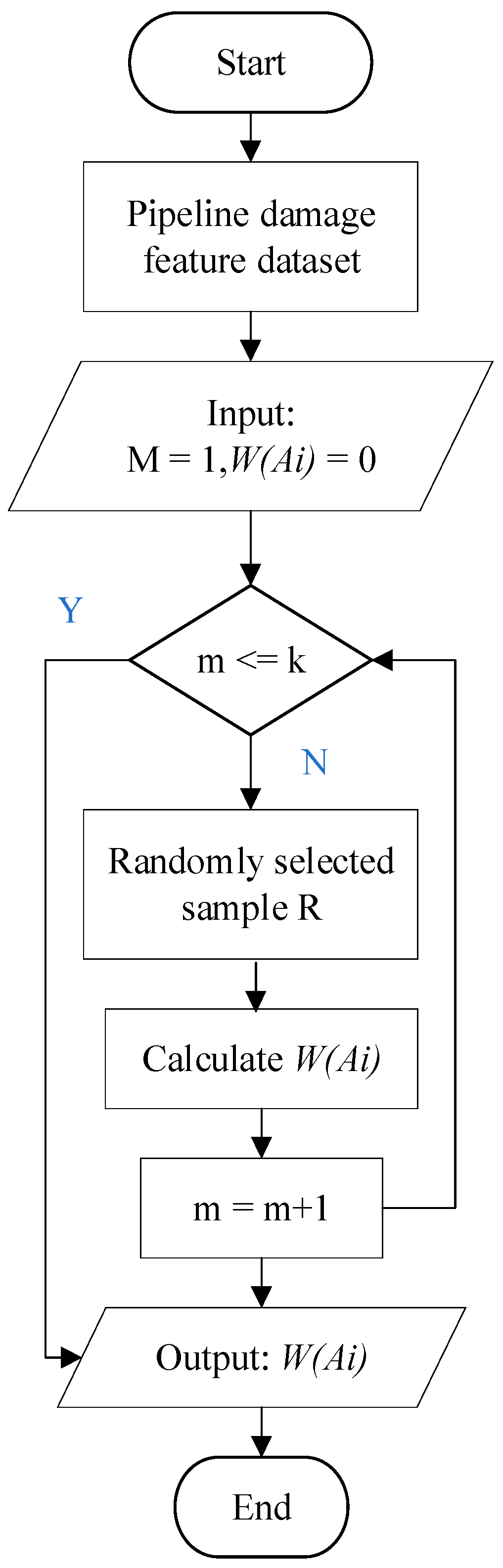

3.1.2. Feature-Simplified Random Forest Algorithm

- Step 1

- A sample is randomly drawn from the candidate set of pipeline damage features, with samples from the same class being adjacent and randomly drawn from a different class of samples.

- Step 2

- Select one of the three samples which is a unique feature .

- Step 3

- Calculate the Euclidean distance between the feature of the sample and the feature of the sample , denoted as , and the Euclidean distance between the feature of the sample and the feature of the sample , denoted as .

- Step 4

- Repeat steps 1 to 3 and calculate the weights for each feature with the following formula.

3.2. SMA-SVM Classifier Design

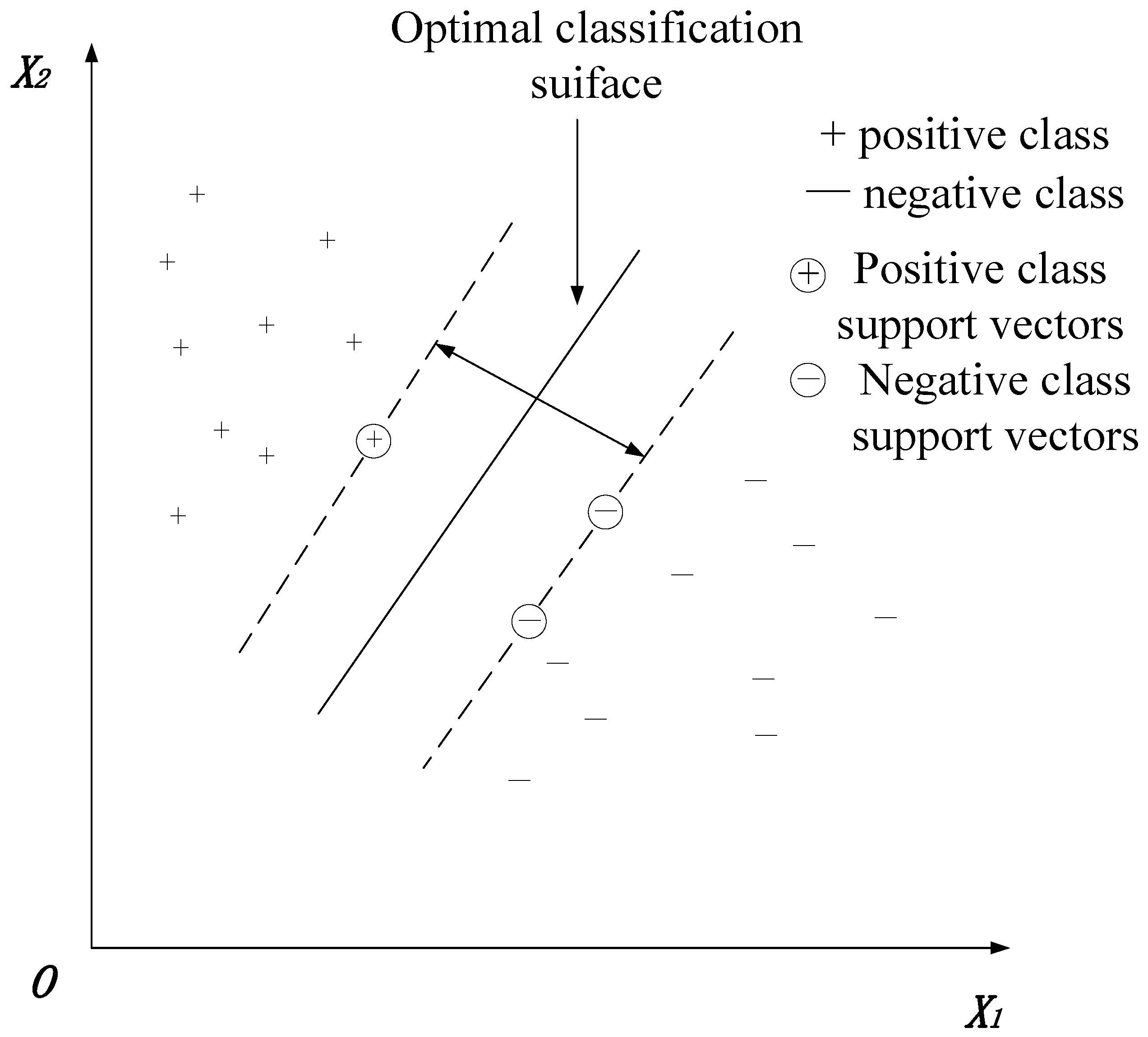

3.2.1. Support Vector Machine Principles

3.2.2. Slime Mold Optimization Algorithm

3.2.3. SMA-SVM Classification Model

- Step 1

- Numerical initialization, setting the relevant parameters of the SMA, such as the number of populations, the maximum number of iterations, the number of optimization parameters, the upper and lower bounds for the values of , etc.

- Step 2

- Initialize the slime population , and randomize the initial population location.

- Step 3

- Use the SVM classification model to calculate the fitness of each slime and rank the slime with the smallest fitness as the target location .

- Step 4

- Update the optimal position of the slime bacteria, as per Equation (8).

- Step 5

- Determine whether the maximum number of iterations has been reached. If so, continue with Step 6; otherwise, jump to Step 3 to continue the execution.

- Step 6

- Output the optimal parameters and map them to the SVM parameters to obtain the initial SVM model, then train the SVM model and test the SVM model.

4. Experiments

4.1. Experimental Environment Platform

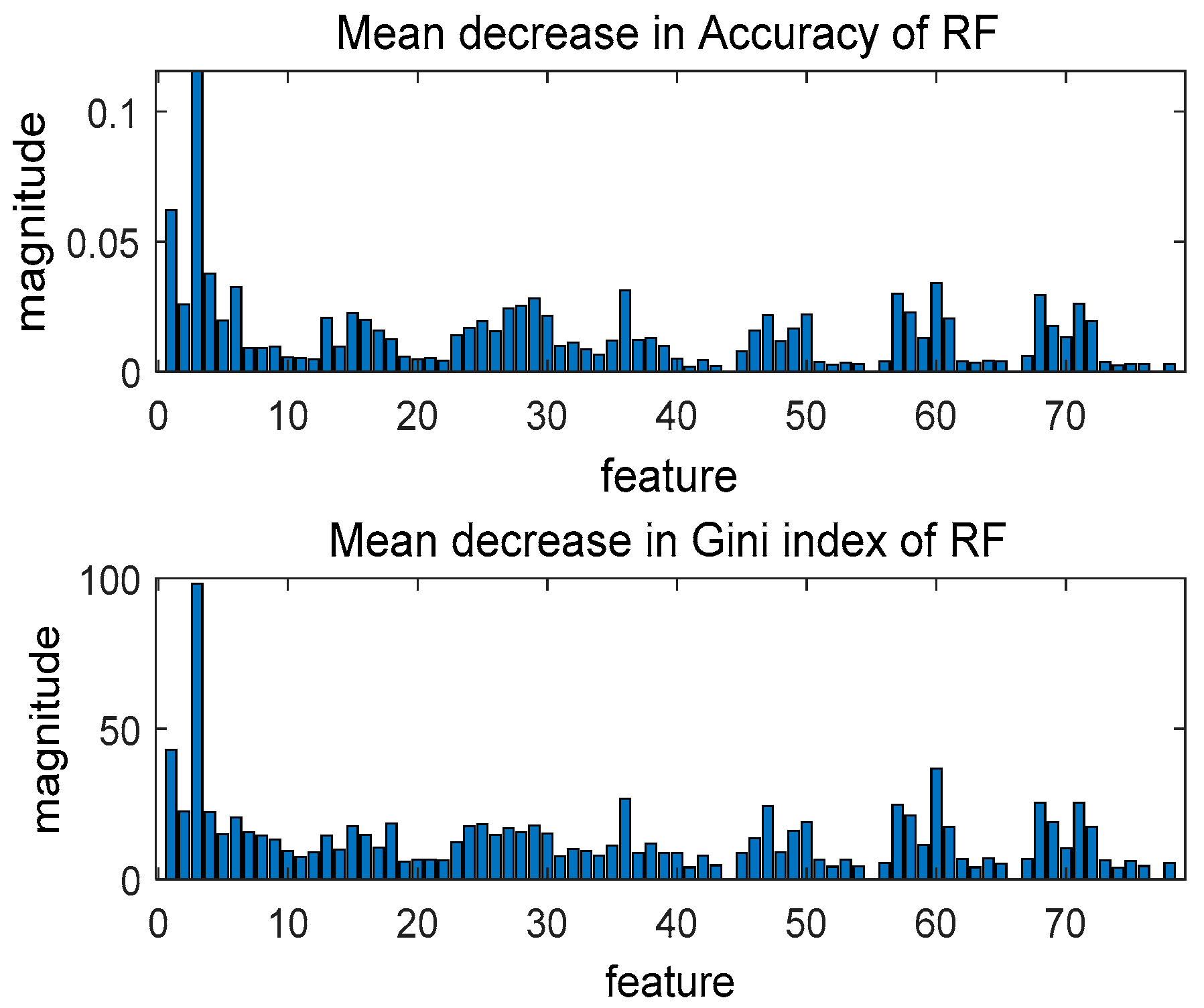

4.2. Feature-Simplified Random Forest Algorithm

4.3. Experimental Parameter Setting

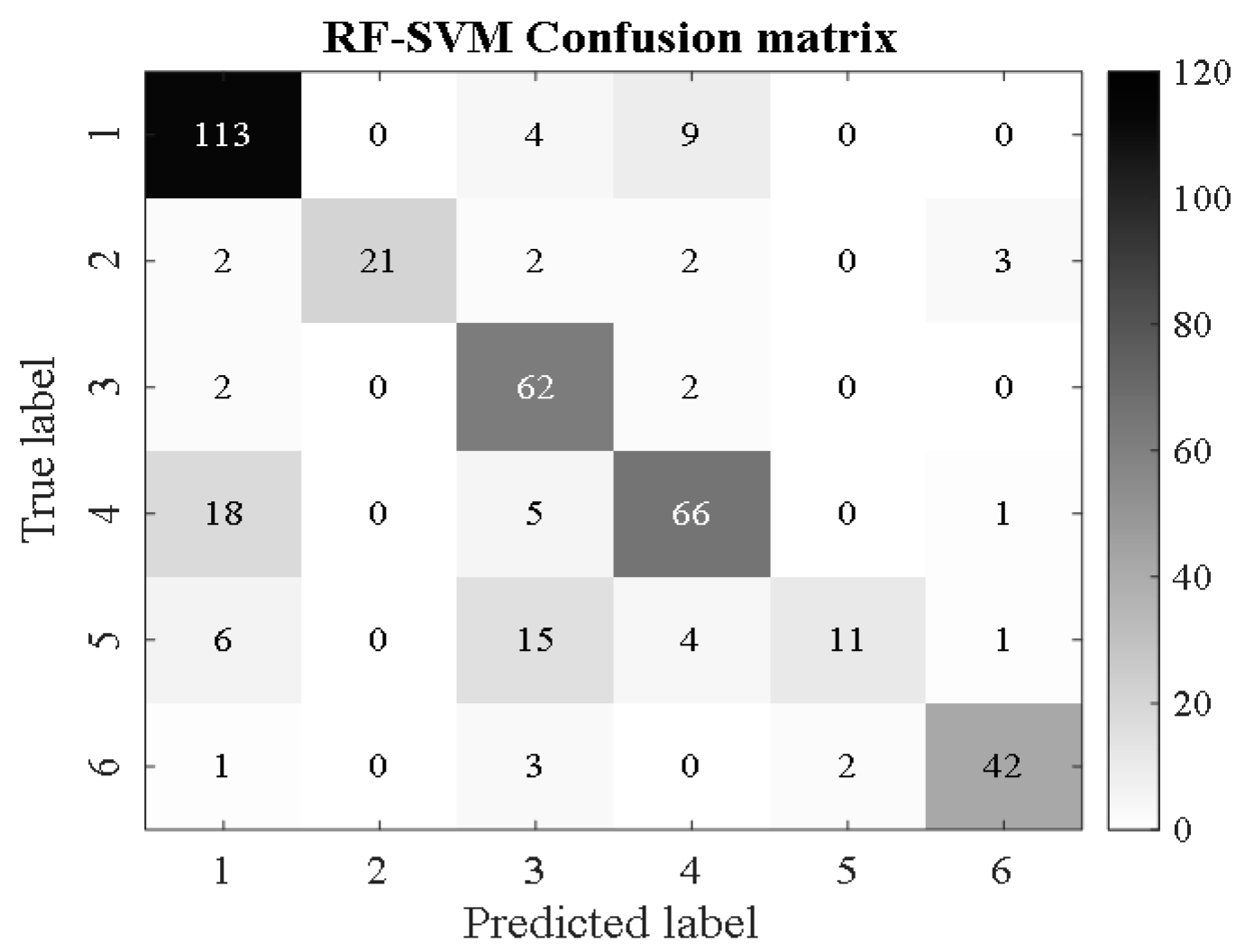

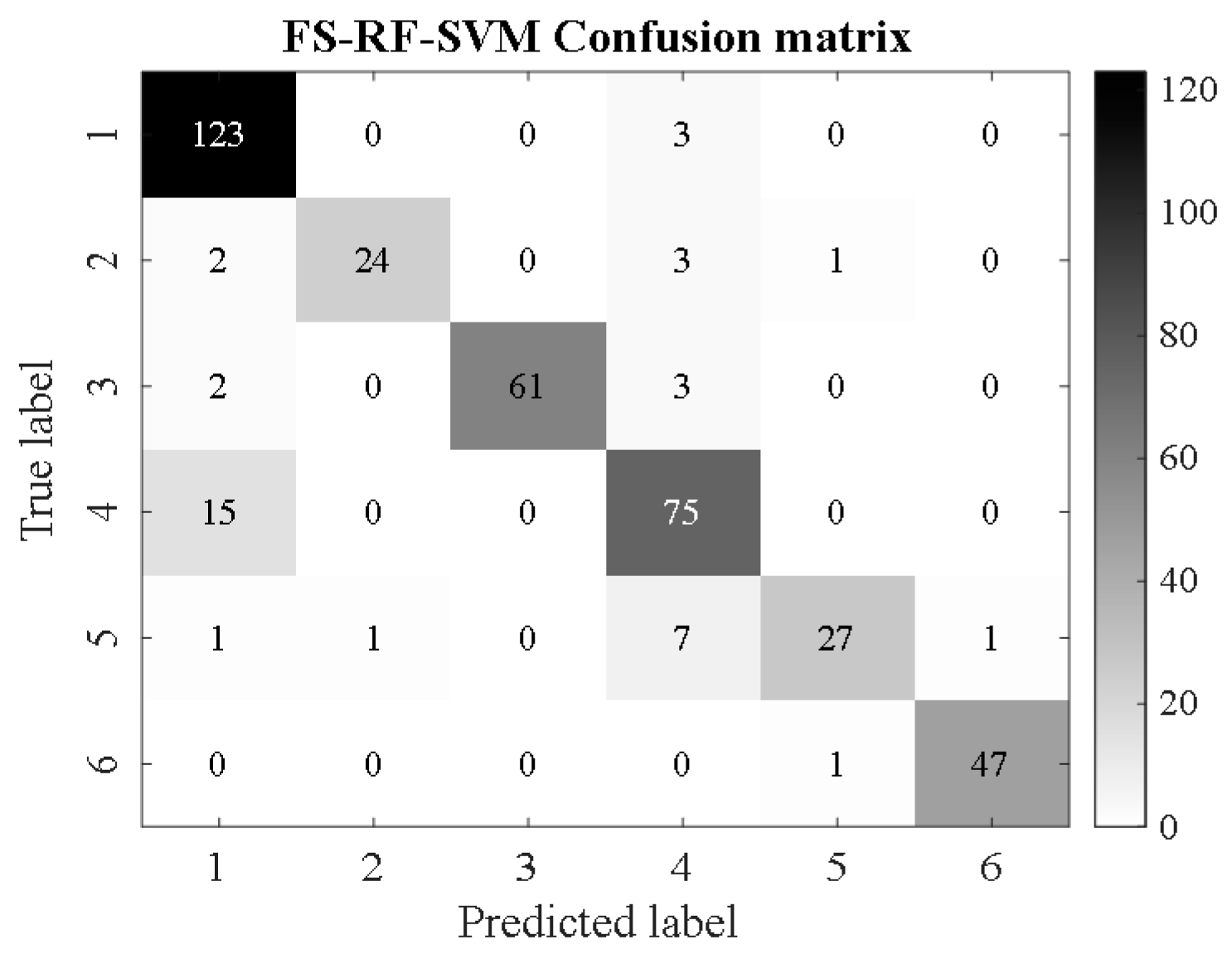

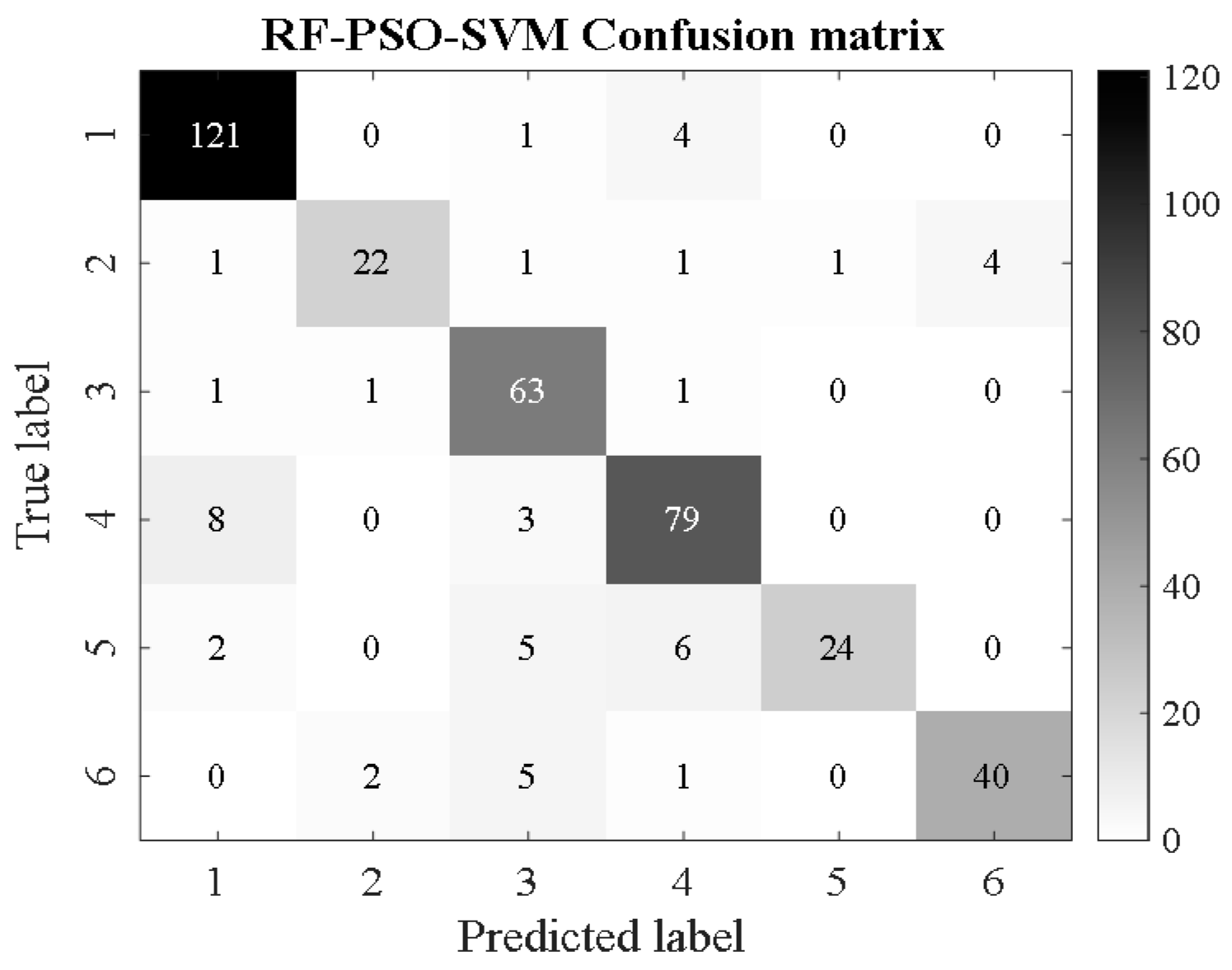

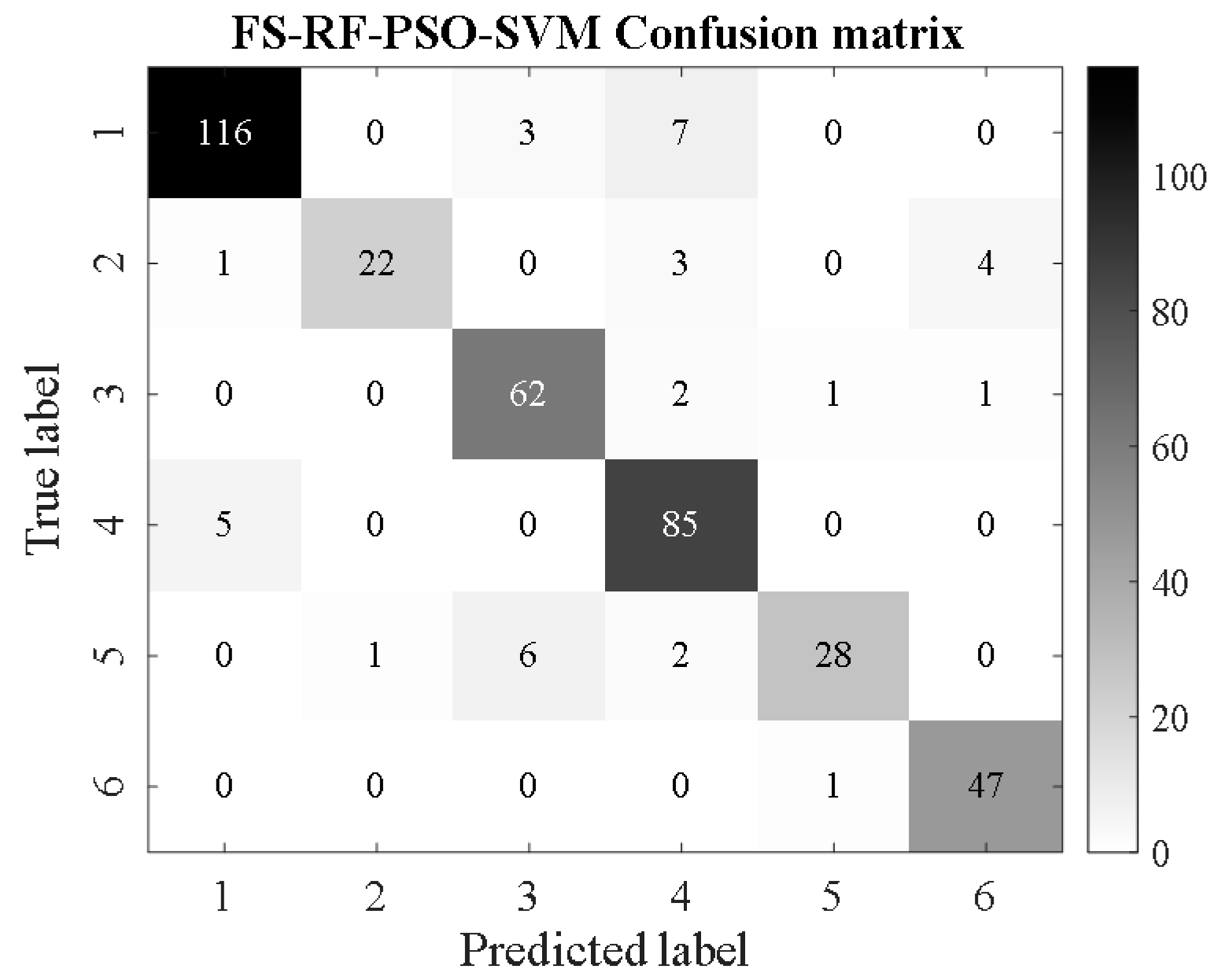

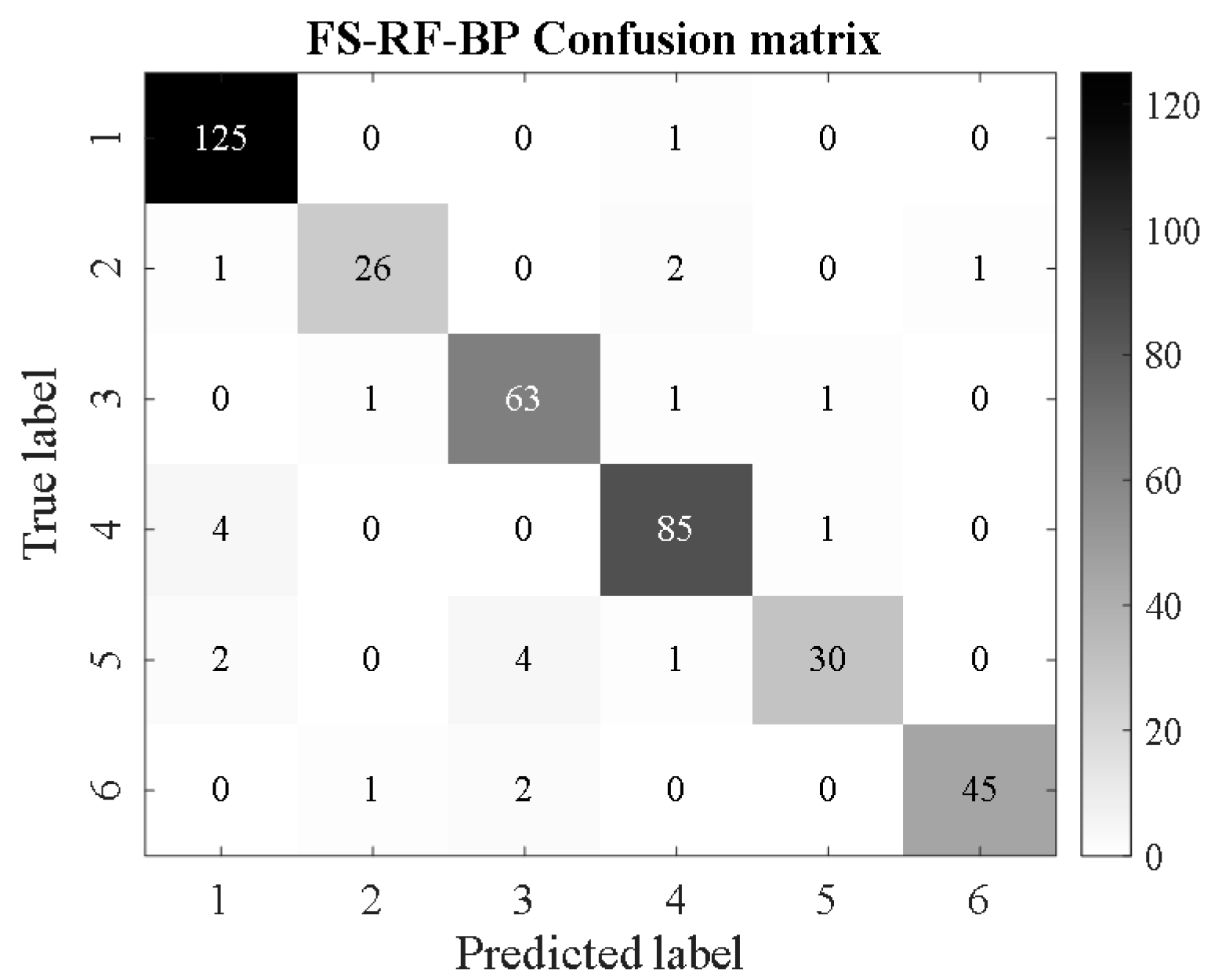

4.4. Classification Results of the FS-RF-SMA-SVM Model

5. Conclusions

- (1)

- In terms of feature dimensionality reduction, this paper uses an improvement of the traditional random forest algorithm, which has good results for the feature data in this paper. However, the classification effect on the new feature data set still needs to be studied; therefore, further improving the generality of the algorithm and overcoming the limitations of the feature data are the key points to be learned in the future.

- (2)

- In terms of research objects, this paper only studied the common damage (corrosion) on the inner wall of the pipeline, and further research is needed to identify other damage categories, such as pipeline cracks, pipeline fractures, etc.

- (3)

- From the aspect of damage identification and classification, the popular depth learning technology can be used to realize the identification of pipe wall damage, and further improve the accuracy of identification.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Clercq, D.; Smith, K.; Chou, B.; Gonzalez, A.; Kothapalle, R.; Li, C.; Dong, X.; Liu, S.; Wen, Z. Identification of urban drinking water supply patterns across 627 cities in China based on supervised and unsupervised statistical learning. J. Environ. Manag. 2018, 223, 658–667. [Google Scholar] [CrossRef] [PubMed]

- D’Orto, B.; Polizzi, E.; Nagni, M.; Tete, G.; Cappare, P. Full arch implant-prosthetic rehabilitation in patients with type i diabetes mellitus: Retrospective clinical study with 10 year follow-up. Int. J. Environ. Res. Public Health 2022, 19, 11735. [Google Scholar] [CrossRef] [PubMed]

- Cappare, P.; D’Ambrosio, R.; De Cunto, R.; Darvizeh, A.; Nagni, M.; Gherlone, E. The usage of an air purifier device with HEPA 14 filter during dental procedures in COVID-19 pandemic: A randomized clinical trial. Int. J. Environ. Res. Public Health 2022, 19, 5139. [Google Scholar] [CrossRef] [PubMed]

- Cagidiaco, E.F.; Carboncini, F.; Parrini, S.; Doldo, T.; Nagni, M.; Nuti, N.; Ferrari, M. Functional implant prosthodontic score of a one-year prospective study on three different connections for single-implant restorations. J. Osseointegration 2018, 10, 130–135. [Google Scholar]

- Ou, Z.; Han, Z.; Du, D. Magnetic Flux Leakage Testing for Steel Plate Using Pot-Shaped Excitation Structure. IEEE Trans. Magn. 2022, 58, 1–7. [Google Scholar] [CrossRef]

- Miao, X.J.; Li, X.B.; Hu, H.W.; Gao, G.J.; Zhang, S.Z. Effects of the oxide coating thickness on the small flaw sizing using an ultrasonic test technique. Coatings 2018, 8, 69. [Google Scholar] [CrossRef]

- Rayhana, R.; Jiao, Y.T.; Zaji, A.; Liu, Z. Automated vision systems for condition assessment of sewer and water pipelines. IEEE Trans. Autom. Sci. Eng. 2021, 18, 1861–1878. [Google Scholar] [CrossRef]

- Li, S.; Zhou, Z.; Fan, E.; Zheng, W.; Liu, M.; Yang, J. Robust GMM least square twin K-class support vector machine for urban water pipe leak recognition. Expert Syst. Appl. 2022, 195, 116525. [Google Scholar] [CrossRef]

- Liao, K.W.; Lee, Y.T. Detection of rust defects on steel bridge coatings via digital image recognition. Autom. Constr. 2016, 71, 294–306. [Google Scholar] [CrossRef]

- Medeiros, F.; Ramalho, G.; Bento, M.P.; Medeiros, L. Erratum 01—On the Evaluation of Texture and Color Features for Nondestructive Corrosion Detection. EURASIP J. Adv. Signal Process. 2019, 2010, 817473. [Google Scholar] [CrossRef]

- Safari, S.; Shoorehdeli, M.A. Detection and isolation of interior defects based on image processing and neural networks: HDPE pipeline case study. J. Pipeline Syst. Eng. Pract. 2018, 9, 05018001.05018001–05018001.05018014. [Google Scholar] [CrossRef]

- Bondada, V.; Pratihar, D.K.; Kumar, C.S. Detection and quantitative assessment of corrosion on pipelines through image analysis. Procedia Comput. Sci. 2018, 133, 804–811. [Google Scholar] [CrossRef]

- Hoang, N.D.; Duc, T.V. Image processing-based detection of pipe corrosion using texture analysis and metaheuristic-optimized machine learning approach. Comput. Intell. Neurosci. 2019, 2019, 8097213. [Google Scholar] [CrossRef] [PubMed]

- Qu, Z.H.; Tang, D.Z.; Wang, Z.; Li, X.Q.; Chen, H.J.; Lv, Y. Pitting judgment model based on machine learning and feature optimization methods. Front. Mater. 2021, 8, 733813. [Google Scholar] [CrossRef]

- Nhat-Duc, H. Image processing-based pitting corrosion detection using metaheuristic optimized multilevel image thresholding and machine-learning approaches. Math. Probl. Eng. 2020, 2020, 6765274. [Google Scholar] [CrossRef]

- Rahman, M.S.; Rahman, M.K.; Kaykobad, M.; Rahman, M.S. isGPT: An optimized model to identify sub-Golgi protein types using SVM and Random Forest based feature selection. Artif. Intell. Med. 2018, 84, 90–100. [Google Scholar] [CrossRef]

- Li, F.; Han, W.; Destech Publicat, I.N.C. Research on failure probability prediction technology of pressure pipeline based on PSO-SVM. In Proceedings of the International Conference on Electrical, Control, Automation and Robotics (ECAR), Xiamen, China, 16–17 September 2018; pp. 532–537. [Google Scholar]

- Li, S.; Chen, H.; Wang, M.; Heidari, A.A.; Mirjalili, S. Slime mould algorithm: A new method for stochastic optimization. Future Gener. Comput. Syst. 2020, 111, 300–323. [Google Scholar] [CrossRef]

- Zhang, D.; Gao, W.; Yan, X. Determination of natural frequencies of pipes using white noise for magnetostrictive longitudinal guided-wave nondestructive testing. IEEE Trans. Instrum. Meas. 2020, 69, 2678–2685. [Google Scholar] [CrossRef]

- Guo, X.; Wang, Z.; Zhou, W.; Zhang, Z. Research on design, calibration and real-time image expansion technology of unmanned system variable-scale panoramic vision system. Sensors 2021, 21, 4708. [Google Scholar] [CrossRef]

- Zhang, Q.; Nie, Y.; Zheng, W.S. Dual Illumination Estimation for Robust Exposure Correction; John Wiley Sons Ltd.: Hoboken, NJ, USA, 2019. [Google Scholar]

- Ghahremani, M.; Ghadiri, H.; Hamghalam, M. Local features integration for content-based image retrieval based on color, texture, and shape. Multimed. Tools Appl. 2021, 80, 28245–28263. [Google Scholar] [CrossRef]

- Vimina, E.R.; Jacob, K.P. Feature fusion method using BoVW framework for enhancing image retrieval. Image Process. IET 2019, 13, 1979–1985. [Google Scholar] [CrossRef]

- Pan, H.; Gao, P.; Zhou, H.; Ma, R.; Yang, J.; Zhang, X. Roughness analysis of sea surface from visible images by texture. IEEE Access 2020, 8, 46448–46458. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, Y.J.; Kim, K.G.; Park, J.S. Preoperative CT texture features predict prognosis after curative resection in pancreatic cancer. Sci. Rep. 2019, 9, 17389. [Google Scholar] [CrossRef] [PubMed]

- Ortlepp, I.; Stauffenberg, J.; Manske, E. Processing and analysis of long-range scans with an atomic force microscope (AFM) in combination with nanopositioning and nanomeasuring technology for defect detection and quality control. Sensors 2021, 21, 5862. [Google Scholar] [CrossRef]

- Schonlau, M.; Zou, R.Y. The random forest algorithm for statistical learning. Stata J. 2020, 20, 3–29. [Google Scholar] [CrossRef]

- Gong, R.; Chu, M.; Yang, Y.; Feng, Y. A multi-class classifier based on support vector hyper-spheres for steel plate surface defects. Chemom. Intell. Lab. Syst. 2019, 188, 70–78. [Google Scholar] [CrossRef]

- Ornek, B.N.; Aydemir, S.B.; Duzenli, T.; Ozak, B. A novel version of slime mould algorithm for global optimization and real world engineering problems Enhanced slime mould algorithm. Math. Comput. Simul. 2022, 198, 253–288. [Google Scholar] [CrossRef]

- Nicodemus, K.K. Letter to the editor: On the stability and ranking of predictors from random forest variable importance measures. Brief. Bioinform. 2011, 12, 369–373. [Google Scholar] [CrossRef]

- Wang, X.; Luo, F.; Sang, C.; Zeng, J.; Hirokawa, S. Personalized movie recommendation system based on support vector machine and improved particle swarm optimization. PLoS ONE 2017, 11, e0165868. [Google Scholar]

- Li, T.; Sun, J.; Wang, L. An intelligent optimization method of motion management system based on BP neural network. Neural Comput. Appl. 2020, 33, 707–722. [Google Scholar] [CrossRef]

- Song, X.; Wang, C. Hyperspectral remote sensing image classification based on spectral-spatial feature fusion and PSO algorithm. J. Phys. Conf. Ser. 2022, 2189, 012010. [Google Scholar] [CrossRef]

| Pipeline Category | Mean Value | Standard Deviation | Skewness | Kurtosis | Color Entropy | Color Range | |

|---|---|---|---|---|---|---|---|

| Normal pipe | R | 107.844 | 23.941 | 0.292 | 1.990 | 6.428 | 117 |

| G | 97.574 | 23.492 | 0.308 | 1.939 | 6.374 | 113 | |

| B | 167.188 | 30.549 | 0.003 | 1.972 | 6.856 | 155 | |

| Color order corrosion | R | 84.769 | 16.854 | 0.197 | 2.739 | 6.028 | 221 |

| G | 80.407 | 16.747 | 0.132 | 2.853 | 6.022 | 225 | |

| B | 150.145 | 29.435 | 0.201 | 2.113 | 6.814 | 172 | |

| Texture order corrosion | R | 83.570 | 11.230 | −0.771 | 3.215 | 5.387 | 70 |

| G | 74.736 | 11.643 | −0.447 | 3.068 | 5.489 | 77 | |

| B | 136.067 | 35.168 | −0.026 | 1.832 | 6.991 | 158 | |

| Pitting corrosion | R | 100.661 | 21.139 | 0.376 | 2.698 | 6.386 | 123 |

| G | 93.763 | 20.932 | 0.391 | 2.553 | 6.359 | 115 | |

| B | 158.628 | 31.468 | −0.246 | 2.203 | 6.909 | 151 | |

| Localized corrosion | R | 80.059 | 16.561 | 1.416 | 5.681 | 5.866 | 121 |

| G | 80.037 | 13.787 | 0.804 | 3.274 | 5.707 | 91 | |

| B | 164.378 | 23.403 | −0.174 | 2.888 | 6.571 | 152 | |

| Global corrosion | R | 98.441 | 14.020 | 0.476 | 3.199 | 5.813 | 94 |

| G | 89.284 | 12.502 | 0.409 | 3.186 | 5.663 | 86 | |

| B | 142.005 | 21.896 | 0.353 | 2.506 | 6.427 | 125 | |

| Pipeline Category | Angular Second Moment | Contrast Ratio | Relevance | Entropy | |

|---|---|---|---|---|---|

| Normal pipe | 0° | 0.160 | 0.083 | 0.413 | 2.086 |

| 45° | 0.145 | 0.136 | 0.410 | 2.230 | |

| 90° | 0.150 | 0.115 | 0.411 | 2.179 | |

| 135° | 0.141 | 0.151 | 0.408 | 2.258 | |

| Color order corrosion | 0° | 0.190 | 0.145 | 0.756 | 1.970 |

| 45° | 0.1529 | 0.271 | 0.719 | 2.212 | |

| 90° | 0.159 | 0.240 | 0.728 | 2.168 | |

| 135° | 0.147 | 0.292 | 0.712 | 2.249 | |

| Texture order corrosion | 0° | 0.313 | 0.032 | 1.220 | 1.428 |

| 45° | 0.296 | 0.069 | 1.202 | 1.549 | |

| 90° | 0.302 | 0.057 | 1.213 | 1.510 | |

| 135° | 0.295 | 0.070 | 1.201 | 1.553 | |

| Pitting corrosion | 0° | 0.175 | 0.073 | 0.510 | 2.020 |

| 45° | 0.153 | 0.141 | 0.505 | 2.205 | |

| 90° | 0.160 | 0.119 | 0.508 | 2.149 | |

| 135° | 0.153 | 0.145 | 0.505 | 2.212 | |

| Localized corrosion | 0° | 0.281 | 0.068 | 1.170 | 1.561 |

| 45° | 0.250 | 0.132 | 1.128 | 1.730 | |

| 90° | 0.261 | 0.109 | 1.142 | 1.675 | |

| 135° | 0.252 | 0.130 | 1.130 | 1.724 | |

| Global corrosion | 0° | 0.279 | 0.070 | 1.187 | 1.589 |

| 45° | 0.242 | 0.143 | 1.134 | 1.779 | |

| 90° | 0.254 | 0.115 | 1.151 | 1.717 | |

| 135° | 0.244 | 0.137 | 1.138 | 1.768 | |

| Parameter | Normal Pipe | Color Order Corrosion | Texture Order Corrosion | Pitting Corrosion | Localized Corrosion | Global Corrosion | |

|---|---|---|---|---|---|---|---|

| SRE | 0° | 0.771 | 0.857 | 0.621 | 0.809 | 0.832 | 0.809 |

| 45° | 0.865 | 0.929 | 0.786 | 0.867 | 0.915 | 0.914 | |

| 90° | 0.833 | 0.918 | 0.737 | 0.854 | 0.897 | 0.904 | |

| 135° | 0.849 | 0.921 | 0.783 | 0.875 | 0.908 | 0.911 | |

| LRE | 0° | 6.071 | 4.328 | 17.270 | 8.522 | 4.039 | 4.758 |

| 45° | 2.106 | 0.929 | 3.062 | 2.134 | 1.574 | 1.486 | |

| 90° | 2.783 | 1.747 | 4.522 | 2.604 | 1.845 | 1.730 | |

| 135° | 2.256 | 1.554 | 3.133 | 2.017 | 1.597 | 1.507 | |

| GLN | 0° | 442.623 | 740.262 | 599.922 | 454.300 | 681.941 | 746.097 |

| 45° | 581.45 | 886.416 | 947.395 | 554.823 | 877.198 | 975.340 | |

| 90° | 543.257 | 862.205 | 823.412 | 543.484 | 848.442 | 943.703 | |

| 135° | 563.991 | 874.832 | 939.930 | 563.330 | 869.975 | 971.063 | |

| RLN | 0° | 19,966.020 | 29,580.394 | 8621.792 | 21,687.847 | 27,213.109 | 24,183.847 |

| 45° | 33,794.335 | 44,607.519 | 24,049.713 | 33,965.463 | 42,129.079 | 42,296.771 | |

| 90° | 28,945.779 | 42,181.717 | 18,916.917 | 31,661.123 | 38,679.191 | 39,982.996 | |

| 135° | 31,665.173 | 43,093.962 | 23,667.970 | 35,348.021 | 40,958.871 | 41,829.793 | |

| RP | 0° | 1.197 | 0.767 | 1.097 | 1.023 | 1.341 | 1.355 |

| 45° | 1.588 | 0.967 | 1.971 | 1.391 | 1.683 | 1.813 | |

| 90° | 1.476 | 0.938 | 1.756 | 1.338 | 1.618 | 1.755 | |

| 135° | 1.550 | 0.953 | 1.955 | 1.415 | 1.668 | 1.805 | |

| LGRE | 0° | 0.002 | 0 | 0 | 0.001 | 0 | 0 |

| 45° | 0.003 | 0 | 0.001 | 0.002 | 0 | 0 | |

| 90° | 0.003 | 0 | 0.001 | 0.002 | 0 | 0 | |

| 135° | 0.003 | 0 | 0.001 | 0.002 | 0 | 0 | |

| HGRE | 0° | 3172.112 | 4325.982 | 2265.700 | 4565.655 | 2957.301 | 2633.387 |

| 45° | 2730.462 | 4058.447 | 1998.330 | 3892.727 | 2832.746 | 2383.500 | |

| 90° | 2767.959 | 4070.036 | 1944.681 | 3897.827 | 2839.865 | 2364.071 | |

| 135° | 2752.042 | 4070.046 | 1986.400 | 3846.712 | 2827.241 | 2383.808 | |

| SRLGE | 0° | 0.001 | 0 | 0 | 0 | 0 | 0 |

| 45° | 0.002 | 0 | 0 | 0.001 | 0.001 | 0 | |

| 90° | 0.002 | 0 | 0 | 0.001 | 0.001 | 0 | |

| 135° | 0.002 | 0 | 0 | 0.001 | 0.001 | 0 | |

| SRHGE | 0° | 2707.915 | 3768.246 | 1461.829 | 3965.357 | 2513.504 | 2210.679 |

| 45° | 2487.672 | 3798.357 | 1573.591 | 3566.641 | 2614.016 | 2184.739 | |

| 90° | 2438.457 | 3762.410 | 1412.859 | 3514.164 | 2570.794 | 2134.102 | |

| 135° | 2476.439 | 3782.280 | 1551.406 | 3538.903 | 2587.578 | 2180.085 | |

| LRLGE | 0° | 1 | 1 | 1 | 1 | 1 | 1 |

| 45° | 1 | 1 | 1 | 1 | 1 | 1 | |

| 90° | 1 | 1 | 1 | 1 | 1 | 1 | |

| 135° | 1 | 1 | 1 | 1 | 1 | 1 | |

| LRHGE | 0° | 7971.153 | 12,460.391 | 27,913.795 | 14,437.773 | 9478.739 | 8410.301 |

| 45° | 4120.572 | 5516.019 | 5875.481 | 5900.670 | 4126.334 | 3485.919 | |

| 90° | 5105.659 | 6274.054 | 9086.611 | 6978.469 | 4725.028 | 4119.797 | |

| 135° | 4357.937 | 5729.299 | 6077.917 | 5732.068 | 4229.234 | 3540.333 | |

| 1~78: Ranking of Original Features; A Ranking of RF Feature Evaluation Results; B: Ranking of Improved RF Feature Evaluation Results | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| A3 | A1 | A60 | A4 | A57 | A29 | A36 | A68 | A6 | A58 | A2 | A61 | A28 | A71 | A30 |

| B3 | B1 | B4 | B60 | B6 | B36 | B57 | B68 | B29 | B71 | B2 | B28 | B27 | B58 | B15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 |

| A27 | A15 | A25 | A69 | A50 | A72 | A13 | A47 | A16 | A24 | A17 | A5 | A49 | A46 | A70 |

| B50 | B47 | B30 | B13 | B61 | B16 | B5 | B72 | B25 | B69 | B24 | B49 | B17 | B46 | B26 |

| 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 |

| A23 | A48 | A26 | A18 | A32 | A33 | A39 | A9 | A35 | A38 | A8 | A37 | A14 | A59 | A7 |

| B23 | B70 | B38 | B59 | B18 | B37 | B35 | B48 | B32 | B39 | B31 | B14 | B9 | B7 | B8 |

| 46 | 47 | 48 | 49 | 50 | 51 | 52 | 53 | 54 | 55 | 56 | 57 | 58 | 59 | 60 |

| A31 | A34 | A45 | A19 | A12 | A67 | A11 | A22 | A10 | A64 | A21 | A42 | A20 | A40 | A56 |

| B33 | B45 | B34 | B67 | B19 | B10 | B21 | B11 | B40 | B20 | B12 | B42 | B22 | B64 | B56 |

| 61 | 62 | 63 | 64 | 65 | 66 | 67 | 68 | 69 | 70 | 71 | 72 | 73 | 74 | 75 |

| A65 | A62 | A78 | A51 | A76 | A52 | A53 | A75 | A73 | A54 | A74 | A63 | A43 | A41 | A44 |

| B62 | B65 | B51 | B73 | B53 | B63 | B78 | B75 | B76 | B54 | B52 | B74 | B43 | B41 | B44 |

| 76 | 77 | 78 | ||||||||||||

| A55 | A66 | A77 | ||||||||||||

| B5 | B66 | B77 | ||||||||||||

| Pipeline Category | SVM | Literature [13] | Literature [31] | Literature [32] | Algorithms in This Paper |

|---|---|---|---|---|---|

| Normal pipeline (126) | 123 (97.2%) | 116 (92.1%) | 116 (92.1%) | 125 (99.21%) | 125 (99.21%) |

| Color order corrosion (66) | 61 (92.42%) | 62 (93.94%) | 62 (93.94%) | 63 (95.45%) | 62 (93.94%) |

| Texture order corrosion (90) | 75 (83.33%) | 86 (95.55%) | 85 (94.44%) | 85 (94.44%) | 82 (91.11%) |

| Pitting corrosion (30) | 24 (80.00%) | 23 (76.67%) | 22 (73.33%) | 26 (86.67%) | 27 (90.00%) |

| Localized corrosion (37) | 27 (72.97%) | 30 (81.08%) | 28 (75.67%) | 30 (81.08%) | 35 (94.59%) |

| Global corrosion (48) | 47 (97.92%) | 47 (97.92%) | 47 (97.92%) | 45 (93.75%) | 45 (93.75%) |

| Total number of correct (397) | 357 | 364 | 360 | 374 | 376 |

| Classification accuracy | 89.924% | 91.687% | 90.680% | 94.207% | 94.710% |

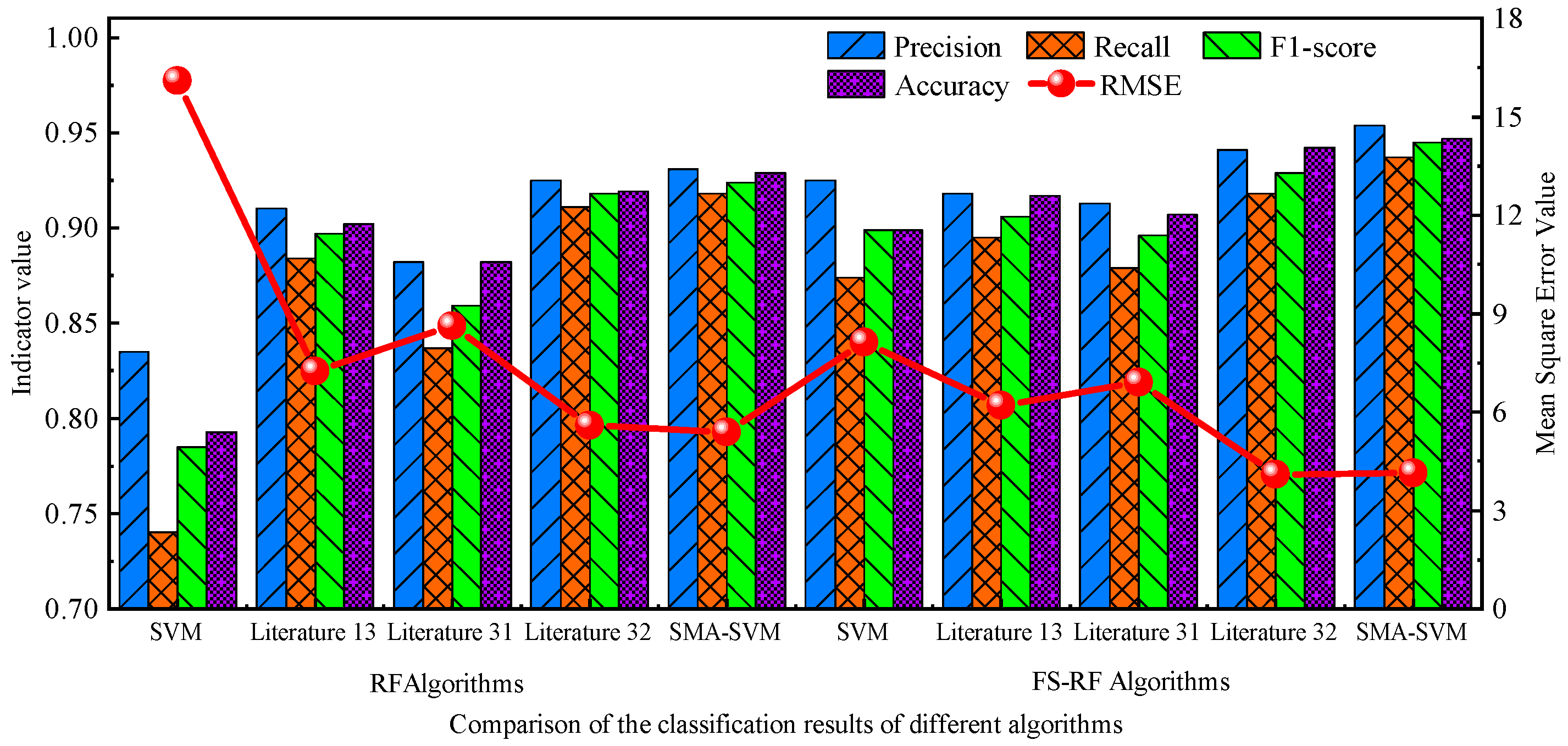

| Parametric Algorithms | Precision | Recall | F1-Score | RMSE. | Accuracy | |

|---|---|---|---|---|---|---|

| RF | SVM | 0.835 | 0.740 | 0.785 | 16.093 | 79.345% |

| Literature 13 | 0.910 | 0.884 | 0.897 | 7.245 | 90.176% | |

| Literature 31 | 0.882 | 0.837 | 0.859 | 8.631 | 88.161% | |

| Literature 32 | 0.925 | 0.911 | 0.918 | 5.598 | 91.940% | |

| SMA-SVM | 0.931 | 0.918 | 0.924 | 5.385 | 92.947% | |

| FS-RF | SVM | 0.925 | 0.874 | 0.899 | 8.124 | 89.924% |

| Literature 13 | 0.918 | 0.895 | 0.906 | 6.205 | 91.688% | |

| Literature 31 | 0.913 | 0.879 | 0.896 | 6.916 | 90.680% | |

| Literature 32 | 0.941 | 0.918 | 0.929 | 4.103 | 94.207% | |

| SMA-SVM | 0.954 | 0.937 | 0.945 | 4.143 | 94.710% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Li, L.; Zhang, L.; Zhao, M. Recognition of Corrosion State of Water Pipe Inner Wall Based on SMA-SVM under RF Feature Selection. Coatings 2023, 13, 26. https://doi.org/10.3390/coatings13010026

Zhao Q, Li L, Zhang L, Zhao M. Recognition of Corrosion State of Water Pipe Inner Wall Based on SMA-SVM under RF Feature Selection. Coatings. 2023; 13(1):26. https://doi.org/10.3390/coatings13010026

Chicago/Turabian StyleZhao, Qian, Lu Li, Lihua Zhang, and Man Zhao. 2023. "Recognition of Corrosion State of Water Pipe Inner Wall Based on SMA-SVM under RF Feature Selection" Coatings 13, no. 1: 26. https://doi.org/10.3390/coatings13010026

APA StyleZhao, Q., Li, L., Zhang, L., & Zhao, M. (2023). Recognition of Corrosion State of Water Pipe Inner Wall Based on SMA-SVM under RF Feature Selection. Coatings, 13(1), 26. https://doi.org/10.3390/coatings13010026