Testing the Mechanical Properties of High-Strength Zinc-Coated Bolts: FEM Approach

Abstract

1. Introduction

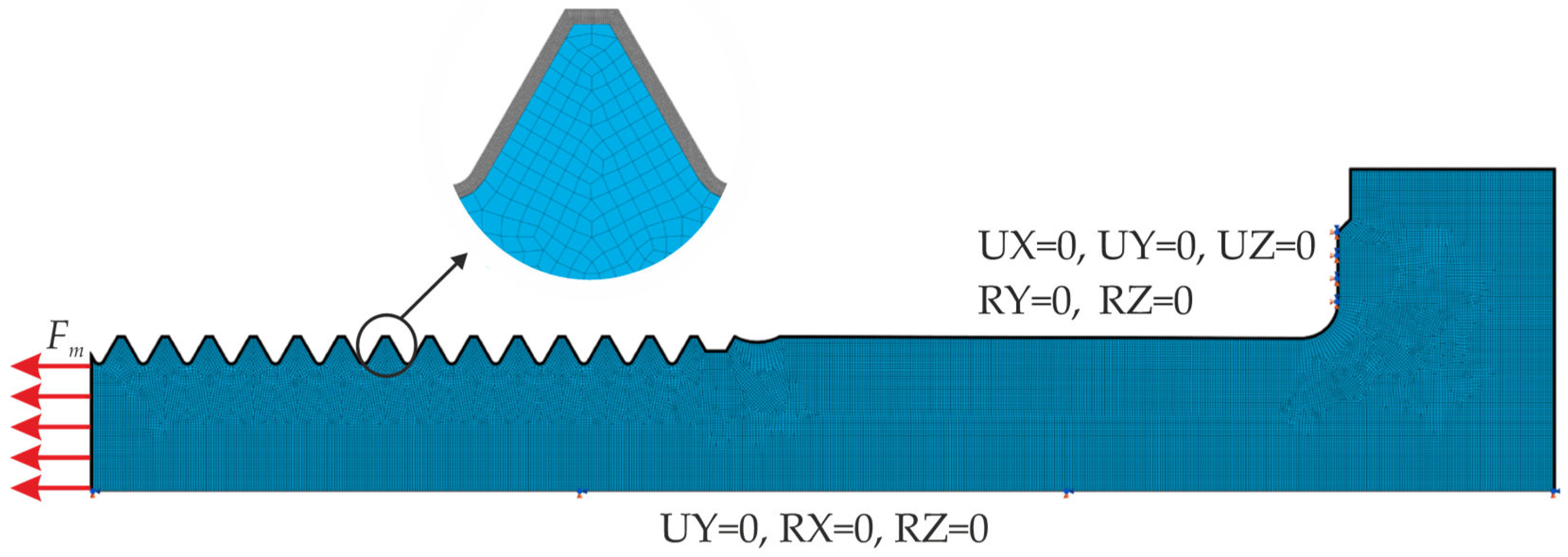

2. Materials and Methods

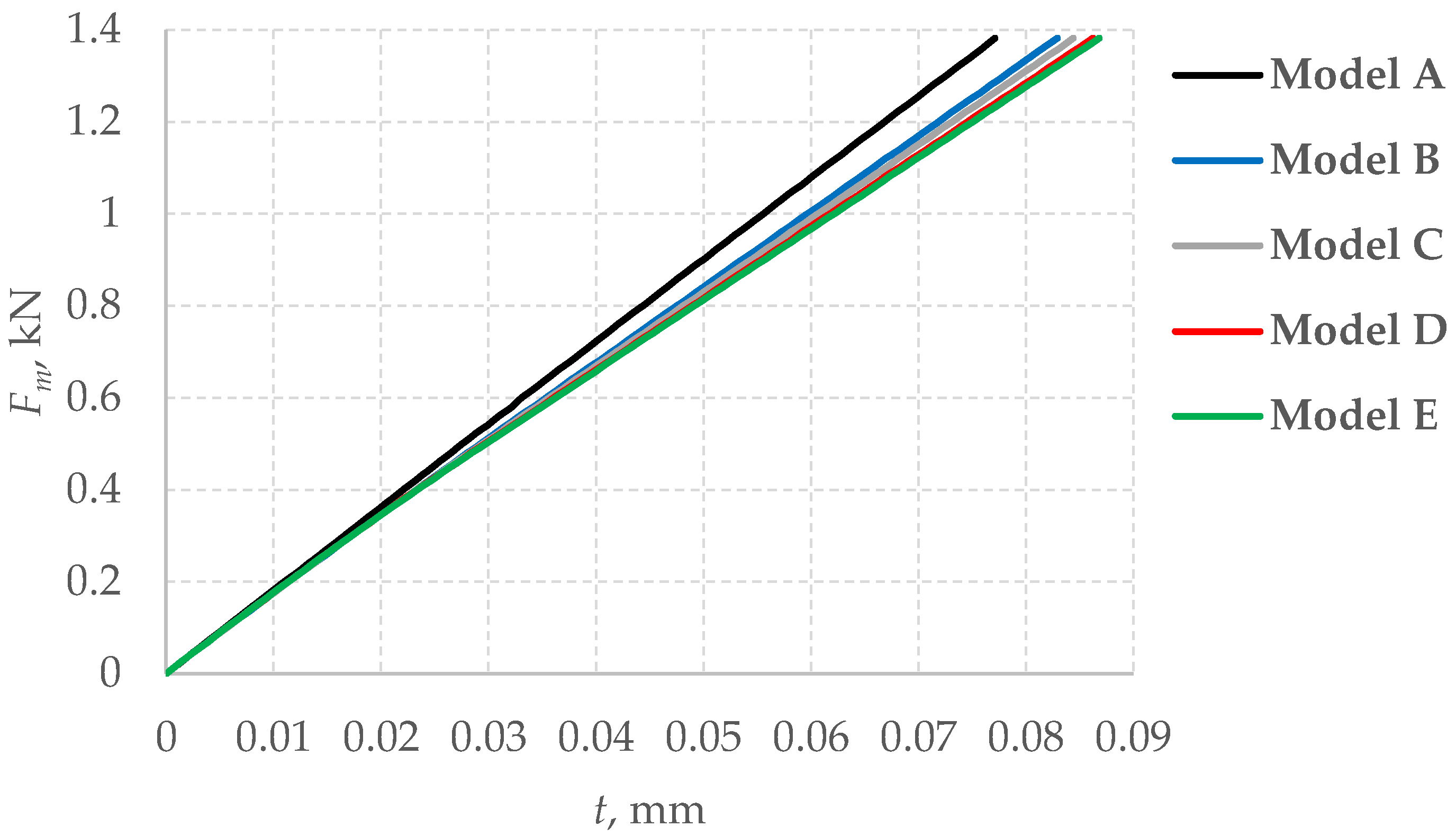

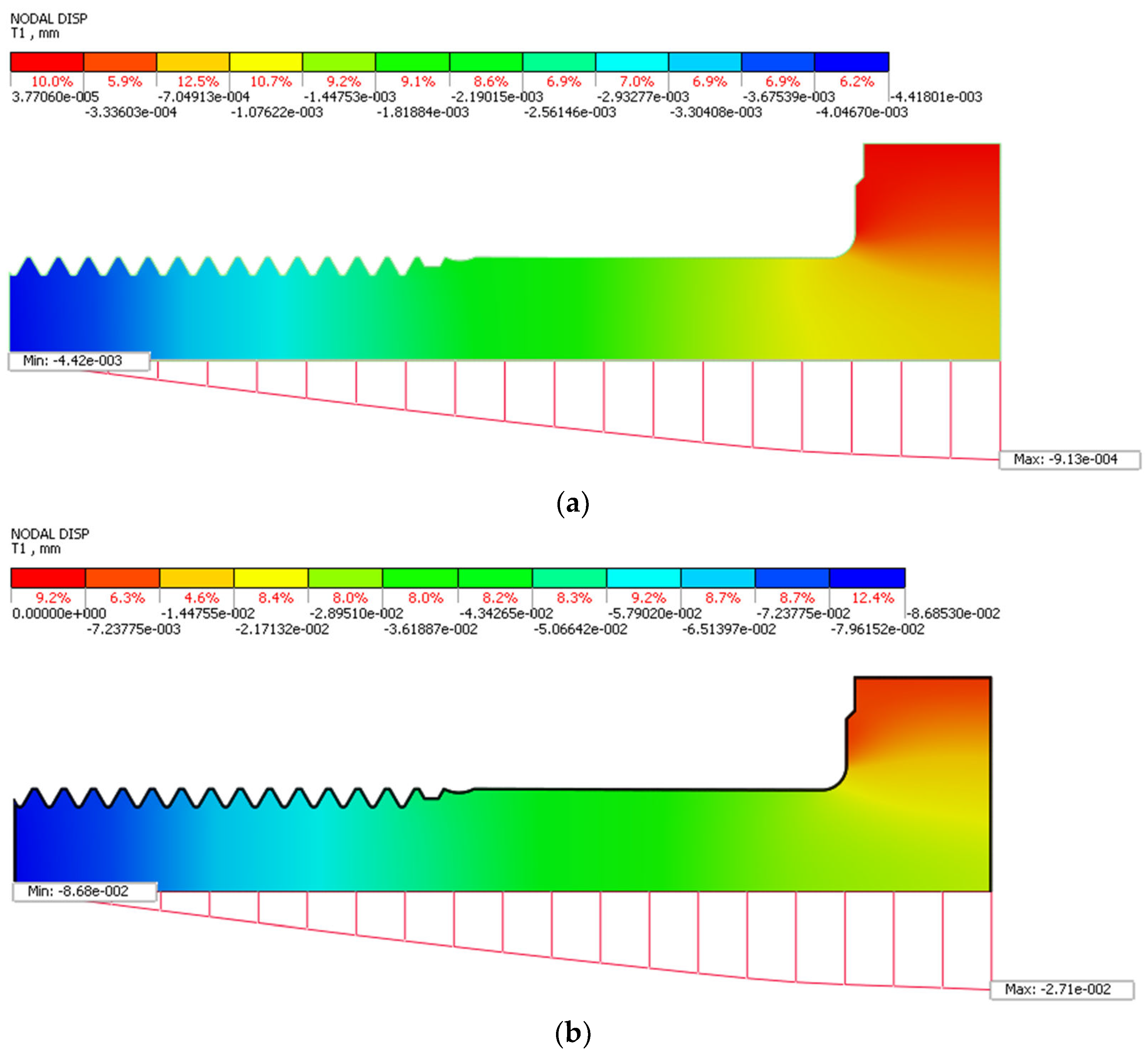

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lachowicz, M.B.; Lachowicz, M.M. Influence of corrosion on fatigue of the fastening bolts. Materials 2021, 14, 1485. [Google Scholar] [CrossRef] [PubMed]

- Votava, J. Anticorrosion protection of strength bolts. Acta Univ. Agric. Silvic. Mendel. Brun. 2012, 60, 181–188. [Google Scholar] [CrossRef]

- Chung, P.P.; Wang, J.; Durandet, Y. Deposition processes and properties of coatings on steel fasteners—A review. Friction 2019, 7, 389–416. [Google Scholar] [CrossRef]

- Dubiel, T.; Balawender, T.; Osetek, M. The fibrous structure of the bolt and its effect on the joint reliability. Arch. Metall. Mater. 2021, 66, 1075–1085. [Google Scholar]

- PN-EN ISO 1461, 2011; Hot Dip Galvanised Coatings on Fabricated Iron and Steel Articles, Specifications and Test Methods. Polish Committee for Standardization: Warsaw, Poland, 2011.

- Jędrzejczyk, D.; Szatkowska, E. The influence of heat treatment on corrosion resistance and microhardness of hot-dip zinc coating deposited on steel bolts. Materials 2022, 15, 5887. [Google Scholar] [CrossRef] [PubMed]

- Grabon, W.A.; Osetek, M.; Mathia, T.G. Friction of threaded fasteners. Tribol. Int. 2018, 118, 408–420. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Fini, S.; Olmi, G. Tribological properties of bolts depending on different screw coatings and lubrications: An experimental study. Tribol. Int. 2017, 107, 199–205. [Google Scholar] [CrossRef]

- PN-EN ISO 14713-1, 2017–08; Zinc Coatings, Guidelines and Recommendations for the Protection against Corrosion of Iron and Steel in Structures, Part 1: General Principles of Design and Corrosion Resistance. Polish Committee for Standardization: Warsaw, Poland, 2017.

- Razavi, S.M.J.; Peron, M.; Torgersen, J.; Berto, F.; Mutignani, F. Effect of hot dip galvanisation on the fatigue strength of steel bolted connections. Frat. Integrità Strutt. 2017, 41, 432–439. [Google Scholar] [CrossRef]

- Kania, H.; Sipa, J. Microstructure characterisation and corrosion resistance of zinc coating obtained on high-strength grade 10.9 bolts using a new thermal diffusion process. Materials 2019, 12, 1400. [Google Scholar] [CrossRef]

- Ferraz, G.; Rossi, B. On the fatigue behaviour of hot dip galvanised structural steel details. Eng. Fail. Anal. 2020, 118, 104834. [Google Scholar] [CrossRef]

- Chekirou, F.; Brahimi, K.; Bournine, H.; Hamouda, K.; Haddad, M.; Benkajouh, T.; Le Bot, A. Analysis of the vibrational behavior of a bolted beam in the presence of friction. Russ. J. Nonlinear Dyn. 2022, 18, 3–18. [Google Scholar]

- Pereira, H.B.; Maia, R.R.; Shen, J.; Tong, Q.; de Farias Azevedo, C.R.; Tschiptschin, A.P. In-service failure of mechanically galvanised low alloy steel bolts of three 25,000 m3 bolted water tanks. Eng. Fail. Anal. 2022, 142, 106839. [Google Scholar] [CrossRef]

- Liu, J.; Ouyang, H.; Peng, J.; Zhang, C.; Zhou, P.; Ma, L.; Zhu, M. Experimental and numerical studies of bolted joints subjected to axial excitation. Wear 2016, 346–347, 66–77. [Google Scholar] [CrossRef]

- Sriraman, K.R.; Strauss, H.W.; Brahimi, S.; Chromik, R.R.; Szpunar, J.A.; Osborne, J.H.; Yue, S. Tribological behavior of electrodeposited Zn, Zn–Ni, Cd and Cd–Ti coatings on low carbon steel substrates. Tribol. Int. 2012, 56, 107–120. [Google Scholar] [CrossRef]

- Almeida, M.E.M. Minimisation of steel atmospheric corrosion: Updated structure of intervention. Prog. Org. Coat. 2005, 54, 81–90. [Google Scholar] [CrossRef]

- Shibli, S.M.A.; Jayalekshmi, A.C.; Remya, R. Electrochemical and structural characterisation of the mixed oxides-reinforced hot-dip zinc coating. Surf. Coat. Technol. 2007, 201, 7560–7565. [Google Scholar] [CrossRef]

- Di Cocco, V.; Iacoviello, F.; Natali, S. Damaging micromechanisms in hot-dip galvanising Zn based coatings. Theor. Appl. Fract. Mech. 2014, 70, 91–98. [Google Scholar] [CrossRef]

- Natali, S.; Volpe, V.; Zortea, L.; Burattini, C.; Di Cocco, V.; Iacoviello, F. Mechanical and structural characterisation of Zn-Ti colored coatings. Procedia Eng. 2015, 109, 105–112. [Google Scholar] [CrossRef]

- Vantadori, S.; Carpinteri, A.; Di Cocco, V.; Fortese, G.; Iacoviello, F.; Natali, S.; Ronchei, C.; Scorza, D.; Zanichelli, A. Novel zinc-based alloys used to improve the corrosion protection of metallic substrates. Eng. Fail. Anal. 2017, 82, 327–339. [Google Scholar] [CrossRef]

- Rusiński, E.; Czmochowski, J.; Pietrusiak, D. Problems of steel construction modal models identification. Eksploat. Niezawodn. Maint. Reliab. 2012, 14, 54–61. [Google Scholar]

- Mandal, B.; Chakrabarti, A. Numerical failure assessment of multi-bolt FRP composite joints with varying sizes and preloads of bolts. Compos. Struct. 2018, 187, 169–178. [Google Scholar] [CrossRef]

- Kaczmarczyk, J.; Kozłowska, A.; Grajcar, A.; Sławski, S. Modelling and microstructural aspects of ultra-thin sheet metal bundle cutting. Metals 2019, 9, 162. [Google Scholar] [CrossRef]

- Łukaszewicz, A. Temperature field in the contact zone in the course of rotary friction welding of metals. Mater. Sci. 2019, 55, 39–45. [Google Scholar] [CrossRef]

- Borawski, A.; Tarasiuk, W.; Borawska, E.; Szczucka-Lasota, B.; Krzysztoforski, M. Evaluation of the influence of the percentage of copper content on the physical and chemical properties of the friction material. Transp. Probl. 2020, 15, 29–38. [Google Scholar] [CrossRef]

- Belardi, V.G.; Fanelli, P.; Vivio, F. Analysis of multi-bolt composite joints with a user-defined finite element for the evaluation of load distribution and secondary bending. Compos. Part B Eng. 2021, 227, 109378. [Google Scholar] [CrossRef]

- Kim, S.I.; Her, J.U.; Jang, Y.C.; Lee, Y. Experimental and finite element analysis for fracture of coating layer of galvannealed steel sheet. Trans. Nonferrous Met. Soc. China 2011, 21 (Suppl. S1), s111–s116. [Google Scholar] [CrossRef]

- Song, G.M.; Sloof, W.G.; Pei, Y.T.; De Hosson, J.T.M. Interface fracture behavior of zinc coatings on steel: Experiments and finite element calculations. Surf. Coat. Technol. 2006, 201, 4311–4316. [Google Scholar] [CrossRef]

- Kashyzadeh, K.R.; Arghavan, A. Study of the effect of different industrial coating with microscale thickness on the CK45 steel by experimental and finite element methods. Strength Mater. 2013, 45, 748–757. [Google Scholar] [CrossRef]

- Tang, G.; Yin, L.; Guo, X.; Cui, J. Finite element analysis and experimental research on mechanical performance of bolt connections of corrugated steel plates. Int. J. Steel Struct. 2015, 15, 193–204. [Google Scholar] [CrossRef]

- Ajaei, B.B.; Soyoz, S. Effects of preload deficiency on fatigue demands of wind turbine tower bolts. J. Constr. Steel Res. 2020, 166, 105933. [Google Scholar] [CrossRef]

- Hu, Y.; Shen, L.; Nie, S.; Yang, B.; Sha, W. FE simulation and experimental tests of high-strength structural bolts under tension. J. Constr. Steel Res. 2016, 126, 174–186. [Google Scholar] [CrossRef]

- Li, B.; Zhan, Y. A new joint-slippage model for galvanised steel bolted joints with slippage. Structures 2021, 34, 1034–1047. [Google Scholar] [CrossRef]

- Souto, C.D.S.; Gomes, V.M.G.; Da Silva, L.F.R.C.; Figueiredo, M.V.; Correia, J.A.F.O.; Lesiuk, G.; Fernandes, A.A.; De Jesus, A.M.P. Global-local fatigue approaches for snug-tight and preloaded hot-dip galvanised steel bolted joints. Int. J. Fatigue 2021, 153, 106486. [Google Scholar] [CrossRef]

- Tronci, G.; Marshall, M.B. Understanding the behaviour of silver as a low friction coating in aerospace fasteners. Tribol. Int. 2016, 100, 162–170. [Google Scholar] [CrossRef]

- Oechsner, M.; Beyer, J.; Simonsen, F.; Schaumann, P.; Eichstädt, R. Experimental and analytical assessment of the fatigue strength of bolts with large dimensions under consideration of boundary layer effects. In Proceedings of the MATEC & 2nd ESTAD 2015 European Steel Technology and Application Days, Düsseldorf, Germany, 15–19 June 2015. [Google Scholar]

- Khare, A.; Dwivedi, S.K.; Vishwakarma, M.; Ahmed, S. Experimental investigation of hydrogen embrittlement during coating process and effect on mechanical properties of high strength steel used for fasteners. Mater. Today Proc. 2018, 5, 18707–18715. [Google Scholar] [CrossRef]

- Glienke, R.; Schwarz, M.; Marten, F.; Eichstädt, R.; Schwerdt, D.; Meyer, M.; Dörre, M. On fatigue strength of large-size bolt-assemblies in steel constructions under consideration of manufacturing and surface condition related impacts—Part 2: Evaluation of fatigue tests. Stahlbau 2022, 91, 20–38. (In German) [Google Scholar] [CrossRef]

- Berto, F.; Mutignani, F.; Guido, E. Effect of hot dip galvanisation on the fatigue behaviour of steel bolted connections. Int. J. Fatigue 2016, 93, 168–172. [Google Scholar] [CrossRef]

- Kozuń, M.; Kobielarz, M.; Chwiłkowska, A.; Pezowicz, C. The impact of development of atherosclerosis on delamination resistance of the thoracic aortic wall. J. Mech. Behav. Biomed. Mater. 2018, 79, 292–300. [Google Scholar] [CrossRef]

- Wysmulski, P.; Debski, H. Post-buckling and limit states of composite channel-section profiles under eccentric compression. Compos. Struct. 2020, 245, 112356. [Google Scholar] [CrossRef]

- Szachogluchowicz, I.; Sniezek, L.; Slezak, T.; Kluczyński, J.; Grzelak, K.; Torzewski, J.; Fras, T. Mechanical properties analysis of the AA2519-AA1050-Ti6Al4V explosive welded laminate. Materials 2020, 13, 4348. [Google Scholar] [CrossRef]

- Borawski, A. Impact of operating time on selected tribological properties of the friction material in the brake pads of passenger cars. Materials 2021, 14, 884. [Google Scholar] [CrossRef] [PubMed]

- Rozylo, P.; Wysmulski, P. Failure analysis of thin-walled composite profiles subjected to axial compression using progressive failure analysis (PFA) and cohesive zone model (CZM). Compos. Struct. 2021, 262, 113597. [Google Scholar] [CrossRef]

- Borawski, A. Testing passenger car brake pad exploitation time’s impact on the values of the coefficient of friction and abrasive wear rate using a pin-on-disc method. Materials 2022, 15, 1991. [Google Scholar] [CrossRef] [PubMed]

- PN-EN 14399-4, 2015–04; High-Strength Structural Bolting Assemblies for Preloading, Part 4: System HV, Hexagon Bolt and Nut Assemblies. Polish Committee for Standardization: Warsaw, Poland, 2015.

- PN-EN ISO 10684, 2006; Fasteners, Hot Dip Galvanised Coatings. Polish Committee for Standardization: Warsaw, Poland, 2006.

- Zhang, W.; Xie, J.; Li, T.; Ding, Y. Tensile low-cycle fatigue performance and life prediction of high-strength bolts. J. Constr. Steel Res. 2022, 197, 107468. [Google Scholar] [CrossRef]

- Shakeri, I.; Danielsen, H.K.; Tribhou, A.; Fæster, S.; Mishin, O.V.; Eder, M.A. Effect of manufacturing defects on fatigue life of high strength steel bolts for wind turbines. Eng. Fail. Anal. 2022, 141, 106630. [Google Scholar] [CrossRef]

- Dao, M.; Chollacoop, N.; Van Vliet, K.J.; Venkatesh, T.A.; Suresh, S. Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 2001, 49, 3899–3918. [Google Scholar] [CrossRef]

- Shisode, M.P.; Hazrati, J.; Mishra, T.; de Rooij, M.B.; van den Boogaard, A.H. Semi-analytical contact model to determine the flattening behavior of coated sheets under normal load. Tribol. Int. 2020, 146, 106182. [Google Scholar] [CrossRef]

- PN-EN 1993-1-8, 2006; Eurocode 3: Design of Steel Structures, Part 1–8: Design of Joints. Polish Committee for Standardization: Warsaw, Poland, 2006.

- Zinc and Its Uses. Available online: https://www.azom.com/article.aspx?ArticleID=749 (accessed on 12 November 2022).

- Grzejda, R. FE-modelling of a bolted lap connection using a simplified bolt model. Model. Eng. 2017, 31, 24–28. [Google Scholar]

- Duarte, T.; Meyer, Y.A.; Osório, W.R. The holes of Zn phosphate and hot dip galvanizing on electrochemical behaviors of multi-coatings on steel substrates. Metals 2022, 12, 863. [Google Scholar] [CrossRef]

- Saeedikhani, M.; Blackwood, D.J. Finite element method for thin film corrosion modelling: Where we advanced and where we would like to advance? Corros. Mater. Degrad. 2020, 1, 273–281. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Thread diameter, d | 12 mm |

| Thread pitch, P | 1.75 mm |

| Thread flank angle, α | 60° |

| Bearing diameter of the bolt head, dw | 20.5 mm |

| Model Name | Zinc Coating Thickness [µm] |

|---|---|

| Model A | – |

| Model B | 40 |

| Model C | 60 |

| Model D | 84 |

| Model E | 92 |

| Material | Young’s Modulus, E (GPa) | Poisson’s Ratio | Yield Strength, σy (MPa) | Ultimate Tensile Strength, σu (MPa) |

|---|---|---|---|---|

| Zinc coating | 100 | 0.25 | 120 | 145 |

| Steel substrate | 210 | 0.3 | 900 | 1000 |

| Model Name | Number of Elements | Number of Nodes |

|---|---|---|

| Model B | 39,619 | 49,414 |

| Model C | 59,235 | 69,010 |

| Model D | 79,491 | 89,275 |

| Model E | 89,097 | 98,823 |

| Model Name | k, kN/mm | Z, % |

|---|---|---|

| Model A | 17.90 | – |

| Model B | 16.65 | 7.0 |

| Model C | 16.35 | 8.7 |

| Model D | 16.01 | 10.6 |

| Model E | 15.90 | 11.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grzejda, R.; Kobielarz, M. Testing the Mechanical Properties of High-Strength Zinc-Coated Bolts: FEM Approach. Coatings 2023, 13, 27. https://doi.org/10.3390/coatings13010027

Grzejda R, Kobielarz M. Testing the Mechanical Properties of High-Strength Zinc-Coated Bolts: FEM Approach. Coatings. 2023; 13(1):27. https://doi.org/10.3390/coatings13010027

Chicago/Turabian StyleGrzejda, Rafał, and Magdalena Kobielarz. 2023. "Testing the Mechanical Properties of High-Strength Zinc-Coated Bolts: FEM Approach" Coatings 13, no. 1: 27. https://doi.org/10.3390/coatings13010027

APA StyleGrzejda, R., & Kobielarz, M. (2023). Testing the Mechanical Properties of High-Strength Zinc-Coated Bolts: FEM Approach. Coatings, 13(1), 27. https://doi.org/10.3390/coatings13010027