Electroplating on Al6082 Aluminium: A New Green and Sustainable Approach

Abstract

1. Introduction

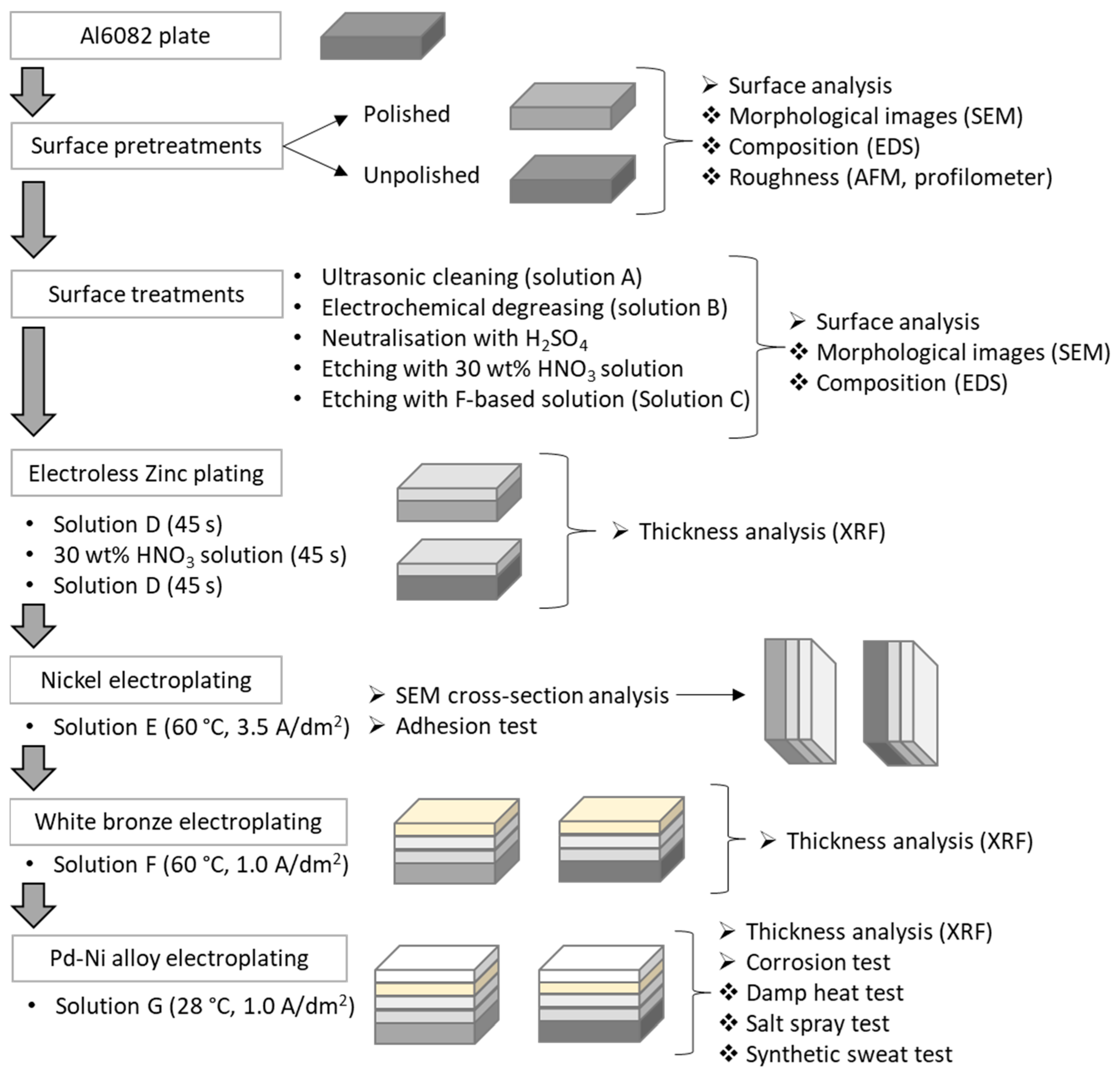

2. Materials and Methods

3. Results

3.1. Al6082 Aluminium Plate Surface Analysis

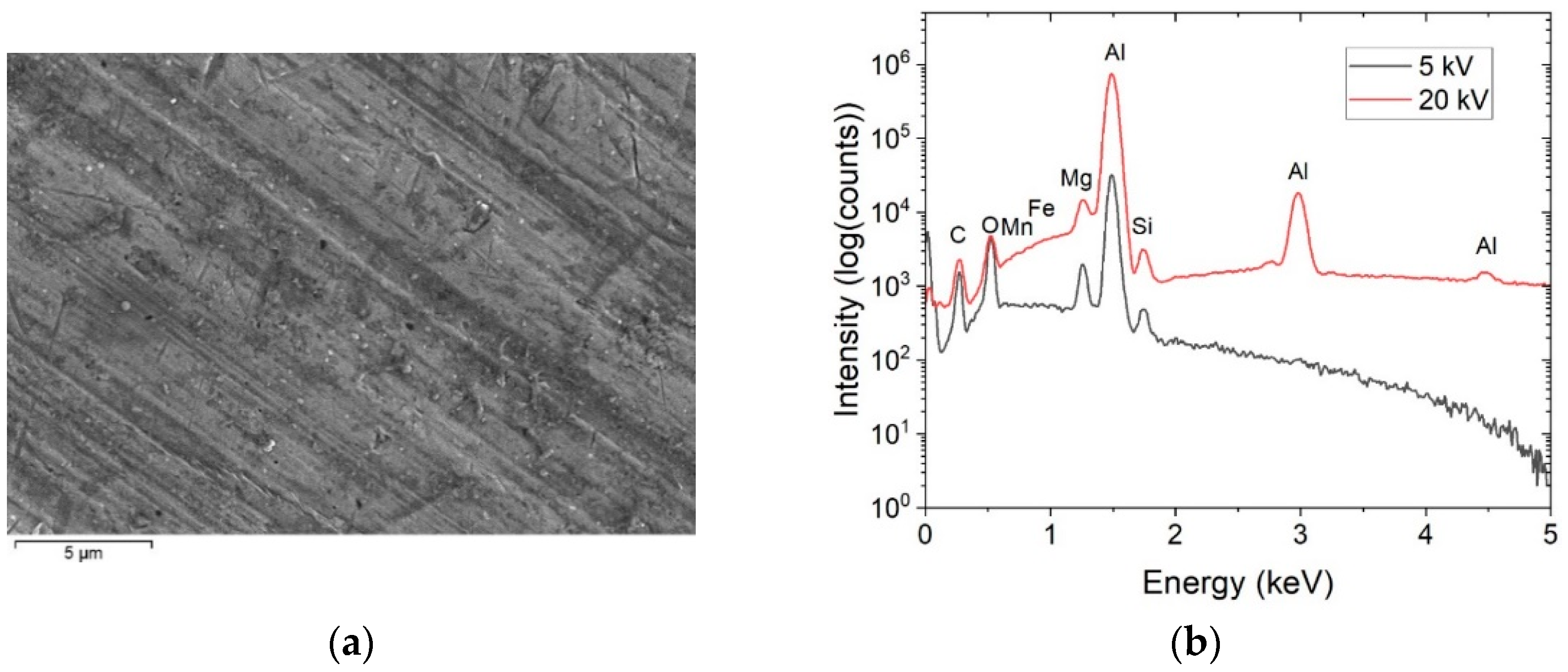

3.1.1. Unpolished Aluminium Samples

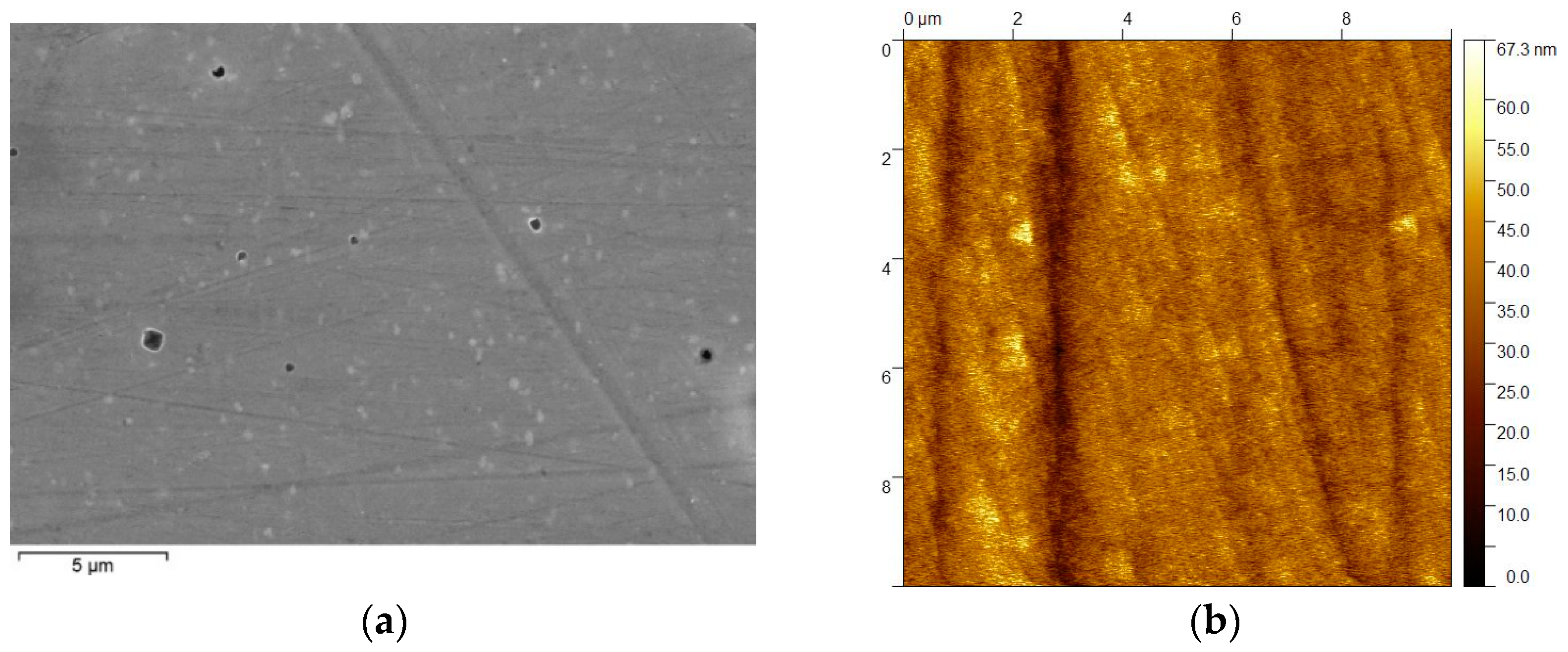

3.1.2. Polished Aluminium Samples

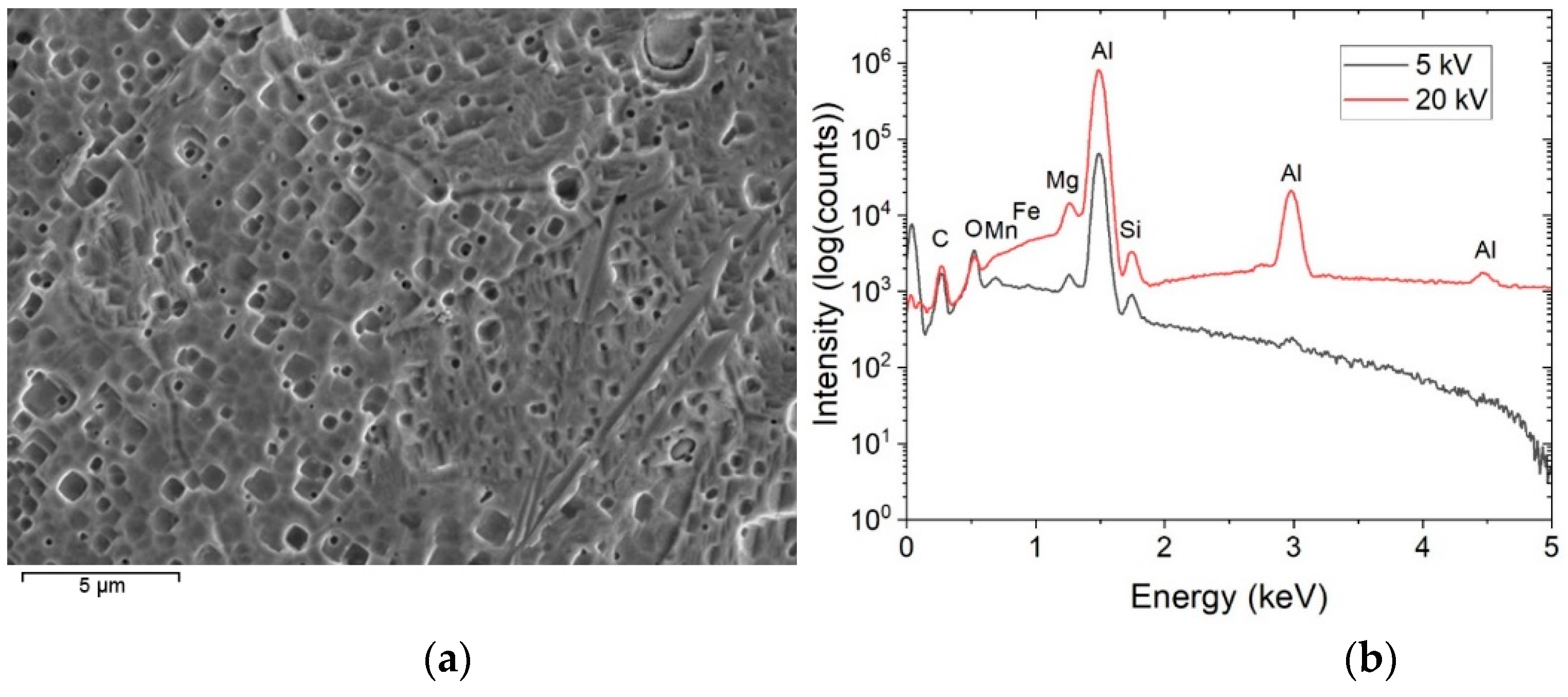

3.2. Samples Pretreatment

- Each aluminium sample was tied with copper wire and soaked into an ultrasound bath filled with Solution A at 65 °C for 3 min.

- After thoroughly rinsing the sample with deionized water, a cathodic alkaline electrochemical degreasing was performed by immersion for 10 s into a two-electrode electrochemical cell containing Solution B applying 25 V.

- Samples were again rinsed with deionized water and neutralized into a 3 wt% H2SO4 solution.

- After deionized water rinsing, 30 wt% HNO3 solution was used to etch aluminium surface (45 s at room temperature).

- After water rinsing, a fluoride-based solution (Solution C) was used to reduce the presence of silicon on the surface of the samples (45 s at room temperature).

3.3. Zinc Plating

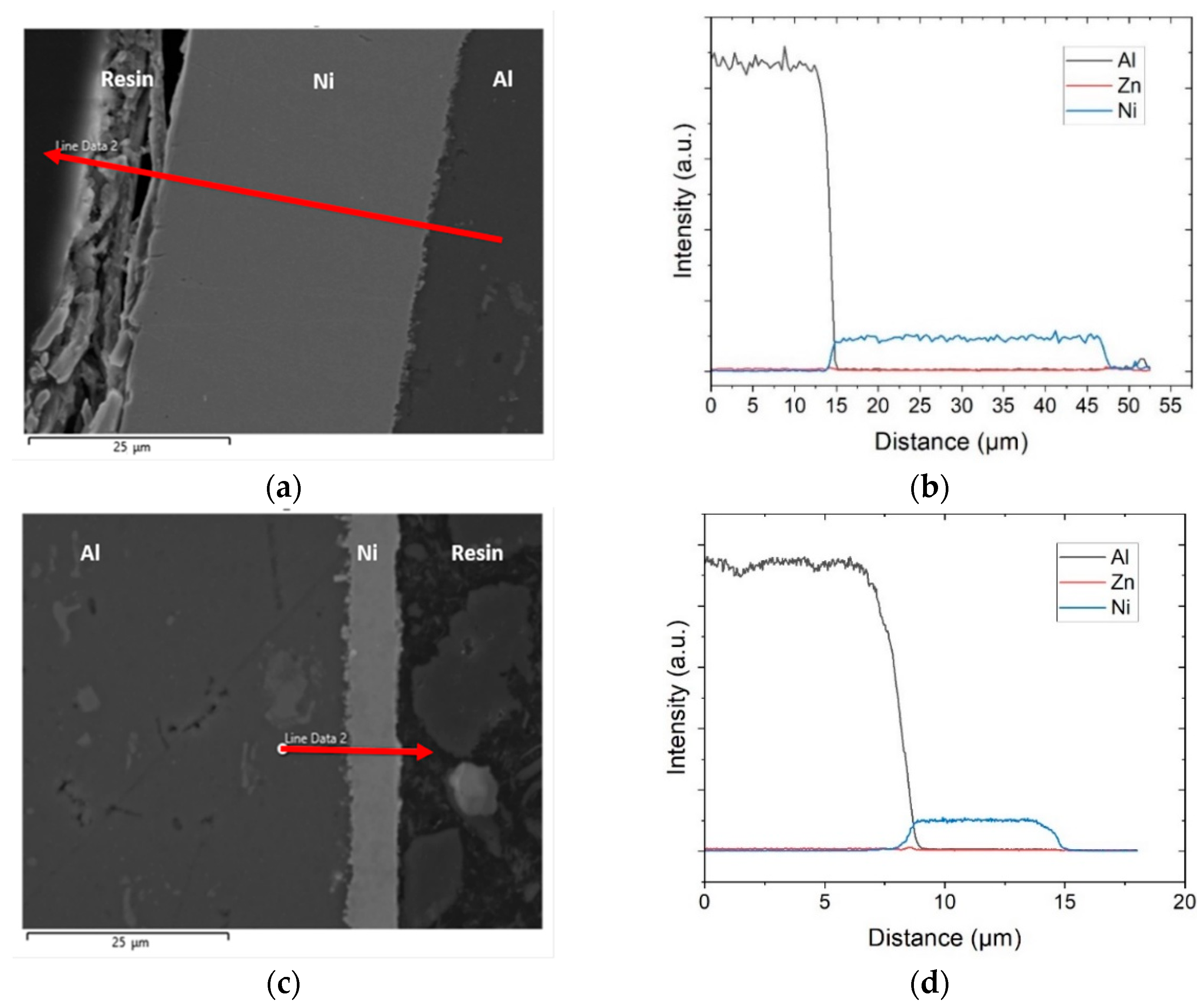

3.4. Cross-Section Analysis of Nickelated Samples

3.4.1. Unpolished Samples

3.4.2. Polished Samples

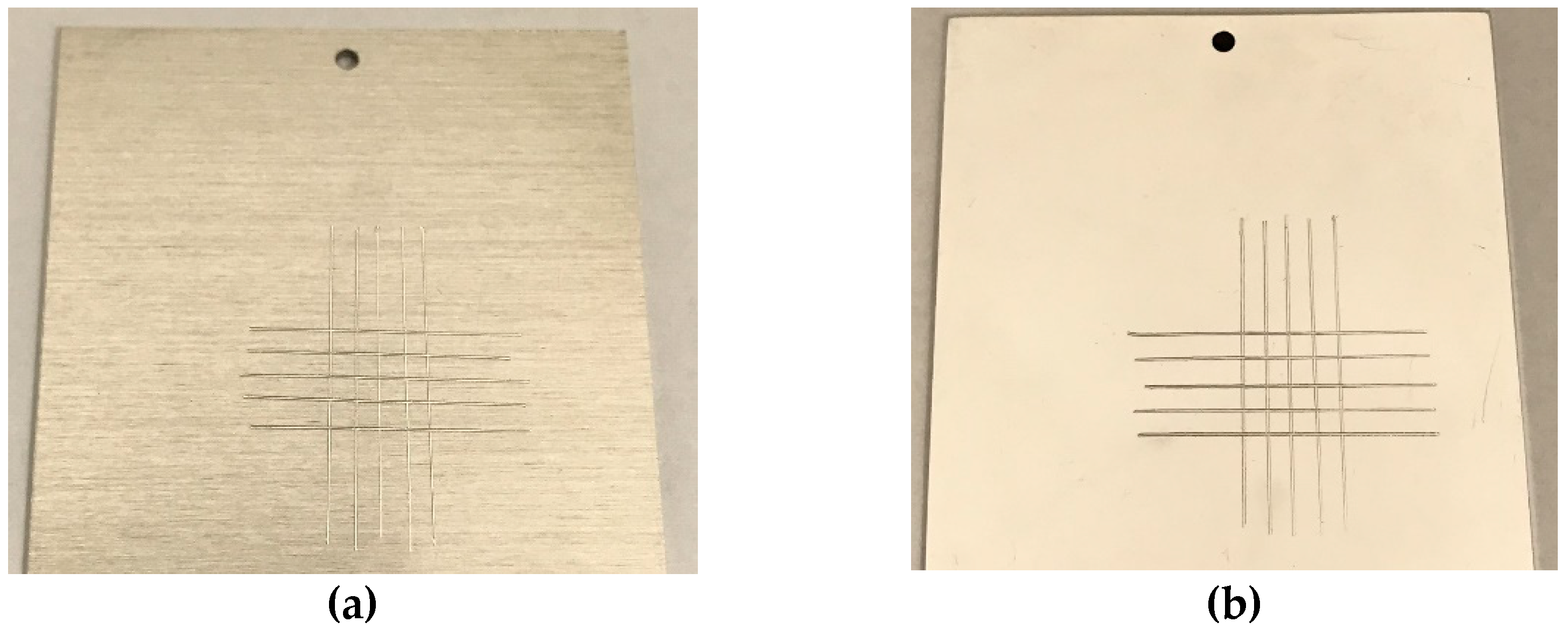

3.5. Adhesion Test

3.6. Corrosion Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, L.; Wang, Z.; Yilmaz, H.Ü.; Poganietz, W.R.; Ren, H.; Guo, Y. Considering the Impacts of Metal Depletion on the European Electricity System. Energies 2021, 14, 1560. [Google Scholar] [CrossRef]

- Jowitt, S.M.; Mudd, G.M.; Thompson, J.F.H. Future Availability of Non-Renewable Metal Resources and the Influence of Environmental, Social, and Governance Conflicts on Metal Production. Commun. Earth Environ. 2020, 1, 13. [Google Scholar] [CrossRef]

- Giurlani, W.; Zangari, G.; Gambinossi, F.; Passaponti, M.; Salvietti, E.; Di Benedetto, F.; Caporali, S.; Innocenti, M. Electroplating for Decorative Applications: Recent Trends in Research and Development. Coatings 2018, 8, 260. [Google Scholar] [CrossRef]

- De Beni, E.; Giurlani, W.; Fabbri, L.; Emanuele, R.; Santini, S.; Sarti, C.; Martellini, T.; Piciollo, E.; Cincinelli, A.; Innocenti, M. Graphene-Based Nanomaterials in the Electroplating Industry: A Suitable Choice for Heavy Metal Removal from Wastewater. Chemosphere 2022, 292, 133448. [Google Scholar] [CrossRef] [PubMed]

- Passaponti, M.; Lari, L.; Bonechi, M.; Bruni, F.; Giurlani, W.; Sciortino, G.; Rosi, L.; Fabbri, L.; Vizza, M.; Lazarov, V.K.; et al. Optimisation Study of Co Deposition on Chars from MAP of Waste Tyres as Green Electrodes in ORR for Alkaline Fuel Cells. Energies 2020, 13, 5646. [Google Scholar] [CrossRef]

- Giurlani, W.; Sergi, L.; Crestini, E.; Calisi, N.; Poli, F.; Soavi, F.; Innocenti, M. Electrochemical Stability of Steel, Ti, and Cu Current Collectors in Water-in-Salt Electrolyte for Green Batteries and Supercapacitors. J. Solid State Electrochem. 2022, 26, 85–95. [Google Scholar] [CrossRef]

- Giurlani, W.; Dell’Aquila, V.; Vizza, M.; Calisi, N.; Lavacchi, A.; Irrera, A.; Lo Faro, M.J.; Leonardi, A.A.; Morganti, D.; Innocenti, M. Electrodeposition of Nanoparticles and Continuous Film of CdSe on N-Si (100). Nanomaterials 2019, 9, 1504. [Google Scholar] [CrossRef]

- Foresti, M.L.; Pozzi, A.; Innocenti, M.; Pezzatini, G.; Loglio, F.; Salvietti, E.; Giusti, A.; D’Anca, F.; Felici, R.; Borgatti, F. In Situ X-ray Analysis under Controlled Potential Conditions: An Innovative Setup and Its Application to the Investigation of Ultrathin Films Electrodeposited on Ag(111). Electrochim. Acta 2006, 51, 5532–5539. [Google Scholar] [CrossRef]

- Auzins, K.; Zolotarjovs, A.; Bite, I.; Laganovska, K.; Vitola, V.; Smits, K.; Millers, D. Production of Phosphorescent Coatings on 6082 Aluminum Using Sr0.95Eu0.02Dy0.03Al2O4-δ Powder and Plasma Electrolytic Oxidation. Coatings 2019, 9, 865. [Google Scholar] [CrossRef]

- Mariani, E.; Giurlani, W.; Bonechi, M.; Dell’Aquila, V.; Innocenti, M. A Systematic Study of Pulse and Pulse Reverse Plating on Acid Copper Bath for Decorative and Functional Applications. Sci. Rep. 2022, 12, 18175. [Google Scholar] [CrossRef]

- Pizzetti, F.; Salvietti, E.; Giurlani, W.; Emanuele, R.; Fontanesi, C.; Innocenti, M. Cyanide-Free Silver Electrodeposition with Polyethyleneimine and 5,5-Dimethylhydantoin as Organic Additives for an Environmentally Friendly Formulation. J. Electroanal. Chem. 2022, 911, 116196. [Google Scholar] [CrossRef]

- Fabbri, L.; Giurlani, W.; Mencherini, G.; De Luca, A.; Passaponti, M.; Piciollo, E.; Fontanesi, C.; Caneschi, A.; Innocenti, M. Optimisation of Thiourea Concentration in a Decorative Copper Plating Acid Bath Based on Methanesulfonic Electrolyte. Coatings 2022, 12, 376. [Google Scholar] [CrossRef]

- Green, J.A.S. Aluminum Recycling and Processing for Energy Conservation and Sustainability; ASM International: Almere, The Netherlands, 2007; Volume 267. [Google Scholar]

- Siddesh Kumar, N.M.; Dhruthi; Pramod, G.K.; Samrat, P.; Sadashiva, M. A Critical Review on Heat Treatment of Aluminium Alloys. Mater. Today Proc. 2022, 58, 71–79. [Google Scholar] [CrossRef]

- Mohan, D.; Chinnasamy, B.; Naganathan, S.K.; Nagaraj, N.; Jule, L.; Badassa, B.; Ramaswamy, K.; Kathirvel, P.; Murali, G.; Vatin, N.I. Experimental Investigation and Comparative Analysis of Aluminium Hybrid Metal Matrix Composites Reinforced with Silicon Nitride, Eggshell and Magnesium. Materials 2022, 15, 6098. [Google Scholar] [CrossRef] [PubMed]

- Kozhukhova, A.E.; du Preez, S.P.; Bessarabov, D.G. Preparation of Anodized Aluminium Oxide at High Temperatures Using Low Purity Aluminium (Al6082). Surf. Coat. Technol. 2019, 378, 124970. [Google Scholar] [CrossRef]

- Bruera, F.A.; Kramer, G.R.; Vera, M.L.; Ares, A.E. Low-Cost Nanostructured Coating of Anodic Aluminium Oxide Synthesized in Sulphuric Acid as Electrolyte. Coatings 2021, 11, 309. [Google Scholar] [CrossRef]

- Burgess, J. Electroplating onto Aluminium and Its Alloys. Trans. IMF 2019, 97, 285–288. [Google Scholar] [CrossRef]

- Berg, R.V. Vanden Electroplating Aluminium Alloys. Trans. IMF 2017, 45, 161–173. [Google Scholar] [CrossRef]

- Evertsson, J.; Bertram, F.; Zhang, F.; Rullik, L.; Merte, L.R.; Shipilin, M.; Soldemo, M.; Ahmadi, S.; Vinogradov, N.; Carlà, F.; et al. The Thickness of Native Oxides on Aluminum Alloys and Single Crystals. Appl. Surf. Sci. 2015, 349, 826–832. [Google Scholar] [CrossRef]

- Mandin, P.; Wüthrich, R.; Roustan, H. Industrial Aluminium Production: The Hall-Heroult Process Modelling. ECS Trans. 2009, 19, 1. [Google Scholar] [CrossRef]

- Gaustad, G.; Olivetti, E.; Kirchain, R. Improving Aluminum Recycling: A Survey of Sorting and Impurity Removal Technologies. Resour. Conserv. Recycl. 2012, 58, 79–87. [Google Scholar] [CrossRef]

- Uhlmann, E.; Jaczkowski, R. Mechanical Pretreatment before Electroplating of Aluminium Alloy AlSi12. Surf. Coat. Technol. 2018, 352, 483–488. [Google Scholar] [CrossRef]

- Tirta Nindhia, T.G.; Putra Negara, D.n.K.; Agus Saputra, I.W.; Sharma, P.K. Development Method for Nickel Electroplating on Aluminium. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1007, 012105. [Google Scholar] [CrossRef]

- Son, S.H.; Kwon, D.C.; Jeong, D.W. Development of Free Nitric Acid, Non-P Desmut Solution for Surface Treatment Aluminium Alloys. Mater. Sci. Forum 2008, 569, 309–312. [Google Scholar] [CrossRef]

- Monteiro, F.J.; Barbosa, M.A.; Gabe, D.R.; Ross, D.H. Surface Pretreatments of Aluminium for Electroplating. Surf. Coat. Technol. 1988, 35, 321–331. [Google Scholar] [CrossRef]

- Pachchigar, V.; Varshney, J.; Ghosh, S.K.; Kain, V. Reinvestigation of Nucleation and Growth of Zn on Al Surface during Modified Alloy Zincating. Surf. Coat. Technol. 2020, 382, 125191. [Google Scholar] [CrossRef]

- Moradi, M.; Gerami Shirazi, B.; Sadeghi, A.; Seidi, S. Electroless Plating of Sn/Cu/Zn Triple Layer on AA6082 Aluminum Alloy. Int. J. Light. Mater. Manuf. 2022, 5, 1–10. [Google Scholar] [CrossRef]

- Egoshi, S.; Azumi, K.; Konno, H.; Ebihara, K.; Taguchi, Y. Effects of Minor Elements in Al Alloy on Zincate Pretreatment. Appl. Surf. Sci. 2012, 261, 567–573. [Google Scholar] [CrossRef]

- Lee, S.-K.; Lee, J.-H.; Kim, Y.-H. Nucleation and Growth of Zinc Particles on an Aluminum Substrate in a Zincate Process. J. Electron. Mater. 2007, 36, 1442–1447. [Google Scholar] [CrossRef]

- Goyal, B.; Parmar, J.; Gohil, R.; Jariwala, F.; Patel, S.; Rao, V. Electroplating of Nickel and Chromium on Aluminum 6082-T6 Alloy. In Proceedings of the International Conference on Recent Advances in Metallurgy for Sustainable Development, Vadodara, Gujarat, India, 1–3 February 2018. [Google Scholar]

- Lowenheim, F.A.; Senderoff, S. Modern Electroplating; Schlesinger, M., Paunovic, M., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; Volume 111, ISBN 9780470602638. [Google Scholar]

- Robertson, S.G.; Ritchie, I.M. The Role of Iron(III) and Tartrate in the Zincate Immersion Process for Plating Aluminium. J. Appl. Electrochem. 1997, 27, 799–804. [Google Scholar] [CrossRef]

- Azumi, K.; Fujishige, Y.; Seo, M.; Nanis, L.; Nakao, H.; Tashiro, K. Effect Of Solution Composition On Double Zincate Process of Aluminum. J. Surf. Finish. Soc. Jpn. 1996, 47, 802–807. [Google Scholar] [CrossRef]

- Giurlani, W.; Berretti, E.; Innocenti, M.; Lavacchi, A. Measuring the Thickness of Metal Coatings: A Review of the Methods. Coatings 2020, 10, 1211. [Google Scholar] [CrossRef]

- Needs, R.J.; Towler, M.D.; Drummond, N.D.; López Ríos, P.; Trail, J.R. Variational and Diffusion Quantum Monte Carlo Calculations with the CASINO Code. J. Chem. Phys. 2020, 152, 154106. [Google Scholar] [CrossRef] [PubMed]

- Giurlani, W.; Berretti, E.; Lavacchi, A.; Innocenti, M. Thickness Determination of Metal Multilayers by ED-XRF Multivariate Analysis Using Monte Carlo Simulated Standards. Anal. Chim. Acta 2020, 1130, 72–79. [Google Scholar] [CrossRef]

- John, D. Aluminum and Aluminum Alloys. In Alloying; ASM Internation: Almere, The Netherlands, 2001; pp. 351–416. [Google Scholar] [CrossRef]

- Ashtari, P.; Davis, B.; Sadayappan, K. Removal of Si from Recycled Aluminium Alloys. Int. J. Cast Met. Res. 2012, 25, 100–102. [Google Scholar] [CrossRef]

- Othman, I.S.; Starink, M.J.; Wang, S.C.; Pembuatan, F.K. Impact of Single and Double Zincating Treatment on Adhesion of Electrodeposited Nickel Coating on Aluminium Alloy 7075. J. Adv. Manuf. Technol. 2018, 12, 179–192. [Google Scholar]

- Court, S.; Kerr, C.; Ponce de León, C.; Smith, J.R.; Barker, B.D.; Walsh, F.C. Monitoring of Zincate Pre-Treatment of Aluminium Prior to Electroless Nickel Plating. Trans. IMF 2017, 95, 97–105. [Google Scholar] [CrossRef]

- Sharifalhoseini, Z.; Davoodi, A. Uniform Nucleation of Zincate Layer through the Optimized Etching Process to Prevent Failure in Electroless Plating on 2024 Aluminum Alloy. Eng. Fail. Anal. 2021, 124, 105326. [Google Scholar] [CrossRef]

- David, L. Plating on Aluminum: A Review. In Plating & Surface Finishing; American Electroplaters and Surface Finishers Society: Orlando, FL, USA, 1985; pp. 36–39. [Google Scholar]

- Oduoza, C.F.; Khan, E.; Sihra, T. Chromium Electroplating of Aluminium Alloys Using Electroless Nickel as Underlayer. J. Mater. Sci. Chem. Eng. 2014, 2, 59–74. [Google Scholar] [CrossRef][Green Version]

- Chen, M.; Dong, W.; Qin, C. A Method for Electroless Nickel Plating on Aluminum Alloy Surface. Eng. Sci. 2020, 5, 33. [Google Scholar] [CrossRef]

- Such, T.E.; Wyszynski, A.E. An Improvement in the Zincate Method for Plating on Aluminum. Nasf Surf. Technol. White Pap. 2019, 83, 8–18. [Google Scholar]

- Berretti, E.; Calisi, N.; Capaccioli, A.; Capozzoli, L.; Hamouda, A.M.S.; Giaccherini, A.; Giurlani, W.; Ienco, A.; Martinuzzi, S.; Innocenti, M.; et al. Electrodeposited White Bronzes on Brass: Corrosion in 3.5% Sodium Chloride Solution. Corros. Sci. 2020, 175, 108898. [Google Scholar] [CrossRef]

| wt% | |||

|---|---|---|---|

| Element | Theoretical | 5 kV | 20 kV |

| Al | Remaining | 95.5 ± 0.2 | 97.4 ± 0.1 |

| Si | 0.7−1.3 | 1.3 ± 0.1 | 0.8 ± 0.1 |

| Fe | 0.5 | - | 0.3 ± 0.1 |

| Mg | 0.6−1.2 | 3.2 ± 0.1 | 1.0 ± 0.1 |

| Mn | 0.4−1.0 | - | 0.6 ± 0.1 |

| Cr | 0.25 | - | - |

| Cu | 0.10 | - | - |

| Zn | 0.20 | - | - |

| Ti | 0.10 | - | - |

| Roughness Parameter | Average (µm) | Standard Deviation |

|---|---|---|

| Ra | 0.40 | 0.01 |

| Rz | 1.98 | 0.04 |

| Roughness Parameter | Value (nm) |

|---|---|

| Sa | 5.09 |

| Sq | 6.55 |

| Element | 5 kV | 20 kV |

|---|---|---|

| Al | 99.2 ± 0.1 | 97.7 ± 0.1 |

| Si | 0.5 ± 0.1 | 0.8 ± 0.1 |

| Fe | - | 0.2 ± 0.1 |

| Mg | 0.3 ± 0.1 | 0.8 ± 0.1 |

| Mn | - | 0.5 ± 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Comparini, A.; Del Pace, I.; Giurlani, W.; Emanuele, R.; Verrucchi, M.; Bonechi, M.; Innocenti, M. Electroplating on Al6082 Aluminium: A New Green and Sustainable Approach. Coatings 2023, 13, 13. https://doi.org/10.3390/coatings13010013

Comparini A, Del Pace I, Giurlani W, Emanuele R, Verrucchi M, Bonechi M, Innocenti M. Electroplating on Al6082 Aluminium: A New Green and Sustainable Approach. Coatings. 2023; 13(1):13. https://doi.org/10.3390/coatings13010013

Chicago/Turabian StyleComparini, Andrea, Ivan Del Pace, Walter Giurlani, Roberta Emanuele, Margherita Verrucchi, Marco Bonechi, and Massimo Innocenti. 2023. "Electroplating on Al6082 Aluminium: A New Green and Sustainable Approach" Coatings 13, no. 1: 13. https://doi.org/10.3390/coatings13010013

APA StyleComparini, A., Del Pace, I., Giurlani, W., Emanuele, R., Verrucchi, M., Bonechi, M., & Innocenti, M. (2023). Electroplating on Al6082 Aluminium: A New Green and Sustainable Approach. Coatings, 13(1), 13. https://doi.org/10.3390/coatings13010013