Vertical Growth Dynamics and Multifractality of the Surface of Electropolymerized Poly(o-ethoxyaniline) Thin Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. AFM Imaging and Morphological Analysis

2.3. Multifractal Analysis

2.4. Statistical Analysis

3. Results

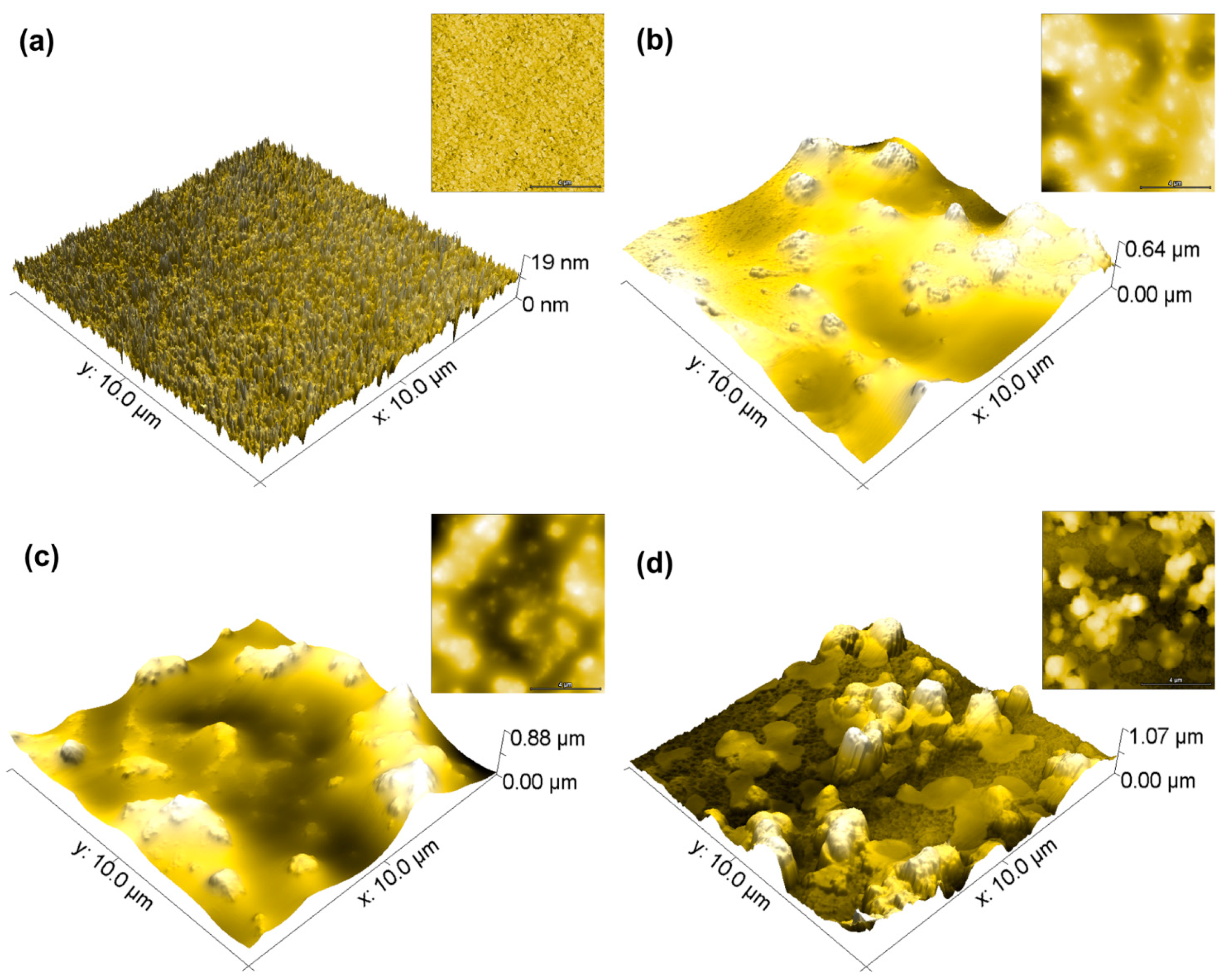

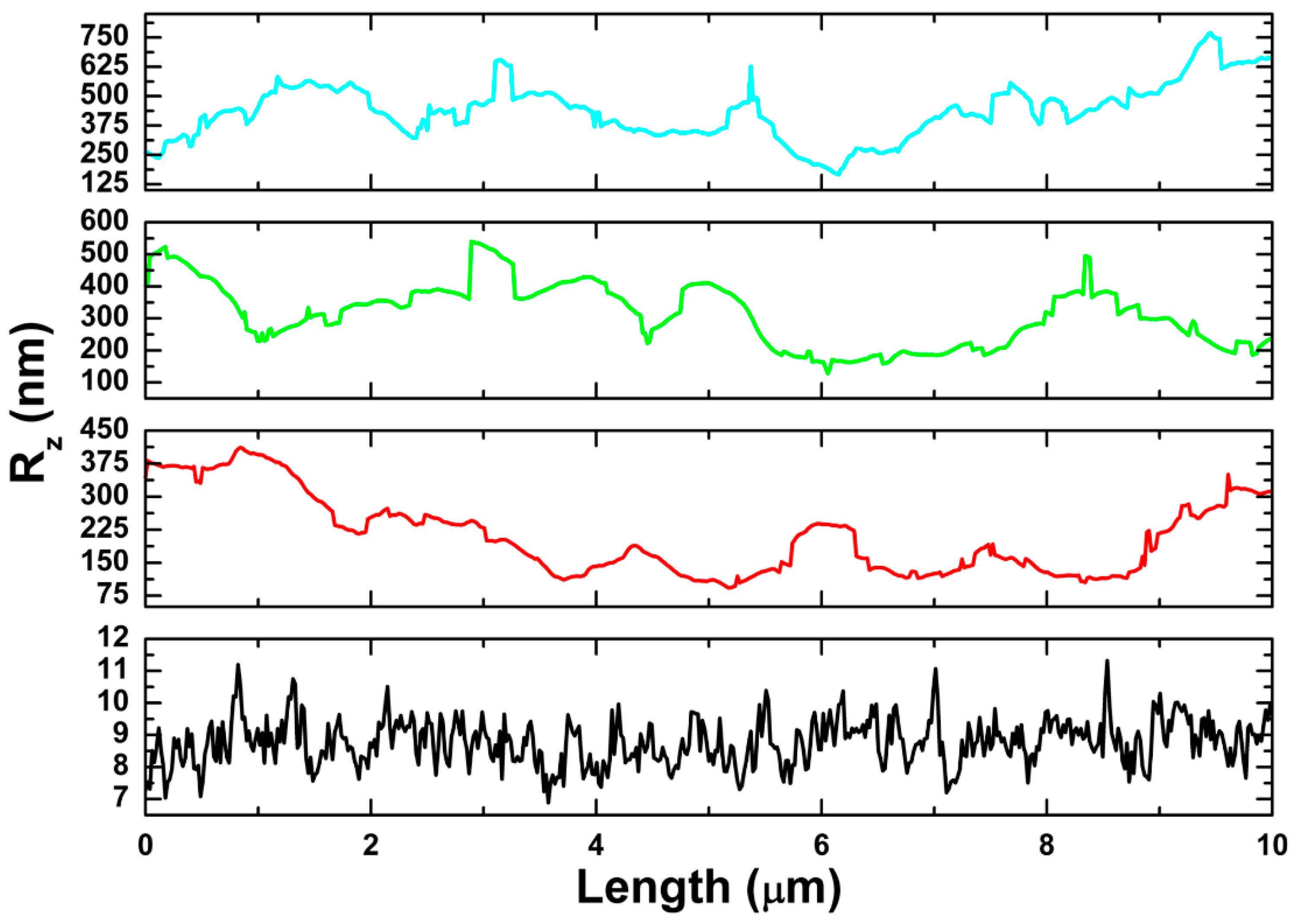

3.1. AFM Measurements

3.2. Spatial Autocorrelation (ACF)

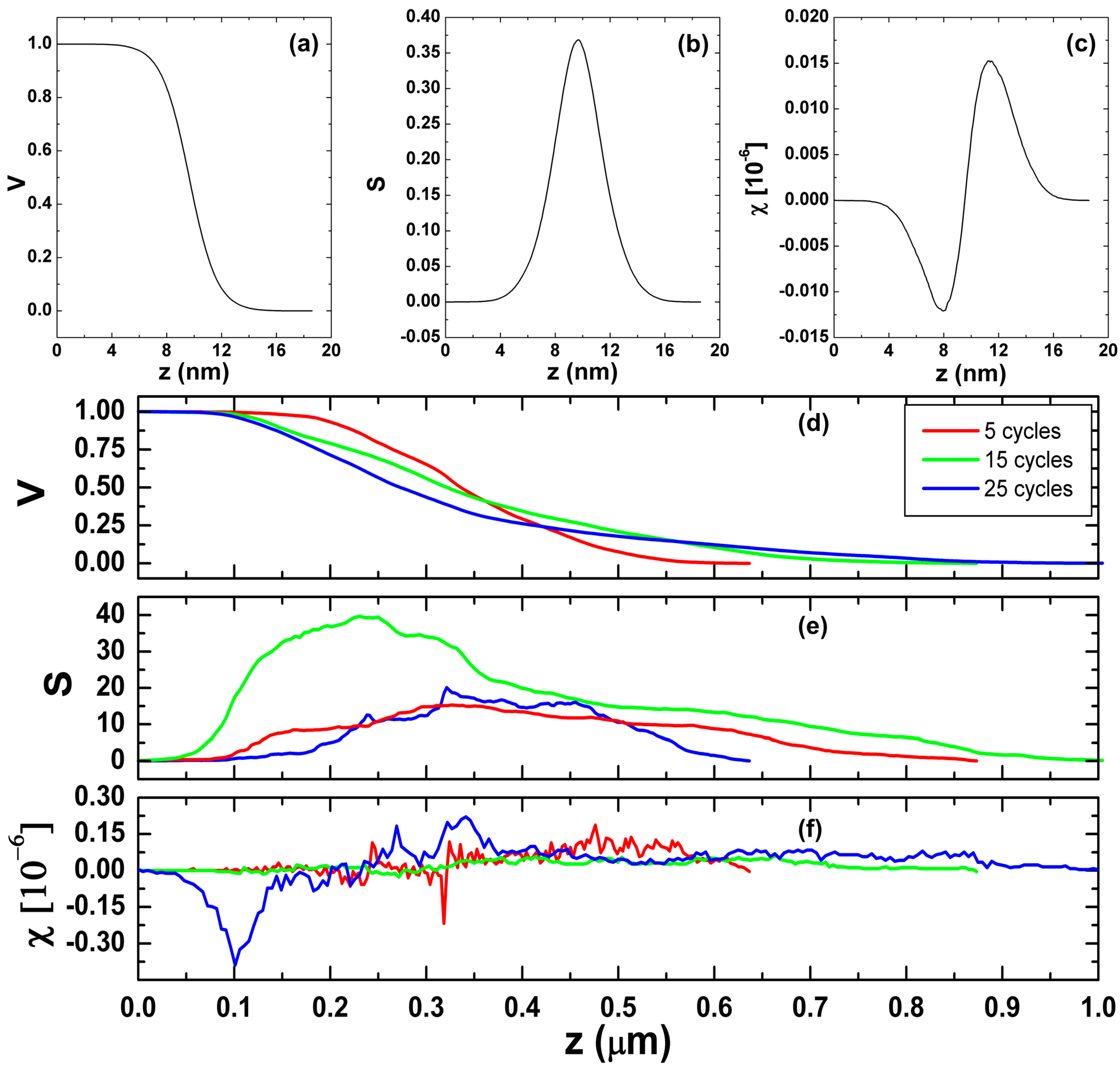

3.3. Minkowski Functionals

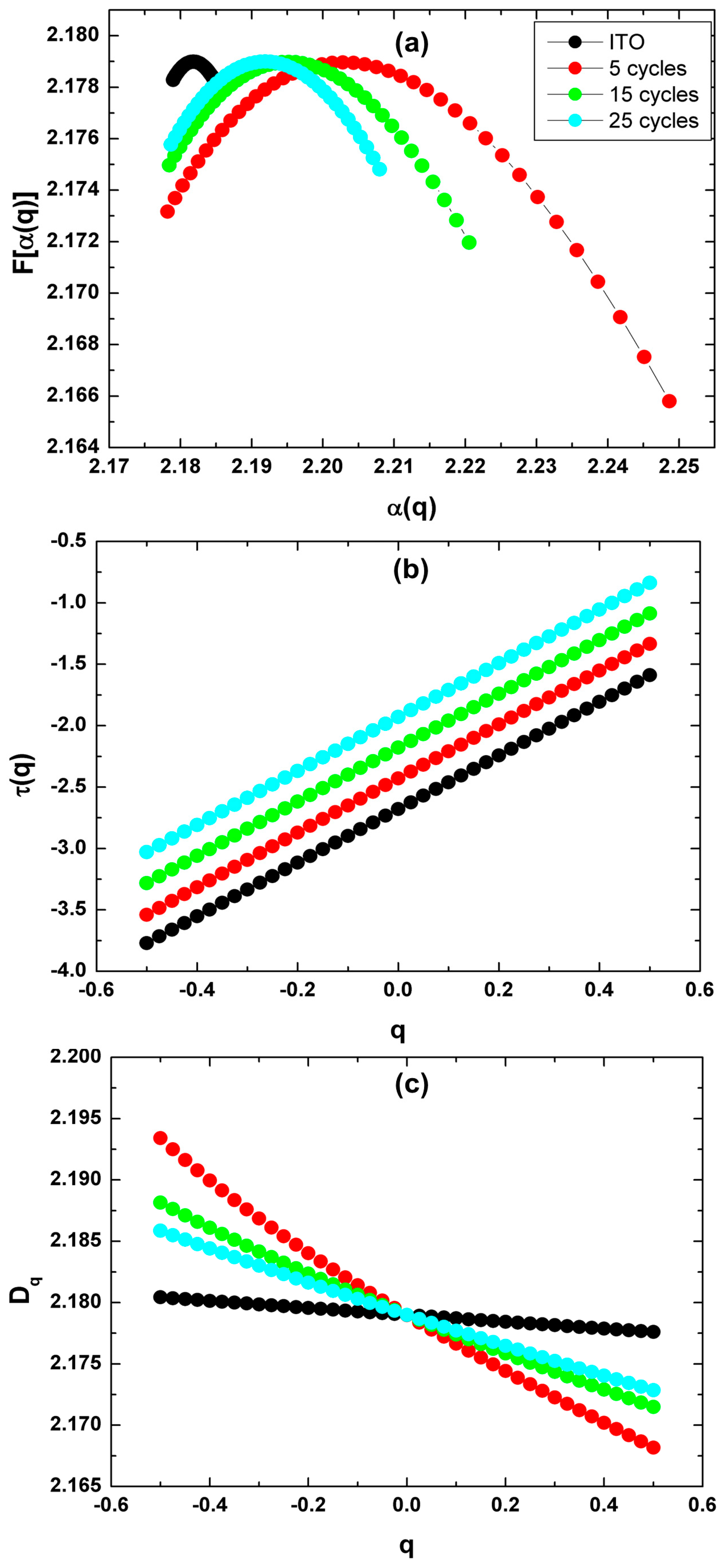

3.4. Multifractal Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, C.-C.; Wei, S.-C.; Luo, S.-C. Recent advances and biomedical applications of peptide-integrated conducting polymers. ACS Appl. Bio Mater. 2022, 5, 1916–1933. [Google Scholar] [CrossRef] [PubMed]

- Ghomi, M.; Zare, E.N.; Varma, R.S. Properties of conducting polymers. ACS Symp. Ser. 2022, 1405, 39–65. [Google Scholar] [CrossRef]

- Macinnes, D.; Funt, B.L. Poly-o-methoxyaniline: A new soluble conducting polymer. Synth. Met. 1988, 25, 235–242. [Google Scholar] [CrossRef]

- Bergeron, J.-Y.; Chevalier, J.-W.; Dao, L.H. Water-soluble conducting poly(aniline) polymer. J. Chem. Soc. Chem. Commun. 1990, 2, 180. [Google Scholar] [CrossRef]

- Nogueira, J.S.; Mattoso, L.H.c.; Lepienski, C.M.; Faria, R.M. AC conduction of poly(o-methoxyaniline). Synth. Met. 1995, 69, 259–260. [Google Scholar] [CrossRef]

- Sathiyanarayanan, S.; Dhawan, S.K.; Trivedi, D.C.; Balakrishnan, K. Soluble conducting poly ethoxy aniline as an inhibitor for iron in HCl. Corros. Sci. 1992, 33, 1831–1841. [Google Scholar] [CrossRef]

- Daouadji, M.M.; Chelali, N. Influence of molecular weight of poly(ortho-ethoxyaniline) on the corrosion inhibition efficiency of mild steel in acidic media. J. Appl. Polym. Sci. 2004, 91, 1275–1284. [Google Scholar] [CrossRef]

- Mello, S.V.; Mattoso, L.H.C.; Santos, J.R.; Gonçalves, D.; Faria, R.M.; Oliveira, O.N. Electrochemical response of poly(o-ethoxyaniline) films produced by different techniques. Electrochim. Acta 1995, 40, 1851–1855. [Google Scholar] [CrossRef]

- Ito, R.M.; de Souza, C.C.; Gandarilla, A.M.D.; de Oliveira, L.M.; Brito, W.R.; Sanches, E.A.; Matos, R.S.; da Fonseca Filho, H.D. Micromorphology and microtexture evaluation of poly(o-ethoxyaniline) films using atomic force microscopy and fractal analysis. J. Polym. Res. 2020, 27, 299. [Google Scholar] [CrossRef]

- Ţălu, Ş. Micro and Nanoscale Characterization of Three Dimensional Surfaces. Basics and Applications; Napoca Star Publishing House: Cluj-Napoca, Romania, 2015; pp. 199–210. [Google Scholar]

- Korpi, A.R.G.; Rezaee, S.; Luna, C.; Ţălu, Ş.; Arman, A.; Ahmadpourian, A. Influence of the oxygen partial pressure on the growth and optical properties of RF-sputtered anatase TiO2 thin films. Results Phys. 2017, 7, 3349–3352. [Google Scholar] [CrossRef]

- Novikov, V.U.; Kozlov, G. V Fractal analysis of macromolecules. Russ. Chem. Rev. 2000, 69, 347–366. [Google Scholar] [CrossRef]

- Valle, F.; Brucale, M.; Chiodini, S.; Bystrenova, E.; Albonetti, C. Nanoscale morphological analysis of soft matter aggregates with fractal dimension ranging from 1 to 3. Micron 2017, 100, 60–72. [Google Scholar] [CrossRef]

- Li, Y.-C.; Chen, K.-B.; Chen, H.-L.; Hsu, C.-S.; Tsao, C.-S.; Chen, J.-H.; Chen, S.-A. Fractal aggregates of conjugated polymer in solution state. Langmuir 2006, 22, 11009–11015. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, L.M.; Matos, R.S.; Campelo, P.H.; Sanches, E.A.; da Fonseca Filho, H.D. Evaluation of the nanoscale surface applied to biodegradable nanoparticles containing Allium sativum essential oil. Mater. Lett. 2020, 275, 128111. [Google Scholar] [CrossRef]

- De Oliveira, L.M.; Matos, R.S.; Ţălu, Ş.; Rocha, A.L.F.; de Aguiar Nunes, R.Z.; Bezerra, J.d.A.; Campelo Felix, P.H.; Inada, N.M.; Sanches, E.A.; da Fonseca Filho, H.D. Three-dimensional nanoscale morphological surface analysis of polymeric particles containing Allium sativum Essential Oil. Materials 2022, 15, 2635. [Google Scholar] [CrossRef]

- Nečas, D.; Klapetek, P. Gwyddion: An open-source software for SPM data analysis. Cent. Eur. J. Phys. 2012, 10, 181–188. [Google Scholar] [CrossRef]

- Ţălu, Ş.; Bramowicz, M.; Kulesza, S.; Shafiekhani, A.; Rahmati, M.; Ghaderi, A.; Ahmadirad, M.; Solaymani, S. Microstructure of nickel nanoparticles embedded in carbon films: Case study on annealing effect by micromorphology analysis. Surf. Interface. Anal. 2017, 49, 153–160. [Google Scholar] [CrossRef]

- Bielejewska, N.; Hertmanowski, R. Surface characterization of nanocomposite Langmuir films based on liquid crystals and cellulose nanocrystals. J. Mol. Liq. 2021, 323, 115065. [Google Scholar] [CrossRef]

- Dong, W.P.; Sullivan, P.J.; Stout, K.J. Comprehensive study of parameters for characterising three-dimensional surface topography. Wear 1994, 178, 45–60. [Google Scholar] [CrossRef]

- Yao, B.; Imani, F.; Sakpal, A.S.; Reutzel, E.W.; Yang, H. Multifractal analysis of image profiles for the characterization and detection of defects in additive manufacturing. J. Manuf. Sci. Eng. 2018, 140, 031014. [Google Scholar] [CrossRef]

- Imani, F.; Yao, B.; Chen, R.; Rao, P.; Yang, H. Joint Multifractal and Lacunarity Analysis of Image Profiles for Manufacturing Quality Control. J. Manuf. Sci. Eng. 2019, 141, 044501. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, H. Numerical simulation and pattern characterization of nonlinear spatiotemporal dynamics on fractal surfaces for the whole-heart modeling applications. Eur. Phys. J. B 2016, 89, 181. [Google Scholar] [CrossRef]

- Ţălu, Ş.; Stach, S.; Valedbagi, S.; Bavadi, R.; Elahi, S.M.; Ţălu, M. Multifractal characteristics of titanium nitride thin films. Mater. Sci.-Poland 2015, 33, 541–548. [Google Scholar] [CrossRef]

- Block, A.; von Bloh, W.; Schellnhuber, H.J. Efficient box-counting determination of generalized fractal dimensions. Phys. Rev. A 1990, 42, 1869–1874. [Google Scholar] [CrossRef] [PubMed]

- Leite, F.L.; Alves, W.F.; Mir, M.; Mascarenhas, Y.P.; Herrmann, P.S.P.; Mattoso, L.H.C.; Oliveira, O.N. TEM, XRD and AFM study of poly(o-ethoxyaniline) films: New evidence for the formation of conducting islands. Appl. Phys. A 2008, 93, 537. [Google Scholar] [CrossRef]

- Kuznetsov, G.V.; Islamova, A.G.; Orlova, E.G.; Ivashutenko, A.S.; Shanenkov, I.I.; Zykov, I.Y.; Feoktistov, D.V. Influence of roughness on polar and dispersed components of surface free energy and wettability properties of copper and steel surfaces. Surf. Coatings Technol. 2021, 422, 127518. [Google Scholar] [CrossRef]

- Nečas, D.; Klapetek, P. One-dimensional autocorrelation and power spectrum density functions of irregular regions. Ultramicroscopy 2013, 124, 13–19. [Google Scholar] [CrossRef]

- Blateyron, F. The Areal Field Parameters. In Characterisation of Areal Surface Texture; Springer: Berlin/Heidelberg, Germany, 2013; pp. 15–43. [Google Scholar]

- Mantz, H.; Jacobs, K.; Mecke, K. Utilizing Minkowski functionals for image analysis: A marching square algorithm. J. Stat. Mech. Theory Exp. 2008, 2008, P12015. [Google Scholar] [CrossRef]

- Mwema, F.M.; Akinlabi, E.T.; Oladijo, O.P.; Fatoba, O.S.; Akinlabi, S.A.; Ţălu, Ş. Advances in manufacturing analysis: Fractal theory in modern manufacturing. In Modern Manufacturing Processes, 1st ed.; Woodhead Publishing: Philadelphia, PA, USA, 2020; pp. 13–39. [Google Scholar] [CrossRef]

- Salerno, M.; Banzato, M. Minkowski measures for image analysis in scanning probe microscopy. Microsc. Anal. 2005, 19, 13–15. [Google Scholar]

- Ghosh, K.; Pandey, R.K. Annealing time induced roughening in ZnO thin films: A fractal and multifractal assessment. Mater. Sci. Semicond. Process. 2020, 106, 104771. [Google Scholar] [CrossRef]

- Astinchap, B.; Moradian, R.; Namdari, T.; Jurecka, S.; Ţălu, Ş. Prepared σ-MnO2 thin films by chemical bath deposition methods and study of its optical and microstructure properties. Opt. Quantum Electron 2019, 51, 170. [Google Scholar] [CrossRef]

- Shakoury, R.; Arman, A.; Mwema, F.M.; Luna, C.; Ghosh, K.; Jurečka, S.; Ţălu, Ş.; Rezaee, S.; Korpi, A.G. Multifractal and optical bandgap characterization of Ta2O5 thin films deposited by electron gun method. Opt. Quantum Electron. 2020, 52, 95. [Google Scholar] [CrossRef]

| Parameter | Unit | #1 | #2 | #3 | #4 |

|---|---|---|---|---|---|

| w | nm | 1.83 ± 0.09 | 121.88 ± 18.24 | 138.95 ± 22.22 | 194.15 ± 150.05 |

| Ra | nm | 1.41 ± 0.07 | 96.15 ± 12.03 | 110.68 ± 21.09 | 150.05 ± 22.28 |

| Rz | nm | 8.77 ± 0.73 | 210.00 ± 88.45 | 313.10 ± 97.86 | 440.00 ± 12.00 |

| Parameter | Unit | #1 | #2 | #3 | #4 |

|---|---|---|---|---|---|

| V | - | 0.50 | 0.54 | 0.83 | 0.58 |

| S (10−3) | - | 3.32 | 0.98 | 1.75 | 6.86 |

| χ (10−6) | - | 1.71 | 72.45 | 24.30 | 1.61 |

| Parameter | Unit | #1 | #2 | #3 | #4 |

|---|---|---|---|---|---|

| Multifractal Parameters | |||||

| αmax | - | 2.185 | 2.247 | 2.221 | 2.208 |

| αmin | - | 2.179 | 2.178 | 2.178 | 2.179 |

| Δα | - | 0.006 | 0.069 | 0.043 | 0.029 |

| f(αmax) | - | 2.178 | 2.166 | 2.171 | 2.175 |

| f(αmin) | - | 2.178 | 2.173 | 2.175 | 2.176 |

| Δf | - | 0.00 | 0.007 | 0.004 | 0.001 |

| Parameter | Unit | #1 | #2 | #3 | #4 |

|---|---|---|---|---|---|

| τa1 | ° | 45.0 | 15.6 | −9.67 | −87.2 |

| τa2 | ° | −52.1 | −44.2 | 50.9 | −53.4 |

| Sa1 | µm | 69.1 × 10−3 | 1.27 | 1.34 | 0.99 |

| Sa2 | µm | 111.3 × 10−3 | 2.79 | 4.11 | 2.18 |

| Str | - | 0.62 | 0.45 | 0.25 | 0.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Souza, C.C.; Gandarilla, A.M.D.; Brito, W.R.; Sanches, E.A.; Das, A.; Kumar, S.; Matos, R.S.; Ţălu, Ş.; da Fonseca Filho, H.D. Vertical Growth Dynamics and Multifractality of the Surface of Electropolymerized Poly(o-ethoxyaniline) Thin Films. Coatings 2022, 12, 1216. https://doi.org/10.3390/coatings12081216

de Souza CC, Gandarilla AMD, Brito WR, Sanches EA, Das A, Kumar S, Matos RS, Ţălu Ş, da Fonseca Filho HD. Vertical Growth Dynamics and Multifractality of the Surface of Electropolymerized Poly(o-ethoxyaniline) Thin Films. Coatings. 2022; 12(8):1216. https://doi.org/10.3390/coatings12081216

Chicago/Turabian Stylede Souza, Cindel Cavalcante, Ariamna María Dip Gandarilla, Walter Ricardo Brito, Edgar Aparecido Sanches, Abhijeet Das, Sanjeev Kumar, Robert Saraiva Matos, Ştefan Ţălu, and Henrique Duarte da Fonseca Filho. 2022. "Vertical Growth Dynamics and Multifractality of the Surface of Electropolymerized Poly(o-ethoxyaniline) Thin Films" Coatings 12, no. 8: 1216. https://doi.org/10.3390/coatings12081216

APA Stylede Souza, C. C., Gandarilla, A. M. D., Brito, W. R., Sanches, E. A., Das, A., Kumar, S., Matos, R. S., Ţălu, Ş., & da Fonseca Filho, H. D. (2022). Vertical Growth Dynamics and Multifractality of the Surface of Electropolymerized Poly(o-ethoxyaniline) Thin Films. Coatings, 12(8), 1216. https://doi.org/10.3390/coatings12081216