Modification of Cold-Sprayed Cu-Al-Ni-Al2O3 Composite Coatings by Friction Stir Technique to Enhance Wear Resistance Performance

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructural and Mechanical Characterization

3.2. Sliding Wear Behavior

4. Conclusions

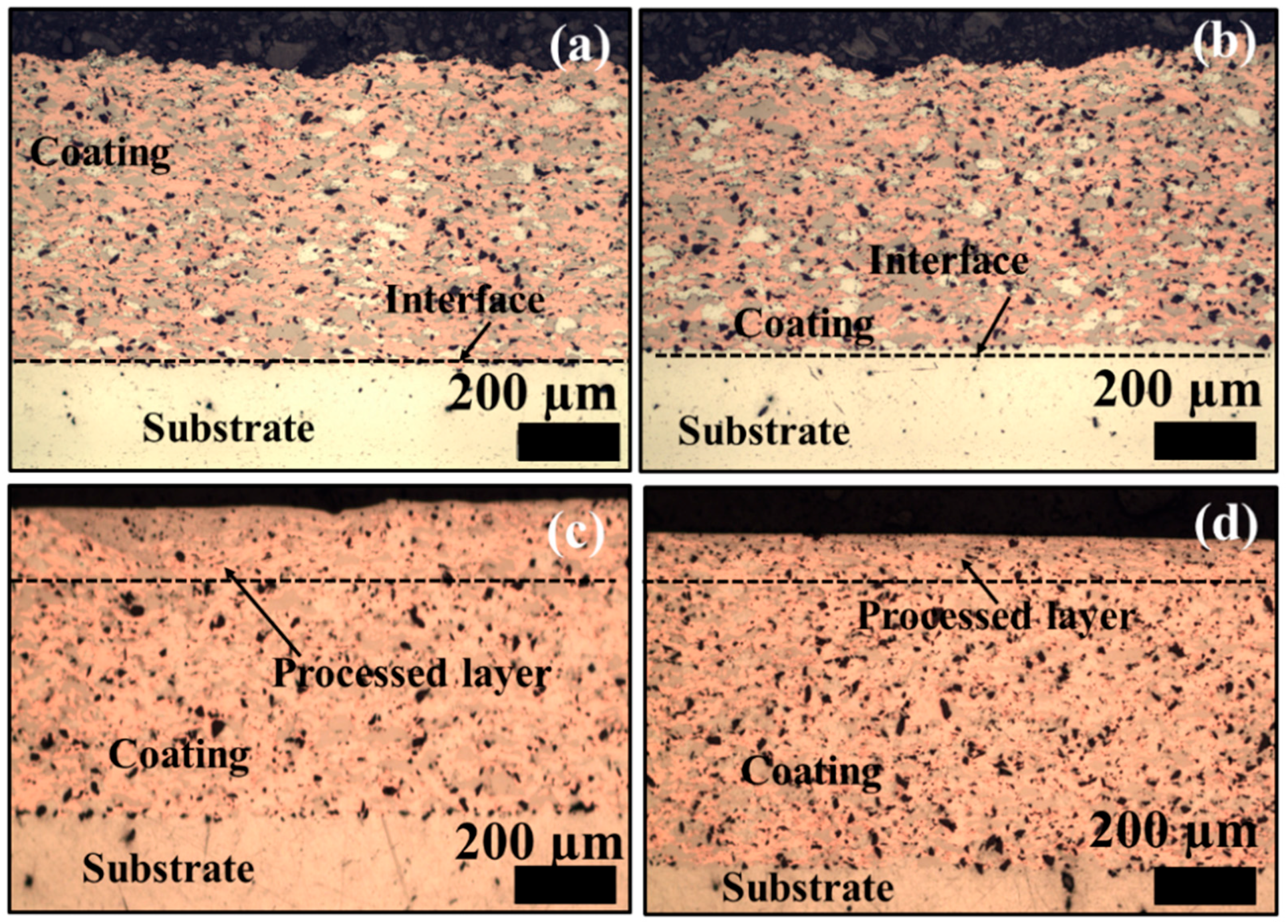

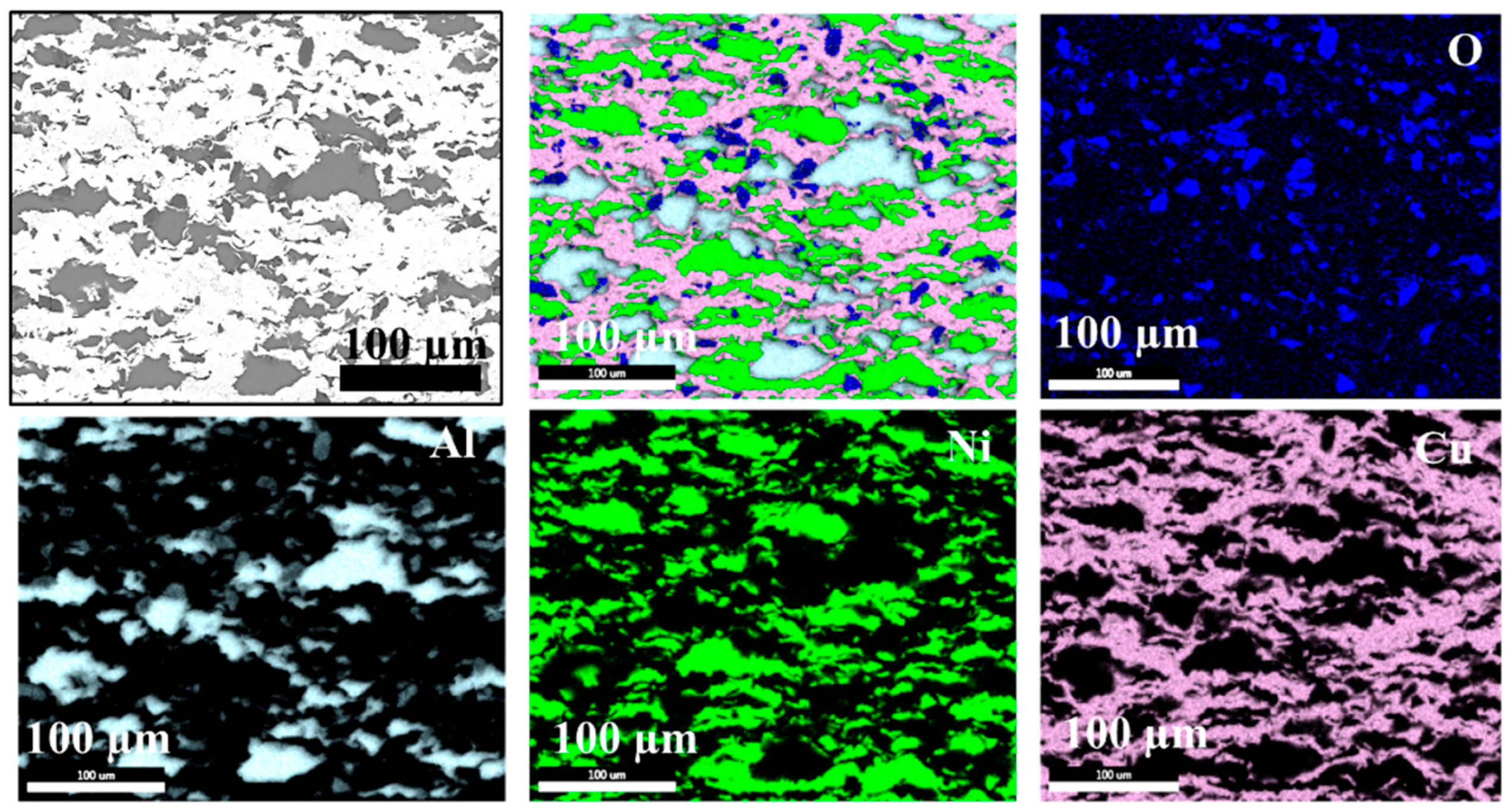

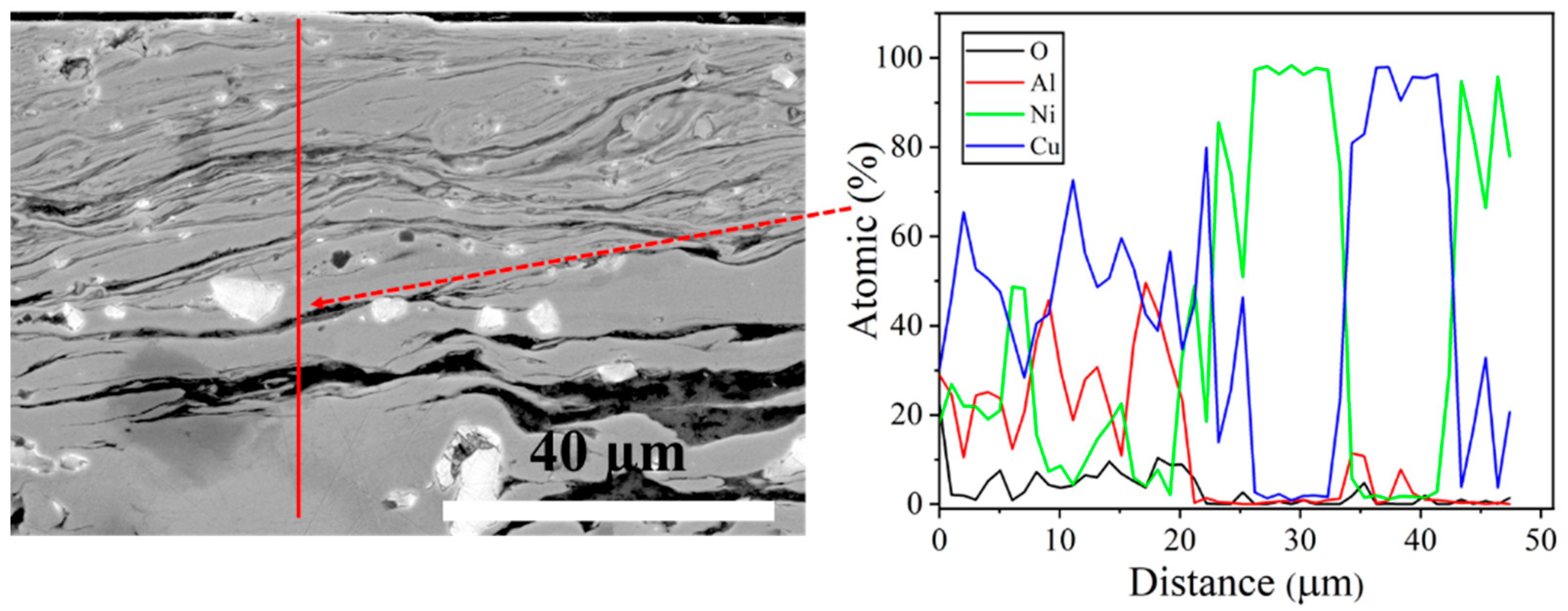

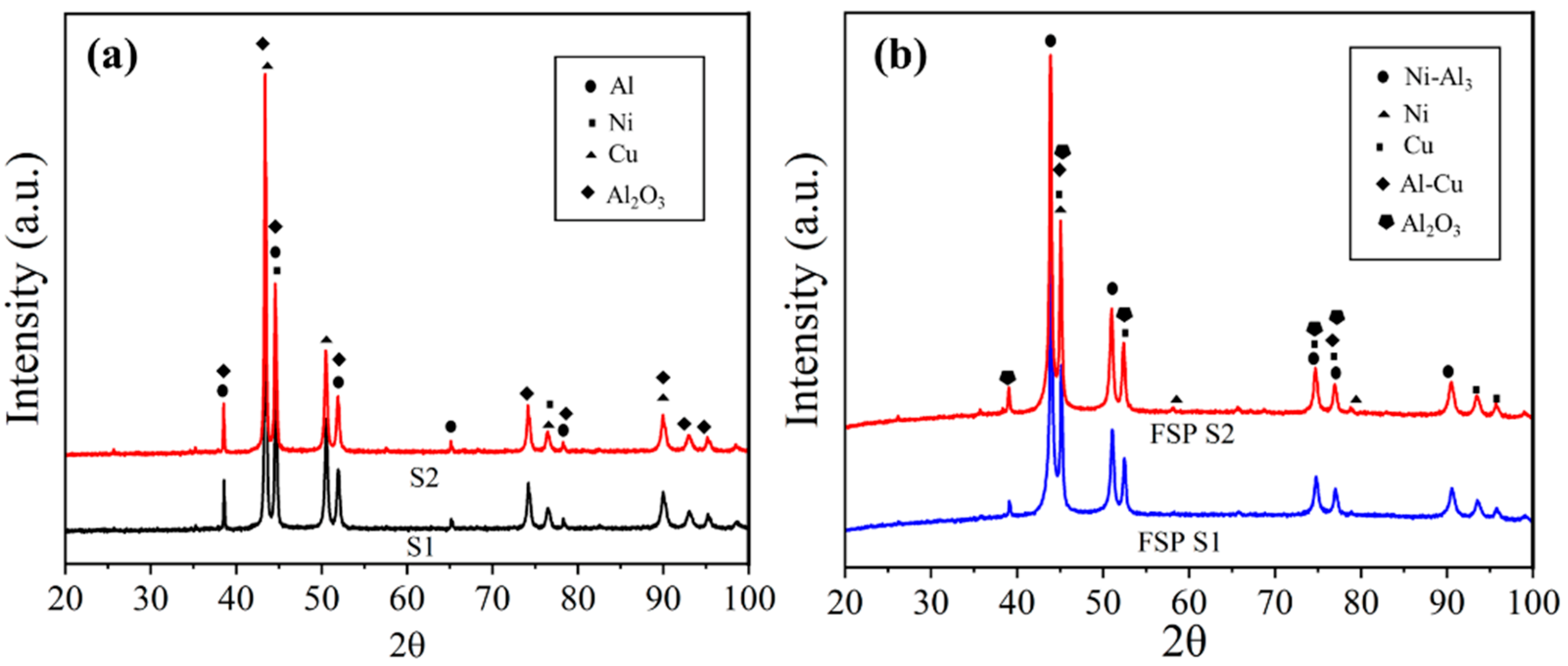

- These coatings showed a well-bonded substrate interface without the presence of any interfacial cracking, and with a very low level of porosity. The developed coatings had an average coating thickness of around 600 ± 10 µm. The as-sprayed coatings showed areas that were either rich in Cu, Ni and Al, while the distribution of alumina particles was nearly uniform across the coating layers.

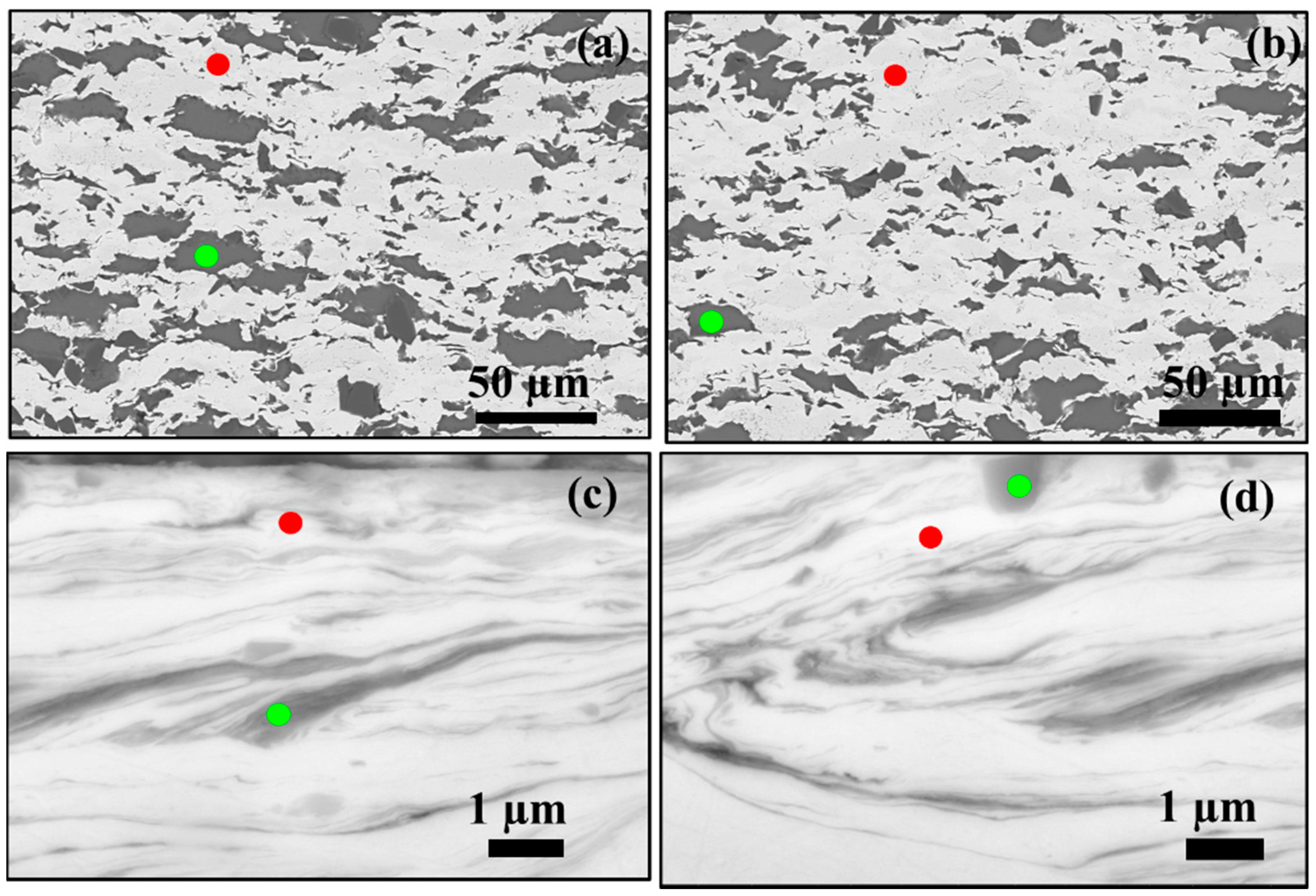

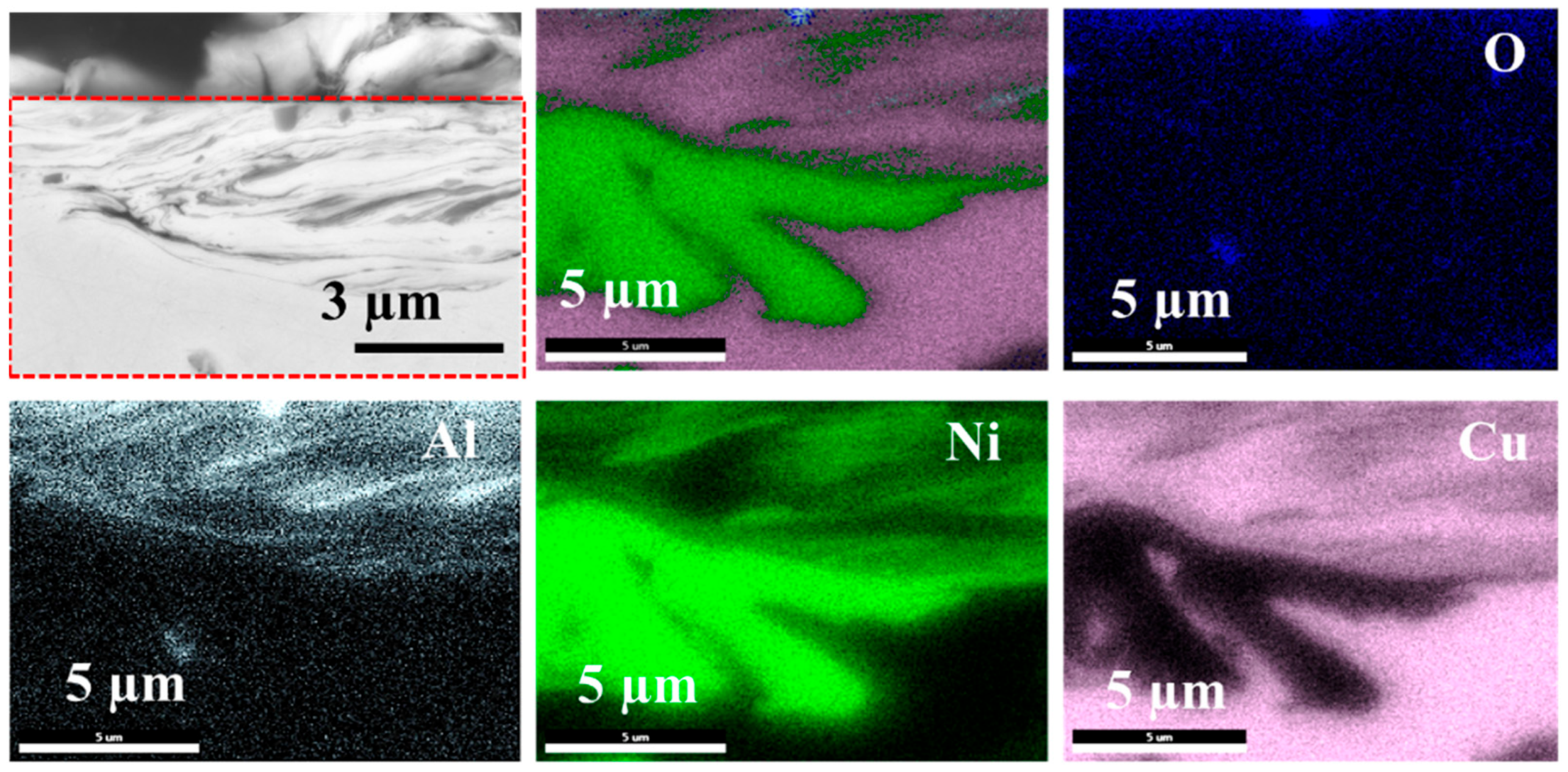

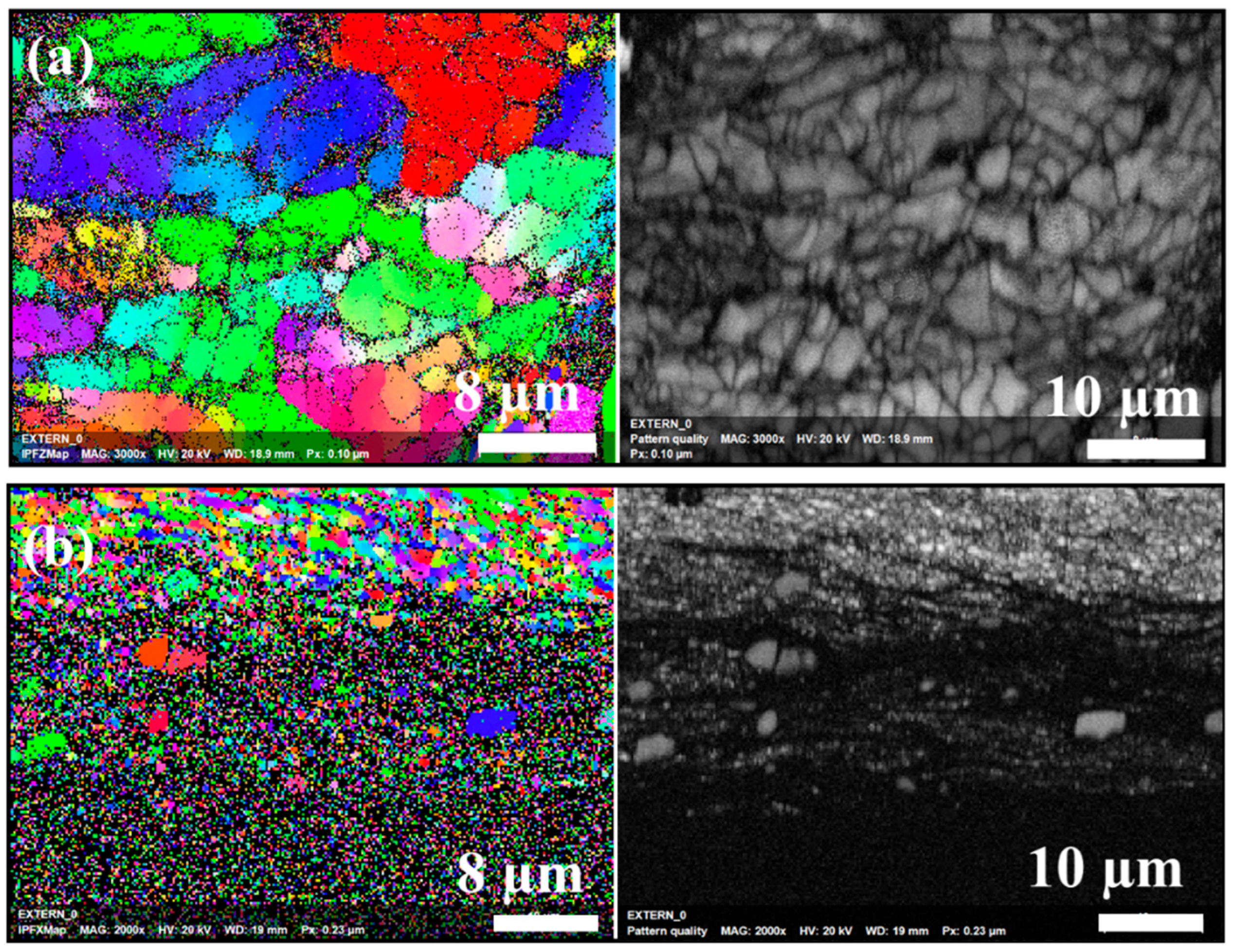

- Post-processing of the cold-sprayed Cu-Ni-Al alumina composite coatings was achieved using a high strain rate deformation technique during a friction stir processing operation with the aim to enhance the microstructural and mechanical properties. FSP aided in a significant amount of grain refinement and better dispersion of fine alumina particles across the processed layer.

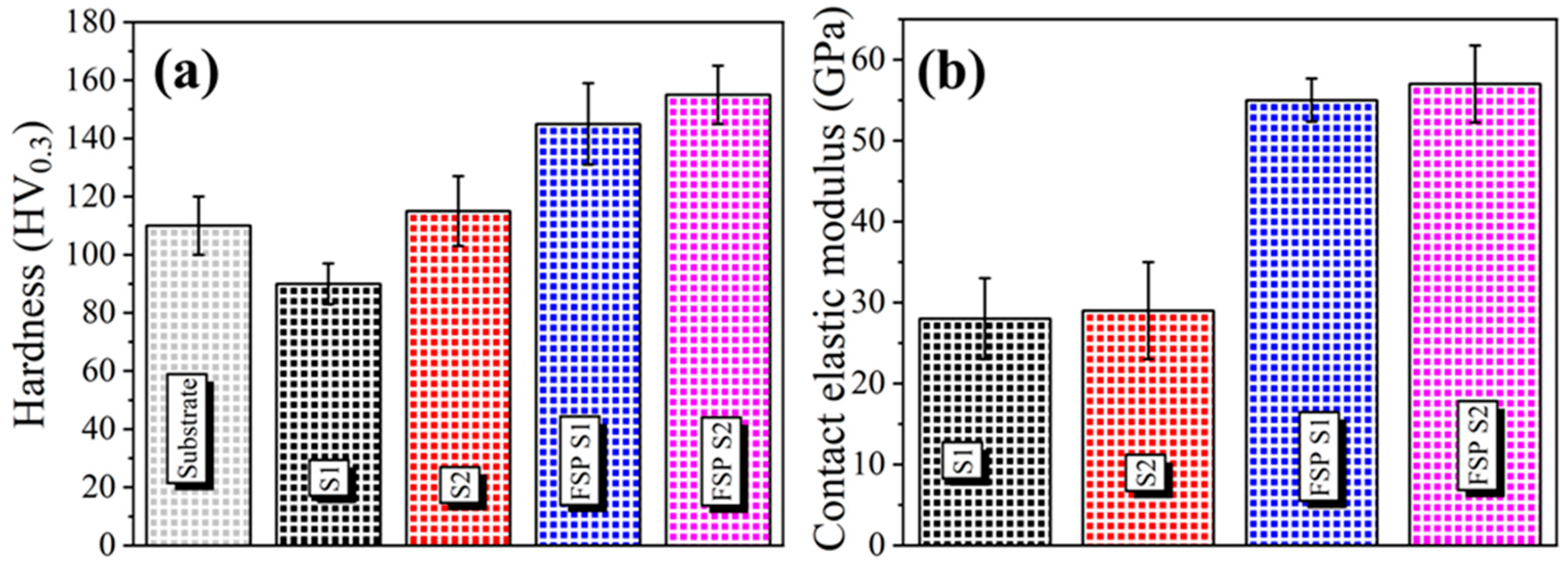

- The processed coating showed a nearly 2-times enhancement in the contact elastic modulus compared to its unprocessed counterpart, along with a 1.4 times increase in microhardness. Furthermore, the FSP samples showed a slightly lower wear rate than their unprocessed counterparts.

- Friction stir processing leads to a nearly three-times reduction in the specific wear rare of the as-sprayed coating during sliding wear. This improvement in wear resistance could be attributed to the processed coating layers’ superior microstructure and mechanical properties.

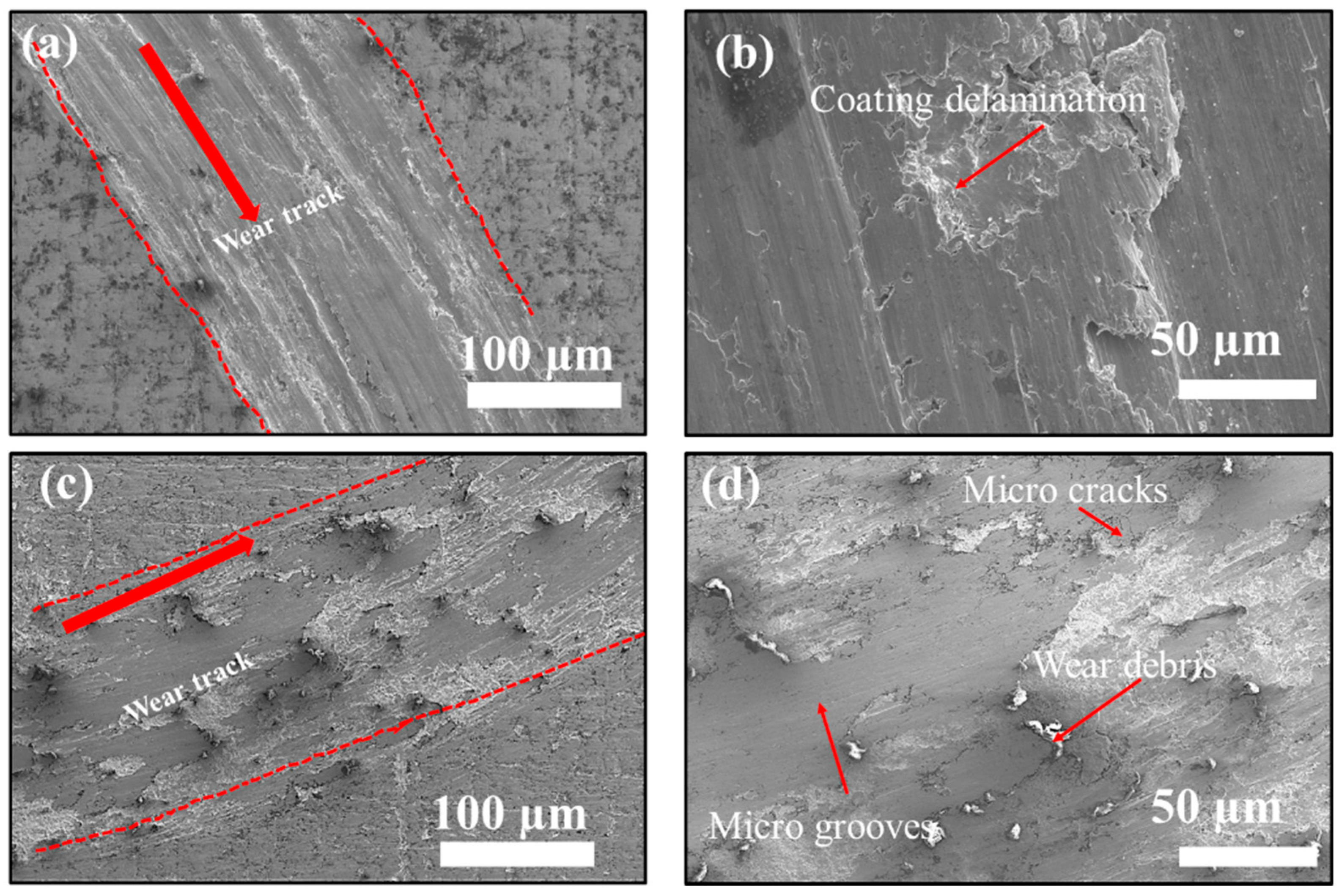

- From the SEM studies, it was evident that as-sprayed coatings layers showed deeper wear marks where the large portion of the coating surface were delaminated from the surface, while in the processed coating, a large area of the surface remains intact with negligible amount of coating damage. The primary mode of coating failure during sliding wear for the as-sprayed and friction stir processed coatings could be attributed to the delamination, micro-cracks, galling and groove formation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khonsari, M.M.; Booser, E.R. Applied Tribology: Bearing Design and Lubrication; John Wiley & Sons: New York, NY, USA, 2017. [Google Scholar]

- Pulkrabek, W.W. Engineering Fundamentals of the Internal Combustion Engine; Prentice Hall of India: New Delhi, India, 2000. [Google Scholar]

- Peng, J.; Liu, D.; Parnell, J.; Kessissoglou, N. Influence of translational vehicle dynamics on heavy vehicle noise emission. Sci. Total Environ. 2019, 689, 1358–1369. [Google Scholar] [CrossRef] [PubMed]

- Pratt, G.C. Materials for plain bearings. Int. Metall. Rev. 1973, 18, 62–88. [Google Scholar] [CrossRef]

- Tung, S.C.; McMillan, M.L. Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- Gebretsadik, D.W.; Hardell, J.; Prakash, B. Tribological performance of tin-based overlay plated engine bearing materials. Tribol. Int. 2015, 92, 281–289. [Google Scholar] [CrossRef]

- Mann, R.M.; Vijver, M.G.; Peijnenburg, W. Metals and metalloids in terrestrial systems: Bioaccumulation, biomagnification and subsequent adverse effects. In Ecologica l Impacts of Toxic Chemicals; Bentham Science Publishers: Karachi, Pakistan, 2011; pp. 43–62. [Google Scholar]

- Kerr, I.; Priest, M.; Okamoto, Y.; Fujita, M. Friction and wear performance of newly developed automotive bearing materials under boundary and mixed lubrication regimes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2007, 221, 321–331. [Google Scholar] [CrossRef]

- Thomson, J.; Zavadil, R.; Sahoo, M.; Dadouche, A.; Dmochowski, W.; Conlon, M. Development of a lead-free bearing material for aerospace applications. Int. J. Met. 2010, 4, 19–30. [Google Scholar] [CrossRef]

- Langbein, F.; Loidl, M.; Eberhard, A.; Mergen, R. Slide bearing types for combustion engines designed for upcoming emission regulations. In Proceedings of the Internal Combustion Engine Division Fall Technical Conference, Lucerne, Switzerland, 27–30 September 2009; pp. 533–541. [Google Scholar]

- Ning, X.-J.; Kim, J.-H.; Kim, H.-J.; Lee, C. Characteristics and heat treatment of cold-sprayed Al–Sn binary alloy coatings. Appl. Surf. Sci. 2009, 255, 3933–3939. [Google Scholar] [CrossRef]

- Thakare, J.G.; Pandey, C.; Mahapatra, M.; Mulik, R.S. Thermal barrier coatings—A state of the art review. Met. Mater. Int. 2021, 27, 1947–1968. [Google Scholar] [CrossRef]

- Babu, A.; Arora, H.; Behera, S.N.; Sharma, M.; Grewal, H. Towards highly durable bimodal composite claddings using microwave processing. Surf. Coat. Technol. 2018, 349, 655–666. [Google Scholar] [CrossRef]

- Dzhurinskiy, D.; Babu, A.; Pathak, P.; Elkin, A.; Dautov, S.; Shornikov, P. Microstructure and wear properties of atmospheric plasma-sprayed Cr3C2-NiCr composite coatings. Surf. Coat. Technol. 2021, 428, 127904. [Google Scholar] [CrossRef]

- Lu, X.-L.; Liu, X.-B.; Yu, P.-C.; Qiao, S.-J.; Zhai, Y.-J.; Wang, M.-D.; Chen, Y.; Xu, D. Synthesis and characterization of Ni60-hBN high temperature self-lubricating anti-wear composite coatings on Ti6Al4V alloy by laser cladding. Opt. Laser Technol. 2016, 78, 87–94. [Google Scholar] [CrossRef]

- Guo, F.; Jiang, W.; Tang, G.; Xie, Z.; Dai, H.; Wang, E.; Chen, Y.; Liu, L. Enhancing anti-wear and anti-corrosion performance of cold spraying aluminum coating by high current pulsed electron beam irradiation. Vacuum 2020, 182, 109772. [Google Scholar] [CrossRef]

- Thakare, J.; Pandey, C.; Mulik, R.S.; Mahapatra, M. Mechanical property evaluation of carbon nanotubes reinforced plasma sprayed YSZ-alumina composite coating. Ceram. Int. 2018, 44, 6980–6989. [Google Scholar] [CrossRef]

- Chi, W.; Sampath, S.; Wang, H. Ambient and high-temperature thermal conductivity of thermal sprayed coatings. J. Therm. Spray Technol. 2006, 15, 773–778. [Google Scholar] [CrossRef]

- Herman, H.; Sampath, S.; McCune, R. Thermal spray: Current status and future trends. MRS Bull. 2000, 25, 17–25. [Google Scholar] [CrossRef]

- Sun, J.; Fu, Q.-G.; Yuan, R.-M.; Dong, K.-Y.; Guo, J.-J. Corrosion and thermal cycling behavior of plasma sprayed thermal barrier coatings on die steel. Mater. Des. 2017, 114, 537–545. [Google Scholar] [CrossRef]

- Babu, A.; Arora, H.; Grewal, H. Development of cavitation erosion–resistant microwave processed WC-based cladding. Tribol. Trans. 2021, 64, 1118–1126. [Google Scholar] [CrossRef]

- Babu, A.; Arora, H.; Singh, R.; Grewal, H. Slurry erosion resistance of microwave derived Ni-SiC composite claddings. Silicon 2022, 14, 1069–1081. [Google Scholar] [CrossRef]

- Kosarev, V.; Klinkov, S.; Alkhimov, A.; Papyrin, A. On some aspects of gas dynamics of the cold spray process. J. Therm. Spray Technol. 2003, 12, 265–281. [Google Scholar] [CrossRef]

- Shockley, J.; Strauss, H.; Chromik, R.; Brodusch, N.; Gauvin, R.; Irissou, E.; Legoux, J.-G. In situ tribometry of cold-sprayed Al-Al2O3 composite coatings. Surf. Coat. Technol. 2013, 215, 350–356. [Google Scholar] [CrossRef]

- Szala, M.; Łatka, L.; Walczak, M.; Winnicki, M. Comparative study on the cavitation erosion and sliding wear of cold-sprayed Al/Al2O3 and Cu/Al2O3 coatings, and stainless steel, aluminium alloy, copper and brass. Metals 2020, 10, 856. [Google Scholar] [CrossRef]

- Podrabinnik, P.; Grigoriev, S.; Shishkovsky, I. Laser post annealing of cold-sprayed Al/alumina–Ni composite coatings. Surf. Coat. Technol. 2015, 271, 265–268. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gärtner, F.; Klassen, T. Cold spraying—A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef] [Green Version]

- Champagne, V.; Helfritch, D. The unique abilities of cold spray deposition. Int. Mater. Rev. 2016, 61, 437–455. [Google Scholar] [CrossRef]

- Koivuluoto, H.; Vuoristo, P. Effect of ceramic particles on properties of cold-sprayed Ni-20Cr + Al2O3 coatings. J. Therm. Spray Technol. 2009, 18, 555–562. [Google Scholar] [CrossRef]

- Van Steenkiste, T.; Smith, J.; Teets, R. Aluminum coatings via kinetic spray with relatively large powder particles. Surf. Coat. Technol. 2002, 154, 237–252. [Google Scholar] [CrossRef]

- Stoltenhoff, T.; Kreye, H.; Richter, H. An analysis of the cold spray process and its coatings. J. Therm. Spray Technol. 2002, 11, 542–550. [Google Scholar] [CrossRef]

- Mahdavi, A.; McDonald, A. Effect of substrate and process parameters on the gas-substrate convective heat transfer coefficient during cold spraying. J. Therm. Spray Technol. 2018, 27, 433–445. [Google Scholar] [CrossRef]

- Nair, R.B.; Perumal, G.; McDonald, A. Effect of microstructure on wear and corrosion performance of thermally sprayed AlCoCrFeMo high-entropy alloy coatings. Adv. Eng. Mater. 2022, 2101713. [Google Scholar] [CrossRef]

- Yin, S.; Li, W.; Song, B.; Yan, X.; Kuang, M.; Xu, Y.; Wen, K.; Lupoi, R. Deposition of FeCoNiCrMn high entropy alloy (HEA) coating via cold spraying. J. Mater. Sci. Technol. 2019, 35, 1003–1007. [Google Scholar] [CrossRef]

- Lehtonen, J.; Koivuluoto, H.; Ge, Y.; Juselius, A.; Hannula, S.-P. Cold gas spraying of a high-entropy CrFeNiMn equiatomic alloy. Coatings 2020, 10, 53. [Google Scholar] [CrossRef] [Green Version]

- Melendez, N.; Narulkar, V.; Fisher, G.; McDonald, A. Effect of reinforcing particles on the wear rate of low-pressure cold-sprayed WC-based MMC coatings. Wear 2013, 306, 185–195. [Google Scholar] [CrossRef]

- Farfán-Cabrera, L.I.; Gallardo-Hernández, E.A. Wear evaluation of journal bearings using an adapted micro-scale abrasion tester. Wear 2017, 376, 1841–1848. [Google Scholar] [CrossRef]

- Yue, T.M.; Li, T. Laser cladding of Ni/Cu/Al functionally graded coating on magnesium substrate. Surf. Coat. Technol. 2008, 202, 3043–3049. [Google Scholar] [CrossRef]

- Rahbar-Kelishami, A.; Abdollah-Zadeh, A.; Hadavi, M.; Seraj, R.; Gerlich, A. Improvement of wear resistance of sprayed layer on 52100 steel by friction stir processing. Appl. Surf. Sci. 2014, 316, 501–507. [Google Scholar] [CrossRef]

- Hodder, K.; Izadi, H.; McDonald, A.; Gerlich, A. Fabrication of aluminum–alumina metal matrix composites via cold gas dynamic spraying at low pressure followed by friction stir processing. Mater. Sci. Eng. A 2012, 556, 114–121. [Google Scholar] [CrossRef]

- Peat, T.; Galloway, A.; Toumpis, A.; McNutt, P.; Iqbal, N. The erosion performance of cold spray deposited metal matrix composite coatings with subsequent friction stir processing. Appl. Surf. Sci. 2017, 396, 1635–1648. [Google Scholar] [CrossRef] [Green Version]

- Rolland, G.; Sallamand, P.; Guipont, V.; Jeandin, M.; Boller, E.; Bourda, C. Damage study of cold-sprayed composite materials for application to electrical contacts. J. Therm. Spray Technol. 2012, 21, 758–772. [Google Scholar] [CrossRef]

- Poza, P.; Múnez, C.; Garrido-Maneiro, M.; Vezzù, S.; Rech, S.; Trentin, A. Mechanical properties of Inconel 625 cold-sprayed coatings after laser remelting. Depth sensing indentation analysis. Surf. Coat. Technol. 2014, 243, 51–57. [Google Scholar] [CrossRef]

- Astarita, A.; Genna, S.; Leone, C.; Minutolo, F.M.C.; Rubino, F.; Squillace, A. Study of the laser remelting of a cold sprayed titanium layer. Procedia Cirp 2015, 33, 452–457. [Google Scholar] [CrossRef]

- Babu, A.; Arora, H.; Nair, R.; Chakraborty, I.; Chauhan, A.; Grewal, H. Wear behavior of microwave-annealed and cryogenically treated thermal spray coatings: A comparative evaluation. Mater. Today Proc. 2020, 33, 5348–5353. [Google Scholar] [CrossRef]

- Babu, A.; Arora, H.; Grewal, H. Microwave-assisted post-processing of detonation gun-sprayed coatings for better slurry and cavitation erosion resistance. J. Therm. Spray Technol. 2019, 28, 1565–1578. [Google Scholar] [CrossRef]

- Hall, A.C.; Cook, D.; Neiser, R.; Roemer, T.; Hirschfeld, D. The effect of a simple annealing heat treatment on the mechanical properties of cold-sprayed aluminum. J. Therm. Spray Technol. 2006, 15, 233–238. [Google Scholar] [CrossRef]

- Meng, X.-M.; Zhang, J.-B.; Han, W.; Zhao, J.; Liang, Y.-L. Influence of annealing treatment on the microstructure and mechanical performance of cold sprayed 304 stainless steel coating. Appl. Surf. Sci. 2011, 258, 700–704. [Google Scholar] [CrossRef]

- Sun, W.; Tan, A.W.-Y.; Wu, K.; Yin, S.; Yang, X.; Marinescu, I.; Liu, E. Post-process treatments on supersonic cold sprayed coatings: A review. Coatings 2020, 10, 123. [Google Scholar] [CrossRef] [Green Version]

- Perard, T.; Sova, A.; Robe, H.; Robin, V.; Zedan, Y.; Bocher, P.; Feulvarch, E. Friction stir processing of austenitic stainless steel cold spray coating deposited on 304L stainless steel substrate: Feasibility study. Int. J. Adv. Manuf. Technol. 2021, 115, 2379–2393. [Google Scholar] [CrossRef]

- Selvam, K.; Rakesh, B.; Grewal, H.; Arora, H.; Singh, H. High strain deformation of austenitic steel for enhancing erosion resistance. Wear 2017, 376, 1021–1029. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.; McFadden, S.; Mara, N.; Mukherjee, A. High strain rate superplasticity in a friction stir processed 7075 Al alloy. Scr. Mater. 1999, 42, 163–168. [Google Scholar] [CrossRef]

- Morisada, Y.; Fujii, H.; Mizuno, T.; Abe, G.; Nagaoka, T.; Fukusumi, M. Modification of thermally sprayed cemented carbide layer by friction stir processing. Surf. Coat. Technol. 2010, 204, 2459–2464. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z. Friction stir processing technology: A review. Metall. Mater. Trans. A 2008, 39, 642–658. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, X.; Cui, H.; Zhang, J. Cold-spray processing of a high density nanocrystalline aluminum alloy 2009 coating using a mixture of as-atomized and as-cryomilled powders. J. Therm. Spray Technol. 2011, 20, 1125–1132. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold spray coating: Review of material systems and future perspectives. Surf. Eng. 2014, 30, 369–395. [Google Scholar] [CrossRef]

- Yang, K.; Li, W.; Niu, P.; Yang, X.; Xu, Y. Cold sprayed AA2024/Al2O3 metal matrix composites improved by friction stir processing: Microstructure characterization, mechanical performance and strengthening mechanisms. J. Alloys Compd. 2018, 736, 115–123. [Google Scholar] [CrossRef]

- Huang, C.; Yan, X.; Li, W.; Wang, W.; Verdy, C.; Planche, M.; Liao, H.; Montavon, G. Post-spray modification of cold-sprayed Ni-Ti coatings by high-temperature vacuum annealing and friction stir processing. Appl. Surf. Sci. 2018, 451, 56–66. [Google Scholar] [CrossRef]

- Arora, H.S.; Perumal, G.; Rani, M.; Grewal, H.S. Facile and green engineering approach for enhanced corrosion resistance of Ni–Cr–Al2O3 thermal spray coatings. ACS Omega 2020, 5, 24558–24566. [Google Scholar] [CrossRef] [PubMed]

- Ashrafizadeh, H.; Lopera-Valle, A.; McDonald, A.; Gerlich, A. Effect of friction-stir processing on the wear rate of WC-based MMC coatings deposited by low-pressure cold gas dynamic spraying. In Proceedings of the International Thermal Spray Conference and Exposition, Long Beach, CA, USA, 11–14 May 2015; pp. 41–47. [Google Scholar]

- Arora, H.; Rani, M.; Perumal, G.; Roy, M.; Singh, H.; Grewal, H. Structural rejuvenation of thermal spray coating through stationary friction processing. Surf. Coat. Technol. 2020, 389, 125631. [Google Scholar] [CrossRef]

- Xiong, Y.-J.; Qiu, Z.-L.; Li, R.-D.; Yuan, T.-C.; Hong, W.; Liu, J.-H. Preparation of ultra-fine grain Ni–Al–WC coating with interlocking bonding on austenitic stainless steel by laser clad and friction stir processing. Trans. Nonferrous Met. Soc. China 2015, 25, 3685–3693. [Google Scholar] [CrossRef]

- Liu, F.; Ji, Y.; Meng, Q.; Li, Z. Microstructure and corrosion resistance of laser cladding and friction stir processing hybrid modification Al-Si coatings on AZ31B. Vacuum 2016, 133, 31–37. [Google Scholar] [CrossRef]

- G99 2000; A Standard test method for wear testing with a pin-on-disk apparatus. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2016.

- Gershman, I.S.; Gershman, E.I.; Fox-Rabinovich, G.S.; Veldhuis, S.C. Description of seizure process for gas dynamic spray of metal powders from non-equilibrium thermodynamics standpoint. Entropy 2016, 18, 315. [Google Scholar] [CrossRef]

- Grigoriev, S.; Gershman, E.; Gershman, I.; Mironov, A.; Podrabinnik, P. Microstructural studies of the copper-based coating obtained by cold gas-dynamic spraying for the restoration of worn-out contact wires. Coatings 2021, 11, 1067. [Google Scholar] [CrossRef]

- Lee, C.; Huang, J.; Hsieh, P. Mg based nano-composites fabricated by friction stir processing. Scr. Mater. 2006, 54, 1415–1420. [Google Scholar] [CrossRef]

- Toumpis, A.; Galloway, A.; Cater, S.; McPherson, N. Development of a process envelope for friction stir welding of DH36 steel–a step change. Mater. Des. (1980–2015) 2014, 62, 64–75. [Google Scholar]

- Rani, M.; Perumal, G.; Roy, M.; Grewal, H.; Singh, H.; Arora, H. Post-processing of Ni-Cr-Al2O3 thermal spray coatings through friction stir processing for enhanced erosion–corrosion performance. J. Therm. Spray Technol. 2019, 28, 1466–1477. [Google Scholar] [CrossRef]

- Zou, Y.; Qin, W.; Irissou, E.; Legoux, J.-G.; Yue, S.; Szpunar, J.A. Dynamic recrystallization in the particle/particle interfacial region of cold-sprayed nickel coating: Electron backscatter diffraction characterization. Scr. Mater. 2009, 61, 899–902. [Google Scholar] [CrossRef]

- Humphreys, F. Characterisation of fine-scale microstructures by electron backscatter diffraction (EBSD). Scr. Mater. 2004, 51, 771–776. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.; Kaloshkin, S.; Tcherdyntsev, V.; Gorshenkov, M.; Komissarov, A.; Zadorozhnyy, M. Formation of intermetallic Ni–Al coatings by mechanical alloying on the different hardness substrates. J. Alloys Compd. 2014, 586, S373–S376. [Google Scholar] [CrossRef]

- Babu, A.; Perumal, G.; Arora, H.; Grewal, H. Enhanced slurry and cavitation erosion resistance of deep cryogenically treated thermal spray coatings for hydroturbine applications. Renew. Energy 2021, 180, 1044–1055. [Google Scholar] [CrossRef]

- Babu, A.; Arora, H.; Singh, H.; Grewal, H. Microwave synthesized composite claddings with enhanced cavitation erosion resistance. Wear 2019, 422, 242–251. [Google Scholar] [CrossRef]

- Waterhouse, R. The role of adhesion and delamination in the fretting wear of metallic materials. Wear 1977, 45, 355–364. [Google Scholar] [CrossRef]

- Dubourg, L.; Pelletier, H.; Vaissiere, D.; Hlawka, F.; Cornet, A. Mechanical characterisation of laser surface alloyed aluminium–copper systems. Wear 2002, 253, 1077–1085. [Google Scholar] [CrossRef]

- Jiang, J.; Stott, F.; Stack, M. The role of triboparticulates in dry sliding wear. Tribol. Int. 1998, 31, 245–256. [Google Scholar] [CrossRef]

- Alidokht, S.; Manimunda, P.; Vo, P.; Yue, S.; Chromik, R. Cold spray deposition of a Ni-WC composite coating and its dry sliding wear behavior. Surf. Coat. Technol. 2016, 308, 424–434. [Google Scholar] [CrossRef] [Green Version]

- Jiang, J.; Stott, F.; Stack, M. Some frictional features associated with the sliding wear of the nickel-base alloy N80A at temperatures to 250 C. Wear 1994, 176, 185–194. [Google Scholar] [CrossRef]

| Coatings | Elements in wt.% | |||

|---|---|---|---|---|

| Cu | Al | Ni | Al2O3 | |

| S1 | 33 | 14 | 30 | 23 |

| S2 | 26 | 11 | 23 | 40 |

| Coatings | Elements Are in wt% | ||||

|---|---|---|---|---|---|

| Ni | Cu | Al | O | ||

| S1 |  | - | - | 44.75 | 55.17 |

| 12.17 | 21.01 | 66.13 | 0.69 | |

| S2 |  | - | - | 44.83 | 55.17 |

| 11.17 | 67.13 | 21.01 | 0.69 | |

| FSP-S1 |  | - | - | 97.07 | 2.93 |

| 96.66 | 0.81 | 1.63 | 0.9 | |

| FSP-S2 |  | - | 1.41 | 97.57 | 2.92 |

| 89.66 | 2.81 | 4.63 | 0.9 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dzhurinskiy, D.; Babu, A.; Dautov, S.; Lama, A.; Mangrulkar, M. Modification of Cold-Sprayed Cu-Al-Ni-Al2O3 Composite Coatings by Friction Stir Technique to Enhance Wear Resistance Performance. Coatings 2022, 12, 1113. https://doi.org/10.3390/coatings12081113

Dzhurinskiy D, Babu A, Dautov S, Lama A, Mangrulkar M. Modification of Cold-Sprayed Cu-Al-Ni-Al2O3 Composite Coatings by Friction Stir Technique to Enhance Wear Resistance Performance. Coatings. 2022; 12(8):1113. https://doi.org/10.3390/coatings12081113

Chicago/Turabian StyleDzhurinskiy, Dmitry, Abhishek Babu, Stanislav Dautov, Anil Lama, and Mayuribala Mangrulkar. 2022. "Modification of Cold-Sprayed Cu-Al-Ni-Al2O3 Composite Coatings by Friction Stir Technique to Enhance Wear Resistance Performance" Coatings 12, no. 8: 1113. https://doi.org/10.3390/coatings12081113

APA StyleDzhurinskiy, D., Babu, A., Dautov, S., Lama, A., & Mangrulkar, M. (2022). Modification of Cold-Sprayed Cu-Al-Ni-Al2O3 Composite Coatings by Friction Stir Technique to Enhance Wear Resistance Performance. Coatings, 12(8), 1113. https://doi.org/10.3390/coatings12081113