Abstract

WSiN films were produced through hybrid pulse direct current/radio frequency magnetron co-sputtering and evaluated as diffusion barriers for Cu metallization. The Cu/WSiN/Si assemblies were annealed for 1 h in a vacuum at 500–900 °C. The structural stability and diffusion barrier performance of the WSiN films were explored through X-ray diffraction, Auger electron spectroscopy, and sheet resistance measurement. The results indicated that the Si content of WSiN films increased from 0 to 9 at.% as the power applied to the Si target was increased from 0 to 150 W. The as-deposited W76N24, W68Si0N32, and W63Si4N33 films formed a face-centered cubic W2N phase, whereas the as-deposited W59Si9N32 film was near-amorphous. The lattice constants of crystalline WSiN films decreased after annealing. The sheet resistance of crystalline WSiN films exhibited a sharp increase as they were annealed at 800 °C, accompanied by the formation of a Cu3Si compound. The failure of the near-amorphous W59Si9N32 barrier against Cu diffusion was observed when annealed at 900 °C.

1. Introduction

Cu metallization has been applied as an interconnecting conductor in ultra-large-scale integrated circuits because of its high conductivity and excellent electromigration resistance [1,2,3]. The prohibition of Cu diffusion in Si and SiO2 by introducing diffusion barriers has become the crucial subject for preventing the deterioration of device performance [4,5]. The formation of Cu3Si after annealing is an indicator used to evaluate the failure of the barrier, which is accompanied by an increase in the electrical resistance [6,7]. Distinct materials such as passive, stuffed, sacrificial, and amorphous barriers have been proposed as thin-film diffusion barriers [8]. Amorphous materials without grain boundaries exhibited excellent diffusion resistance [9,10] and were applied in the field of Cu metallization. Ta and W films play the role of diffusion barriers against Cu at 600 °C in H2 for 1 h [11], which is attributed to their high melting temperatures and immiscibility with Cu [7,12]. Amorphous binary and ternary nitrides (TaNx [7,13], WNx [14,15], Ta–W–N [16], and W–Ti–N [17]) have been used to raise the barrier temperatures to 600–800 °C. High-entropy alloy nitride films, such as (AlMoNbSiTaTiVZr)50N50 [10], (AlCrTaTiZr)N [18], and (AlCrTaTiZrMo)N [19], with amorphous structures and large lattice distortions, have been applied as diffusion barriers [20]. The phase transformation of the aforementioned nitride films at elevated temperatures affected the performance of diffusion barriers. Dalili et al. [7] reported that amorphous TaNx films crystallized into a Ta2N structure at 600 °C when annealed in a 5% H2–N2 mixture for 30 min. Similarly, Uekubo et al. [14] stated that amorphous WNx films crystallized when annealed at 600 °C in 5% H2–N2 for 30 min. The annealing temperature for Cu to penetrate the diffusion barrier in a fixed time was correlated to the film thickness because of the diffusion-controlled process [7]. Suh et al. [15] reported that the as-deposited 100 nm-thick WNx films with 16%–32% N were X-ray amorphous, which crystallized after being annealed at 500–600 °C, and the barrier property was maintained up to 800 °C. Shen et al. [21] reported that 150 nm-thick amorphous WNx films crystallized above 600 °C when annealed in a vacuum for 30 min, and the crystallized W2N decomposed by releasing nitrogen above 820 °C. As-deposited WNx films could be either crystalline [22,23] or amorphous [21,23]. Si has been introduced into WNx films to change structures from crystalline to nanocomposite or amorphous, and the formed WSiN films exhibited improved mechanical properties [24,25], thermal stability [25], oxidation resistance [25,26,27], and corrosion resistance [28]. Thermal stability is a vital characteristic of the diffusion barrier. Louro and Cavaleiro [24] reported that amorphous WSiN films crystallized at 750–950 °C. Atomic layer deposition (ALD)-grown WSiN films were amorphous up to 800 °C and crystallized at 900 °C [29]. The diffusion of Cu into Si was prevented by a 6-nm-thick ALD-WSiN film when annealed in a vacuum at temperatures up to 600 °C for 30 min [29]. In contrast, a sputtered WSiN film with a thickness of 10 nm underwent 1 min annealing in N2 up to 750 °C [30]. Chemical vapor deposition-prepared W47Si9N44 films (100 nm thick) were useful barriers up to 700 °C [31]. In addition to the achievement of amorphous films, crystalline nitride films have also been applied as diffusion barriers [6]. Zhang et al. [32] reported that crystalline W2N films were stable up to 600 °C and decomposed at 800 °C in a vacuum. Takeyama and Noya [33] reported that a W65N35 film in the W2N phase exhibited barrier properties up to 800 °C for 1 h annealing. A 5-nm-thick TaWN film with a (111) orientation exhibited barrier properties against Cu diffusion at 500 °C in a vacuum for 1 h [34]. Crystalline CrWN films were applied as a diffusion barrier up to 650 °C in a vacuum for 1 h, as reported in a previous study [35]. In [36], a co-sputtered W28Si24N48 film exhibited high oxidation resistance at 600 °C in an oxygen-containing atmosphere because of its amorphous structure and the formation of the SiO2 scale, which implied its potential application for diffusion barriers. In this study, WSiN films were fabricated through hybrid pulse direct current/radio frequency magnetron co-sputtering. Crystalline and near-amorphous WSiN films with various Si contents were produced. The evolution in the crystalline structure and the variation in the diffusion barrier property caused by Si addition were investigated and correlated. The diffusion barrier characteristics of WSiN films that experienced annealing treatments in a vacuum at 500–900 °C for 1 h were evaluated.

2. Materials and Methods

WSiN films were co-sputtered with a W target (99.95%, 76.2 mm in diameter) linked to a pulse power supply and an Si target (99.999%, 50.8 mm in diameter) attached to a radio frequency (RF) power generator. The distance between targets and the substrate holder was 120 mm. The sputter guns were titled at an angle of 30° with respect to the substrate holder, which focused plasma toward the center of the substrate holder. The average power applied on W target (PW) was fixed at 200 W, whereas the RF power on Si target (PSi) varied from 0 to 50, 100, and 150 W, which fabricated samples S0, S50, S100, and S150, respectively, as Table 1 shows. The substrate holder was rotated at 10 rpm and maintained at 150 °C. The flow rates of Ar and N2 gas were, respectively, set at 30 and 9 sccm for reactive sputtering. The working pressure was 0.4 Pa. Table 1 lists the experimental parameters for co-sputtering WSiN films. These samples were also designated by their chemical compositions examined using Auger electron spectroscopy (AES, PHI700, ULVAC-PHI, Kanagawa, Japan). The sputter etching rate for analyzing AES depth profiles was set at 9.1 or 9.5 nm/min for SiO2. The chemical compositions of the WSiN films were determined as the average values related to depth ranges with sputter times of 11–25, 13–28, 15–30, and 10–20 min for samples S0, S50, S100, and S150, respectively, which exhibited W76N24, W68Si0N32, W63Si4N33, and W59Si9N32, respectively, as the O content was ignored. These samples were laminated with a 107-nm-thick Cu layer prepared through direct current (DC) magnetron sputtering with a Cu target (99.99%, 76.2 mm in diameter) and DC power of 100 W for 18.5 min in a 30 sccm Ar flow and a working pressure of 0.4 Pa. Annealing experiments for evaluating the diffusion barrier characteristics were performed at 500–900 °C in a vacuum of 7 × 10−4 Pa for 1 h. The bonding characteristics of films were analyzed by using an X-ray photoelectron spectroscope (XPS, PHI 1600, PHI, Kanagawa, Japan). The C 1s line of the free surface of the W76N24 films was 283.97 eV. The C 1s line was calibrated using the Greczynski–Hultman method [37,38,39], which suggested a value of 0.18 eV for correcting binding energy levels in this study. The sputter etching rate in XPS analyses was 8.4 nm/min for SiO2. An X-ray diffractometer (XRD, X’Pert PRO MPD, PANalytical, Almelo, The Netherlands) in the grazing incidence mode was used to analyze the phases. The lattice constants, a0, of crystalline films were determined according to the following equation

where a is the lattice constant for the (111), (200), (220), and (311) reflection; K is the constant; θ is the diffraction angle. The sheet resistance of the Cu/WSiN/Si samples was determined using a four-point probe [35]. The standard deviations for sheet resistance data were calculated from 3 measurements.

Table 1.

Co-sputtering parameters of WSiN films.

3. Results and Discussion

3.1. Chemical Compositions and Phase Structures of As-Deposited W–Si–N Films

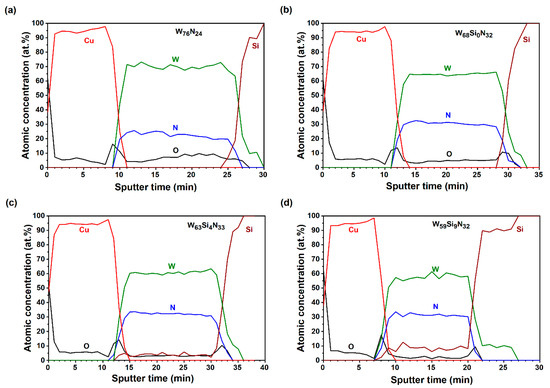

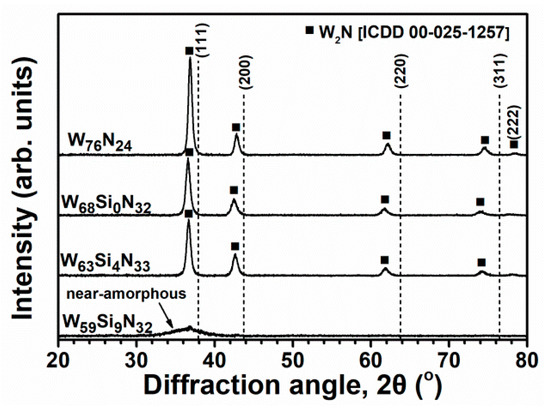

Figure 1 displays the AES depth profiles of the as-deposited Cu/WSiN/Si samples. The O content was contributed from the residual gas in the vacuum chamber. The relatively high O contents at the Cu/WSiN interfaces were attributed to the exposure of the chamber to the ambient environment for target changing from W to Cu. The chemical composition of the WNx films prepared without applying an RF power to the Si target (PSi) was determined to be W76N24 after ignoring the O content. The WSiN films prepared with PSi levels of 50, 100, and 150 W exhibited chemical compositions of W68Si0N32, W63Si4N33, and W59Si9N32, respectively. The Si content of the W68Si0N32 films prepared with a PSi level of 50 W was not detectable. The N content of the WSiN films was maintained at a level of 32 at.%–33 at.%, which was close to the stoichiometric ratio of 2:1 for W:N in the W2N lattice [40]. The standard formation enthalpies for W2N and Si3N4 at 298 K are −22 [41] and −745 kJ/mol [42], respectively, which indicates a low affinity between N and W. Therefore, the W76N24 film exhibited a low N content. Moreover, the reactive co-sputtering with a Si target assisted in raising the N content in the films. However, the re-sputtering of light Si adatoms on the substrate affected the Si contents of the fabricated WSiN films [43]. The deposition rate increased from 3.48 to 5.00, 5.18, and 6.10 nm/min as the PSi was increased from 0 to 50, 100, and 150 W. The film thicknesses were fixed at 101–112 nm by controlling the deposition times (Table 1). Figure 2 exhibits the GIXRD patterns of the as-deposited WSiN films. The W76N24, W68Si0N32, and W63Si4N33 films formed a W2N phase (ICDD 00-025-1257), whereas the W59Si9N32 film was nanocrystalline or near-amorphous. The dash lines in Figure 2 indicate the standard 2θ values of the W2N reflections (ICDD 00-025-1257) with a lattice constant of 0.4126 nm. The reflections of WSiN films shifted left with respect to the standard values of W2N, implying expanded lattices for the WSiN films. The lattice constants of crystalline WSiN films were determined to be 0.4220, 0.4240, and 0.4229 nm for the W76N24, W68Si0N32, and W63Si4N33 films, respectively. Similar peak shifts and lattice expansion were reported for the W–N films [21,22], which was attributed to excess nitrogen interstitials and intrinsic compressive stress [43]. The W68Si0N32 films exhibited a higher lattice constant than the W76N24 films because of the N-deficient compositions for the W76N24 films, whereas the W63Si4N33 films exhibited a lattice constant lower than that of the W68Si0N32 films, which implied the substitution of small Si atoms replacing W atoms in the W2N lattice. Ju et al. [26] reported that the addition of Si into W–N films decreased the lattice constant; the films with a Si content < 5.2 at.% exhibited a W2N phase, whereas the films with a Si content in the range of 14.3 at.%–28.8 at.% were X-ray amorphous. The lattice shrinkage of these crystalline WSiN films after annealing is further discussed in Section 3.2.

Figure 1.

AES analyses of the as-deposited Cu/WSiN/Si samples with barrier layers: (a) W76N24, (b) W68Si0N32, (c) W63Si4N33, and (d) W59Si9N32. (Sputter etching rates: 9.1 nm/min for (b,c) and 9.5 nm/min for (a,d).)

Figure 2.

GIXRD patterns of the as-deposited WSiN films.

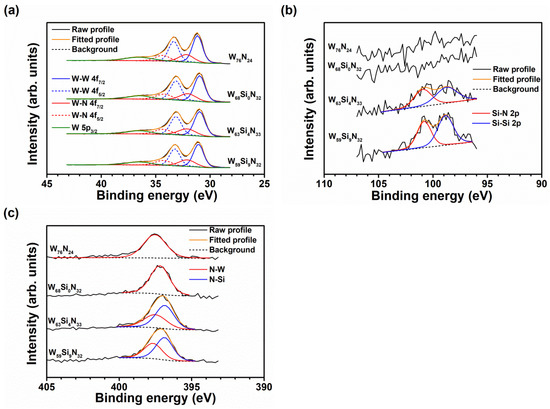

Figure 3 shows the XPS profiles at a depth of 33.6 nm of the as-deposited WSiN films without a Cu top layer. The profiles of the W 4f, Si 2p, and N 1s core levels of the aforementioned WSiN films are displayed. The W signals were split into two doublets, W–W and W–N, overlapped with a minor W 5p3/2 component (Figure 3a). Table 2 summarizes the XPS analysis results at depths of 8.4, 16.8, 25.2, and 33.6 nm. The binding energies of W 4f7/2 were 30.97–31.17 and 32.13–32.19 eV for the W–W and W–N bonds, respectively, which were comparable to the reported values of 31.26–31.52 and 32.36–32.56 eV [44], respectively. Figure 3b exhibits the Si 2p signals. The Si signal of the W68Si0N32 films was not observed because of the low Si content, whereas the Si signals of the W63Si4N33 and W59Si9N32 films comprised two components for the Si–Si and Si–N bonds. The binding energies were 98.96–99.06 and 101.03–101.06 eV for the Si–Si and Si–N bonds, respectively, which were comparable with the reported values of 99.29–99.53 and 101.25–101.42 eV [44]. Figure 3c shows the N 1s signals, which comprise N–W and N–Si bonds of 397.20–397.65 and 396.84–396.88 eV, respectively.

Figure 3.

XPS patterns of (a) W 4f, (b) Si 2p, and (c) N 1s of the as-deposited WSiN films at a depth of 33.6 nm.

Table 2.

XPS analysis results for the WSiN films at depths of 8.39–33.56 nm.

3.2. Structural Evolution after Annealing

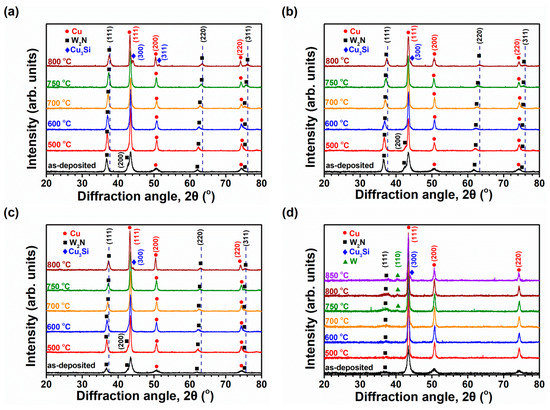

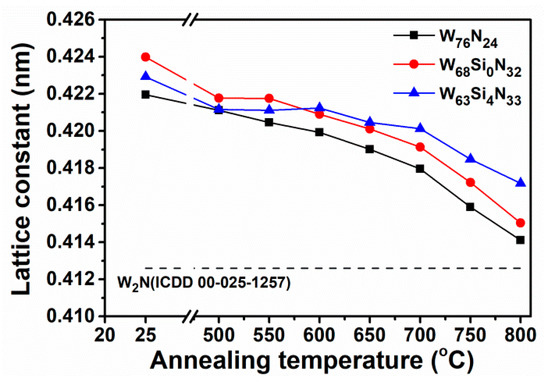

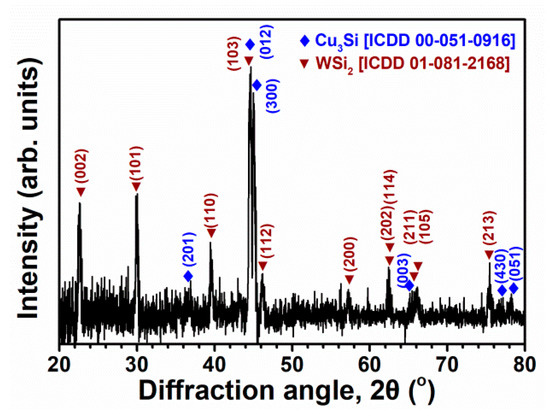

Figure 4 exhibits the GIXRD patterns of the Cu/WSiN/Si samples after 1 h annealing in a vacuum at 500–900 °C. The samples with crystalline W76N24, W68Si0N32, and W63Si4N33 barrier films maintained Cu (ICDD 00-004-0836) and W2N phases after they were annealed up to 750 °C, and an extra Cu3Si (300) phase (ICDD 00-051-0916) was observed for the 800 °C-annealed samples. Moreover, these W2N reflections shifted toward higher 2θ values when increasing the annealing temperature, which resulted in the overlap of W2N (200) and Cu (111) reflections. Figure 5 shows the lattice constants of the aforementioned annealed WSiN films determined using (111), (220), and (311) reflections, which reveals a common decreasing tendency toward the standard lattice constant of the W2N phase when increasing the annealing temperatures. These originally expanded lattices shrunk after annealing, indicating that these crystalline WSiN films became more ordered after annealing. The low decreasing slope of the lattice constants of the W63Si4N33 films with respect to annealing temperature was because of the formation of a certain volume of amorphous SiNx. In contrast, the Cu/W59Si9N32/Si samples were maintained as near-amorphous after annealing up to 800 °C, as indicated by a weak and broad W2N (111) reflection in the XRD patterns. Moreover, a tiny W (110) reflection (ICDD 00-004-0806) was observed at annealing temperatures higher than 750 °C. Furthermore, a Cu3Si (300) reflection was observed for the 850 °C and 1 h-annealed Cu/W59Si9N32/Si sample. However, the Cu3Si (300) reflection was not shown for the XRD pattern of an 850 °C and 30 min-annealed Cu/W59Si9N32/Si sample. Figure 6 depicts the GIXRD pattern of the 900 °C-annealed Cu/W59Si9N32/Si sample, and Cu and W2N phases are replaced by Cu3Si and WSi2 (ICDD 01-081-2168) phases.

Figure 4.

GIXRD patterns of the annealed Cu/WSiN/Si samples with barrier layers: (a) W76N24, (b) W68Si0N32, (c) W63Si4N33, and (d) W59Si9N32.

Figure 5.

Lattice constant variations in the crystalline WSiN films after annealing.

Figure 6.

GIXRD pattern of the Cu/W59Si9N32/Si sample after annealing at 900 °C for 1 h.

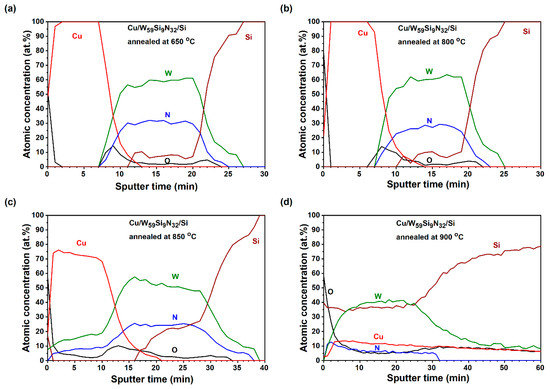

3.3. Diffusion Barrier Properties

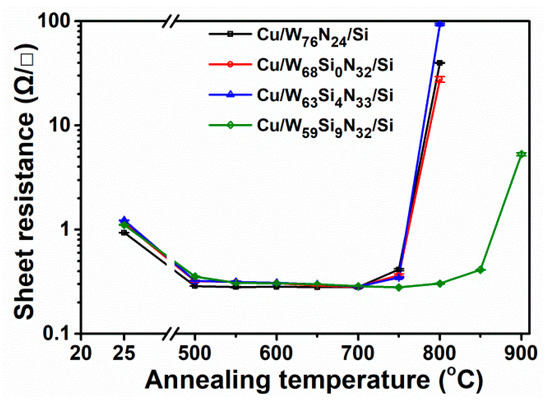

Figure 7 displays the sheet resistance of the Cu/WSiN/Si samples at the as-deposited state and after annealing in a vacuum for 1 h at various temperatures. The sheet resistance of these Cu/WSiN/Si samples decreased from 0.9–1.2 Ω/□ to approximately 0.3 Ω/□ after they were annealed at 500 °C because of the defect annihilation and grain growth of Cu films [35,45], and then the sheet resistance of the aforementioned samples was maintained at the level of 0.3 Ω/□ up to 700 °C annealing. The sheet resistance of the aforementioned samples with crystalline WSiN barriers slightly increased to 0.4 Ω/□ when annealed at 750 °C and abruptly increased to 28–94 Ω/□ when annealed at 800 °C, which was accompanied by the formation of Cu3Si (Figure 4). In contrast, the sheet resistance of the Cu/W59Si9N32/Si sample was maintained at 0.3 Ω/□ up to 800 °C annealing, slightly increased to 0.4 Ω/□ after annealing at 850 °C, and abruptly increased to 5 Ω/□ after annealing at 900 °C.

Figure 7.

Sheet resistance of the annealed Cu/WSiN/Si samples.

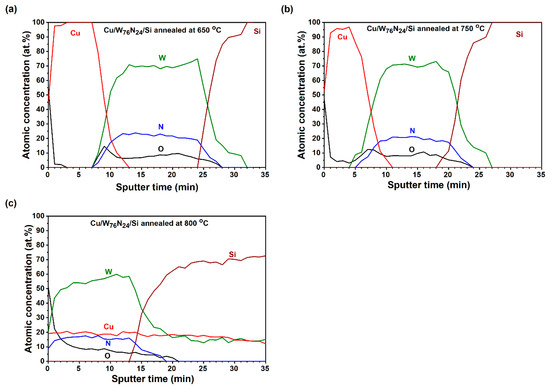

Figure 8 shows the AES analysis results of the 650, 750, and 800 °C-annealed Cu/W76N24/Si samples. Correlated to the AES analysis results of the as-deposited Cu/W76N24/Si sample (Figure 1a), both the interdiffusion across the interfaces between Cu/W76N24 and W76N24/Si at 650 and 750 °C were limited; however, the formation of the Cu–Si compound did not happen, which agreed with that shown in the XRD pattern (Figure 4a). Further raising the annealing temperature to 800 °C resulted in the intermixing of the original Cu and W76N24 layers, the diffusion of Cu into the Si substrate, and the formation of a Cu3Si phase as indicated in the XRD pattern, which was accompanied by a sharp increase in the sheet resistance of the Cu/W76N24/Si sample (Figure 7). Figure 9 displays the AES depth profiles of the 650, 800, 850, and 900 °C-annealed Cu/W59Si9N32/Si samples. Both the interdiffusion behaviors across the interfaces between Cu/W59Si9N32 and W59Si9N32/Si at 650–800 °C were restricted. The intermixing of the original Cu and W59Si9N32 layers occurred after 850 °C annealing. Because Cu and W were immiscible and Cu and N formed no compound, the newborn phase formed due to the intermixing of Cu and W59Si9N32 layers was Cu3Si, as shown in the XRD pattern (Figure 4d); however, the amount of Cu3Si phase was little, and the sheet resistance increased from 0.3 Ω/□ for samples annealed below 800 °C to 0.4 Ω/□ for the sample annealed at 850 °C. Moreover, the nitrogen-loss behavior was observed above 850 °C. Shen et al. [21] reported that the W2N phase was stable up to 800 °C and started to evaporate at 820 °C in a vacuum. Further raising the annealing temperature to 900 °C resulted in the inward diffusion of Cu into the Si substrate, the disappearance of the Cu layer, the outward diffusion of Si, the formation of Cu3Si and WSi2 phases, and an increase in sheet resistance to 5 Ω/□. The sheet resistance measurement and AES analyses confirmed the diffusion barrier characteristics for both the crystalline and near-amorphous WSiN films.

Figure 8.

AES analysis results of (a) 650 °C-, (b) 750 °C-, and (c) 800 °C-annealed Cu/W76N24/Si samples. (Sputter etching rate: 9.5 nm/min.)

Figure 9.

AES analysis results of (a) 650 °C-, (b) 800 °C-, (c) 850 °C-, and (d) 900 °C-annealed Cu/W59Si9N32/Si samples. (Sputter etching rates: 9.1 nm/min for (c,d) and 9.5 nm/min for (a,b).)

4. Conclusions

The feasibility of WSiN films as diffusion barriers for Cu metallization was explored in this study. Both crystalline and near-amorphous WSiN films behaved as excellent diffusion barriers. The crystalline WSiN films with Si contents of 0 at.%–4 at.% exhibited diffusion barrier characteristics after annealing up to 750 °C in a vacuum for 1 h. The formation of the Cu3Si phase observed from XRD patterns, the inward diffusion of Cu through the films into Si substrates verified by AES analyses, and the sharp increase in sheet resistance indicated the failure of these crystalline WSiN barrier films when they were annealed at 800 °C for 1 h. The diffusion barrier characteristics of the WSiN films were further improved by raising the Si content to 9 at.%, which formed a near-amorphous structure in the as-deposited state and increased the failure temperature against Cu diffusion to 900 °C. Further research on shrinking the depth of WSiN films to the nano-scale accompanied by compatible diffusion barrier characteristics is crucial.

Author Contributions

Conceptualization, Y.-I.C. and L.-C.C.; validation, L.-C.C.; formal analysis, K.-H.Y.; investigation, K.-H.Y. and T.-Y.O.; resources, L.-C.C.; data curation, Y.-I.C.; writing—original draft preparation, Y.-I.C.; writing—review and editing, L.-C.C.; project administration, Y.-I.C. and L.-C.C.; funding acquisition, Y.-I.C. and L.-C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Technology, Taiwan, grant numbers 110-2221-E-131-013 and 110-2221-E-019-015. The APC was funded by Ming Chi University of Technology.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The analysis support from the Instrumentation Center at the National Tsing Hua University for the AES, XPS, and EPMA characterizations is acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nitta, T.; Ohmi, T.; Hoshi, T.; Sakai, S.; Sakaibara, K.; Imai, S.; Shibata, T. Evaluating the large electromigration resistance of copper interconnects employing a newly developed accelerated life-test method. J. Electrochem. Soc. 1993, 140, 1131–1137. [Google Scholar] [CrossRef]

- Shacham-Diamand, Y. Barrier layers for Cu ULSI metallization. J. Electron. Mater. 2001, 30, 336–344. [Google Scholar] [CrossRef]

- Tu, K.N. Recent advances on electromigration in very-large-scale-integration of interconnects. J. Appl. Phys. 2003, 94, 5451–5473. [Google Scholar] [CrossRef]

- McBrayer, J.D.; Swanson, R.M.; Sigmon, T.W. Diffusion of metals in silicon dioxide. J. Electrochem. Soc. 1986, 133, 1242–1246. [Google Scholar] [CrossRef]

- Istratov, A.A.; Flink, C.; Hieslmair, H.; Weber, E.R. Intrinsic diffusion coefficient of interstitial copper in silicon. Phys. Rev. Lett. 1998, 81, 1243–1246. [Google Scholar] [CrossRef]

- Kuo, Y.L.; Huang, J.J.; Lin, S.T.; Lee, C.; Lee, W.H. Diffusion barrier properties of sputtered TaNx between Cu and Si using TaN as the target. Mater. Chem. Phys. 2003, 80, 690–695. [Google Scholar] [CrossRef]

- Dalili, N.; Liu, Q.; Ivey, D.G. Thermal and electrical stability of TaNx diffusion barriers for Cu metallization. J. Mater. Sci. 2013, 48, 489–501. [Google Scholar] [CrossRef]

- Nicolet, M.-A. Diffusion barriers in thin films. Thin Solid Films 1978, 52, 415–443. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Tsai, M.H.; Wang, C.W.; Lai, C.H.; Yeh, J.W.; Gan, J.Y. Thermally stable amorphous (AlMoNbSiTaTiVZr)50N50 nitride film as diffusion barrier in copper metallization. Appl. Phys. Lett. 2008, 92, 052109. [Google Scholar] [CrossRef]

- Ono, H.; Nakano, T.; Ohta, T. Diffusion barrier effects of transition metals for Cu/M/Si multilayers (M = Cr, Ti, Nb, Mo, Ta, W). Appl. Phys. Lett. 1994, 64, 1511–1513. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, T.; Zhao, S.; Xu, Z.; Lv, Y.; Fan, J.; Han, Y. Size-dependent alloying ability of immiscible W-Cu bimetallic nanoparticles: A theoretical and experimental study. Nanomaterials 2021, 11, 1047. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.F.; Wang, S.J.; Yang, T.H.; Yang, Z.D.; Bor, H.Y.; Wei, C.N. Effect of nitrogen flow rate on TaN diffusion barrier layer deposited between a Cu layer and a Si-based substrate. Ceram. Int. 2017, 43, 12505–12510. [Google Scholar] [CrossRef]

- Uekubo, M.; Oku, T.; Nii, K.; Murakami, M.; Takahiro, K.; Yamaguchi, S.; Nakano, T.; Ohta, T. WNx diffusion barriers between Si and Cu. Thin Solid Films 1996, 286, 170–175. [Google Scholar] [CrossRef]

- Suh, B.S.; Lee, Y.J.; Hwang, J.S.; Park, C.O. Properties of reactively sputtered WNx as Cu diffusion barrier. Thin Solid Films 1999, 348, 299–303. [Google Scholar] [CrossRef]

- Liu, Y.; Song, S.; Mao, D.; Ling, H.; Li, M. Diffusion barrier performance of reactively sputtered Ta–W–N between Cu and Si. Microelectron. Eng. 2004, 75, 309–315. [Google Scholar] [CrossRef]

- Qingxiang, W.; Shuhua, L.; Xianhui, W.; Zhikang, F. Diffusion barrier performance of amorphous W–Ti–N films in Cu metallization. Vacuum 2010, 84, 1270–1274. [Google Scholar] [CrossRef]

- Chang, S.Y.; Chen, D.S. (AlCrTaTiZr)N/(AlCrTaTiZr)N0.7 bilayer structure of high resistance to the interdiffusion of Cu and Si at 900 °C. Mater. Chem. Phys. 2011, 125, 5–8. [Google Scholar] [CrossRef]

- Li, R.; Li, M.; Jiang, C.; Qiao, B.; Zhang, W.; Xu, J. Thermal stability of AlCrTaTiZrMo-nitride high entropy film as a diffusion barrier for Cu metallization. J. Alloys Compd. 2019, 773, 482–489. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Wang, X.; Yao, W.; Liang, X. Structure and properties of high-entropy amorphous thin films: A review. JOM 2022, 74, 794–807. [Google Scholar] [CrossRef]

- Shen, Y.G.; Mai, Y.W.; McBride, W.E.; Zhang, Q.C.; McKenzie, D.R. Structural properties and nitrogen-loss characteristics in sputtered tungsten nitride films. Thin Solid Films 2000, 372, 257–264. [Google Scholar] [CrossRef]

- Lou, B.S.; Moirangthem, I.; Lee, J.W. Fabrication of tungsten nitride thin films by superimposed HiPIMS and MF system: Effects of nitrogen flow rate. Surf. Coat. Technol. 2020, 393, 125743. [Google Scholar] [CrossRef]

- Jiang, P.C.; Chen, J.S.; Lin, Y.K. Structural and electrical characteristics of W–N thin films prepared by reactive rf sputtering. J. Vac. Sci. Technol. A 2003, 21, 616–622. [Google Scholar] [CrossRef]

- Louro, C.; Cavaleiro, A. Mechanical behaviour of amorphous W–Si–N sputtered films after thermal annealing at increasing temperatures. Surf. Coat. Technol. 2000, 123, 192–198. [Google Scholar] [CrossRef]

- Musil, J.; Daniel, R.; Soldan, J.; Zeman, P. Properties of reactively sputtered W–Si–N films. Surf. Coat. Technol. 2006, 200, 3886–3895. [Google Scholar] [CrossRef]

- Ju, H.; He, S.; Yu, L.; Asempah, I.; Xu, J. The improvement of oxidation resistance, mechanical and tribological properties of W2N films by doping silicon. Surf. Coat. Technol. 2017, 317, 158–165. [Google Scholar] [CrossRef]

- Bai, X.; Li, K.; Chen, Y.; Feng, Q.; Ge, F.; Huang, F. Large solubility of silicon in an incongruent nitride: The case of reactively magnetron co-sputtered W-Si-N coatings. Surf. Coat. Technol. 2021, 412, 127047. [Google Scholar] [CrossRef]

- Zhao, H.; Ye, F. Effect of Si-incorporation on the structure, mechanical, tribological and corrosion properties of WSiN coatings. Appl. Surf. Sci. 2015, 256, 958–966. [Google Scholar] [CrossRef]

- Hong, T.E.; Jung, J.H.; Yeo, S.; Cheon, T.; Bae, S.I.; Kim, S.H.; Yeo, S.J.; Kim, H.S.; Chung, T.M.; Park, B.K.; et al. Highly conformal amorphous W−Si−N thin films by plasma-enhanced atomic layer deposition as a diffusion barrier for Cu metallization. J. Phys. Chem. C 2015, 119, 1548–1556. [Google Scholar] [CrossRef]

- Qu, X.P.; Lu, H.; Peng, T.; Ru, G.P.; Li, B.Z. Effects of preannealing on the diffusion barrier properties for ultrathin W–Si–N thin film. Thin Solid Films 2004, 462–463, 67–71. [Google Scholar] [CrossRef]

- Fleming, J.G.; Roherty-Osmun, E.; Smith, P.M.; Custer, J.S.; Kim, Y.-D.; Kacsich, T.; Nicolet, M.-A.; Galewski, C.J. Growth and properties of W–Si–N diffusion barriers deposited by chemical vapor deposition. Thin Solid Films 1998, 320, 10–14. [Google Scholar] [CrossRef]

- Zhang, X.X.; Wu, Y.Z.; Mu, B.; Qiao, L.; Li, W.X.; Li, J.J.; Wang, P. Thermal stability of tungsten sub-nitride thin film prepared by reactive magnetron sputtering. J. Nucl. Mater. 2017, 485, 1–7. [Google Scholar] [CrossRef]

- Takeyama, M.; Noya, A. Preparation of WNx films and their diffusion barrier properties in Cu/Si contact systems. Jpn. J. Appl. Phys. 1997, 36, 2261–2266. [Google Scholar] [CrossRef]

- Takeyama, M.B.; Sato, M.; Yasuda, M. Relationship between ⟨111⟩-oriented Cu film and thin Ta–W–N barrier. Jpn. J. Appl. Phys. 2020, 59, SLLD02. [Google Scholar] [CrossRef]

- Chang, L.C.; Wu, C.E.; Ou, T.Y. Mechanical properties and diffusion barrier performance of CrWN coatings fabricated through hybrid HiPIMS/RFMS. Coatings 2021, 11, 690. [Google Scholar] [CrossRef]

- Liu, Y.H.; Chang, L.C.; Liu, B.W.; Chen, Y.I. Mechanical properties and oxidation behavior of W–Si–N coatings. Surf. Coat. Technol. 2019, 375, 727–738. [Google Scholar] [CrossRef]

- Greczynski, G.; Hultman, L. C1s peak of adventitious carbon aligns to the vacuum level: Dire consequences for material’s bonding assignment by photoelectron spectroscopy. ChemPhysChem 2017, 18, 1507–1512. [Google Scholar] [CrossRef] [PubMed]

- Greczynski, G.; Hultman, L. Reliable determination of chemical state in x-ray photoelectron spectroscopy based on sample-work-function referencing to adventitious carbon: Resolving the myth of apparent constant binding energy of the C 1s peak. Appl. Surf. Sci. 2018, 451, 89–103. [Google Scholar] [CrossRef]

- Chang, L.C.; Sung, M.C.; Chen, Y.I. Effects of bias voltage and substrate temperature on the mechanical properties and oxidation behavior of CrSiN films. Vacuum 2021, 194, 110580. [Google Scholar] [CrossRef]

- Baker, C.C.; Shah, S.I. Reactive sputter deposition of tungsten nitride thin films. J. Vac. Sci. Technol. A 2002, 20, 1699–1703. [Google Scholar] [CrossRef]

- de Boer, F.R.; Boom, R.; Mattens, W.C.M.; Miedema, A.R.; Niessen, A.K. Transition Metal Alloys; North-Holland: Amsterdam, The Netherlands, 1988. [Google Scholar]

- Barin, I. Thermochemical Data of Pure Substances, 3rd ed.; VCH: New York, NY, USA, 1995. [Google Scholar]

- Vomiero, A.; Boscolo Marchi, E.; Quaranta, A.; Della Mea, G.; Brusa, R.S.; Mariotto, G.; Felisari, L.; Frabboni, S.; Tonini, R.; Ottaviani, G.; et al. Structural properties of reactively sputtered W–Si–N thin films. J. Appl. Phys. 2007, 102, 033505. [Google Scholar] [CrossRef]

- Chang, C.L.; Chiou, T.H.; Chen, P.H.; Chen, W.C.; Ho, C.T.; Wu, W.Y. Characteristics of TiN/W2N multilayers prepared using magnetron sputter deposition with dc and pulsed dc powers. Surf. Coat. Technol. 2016, 303, 25–31. [Google Scholar] [CrossRef]

- Kim, J.B.; Nandi, D.K.; Kim, T.H.; Jang, Y.; Bae, J.S.; Hong, T.E.; Kim, S.H. Atomic layer deposition of WNx thin films using a F-free tungsten metalorganic precursor and NH3 plasma as a Cu-diffusion barrier. Thin Solid Films 2019, 685, 393–401. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).